Finding reliable precision machining for energy projects feels like navigating a minefield. One wrong supplier choice can derail your entire timeline, blow your budget, and compromise safety standards that simply cannot fail.

Energy CNC precision machining combines advanced computer-controlled manufacturing with specialized expertise to produce critical components for power generation, renewable energy systems, and infrastructure projects. This technology delivers the tight tolerances, consistent quality, and reliable delivery schedules that energy sector decision-makers demand for mission-critical applications.

I’ve worked with energy sector clients who learned these lessons the hard way. This guide covers everything from selecting the right machining partner to ensuring your components meet the rigorous standards your projects require. You’ll discover practical strategies that can save both time and money while maintaining the quality your reputation depends on.

The Ultimate Guide to Energy CNC Precision Machining

The energy sector demands extreme precision. Components must withstand harsh environments. Failure isn’t an option for these critical applications.

Perché la precisione è importante

This is where energy CNC precision machining comes in. It delivers the accuracy needed for mission-critical parts. It ensures reliability, from deep-sea oil rigs to towering wind turbines.

Efficiency in Production

Modern energy projects require speed and consistency. CNC machining provides both. It helps reduce material waste and significantly shortens production lead times.

| Caratteristica | Lavorazione tradizionale | Lavorazione CNC |

|---|---|---|

| Tolleranza | Più basso | Più alto |

| Coerenza | Variabile | Alto |

| Complessità | Limitato | Alto |

This guide explores the vital role of precision machining.

In the energy sector, components often operate under extreme pressure and temperature. There is simply no room for error. Precision machining for the energy industry isn’t just a preference; it’s a strict requirement for safety and performance.

Beyond Traditional Methods

Traditional manufacturing struggles to meet these demands. Complex geometries for turbine blades or specialized valves require advanced techniques. CNC ensures every part meets exact specifications, every single time. It is a core process of modern produzione sottrattiva1.

Enabling a Sustainable Future

The global shift to renewables highlights CNC’s importance. Wind turbines and solar panel mounts need components with incredibly tight tolerances. These parts must last for decades in challenging outdoor conditions. CNC machining makes this level of durable quality possible.

Key Applications in Energy

| Settore energetico | Componenti lavorati a CNC |

|---|---|

| Petrolio e gas | Valves, flanges, drill bits |

| Wind Power | Turbine hubs, gearbox parts |

| Solar Power | Mounting brackets, frames |

| Nucleare | Reactor components, control rods |

This technology is foundational for building and maintaining our global energy infrastructure.

CNC precision machining is non-negotiable for the modern energy industry. It delivers the required accuracy for demanding applications, supports innovation in renewables, and ensures the reliability of critical infrastructure. It’s the cornerstone of advanced energy manufacturing.

How Precision Machining Solves Critical Energy Sector Challenges

The energy sector operates under extreme pressure. Components must withstand intense heat, corrosion, and high stress. Failure is not an option.

Common Manufacturing Headaches

Engineers face two major issues. They need incredibly tight tolerances. They also work with exotic, hard-to-machine materials.

Here’s a quick look at the core problems and how we address them.

| Problema | CNC Solution |

|---|---|

| Inconsistent Quality | Repeatable Precision |

| Difficult Materials | Specialized Tooling & Processes |

| Tolleranze strette | High-Accuracy Machining |

Qui è dove energy cnc precision machining becomes essential for safety and reliability.

In the energy sector, it’s not just about making a part fit. The manufacturing process itself can compromise the material’s strength. This is a critical point many overlook.

Problem: Material Integrity Under Stress

Traditional machining can introduce stress into components. This is especially true with superalloys like Inconel or Titanium. These materials are prone to indurimento del lavoro2. Improper techniques can create weak points that fail under pressure. This directly impacts operational safety.

Solution: Strategic CNC Machining

Moderno energy sector CNC machining offers precise control over every variable. We use optimized toolpaths and constant coolant flow. This minimizes heat and mechanical stress on the part. At PTSMAKE, we combine 5-axis capabilities with advanced software simulations. This ensures the final component maintains its designed structural integrity.

Our focus is on delivering parts that are not only dimensionally accurate but also metallurgically sound. This approach provides the reliability the industry demands.

| Caratteristica | Lavorazione tradizionale | Moderna lavorazione CNC |

|---|---|---|

| Gestione del calore | Often inconsistent | Actively controlled |

| Sollecitazione del materiale | High risk | Ridotto al minimo |

| Parte Complessa | Limitato | Highly capable |

| Ripetibilità | Basso | Estremamente alto |

We’ve found this level of process control is non-negotiable for critical applications.

The energy industry demands extreme precision and material resilience. Common manufacturing struggles with tight tolerances and tough alloys risk component failure. CNC technology directly addresses these issues, ensuring the reliability and quality essential for critical applications.

Top 5 Applications of CNC Machining in Renewable Energy

CNC machining is crucial for renewable energy. The industry demands precision parts that last for decades. These components must perform under harsh conditions.

Let’s explore specific CNC machining for renewable energy applications.

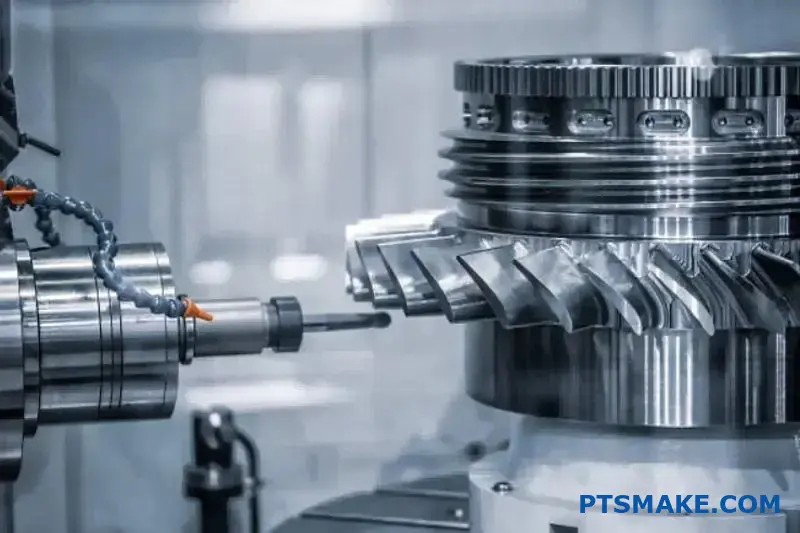

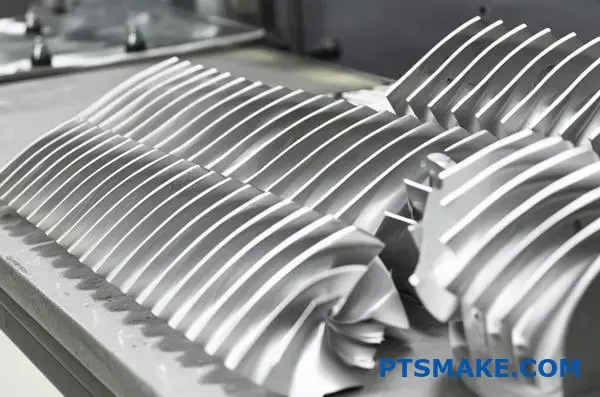

Wind Energy Components

Turbine parts require extreme precision. CNC machines create hubs, gearbox components, and blade roots. Perfect balance is non-negotiable for efficiency and safety.

Solar Power Structures

Solar panel frames and trackers need accuracy. CNC machining produces mounts that ensure optimal alignment. This directly boosts energy generation.

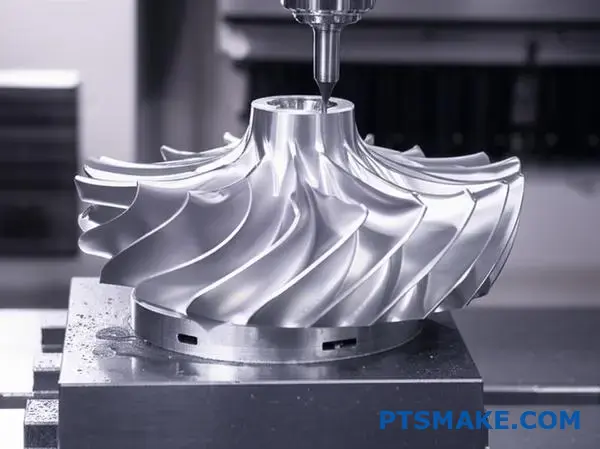

Hydropower Systems

Hydropower relies on durable parts. CNC creates turbine runners and gates from tough alloys. These parts must withstand immense water pressure.

A look at key energy component applications:

| Settore energetico | Esempio di componente | Key CNC Benefit |

|---|---|---|

| Wind | Turbine Gearbox | High-Tolerance Gearing |

| Solar | Mounting Bracket | Precise Angles & Fit |

| Hydro | Turbine Runner | Geometrie complesse |

Let’s dig deeper into these applications. The link between design innovation and manufacturing feasibility is where precision machining becomes a game-changer. It’s not just about making a part; it’s about enabling a more efficient energy future.

The Role of Precision in Performance

For a wind turbine, even a tiny imbalance can cause catastrophic failure. 5-axis CNC milling creates the complex aerodynamic surfaces on blades and hubs. This ensures maximum energy capture and operational safety. At PTSMAKE, we focus on this level of detail.

Material and Structural Integrity

Solar tracking systems must move smoothly for years. CNC machining produces lightweight yet strong aluminum frames. These parts resist corrosion and wear. This extends the system’s operational life significantly.

Hydropower turbines use materials like stainless steel. These alloys are tough and difficult to machine. Precision CNC ensures the final part has uniform strength and consistent Isotropic material properties3. This is critical for parts under constant stress.

Based on our work with clients, the choice of machining strategy directly impacts part longevity.

| Settore | Focus sui materiali | Vantaggio della lavorazione CNC |

|---|---|---|

| Wind | Composites & Steel | Complex surface contouring |

| Solar | Leghe di alluminio | High-speed, repeatable production |

| Hydro | Acciaio inox | Handling hard, durable materials |

CNC machining is the backbone of manufacturing for wind, solar, and hydropower. It delivers the precision and reliability needed for high-performance renewable energy components, directly impacting efficiency and system longevity.

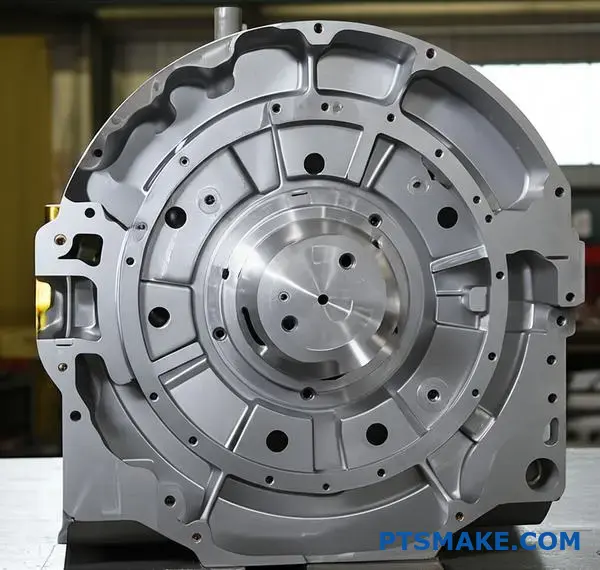

Ensuring Unmatched Accuracy for Safety-Critical Energy Parts

In sectors like nuclear and oil & gas, component failure is not an option. Parts operate under extreme pressure and temperature. The stakes are incredibly high.

This demands a level of precision that goes far beyond standard manufacturing. Here, accuracy is directly linked to safety and environmental protection.

The Demands of Extreme Environments

For these industries, safety-critical CNC machining is essential. Even a microscopic deviation in a part can lead to catastrophic system failure. We focus on achieving impeccable tolerances.

| Industria | Sfida primaria | Conseguenza del fallimento |

|---|---|---|

| Nucleare | Radiation Resistance, Sealing | Radioactive Leak |

| Petrolio e gas | High Pressure, Corrosion | Explosion, Oil Spill |

This is why energy cnc precision machining requires a specialized approach from the start.

Adherence to Unyielding Standards

Meeting specifications in these fields means strict compliance with established standards. It’s not just about making a part; it’s about proving it’s perfect every time. We see this with API standards in oil & gas or ASME codes for nuclear applications.

These standards dictate everything from material traceability to final inspection protocols. They are the rulebook for ensuring safety.

Case in Point: Subsea Valve Components

Consider a valve body for a subsea pipeline. It must withstand immense external pressure while controlling internal flow precisely. The sealing surfaces require tolerances measured in microns to prevent leaks.

Our quality control process validates every critical feature. This involves advanced Metrologia4 to ensure every single part conforms perfectly. Without this, the component simply cannot be used.

Quality Control Checkpoints

| Palcoscenico | Metodo di ispezione | Scopo |

|---|---|---|

| Materia prima | Test PMI | Verify Alloy Composition |

| In corso | Ispezione CMM | Confirm Geometric Accuracy |

| Finale | Test di pressione | Validate Performance Under Load |

At PTSMAKE, our process for precision energy components is built around this rigorous validation.

In safety-critical energy sectors, precision is a mandate, not a preference. Strict adherence to industry standards and advanced quality control are non-negotiable for manufacturing components that ensure operational safety and compliance.

Cost-Effective Strategies for Energy Project Manufacturing

Achieving cost savings in energy project manufacturing is critical. It doesn’t mean cutting corners. Smart strategies can lower expenses while maintaining high quality. This is where efficiency makes a difference.

At PTSMAKE, we focus on practical, actionable steps. These steps help our clients optimize their production processes.

Progettazione per la producibilità (DFM)

Optimizing your design is the first step. Small changes can lead to significant savings in machining time and material waste. This is key for cost-effective CNC machining.

| Scelta del design | Impatto sui costi |

|---|---|

| Complex, tight tolerances | Higher machining time, increased cost |

| Standardized features | Faster setup, lower tooling cost |

Selezione strategica dei materiali

Choosing the right material is a balance. You need performance without overspending. We often help clients evaluate alternatives that meet project specs for less.

True energy project cost savings come from a holistic view. It’s not just about one part. It’s about the entire manufacturing process, from design to final assembly. Efficiency is the core principle.

Il potere della produzione in lotti

Producing parts in batches is a classic strategy. It reduces machine setup time per part. This significantly lowers the unit cost. For any energy cnc precision machining project, this method offers great value. It is especially useful for recurring orders.

We often advise clients to plan their inventory needs. This allows for larger, more economical production runs.

Consolidating Parts

Can one machined part replace two or three assembled components? Part consolidation simplifies assembly. It also reduces potential points of failure. This approach enhances reliability and cuts down on labor and inventory costs. Careful design is essential here. A deep understanding of Dimensionamento e tolleranza geometrica5 is necessary to ensure the consolidated part functions correctly.

| Strategia di produzione | Vantaggi principali | Applicazione ideale |

|---|---|---|

| Batch Production | Costo unitario inferiore | Projects with stable, repeating demand |

| Part Consolidation | Reduced assembly time, higher reliability | Complex assemblies in a single component |

Effective cost-saving combines smart design, material knowledge, and efficient production methods. By optimizing design, selecting appropriate materials, and leveraging batch production, you can reduce manufacturing costs significantly without ever compromising the quality or integrity of your energy project components.

In the energy sector, delays are not just inconvenient. They can halt entire projects. This impacts budgets and timelines significantly.

Success hinges on mastering three core areas. These are meticulous planning, streamlined logistics, and robust supplier reliability.

The Foundation of Success

Comprehensive planning is your first line of defense. It sets clear expectations and timelines for every component. This is especially true for energy cnc precision machining parts.

Choosing Your Partners Wisely

Logistics and supplier choice are equally critical. A reliable partner understands the urgency and precision your industry demands. They help you maintain supply chain efficiency.

| Approccio | Planning Focus | Risultato |

|---|---|---|

| Proattivo | Risk mitigation, buffer stocks | On-time, on-budget |

| Reattivo | Problem-solving, expediting | Delays, cost overruns |

True on-time delivery in energy projects comes from strong partnerships. It’s about moving beyond simple transactions with your suppliers. It becomes a collaborative effort. At PTSMAKE, we prioritize transparent communication. This keeps our clients informed at every stage.

This approach builds trust. It also allows for quick adjustments when challenges arise. A strong supplier relationship means they understand your project’s specific needs. They can anticipate potential issues before they cause delays. This is key for parts requiring energy cnc precision machining.

Enhancing Supplier Reliability

We regularly review performance metrics. This ensures our process aligns with project goals. Using technology for real-time tracking provides an extra layer of security. It helps us build a more predictable and efficient supply chain. This focus on resilienza della catena di approvvigionamento6 is what protects projects from unforeseen disruptions.

| Vetting Criterion | Importanza | Esempio di metrica |

|---|---|---|

| Comunicazione | Alto | < 12-hour response time |

| Controllo qualità | Alto | < 1% defect rate |

| Tempi di consegna | Medio | Consistent delivery within the quoted window |

| Abilità tecnica | Alto | Certifications (e.g., ISO 9001) |

Mastering on-time delivery is not about luck. It is about a deliberate strategy. Proactive planning, smart logistics, and strong supplier collaboration are the keys to ensuring your energy projects stay on track and within budget.

Advanced Material Selection for High-Performance Energy Parts

Selecting the right material is a critical step. For high-performance energy parts, standard metals often fall short. Advanced materials offer superior capabilities.

We must consider options like titanium and composites. These materials boost durability and overall performance significantly. However, they require specialized machining expertise.

Titanium in Energy Applications

Titanium offers an exceptional strength-to-weight ratio. It also provides superior corrosion resistance. This makes it perfect for demanding energy environments.

Composites for Modern Demands

Composites are lightweight and incredibly strong. Their properties can be customized for specific needs, which is a major benefit for innovative energy cnc precision machining.

| Materiale | Beneficio primario | Typical Energy Application |

|---|---|---|

| Leghe di titanio | Corrosion Resistance & Strength | Subsea components, turbine parts |

| Materiali compositi | Elevato rapporto resistenza/peso | Wind turbine blades, pressure vessels |

Machining Considerations for Advanced Materials

Choosing these advanced CNC machining materials for energy applications is just the start. The real challenge often lies in manufacturing.

Titanium has very low thermal conductivity. Heat builds up at the cutting edge quickly. This causes rapid tool wear. To counter this, we use specific coolants and adjust machining parameters carefully.

Composites are a different story. Their layered structure can lead to delamination during machining. The proprietà anisotrope7 of these materials mean strength varies by direction. This directly impacts our cutting strategy.

At PTSMAKE, our experience with high-performance energy parts is extensive. We’ve refined our processes to handle these complexities. This ensures the component’s integrity is never compromised. Success depends on understanding how each material behaves under stress.

Un rapido confronto

Here’s how these materials stack up from a machining perspective.

| Fattore | Titanio | Compositi in fibra di carbonio |

|---|---|---|

| Sfida principale | Gestione del calore | Preventing Delamination |

| Usura degli utensili | Alto | High (Abrasive Nature) |

| Required Tools | Carbide with specific coatings | Diamond-coated or PCD tools |

| Uso del refrigerante | Essential, high-pressure | Often machined dry |

| Post-elaborazione | Often involves stress relief | Sealing edges may be needed |

Advanced materials like titanium and composites provide significant advantages for high-performance energy parts. However, their benefits are only realized through expert CNC machining that addresses their unique properties and challenges, ensuring reliability and performance in the final product.

A Complete Checklist for Choosing an Energy CNC Partner

Selecting the right partner for energy CNC precision machining is critical. Your project’s success hinges on this decision. A wrong choice can lead to delays and quality issues.

This guide provides a clear checklist. It helps you evaluate potential suppliers systematically. Let’s build a reliable partnership from the start.

Initial Screening Questions

Before diving deep, ask these preliminary questions. They quickly filter out unsuitable suppliers.

| Domanda | Perché è importante |

|---|---|

| Industry Experience? | Do they understand the demands of the energy sector? |

| Key Certifications? | Certs like ISO 9001 show a commitment to quality. |

| Machine Park? | Do they have the right equipment for your parts? |

A systematic approach is essential. This energy manufacturing supplier checklist is your roadmap. It helps you move beyond a supplier’s sales pitch and into their actual capabilities.

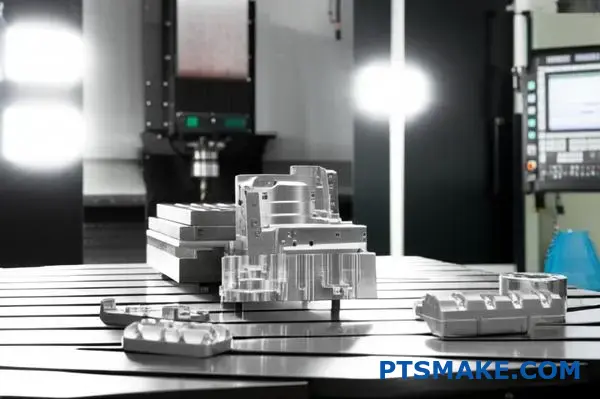

Technical Deep Dive

Once you have a shortlist, it’s time for a deeper look. Assess their technical prowess and quality management systems. This is where you separate the good from the great.

For complex energy components, material traceability is non-negotiable. You must be able to track materials from source to final part. Ask for their documentation process.

Avanzato metrologia8 equipment is also crucial. Without it, verifying the tight tolerances required in the energy sector is impossible. We at PTSMAKE invest heavily in these systems to guarantee compliance.

Comunicazione e assistenza

Technical skills are only half the story. How a partner communicates can make or break a project.

| Aspetto della comunicazione | Ideal Partner | Bandiera rossa |

|---|---|---|

| Reattività | Quick, clear replies | 24hr+ wait times |

| Proactivity | Flags potential issues | Waits for problems to arise |

| Segnalazione | Aggiornamenti regolari sui progressi compiuti | Vague or no updates |

When you choose a CNC partner for energy projects, you need a team that acts as an extension of your own. Open and transparent communication is the foundation of that relationship.

A structured evaluation process is your best tool. This checklist helps you assess a supplier’s technical ability, quality systems, and communication protocols, ensuring you choose a CNC partner for energy projects who can deliver results.

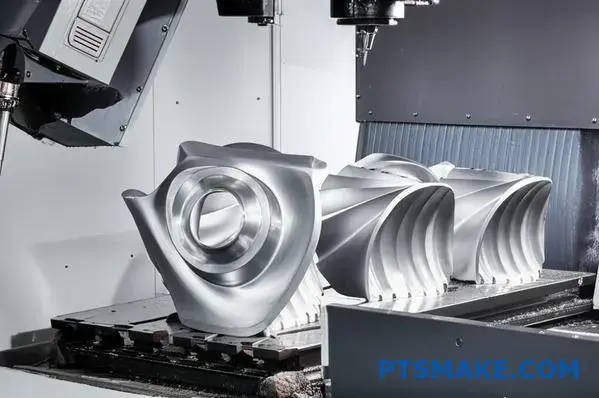

Case Study: Successful Wind Turbine Component Production

Theory is one thing, but results are what matter. Let’s look at a real-world wind turbine CNC case study. A client needed a critical gearbox component.

The part required extreme precision. It was made from a durable, hard-to-machine alloy. This is a common challenge in energy component manufacturing.

Here were the initial project challenges:

| Sfida | Specifiche | Impatto sulle prestazioni |

|---|---|---|

| Durezza del materiale | Inconel 718 | Elevata usura degli utensili, velocità ridotte |

| Tolleranza | ±0,005 mm | Bearing fit and lifespan |

| Geometria | Canali interni complessi | Cooling fluid dynamics |

Our task was to deliver a solution that was both precise and repeatable for production. This is a typical energy machining success story we aim for.

This project tested our energy cnc precision machining capabilities. The primary hurdle was the material itself. Inconel is notoriously difficult to work with. It causes rapid tool wear and requires very specific machining parameters to avoid work hardening.

Our initial approach with standard carbide tools was inefficient. It resulted in high costs and long lead times. We knew a different strategy was necessary for this wind turbine component.

We shifted to using ceramic cutting inserts. We also optimized the cutting paths with advanced CAM software. This change alone significantly reduced machining time. The material’s behavior under stress was a key factor; its uniform Isotropic Material Properties9 allowed for predictable cutting forces once we found the right parameters.

After collaborating with the client’s engineering team, we implemented a multi-stage process. This involved roughing, semi-finishing, heat treatment, and then final finishing on a 5-axis CNC machine.

The results from our process optimization were clear.

| Metrico | Previous Method | Soluzione PTSMAKE | Miglioramento |

|---|---|---|---|

| Tempo di ciclo | 42 hours/part | 31 hours/part | 26% Reduction |

| Vita dell'utensile | 2 parts/tool | 7 parts/tool | 250% Increase |

| Tasso di rifiuto | 8% | <1% | 87,5% Riduzione |

This successful wind turbine CNC case study shows how tackling material and process challenges head-on leads to better outcomes. We provided a reliable production method, not just a single part.

This case study demonstrates how specialized tooling and process optimization solved a complex machining challenge. Our solution for the wind turbine component reduced cycle time and costs while improving quality, building trust through proven results.

The Role of Precision in Nuclear Energy Component Fabrication

In nuclear energy, safety isn’t just a goal; it’s the absolute foundation. There is no room for error. This is where the importance of precision manufacturing becomes clear.

Specifically, nuclear energy CNC machining is not merely a production method. It is a critical safety requirement.

The Unforgiving Environment

Components in a nuclear reactor face extreme conditions. They endure high temperatures, intense pressure, and constant radiation. Any microscopic flaw can lead to catastrophic failure. Precision is the only safeguard.

| Caratteristica | Lavorazione tradizionale | Lavorazione CNC |

|---|---|---|

| Tolleranza | +/- 0.1 mm | Up to +/- 0.005 mm |

| Coerenza | Variabile | Altamente ripetibile |

| Complessità | Limitato | Alto |

| Sicurezza | Operator Dependent | System Controlled |

This level of precision ensures parts fit perfectly. It also guarantees they perform reliably under stress for decades.

The nuclear industry is governed by some of the world’s strictest standards. Regulations like ASME NQA-1 and 10 CFR Part 50 dictate every step. This includes material sourcing, fabrication, and documentation.

Navigating Regulatory Hurdles with Precision

CNC machining is vital for meeting these complex rules. It provides the traceability and repeatability that regulators demand. Every cut is programmed, executed, and documented. This removes the human error variable.

At PTSMAKE, our quality management system is built for this. It ensures full compliance with every client specification and regulatory body. We understand that a component’s history is as important as its physical dimensions. For instance, material selection must account for factors like potential neutron embrittlement10.

This is a critical consideration for long-term operational safety. Precision machining allows us to work with specialized, radiation-resistant alloys.

| CNC Machining Benefit | Impact on Nuclear Compliance |

|---|---|

| High Accuracy | Meets tight design tolerances for safety. |

| Ripetibilità | Ensures all parts are identical, simplifying certification. |

| Full Traceability | Provides detailed data logs for audits. |

| Movimentazione dei materiali | Capable of machining exotic, tough alloys. |

Ultimately, energy cnc precision machining delivers the confidence needed to operate nuclear facilities safely and effectively for their entire lifespan.

CNC machining’s unparalleled precision is not just a feature but a necessity. It is fundamental to meeting the rigorous safety standards and regulatory demands of the nuclear energy sector, ensuring component integrity and operational reliability.

Scalable Solutions: From Prototype to Mass Production

In the energy sector, the journey from a single concept to thousands of units is critical. Scalable CNC machining is the key to this transition. It supports both initial prototyping and mass production seamlessly.

This flexibility allows for rapid design validation. Then, it scales up without major process changes. This ensures consistency and controls costs.

Prototyping vs. Production

| Caratteristica | Fase di prototipazione | Fase di produzione di massa |

|---|---|---|

| Obiettivo | Convalidare il design e la funzione | Consistent, high-volume output |

| Velocità | Fast turnaround is key | Optimized for cycle time |

| Costo | Higher per-unit cost | Costo unitario inferiore |

| Flessibilità | Easy design changes | Standardized process |

This dual capability makes CNC machining an ideal solution for the demanding energy industry. It bridges the gap effectively.

Scaling from prototype to production using CNC machining is a structured process. It ensures that the final parts meet the strict demands of the energy industry, from wind turbines to solar panel components.

The Prototyping Stage

Initially, we focus on speed and accuracy. The goal is to create a functional prototype for testing. This part might be machined from a solid block to test form, fit, and function quickly. Design changes are common and easily implemented at this stage.

The Transition to Production

Once the design is approved, the focus shifts. We analyze the process for efficiency. This is where principles of Progettazione per la producibilità (DFM)11 are crucial. We refine toolpaths, design custom fixtures, and select materials that balance performance with cost for large volumes. This step is vital for successful scaling.

Full-Scale Production

For mass production, automation is key. We use multi-axis CNC centers and automated loading systems to run operations continuously. This boosts output and ensures every part maintains tight tolerances. Consistent quality control is embedded throughout the process.

| Palcoscenico | Attività chiave | CNC Machining’s Role |

|---|---|---|

| 1. Prototype | Design validation, rapid iteration | Fast, flexible machining of 1-10 units |

| 2. Pre-production | Process optimization, fixture design | Refining programs for efficiency |

| 3. Mass Production | Automated, high-volume output | Continuous operation with minimal oversight |

This phased approach, which we guide our clients through at PTSMAKE, guarantees a smooth and predictable path for any energy cnc precision machining project.

CNC machining offers a uniquely scalable path from a single prototype to full production. This integrated approach ensures design intent is maintained, provides cost control, and offers the flexibility needed for innovation in the energy sector.

Quality Assurance Best Practices for Energy Industry Parts

In the energy sector, part failure is not an option. A robust Quality Assurance (QA) protocol is the bedrock of reliability. It prevents catastrophic failures. This involves more than a final check.

It’s a comprehensive process. It begins before machining and ends long after delivery.

Key Inspection Stages

Effective QA integrates multiple inspection points. Each stage serves a specific purpose, ensuring standards are met throughout the manufacturing cycle for energy parts.

| Tipo di ispezione | Scopo | Strumenti utilizzati |

|---|---|---|

| Ispezione del primo articolo | Verifies the setup | CMM, Calipers |

| Ispezione in corso d'opera | Monitoraggio della coerenza | Gauges, SPC Software |

| Ispezione finale | Confirms all specs are met | All relevant tools |

This structured approach is vital for any energy cnc precision machining project. It ensures every part is perfect.

A comprehensive QA strategy goes beyond simple measurements. It involves a documented, repeatable system that ensures consistency and adherence to strict industry standards. This is the core of effective CNC machining quality control.

Implementing QA Standards

The first step is adopting a recognized standard. ISO 9001 provides a strong framework. From there, we build specific protocols for the energy industry’s unique demands. This includes full material traceability and stringent testing procedures.

At PTSMAKE, we integrate these steps directly into our workflow. This ensures that energy part quality assurance is not just a final step, but a continuous process. We use methods like Controllo statistico dei processi12 to monitor our processes in real-time. This allows us to identify and correct potential deviations before they result in a non-conforming part.

A Phased Implementation Approach

Implementing a new QA protocol should be systematic. We follow a clear, phased approach to guarantee success and minimize disruption.

| Fase | Azioni chiave | Obiettivo |

|---|---|---|

| 1. Pianificazione | Define quality metrics, select tools. | Establish a clear quality baseline. |

| 2. Training | Educate team on new standards. | Ensure consistent execution. |

| 3. Esecuzione | Deploy inspection protocols. | Integrate QA into production. |

| 4. Review | Analyze data, gather feedback. | Continuously improve the process. |

This structured implementation ensures that every component we produce meets the high-stakes requirements of the energy sector.

Rigorous QA protocols are non-negotiable for energy industry parts. A multi-stage approach—from material verification to in-process checks and final testing—is essential. This systematic process ensures part reliability and prevents costly, dangerous failures in the field.

Environmental Sustainability in Energy Manufacturing

In the energy sector, sustainability isn’t just a goal; it’s a necessity. This applies directly to manufacturing partners. CNC machining plays a critical role.

Eco-friendly practices in CNC machining are crucial. They involve reducing waste and improving energy efficiency. This approach benefits everyone involved.

Sustainable machining directly supports the energy sector’s mission. It helps create a cleaner and more responsible supply chain.

Key Shifts in Machining Practices

We see a clear move toward greener methods. This isn’t just about public image. It’s about operational excellence.

| Metodo tradizionale | Sustainable Alternative |

|---|---|

| High-volume coolant use | Minimal Quantity Lubrication (MQL) |

| Disposing of scrap metal | Comprehensive material recycling |

| Standard toolpaths | Optimized, energy-saving toolpaths |

These changes make eco-friendly energy manufacturing a reality. They reduce environmental impact and often cut costs.

Deeper Dive into Sustainable Practices

Implementing sustainable CNC machining requires a strategic approach. It’s more than just recycling metal shavings. We focus on optimizing the entire process, from material selection to final delivery.

Energy Efficiency in Operations

Modern CNC machines are more energy-efficient. But efficiency also comes from how we use them. Optimized toolpaths, for example, reduce machine run-time. This directly lowers electricity consumption for each part produced.

Based on our internal studies, smart toolpath strategies can cut energy use by up to 15% per cycle. This is a significant saving when applied to large production runs for the energy industry.

Waste and Material Management

Reducing waste is fundamental. This starts with using near-net-shape raw materials. It minimizes the amount of material that needs to be machined away.

We also use advanced biodegradable coolants. They are less harmful to the environment. Proper management of these fluids is key. A comprehensive life-cycle assessment13 helps us understand the full impact of our material choices.

Here’s how we approach material efficiency in energy cnc precision machining.

| Pratica | Beneficio primario | Beneficio secondario |

|---|---|---|

| Material Scrap Recycling | Reduces landfill waste | Generates revenue from scrap |

| Biodegradable Coolants | Lowers environmental toxicity | Improves workshop air quality |

| Near-Net-Shape Materials | Cuts machining time | Reduces material cost |

Sustainable CNC machining is a core part of our philosophy at PTSMAKE. It ensures we meet client needs while respecting our environmental responsibilities.

Sustainable CNC machining reduces waste and saves energy. These eco-friendly practices align with energy sector goals, offering clear environmental and economic benefits. It is a practical and necessary step for modern eco-friendly energy manufacturing.

Global Partnerships: Leveraging Expertise for Local Energy Projects

Local energy projects are complex. They require specialized components and deep expertise. This is where a global CNC partner for energy projects becomes invaluable.

International suppliers are more than just vendors. They bring a wealth of experience. This experience helps navigate challenges in design and production.

The Advantage of Global Expertise

A partner like PTSMAKE provides access to advanced manufacturing technologies. This helps local teams innovate faster. They also benefit from established logistical networks, ensuring timely delivery.

| Partnership Aspect | Local Team Focus | Global Partner Contribution |

|---|---|---|

| Competenza | Project Management & Installation | Progettazione per la producibilità (DFM) |

| Tecnologia | Integrazione del sistema | Advanced CNC Machining |

| Logistica | Site Coordination | Global Supply Chain Management |

This collaboration speeds up timelines. It also improves the final project quality.

Relying solely on local suppliers can sometimes limit access to specific technologies or materials. International energy manufacturing partners overcome these limitations. They provide a bridge to a global supply chain.

Streamlining Complex Operations

A key role for a global partner is managing production logistics. This frees up the local project team. They can focus on installation and commissioning. This division of labor is efficient.

We’ve found that this model reduces project bottlenecks significantly. For instance, when a complex component for an energy project requires specific alloys, an international partner can source them more effectively through their global network.

This approach transforms the supply chain. It becomes a strategic asset rather than a logistical hurdle. The concept of Distributed Manufacturing14 is central here. It leverages global capacities for local needs, creating a more resilient and efficient system.

Key Support Areas

- Approvvigionamento di materiali: Accessing specialized materials globally.

- Lavorazione di precisione: Providing high-tolerance energy cnc precision machining.

- Garanzia di qualità: Implementing rigorous, globally recognized quality standards.

- Global Shipping: Managing customs and international freight seamlessly.

| Responsibility | Local Project Team | International Manufacturing Partner |

|---|---|---|

| Design | Core System Design | Component-Level DFM Analysis |

| Produzione | Montaggio finale | Precision Part Manufacturing |

| Logistica | On-site Material Handling | International Shipping & Customs |

| QA | Final System Testing | Component-Level Quality Control |

This partnership structure ensures every part of the process is handled by experts.

Global partnerships provide crucial expertise and logistical support. This collaboration allows local energy initiatives to access advanced manufacturing and streamlined supply chains, which are essential for project success and innovation in the energy sector.

Take the Next Step with PTSMAKE for Your Energy CNC Needs

Ready to elevate your energy projects with unmatched CNC precision machining? Contact PTSMAKE today for a fast, personalized quote. Our expertise ensures top-notch quality, efficiency, and on-time delivery—trusted by leading innovators worldwide. Let us deliver the precision your energy components require. Send your inquiry now!

Learn how this core process differs from additive methods and why it’s crucial for high-strength parts. ↩

Click to understand how this material property impacts machining and part longevity. ↩

Understand how uniform material characteristics are crucial for parts under extreme operational stress. ↩

Explore the science of measurement and its critical role in guaranteeing manufacturing accuracy. ↩

Learn how this symbolic language improves design clarity and reduces costly errors. ↩

Learn how building a resilient supply chain can safeguard your projects against unexpected disruptions and ensure long-term stability. ↩

Learn more about how this key material characteristic affects structural integrity and manufacturing strategy. ↩

Learn how precision measurement science ensures your parts meet exact energy industry specifications. ↩

Learn how material properties influence precision machining outcomes and component reliability. ↩

Understand how radiation affects material integrity and why it is critical for nuclear component design and longevity. ↩

Learn how DFM principles can optimize your designs for cost-effective, large-scale production. ↩

Learn how this data-driven method improves manufacturing consistency and part quality. ↩

Discover how this framework evaluates a product’s total environmental impact, from creation to disposal. ↩

Discover how this manufacturing model can de-risk your supply chain and improve project efficiency. ↩