Finding the right CNC machining partner in Melbourne feels impossible when you’re juggling tight deadlines, quality requirements, and budget constraints. Most procurement teams waste weeks evaluating suppliers only to discover hidden costs, delivery delays, or quality issues that could derail entire projects.

This comprehensive guide provides Melbourne engineers, CTOs, and procurement managers with practical strategies to source reliable CNC machining partners, optimize costs, streamline prototyping cycles, and ensure consistent quality from prototype to production.

Whether you’re launching your first prototype or scaling production, this guide covers everything from supplier evaluation checklists to cost optimization strategies. I’ll share insights from working with Melbourne-based teams who’ve successfully navigated these challenges and built strong manufacturing partnerships.

The Complete Checklist For Sourcing CNC Machining Suppliers In Melbourne

Finding the right partner for CNC machining in Melbourne can be challenging. A great supplier delivers more than just parts; they provide reliability and expertise. This checklist simplifies the process.

It helps engineers and procurement teams make informed decisions. Using a structured approach ensures you find a partner who meets your technical and business needs.

Initial Screening Questions

| Critérios | Perguntas a fazer |

|---|---|

| Experiência | How many years have you served our industry? |

| Localização | Does your facility support project oversight? |

| Orçamento inicial | Is the quoting process clear and detailed? |

This framework helps you quickly shortlist potential vendors for a deeper evaluation.

When you begin your Melbourne CNC vendor evaluation, move beyond the basics of price and delivery. True partnership is built on proven capability and trust. It’s crucial to assess a supplier’s technical depth.

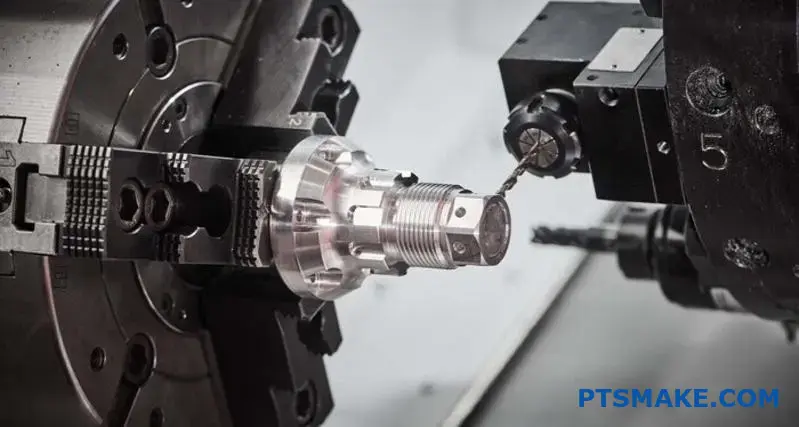

Avaliação das capacidades técnicas

What materials do they specialize in? Ask for examples of past projects using similar materials to your own. This provides real-world proof of their skills. Also, review their machinery list. Modern, well-maintained equipment is a key indicator of quality.

At PTSMAKE, we believe transparency is key. We openly share case studies and our equipment specifications. This helps clients verify our capabilities from the start.

Key Supplier Evaluation Criteria

When considering how to choose a CNC machining supplier in Melbourne, your checklist should be detailed. This ensures no critical factor is overlooked. A supplier’s quality system is fundamental.

| Área de avaliação | Principais métricas | Target Standard |

|---|---|---|

| Certificações | ISO 9001, AS9100 | Must be current and valid |

| Lead Times | Quoted vs. Actual | History of 95%+ on-time delivery |

| Tolerâncias | Stated capabilities | Proof of achieving ±0.005mm or better |

| Comunicação | Tempo de resposta | Dedicated contact, replies within 24 hours |

A supplier’s proficiency in Dimensionamento Geométrico e Tolerância1 (GD&T) is also non-negotiable for complex parts. It shows they understand the precise language of engineering drawings.

A structured evaluation using a clear checklist is vital. It helps you compare suppliers objectively, moving beyond surface-level quotes to assess true capability, reliability, and technical expertise for your CNC machining needs in Melbourne.

How Melbourne Engineers Can Simplify CNC Prototyping Cycles

Streamlining your prototyping cycle is crucial. It saves time and reduces costs. The key is to optimize your process from the very start.

Effective Prototyping Strategies

Close collaboration with your supplier is vital. It eliminates guesswork and ensures designs are manufacturable. This is essential for rapid CNC prototyping Melbourne projects.

Integrating feedback loops is equally important. Early-stage part testing allows for quick adjustments, preventing major issues later. This approach accelerates development significantly.

| Estratégia | Benefício chave |

|---|---|

| Colaboração de fornecedores | Improved Design for Manufacturability (DFM) |

| Integrated Feedback | Faster Iterations and Problem Solving |

This structured method helps deliver high-quality Melbourne CNC prototypes faster.

Enhancing Collaboration for Better Outcomes

True collaboration begins before a design is final. I always advise engineers to engage with their CNC machining Melbourne partner early. This proactive communication is a game-changer. It allows us to provide input on material selection and tolerance capabilities.

This early engagement supports a process similar to Engenharia simultânea2. By working together, we can identify potential production hurdles. This prevents costly redesigns down the line. It’s about making smart decisions upfront.

The Feedback Loop Advantage

A swift and effective feedback loop is critical. Once you receive your initial Melbourne CNC prototypes, the testing phase begins.

Your feedback on performance and fit is invaluable. It allows us to make precise adjustments for the next iteration. This iterative cycle of testing and refining ensures the final part meets your exact specifications. It’s a foundational step for successful production.

| Fase de prototipagem | Área de incidência | Objetivo |

|---|---|---|

| Early Engagement | Design & Material Review | Prevent future manufacturing issues. |

| Initial Prototype | Fit & Function Testing | Gather performance data quickly. |

| Iteration | Implementing Feedback | Refine the design for production. |

This method transforms the prototyping process from a linear path to a dynamic, responsive cycle.

Effective prototyping combines close supplier partnerships with rapid feedback loops. This integrated approach minimizes errors, streamlines development, and accelerates your time-to-market for complex engineering projects. It makes the entire process more efficient and predictable.

Ultimate Guide To CNC Material Selection For Melbourne Buyers

Selecting the right material is a critical first step. It directly impacts your part’s performance, cost, and durability. For any CNC machining project in Melbourne, this choice is foundational.

You must think about the part’s final use.

Function and Stress Tolerance

What will the part do? Will it bear heavy loads? Will it be exposed to chemicals or high temperatures? Answering these questions helps narrow your options significantly, guiding you to a successful outcome.

A simple comparison can help start the process.

| Material | Caraterísticas principais | Melhor para |

|---|---|---|

| Alumínio 6061 | Lightweight, Good Strength | Structural parts, prototypes |

| Plástico ABS | Impact Resistant, Low Cost | Enclosures, consumer goods |

This initial decision sets the foundation for your project.

A Practical CNC Machining Material Guide for Melbourne Innovators

Choosing between metals and plastics is a common starting point. Your part’s function and budget are the primary drivers. At PTSMAKE, we help clients navigate these options to find the perfect fit for their application.

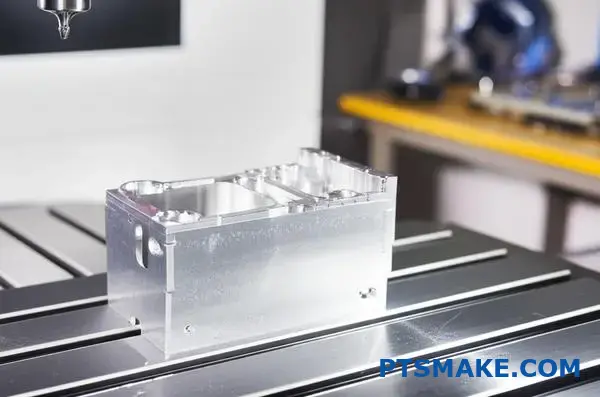

Metals: For Strength and Precision

Metals are ideal for parts needing high strength and rigidity. Aluminum 6061 is a go-to choice for many Melbourne projects. It has an excellent strength-to-weight ratio and is easily machined, making it very versatile.

Stainless Steel 304 offers superior corrosion resistance and durability. This makes it perfect for medical devices or food-grade parts. The properties of some metals can be anisotrópico3, which is an important consideration for high-stress components.

Plastics: For Versatility and Prototyping

Plastics are often the best CNC materials for prototyping. They offer lower material costs and faster machining times. ABS is a fantastic general-purpose plastic, great for housings, fixtures, and early-stage models.

For high-performance needs, we often suggest PEEK. It has exceptional chemical resistance and performs well at high temperatures.

| Material | Resistência à tração (MPa) | Maquinabilidade | Fator de custo |

|---|---|---|---|

| Alumínio 6061 | ~310 | Excelente | Médio |

| Aço inoxidável 304 | ~586 | Justo | Elevado |

| ABS | ~40 | Excelente | Baixa |

| PEEK | ~97 | Bom | Muito elevado |

This basic guide helps simplify choices for your next project.

Choosing the right material involves balancing function, stress tolerance, and cost. This decision is fundamental to achieving desired performance for your CNC machined parts. Careful selection in the early stages prevents costly redesigns and ensures your project’s success in Melbourne.

How Melbourne Procurement Teams Can Reduce CNC Machining Costs

Effective cost optimization for CNC machining in Melbourne goes beyond finding the cheapest quote. It starts much earlier.

Smart procurement teams focus on strategic decisions. These choices can drastically lower unit costs without sacrificing quality.

Strategic Ordering

Ordering in larger quantities almost always reduces the per-unit price. This is due to setup time savings and material discounts. Planning your inventory needs can lead to significant savings.

| Quantidade da encomenda | Estimated Cost Per Unit (Index) |

|---|---|

| 10 | 100% |

| 100 | 65% |

| 1000 | 40% |

Smarter Part Designs

Simple changes can cut machining time. For example, using standard hole sizes or avoiding very deep pockets helps.

To truly reduce CNC part cost in Australia, we need to look deeper than just the purchase order. It involves a collaborative approach between your design team and your manufacturing partner. This is where we can unlock real, sustainable savings.

Standardize Your Materials

Using a common material across multiple parts simplifies procurement. It also allows your supplier to buy in bulk. This reduces material costs and lead times. We often guide clients to select versatile alloys that meet specifications for several components.

Optimize Tolerances for Function

One of the biggest cost drivers is unnecessarily tight tolerances. Every tight tolerance adds machining time and requires more complex inspection. This increases the scrap rate and overall cost. You should always ask if a specific tolerance is critical for function.

| Nível de tolerância | Custo relativo de maquinagem |

|---|---|

| Loose (+/- 0.5mm) | 1x |

| Standard (+/- 0.1mm) | 1.5x |

| Tight (+/- 0.01mm) | 4x |

Applying principles of Conceção para a capacidade de fabrico4 is crucial. At PTSMAKE, we work with engineering teams to review designs. We identify areas where loosening a non-critical tolerance can save money without affecting performance.

Strategic procurement involves smart design, material standardization, and bulk ordering. These methods provide a clear path for Melbourne teams to achieve significant cost savings in CNC machining without compromising on the quality or function of their parts.

The Truth About Local Vs Overseas CNC Manufacturing For Melbourne Buyers

Deciding between local and overseas suppliers is a critical choice for any Melbourne business. It’s a balance of cost, speed, and communication. There is no single right answer for every project.

Local Melbourne Shops: The Pros

Local shops offer unmatched speed for prototypes. Communication is simple due to shared time zones and language. This makes quick design changes much easier to handle.

Overseas Partners: The Global Edge

International partners, on the other hand, often provide significant cost advantages. This is especially true for larger production runs where economies of scale are vital.

Here is a quick overview.

| Caraterística | Local Melbourne | Overseas Partner |

|---|---|---|

| Prazo de execução | Faster (days) | Slower (weeks) |

| Custo unitário | Mais alto | Inferior |

| Comunicação | Mais simples | Mais complexo |

| Escalabilidade | Limitada | Elevado |

The debate of offshore CNC machining vs local Melbourne goes beyond the initial quote. You must consider the entire manufacturing ecosystem and how it aligns with your project’s lifecycle. It’s a question of strategic fit.

Comparing CNC Part Sourcing: Australia & China

For many, this choice boils down to CNC part sourcing Australia & China. Australian shops excel at rapid turnaround and high-mix, low-volume production. Their proximity makes in-person visits and quality checks straightforward for any local cnc machining melbourne projeto.

However, when production scales up, the cost structure often favors an overseas partner. A key factor is the investment in technology and automation, which can be higher in regions like China. This often translates to lower costs for complex, high-volume parts. You should also consider the total cost of ownership5, not just the per-part price.

A Deeper Look at Key Differences

Let’s break down the practical considerations for your decision.

| Aspeto | Local Melbourne Supplier | Overseas Partner (e.g., PTSMAKE) |

|---|---|---|

| Intellectual Property | Stronger legal protection | Requires careful vetting |

| Aprovisionamento de materiais | Standard materials readily available | Wider range of specialized materials |

| Ideal Project | Prototypes, small runs, urgent needs | High-volume production, cost-sensitive parts |

| Flexibilidade | High for quick design changes | High for production volume changes |

At PTSMAKE, we bridge this gap by offering robust communication protocols. This ensures that even from afar, you get the clarity and reliability you need for successful production.

The decision between local and offshore CNC machining is a strategic one. Melbourne offers speed and simplicity for initial stages, while global partners provide unmatched scalability and cost benefits for production, impacting your project’s overall financial success.

What Every CTO In Melbourne Should Ask Before Partnering With A CNC Shop

Finding the right partner for CNC machining in Melbourne goes beyond a simple quote. As a CTO, your focus should be on building a resilient supply chain.

This requires asking pointed technical and strategic questions. You need to verify their capabilities, quality systems, and ability to scale. This is about finding a growth partner, not just a parts supplier.

Here are some high-level questions to start with.

| Categoria | Pergunta-chave |

|---|---|

| Technical | What is your standard inspection protocol for complex parts? |

| Strategic | How do you manage a sudden 50% increase in order volume? |

| Risco | What are your specific contingency plans for machine downtime? |

This structured inquiry helps you identify true long-term partners.

Um bom CNC shop vetting guide for Australia must probe deeper into a potential partner’s operational DNA. It’s about understanding their daily processes and their crisis-response plans. The quality of their answers reveals their suitability as a long-term partner.

Technical and Quality Assurance Protocols

Go beyond asking if they perform quality checks. Ask for their specific inspection protocols and the equipment they use. Do their technicians have expertise in advanced metrologia6? Clear inspection processes are fundamental to building trust. At PTSMAKE, we provide detailed inspection reports to ensure full transparency.

Another critical point is material traceability. Ask for their process for tracking raw materials from sourcing to the final product, including certifications. This is non-negotiable for industries requiring strict compliance.

Strategic Alignment and Risk Mitigation

Your production needs will change. A valuable partner must be able to scale efficiently. Ask how they manage production scheduling and what their capacity utilization rates are. This helps you gauge if they can handle your growth. These are vital ‘Melbourne CTO CNC machining questions’.

| Vetting Area | Specific Question to Ask |

|---|---|

| Inspection Protocols | Can you share a sample First Article Inspection (FAI) report? |

| Escalabilidade | What is your process for onboarding a new high-volume project? |

| Risk Mitigation | What is your data security and disaster recovery plan? |

| Manuseamento de materiais | How do you verify the authenticity of material certifications? |

These questions help you filter for shops that think strategically about your project’s success, not just the current order.

Asking these detailed questions is crucial. It helps you assess a shop’s real-world capabilities, risk management, and scalability. This ensures you secure a reliable long-term partner for your CNC machining needs in Melbourne, not just a short-term supplier.

How To Ensure Consistency Across Repeated CNC Machining Orders In Melbourne

Consistency is everything in manufacturing. For repeat orders, it’s non-negotiable. Your tenth batch must be identical to your first. This is crucial for any project.

Achieving this requires a systematic approach. It is not about luck. It’s about planning and control.

The Pillars of Consistency

Strong quality control is the foundation. It ensures every part meets spec. It’s how we deliver repeatable CNC parts Melbourne businesses can trust.

A clear plan prevents errors. It makes the process reliable and predictable. This ensures consistent CNC production Australia wide.

| Ponto de controlo | Objetivo | Frequência |

|---|---|---|

| First-Off Inspection | Verify initial setup and accuracy | At the start of each run |

| In-Process Checks | Monitor dimensions during production | Periodically |

| Inspeção final | Confirm final parts meet all specs | 100% or statistical sampling |

Beyond initial checks, a robust system is vital. It’s about creating a repeatable framework. This framework guarantees identical outcomes every time. It’s a core part of our process at PTSMAKE.

The Digital Blueprint for Success

Your digital part files are the single source of truth. We treat them as the master blueprint for every production run.

This eliminates any guesswork. Every specification is locked in from the start.

Digital files lock in every detail. This includes complex specifications guided by principles like Dimensionamento Geométrico e Tolerância7. This ensures a perfect match to your design every time.

A formal repeatability plan is key. It documents every single variable for the job. This includes machine setups and specific tooling.

| Repeatability Plan Element | Descrição |

|---|---|

| Program Version | Ensures the correct G-code is always used. |

| Tooling List | Specifies exact tools, holders, and lengths. |

| Fixturing Instructions | Details how the part is held for machining. |

| Material Batch | Tracks the specific material lot for traceability. |

By controlling these factors, we can replicate any order. We achieve precision down to the micron. It is how we produce repeatable CNC parts Melbourne clients rely on for their critical applications.

A robust quality control system, detailed repeatability plans, and the strict use of digital files as a single source of truth are essential. These elements ensure every batch of your CNC machined parts is perfectly consistent with the last.

How To Align CNC Part Specs With Melbourne’s Industry Standards

Aligning your CNC part specifications with industry standards is not optional. Especially in Melbourne’s advanced sectors like healthcare and aerospace. It is a fundamental requirement.

This alignment ensures safety, reliability, and interoperability. Achieving CNC standards compliance in Melbourne means your parts are fit for purpose. They meet the strict demands of their application.

Key Standards for Critical Sectors

Different industries follow specific standards. Understanding these is the first step. For any cnc machining melbourne project, clarity here is crucial.

| Indústria | Primary Standard | Área de incidência |

|---|---|---|

| Cuidados de saúde | ISO 13485 | Medical Device Quality Management |

| Aeroespacial | AS9100 | Gestão da qualidade aeroespacial |

| Defence | MIL-SPEC | Military Performance Specifications |

These standards dictate everything from material choice to final inspection processes.

The Compliance Pathway: From Paper to Part

Achieving compliance is a systematic process. It starts long before the first chip is cut. It involves a deep dive into the specific standard’s requirements. At PTSMAKE, we guide our clients through this from the very beginning.

Documentação e rastreabilidade

First, every requirement must be documented. Your specifications must clearly reference the applicable standards. This includes material grades, tolerance callouts, and finishing requirements.

Full rastreabilidade dos materiais8 is essential. You must be able to track a material from its source certificate all the way to the finished part. This is a non-negotiable for aerospace and medical components.

Process Validation and Control

Next, the manufacturing process itself must be validated. This proves that your chosen method consistently produces parts that meet the spec. This is a core tenet of certified CNC machining Australia.

We use a simple framework to manage this.

| Etapa | Ação | Método de verificação |

|---|---|---|

| 1. Revisão | Analyse part spec against the standard. | Create a compliance checklist. |

| 2. Materials | Procure certified materials only. | Maintain Mill Test Reports (MTRs). |

| 3. Maquinação | Set up validated machine processes. | First Article Inspection (FAI). |

| 4. Inspection | Use calibrated tools for measurement. | CMM reports, quality records. |

Following these steps ensures that every part delivered is fully compliant and ready for its critical application. It is the only way to operate responsibly in these high-stakes industries.

Aligning specifications with standards like ISO and AS is a detailed process. It requires rigorous documentation, validated processes, and full traceability to ensure safety and reliability in critical sectors like healthcare and aerospace.

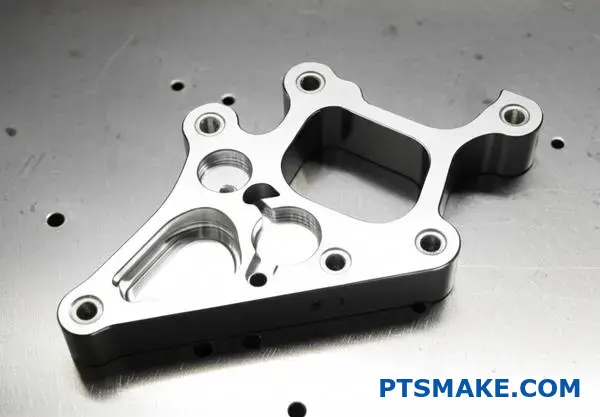

Smart Design Tips To Make CNC Machining Easier For Melbourne Factories

Simplifying your design is the fastest way to reduce costs. It directly impacts machining time and complexity. Smart design choices lead to fewer machine setups.

This approach is central to Design for Manufacturability (DFM). For any DFM CNC Melbourne project, the goal is always clear. We aim for easy to machine part designs.

Key Simplification Areas

Consider how geometry affects the process. Complex shapes often require multiple operations and specialized tooling.

| Caraterística | Complex (More Setups) | Simple (Fewer Setups) |

|---|---|---|

| Cantos | Cantos internos afiados | Cantos interiores arredondados |

| Furos | Angled or deep holes | Through-holes on one plane |

| Superfícies | Complex 3D curves | Flat, 2D surfaces |

These small adjustments significantly speed up production. They are fundamental to efficient CNC machining.

True efficiency in CNC machining comes from minimizing setups. Every time a part is re-fixtured, it adds time and potential for error. This is a core challenge for any CNC machining Melbourne service.

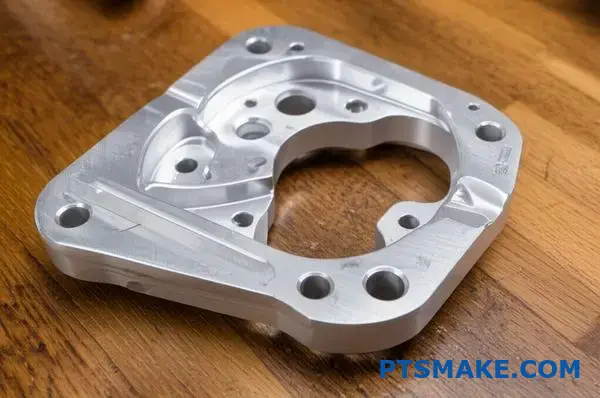

Reducing Setups and Operations

A great strategy is to consolidate features onto a single plane. If possible, design parts so all milling can happen from one direction. This eliminates the need to rotate and re-clamp the workpiece, saving significant time.

Another key aspect is managing tolerância9. Overly tight tolerances where they aren’t functionally necessary drive up costs. They require more precise machining, slower speeds, and extra inspection steps.

Standardizing for Efficiency

Standardization is another powerful tool. Using common hole sizes, standard thread types, and consistent fillet radii allows us to use fewer tools.

| Escolha do design | Impacto na maquinagem | Recomendação |

|---|---|---|

| Non-Standard Holes | Requires custom drills | Use standard drill bit sizes |

| Varied Radii | Multiple tool changes | Use one or two radii sizes |

| Tolerâncias apertadas | Slower machine speeds | Specify only where critical |

At PTSMAKE, we often collaborate with clients on these details. A quick design review can often reveal simple changes that yield big savings without compromising the part’s function or integrity. This is how easy to machine part designs are born.

By simplifying designs, engineers can significantly reduce machine setups and complexity. This DFM approach cuts production time and costs, ensuring more efficient manufacturing for Melbourne factories without sacrificing quality.

The Quick-Start Procurement Guide For New CNC Projects In Melbourne

Navigating the CNC project procurement Melbourne landscape can seem complex. But a clear roadmap simplifies the journey. It ensures nothing is missed.

This guide provides a step-by-step plan. It covers everything from your initial request to final delivery. Following these stages is key.

Key Procurement Milestones

A structured approach prevents delays and cost overruns. It keeps your project on track.

| Estágio | Ação-chave | Objetivo |

|---|---|---|

| 1. PEDIDO DE COTAÇÃO | Submit detailed documents | Receive accurate quotes |

| 2. Vetting | Evaluate supplier capabilities | Select the right partner |

| 3. Production | Monitor progress | Ensure quality standards |

| 4. Delivery | Final inspection & logistics | Receive parts on time |

This framework is essential for success.

A structured procurement plan is your best tool. It transforms a complex process into manageable steps. This is crucial when you start buying CNC parts Australia-wide or globally. It avoids common pitfalls I’ve seen derail otherwise good projects.

The Detailed Roadmap

Your Request for Quotation (RFQ) is the foundation. A weak RFQ leads to inaccurate quotes and delays. Your package must be comprehensive. Include 3D CAD files, 2D drawings with tolerances, material specs, quantity, and finishing requirements. This clarity helps us at PTSMAKE provide a precise quote quickly.

From Vetting to Final Part

Once quotes are in, vet your suppliers. Look beyond price. Consider their quality control systems, communication, and experience with similar projects.

After selecting a partner, the process moves to production. A critical step here is the Inspeção do primeiro artigo (FAI)10. This verifies that the first part produced meets all specifications before mass production begins. Clear communication during this phase is vital for any cnc machining melbourne project.

Finally, manage logistics for delivery. Ensure parts are packed correctly to avoid damage during transit.

| RFQ Checklist | Detalhes necessários |

|---|---|

| Ficheiros de design | 3D (e.g., STEP) & 2D (PDF) |

| Material | Specific grade and standard |

| Tolerâncias | Geometric Dimensioning & Tolerancing |

| Quantidade | Include potential future orders |

| Acabamento | Anodizing, plating, painting, etc. |

| Linha do tempo | Desired delivery date |

A structured procurement roadmap, from a detailed RFQ to final delivery inspection, is essential. This systematic approach ensures clarity, manages expectations, and minimizes risks for any CNC project in Melbourne, leading to a successful outcome.

How Melbourne Startups Can Accelerate Product Launches With CNC Machining

Melbourne’s startup scene is incredibly competitive. Speed is everything. When you have a new hardware idea, you need to test it quickly. This is where CNC machining becomes a powerful ally for early-stage development.

Prototyping at Startup Speed

Startups can’t afford long waits for prototypes. CNC machining offers a direct path from a digital file to a physical part. This speed is crucial for testing and validation. It allows for fast iterations.

Small Runs and Market Testing

Once a design is validated, you need parts for market testing. CNC is ideal for these small production runs. You avoid the high upfront costs associated with traditional tooling for mass production.

| Estágio | Traditional Method (e.g., Molding) | CNC Machining Approach |

|---|---|---|

| Conceito | Slow, expensive tooling | Fast, direct from CAD |

| Protótipo | Semanas ou meses | Dias |

| Small Run | High cost per unit | Rentável |

| Pivot | Requires new, costly tools | Simple design file update |

This agile approach helps startups stay lean. You can make changes and adapt without breaking the budget.

For Melbourne startups, the product development cycle is a race against time. The ability to quickly pivot based on user feedback is not a luxury; it is a necessity. This is a key advantage for startups and CNC machining.

Navigating the Pivot Cycle

A pivot requires changing your product design. With methods like injection molding, a pivot means creating entirely new molds. This is a major expense and can take months.

CNC machining eliminates this barrier. A design change is just a software update. Your manufacturing partner can produce the revised part almost immediately. This allows for true agile hardware development.

Finding the right CNC prototype partner Melbourne is critical. You need a partner who understands the startup mindset. They must be responsive and capable of handling quick turnarounds and design modifications.

A good partner will also provide feedback on manufacturability. This ensures your prototype isn’t just a one-off. It’s a step towards a scalable product. Early attention to details like Dimensionamento Geométrico e Tolerância (GD&T)11 can save significant costs later. At PTSMAKE, we guide our clients through this process.

| Pivot Phase | CNC Machining Benefit | Impact on Startup |

|---|---|---|

| Feedback Analysis | Design can be quickly altered in CAD. | Reduced time to decision. |

| Iteração do projeto | No new tooling is required. | Minimal financial risk. |

| New Prototype | Parts produced within days. | Faster validation cycle. |

| Market Re-test | Small runs are economically viable. | Agile response to market needs. |

This process de-risks product development significantly.

CNC machining provides the speed and flexibility essential for startups. It supports rapid prototyping, cost-effective small runs, and agile pivots. This helps Melbourne startups get to market faster and with less financial risk, turning innovative ideas into successful products.

The Real Cost Drivers Behind CNC Machining In The Melbourne Market

Ever wonder what’s behind a CNC machining quote? It’s not just one number. The price reflects a careful calculation of several key factors. Understanding this helps you design more cost-effective parts.

The final cost of CNC parts in Melbourne is a sum of four main things.

The Core Four Cost Drivers

These elements form the foundation of any quote.

| Fator de custo | Descrição | Impacto no preço |

|---|---|---|

| Material | The raw stock used for the part | Varies by type and quantity |

| Tempo da máquina | Hours the CNC machine is running | A major cost component |

| Trabalho | Skilled human setup and oversight | Crucial for quality and setup |

| Ferramentas | Cutters and fixtures needed | Can be a one-time or ongoing cost |

Este CNC pricing breakdown Melbourne shows how each part contributes to your final invoice.

Let’s dig deeper into how these factors truly influence the cost. It’s more complex than it first appears. The relationship between them is what really shapes the final price for cnc machining melbourne.

Material Selection’s Ripple Effect

Choosing an exotic alloy doesn’t just raise the raw material cost. Harder materials wear down tools faster, increasing tooling expenses. They also require slower machine speeds. This directly increases the machine time needed to produce a single part.

The Hidden Costs in Machine Time

Machine time isn’t just about the minutes spent cutting. It includes the crucial setup phase. This is where a skilled machinist prepares the machine, which can take hours. Complex parts require more setup, adding to the cost before any cutting begins.

Labor: Beyond the Operator

Labor costs are not just for the person watching the machine. Highly skilled programmers are needed to translate your CAD file into machine instructions (G-code). Their expertise is a vital part of the cost of CNC parts in Melbourne, ensuring precision and efficiency. Effective programming can actually reduce machine time.

O processo de amortização12 is often applied to initial setup and tooling costs. This happens especially over larger production volumes.

| Fator | Hidden Influence |

|---|---|

| Material | Affects tool life and machining speed. |

| Tempo da máquina | Includes non-cutting setup and programming time. |

| Trabalho | Involves expert CAM programming, not just operation. |

| Ferramentas | Custom tools add significant upfront cost. |

Understanding this interplay is key.

The true cost of a CNC part is a blend of material, machine time, skilled labor, and specific tooling. Each factor influences the others, creating a complete pricing picture that goes beyond just the raw numbers.

Get Your CNC Machining Project Started with PTSMAKE Today!

Ready to solve your CNC machining Melbourne challenges? Partner with PTSMAKE for fast, reliable quotes, expert engineering support, and industry-leading precision from prototype to production. Send us your RFQ now and experience trusted, hassle-free manufacturing with PTSMAKE—your next-generation precision partner!

Discover how GD&T ensures your design intent is perfectly translated into a physical, high-precision part. ↩

Discover how this collaborative method merges design and manufacturing phases to drastically shorten development timelines and boost product quality. ↩

Discover how a material’s directional properties can impact your part’s strength and performance. ↩

Discover how these design principles can streamline production and significantly lower your manufacturing expenses. ↩

Learn how factors beyond the initial price influence your project’s budget and long-term viability. ↩

Learn how the science of measurement ensures your parts meet exact design specifications and quality standards. ↩

Saiba como esta linguagem simbólica garante que a sua intenção de design é perfeitamente traduzida numa peça física. ↩

Understand how this crucial process guarantees the integrity and safety of every component. ↩

Learn how precise tolerancing can impact your project’s cost and functionality. ↩

Learn why this quality step is crucial for validating your design and manufacturing process. ↩

Learn how this system creates a universal design language for engineers. ↩

See how initial one-time expenses are distributed across parts to lower the per-unit cost. ↩