Finding a trustworthy CNC machining supplier in Adelaide feels impossible when your project deadlines are on the line. You’ve probably experienced the frustration of suppliers who promise precision but deliver inconsistent quality, leaving you scrambling to find alternatives while your production schedule falls apart.

The key to successful CNC machining in Adelaide lies in understanding exactly what questions to ask suppliers, how to evaluate their capabilities, and establishing clear communication channels before committing to any partnership.

I’ve worked with manufacturing teams across different industries, and I see the same challenges repeatedly. The good news is that Adelaide has capable CNC shops – you just need to know how to identify them and set up partnerships that actually work for your specific needs.

The Complete Guide to Finding a Reliable CNC Machining Partner in Adelaide

Finding a trustworthy CNC machining supplier in Adelaide can be tough. The success of your project often hinges on this choice. A reliable partner ensures your timelines are met.

The Challenge in Adelaide

The core issue is separating skilled machinists from those who overpromise. Your goal is to find a partner who delivers on time, every time.

Why Reliability is Non-Negotiable

A single delay can have a ripple effect. It pushes back assembly, testing, and your product launch. Finding reliable CNC machining in Adelaide is essential for project stability.

| Fator | Reliable Partner | Unreliable Partner |

|---|---|---|

| Timelines | Consistently On-Time | Frequent Delays |

| Qualidade | Meets Specs | High Reject Rate |

| Comunicação | Proactive & Clear | Slow or Vague |

This guide will show you how to find a CNC machining supplier in Adelaide that you can count on.

The search for trusted CNC machining services in Adelaide goes beyond just finding a workshop with the right equipment. The real test is in their process, communication, and commitment to quality. Choosing the wrong supplier introduces significant risks to your project.

The Hidden Costs of a Poor Partner

An unreliable supplier creates more than just delays. It leads to material waste from rejected parts. This directly impacts your budget. It can also damage your company’s reputation if final product quality suffers as a result. These are costs that don’t appear on the initial quote.

Evaluating True Competence

How do you find a truly reliable CNC machining Adelaide service? Look beyond their machine list. Ask about their quality control processes. Request examples of past work with similar complexity and materials to your own project.

A key indicator is their understanding of technical drawings. Their team must be fluent in interpreting every detail. This includes specifications for surface finish, material hardness, and complex geometries. Their ability to understand Dimensionamento Geométrico e Tolerância1 is absolutely critical for precision work.

| Área de avaliação | O que procurar |

|---|---|

| Sistemas de qualidade | ISO 9001 or equivalent certification |

| Conhecimentos técnicos especializados | In-house engineering support |

| Past Performance | Case studies or client testimonials |

| Comunicação | A clear point of contact |

Choosing the right partner is an investment in your project’s success.

Finding a reliable CNC machining partner in Adelaide requires looking past quotes to evaluate their process and technical expertise. A supplier’s commitment to quality control and clear communication is crucial for avoiding costly delays, budget overruns, and reputational damage.

Critical Questions to Ask Your Adelaide CNC Machining Supplier

Finding the right CNC machining partner in Adelaide is critical. Your project’s success hinges on their capabilities. A simple conversation isn’t enough. You need a structured approach to evaluation.

This checklist provides essential questions. It helps you vet potential suppliers effectively. We will focus on the core areas that truly matter for your project’s outcome.

Key Vetting Areas

| Categoria | Foco |

|---|---|

| Controlo de qualidade | Consistency and adherence to specs |

| Production Capacity | Ability to meet your deadlines |

| Comunicação | Transparency and project updates |

Using these targeted CNC machining supplier Adelaide questions will help you make a much more informed decision.

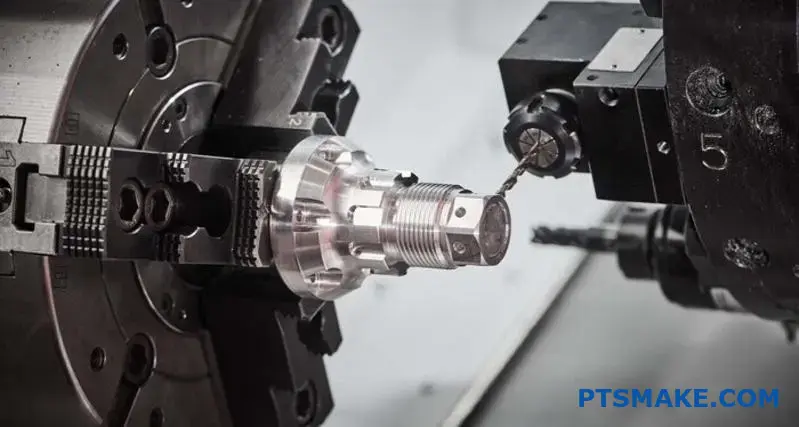

When evaluating CNC shops in Adelaide, you must look beyond the price quote. Dig deeper into their operational processes. This is the only way to ensure they can handle your specific needs for precision parts.

Drilling Down on Quality Assurance

Your first question should target their Quality Management System (QMS). Ask if they hold certifications like ISO 9001. This serves as a fundamental benchmark for quality.

Inquire about their inspection process and equipment. Do they use Coordinate Measuring Machines (CMMs)? How often are their tools calibrated? This shows their true commitment to precision. You also need to understand their Rastreabilidade dos materiais2 process, from raw stock to the final component.

Assessing Capacity and Scalability

Next, discuss their production capabilities. Ask about the types and number of CNC machines they operate. It’s important to know their limitations on part size and complexity before you commit.

A crucial part of what to ask a CNC machining company Adelaide involves lead times. Ask for realistic estimates for a project similar to yours. Also, inquire how they manage unexpected production surges. A reliable partner will have a clear contingency plan.

Evaluating Communication Protocols

Clear and consistent communication prevents costly errors and delays. Ask who your dedicated point of contact will be. How will they provide status updates throughout the manufacturing process?

| Red Flags (Poor Answers) | Green Flags (Good Answers) |

|---|---|

| "We just check parts at the end." | "We have in-process and final inspections." |

| "Lead times can vary a lot." | "Our standard lead time is X weeks; we can expedite." |

| "Just email the general info address." | "You’ll have a dedicated project manager." |

This checklist provides a framework for your vetting process. Asking these questions about quality, capacity, and communication helps you identify a truly capable Adelaide CNC machining partner, ensuring your project’s success from the start.

Secrets to Ensuring Consistent Part Quality from Adelaide CNC Shops

Inconsistent quality is a project killer. One batch of parts is perfect, but the next causes major assembly headaches. This is not just bad luck. It is a fundamental failure of process.

Achieving high-quality CNC machining in Adelaide is never an accident. It comes from a robust and repeatable quality assurance system.

Before you partner with any shop, you must demand clear evidence of their quality control framework. These processes are your only true guarantee.

The Non-Negotiable Quality Checklist

To get consistent results, your partner must be dedicated to quality control. Vague promises about quality are a red flag. Always ask for specific, documented processes. This is essential for ensuring part accuracy in Adelaide.

Foundational Standards: ISO 9001

An ISO 9001 certification is your starting point. It proves the shop has a documented quality management system. This isn’t just a certificate on the wall. It shows a real commitment to process control and improvement.

Critical Inspection Gateways

First-Article Inspection (FAI) is a critical step. It confirms the first part from a production run meets every single specification. This must happen before full production starts.

In-process quality checks are just as vital. These inspections during the run catch any potential issues early. This active approach is central to effective CNC machining quality control in Adelaide. For the most complex and critical dimensions, we rely on detailed reporting from a Máquina de medição por coordenadas (CMM)3. This equipment provides objective proof of accuracy.

| Quality Process | Objetivo | Why It Matters For You |

|---|---|---|

| ISO 9001 | Standardized Quality Management | Ensures a reliable and consistent system. |

| First-Article Inspection | Verifies Initial Setup & Programming | Prevents large-scale production errors. |

| CMM Reporting | High-Precision Dimensional Verification | Guarantees complex parts meet all specs. |

This systematic approach delivers the precision CNC parts Adelaide projects need. It removes guesswork and ensures predictability.

Don’t settle for simple promises. For consistent part quality, demand documented proof of a robust quality system. Insist on seeing certifications, FAI reports, and CMM data. This is how you secure reliable project outcomes.

The Ultimate Guide to CNC Machining Tolerances for Adelaide Engineers

For Adelaide engineers, understanding tolerances is key. It’s about balancing function and cost. Not every feature needs the tightest possible tolerance.

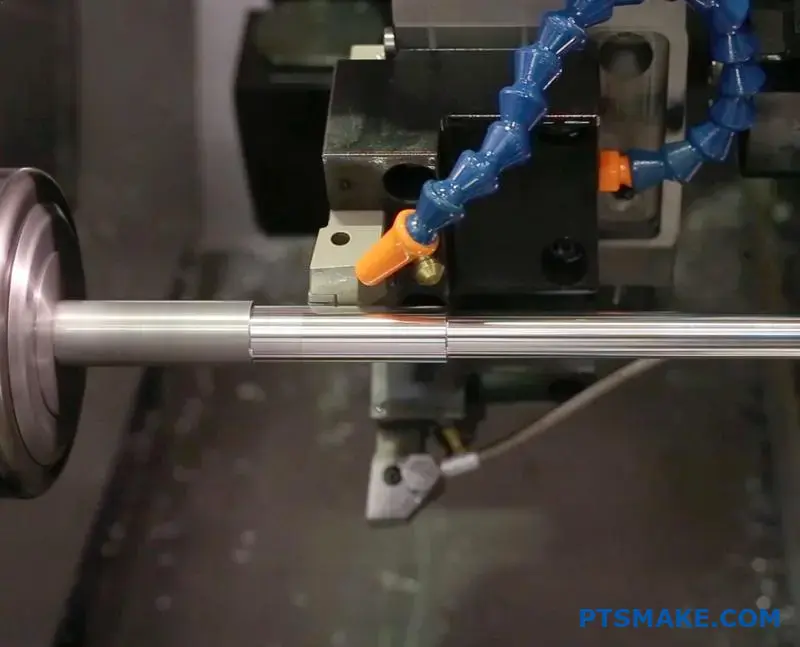

Standard Tolerances: The Baseline

Standard CNC tolerances are a great starting point. They offer reliable precision for most applications without inflating your budget. This is a common benchmark for general machining.

Typical Standard Tolerances

| Material | Tolerância padrão |

|---|---|

| Alumínio | ±0,1 mm |

| Aço | ±0,1 mm |

| Plastics (ABS, PC) | ±0,15 mm |

These values work for many parts we see in precision machining Adelaide.

Specifying tolerances that are too tight is a frequent issue. It drives up costs unnecessarily. Tighter tolerances require more machine time, specialized tooling, and rigorous inspection. This is a crucial factor in CNC machining tolerances Adelaide.

O custo da precisão

Every zero you add to a tolerance value can impact the final price. The relationship between tolerance and cost is not linear; it’s exponential. At PTSMAKE, we advise clients to apply tight tolerances only where absolutely necessary.

This prevents over-engineering and keeps projects on budget. It’s a common discussion we have for tight tolerance machining Adelaide. We often help review designs to find a cost-effective balance.

Function vs. Cost Analysis

Consider the part’s function. Does a non-critical surface really need a ±0.01mm tolerance? Probably not. Focusing precision on mating surfaces or critical interfaces is a smarter approach. Understanding this helps manage the costs of [Geometric Dimensioning and Tolerancing](https://en.wikipedia.org/wiki/Geometric_dimensioning_and_tolerancing)[^4].

Eis uma comparação rápida:

| Nível de tolerância | Impacto nos custos | Tempo de maquinagem | Melhor para |

|---|---|---|---|

| Padrão (por exemplo, ±0,1mm) | Baixa | Padrão | Peças de uso geral |

| Apertado (por exemplo, ±0,025mm) | Médio | Aumento | Mating parts, fits |

| Muito apertado (por exemplo, <±0,01 mm) | Elevado | Aumento significativo | High-precision fits |

Understanding standard versus tight tolerances is vital for managing costs in CNC machining projects. Specifying precision only where functionally required ensures you get high-quality parts without overspending on non-critical features.

Choosing the right material is a critical first step. It directly impacts your project’s performance, cost, and production timeline. Your decision balances function, budget, and manufacturability for any cnc machining adelaide project.

We will explore common materials for CNC machining. This includes popular options like aluminum, stainless steel, and various engineering plastics. Each offers unique benefits and trade-offs.

Here is a quick overview of common choices:

| Material | Caraterísticas principais | Melhor para |

|---|---|---|

| Alumínio | Lightweight, excellent machinability | Prototypes, aerospace components |

| Aço inoxidável | Forte, resistente à corrosão | Medical devices, food-grade parts |

| Plastics (e.g., ABS) | Versatile, cost-effective | Enclosures, consumer products |

Understanding these basics helps identify the best materials for CNC machining Adelaide.

Selecting CNC machining materials in Adelaide requires a deeper look. The final application should always be your starting point. What specific function must this part perform? Answering this question narrows your options considerably.

Equilíbrio entre desempenho, custo e maquinabilidade

A component requiring high strength might suggest stainless steel. But you must consider the budget. Stainless steel machining Adelaide can be more expensive than other metals. This is due to slower cutting speeds and increased tool wear.

With aluminum CNC machining Adelaide, you gain efficiency. Aluminum is easy to cut, leading to faster production cycles. This can lower the overall project cost. It is a perfect example of how machinability impacts the final price.

Plastics offer incredible versatility. Materials like PEEK provide high-temperature resistance. Others, like Delrin, offer excellent lubricity for moving parts. Some materials can be anisotrópico4, which affects their strength based on the part’s orientation.

Local Availability in Adelaide

Always consider what materials are readily available. Sourcing common stock in Adelaide reduces lead times significantly. It also cuts down on shipping costs. This is a practical advantage for projects with tight deadlines.

Eis uma comparação mais pormenorizada:

| Fator | Alumínio (6061) | Aço inoxidável (304) | Plastic (Delrin) |

|---|---|---|---|

| Resistência ao peso | Excelente | Bom | Justo |

| Resistência à corrosão | Bom | Excelente | Excelente |

| Maquinabilidade | Excelente | Justo | Excelente |

| Custo relativo | Médio | Elevado | Baixo-Médio |

This framework helps you ask the right questions. At PTSMAKE, we often guide clients through this decision-making process. We ensure your choice aligns with both technical needs and business goals.

Material selection is a critical balance. You must weigh the application’s demands against machinability, cost, and local Adelaide availability. This ensures your final CNC machined part meets both performance specifications and budget constraints.

The Hidden Costs of CNC Machining in Adelaide You Must Know

As a procurement manager, your focus is the bottom line. You look at the unit price and make a decision. But that number is often just the beginning.

Understanding the full CNC machining cost in Adelaide is key. Many factors hide behind that initial quote.

Breaking Down the Quote

True cost analysis goes beyond the price-per-part. You need to account for several other essential expenses.

Let’s look at the main components.

| Componente de custo | Descrição |

|---|---|

| Setup Fees | Preparing the CNC machine for a specific job. |

| Ferramentas | Costs for cutting tools, jigs, or fixtures. |

| Secondary Ops | Post-machining finishes or treatments. |

| Logística | Shipping, customs, and delivery charges. |

Ignoring these can lead to unexpected budget overruns. A detailed quote is crucial for finding affordable CNC machining in Adelaide.

A Deeper Look at Cost Factors

Let’s dissect these hidden costs further. Understanding CNC machining pricing in Adelaide means knowing what each line item represents. This is where a partnership with a transparent manufacturer like PTSMAKE becomes invaluable.

Setup and Tooling Charges

Setup costs cover CAM programming and physical machine preparation. This is a fixed cost. For small batches, it significantly impacts the per-unit price. For larger runs, its effect lessens.

Tooling can be a major expense, especially for complex parts requiring custom tools. Standard tools have minimal impact. But a custom fixture, while costly upfront, can ensure precision and reduce cycle times later. This is a critical part of evaluating the cost factors for CNC parts in Adelaide.

Secondary Operations & Logistics

Parts often need finishing touches after machining. These secondary operations are essential for function or appearance.

| Funcionamento | Objetivo | Impacto nos custos |

|---|---|---|

| Anodização | Resistência à corrosão, cor | Moderado |

| Tratamento térmico | Hardness, durability | Moderado a elevado |

| Polimento | Surface finish, aesthetics | Varies with spec |

| Montagem | Combining multiple parts | Labor-driven cost |

These processes add cost and time. Logistics, including freight from our facility to Adelaide and final delivery, must also be budgeted. We work with clients to optimize shipping for cost-effectiveness. The Amortização5 of these one-time costs over the production volume is key to getting an accurate per-part cost.

Beyond the unit price, total CNC machining cost includes setup, tooling, finishing, and logistics. A comprehensive quote is vital for accurate budgeting and finding a truly affordable CNC machining solution in Adelaide.

A Proven Framework for Managing CNC Machining Lead Times in Adelaide

Delivery delays are a constant source of frustration. Understanding a realistic CNC machining lead time in Adelaide is the first step to managing it. The process is more than just machine time.

It involves quoting, planning, and finishing. Let’s break down a typical project timeline. This helps set clear expectations from the start.

Typical Timeline from RFQ to Delivery

| Fase | Duration (Business Days) |

|---|---|

| RFQ & Quoting | 1-2 |

| Order Confirmation & Planning | 1-2 |

| Aquisição de materiais | 2-7 |

| CNC Programming & Setup | 1-3 |

| Machining & Production | 3-10 |

| Finishing & Quality Control | 1-3 |

| Embalagem e envio | 1-2 |

Many factors influence this timeline. So, how do you achieve fast CNC machining in Adelaide without issues? The key is proactive collaboration. It’s about working smarter, not just faster.

Reducing CNC production time in Adelaide starts long before a machine is turned on. Clear and complete technical drawings are crucial. Ambiguity leads to questions and delays. We’ve seen well-prepared RFQs get quoted and processed a day faster.

Strategies for Acceleration

Effective planning makes a huge difference. Providing an annual forecast allows us to pre-order raw materials. This can cut procurement time significantly, especially for less common alloys.

Another powerful approach is adopting a concurrent engineering6 mindset. This means design and manufacturing planning happen in parallel, not sequentially. It helps identify potential production issues early on.

Comparing Timelines

Let’s see the potential impact.

| Estratégia | Standard Timeline (Days) | Accelerated Timeline (Days) |

|---|---|---|

| Detailed RFQ | 2 | 1 |

| Material Pre-Ordering | 7 | 2 |

| DFM Feedback Loop | 3 | 1 |

These small changes compound. They can shorten your overall lead time by a week or more. It all comes down to communication and planning.

This chapter breaks down the typical CNC machining timeline in Adelaide. It highlights key phases and provides actionable strategies, such as clear communication and proactive material planning, to accelerate the process from RFQ to final delivery without compromising on quality.

How to Mitigate Supply Chain Risk with Your Adelaide CNC Supplier

Building a resilient supply chain is not about preventing every problem. It’s about being prepared to handle them. Relying on a single source can be risky.

Smart strategies are essential for stability. These include diversifying suppliers and managing inventory wisely. Clear communication is the foundation of it all.

Key Resilience Strategies

Below are some effective tactics. Each has its own benefits and challenges for your Adelaide operations.

| Estratégia | Benefício primário | Considerações fundamentais |

|---|---|---|

| Dual Sourcing | Reduces dependency | Requires managing multiple relationships |

| Inventory Buffers | Absorbs demand spikes | Increases holding costs |

| Comunicação | Evita mal-entendidos | Needs a transparent partner |

These methods are crucial for reducing manufacturing risk in Adelaide. They ensure your production continues smoothly, even when disruptions occur.

The Power of a Transparent Partnership

Beyond tactics, your relationship with your supplier is key. A partnership thrives on open, honest communication. This is what makes a reliable manufacturing partner Adelaide truly valuable. It helps manage expectations and solve problems quickly.

Proactive communication prevents small delays from becoming major shutdowns. Discussing potential issues with your supplier before they escalate is a non-negotiable practice for us at PTSMAKE. This approach is fundamental to reducing manufacturing risk Adelaide.

Building a Strong Communication Framework

A solid communication plan addresses potential points of failure. This ensures everyone is aligned from design to delivery, minimizing the chance of a supply chain disruption CNC Adelaide.

Using a strategy like Dual Sourcing7 provides a safety net. However, without transparent dialogue, even the best plans can fail. A strong partnership is your best defense.

Here are key communication points to establish:

| Communication Point | Frequência | Objetivo |

|---|---|---|

| Project Kick-off | Once per project | Align on scope, specs, and timeline |

| Weekly Updates | Semanal | Track progress and address minor issues |

| Controlos de qualidade | Per milestone | Confirm parts meet specifications |

| Shipping Notices | Por remessa | Provide tracking and delivery estimates |

This structured communication turns your CNC machining supply chain Adelaide from a liability into a strategic asset.

Building resilience requires a multi-faceted approach. Diversifying suppliers, maintaining inventory buffers, and fostering transparent communication with your manufacturing partner are essential. These strategies work together to protect your operations from unexpected disruptions and ensure stability.

The Truth About Surface Finishes for CNC Machined Parts in Adelaide

The journey of a part doesn’t end when the CNC machine stops. The right surface finish is crucial. It’s not just about looks.

A finish protects against corrosion, improves wear resistance, and enhances functionality. Choosing the best option requires balancing performance, cost, and project timelines.

Common Finishing Choices

Here’s a quick look at popular finishing options for machined parts Adelaide. Each serves a distinct purpose for different applications.

| Tipo de acabamento | Material primário | Benefício chave |

|---|---|---|

| Anodização | Alumínio | Resistência à corrosão |

| Revestimento em pó | A maioria dos metais | Durabilidade e cor |

| Revestimento | A maioria dos metais | Conductivity/Corrosion |

These choices significantly impact the final product’s quality and lifespan.

Selecting the right CNC machining surface finish in Adelaide involves critical trade-offs. It’s a key part of post-processing CNC Adelaide projects that I see often overlooked in initial planning stages.

Deeper Dive: Balancing Factors

For example, anodizing services in Adelaide for CNC parts are excellent for aluminum. They create a hard, protective layer. However, this process adds a few days to the lead time.

Powder coating offers a tough, decorative finish in many colors. It’s generally more cost-effective than painting for medium to large batches. But, it can add thickness, which must be accounted for in the design tolerances.

Plating with materials like nickel or chrome offers superior hardness and lubricity. The complexity of the process can increase costs and lead times more significantly than other options. The condition of the original part Substrato8 is also vital for plating adhesion and quality.

Cost and Lead Time Comparison

This table provides a general comparison. Actual impact varies based on part complexity and batch size.

| Finish Option | Impacto nos custos | Impacto dos prazos de entrega | Melhor para |

|---|---|---|---|

| Anodização (Tipo II) | Baixo a médio | +2-4 Days | Aluminum corrosion protection |

| Revestimento em pó | Médio | +3-5 Days | Durable, colorful finishes |

| Niquelagem electrolítica | Médio a elevado | +5-10 Days | Wear resistance, uniformity |

Choosing a surface finish is a crucial decision. It directly impacts your part’s performance, final cost, and delivery schedule. This choice must be integrated into the initial design and production planning for any CNC machining project.

Secrets to Effective Communication with Your Adelaide Machine Shop

Poor communication is the silent killer of many CNC machining projects. A simple misunderstanding can lead to costly rework, missed deadlines, and strained partnerships.

Effective CNC machining communication in Adelaide isn’t about constant calls. It’s about clarity and structure.

This ensures your design intent is perfectly understood. It helps your project stay on track from the start. Let’s explore how to build this foundation for successful machine shop collaboration in Adelaide.

The most common point of failure is the initial technical brief. Ambiguity here creates a ripple effect of problems later on. Assuming your supplier "just knows" is a recipe for disappointment. Clear, documented instructions are non-negotiable for success.

Creating a Bulletproof Communication Plan

A structured approach to project management for machining in Adelaide is key. Start by defining the communication framework before the first chip is cut. This sets expectations for both parties and prevents confusion.

Clear Technical Documentation

This is more than just a 3D model. Your documentation package should be complete. Include detailed 2D drawings with all critical dimensions and tolerances clearly marked. Specify material types, required finishes, and any post-processing steps. Using a system like Dimensionamento Geométrico e Tolerância (GD&T)9 removes any guesswork.

Regular Updates and Escalation

Agree on a schedule for progress updates. A weekly email with photos can be very effective. It keeps you informed and allows for course correction if needed. Also, establish a clear escalation path for issues. Who do you contact if a problem arises?

Here is a simple template we use at PTSMAKE:

| Communication Type | Frequência | Key Information | Point of Contact |

|---|---|---|---|

| Kick-off Meeting | Once | Project scope, timeline, specs | Gestor de projectos |

| Progress Report | Semanal | Milestones met, photos | Gestor de projectos |

| Issue Alert | As Needed | Problem description, impact | Lead Engineer |

| Revisão final | Once | Part inspection, sign-off | Controlo de qualidade |

This structure answers the question of how to communicate with CNC suppliers in Adelaide effectively. It builds trust and ensures everyone is aligned.

A structured communication plan is vital. It should cover clear technical briefs, regular progress reports, and a defined issue escalation path. This proactive approach ensures successful machine shop collaboration and prevents costly project delays.

How to Choose the Right Machining Process for Your Project in Adelaide

Choosing between 3-axis and 5-axis machining is crucial. The right choice impacts your budget, timeline, and final part quality. It’s a common dilemma for projects in Adelaide.

This isn’t just about capability. It’s about efficiency. For simpler parts, 3-axis is faster and more cost-effective. But for complex geometries, 5-axis machining often wins.

Quick Decision Factors

Consider these points when making a choice.

| Fator | CNC de 3 eixos | CNC de 5 eixos |

|---|---|---|

| Complexidade | Best for simple, prismatic parts | Ideal para formas complexas e orgânicas |

| Configurações | May require multiple setups | Often single setup (done-in-one) |

| Custo | Custo inicial mais baixo | Higher, but can be cheaper overall |

| Prazo de execução | Faster for simple jobs | Faster for complex jobs |

Making the right decision in the 3-axis vs 5-axis machining Adelaide debate starts here.

Choosing the right cnc machining adelaide service depends on your part’s geometry. You must analyze the design features carefully before deciding.

Análise da complexidade da peça

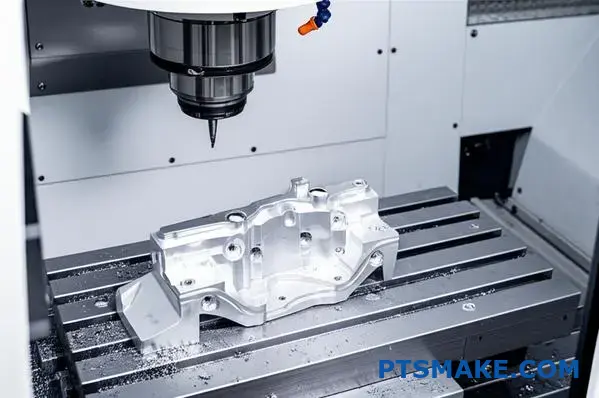

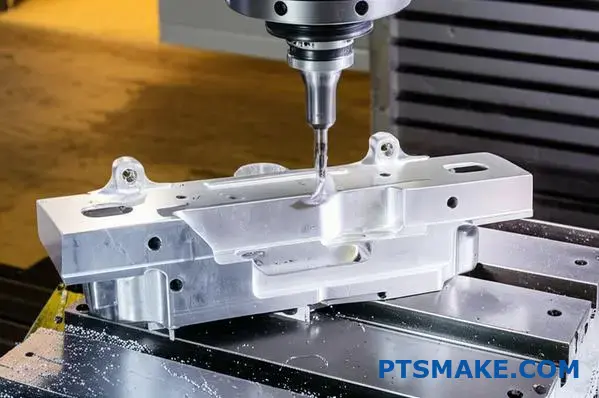

Simple parts with features on one plane are perfect for 3-axis machines. Think of plates with holes or basic brackets. The machine works along the X, Y, and Z axes without tilting. This is straightforward and economical.

However, parts with undercuts, curved surfaces, or deep cavities present a challenge. Multiple setups on a 3-axis machine increase labor costs and the risk of errors.

É aqui que 5-axis CNC machining Adelaide shines. By adding two rotational axes, the machine can reach five sides of a part in a single setup. This reduces handling and improves accuracy. The benefits of 5-axis CNC Adelaide become clear with complex designs.

Cost vs. Efficiency

The single-setup advantage of multi-axis machining is significant. It shortens lead times and lowers the total cost for intricate parts. The complex percurso da ferramenta10 programming is a one-time investment that pays off.

Here’s a guide to help you choose:

| Feature Requirement | Processo recomendado | Justificação |

|---|---|---|

| Flat surfaces, simple holes | Maquinação de 3 eixos | Most cost-effective and fastest method. |

| Angled holes, side features | 3-Axis with multiple setups or 5-Axis | 5-axis avoids re-fixturing, saving time. |

| Complex curves, undercuts | Maquinação de 5 eixos | Only way to achieve geometry efficiently. |

| High precision across faces | Maquinação de 5 eixos | Single setup eliminates tolerance stack-up. |

At PTSMAKE, we help clients run this analysis to ensure they select the most efficient process.

Choosing between 3-axis and 5-axis machining isn’t about which is better, but which is right for your part. Analyze complexity, required precision, and budget to find the most cost-effective solution for your Adelaide-based project.

A Strategic Guide to Scaling Production with Your Adelaide CNC Partner

Moving from a single prototype to full production is a huge step. This transition is where many projects face challenges. Careful planning is essential for success.

Your partner plays a key role in this. A good one helps you prepare for what’s next.

Planning for Volume

The journey from prototype to production CNC Adelaide requires a shift in mindset. You’re no longer just making one part work. You’re making thousands work perfectly.

This involves looking at materials, tooling, and processes differently.

| Fase | Foco principal | Objetivo |

|---|---|---|

| Protótipo | Functionality & Design | Proof of Concept |

| Produção | Efficiency & Consistency | Scalability & Cost-Control |

Success in scaling manufacturing Adelaide depends on this strategic foresight. We help our clients map this journey carefully.

Executing the Scale-Up Strategy

A solid plan is the foundation. Executing it properly ensures a smooth transition to high-volume CNC machining Adelaide. This involves several critical steps.

At PTSMAKE, we break this process down into manageable stages. This approach minimizes risks and maintains consistency.

Material Sourcing and Tooling

For mass production, material sourcing changes. We move from small batches to bulk purchasing. This helps secure better pricing and ensures a steady supply.

Tooling also needs to be upgraded. Prototype tools are not built for thousands of cycles. We design robust fixtures and jigs for durability.

Process and Quality Control

We refine CNC programs to cut cycle times without sacrificing quality. Every second saved matters in mass production CNC machining Adelaide.

Quality control becomes more systematic. We implement checks at key stages of the process. This is where methods like Controlo Estatístico do Processo11 become vital. They help us monitor and control the manufacturing process to ensure every part meets specifications.

| Estágio | Item de ação | Resultado |

|---|---|---|

| Pré-Produção | Finalize DFM, source bulk materials. | Cost-effective and stable supply chain. |

| Initial Run | Calibrate machines, run test batches. | Verified process and quality standards. |

| Produção completa | Implement SPC, automate where possible. | Consistent quality and optimal efficiency. |

This structured approach ensures that quality and cost remain consistent as volume increases.

Scaling from a prototype to high-volume production requires careful planning and execution. A strategic approach covering material sourcing, process optimization, and robust quality control is essential for ensuring consistency in both cost and quality. A reliable partner is key.

Critical Factors for CNC Machining Complex Geometries in Adelaide

Machining intricate parts in Adelaide presents unique hurdles. Success hinges on mastering details that standard jobs don’t require. We must address these technical challenges head-on.

The Deep Pocket Dilemma

Deep pockets require long, slender tools. This increases the risk of tool vibration and deflection, compromising accuracy. Chip evacuation also becomes a major issue.

Navigating Thin Walls

Thin walls are prone to warping or breaking under cutting pressure. Maintaining rigidity is the primary concern for ensuring the part holds its specified tolerance.

| Tipo de caraterística | Tool Rigidity Concern | Primary Solution |

|---|---|---|

| Bolsos fundos | High (Tool Deflection) | Reduced Step-Downs |

| Paredes finas | High (Workpiece Vibration) | Fixação especializada |

Mastering complex CNC machining Adelaide requires a deep understanding of these specific mechanical behaviours.

Moving beyond the challenges, we focus on the solutions that deliver precision complex parts Adelaide. At PTSMAKE, we’ve refined our methods to handle these demanding designs. It’s about a combination of technology and strategy.

Estratégias avançadas de percursos de ferramenta

Modern CAM software is essential. It allows us to create toolpaths that minimize tool load and heat buildup. Techniques like trochoidal milling12 are perfect for deep pockets. This method uses circular motions to clear material.

This approach maintains a consistent cutting force. It significantly reduces the risk of tool breakage and improves surface finish. This is key for CNC for complex geometries Adelaide.

Material and Fixture Stability

The material itself dictates our approach. Harder alloys generate more heat and stress. Softer materials may deflect more easily. Our fixture design must be robust. It needs to support thin walls and dampen any vibration.

| Desafio de maquinagem | Solução estratégica | Resultados esperados |

|---|---|---|

| Tool Vibration | Optimize feed/speed, use shorter tools | Melhoria do acabamento da superfície |

| Workpiece Deflection | Custom, supportive fixturing | Maintained dimensional accuracy |

| Evacuação de chips deficiente | High-pressure coolant, air blasts | Prevents tool binding and breakage |

A holistic strategy is the only way to succeed when machining intricate parts Adelaide.

Machining complex geometries requires more than just advanced equipment. It demands strategic toolpath programming, careful tool selection, and robust workholding to overcome challenges like deep pockets and thin walls, ensuring final part precision.

Get CNC Machining Adelaide Results with PTSMAKE Expertise

Ready to take your Adelaide CNC machining project to the next level? Trust PTSMAKE for reliable quotes, top-quality precision, and expert support from prototype to production. Send your RFQ now and let PTSMAKE help you achieve perfect results—on time, every time!

Learn more about these critical engineering principles to better vet your next manufacturing partner. ↩

Learn how this process ensures your parts meet strict material specifications and compliance. ↩

Learn how CMM technology provides objective data, guaranteeing your parts meet the most stringent specifications. ↩

Learn how material properties can differ in various directions and why it matters for your part’s design. ↩

Learn how spreading upfront costs over your production run impacts your total project budget and final per-unit price. ↩

Learn how this integrated approach can drastically cut your product development cycle. ↩

Learn how diversifying your supplier base can enhance supply chain security and reduce dependency. ↩

Learn why the base material is critical for finish adhesion and overall part durability. ↩

Learn how this symbolic language precisely communicates design intent, eliminating manufacturing ambiguity. ↩

Discover how an optimized toolpath can dramatically reduce machining time and project costs. ↩

Learn how this data-driven methodology ensures consistent quality in large-scale manufacturing. ↩

Learn how this milling strategy minimizes tool wear and boosts efficiency on complex part manufacturing. ↩