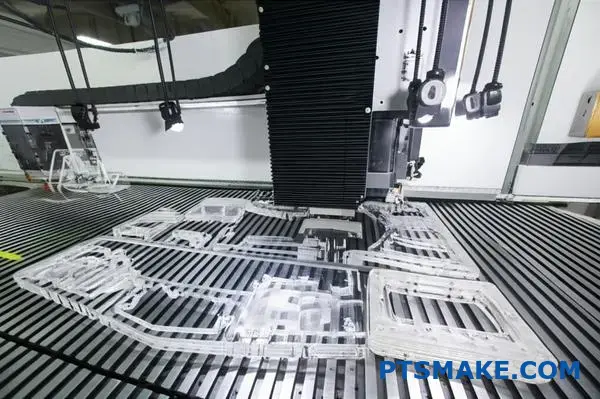

You’re designing a critical plastic component for your latest project. Metal seems too heavy and expensive, but you’re not sure if CNC plastic machining can deliver the precision you need. Every engineer faces this dilemma when tight tolerances meet budget constraints.

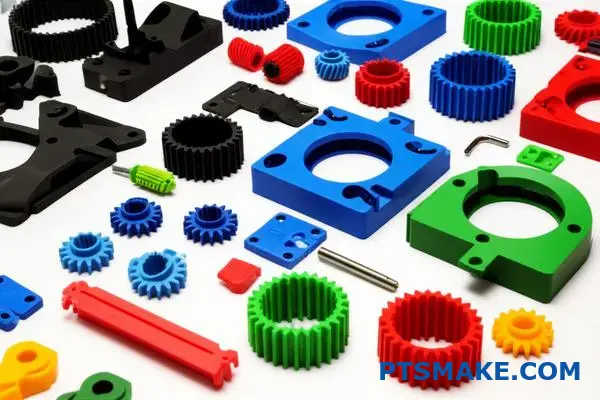

CNC plastic machining services offer engineers precise, cost-effective solutions for complex parts using advanced polymers like POM, PEEK, and Nylon. This process delivers tight tolerances, superior surface finishes, and faster turnaround times compared to metal machining for many applications.

I’ve worked with hundreds of engineers who switched from metal to plastic machining and never looked back. The key is understanding which materials work best, how to avoid common pitfalls like warping, and what questions to ask your supplier upfront.

The Complete Breakdown Of CNC Plastic Machining Vs. Metal Machining

Choosing between CNC plastic machining and metal machining is a critical decision for engineers. The right choice impacts everything from performance to budget.

While both processes use subtractive manufacturing, the similarities end there. The fundamental differences in materials drive distinct approaches to tooling, speed, and cost. Understanding these nuances is key.

A quick comparison highlights the core differences in these CNC machining materials.

| Fonctionnalité | Usinage CNC des matières plastiques | CNC Metal Machining |

|---|---|---|

| Matériau Dureté | Plus bas | Plus élevé |

| Outillage | Sharper, specialized geometry | Stronger, heat-resistant |

| Vitesse d'usinage | Généralement plus rapide | Plus lent |

| Production de chaleur | Lower, but melts easily | Plus élevé |

This initial overview sets the stage for a deeper analysis.

Key Technical Differences

When we move from theory to practice, the distinctions become even more pronounced. The choice isn’t just about the final part’s properties. It’s about the entire manufacturing process.

Material Properties and Tooling Strategy

Metals are strong and hard. They require robust tooling and generate significant heat. Coolant is essential to manage temperature and prevent tool wear.

Plastics, however, are softer and have a low melting point. Heat management is crucial to avoid melting, warping, or gumming up the tool. This is a common failure point we’ve seen in less experienced shops. The high coefficient de dilatation thermique1 in many plastics also demands careful handling to maintain tight tolerances.

Effective CNC plastic machining requires specific tools. These tools often have sharper cutting edges and wider flutes for efficient chip evacuation.

Speed, Feed Rates, and Cost Impact

The softer nature of plastics allows for much faster machining speeds and higher feed rates compared to metals. This directly translates to shorter cycle times.

Our tests confirm this can significantly reduce per-part costs.

| Paramètres | Plastic (e.g., ABS) | Metal (e.g., Aluminum) |

|---|---|---|

| Spindle Speed (RPM) | 5,000 – 15,000 | 4,000 – 10,000 |

| Vitesse d'alimentation (IPM) | 100 – 300 | 50 - 150 |

| Usure des outils | Faible | Modéré à élevé |

This efficiency is a major advantage of plastic vs metal machining. However, it requires a deep understanding of each polymer’s unique properties. This is where professional cnc plastic machining services add real value.

Choosing between plastic and metal involves a trade-off. Plastics offer speed and lower machining costs. Metals provide superior strength and thermal stability. The final decision depends entirely on your part’s specific application and performance requirements.

Top Questions Engineers Should Ask Before Choosing A CNC Plastic Machining Vendor

When selecting a CNC plastic machining supplier, a structured approach is crucial. A simple checklist can help you compare potential vendors effectively. This avoids overlooking critical details.

This framework covers the essential areas. It guides you in making an informed decision for your project’s success.

Your Plastic Machining Vendor Checklist

Start by evaluating their core capabilities. Focus on technical skill, material knowledge, and production capacity. A good partner excels in all three areas.

Here is a quick reference table.

| Catégorie | Key Questions |

|---|---|

| Tolérances | What is your standard tolerance? Can you hold ±0.001"? |

| Matériaux | What plastics do you specialize in? How do you source them? |

| Délai d'exécution | What is your typical lead time for prototypes vs. production? |

| Volume Capacity | What are your minimum and maximum order quantities (MOQ/Max)? |

This initial screening helps you create a shortlist of qualified suppliers.

Going beyond the basic checklist is where you find a true partner. It’s not just about what a vendor claims they can do. It’s about comment they do it. This is a critical step in selecting the right provider for your cnc plastic machining services.

Deeper Evaluation: Probing for True Capability

Don’t just ask if they can meet a tolerance. Ask for their quality control reports. Ask about their CMM inspection process. This reveals their commitment to precision. A reliable vendor will have robust systems in place to verify every part.

For materials, ask how they handle and store sensitive plastics like PEEK or Ultem. Improper storage can affect material stability. Some filled plastics can even become anisotrope2 if not processed correctly. This can cause unexpected issues during machining and in the final application.

Asking Smarter Questions

Instead of asking simple yes/no questions, frame them to reveal processes and expertise. This approach provides much deeper insight into a potential supplier’s operations.

| Instead of Asking This… | Ask This Instead… |

|---|---|

| "Can you machine PEEK?" | "What are your specific procedures for machining PEEK to prevent internal stress?" |

| "What is your lead time?" | "What is your on-time delivery rate over the last year? Can you share data?" |

| "Do you offer design feedback?" | "Can you provide a DFM report on our design to identify cost-saving opportunities?" |

These questions test a supplier’s experience and willingness to be a partner, not just a parts provider. At PTSMAKE, we welcome these discussions as they build the foundation for a successful, long-term relationship.

This structured checklist provides a solid foundation. It helps you move past surface-level claims and evaluate a supplier’s true technical and logistical capabilities, ensuring you find a reliable partner for your cnc plastic machining services.

Insider Secrets To Avoid Warping In CNC Machined Plastic Parts

Plastic part deformation is a common headache. It compromises precision and causes costly delays. But you can avoid it.

Success comes from mastering three key areas. These are fixturing, material choice, and your machining strategy. Get these right, and warping becomes a non-issue.

Fixturing: Your First Line of Defense

Improper clamping is a primary cause of stress. Over-tightening a vise will deform a part before a tool even touches it. Use minimal, even pressure.

Material Choice is Crucial

Every plastic responds to heat differently. Understanding this is key to avoiding issues.

| Matériau | Stabilité thermique | Tendance à la déformation |

|---|---|---|

| PEEK | Excellent | Faible |

| Acétal (Delrin) | Bon | Faible-modéré |

| ABS | Juste | Modérée-élevée |

Choosing the right material from the start simplifies everything.

Warping is almost always a heat management problem. When you cut plastic, you generate friction. This friction creates heat, which causes the material to expand. After cooling, it contracts unevenly, resulting in warping.

This is a critical issue for ‘plastic machining tolerances’. A warped part is a failed part.

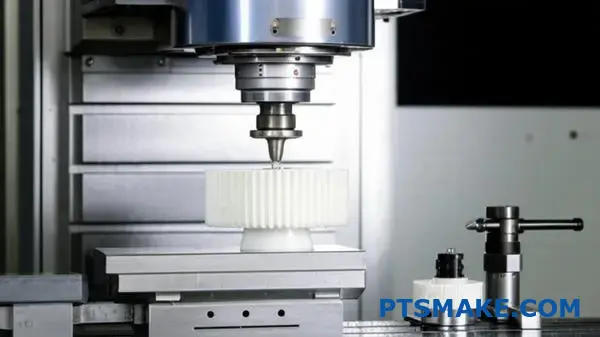

Advanced Heat Control Techniques

Effective heat management is central to our process. We focus on two main areas: cooling and cutting parameters. This is how we avoid part deformation CNC problems for our clients.

Strategic Cooling and Lubrication

Proper cooling is non-negotiable. We use flood coolants to dissipate heat quickly from the cutting zone. This prevents thermal buildup in the part. Air blasts can also work for some materials.

Tooling and Speeds

Sharp tools are essential. A dull tool plows through material instead of shearing it, which generates excessive heat. We also optimize feed rates and spindle speeds. This reduces tool contact time and minimizes thermal input. This approach is fundamental to our cnc plastic machining services.

A material’s Coefficient de dilatation thermique3 dictates how much it expands with heat. High CTE materials are more prone to warping.

| Stratégie | Impact on Heat | Résultat |

|---|---|---|

| Outils tranchants | Reduces Friction | Less Warping |

| Liquide de refroidissement | Dissipates Heat | Stable Part |

| Optimized Feed Rate | Minimizes Contact | Less Heat Buildup |

By controlling these factors, we ensure dimensional stability.

To prevent CNC plastic part warping, focus on secure fixturing, smart material selection, and active heat management. These strategies ensure your parts meet tight tolerances and avoid deformation, saving you time and resources.

The Ultimate Guide To CNC Plastics: What Material Is Best For Your Application?

Selecting the right material is a critical first step. The choice directly affects your part’s performance, durability, and final cost. Many CNC machinable polymers are available.

Each one has a unique profile. Understanding these differences is key to success.

Une comparaison rapide

Here is a brief overview. We will compare some of the most popular engineering plastics we work with at PTSMAKE. This helps you find the best plastic for CNC machining.

| Matériau | Caractéristiques principales | Meilleur pour... |

|---|---|---|

| POM | Grande rigidité | Engrenages, roulements, bagues |

| ABS | Rentabilité | Prototypes, Enclosures |

| PC | Résistance aux chocs | Lenses, Guards, Housings |

| Nylon | Résistance à l'usure | Wear Pads, Rollers, Screws |

Choosing the ideal polymer requires a deeper look into material properties. Your part’s operating environment, mechanical stresses, and desired finish all play a role. There is no single "best" material for every job.

At PTSMAKE, our cnc plastic machining services are tailored to these specific needs. We help clients navigate these choices daily.

Detailed Material Properties

Based on our internal testing, the following table provides a more detailed comparison. It covers strength, temperature limits, and the typical surface quality we achieve.

| Matériau | Résistance à la traction (MPa) | Max Service Temp (°C) | Qualité de la surface |

|---|---|---|---|

| POM | 60 – 75 | 90 – 110 | Excellent |

| ABS | 40 – 50 | 80 – 95 | Bon |

| PTFE | 20 – 35 | 260 | Juste |

| PC | 55 – 65 | 120 – 135 | Très bon |

| Nylon (PA66) | 70 - 85 | 80 – 120 | Bon |

| PEI | 100 – 115 | 170 | Excellent |

| PVC | 40 – 50 | 60 | Bon |

Nylon is an excellent material for wear resistance. However, it is important to note that it can be Hygroscopique4, meaning it absorbs moisture from the air. This can affect its dimensional stability if not properly considered during the design phase.

For high-temperature applications, PEI (Ultem) is a superior choice. It maintains its strength and stiffness at elevated temperatures but comes at a higher cost. For general-purpose parts where toughness is key, PC is often my recommendation.

Each material presents unique machining challenges and benefits.

Each plastic has distinct advantages. POM offers stiffness, PC provides impact strength, and PTFE delivers chemical resistance. Your application’s specific demands—from mechanical load to thermal exposure—will determine the optimal choice from these versatile CNC machinable polymers.

Why Tight Tolerances In Plastic CNC Parts Are Not As Simple As They Seem

Unlike metals, plastics are dynamic materials. Their dimensions are not fixed. They react to their environment in ways that can challenge even the most skilled machinist. Achieving tight tolerance CNC machining on plastics requires a deep understanding of their behavior. It’s not just about cutting; it’s about predicting and controlling change.

The Impact of Machining Stress

The cutting process itself introduces stress into a plastic part. This can cause warping or distortion after machining is complete.

Facteurs environnementaux

Heat and humidity are major players. Plastics expand with heat and can absorb moisture from the air, causing them to swell.

Common Plastic Responses

| Matériau | Sensibilité à la chaleur | Absorption de l'humidité |

|---|---|---|

| Nylon | Modéré | Haut |

| Acétal (Delrin) | Faible | Faible |

| PEEK | Très faible | Très faible |

| Polycarbonate | Modéré | Faible |

Achieving plastic machining dimensional accuracy is a constant battle against the material’s nature. Every plastic has a unique personality when it comes to holding a tight tolerance.

Understanding Thermal Effects

Heat generated during machining is a primary concern. Aggressive cutting can heat a part, causing it to expand. If you measure it while it’s warm, the dimensions will be wrong once it cools. This is directly related to the Coefficient de dilatation thermique5 of the material. Materials like PEEK have a low CTE, making them very stable.

The Challenge of Humidity

Moisture absorption is another critical factor. Materials like Nylon can swell significantly in a humid environment. We once had a project where parts met spec in our climate-controlled shop but were out of tolerance at the client’s humid facility. This taught us the importance of accounting for the end-use environment.

At PTSMAKE, our cnc plastic machining services always consider these variables. We carefully select cutting strategies and control the environment to ensure stability.

Tolérances typiques réalisables

After extensive testing with our clients, we’ve found these general guidelines to be reliable.

| Matière plastique | Tolérance standard | Tightest Achievable Tolerance |

|---|---|---|

| PEEK | ±0.002" (±0.05 mm) | ±0.0005" (±0.013 mm) |

| Acetal (Delrin®) | ±0.002" (±0.05 mm) | ±0,001" (±0,025 mm) |

| Polycarbonate | ±0.003" (±0.075 mm) | ±0.002" (±0.05 mm) |

| ABS | ±0.004" (±0.10 mm) | ±0.002" (±0.05 mm) |

| Nylon (6/6) | ±0.005" (±0.125 mm) | ±0.003" (±0.075 mm) |

Plastic’s inherent instability from heat, moisture, and machining stress complicates tight tolerance goals. Successful outcomes depend heavily on material choice and controlling environmental and process variables. True precision requires deep expertise in plastic behavior.

Avoiding Cost Traps In Low-Volume CNC Plastic Machining Orders

OEMs often need low-volume CNC plastic parts. These parts are vital for prototypes and pilot runs. But the cost per piece can seem high.

This is mostly due to initial setup costs. It includes CAM programming and creating the right workholding fixtures.

The Setup Cost Hurdle

A unique setup is required for each new part design. This fixed cost remains the same for one part or 100 parts.

Small Batch Economics

For cost-effective plastic machining small runs, this setup fee is spread over fewer items. This is what drives the unit price up. Strategic planning is essential.

Balancing Cost and Quantity

At PTSMAKE, we guide clients through this process. Smart planning is more effective than simply trying to cut corners on quality. It’s a core part of our cnc plastic machining services.

Leveraging Batch Setup Costs

Setup is a one-time charge for a production run. As you increase the number of parts, the impact of this setup cost per part decreases. This is known as Amortissement6.

Moving from 10 pieces to 25 doesn’t mean 2.5 times the cost. The price increase is much smaller since the setup is already covered.

The Value of Reusable Tooling

If you expect to place repeat orders, tell your manufacturing partner. We can create and save durable fixtures specifically for your project.

This preparation dramatically cuts down setup time and costs on future runs. It turns a one-time project cost into a reusable asset.

Finding Your Optimal Volume

There is always a sweet spot where the price per part drops. Identifying this quantity is crucial for budget planning. We often run quotes at different volumes to show clients this benefit.

| Quantité commandée | Price Per Part (Index) | Total Cost (Index) |

|---|---|---|

| 10 Units | 100% | 100% |

| 25 Units | 70% | 175% |

| 50 unités | 55% | 275% |

| 100 Units | 45% | 450% |

The table above illustrates the savings. Ordering slightly more initially can lead to significant long-term savings on your low-volume CNC plastic parts.

Managing setup fees, planning for tooling reuse, and finding the optimal order quantity are key. These strategies make low-volume prototyping and pilot runs cost-effective, protecting your budget while ensuring you get the high-quality parts you need.

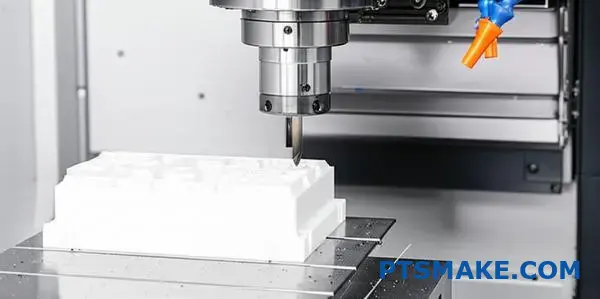

Design Engineering Tips For Flawless CNC Machined Plastic Parts

Applying Design for Manufacturability (DFM) is crucial for plastics. It’s different from working with metals. Plastics can warp, melt, or crack if designs ignore their unique properties.

Following a few key rules makes a huge difference. These rules cover internal radii, wall thickness, and threads. Proper design ensures your parts are strong and accurate. It also makes them easier to machine, saving time and cost.

Here are some core DFM for CNC plastics principles.

| Fonctionnalité | Poor Design Choice | Recommended Design Choice |

|---|---|---|

| Coins internes | Sharp 90° angles | Rounded with a radius |

| Épaisseur de la paroi | Variable de manière significative | Uniform and consistent |

| Fils | Cut directly into soft plastic | Use metal threaded inserts |

Mastering a few specific areas of DFM for CNC plastics is essential. These tips are vital for anyone needing reliable cnc plastic machining services. They help avoid common failures and costly redesigns.

Internal Radii and Fillet Geometries

Sharp internal corners are a major source of part failure. They create stress points that can lead to cracking under load. Also, CNC tools are round, so they cannot create a perfectly sharp internal corner.

Best Practices for Radii

Always design internal corners with a radius. A good rule of thumb is to make the radius at least 1/3 of the wall thickness. Larger radii are even better for distributing stress and making machining smoother. This is a fundamental tip for improving the machinability of plastic parts.

Consistent Wall Thickness

Maintaining a uniform wall thickness is perhaps the most critical rule. Drastic changes in thickness can cause warping. This is due to uneven cooling and internal contrainte résiduelle7. This is especially important for materials like Delrin or PEEK.

| Épaisseur de la paroi | Impact sur la qualité des pièces |

|---|---|

| Uniforme | High stability, low warpage |

| Non-uniform | High risk of warping, sink marks |

Designing Threads in Plastic

Threads cut directly into plastic are weak. They can strip easily, especially with repeated use. For durable connections, threaded inserts are a far better solution. They provide strong, reliable metal threads within the plastic part. At PTSMAKE, we almost always recommend inserts for functional prototypes and end-use parts.

Proper DFM for plastics prevents common machining issues like warping and stress cracking. Focusing on radii, uniform walls, and proper threading ensures you get functional, reliable parts the first time, optimizing both cost and performance for your project.

How To Evaluate Surface Finish Options For CNC Machined Plastics

Achieving the right plastic CNC surface finish is crucial. It impacts both appearance and function. Your choice depends entirely on the part’s final application.

You have several options. Matte finishes reduce glare. Polished finishes offer a smooth, reflective look. Textured finishes can hide fingerprints or improve grip.

Primary Finish Categories

Let’s break down the most common choices. Each has unique benefits and is achieved through different methods. The finish quality of CNC plastic parts is not just an afterthought.

| Type de finition | Caractéristique principale | Candidature commune |

|---|---|---|

| Mat | Non-reflective, uniform | Housings, functional parts |

| Poli | Smooth, glossy, clear | Lenses, aesthetic components |

| Texturé | Patterned or rough | Grips, high-wear surfaces |

Understanding these basics helps start the conversation.

The surface finish you get directly from the machine is the "as-machined" finish. This result is not random. It is a direct product of our tooling and settings. At PTSMAKE, we control these variables precisely.

How Machining Creates the Finish

The cutting tool leaves microscopic marks as it moves. The speed and path of that tool create the final surface. A slower feed rate and sharp tool generally produce a smoother finish.

These inherent tool marks create a surface that is anisotrope8. This means its properties differ depending on the direction they are measured. This is a key factor in performance.

When the as-machined finish isn’t enough, we use post-processing. This includes techniques like vapor polishing or bead blasting. These steps add cost but can be essential for specific needs. Our cnc plastic machining services are tailored to meet these exact requirements.

Machining Parameters vs. Surface Roughness

Based on our internal testing, we’ve seen a clear relationship between settings and outcomes.

| Paramètres d'usinage | Impact on Finish Quality | Recommandation |

|---|---|---|

| Affûtage de l'outil | A sharp tool cuts cleanly | Use new or freshly sharpened tools |

| Vitesse de la broche | Higher speeds can reduce burrs | Optimize per material |

| Vitesse d'alimentation | Slower rates create smoother surfaces | Balance finish needs with cycle time |

| Cut Depth | Lighter passes improve finish | Use a final finishing pass |

These factors are fundamental to achieving the desired finish quality for CNC plastic parts without secondary operations.

The final surface finish for CNC plastics is determined by machining parameters and post-processing choices. The as-machined finish is often sufficient, but polishing or texturing can be applied when specific functional or aesthetic qualities are required for the part.

Solving The #1 Headache In CNC Plastic Machining: Vendor Communication

Nothing stalls a project faster than a non-responsive supplier. You send a critical email and get silence. This communication void introduces risk and kills momentum.

Setting Clear Expectations

A truly reliable CNC machining supplier establishes communication protocols upfront. This includes expected response times and key contacts.

The Right Communication Channels

We’ve learned that a dedicated channel is best. It centralizes project history and prevents vital details from getting lost.

| Méthode | Pro | Con |

|---|---|---|

| Courriel | Documented Trail | Can Be Slow |

| Phone Call | Immediate Feedback | No Written Record |

| Project Portal | Centralized Info | Requires System Access |

To truly solve communication gaps, you need a system, not just good intentions. It’s about building a framework for transparency from the start.

The Power of a Single Contact

One of the most effective strategies is assigning a dedicated project manager. This person acts as your single point of contact (SPOC). They are responsible for all updates on your cnc plastic machining services order.

From Reactive to Proactive Tracking

Don’t settle for a supplier you constantly have to chase. A great partner provides consistent updates. This offers excellent plastic part order support. For instance, a simple weekly status report with photos can build immense trust.

A Framework for Resolving Issues

When problems do occur, a clear process is essential. Instead of quick fixes, it’s better to find the fundamental cause. A deep dive into the Analyse des causes profondes9 provides a permanent solution, not just a temporary patch.

Here’s a quick comparison of communication styles we’ve observed:

| Aspect | Fournisseur réactif | Proactive Supplier |

|---|---|---|

| Mises à jour | Only when asked | Scheduled and regular |

| Problems | Reports after they happen | Flags potential risks early |

| Solutions | Quick, temporary fixes | Durable, long-term solutions |

| Tone | Often defensive | Always collaborative |

Effective communication is not a "nice-to-have." It is a core requirement. By demanding clear protocols, proactive tracking, and structured issue resolution, you can secure a true manufacturing partner who ensures your project’s success.

CNC Plastic Machining For Aerospace & Medical: What You Must Know

Aerospace and medical industries demand absolute precision. There is no room for error in these fields. Every component must meet stringent standards.

This requires deep expertise in materials and processes. It also demands a commitment to quality that goes beyond standard manufacturing.

Critical Compliance and Documentation

Documentation is not optional. Full traceability from raw material to the final part is essential. This ensures safety and accountability.

Sélection de matériaux haute performance

Choosing the right material is critical. Performance under extreme conditions is a key factor for aerospace plastic machining.

| Matériau | Propriété principale | Candidature commune |

|---|---|---|

| PEEK | High strength, chemical resistance | Medical implants, aircraft parts |

| Ultem | High heat resistance, strength | Surgical tools, electrical connectors |

| Delrin | High stiffness, low friction | Roulements, engrenages, isolateurs |

Notre cnc plastic machining services specialize in these advanced polymers.

The Role of Sophisticated Quality Assurance (QA)

In these sectors, a standard QA process is not enough. We must implement sophisticated protocols to ensure every part is perfect. This involves much more than a final check.

Quality is built into every step of our cnc plastic machining services workflow. From initial design review to final inspection, we maintain rigorous oversight. This prevents errors before they happen.

Traceability and Validation

Every part requires a detailed history. This includes material certifications and inspection reports. This documentation is crucial for regulatory approval. Validation confirms the process consistently produces parts to spec.

Material Focus for Critical Applications

For medical grade plastic CNC, materials must be biocompatible10. This means they won’t cause adverse reactions in the human body. Our team at PTSMAKE helps clients select the right certified materials.

This table shows a simplified QA workflow for a critical component.

| QA Stage | Action requise | Documentation |

|---|---|---|

| Réception des matériaux | Verify material certs | Certificat de conformité (CoC) |

| Premier article | Inspection dimensionnelle complète | Rapport d'inspection du premier article (FAIR) |

| En cours | Key dimension monitoring | Statistical Process Control (SPC) charts |

| Inspection finale | 100% visual and dimensional check | Rapport d'inspection final |

This structured approach guarantees that parts meet the exacting standards of aerospace and medical applications.

For aerospace and medical parts, success depends on three pillars. These are strict regulatory compliance, correct high-performance material selection, and an exhaustive quality assurance system. These elements are non-negotiable for ensuring component safety, reliability, and performance in critical applications.

How To Balance Price And Precision In CNC Plastic Machining

Finding the sweet spot between cost and precision is a constant challenge. It’s about making smart, informed decisions early in the design process. You don’t always need the tightest tolerances everywhere.

Engineers and purchasers often face this dilemma. The key is knowing where you can compromise without sacrificing performance. This balance is central to affordable plastic machining.

Strategic Design Adjustments

Small changes in your design can lead to significant savings. Consider simplifying complex curves or reducing the number of deep pockets. Every complex feature adds machine time.

The debate over precision vs. price for CNC parts often ends here.

| Type de caractéristique | Impact sur les coûts | Recommandation |

|---|---|---|

| Coins internes tranchants | Haut | Use fillets with a standard tool radius |

| Non-Standard Tolerances | Haut | Specify tight tolerances only where necessary |

| Murs minces | Moyen | Increase wall thickness for stability |

A common oversight is focusing only on a material’s datasheet properties. While important, a material’s machinability plays a massive role in the final part cost. It dictates cutting speeds, tool wear, and overall cycle time.

For instance, PEEK offers incredible performance. However, it is abrasive and tough to machine. This drives up the cost of our cnc plastic machining services. An alternative like PEI (Ultem) might meet 95% of your requirements but machine 30% faster, based on our internal tests.

Material Choice vs. Machining Time

Choosing a slightly less robust but more machinable plastic can be a brilliant move. This reduces both labor and tooling costs without a functional trade-off. It’s about understanding the entire manufacturing context. A material’s stabilité dimensionnelle11 is critical, but so is the cost to achieve it.

At PTSMAKE, we guide clients through these trade-offs. We analyze the application to find the most cost-effective material that meets all critical specifications.

| Matériau | Coût relatif | Usinabilité | Principaux avantages |

|---|---|---|---|

| Delrin® (POM) | Faible | Excellent | Great for general mechanical parts |

| PEEK | Haut | Difficile | Superior thermal/chemical resistance |

| Ultem® (PEI) | Moyenne-élevée | Bon | Excellent balance of properties |

Balancing affordability and accuracy isn’t about cutting corners. It’s about making strategic choices in design geometry and material selection. Simplifying features and opting for more machinable plastics, where appropriate, can significantly reduce costs without compromising the part’s essential function.

Real-World Case Studies: CNC Plastic Machined Components That Saved Projects

Theory is one thing; project deadlines are another. The right material can make all the difference. Sometimes, a high-performance plastic is not just an alternative. It’s the only solution that works.

This is especially true in fast-moving industries. Let’s look at some real-world CNC part success stories. These cases show how precision-machined plastics solved urgent problems.

Key Industries and Solutions

| L'industrie | Common Problem | Plastic Solution |

|---|---|---|

| Médical | Sterilization, MRI compatibility | PEEK, Ultem |

| Robotique | Weight, electrical insulation | Delrin (POM), Nylon |

| Électronique | Signal interference, heat | PTFE, ABS |

These examples highlight why a deep understanding of materials is crucial.

I recall a project with a medical device company. They needed a complex housing for a surgical guidance system. Their initial metal prototype was causing artifacts in MRI scans. This made it unusable. The project was on hold.

They needed a material that was strong, sterilizable, and radiolucent.

The Medical Device Breakthrough

We proposed machining the part from PEEK. Its strength is comparable to some metals. It can also withstand repeated autoclave sterilization cycles. Most importantly, it’s transparent to X-rays and MRI.

After we provided the PEEK prototypes, their imaging tests were clear. The component’s required biocompatibilité12 was also a key factor in its success. Our precision cnc plastic machining services ensured the tight tolerances were met.

A Robotics Agility Challenge

Another case involved a robotics startup. They were building a high-speed pick-and-place arm. The original aluminum gripper was too heavy. This limited the arm’s acceleration and caused motor strain.

| Métrique | Aluminum Gripper | Delrin (POM) Gripper |

|---|---|---|

| Poids | 150g | 45g |

| Durée du cycle | 1.2s | 0.8s |

| Motor Strain | Haut | Faible |

We machined a new gripper from Delrin (POM). The weight reduction was significant. Based on our client’s feedback, the robotic arm’s speed increased by over 30%. This single component change saved their performance targets. These plastic CNC case studies show the power of material selection.

These real-world examples show that CNC machined plastics are not just replacements. They are often superior engineering solutions. They solve critical issues related to weight, electrical properties, and compatibility that metals cannot address.

Choose PTSMAKE for Your Next CNC Plastic Machining Project

Ready to achieve perfect precision, fast turnaround, and total reliability for your CNC plastic machining needs? Submit your inquiry to PTSMAKE today and let our expert team deliver the engineered solutions you require—from prototype to production. Take the first step and request your quote now!

Understand how this property affects dimensional stability and design choices. ↩

Understand how this material property can affect your part’s strength and stability. ↩

Understand how this property affects material choice and prevents warping in your designs. ↩

Learn how moisture absorption can impact material stability and dimensional accuracy in your CNC machined parts. ↩

Learn how this critical property impacts material selection for precision applications. ↩

Learn how spreading initial costs over units can significantly lower your per-part price in manufacturing. ↩

Learn how this internal force impacts part accuracy, stability, and long-term performance. ↩

Learn more about how anisotropic surfaces can affect part friction and wear. ↩

Learn how this systematic method prevents recurring issues in your manufacturing projects. ↩

Learn about the material properties required for medical devices and ensuring patient safety. ↩

Learn how a material’s ability to resist changes in size impacts long-term part performance. ↩

Understand this crucial material property for medical device safety and compliance. ↩