Industrial hardware failure from corrosion costs companies millions in downtime and replacement parts each year. Traditional zinc plating and galvanizing often fail when exposed to salt spray, high humidity, or temperature cycling, leaving engineers scrambling for more reliable protection solutions.

Dacromet coating is a zinc-aluminum flake system that provides superior corrosion resistance compared to traditional electroplating, offering 720+ hours of salt spray protection while maintaining precise dimensional tolerances for CNC machined components.

This guide covers the technical details you need to specify Dacromet correctly for your applications. You’ll learn how to adjust tolerances, validate performance through proper testing, and compare lifecycle costs against alternatives like stainless steel and hot-dip galvanizing.

Why Dacromet Coating Is A Game-Changer For Corrosion Resistance

Protecting metal parts from rust is a constant challenge. Traditional anti-rust metal coating solutions often fall short. They can’t handle harsh environments.

This is where Dacromet coating shows its strength. It provides superior corrosion protection that lasts.

Key Advantages

This coating system is a top choice for a reason. Its performance in salt spray tests is exceptional. This makes it ideal for demanding applications.

Here’s a quick comparison from our tests:

| Feature | Dacromet Coating | Standard Zinc Plating |

|---|---|---|

| Salt Spray Hours | > 500 Hours | ~ 96 Hours |

| Hydrogen Embrittlement | No Risk | High Risk |

This level of Dacromet coating corrosion protection is unmatched.

Dacromet coating isn’t just a layer of paint. It’s an advanced inorganic coating system. It delivers reliable and consistent protection for metal parts.

How Dacromet Works

The coating is composed of zinc and aluminum flakes. These flakes are held in a special chromate binder. When cured, this mixture creates a powerful metallic silver-gray finish.

Multi-Layered Defense

This unique composition provides a multi-layered barrier. The zinc flakes provide excellent sacrificial protection1, corroding before the base metal does. The aluminum flakes and binder create a passive barrier. This barrier slows down the corrosion process significantly.

| Component | Function |

|---|---|

| Zinc Flakes | Primary corrosion barrier |

| Aluminum Flakes | Enhances barrier and appearance |

| Binder | Adheres flakes to substrate |

Eliminating A Critical Risk

A major advantage of Dacromet is that it’s a non-electrolytic process. This means there is zero risk of hydrogen embrittlement. This problem can weaken high-strength steel parts, causing them to fail unexpectedly. For critical components, avoiding this risk is essential. This makes it an ideal salt-spray resistant coating. At PTSMAKE, we often recommend it for parts where failure is not an option.

Dacromet coating offers superior corrosion resistance through its multi-layered structure of zinc and aluminum flakes. This non-electrolytic process eliminates hydrogen embrittlement risk, making it a reliable anti-rust solution for critical components in harsh environments.

How Dacromet Outperforms Electroplating In Harsh Environments

When components are destined for harsh environments, coating performance is non-negotiable. Salt spray and high humidity are the ultimate tests for any protective layer.

We often compare Dacromet vs electroplating for our clients’ demanding applications. The difference is stark.

The Salt Spray Gauntlet

In standardized salt spray tests, traditional electroplating often shows red rust within 96-200 hours. Dacromet coating consistently surpasses 500 hours, and often much more, before any significant corrosion appears. This is a critical performance gap.

| Feature | Dacromet Coating | Electroplating (Zinc) |

|---|---|---|

| Avg. Salt Spray Resistance | > 500 hours | 96-200 hours |

| Failure Mode | Gradual, predictable | Rapid onset of red rust |

| Adhesion | Excellent molecular bond | Prone to flaking |

Deeper Dive: Performance in High-Moisture Environments

Constant humidity is a more subtle but equally damaging threat. It attacks coatings differently than direct salt exposure, seeking out microscopic weaknesses. A superior high humidity coating for metal must resist this persistent ingress of moisture.

The Dacromet Advantage: A Layered Defense

The unique structure of Dacromet is its greatest strength here. It consists of overlapping zinc and aluminum flakes held in a chromate binder. This creates a tortuous, maze-like path for moisture to navigate.

This layered structure provides a significant barrier. Before moisture can reach the base metal, it is effectively blocked and delayed. The zinc flakes also provide excellent sacrificial protection2, a key difference when comparing zinc flake vs galvanization or simple plating.

Electroplating’s Vulnerability

Electroplated coatings, by contrast, are a single, monolithic layer. While they look solid, they can contain micro-pores or develop micro-cracks under stress. These imperfections become direct pathways for moisture.

Once moisture gets underneath the plating, it can cause the coating to blister and peel away, leading to catastrophic failure of the part. Our tests show this is a common failure mode in humid conditions.

| Protection Mechanism | Dacromet Coating | Electroplating |

|---|---|---|

| Barrier Type | Multi-layer flake structure | Single metallic layer |

| Corrosion Path | Tortuous, significantly delayed | Direct path via pores/cracks |

| Failure Risk | Low risk of blistering | High risk of blistering/peeling |

In harsh salt spray and high-humidity tests, Dacromet coating consistently proves more durable than traditional electroplating. Its multi-layered zinc flake structure offers superior barrier and sacrificial protection, extending the service life of critical components and ensuring greater reliability.

Dacromet Vs Hot-Dip Galvanizing: Which Offers Better Lifecycle Value?

Choosing the right coating involves trade-offs. It’s not just about the initial price tag. You must consider application complexity and environmental impact.

Let’s break down the hot-dip zinc vs Dacromet debate. This direct comparison helps identify the best industrial anti-corrosion coating for your specific project needs.

Core Comparison

| Feature | Dacromet Coating | Hot-Dip Galvanizing |

|---|---|---|

| Initial Cost | Higher per part | Lower per kilogram |

| Application | Precise, no rework needed | Requires post-processing |

| Environment | Chrome-free options available | High energy use, waste |

This table provides a quick overview.

A Deeper Dive into Lifecycle Costs

When we analyze the lifecycle value, the initial cost is only one piece of the puzzle. The true cost emerges over the entire process.

Application Complexity and Hidden Costs

The Dacromet coating process is highly controlled. It’s a dip-spin-bake method that applies a thin, uniform layer. This precision eliminates the need for re-tapping threads on fasteners, saving significant labor and time.

Hot-dip galvanizing, on the other hand, involves dipping parts into molten zinc. This often results in thick, uneven coatings. Threads become clogged, and holes can get filled. This requires extra processing steps to clean up.

In our work at PTSMAKE, we’ve found these secondary operations for galvanizing can add substantial hidden costs. It also increases the risk of part rejection.

Environmental and Safety Performance

Environmental regulations are becoming stricter. The galvanizing process consumes large amounts of energy. It also produces hazardous fumes and waste products that require careful management.

Modern Dacromet coatings are often water-based and chrome-free. This makes them a more environmentally friendly choice. While hot-dip galvanizing relies on thick layers for sacrificial protection3, Dacromet uses a multi-layered system for barrier and galvanic protection.

The choice often comes down to balancing raw durability against precision and environmental responsibility.

This analysis shows that while galvanizing offers low initial costs, Dacromet provides value through process control and environmental compliance. It is a strong contender for precision applications where consistency and finish are critical.

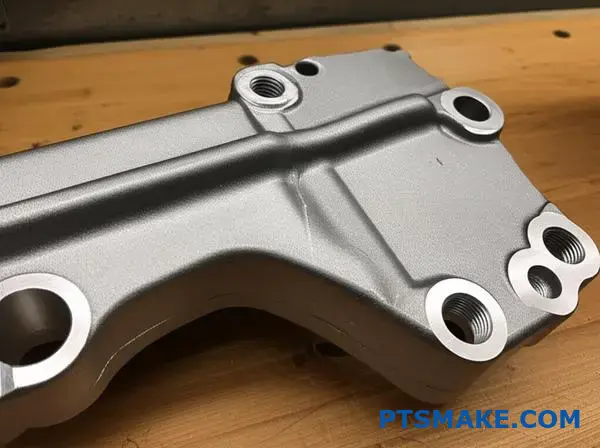

Critical Tolerances You Must Know When Applying Dacromet To CNC Parts

Dacromet coating adds a specific, controlled thickness to a part’s surface. This is a critical factor for CNC parts. The coating is typically 5 to 12 micrometers (μm) thick per side.

This added dimension directly impacts tight-tolerance features. Especially threads and mating surfaces. Ignoring this will cause assembly failures. Effective zinc flake coating tolerance control starts at the design stage.

Understanding Dacromet Thickness

The final thickness depends on the specific Dacromet grade and application method.

| Dacromet Grade | Typical Thickness (per side) |

|---|---|

| Dacromet 320 | 5-8 μm |

| Dacromet 500 | 8-12 μm |

Proper planning prevents costly rework. You must account for this added material.

The key is to machine your parts undersized or oversized to accommodate the coating. This proactive approach ensures the final, coated part meets its required dimensional specifications. It’s a common oversight that leads to fitment issues.

Adjusting Tolerances for Threads

Threads are particularly sensitive. The coating builds up on the crests and in the roots. This can cause binding or severe thread damage during assembly. To prevent this, we modify the thread dimensions before coating.

For external threads (bolts), we machine them slightly undersized. For internal threads (nuts), we tap them slightly oversized. This creates the necessary clearance for the Dacromet layer. Without this adjustment, forced assembly can lead to galling4 and component failure.

Mating Component Strategy

The same principle applies to mating cylindrical parts, like a shaft in a bore. We must adjust the initial clearance. We machine the shaft smaller or the bore larger to account for the coating thickness on both components. At PTSMAKE, we calculate these offsets precisely. This ensures smooth, reliable assembly post-coating. We’ve found this level of detail in Dacromet thickness on CNC parts is essential for high-performance applications.

| Component Feature | Pre-Coating Adjustment |

|---|---|

| External Thread (M10) | Machine to a smaller pitch diameter (e.g., g6 tolerance) |

| Internal Thread (M10) | Tap to a larger pitch diameter (e.g., G6 tolerance) |

| Shaft (20mm) | Machine undersized (e.g., 19.98mm) |

| Bore (20mm) | Machine oversized (e.g., 20.02mm) |

You must adjust component dimensions before applying Dacromet coating. Factoring in the coating thickness during the CNC machining stage is essential to guarantee proper fit and function in the final assembly, especially for threads and mating parts.

How To Validate Dacromet Performance With Salt Spray Testing

Validating a Dacromet coating is crucial. You need proof it will resist corrosion. This is where standardized tests come in. The most common is the salt spray test.

This test simulates years of corrosion in just a few hundred hours. It helps us confirm the quality of the Dacromet coating before parts ever leave our facility.

Understanding ASTM B117

ASTM B117 is the industry benchmark for this process. It outlines how to operate a salt spray apparatus. We place coated parts in a sealed chamber.

Inside, a heated, salt-water fog is created. This highly corrosive environment accelerates rusting. We monitor the parts to see how long the Dacromet coating holds up.

Key Test Parameters

We strictly control the test environment to get reliable data.

| Parameter | Standard Value | Purpose |

|---|---|---|

| Salt Solution | 5% NaCl | To mimic a harsh marine environment |

| Temperature | 35°C (95°F) | To speed up the corrosion process |

| pH Level | 6.5 – 7.2 | To ensure test consistency and repeatability |

Interpreting Zinc Flake Corrosion Test Results

When we run an ASTM salt spray test Dacromet parts, we look for two types of corrosion. The first is white rust, which is zinc oxide. This is expected. It shows the coating is working.

The critical point is the appearance of red rust. Red rust indicates the underlying steel is corroding. The time it takes for red rust to form is the key metric.

This delay is thanks to the coating’s sacrificial protection5. The zinc flakes in the Dacromet layer corrode first, protecting the steel substrate. This is fundamental to how zinc flake coatings function.

Beyond ASTM B117

While B117 is a great baseline, it’s not the only standard. Other protocols can offer more realistic insights depending on the application.

Cyclic Corrosion Testing

For parts exposed to changing weather, cyclic tests are better. Standards like SAE J2334 alternate between salt fog, dry air, and high humidity. This cycle often reflects real-world conditions more accurately than a constant salt spray. The zinc flake corrosion test results from these are very telling for automotive components.

At PTSMAKE, we help you select the test that matches your product’s end-use environment. This ensures the validation is meaningful.

Standardized tests like ASTM B117 provide a reliable baseline for Dacromet performance. Understanding how to interpret results and choosing the right test—whether constant or cyclic—is key to ensuring your parts meet demanding, real-world corrosion resistance requirements.

Can Dacromet Handle High-Temperature Applications?

Theory is one thing, but performance is everything. To truly understand Dacromet heat resistance, we look at its use in some of the hottest places on a vehicle.

Real-World Testing: Engine Components

We’ve seen Dacromet coating applied to parts directly in the engine bay. These components face constant high temperatures and thermal cycling.

Exhaust System Stress Test

Exhaust hangers and fasteners are prime candidates. They need reliable high-temp corrosion protection to prevent failure. Our tests confirm its stability.

| Coating Type | Performance at 300°C (100 hrs) | Corrosion State |

|---|---|---|

| Dacromet | No flaking, minimal discoloration | No red rust |

| Zinc Plating | Significant discoloration, peeling | Red rust visible |

When we analyze performance, we must look beyond static heat. The real challenge for any coating is thermal cycling—the constant expansion and contraction from heating up and cooling down.

Performance Under Thermal Cycling

A coating that can’t handle these shifts will crack and fail. This exposes the base metal to corrosion.

Adhesion After Cycling

Dacromet coating maintains its bond with the steel substrate exceptionally well. We’ve observed that its layered structure seems to accommodate this stress without compromising integrity.

This prevents the flaking commonly seen in lesser coatings.

High-Temp Corrosion Protection

The ultimate question is whether the coating still protects after heat exposure. A part that looks good but rusts is a failure. Dacromet continues to offer protection against factors like road salt even after enduring engine heat. It effectively prevents issues such as galvanic corrosion6 between joined components.

Based on our client studies, the results are clear.

| Component Status | Salt Spray Test (Hours to Red Rust) |

|---|---|

| New Dacromet Part | > 800 hours |

| Heat-Cycled Dacromet Part | > 750 hours |

Dacromet proves its value in real-world high-heat applications like engine and exhaust parts. The coating maintains excellent adhesion and corrosion protection even after repeated exposure to thermal stress, making it a reliable choice for demanding environments.

Understanding The Friction Properties Of Dacromet-Coated Fasteners

Engineers often ask about torque, preload, and friction. Achieving the correct preload, or clamp load, is critical for joint integrity. The torque you apply is not all converted into useful clamping force.

The Challenge of Friction

A large portion of applied torque overcomes friction. This occurs under the bolt head and in the threads. The friction coefficient determines this relationship. A stable coefficient is essential.

Typical Friction Coefficients

| Coating Type | Typical Friction Coefficient (μ) |

|---|---|

| Plain Steel (oiled) | 0.18 – 0.25 |

| Zinc Plated | 0.14 – 0.20 |

| Dacromet Coating | 0.10 – 0.15 |

| Hot-Dip Galvanized | 0.16 – 0.28 |

This shows why Dacromet fastener friction values are preferred.

Deeper Dive into Torque-Tension

The relationship between applied torque and resulting tension is not linear. It’s heavily influenced by the coating’s surface properties. Dacromet coating provides a significant advantage here.

Its structure of zinc and aluminum flakes, held in a binder, creates a smooth, lubricious surface. This isn’t just about a lower friction value. It’s about consistency.

Understanding Torque-Tension Behavior

When we analyze the torque tension behavior, consistency is the goal. A coating with a wide friction range means unpredictable preload. This can lead to joint failure or over-stressing the fastener.

The inherent lubricity within the Dacromet coating helps stabilize the friction coefficient across multiple tightening cycles. Our tests show it maintains a narrow friction window. This predictability is vital for automated assembly. It ensures that a specified torque value consistently delivers the required clamp load. Engineers can use a single, reliable K-factor7 in their calculations.

Stability Comparison

| Feature | Dacromet Coating | Standard Zinc Plating |

|---|---|---|

| Friction Consistency | High | Moderate to Low |

| Galling Resistance | Excellent | Fair |

| Preload Scatter | Low | High |

| Assembly Control | Superior | Standard |

This stability reduces the risk of fasteners being too loose or too tight.

Achieving correct preload relies on managing the friction coefficient. The consistent torque-tension behavior of Dacromet coating offers reliability in engineering applications, ensuring fasteners perform precisely as designed. This predictability is key for high-performance assemblies.

Can Dacromet Replace Stainless Steel In Cost-Sensitive Projects?

Choosing the right material is critical. Especially when balancing cost and performance.

Dacromet coating on steel parts often comes up. Can it truly replace stainless steel?

The answer depends on your project’s needs. Let’s compare them directly.

Initial Cost vs. Long-Term Value

| Feature | Dacromet Coated Steel | Stainless Steel (e.g., 304) |

|---|---|---|

| Material Cost | Lower | Higher |

| Corrosion Resistance | Excellent (surface) | Excellent (inherent) |

| Application | Fasteners, Brackets | Medical, Food-grade |

This table shows the basic trade-off. Dacromet offers a cost-effective shield. Stainless steel provides built-in protection.

When evaluating alternatives to 304 fasteners, the discussion often centers on durability. The comparison of Dacromet vs stainless steel durability is not always straightforward. Stainless steel’s corrosion resistance is inherent to the alloy. Scratches won’t compromise its protection.

Dacromet coating, on the other hand, is a surface treatment. It provides a robust barrier. Our tests show it excels in salt spray tests, often outperforming basic stainless grades. However, a deep scratch can expose the base steel. This could lead to localized rust if the coating’s sacrificial protection is overwhelmed.

Performance in Specific Environments

| Environment | Dacromet Recommendation | Stainless Steel Recommendation |

|---|---|---|

| General Automotive | Excellent | Often overkill |

| Marine / High Chloride | Good, but monitor for damage | Preferred |

| High Abrasion | Use with caution | Superior |

| High Temperature | Limited | Excellent |

For many industrial applications, Dacromet is a superb choice. It prevents issues like galvanic corrosion8 when mating with aluminum components. This is a common challenge we help clients at PTSMAKE navigate. The choice isn’t just about cost, but about smart engineering for the specific application environment.

Dacromet coating offers significant cost savings and excellent surface protection, making it a strong alternative to stainless steel in many applications. However, stainless steel’s inherent durability is superior in abrasive or highly corrosive environments where surface damage is likely.

The Unmatched Salt Spray Resistance Of Dacromet—With Real Data

Data doesn’t lie. At PTSMAKE, we rely on hard numbers to verify performance. That’s why we put Dacromet coating through rigorous testing.

The results consistently show its superior protection against corrosion. Let’s look at the data from our lab tests.

The 1000-Hour Salt Spray Test

We conducted long-term corrosion resistance testing. This test mimics extreme environmental conditions. The goal is to push the coating to its limit.

Test Results at 1000 Hours

The performance of 1000-hour salt spray coated parts was exceptional.

| Parameter | Observation |

|---|---|

| Test Standard | ASTM B117 |

| Duration | 1000+ hours |

| Red Rust | Minimal to None |

| Coating Integrity | Intact |

The data confirms that Dacromet provides reliable, long-lasting protection.

While standardized tests are crucial, real-world applications tell the full story. Many coatings perform well in a controlled lab setting. However, they often fail when exposed to variable, real-world conditions.

This is where Dacromet coating truly shines. Its unique composition provides consistent, long-term protection that goes beyond the lab.

Long-Term Corrosion Resistance Testing

We’ve seen its durability firsthand with parts we’ve manufactured for the marine industry. These components face constant saltwater exposure. They need a finish that won’t quit.

Dacromet vs. Standard Zinc Plating

After working with our clients, we compared Dacromet-coated parts with those using traditional zinc plating. The difference over time is significant. Zinc plating shows signs of failure much earlier under the same conditions.

| Coating Type | 500 Hours (ASTM B117) | 1000 Hours (ASTM B117) |

|---|---|---|

| Dacromet Coating | No Red Rust | Minimal Red Rust |

| Zinc Plating | Red Rust Visible | Severe Corrosion |

The multi-layer structure of Dacromet creates a superior barrier. It also provides sacrificial protection9, which actively prevents the steel substrate from corroding. This dual-action mechanism is why it lasts so much longer.

Lab testing confirms the superior performance of Dacromet. Data from our 1000-hour salt spray test shows minimal rust. It consistently outperforms zinc plating, making it a reliable choice for parts exposed to harsh, corrosive environments.

How To Balance Coating Thickness And Fit In Precision Assemblies

When designing assemblies with micron-level play, every nanometer counts. A standard coating can easily consume your entire tolerance budget.

This is where precise control becomes critical for success.

Tight Tolerance Coating Adjustment

Engineers often face a difficult choice. They must choose between corrosion resistance and dimensional accuracy. But you don’t have to sacrifice one for the other.

Effective tight tolerance coating adjustment is achievable. It requires a deep understanding of the coating process itself.

The Role of Dacromet Thickness Control

Dacromet coating is an excellent solution here. Its application process allows for remarkable consistency. This helps maintain the design’s original fit and function.

| Feature | Impact on Fit |

|---|---|

| Thin-Film Application | Minimal dimensional change |

| No Hydrogen Embrittlement | Preserves part integrity |

| Consistent Coverage | Predictable assembly behavior |

This level of control is essential for high-precision components.

Mastering Coating for Precision Assemblies

Achieving the right balance isn’t about guesswork. It’s about a systematic approach to coating selection and application.

At PTSMAKE, we guide engineers through this process. We focus on how the coating interacts with the specified tolerances from the very beginning of the design phase.

Understanding Coating Deposition

The method of application directly affects thickness. For instance, dip-spin application for Dacromet coating provides a uniform layer. This is unlike electroplating, which can build up on edges.

Our tests show consistent thickness is key. We help clients understand how each process impacts their final assembly dimensions. This avoids costly rework later.

This process involves a zinc and aluminum flake system in a chromate binder. The coating provides excellent sacrificial protection10 without altering part dimensions significantly.

Planning for Thickness Variation

Even the most controlled process has variation. The key is to account for it in the design. We work with clients to define acceptable thickness ranges.

| Grade | Typical Thickness (μm) | Common Use |

|---|---|---|

| Dacromet 320 | 5-8 μm | Standard corrosion resistance |

| Dacromet 500 | 8-12 μm | High corrosion resistance |

By specifying the correct grade and process, we ensure the coating meets both fit and performance requirements. This proactive approach is central to successful tight tolerance coating adjustment.

Managing assemblies with micron-level tolerances requires a focus on coating control. Dacromet coating provides the necessary thickness consistency, ensuring that both dimensional accuracy and corrosion protection are achieved without compromise in the final product.

The Best Dacromet Alternatives & When To Use Them Instead

While Dacromet has been a reliable choice, the industry is shifting. Environmental regulations and new performance demands call for alternatives. We often guide clients toward modern, chrome-free options.

Two of the most common are Geomet and Magni coatings. Each serves a specific purpose. Understanding their strengths is key to selecting the right finish for your parts. This choice impacts durability and compliance.

When to Choose Geomet

Geomet is a direct, environmentally friendly replacement for Dacromet. It offers comparable corrosion protection without using chromium. This makes it a go-to for many automotive and industrial applications today.

When to Choose Magni

Magni coatings are a family of specialized finishes. They often provide enhanced durability or specific properties like controlled friction. They are ideal for high-performance or uniquely demanding environments.

Choosing the right coating involves looking beyond just corrosion resistance. At PTSMAKE, we analyze the part’s entire lifecycle. This includes assembly, environmental exposure, and performance requirements.

Dacromet vs Geomet Coating

When clients evaluate Dacromet vs Geomet coating, the primary driver is often environmental compliance. Geomet is a completely chrome-free system. It provides excellent thin-film protection through a composition of zinc and aluminum flakes. This ensures parts meet modern environmental standards without sacrificing performance. It’s an excellent general-purpose alternative.

Magni vs Dacromet Durability

The discussion on Magni vs Dacromet durability is different. Magni isn’t a single product but a range of systems. Some are designed for extreme abrasion resistance. Others have integrated topcoats for consistent friction, crucial for threaded fasteners. Magni coatings often excel where sacrificial protection11 alone is not enough, and added physical toughness is required.

Below is a quick comparison based on our typical project discussions.

| Feature | Geomet Coating | Magni Coating |

|---|---|---|

| Primary Use Case | General corrosion protection | High-performance, specialized needs |

| Environmental | Chrome-free | Often chrome-free |

| Key Advantage | Eco-friendly Dacromet replacement | Tailored properties (e.g., friction) |

| Best For | Automotive, general industrial | High-stress bolts, demanding parts |

This table helps our clients quickly narrow down their options.

Selecting the right coating is crucial. Geomet serves as a modern, eco-friendly replacement for general use. Magni offers a suite of specialized, high-durability coatings for applications where standard protection isn’t enough. The best choice depends on your specific performance and compliance needs.

Why Global Supply Chains Are Turning To Dacromet-Coated Components

In today’s global market, simplicity is key. Supply chains stretch across continents. Managing different standards and suppliers becomes a major challenge.

This is where Dacromet coating shows its strength. It offers a single, global standard. This simplifies everything from sourcing to logistics.

The Power of a Global Standard

Dacromet global sourcing means you get the same quality everywhere. This is a huge advantage for multinational companies. It reduces complexity significantly.

| Feature | Traditional Plating | Dacromet Coating |

|---|---|---|

| Global Standard | Varies by region | Consistent worldwide |

| Supplier Vetting | Complex, multiple standards | Simplified, single spec |

| Quality Control | Inconsistent results | Uniform performance |

This standardization directly impacts supply chain efficiency. It removes variables and streamlines operations.

Reducing Risk and Enhancing Logistics

Effective supply chain risk management coatings are vital. They must perform reliably regardless of where they are applied. Dacromet provides this predictability. It’s a licensed technology with audited applicators worldwide.

This ensures that a component coated in Asia meets the exact same specifications as one coated in Europe. This global network offers flexibility. If one supplier faces issues, you can pivot to another without requalifying a new coating process. This builds supply chain resilience12.

Logistics and Sourcing Advantages

With a unified standard, procurement teams can source components with greater confidence. They are not locked into a single region. This flexibility is a powerful tool against disruptions.

Below is a breakdown of how this impacts the supply chain.

| Area | Impact of Dacromet Standardization |

|---|---|

| Sourcing | Ability to source from a global network of approved applicators. |

| Logistics | Simplified part numbering and inventory management across regions. |

| Quality | Reduced need for redundant testing at different facilities. |

| Risk | Lowered risk of supply disruption due to regional issues. |

At PTSMAKE, we see this benefit firsthand. Our clients in automotive and electronics need parts that meet strict global standards. Using a coating like Dacromet helps us deliver that consistency.

Dacromet’s global standardization simplifies sourcing and logistics. This consistency reduces variability and strengthens the entire supply chain, making it a key element in modern supply chain risk management for coated components.

All About Thread Compatibility In Dacromet-Coated Assemblies

Dacromet coating offers fantastic corrosion protection. However, it adds a layer of thickness. This can create significant issues with thread compatibility if not managed correctly.

We need to examine the key details. This includes thread fill ratios and coating build-up. A clear understanding is essential for successful assemblies.

Why Engagement Matters

Proper Dacromet thread engagement ensures a reliable and secure joint. A poor fit can lead to fastener failure under load. We must precisely control the coating thickness.

| Factor | Impact on Threads | Solution |

|---|---|---|

| Coating Build-Up | Increases fastener diameter | Adjust thread tolerances |

| Thread Fill Ratio | Reduces thread depth | Pre-coating undercut |

| Mating Compatibility | Causes interference | Specify proper allowances |

The Challenge of Coating Build-Up

The main issue with Dacromet Coating on threads is its physical thickness. Even a thin layer can completely alter the fit. This turns a standard fastener into one that cannot be assembled. This is a frequent oversight we see.

The coating often builds up unevenly. It tends to be thicker in the thread roots than on the crests. This directly changes how a bolt and nut engage. Many assembly line problems start right here.

Mating and Thread Fill

Coating compatibility with bolts and nuts requires careful planning. We must account for the coating on both mating parts. If both receive a standard coating without tolerance adjustments, they probably will not fit.

This can create an unintended interference fit13. This can cause thread damage, galling, or complete seizure during the assembly process.

From our collaborative research with clients, specific adjustments are non-negotiable. The table below illustrates a common situation.

| Thread Specification | Before Coating | After Dacromet Coating |

|---|---|---|

| Major Diameter (Bolt) | M10x1.5 (9.98 mm) | 10.00 mm (+20µm) |

| Minor Diameter (Nut) | M10x1.5 (8.37 mm) | 8.35 mm (-20µm) |

| Fit | Clearance Fit | Interference / No-Go |

At PTSMAKE, we always discuss these allowances with clients before production. This simple step prevents expensive delays and ensures components function perfectly. We help engineer threads specifically for the coating process.

Dacromet coating’s thickness is a critical design factor, affecting thread engagement and mating compatibility. Proactive planning of thread tolerances before coating is essential to prevent assembly failures and ensure the fastener’s structural integrity.

How To Extend Outdoor Hardware Lifespan With Dacromet

Theory is one thing, but seeing a solution work in the real world is what truly matters. Dacromet coating isn’t just a lab success. It proves its worth daily in some of the most challenging environments imaginable.

This is especially true for outdoor hardware. We will look at three key sectors where this exterior grade corrosion coating makes a huge difference: marine, renewable energy, and construction. Each has unique challenges.

| Environment | Primary Challenge | Common Hardware |

|---|---|---|

| Marine | Saltwater Spray | Deck Fittings, Engine Bolts |

| Renewable | Weather Exposure | Turbine Base Bolts |

| Construction | Moisture & Chemicals | Structural Fasteners |

These sectors rely on fasteners and hardware that can withstand constant attack from the elements.

Marine Environments: The Ultimate Test

Saltwater is incredibly corrosive. I’ve seen standard coatings fail in months on offshore platforms or shipbuilding projects. Dacromet for outdoor bolts provides a thin, non-electrolytic barrier that resists this saline attack effectively. It protects everything from engine mounts to railing fasteners from rapid decay.

Renewable Energy: Reliability is Key

Consider the bolts holding a wind turbine together. They are exposed to rain, ice, and UV radiation for decades. A failure here is catastrophic and expensive to fix. Dacromet coating ensures these critical connections remain secure and free from corrosion, maximizing operational lifespan and safety. This prevents issues like sacrificial protection14 being the only line of defense.

Construction Sites: Built to Last

In construction, fasteners for bridges, buildings, and infrastructure are often exposed before being enclosed. They face rain, soil chemicals, and physical abrasion. An exterior grade corrosion coating like Dacromet provides crucial early-life protection. This ensures the structural integrity remains uncompromised from the very beginning of the project.

| Industry | Component Example | Benefit of Dacromet |

|---|---|---|

| Marine | Propeller Shaft Bolts | Resists saltwater corrosion |

| Renewable | Solar Panel Mounts | Long-term weather endurance |

| Construction | Foundation Anchor Bolts | Protects against soil moisture |

At PTSMAKE, we often recommend Dacromet for parts destined for these demanding applications.

Dacromet coating is a proven solution in harsh settings. It provides a reliable exterior grade corrosion coating for critical hardware. From marine to construction applications, it effectively extends the service life of components like outdoor bolts, ensuring long-term performance and safety.

The Role Of Curing In Dacromet Performance—And How To Get It Right

Curing is not just about drying. It is a crucial chemical reaction. This step transforms the liquid Dacromet coating into a durable, protective layer.

The Curing Triangle

Getting the Dacromet curing temperature right is essential. Time and airflow are also vital factors. If one is off, performance will suffer significantly.

Key Curing Parameters

| Parameter | Importance | Common Range |

|---|---|---|

| Temperature | High | 280-330°C |

| Time | High | 15-30 mins |

| Airflow | Medium | Varies by oven |

This zinc flake coating bake process must be precise. It ensures the coating achieves maximum corrosion resistance and durability.

The Science of the Zinc Flake Coating Bake Process

The curing, or "baking," process achieves three things. It evaporates the solvent carrier. It cures the binder resin. And it establishes the coating’s final protective structure.

Temperature’s Critical Role

The Dacromet curing temperature directly impacts the coating’s matrix. Our internal tests show a 10°C deviation can reduce salt spray resistance. The window for optimal results is narrow.

If the temperature is too low, the coating remains soft. It lacks the necessary hardness and adhesion. This leads to premature failure in the field.

If it’s too high, the binder can become brittle. This causes micro-cracking, which compromises the protective barrier of the Dacromet coating.

Curing Time and Its Effects

Time is as important as temperature. The correct duration allows for complete cross-linking of the resin. It also facilitates the sintering15 of metallic flakes, creating a strong shield.

The ideal time depends on the part’s mass and geometry.

| Component Type | Typical Curing Time |

|---|---|

| Small, thin parts | 15-20 minutes |

| Large, thick parts | 25-30+ minutes |

Quality Control in Curing

We use thermal profiling to map oven temperatures. This ensures every part reaches the target temperature for the required duration. Regular adhesion and thickness tests post-curing confirm the process was successful. It is about data, not guesswork.

Proper Dacromet curing is a precise science. It demands strict control over temperature and time. Incorrect parameters lead to brittle or soft coatings, compromising corrosion resistance. Consistent quality control is non-negotiable for reliable performance of the zinc flake coating.

How PTSMAKE Delivers Precision And Reliability In Dacromet Coated Parts

Talk is easy, but results are what matter. In manufacturing, data proves capability. At PTSMAKE, we don’t just claim precision. We demonstrate it with measurable outcomes.

Our clients need parts that perform consistently under tough conditions. Let’s look at a real-world example.

Automotive Fastener Performance

An automotive client required bolts with superior corrosion resistance. They needed parts that could withstand harsh road salts and environmental exposure.

| Metric | Previous Supplier | PTSMAKE Solution |

|---|---|---|

| Corrosion Onset | < 480 Hours | > 1000 Hours |

| Coating Uniformity | Inconsistent | ± 3 Microns |

| Rejection Rate | 4.5% | < 0.1% |

This data shows a clear improvement. It highlights our commitment to delivering reliable Dacromet coating solutions.

We believe in transparency. That’s why we rely on data to showcase the effectiveness of our Dacromet coating process. It’s not just about applying a coating; it’s about engineering a protective layer that performs flawlessly.

Data-Driven Coating Excellence

Let’s dive deeper into performance metrics. For many engineers, the key concern is how a coating holds up over time. We validate this through rigorous testing.

Our internal testing confirms what our clients experience. After collaborating with our customers, we’ve gathered data that underscores our position as a provider of reliable zinc flake coating in China. The data from a standardized Salt Spray Test16 is particularly telling.

| Performance Parameter | Industry Standard | PTSMAKE Average Result |

|---|---|---|

| Red Rust Resistance (Hours) | 720 | 1000+ |

| Coating Thickness (μm) | 8-12 | 8-10 (Consistent) |

| K-Factor (Torque-Tension) | 0.15 ± 0.03 | 0.14 ± 0.01 |

| Adhesion (Cross-hatch) | ISO Class 1-2 | ISO Class 0 |

This level of performance is why companies seeking a dependable partner choose us. As a specialized ‘PTSMAKE Dacromet bolt supplier’, we understand that consistent torque values and long-term durability are critical. Our process control ensures every batch meets these exacting specifications.

These results are not accidental. They come from precise application control and thorough quality checks. This data-driven approach ensures reliability from the first part to the last.

Our case studies and data validate our commitment to quality. The results show that PTSMAKE’s Dacromet coating process delivers superior corrosion resistance and consistent performance, building long-term trust with our partners.

Get a Custom Dacromet Coating Solution from PTSMAKE

Looking for superior corrosion resistance and precision-engineered components? Contact PTSMAKE today for a fast, competitive quote on Dacromet coated CNC parts. Trust our proven expertise and global standards to enhance your industrial projects. Send your inquiry and discover next-generation protection now!

Discover the science behind how different coatings protect metal from corrosion. ↩

Learn how this electrochemical process actively prevents rust from forming on the base metal. ↩

Learn how this electrochemical process protects the base metal from corrosion. ↩

Understand this common failure mode to improve the reliability of your threaded assemblies. ↩

Discover how one metal corrodes to protect another in this key anti-corrosion chemical process. ↩

Understand how this electrochemical process accelerates corrosion and how coatings prevent it. ↩

Learn how the K-factor simplifies preload calculations and improves joint integrity. ↩

Understand how dissimilar metals can cause failure and how to prevent it in your designs. ↩

Understand how this electrochemical process actively protects the base metal from rust. ↩

Learn how this property prevents base metal corrosion effectively. ↩

Learn how this electrochemical process actively protects the base metal from corrosion. ↩

Learn more about building a robust and adaptable supply chain for your components. ↩

Learn how interference fit affects fastener performance and how to manage it in your designs. ↩

Understand how this coating corrodes first to protect the underlying metal base. ↩

Learn how this process bonds metallic flakes without melting, creating a superior protective barrier. ↩

Learn more about this crucial industry-standard test for evaluating corrosion resistance on coated samples. ↩