Railroad and skylight projects in Houston face a critical challenge: finding CNC machining partners who truly understand the demanding specifications these industries require. Many procurement managers discover too late that their chosen supplier lacks the precision capabilities, material expertise, or compliance knowledge needed for mission-critical components.

CNC machining for railroads and skylights in Houston requires specialized expertise in high-tolerance manufacturing, industry-specific materials, and strict compliance standards that only experienced precision machining partners can deliver reliably.

This guide draws from real Houston projects where proper CNC partner selection made the difference between project success and costly delays. You’ll discover the specific technical requirements, material considerations, and quality standards that separate capable machining shops from those that simply claim railroad and skylight expertise.

Why Houston Is A Strategic Hub For Railroad And Skylight CNC Machining Projects

Houston is more than just an energy capital. Its unique position makes it ideal for specialized manufacturing. This includes projects for railroads and skylights.

Logistical Powerhouse

The city’s infrastructure is a key advantage. It offers unmatched access to global and domestic markets. This reduces shipping times and costs for materials and finished parts.

Major Transport Links

| Transport Mode | الميزة |

|---|---|

| Port Houston | Busiest port in the U.S. for foreign tonnage |

| Rail Lines | Extensive network connecting the nation |

| Airports | Two international airports for air freight |

This network is crucial for efficient supply chains in CNC machining Houston.

Houston’s strength isn’t just one single factor. It’s the powerful combination of several key elements. This synergy creates a supportive environment for high-precision manufacturing. Many companies find this ecosystem beneficial.

A Hub for Skilled Machinists

Access to talent is critical. Houston has a deep pool of experienced CNC machinists. These professionals understand the tight tolerances required. This is especially true for railroad parts manufacturing Houston. They have experience with complex projects.

This skilled labor force is supported by excellent technical colleges. These institutions ensure a steady flow of new talent into the industry. This is a significant advantage for any company providing custom skylight CNC services Houston. The result is a self-sustaining cycle of innovation and expertise. This is a clear example of agglomeration economies1.

The Industrial Ecosystem Effect

Different industries in Houston support one another. The energy sector’s demand for durable parts drives innovation in metallurgy and machining. This knowledge directly benefits other sectors.

| الصناعة | Contribution to CNC Machining |

|---|---|

| الطاقة | Advanced materials and high-pressure component expertise |

| الفضاء الجوي | Precision engineering and quality control standards |

| الطب الباطني | Experience with exotic alloys and tight tolerances |

This cross-pollination of skills makes Houston’s manufacturing base incredibly versatile and robust. It’s a key reason why we at PTSMAKE see it as a strategic location for complex projects.

Houston’s superior logistics, robust industrial base, and skilled workforce create a prime environment. It’s an ideal hub for specialized CNC machining, particularly for demanding railroad and skylight components that require absolute precision.

Secrets To Eliminating Downtime In Railroad Systems With Precision CNC Machining

Precision is the bedrock of reliability. In railroad systems, even the smallest component deviation can lead to significant wear over time. This accelerates maintenance cycles.

High-precision CNC parts for railroads ensure perfect fits. This reduces friction and stress on the entire system.

The True Cost of "Good Enough"

Standard parts might seem cost-effective initially. However, their imprecise fit creates vibrations and accelerates wear. This leads to more frequent, costly maintenance.

| الميزة | Standard Components | Precision CNC Components |

|---|---|---|

| Fit Tolerance | فضفاض | Exact |

| دورة الصيانة | 6-12 شهرًا | 24-36 Months |

| مخاطر الفشل | معتدل | منخفضة جداً |

| System Stress | عالية | الحد الأدنى |

Choosing precision from the start is an investment in long-term operational efficiency and safety. It directly reduces downtime.

The impact of a single sub-par component can cascade through an entire assembly. In my work, I’ve seen how one poorly machined axle bearing creates stress that travels, eventually causing failure in a completely different part of the system. This is a critical concept in the precision machining rail industry.

Beyond the Component: System Integrity

Precision manufacturing isn’t just about one part. It’s about how hundreds of parts work together seamlessly. Tight tolerances mean less vibration, lower operating temperatures, and reduced Material Fatigue2. Every component, from engine pistons to track fasteners, contributes to the whole.

This holistic approach to quality is essential. That’s why we collaborate with experts across the supply chain, including specialized railroad component suppliers in Houston, to ensure every piece functions perfectly within the larger system. The need for precision covers all infrastructure, from track switches to station skylights, where perfect fits prevent long-term degradation. At PTSMAKE, we ensure our parts enhance system-wide reliability, not just individual performance. Our research with clients confirms that this integrated approach can extend the service life of adjacent components by up to 40%.

High-precision CNC parts fundamentally change railroad maintenance. By ensuring perfect fits and reducing wear, these components decrease failure rates and extend service intervals. This shift makes the entire system more reliable and cost-effective over its lifespan.

Hidden Costs Of Low-Quality CNC Skylight Components (And How To Avoid Them)

The initial price tag on low-quality skylight parts is deceptive. It masks a series of future expenses that can quickly erase any upfront savings.

These hidden costs aren’t just about money. They involve time, reputation, and safety.

The True Cost Equation

Poorly made components fail sooner. This means more frequent replacements, higher labor costs, and potential damage to the surrounding structure. It’s a classic case of paying less now, only to pay much more later.

| عامل التكلفة | Low-Quality Part | High-Precision Part |

|---|---|---|

| Initial Purchase | منخفضة | أعلى |

| الصيانة | متكرر | الحد الأدنى |

| Replacement Cycle | قصير | طويل |

| مخاطر الفشل | عالية | منخفضة |

A small saving today can lead to significant financial strain down the road.

Opting for cheaper components introduces risks that go beyond simple part failure. It’s a decision that can impact the entire integrity of a structure over its lifespan. At PTSMAKE, we focus on preventing these issues from the start.

Breaking Down the Long-Term Financial Drain

When machining skylight frames, poor precision leads to improper fits. These gaps can cause leaks, leading to costly water damage and mold remediation. This is a common issue we’ve seen in projects that initially cut corners.

Low-grade materials also degrade faster. This is especially true for outdoor applications, where parts are exposed to harsh weather. Inferior aluminum can suffer from تآكل النقطي3 much earlier than expected.

Precision CNC skylight fabrication ensures every part meets exact specifications. This is critical for demanding applications, such as railroads skylights cnc machining houston projects.

| Hidden Cost Category | مثال على ذلك | Potential Financial Impact |

|---|---|---|

| Repair & Labor | Replacing leaking seals | 2-3x the initial part cost |

| Structural Damage | Water damage to drywall/framing | Can exceed 10x the part cost |

| Energy Inefficiency | Poor seals leading to heat loss | Ongoing, increased utility bills |

| Reputation Damage | Product failures and recalls | Incalculable |

Investing in high-tolerance aluminum parts Houston from the outset is the most reliable way to secure a project’s long-term value and performance.

Initial savings from low-quality parts are often negated by high long-term costs. These include frequent repairs, increased maintenance, and potential structural damage. Investing in precision manufacturing from the start is the most financially sound approach for any project.

Top CNC Materials For Load-Bearing Railroad Applications

Selecting the right material is the first critical step. For load-bearing railroad parts, strength isn’t optional. It’s the foundation of safety and performance. We primarily look at a few key options.

These include robust carbon steels and stainless steels. High-strength aluminum alloys are also considered. Each material offers a unique set of properties. The final choice depends on the specific application’s demands. We must balance durability with other factors.

| المواد | الميزة الرئيسية | تطبيق مشترك |

|---|---|---|

| الفولاذ الكربوني | High Strength & Cost-Effective | Structural Components, Wheels |

| الفولاذ المقاوم للصدأ | مقاومة التآكل | Fasteners, Exposed Parts |

| سبائك الألومنيوم | نسبة القوة إلى الوزن | Housings, Non-critical Structures |

A Deeper Look at Railroad-Grade CNC Materials

عندما نتحدث عن railroad-grade CNC materials, we mean metals that can withstand extreme conditions. Carbon steels, like 1045 or 4140, are workhorses. They provide immense tensile strength needed for axles and couplings. Their toughness ensures reliability under heavy loads.

Stainless steel, particularly grades like 304 or 316, is chosen for its longevity. It resists rust and environmental decay. This is crucial for parts exposed to weather, extending their service life significantly.

Machining strong alloys presents unique challenges. These materials are tough, which causes rapid tool wear and generates significant heat. Based on tests we’ve conducted with clients, controlling speeds and using specialized cooling are key. Properties like تصلب العمل4 mean the material gets harder as you machine it, requiring a precise strategy.

This is vital for creating impact resistance CNC parts. Aluminum alloys, like 7075, offer a lighter alternative for certain components where weight is a concern but strength cannot be compromised. The principles of material selection are universal in high-stakes industries, including our التصنيع الآلي باستخدام الحاسب الآلي work for railroads clients.

Material Properties Overview

| درجة المادة | Tensile Strength (Approx. MPa) | الميزة الرئيسية |

|---|---|---|

| Carbon Steel 4140 | 655 | Extreme Toughness |

| الفولاذ المقاوم للصدأ 316 | 515 | مقاومة ممتازة للتآكل |

| ألومنيوم 7075-T6 | 572 | نسبة قوة إلى وزن عالية |

Choosing the right material is non-negotiable. Steels offer unparalleled strength for core components, while specific aluminum alloys provide lightweight durability. This selection directly impacts the safety, longevity, and performance of critical railroad parts, ensuring they withstand immense operational stress.

How Engineers Can Reduce Tolerancing Issues In Custom Machined Railroad Parts

Optimizing tolerances starts on the screen. Your CAD model is the blueprint. Clear, well-defined designs prevent costly rework later. This is where smart practices make a difference.

CAD Best Practices for Tolerancing

Clean models are key. Avoid unnecessary features or complex surfaces. This improves manufacturability. We always prefer native CAD files over neutral formats like STEP.

GD&T: The Language of Precision

Geometric Dimensioning and Tolerancing (GD&T) is critical. It clarifies part function. This is vital for high-tolerance CNC machining railroads.

| الرمز | الاسم | الغرض |

|---|---|---|

| ⌖ | المنصب | Defines the location of features. |

| ⏥ | التسطيح | Specifies a surface is flat. |

| ○ | Circularity | Controls the roundness of a feature. |

Going deeper, GD&T is more than symbols. It’s about communicating functional intent clearly. This directly impacts manufacturing success, especially for complex railroad components.

Mastering GD&T for Machinability

Choosing the right datums is the foundation. Datums should reflect how the part is fixtured during machining. This is one of the most effective design tips for machinability I can offer. Incorrect datums lead to interpretation errors.

The Role of Feature Control Frames

The feature control frame is where it all comes together. It links the tolerance, feature, and datums. This compact block of information removes guesswork for the machinist. Establishing a stable Datum Reference Frame5 is the critical first step. It provides a common origin for all measurements.

| الخطأ الشائع | الحل |

|---|---|

| Over-tolerancing | Specify tolerances based on function, not assumption. |

| Missing Datums | Clearly define primary, secondary, and tertiary datums. |

| Ambiguous Callouts | Use specific modifiers like MMC or LMC where needed. |

Our approach at PTSMAKE, often coordinating with partners in Houston precision engineering, involves reviewing these callouts early. This collaborative step ensures the design is both functional and producible without unnecessary cost. For railroads skylights cnc machining houston projects, this precision is non-negotiable.

Effective tolerancing begins in the design phase. By implementing CAD best practices and leveraging the precision of GD&T, engineers can eliminate ambiguity. This ensures custom railroad parts meet strict functional requirements and are machined correctly the first time.

Fast-Track Prototypes For Skylight Innovations Using CNC Machining

In commercial builds, speed is everything. Prototyping cycles for new skylight designs must be short and effective. This is where CNC machining truly shines.

It allows us to create precise skylight CNC prototypes quickly.

This speed facilitates better collaboration. It also enables realistic material mockups. We often produce custom aluminum frames to test concepts. This is key for rapid prototyping Houston projects, where timelines are tight.

Shortening the Prototyping Cycle

Traditional prototyping methods could take weeks. This slowed down innovation and delayed project timelines. CNC machining changes this equation entirely.

We can turn a CAD file into a physical part in days. This accelerated feedback loop is invaluable for developing complex skylight systems. It allows for multiple design iterations in a short period.

| مرحلة النماذج الأولية | الطريقة التقليدية | CNC Machining Method |

|---|---|---|

| Initial Prototype | 2-4 أسابيع | 3-5 أيام |

| Design Iteration 1 | 2-3 أسابيع | 3-5 أيام |

| Final Pre-production | من أسبوع إلى أسبوعين | 2-4 أيام |

The Power of DFM Collaboration

Early collaboration is a cornerstone of success. We use a process called التصميم من أجل قابلية التصنيع (DFM)6. This means our engineering team reviews your design before any metal is cut.

This review identifies potential manufacturing issues. We might suggest small tweaks to a frame’s geometry to improve strength or reduce machining time. This saves significant costs down the line. It ensures the final product meets both design intent and budget.

Creating Realistic Material Mockups

Sketches and renders are useful. But nothing beats a physical mockup. For skylight development, this is critical. We use CNC to create custom aluminum frames from production-grade materials like 6061-T6 aluminum.

These skylight CNC prototypes allow architects and engineers to test assembly. They can check tolerances and evaluate the aesthetic finish firsthand. This ensures the final installation is flawless. The demand for such precision is high, especially in markets like Houston.

To summarize, CNC machining drastically cuts skylight prototyping time. Effective DFM collaboration and accurate material mockups, such as custom aluminum frames, are vital. They help refine designs and ensure manufacturability before committing to full-scale production.

Real Stories: How CNC Machining Solved Unexpected Failures In Rail Infrastructure

Theory is useful, but real-world results are what matter. Unexpected failures in rail infrastructure demand fast, precise solutions.

CNC machining provides these solutions. It’s not just about making a replacement part. It’s about making a better one.

From Failure to Function

We see this often. A standard part fails. A simple replacement isn’t enough. We need a precision redesign for the rail component to prevent future issues. This is where CNC shines.

| التحدي | CNC Solution |

|---|---|

| Recurring Part Failure | Precision Redesign |

| نقطة ضعف جوهرية | Upgraded Alloy Machining |

| Urgent Need | Rapid Prototyping & Production |

These are not hypothetical. These are real Houston success stories.

Let’s look at specific examples of CNC for rail infrastructure. These cases show how we solve complex problems with precision manufacturing.

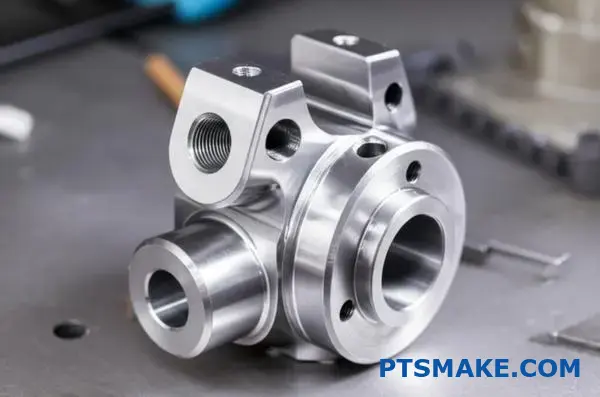

Case Study: Precision Redesign Rail Component

A client in Houston faced repeated failures in a critical switching mechanism. The original cast iron part couldn’t handle the stress. The downtime was becoming a major operational headache.

Our team analyzed the failed component. We found that sharp internal corners created stress concentration points. A direct copy would just fail again.

Using advanced software, we ran simulations to optimize the geometry. This process helped us identify weak points before machining even began. We used تحليل العناصر المحدودة7 to model the loads on the part.

The solution was a complete precision redesign. We machined the new part from a solid billet of 4140 steel. This change improved both strength and fatigue resistance significantly.

Material Upgrade Comparison

This table shows the clear advantage of the new material, based on our material analysis with the client.

| الممتلكات | Original Cast Iron | Machined 4140 Steel |

|---|---|---|

| قوة الشد | ~200 MPa | ~655 MPa |

| مقاومة التعب والإرهاق | منخفضة | عالية |

| عملية التصنيع | الصب | التصنيع الآلي باستخدام الحاسب الآلي |

The result was a permanent fix. This is a great example of the problem-solving power of railroads skylights cnc machining houston services.

These case studies show how CNC machining offers more than just parts. It delivers robust, engineered solutions for rail infrastructure. By redesigning components and upgrading materials, we turn critical failures into long-term successes, ensuring safety and operational reliability.

8. Implement FAI, PPAP, and Repeatability Measures

Moving from prototypes to mass production requires new systems. You need absolute certainty that the 10,000th part is identical to the first. This is where formal quality processes come in.

First Article Inspection (FAI) and the Production Part Approval Process (PPAP) are critical. They are not just paperwork exercises. They are structured methods to guarantee consistent CNC skylight parts. These systems ensure every component meets specifications, every single time. This provides total confidence before committing to a full production run.

For large-scale architectural projects, these processes are non-negotiable. They build a foundation of trust between the client and the manufacturer.

فحص المادة الأولى (FAI)

An FAI is a detailed verification of the first part produced from a new or revised process. We meticulously check every dimension, feature, and note on the drawing. This confirms our tooling and setup are correct before we proceed. It is the first gate in our quality control.

Repeatability Control Through Formal Processes

While FAI focuses on one part, the Production Part Approval Process8 validates the entire manufacturing system. It’s a comprehensive package of documents. It proves our process can reliably produce parts that meet your requirements over the long term. This is key for successful mass production.

For clients seeking quality assurance machining Houston, these frameworks are essential. They provide clear evidence of capability and control, crucial for projects like transportation hubs or large commercial skylight installations. This is how we ensure strict repeatability control.

إليك مقارنة بسيطة:

| الميزة | فحص المادة الأولى (FAI) | Production Part Approval Process (PPAP) |

|---|---|---|

| النطاق | Verifies one initial part. | Validates the entire production process. |

| الغرض | Confirms manufacturing capability. | Ensures consistent quality over time. |

| المخرجات | Detailed inspection report. | A full documentation package. |

At PTSMAKE, we use these tools to de-risk production for our clients.

FAI and PPAP are your best insurance policies for mass production. They formalize the process of verification, ensuring every CNC skylight part is flawless and building a reliable supply chain. This is how true repeatability control is achieved.

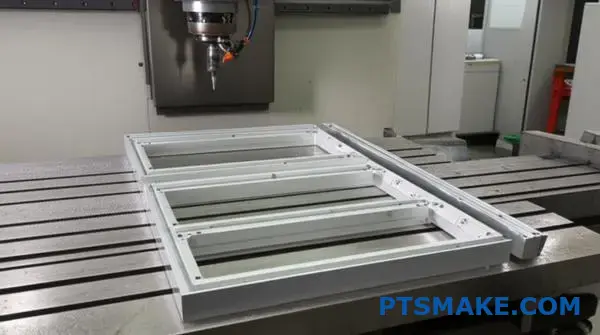

Inside The Ultimate CNC Machining Workflow For Architectural Skylight Frames

The journey from a digital file to a finished part is a precise dance of technology and skill. It’s a process we’ve refined over years.

This workflow is the backbone of producing high-quality components. It ensures every piece is perfect.

From CAD to Component

The entire operation starts with a client’s CAD model. We meticulously analyze it for manufacturability. This critical first step prevents costly errors down the line. It’s the foundation for successful machining of skylight aluminum frames.

Key Workflow Stages

Our process ensures consistency and quality from start to finish. Each step builds upon the last, creating a seamless flow.

| المرحلة | الوصف | النتيجة الرئيسية |

|---|---|---|

| 1. CAD Review | Analyze the 3D model for feasibility. | Optimized Design |

| 2. CAM Programming | Generate CNC machine toolpaths. | Machine Instructions |

| 3. التصنيع الآلي | Cut the aluminum stock to spec. | Physical Part |

| 4. Quality Control | Inspect dimensions and finish. | Verified Component |

| 5. Shipping | Package and deliver the finished parts. | Project Completion |

A well-defined process is essential for architectural metal fabrication. It turns a complex task into a series of manageable, quality-controlled steps. Every skylight frame depends on this structured approach for its integrity and final appearance.

The Machining Journey in Detail

Our workflow for CNC in Houston is built on precision. It starts the moment we receive the design files. We use advanced software to prepare the model for the machine.

CAD to CAM Translation

The first step is translating the CAD file into instructions our CNC machines can understand. This is done using specialized Computer-Aided Manufacturing (CAM)9 software. This software generates the precise toolpaths, speeds, and feed rates. It dictates every movement the machine will make.

The Physical Machining Process

Once programmed, the aluminum stock is secured in the machine. The CNC process begins, removing material layer by layer to create the final shape. We often handle components designed for demanding environments, like those near railroads that require enhanced durability.

| Machining Phase | الإجراء | الغرض |

|---|---|---|

| تحضير المواد | Cut aluminum stock to size. | الكفاءة |

| إعداد الماكينة | Load tools and secure workpiece. | الدقة |

| Roughing Pass | Quickly remove bulk material. | السرعة |

| Finishing Pass | Achieve final dimensions and surface finish. | الدقة |

| إزالة الأزيز | Remove sharp edges. | Safety & Finish |

Final Checks and Shipping

After machining, every part undergoes strict quality assurance. We use precision instruments to verify every dimension against the original CAD file. Once approved, the components are carefully packed and prepared for shipping to the client’s site.

A systematic workflow, from digital design translation to final inspection, is non-negotiable for high-quality architectural components. This process ensures every skylight frame meets exact specifications and functional requirements before shipping.

Why Not All CNC Shops Can Handle Railroad-Grade Compliance

Manufacturing for the railroad industry is not just about meeting tight tolerances. It’s about a deep, verifiable commitment to safety and reliability.

Many CNC shops can make a part to spec. But very few can provide the rigorous documentation and process control that this sector demands. This is where a true partner for ‘railroad compliant CNC’ machining stands apart. It’s a completely different level of operational discipline.

| المتطلبات | التصنيع الآلي القياسي | Railroad-Grade Machining |

|---|---|---|

| التصديق | Optional / ISO 9001 | Mandatory / Industry-Specific |

| التتبع | Basic tracking | Full material and process history |

| الاختبار | Standard QC checks | NDT, CMM, material certs |

| التوثيق | محدودة | Extensive and required |

This system ensures every component, from engine blocks to frames for railroads skylights, is fully accountable.

Achieving railroad compliance goes far beyond the machine itself. It is a comprehensive ecosystem of quality control, documentation, and verification. Without this framework, a shop simply cannot produce parts that meet the industry’s uncompromising safety standards.

The Foundation: Special Certifications

First, certifications are the entry ticket. While ISO 9001 is a great start, it’s often just the baseline. Rail industry standards, sometimes governed by bodies like the Association of American Railroads (AAR), demand specific quality management systems. For clients searching for ‘ISO certified machining Houston’, this next level of certification is a key differentiator. It proves a shop has the established processes to handle high-stakes projects.

The Golden Thread: Absolute Traceability

Traceability is non-negotiable. For any critical ‘CNC for rail safety parts’, we must be able to track its entire lifecycle. This starts with the raw material certificate from the mill and follows the part through every single machining operation, treatment, and inspection. True Material Lot Traceability10 means that if a problem arises years down the line, we can pinpoint its exact origin.

Testing and Verification Protocols

Finally, testing is not just a final check; it’s an integrated part of the process.

| طريقة الاختبار | الغرض | التطبيق |

|---|---|---|

| CMM Reports | Verify dimensional accuracy to the nanometer. | Complex geometries, safety-critical interfaces. |

| الاختبارات غير المدمرة (NDT) | Detect internal flaws without damaging the part. | Welds, castings, high-stress components. |

| تحليل المواد | Confirm chemical composition and properties. | Ensure material meets design specifications. |

Our CNC machining process for Houston-based clients and beyond incorporates these steps not as options, but as standard procedure for railroad projects.

Railroad compliance requires a systematic approach. It combines industry-specific certifications, complete material and process traceability, and rigorous, documented testing. This framework is essential for producing safe, reliable parts that meet the sector’s stringent demands.

What Every Engineer Needs To Know About Machinability Of Skylight Profiles

Design is more than just aesthetics. It directly impacts production costs and timelines. This is especially true for skylight profiles.

Your design choices dictate the ease of manufacturing. Optimizing for machinability early saves time and money.

Features That Improve Machinability

Simple, accessible features are always best. Consider generous corner radii to allow for larger, more stable tools. This improves surface finish and reduces cycle times. Standardized hole sizes also streamline the process.

Features That Hinder Machinability

Complex geometries can be challenging. Thin walls risk vibration and warping, while deep, narrow pockets require specialized tooling. These features increase the machinability of skylight parts complexity.

| نوع الميزة | Good for Machinability | Bad for Machinability |

|---|---|---|

| الجدران | Thick, uniform walls | Very thin walls (<1.5mm) |

| الزوايا | أنصاف أقطار داخلية واسعة | Sharp, square corners |

| الجيوب | جيوب ضحلة وواسعة | جيوب عميقة وضيقة |

| التفاوتات المسموح بها | التفاوتات القياسية | Unnecessarily tight tolerances |

Beyond basic geometry, material choice is key. The specific alloy of CNC aluminum extrusions greatly affects tool life and cutting speeds. For example, 6061 aluminum is a fantastic all-rounder. It offers good machinability and corrosion resistance.

However, a higher-strength alloy like 7075 can be tougher on tools. It requires slower speeds, which increases machine time. This decision has a direct impact on the final part cost.

Advanced Engineer Tips on CNC Profiles

When designing for CNC machining, consider the material’s grain direction. Extruded profiles exhibit تباين الخواص11, meaning properties differ along different axes. Machining across the grain can be more challenging than machining with it. I always advise clients to note this on their drawings. This simple step provides critical information for the machinist.

For projects like large railroads skylights, managing thermal expansion during machining is also vital. A well-designed part with uniform thickness helps dissipate heat evenly. This prevents warping and ensures dimensional accuracy. At PTSMAKE, we provide design feedback to mitigate these risks.

Machining Operation Considerations

Here are some specific engineer tips on CNC profiles to consider.

| العملية | Design Tip to Improve Machinability | التأثير على الإنتاج |

|---|---|---|

| الطحن | Use open pockets instead of closed ones. | Faster material removal, less tool wear. |

| الحفر | Align holes perpendicular to the surface. | Reduces setup complexity and tool breakage. |

| النقر | Design for standard thread sizes. | Lowers tooling costs and improves speed. |

| التشطيب | Specify surface finishes only where needed. | Reduces secondary processing time. |

Thoughtful design is the foundation of efficient manufacturing. By considering features like wall thickness, corner radii, and material choice, engineers can significantly improve the machinability of skylight parts. This leads to lower costs and higher quality.

Future-Proofing Railroad And Skylight Designs With Scalable CNC Machining

The only constant in engineering is change. Designs must evolve. This is where scalable CNC machining becomes a critical asset for future-proofing.

It allows for rapid adaptation. Whether it’s a material upgrade or a design tweak, the process can adjust. This ensures long-term viability.

Adapting to Tomorrow’s Demands

Scalable CNC machining isn’t just about today’s parts. It’s about preparing for tomorrow’s challenges. It provides the flexibility to upgrade components without a complete overhaul. This is key for infrastructure like railroads.

| الميزة | التصنيع التقليدي | Scalable CNC Machining |

|---|---|---|

| Upgrade Path | Costly re-tooling | Simple software update |

| Material Changes | صعب | Highly adaptable |

| المهلة الزمنية | طويل | قصير |

This adaptability ensures that designs remain relevant and functional for years.

Future upgrades are inevitable. New materials emerge, and performance standards increase. Scalable CNC machining is designed to handle this evolution. It allows us to modify digital files and quickly produce updated components.

Embracing New Materials

Consider next-gen railroad parts. As stronger, lighter composites become available, CNC programs can be adjusted. We can machine these new materials with the same precision. No need for entirely new tooling or machinery. This capability is vital for industries focused on longevity and safety. Our work with clients on projects shows this trend.

Integrating Smart Technologies

The next frontier is IoT integration. Adaptive skylight systems, for instance, can incorporate sensors. These systems adjust to weather in real-time. CNC machining makes it possible to create custom housings and mounts for this new electronic hardware.

| التكنولوجيا | CNC Machining Role | مثال على التطبيق |

|---|---|---|

| السبائك المتقدمة | Precise machining of tough materials | High-strength railroad fasteners |

| المركبات | Custom shaping and finishing | Lightweight skylight frames |

| مستشعرات إنترنت الأشياء | Integrated, precise housings | Smart, adaptive skylight systems |

This process allows for seamless integration of smart tech. It bridges the gap between mechanical design and digital functionality. A التوأم الرقمي12 can simulate performance before a single part is made. This saves immense time and resources, particularly for complex systems like railroads and skylights.

Scalable CNC machining provides the agility to adapt designs for future upgrades, new materials, and smart technology integration. It ensures that components for railroads and skylights remain functional and relevant, accommodating advancements without costly overhauls.

Boost Railroads & Skylights Success with PTSMAKE Precision

Ready to minimize downtime and maximize quality for your railroad or skylight CNC machining projects in Houston? Contact PTSMAKE now for a fast, reliable quote. Experience unmatched precision, repeatable quality, and B2B support from prototype to production—engineered for your industry challenges!

Learn how locating in industrial clusters can reduce costs and boost innovation for your manufacturing projects. ↩

Learn how repeated stress causes microscopic cracks that lead to component failure. ↩

Learn how localized corrosion can create small holes in the metal, compromising skylight integrity. ↩

Learn how this metallurgical process can impact both the final part’s strength and the machining strategy. ↩

Click to understand this foundational concept for precise part inspection and manufacturing alignment. ↩

Explore our detailed guide on DFM to optimize your designs and reduce manufacturing costs. ↩

Learn how this powerful simulation tool predicts how a part reacts to real-world forces. ↩

Learn about the 18 required elements of a PPAP submission and why each one matters for your project. ↩

Discover how CAM software is essential for translating digital designs into precise, physical components. ↩

Learn how comprehensive traceability provides a safety net for critical components. ↩

Learn how material property directionality affects machining precision and structural integrity. ↩

Learn how digital twins revolutionize manufacturing from design to maintenance. ↩