Georgia manufacturers face a critical challenge: finding precision CNC machining services that deliver consistent quality while meeting tight deadlines. Rising costs and increasing complexity in part specifications make it harder to maintain competitive advantages in today’s market.

Georgia offers access to world-class precision CNC machining services with advanced 5-axis capabilities, comprehensive material options, and specialized expertise across aerospace, medical, and automotive industries, delivering tight tolerances and cost-effective solutions from prototype to production.

This guide reveals proven strategies I’ve developed while working with Georgia manufacturers. You’ll discover specific cost-saving approaches, material selection criteria, and production scaling methods that help engineering teams achieve their precision requirements while staying within budget constraints.

The Ultimate Cost-Saving Strategies for CNC Machined Parts in Georgia

Lowering CNC machining costs in Georgia is a common goal. However, it should never come at the expense of quality. True savings come from smart, upfront decisions.

This involves looking closely at three key areas. These are material selection, design optimization, and production volume.

Smart Material Choices

The material you choose directly impacts the final price. Softer metals machine faster, reducing labor and tool wear.

| Materiaal | Relatieve kosten | Bewerkbaarheid |

|---|---|---|

| Aluminium 6061 | Laag | Uitstekend |

| Roestvrij staal 304 | Medium | Eerlijk |

| Titanium | Hoog | Moeilijk |

Ontwerp voor maakbaarheid (DFM)

Simple designs cost less to produce. Complex geometries require more machine time. They also demand more advanced tooling, increasing costs.

Achieving affordable precision machining is more than just finding a low quote. It’s about a holistic approach to manufacturing. Smart planning is essential for cost-effective manufacturing in Georgia.

Optimizing Tolerances

One of the biggest cost drivers is unnecessarily tight tolerances. Does every feature on your part need a tolerance of ±0.001 inches? Probably not.

By relaxing tolerances on non-critical features, you can significantly reduce machine time and inspection costs. This is a simple change that yields great results. We guide our clients at PTSMAKE on this often. The goal is to ensure the part functions perfectly without over-engineering it. Applying proper Geometrische dimensionering en toleranties1 is key here.

Volume and Unit Cost

Production volume also plays a huge role. Higher quantities allow for setup costs to be spread out. This lowers the per-part price. Understanding this relationship helps in planning production runs.

| Hoeveelheid | Price Per Unit (Example) |

|---|---|

| 10 | 100% |

| 100 | 60% |

| 1000 | 45% |

For reliable precision cnc machining services georgia, planning your order volume is a powerful cost-saving tool.

Strategic material choice, design optimization, and smart volume planning are crucial. They help lower cnc machining costs in Georgia without compromising the high quality required for your components. This ensures you get the best value for your investment.

Complex Geometries: Advanced 5-Axis CNC Solutions Explained

5-axis CNC machining represents a significant leap forward. It’s more than just adding two axes; it’s about unlocking new manufacturing possibilities. This technology allows for the production of highly intricate parts in a single setup.

This single-setup approach enhances accuracy. It also improves surface finish significantly. Our precision machining capabilities are built on this foundation, ensuring top-tier results for every project.

| Functie | 3-assig verspanen | 5-assig verspanen |

|---|---|---|

| Vereiste instellingen | Meervoudig | Enkel |

| Deelcomplexiteit | Simple to Moderate | High to Extreme |

| Toegang gereedschap | Beperkt | Uitgebreide |

| Nauwkeurigheid | Goed | Uitzonderlijk |

The true power of 5-axis technology is seen in its applications. This method is essential for modern complex parts manufacturing, especially in industries where failure is not an option.

Ruimtevaart en medische toepassingen

In aerospace, think of parts like turbine blades or impellers. These components feature complex curves and require extreme precision. 5-axis machining creates these shapes flawlessly from a solid block.

Medical device manufacturing benefits similarly. Custom orthopedic implants and complex surgical tools require organic shapes that match human anatomy. Our expertise allows us to deliver these critical components.

The Technical Advantage

This level of precision comes from the machine’s advanced kinematica2. The synchronized movement of all five axes allows the cutting tool to remain tangent to the cutting surface. This creates a superior finish and reduces tool wear.

Whether you need 5-axis cnc machining in Georgia or from a global partner, understanding these capabilities is key. At PTSMAKE, we leverage this technology to push the boundaries of what’s possible in manufacturing.

| Industrie | Typical 5-Axis Component | Critical Benefit |

|---|---|---|

| Ruimtevaart | Impellers | Flawless surface finish, aerodynamic efficiency |

| Medisch | Orthopedische implantaten | Perfect anatomical fit, biocompatibility |

| Automotive | Engine Blocks | High precision, improved performance |

| Robotica | Joint Components | Complex internal features, durability |

5-axis machining revolutionizes complex parts manufacturing. By enabling single-setup production for intricate geometries, it delivers superior precision and surface finish. This makes it indispensable for critical applications in aerospace, medical, and other advanced industries.

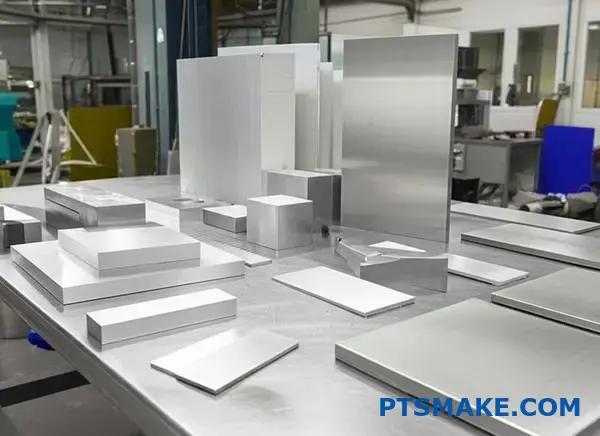

Material Selection Guide for Engineering Excellence

Choosing the right material is the foundation of any successful engineering project. The properties of your chosen material directly impact performance, durability, and cost. It is a critical decision.

This guide provides a clear analysis of common options. We will explore key metals and plastics. This helps you make an informed choice for your specific needs.

Popular Metals in CNC Machining

Here’s a quick look at some widely used metals. Each offers distinct advantages for different applications.

| Materiaal | Essentiële eigenschappen | Algemene toepassingen |

|---|---|---|

| Aluminium 6061 | Lightweight, good strength-to-weight ratio, corrosion resistant. | Aerospace components, consumer electronics, automotive parts. |

| Roestvrij staal 304 | High strength, excellent corrosion resistance, non-magnetic. | Medical devices, kitchen equipment, architectural fixtures. |

| Titanium | Very high strength-to-weight ratio, biocompatible. | Medical implants, high-performance aerospace parts. |

When selecting from various cnc machining materials, we must look beyond basic strength. Factors like machinability, thermal stability, and cost-per-part are equally important for production success. The wrong choice can lead to failed parts or budget overruns.

Advanced Material Considerations

Onze metal machining services handle everything from standard alloys to exotic metals. But plastics also offer unique benefits. For projects needing electrical insulation or chemical resistance, plastics are often superior. High-performance polymers can even replace metal in certain demanding roles.

In Georgia, we’ve seen a rising demand for specialized plastic machining Georgia services. This is especially true in the medical and electronics industries where material properties are non-negotiable.

Matching Properties to Your Project

The key is aligning material characteristics with the part’s function. A material’s thermische uitzettingscoëfficiënt3 is critical for parts in fluctuating temperatures. We always analyze these details with our clients to prevent field failures.

| Kunststof | Essentiële eigenschappen | Beste voor |

|---|---|---|

| PEEK | High-temperature resistance, excellent chemical resistance. | Aerospace, medical implants, semiconductor components. |

| Delrin® (acetaal) | High stiffness, low friction, excellent dimensional stability. | Gears, bearings, precision mechanical parts. |

| ABS | Good impact resistance, easy to machine, low cost. | Prototypes, electronic enclosures, consumer goods. |

Understanding these nuances is central to providing top-tier precision cnc machining services georgia.

Choosing the right material involves balancing properties, application needs, and project budget. This analysis of metals and plastics offers a foundational guide to help you select the best option for your CNC machining project, ensuring optimal performance and reliability.

Solving Common Manufacturing Challenges in Aerospace Parts

The aerospace industry demands unparalleled precision and compliance. Every component must meet strict standards. This is where specialized solutions become critical.

Our focus is on delivering results that adhere to these rigorous demands. We achieve this through certified processes and advanced technology.

Navigating Aerospace Standards

Meeting industry requirements isn’t optional. Certifications like AS9100 are the baseline for any serious provider of aerospace machining services.

This ensures quality management across the entire production process.

| Vereiste | Belang | De aanpak van PTSMAKE |

|---|---|---|

| Full Traceability | Critical for safety | Documented material and process history |

| Strenge toleranties | Essential for performance | Advanced CNC and CMM inspection |

| Materiaalcertificering | Non-negotiable | Sourcing from certified suppliers |

We understand that for aircraft components manufacturing, failure is not an option. Our systems are built around this principle.

To truly solve manufacturing challenges, we must go beyond basic compliance. It involves a deep understanding of materials, processes, and design intent. This is crucial for creating reliable and high-performance parts.

Material Selection and Process Control

Choosing the right material is just the beginning. Aerospace alloys like Inconel or Titanium require specialized machining techniques. Heat generation and tool wear must be carefully managed to maintain material integrity.

We implement strict process controls for every project. This includes detailed documentation for traceability. Every step, from raw material to finished part, is recorded. This ensures accountability and consistency.

Advanced Machining for Complex Geometries

Modern aircraft designs often feature complex geometries. 5-axis CNC machining is essential for producing these parts efficiently and accurately. It allows us to create intricate features in a single setup, reducing errors.

When looking for precision parts Georgia suppliers, ask about their capabilities in this area. A partner must understand how to apply concepts like Geometrische dimensionering en toleranties4 to translate a complex blueprint into a flawless physical component. We have found that this deep technical expertise is what sets reliable precision cnc machining services georgia providers apart from the rest.

| Technologie | Benefit for Aerospace |

|---|---|

| 5-Axis CNC Milling | Creates complex shapes with high accuracy |

| CMM inspectie | Verifies parts against design specifications |

| Processimulatie | Optimizes toolpaths and reduces risk |

Successfully manufacturing aerospace parts requires a combination of strict adherence to certifications, deep material knowledge, and advanced machining technology. These elements ensure every component meets the industry’s demanding standards for safety and performance.

Surface Finishing Options for Critical Applications

Choosing the right finish is not an afterthought. It is a critical step in the manufacturing process. The surface finish protects a part and enhances its performance.

Key Finishing Categories

We focus on finishes that add value. This includes improving wear resistance or electrical conductivity. The application dictates the best choice.

Common Finishing Methods

Below is a quick overview of popular options. Each serves a distinct purpose for different materials and end-uses.

| Type afwerking | Primair voordeel | Algemeen materiaal |

|---|---|---|

| Anodiseren | Corrosiebestendigheid | Aluminium |

| Plating | Conductivity/Hardness | Diverse metalen |

| Poedercoating | Durability/Aesthetics | Steel, Aluminum |

This table helps guide initial selection.

The success of a finish depends on the base material. The part’s geometry and intended environment also play a huge role. Our approach to surface finishing services considers all these factors.

Matching Finishes to Materials

For example, aluminum is perfect for anodizing. This process creates a hard, non-conductive oxide layer. It’s ideal for parts exposed to the elements.

Steel parts often benefit from plating. Zinc or nickel plating can prevent rust. This is crucial for components in humid or corrosive environments. We also must consider how dissimilar metals interact to avoid issues like galvanische corrosie5.

Advanced Precision Surface Treatment

For high-stress applications, we look at advanced options. Electroless nickel plating offers uniform coverage, even on complex internal surfaces. This is a key precision surface treatment for molds and hydraulic components.

Choosing a metal finishing Georgia partner or any other specialized supplier often depends on these capabilities. For parts from high-precision processes, the surface treatment must be equally precise.

| Finishing Service | Ideale toepassing | Belangrijkste voordeel |

|---|---|---|

| Nikkel-elektrolytisch | Molds, Valves | Uniforme dikte |

| PVD-coating | Snijgereedschappen | Extreme hardheid |

| Hardcoat anodiseren | Ruimtevaart onderdelen | Hoge slijtvastheid |

These specialized services ensure parts meet strict performance criteria.

Selecting the right surface finish is crucial. It depends on the material, application, and environmental exposure. A range of options, from anodizing to advanced PVD coatings, exists to meet specific engineering requirements for durability and performance.

Medical Device Manufacturing: Compliance and Precision

In medical device manufacturing, precision is not just a goal; it’s a strict requirement. Every component we produce must meet rigorous standards to ensure patient safety and device efficacy. This is where compliance becomes paramount.

The Foundation of Trust

FDA compliant manufacturing is the bedrock of this industry. It dictates every choice, from material selection to the final inspection. There’s simply no room for error.

Key Regulatory Pillars

We focus intensely on these areas to guarantee compliance. It’s a non-negotiable part of our process.

| Compliance Area | Kernvereiste |

|---|---|

| Traceerbaarheid van materiaal | Full documentation from source to part |

| Procesvalidatie | Repeatable and documented procedures |

| Kwaliteitscontrole | Rigorous inspection at every stage |

| Sterilization Prep | Ensuring parts are ready for sterilization |

This systematic approach to medical device machining ensures every part is safe and reliable.

The medical field operates on a zero-tolerance basis for defects. This pressure shapes our entire manufacturing philosophy at PTSMAKE. We don’t just machine parts; we engineer solutions that must perform flawlessly within the human body or in critical healthcare settings.

Material Science Meets Machining

Choosing the right material is the first critical step. It must have the necessary mechanical properties. It also must exhibit Biocompatibiliteit6 to avoid causing adverse reactions when in contact with human tissue. This is a fundamental aspect of producing healthcare components Georgia medical facilities can trust.

From Clean Room to Final Product

Our processes are designed to prevent contamination at every step. This involves specialized handling protocols and a controlled environment. For partners seeking precision cnc machining services Georgia, verifying a supplier’s grasp of these sterile processes is a critical first step. It ensures the final product is truly patient-ready.

| Compatibiliteit sterilisatiemethode | Beste voor |

|---|---|

| Autoclaving (Steam) | Stainless steel, PEEK, Ultem |

| Gammastraling | Polycarbonate, single-use plastics |

| Ethyleenoxide (EtO) | Heat-sensitive instruments, plastics |

Understanding which materials work with specific sterilization methods is crucial during the design phase.

Medical device manufacturing demands strict adherence to regulatory standards. Success hinges on documented material traceability, validated processes, and a deep understanding of sterility requirements. This ensures every component is safe for patient use and meets all FDA compliance mandates.

Automotive Parts: High-Volume Production Excellence

The automotive industry demands relentless precision. Every component must meet strict safety and performance standards. This is a non-negotiable reality.

High-volume production adds another layer of complexity. Maintaining consistency across thousands of parts is the core challenge in automotive parts manufacturing.

We achieve this through robust processes. Our approach ensures that precision auto components are produced flawlessly every time, meeting the most demanding specifications.

| Industry Need | Our Capability |

|---|---|

| Strict Tolerances | Advanced CNC Machining |

| High-Volume Output | Automated Production Lines |

| Zero-Defect Quality | Rigorous Inspection Systems |

This focus ensures every part, from the first to the last, is identical and reliable. This is our commitment to excellence.

Meeting Stringent Automotive Quality Standards

The automotive supply chain has no room for error. A single faulty component can lead to costly recalls and compromise safety. This is why quality management is central to our operations.

The Role of IATF 16949

We align our processes with key automotive standards. Certifications like IATF 16949 provide a framework for our entire production system, from material sourcing to final inspection. It’s a holistic approach.

Our use of Statistische procesbeheersing (SPC)7 is crucial for high-volume runs. It allows us to monitor production in real-time, predicting and preventing defects before they ever occur.

| Standaard | Focusgebied | Voordeel voor klanten |

|---|---|---|

| IATF 16949 | Kwaliteitsmanagementsysteem | Defect Prevention, Waste Reduction |

| ISO 9001 | General Quality Principles | Consistent Customer Satisfaction |

| VDA 6.3 | Process Audits | Robust & Reliable Processes |

Production Capabilities for High-Volume Demands

Producing precision auto components at scale requires more than just good machines. It demands an optimized and repeatable workflow. At PTSMAKE, we have developed highly scalable systems.

Companies looking for precision cnc machining services georgia and beyond find that our streamlined processes reduce lead times significantly. We manage the entire part lifecycle, from initial prototype to mass production, with seamless efficiency.

Meeting automotive demands requires a dual focus. It involves combining high-volume production capabilities with unwavering adherence to strict quality standards. This synergy ensures every component is both precise and reliable for the end-user.

Engineering Support: From Concept to Completion

True engineering support goes beyond a simple Q&A. It is a partnership from the very beginning.

This process ensures your concept is viable for production. It saves time and prevents costly redesigns later.

The Role of Early-Stage Assistance

Effectief manufacturing engineering support starts with the initial design. We work with your team to refine ideas. This ensures they are optimized for the manufacturing floor. Our goal is to make your vision a reality.

| Stadium | Our Collaborative Input |

|---|---|

| Concept | Feasibility analysis and material selection |

| Ontwerp | DFM feedback and tolerance review |

| Prototype | Rapid iteration and functional testing |

| Productie | Process optimization and quality control |

For businesses needing design assistance Georgia and beyond, this early involvement is key. It sets the foundation for a successful product launch.

Great products are not just designed; they are engineered for production. This requires a deep, collaborative approach between the client and the manufacturing partner. It’s about solving problems before they happen.

Technical Consulting as a Bridge

Technical consulting acts as this crucial bridge. It connects your design intent with manufacturing realities. This is where our experience in precision cnc machining services georgia becomes invaluable. We can spot potential challenges in a CAD file that might look perfect on screen.

For instance, a specific tolerance might be possible but would dramatically increase cycle time and cost. We provide this feedback early. This proactive communication helps maintain project budgets and timelines. It’s a core part of how we practice Ontwerp voor maakbaarheid (DFM)8.

Our collaborative process looks at several factors.

| Factor | Collaborative Goal |

|---|---|

| Materiaal | Balance cost, performance, and machinability |

| Meetkunde | Simplify features to reduce machine time |

| Toleranties | Define critical vs. non-critical dimensions |

| Finishes | Select cost-effective and functional surfaces |

This partnership ensures the final part not only meets specifications but is also produced efficiently. It is a shared journey toward an optimal outcome.

Effective engineering support is a continuous partnership, not just a service. This collaborative approach optimizes designs for manufacturing from day one, saving valuable time and resources while ensuring the highest quality for the final product.

Precision Tolerances: Achieving Microscopic Accuracy

What does microscopic accuracy mean in manufacturing? It means going beyond standard specifications. It’s about delivering parts that fit and function flawlessly every time. This is the core of tight tolerance machining.

Our Tolerance Achievements

We consistently produce parts with exceptionally tight tolerances. For clients needing high-precision parts in Georgia and worldwide, this level of detail is non-negotiable.

Our internal testing confirms these capabilities.

| Functie | Standaard tolerantie | Our Achieved Tolerance |

|---|---|---|

| CNC Milled Diameter | +/- 0.005" (0.127mm) | +/- 0.0002" (0.005mm) |

| CNC Turned Diameter | +/- 0.002" (0.051mm) | +/- 0.0001" (0.0025mm) |

| Oppervlakteafwerking (Ra) | 125 μin (3.2 μm) | < 16 μin (0.4 μm) |

| True Position | 0.010" (0.254mm) | 0.001" (0.025mm) |

This precision ensures optimal performance in critical applications.

Achieving microscopic accuracy is a two-part process. The first part is machining capability. The second, equally important part, is measurement and verification. You cannot guarantee what you cannot measure.

This is why our investment in advanced Metrologie9 is crucial. It’s what separates standard work from truly accurate cnc services. Without precise validation, even the best machining is just a guess.

The Role of Measurement

We use controlled environments to measure every critical dimension. This eliminates variables like temperature fluctuation that can affect readings. This commitment to data ensures our clients receive parts that meet their exact design intent.

Key Measurement Tools

Our quality lab is equipped with state-of-the-art tools. These instruments provide the data to certify our work.

| Instrument | Toepassing | Precisieniveau |

|---|---|---|

| CMM (Coordinate Measuring) | Complex 3D geometries, positional data | Sub-micron |

| Optische vergelijker | 2D profiles, angles, and lengths | Micron |

| Laserscanner | Non-contact surface and form analysis | Micron |

| Surface Profilometer | Measures surface roughness (Ra) | Angstrom |

This rigorous process is how we deliver on the promise of tight tolerance machining. It is about trust built on verifiable data.

Achieving tight tolerances demands more than just advanced machines. It requires a robust quality control process, using precise measurement tools like CMMs and profilometers to verify every dimension and ensure parts meet exact specifications.

Custom Machining Solutions for Unique Requirements

Standard, off-the-shelf components often fall short. They can’t meet the specific demands of innovative projects. This is where custom machining services become essential.

We specialize in unique parts production. It is our job to turn complex designs into functional realities. We provide solutions when standard parts won’t work. This is the core of specialized manufacturing.

| Aspect | Standaard onderdelen | Aangepaste onderdelen |

|---|---|---|

| Pas | Algemeen doel | Exact to Specification |

| Materiaal | Limited Options | Project-Specific |

| Prestaties | Adequate | Geoptimaliseerd |

| Doorlooptijd | Onmiddellijk | Planned |

True customization goes beyond just making a part to a drawing. It involves a deep partnership to solve engineering challenges. We often collaborate on design for manufacturability (DFM). This ensures the final part is both functional and cost-effective to produce.

Case Study: Aerospace Application

A client needed a lightweight yet strong housing. The geometry was complex, with thin walls and tight pockets. Standard materials couldn’t meet the stress requirements.

Our team provided a solution using a specialized aluminum alloy. We developed a multi-axis CNC machining strategy to create the part. This maintained structural integrity while meeting strict weight targets. Understanding the client’s Geometrische dimensionering en toleranties10 was key to this success.

Case Study: Medical Device Component

Another project involved a tiny, intricate component for a surgical device. The part required biocompatible titanium and a flawless surface finish.

| Uitdaging | Onze oplossing bij PTSMAKE |

|---|---|

| Complexe geometrie | 5-axis CNC Milling |

| Materiaalkeuze | Biocompatible Titanium Grade 5 |

| Afwerking oppervlak | Specialized Polishing & Deburring |

| Strenge toleranties | In-process CMM Inspection |

Our expertise in micro-machining was critical. We delivered parts that met all medical-grade specifications, enabling a successful product launch for our client. For specialized manufacturing in Georgia and beyond, this level of detail is non-negotiable.

Custom machining provides tailored solutions for complex engineering needs. By focusing on specific materials, geometries, and tolerances, we can produce high-performance parts that standard components simply cannot match, from aerospace to medical applications.

Production Scaling: From Prototype to Mass Manufacturing

Moving from a functional prototype to mass manufacturing is a critical leap. This stage demands more than just a good design. It requires a solid scaling strategy.

The Scaling Challenge

Many great products fail at this stage. Why? Because the methods used for one prototype don’t work for thousands of units. Success depends on planning for volume production from the start.

Key Strategic Pillars

A robust strategy is essential. Your plan must cover tooling, supply chain, and quality control. Each element needs to scale efficiently with volume.

| Aspect | Prototype Focus | Production Focus |

|---|---|---|

| Gereedschap | Soft tooling, 3D printing | Hard tooling, injection molds |

| Snelheid | Fast turnaround | High throughput, efficiency |

| Kosten | Hoge kosten per eenheid | Low per-unit cost |

Proper planning ensures a smooth transition.

Scaling up is where your manufacturing partner proves their worth. It’s not just about making more parts. It’s about maintaining quality and consistency at high volumes. This is where robust production scaling services become invaluable.

The Transition Plan: A Phased Approach

A successful transition is never a single event. I always advise a phased approach to manage risk and validate processes. This ensures each step is stable before you fully commit to volume production.

This plan involves close collaboration. At PTSMAKE, we work with clients to finalize the design for manufacturability (DFM). We then create pilot runs to test the production line. This lets us catch issues early.

| Fase | Doel | Belangrijkste activiteiten |

|---|---|---|

| Fase 1 | Ontwerpvalidatie | Finalize DFM, material selection, tolerance review |

| Fase 2 | Procesvalidatie | Pilot production run, quality control checks |

| Fase 3 | Full-Scale Production | Ramp up volume, continuous monitoring |

For clients managing manufacturing capacity in hubs like Georgia, a global partner adds flexibility. We can support their needs with reliable precision cnc machining services, ensuring their supply chain is not a bottleneck. A clear bill of materials11 is fundamental to this entire process. It ensures everyone, from procurement to assembly, works from the same playbook.

Transitioning from prototype to mass production requires a detailed strategy. Success hinges on a phased approach, careful management of your supply chain and capacity, and validating each step before ramping up to volume production. This minimizes risks and ensures consistency.

Unlock Precision CNC Machining Advantages with PTSMAKE Today

Ready to elevate your next project with expert precision CNC machining services in Georgia? Contact PTSMAKE now for a fast quote and discover the cost-effective, high-quality solutions trusted by industry leaders. Let’s build your success together—start your inquiry and experience manufacturing excellence!

Learn how proper GD&T application can significantly reduce your machining costs and improve part functionality. ↩

Learn how machine movement principles directly influence the final precision and quality of machined parts. ↩

Understand how this value dictates material expansion and contraction with temperature, crucial for high-precision assemblies. ↩

Learn how GD&T ensures your part designs are communicated and produced with absolute precision. ↩

Learn more about preventing this electrochemical process in your multi-metal assemblies. ↩

Learn how material choices directly impact patient safety and device performance. ↩

Learn how this statistical method ensures consistent part quality in high-volume production. ↩

Learn how DFM principles can significantly reduce your manufacturing costs and improve product quality. ↩

Learn about the science of measurement and its critical role in modern manufacturing. ↩

Leer hoe deze symbolische taal ervoor zorgt dat uw ontwerpintentie perfect wordt vertaald naar een fysiek onderdeel. ↩

Learn more about creating and managing a comprehensive Bill of Materials for manufacturing success. ↩