Finding a powder coating service that delivers consistent quality and meets tight engineering specifications can be challenging. Many suppliers promise perfect finishes but deliver parts with defects, poor adhesion, or color inconsistencies that force costly rework and project delays.

Powder coating provides superior durability, environmental compliance, and cost-effectiveness compared to traditional wet paint systems, making it the preferred finishing method for precision-engineered parts across aerospace, medical, automotive, and consumer electronics industries.

Working with different coating suppliers over the years has taught me that success depends on understanding the technical details. This guide covers everything from defect prevention and tolerance control to material-specific pretreatments and industry standards that ensure your parts meet specifications every time.

Why Smart Engineers Prefer Powder Coating Over Wet Paint

Engineers prioritize performance and reliability. Choosing a finish is not just about aesthetics. It is a critical engineering decision.

The debate of powder coating vs wet paint is common. But for demanding applications, the choice becomes clear.

The Durability Advantage

Powder coating provides a thicker, more uniform layer. This creates a hard finish that is tougher than conventional paint. It resists chipping, scratching, and fading far better.

Efficiency in Application

The application process is also faster. It often requires only a single coat. This speeds up production lines and reduces labor costs. Many engineering parts benefit from this efficiency.

| Feature | Powder Coating | Wet Paint |

|---|---|---|

| Typical Thickness | 1-6 mils (25-150 μm) | 0.5-1 mil (12-25 μm) |

| Hardness (ASTM D3363) | H to 2H | HB to F |

| Application Method | Electrostatic Spray | Spray, Brush, Dip |

For robust and long-lasting components, the benefits of powder coating are undeniable.

When evaluating a finishing process, I look beyond the surface. The entire lifecycle matters, from application to long-term performance and environmental impact. The choice directly affects the quality of the engineering parts we produce.

Superior Finish Quality and Consistency

Powder coating is applied as a dry powder electrostatically. It is then cured under heat. This process allows it to flow and form a skin. The result is a smooth, even surface without drips or runs. This is unlike liquid paint, which can be inconsistent. The material used is a thermosetting polymer1 that cross-links during curing, creating a strong molecular bond. At PTSMAKE, our powder coating services ensure this consistent quality for every part.

Environmental and Safety Benefits

A significant benefit of powder coating is its minimal environmental impact. It contains no solvents and releases negligible volatile organic compounds (VOCs). This makes it safer for operators and the environment.

| Aspect | Powder Coating | Wet Paint |

|---|---|---|

| VOC Emissions | Near zero | High |

| Waste Material | Overspray is recyclable | Overspray is hazardous waste |

| Fire Hazard | Low | High (due to solvents) |

Long-Term Cost-Effectiveness

While initial equipment costs can be higher, powder coating often proves more economical over time. Higher material utilization, lower energy consumption for curing, and reduced disposal costs contribute to significant long-term savings. The durability also reduces warranty claims and rework.

Powder coating offers a durable, efficient, and eco-friendly finish. For engineering applications requiring high performance, its superior consistency and long-term cost savings make it the smarter choice over traditional wet paint.

Top 10 Powder Coating Defects And How To Prevent Them

Understanding common powder coating problems is essential for any engineer or buyer. A flawless finish isn’t just about aesthetics; it’s about performance and durability. Defects often signal deeper issues in the process.

Let’s dive into some frequent powder coating surface defects. These can compromise the integrity and protection of your parts. Knowing their causes helps you have more effective discussions with your manufacturing partners.

Common Visual Flaws

| Defect | Appearance |

|---|---|

| Orange Peel | A bumpy texture resembling an orange’s skin. |

| Pinholes | Tiny, deep holes piercing the coating surface. |

| Bubbles | Small blisters or raised bubbles on the finish. |

Identifying these early can prevent costly rework.

Beyond visual flaws, some defects undermine the coating’s fundamental purpose. Chipping and poor adhesion are two of the most serious powder coating problems. They typically point to failures in the critical preparation stage, long before any powder is sprayed.

The single most important factor for a lasting finish is surface preparation. If the substrate isn’t perfectly clean and treated, the powder simply won’t bond properly. This is the root cause I see most often for coating failure.

Adhesion and Durability Failures

Poor adhesion means the coating can peel away in sheets. Chipping is when the finish breaks off upon impact. Both issues dramatically shorten a part’s service life. The problem often starts with invisible substrate contamination2 or an incorrect curing profile.

These failures may not appear right away. They can surface during assembly or, worse, once the product is in the field. This is why a meticulous process is non-negotiable.

| Defect | Primary Root Cause | Prevention Method |

|---|---|---|

| Chipping | Poor pre-treatment or under-curing. | Verify cleaning process; follow cure schedule. |

| Poor Adhesion | Surface contaminants (oils, grease). | Implement a robust multi-stage cleaning. |

At PTSMAKE, our powder coating services include a rigorous multi-stage pre-treatment process. This ensures the surface is pristine for maximum adhesion and long-term durability.

Recognizing powder coating surface defects like orange peel and poor adhesion is vital. These issues often trace back to application errors or inadequate surface preparation. Understanding this helps you vet and select a high-quality powder coating services provider for your projects.

Aerospace-Grade Requirements For Powder Coated Parts

Meeting aerospace standards isn’t optional. It’s a strict requirement. Every coated part must adhere to precise specifications for safety and performance. This is where professional ‘aerospace powder coating’ truly stands out.

Conformance to Military Specifications

Standards like MIL-PRF-24712 dictate everything. They cover material composition, application, and final performance. Conformance ensures parts can withstand extreme operational conditions. It’s a guarantee of reliability.

Critical Pretreatment Steps

Proper surface preparation is fundamental. Without it, even the best coating will fail. A clean, correctly prepared surface ensures maximum adhesion and corrosion resistance.

| Stage | Purpose |

|---|---|

| Degreasing | Removes oils and contaminants. |

| Rinsing | Cleans away chemical residues. |

| Conversion Coating | Enhances adhesion and corrosion protection. |

| Final Rinse | Ensures a pure surface for coating. |

This detailed process is a hallmark of high-quality ‘powder coating services’.

Beyond initial application, parts must undergo rigorous validation. This process proves the coating can handle the harsh realities of flight. These ‘flight-rated powder coating standards’ separate standard work from aerospace-grade quality.

Environmental and Performance Testing

We subject coated parts to a battery of tests. These simulate real-world environmental stresses. The goal is to verify durability long before the part is ever installed. These tests are essential for any ‘mil spec coating services’.

Here are some of the key validation tests we perform.

| Test Type | Objective |

|---|---|

| Salt Spray (ASTM B117) | Measures corrosion resistance over time. |

| Adhesion (ASTM D3359) | Verifies the bond between the coating and the Substrate. |

| Impact Resistance | Assesses durability against physical strikes. |

| Thickness Measurement | Ensures coating is within specified tolerance. |

The Importance of Full Traceability

Documentation is just as critical as the coating itself. Full traceability is required. Every step, from powder batch number to curing temperature and inspection results, is recorded.

This creates a complete history for each part. It provides accountability and is essential for quality control. It’s a non-negotiable part of our process at PTSMAKE.

Adhering to aerospace specifications like MIL-PRF-24712 is mandatory. This involves meticulous pretreatment, followed by extensive environmental and performance testing. Complete documentation for full traceability ensures every part meets the highest standards for safety and reliability.

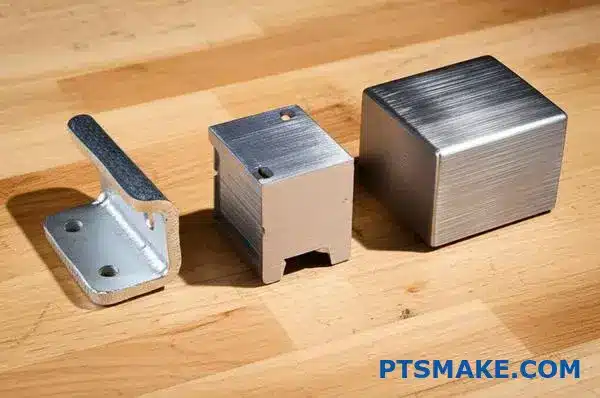

Secrets To Achieving Tight Tolerances After Powder Coating

Powder coating adds a protective layer, but it also adds thickness. This directly impacts your part’s final dimensions. Ignoring this buildup can lead to assembly failures.

Successful projects depend on precise thickness control. It’s a critical factor for parts with tight tolerances.

The Challenge of Coating Buildup

Every surface receives a layer of powder. This can range from 0.002 to 0.005 inches or more. You must account for this during the design phase to maintain critical dimensions.

Initial Planning is Key

We work with clients to define critical areas. This helps us develop a strategy before any powder is applied, ensuring a perfect fit after our powder coating services.

To maintain precision, we focus on two core areas: meticulous masking and intelligent design accommodation. These steps are not optional for high-tolerance components. They are essential for success.

Precision Masking Techniques

Masking protects areas that must remain uncoated. These often include threads, mating surfaces, or grounding points. The choice of masking material is crucial for clean, sharp lines.

| Masking Method | Best For | Temperature Resistance |

|---|---|---|

| High-Temp Tapes | Flat surfaces, sharp edges | High |

| Silicone Plugs/Caps | Holes, threads, studs | Very High |

| Liquid Maskant | Complex or irregular shapes | Varies |

Choosing the right method ensures that only the intended surfaces are coated. This prevents buildup where it would interfere with function. Effective ‘precision masking techniques’ are a cornerstone of quality.

Designing for Surface Buildup

The best strategy is to plan for the coating from the start. This means adjusting the initial CNC machining dimensions to accommodate the added thickness. For example, a hole might be machined slightly oversized. This ensures it’s the correct size after coating. This foresight prevents post-coating modifications. It also avoids issues like the Faraday cage effect3 in tight corners, which can cause uneven coating. At PTSMAKE, we integrate these considerations into our DFM process.

Achieving tight tolerances after coating requires a proactive approach. It combines precise thickness control, strategic masking, and designing parts to accommodate the material buildup. This ensures the final product meets all specifications without costly rework.

Benefits Of Powder Coating For Medical Device Housings

In the medical field, a device’s surface is not just for looks. It’s a critical component for safety and function. The finish must be durable and safe for patient contact.

Powder coating provides a superior solution. It meets the strict demands of healthcare environments effectively.

Biocompatibility and Safety

A key requirement is that the coating must be non-toxic. It cannot react with human tissue. Our medical device powder coating options are formulated for this exact purpose. They provide hospital-safe finishes.

Functional Performance

These coatings also simplify cleaning. A smooth, non-porous surface resists microbial growth. This is crucial for infection control in any clinical setting.

| Feature | Powder Coating | Liquid Paint |

|---|---|---|

| Biocompatibility | Excellent | Varies |

| Durability | High | Moderate |

| Chemical Resistance | High | Moderate-Low |

| Ease of Cleaning | Easy | Can be porous |

When selecting a finish, we must consider the entire lifecycle of a medical device. This includes repeated sterilization and exposure to harsh cleaning agents. A finish that degrades can compromise patient safety and device integrity. This is where the right coating makes a difference.

Enhanced Durability for Hospital Environments

Powder coating creates a tough, cross-linked surface. This is harder and more resilient than conventional paints. The finish resists chipping, scratching, and abrasion from daily use in a busy hospital.

We work with coatings made from durable thermosetting polymers4. This structure ensures the coating remains intact even after exposure to strong chemicals.

Resistance to Cleaning Agents

Medical equipment is cleaned with powerful disinfectants. We have seen finishes fail under this chemical assault. Powder coating, however, stands up exceptionally well. Our powder coating services specifically test for this.

The non-porous surface prevents chemicals from seeping in. This protects the underlying metal housing from corrosion. It also ensures the device remains easy to sterilize over its lifespan. Biocompatible coatings must maintain their integrity.

| Disinfectant Type | Powder Coat Resistance |

|---|---|

| Alcohol-based | High |

| Bleach solutions | High |

| Quaternary Ammonium | High |

| Peracetic Acid | High |

Powder coating offers a superior finish for medical devices, ensuring biocompatibility, chemical resistance, and ease of cleaning. Its durable surface meets the stringent demands of healthcare environments, making it a reliable choice for hospital-safe finishes and overall device integrity.

Protecting Machined Threads And Features During Powder Coating

Protecting critical features during powder coating is non-negotiable. One small error can render a high-precision part useless. It requires a meticulous approach.

Effective masking ensures that threads, bores, and sealing surfaces remain free of coating. This preserves their function and dimensional accuracy.

Common Masking Methods

We primarily use two methods for protecting OEM features during coating. These are high-temperature tapes and specialized plugs.

Technique Comparison

Each method has its ideal application. Choosing the right one is key.

| Method | Best For | Key Advantage |

|---|---|---|

| Tapes | External surfaces, flat areas | Flexibility |

| Plugs | Internal threads, bores | Reusability |

Proper thread masking before powder coat is a critical step in our finishing process.

Selecting the right masking material is just as important as the technique itself. The material must withstand both the electrostatic application and the high-temperature curing process without failing.

High-Temperature Tape Selection

When masking precision parts, not just any tape will do. Polyester and polyimide tapes are industry standards. They offer clean removal without leaving adhesive residue.

We must consider the tape’s thickness and adhesive properties. A thin tape might tear, while a thick one could create an undesirable paint edge. Our experience helps us select the perfect match for each job.

Removable Plugs and Caps

For internal features like threaded holes, silicone plugs are our go-to solution. They are flexible, reusable, and designed for a snug fit. This prevents any powder from seeping in.

The material’s durometer5 is a key factor. It determines the plug’s hardness and sealing capability. A softer plug might conform better to irregular shapes, while a harder one offers more durability. When offering our powder coating services, we stock a wide range to handle any geometry.

Tape Material Guide

Our tests with clients show that material choice directly impacts the final quality.

| Tape Type | Max Temperature | Adhesion | Best Use |

|---|---|---|---|

| Polyester | 400°F (204°C) | Silicone | General purpose, clean edges |

| Polyimide | 500°F (260°C) | Silicone | High-temp, electronics |

| Glass Cloth | 500°F (260°C) | Silicone | Uneven surfaces, sandblasting |

At PTSMAKE, we match the masking method precisely to the part’s geometry and coating requirements, ensuring every feature is protected.

Effective masking is essential for quality powder coating services. Choosing the right high-temperature tapes and silicone plugs protects critical threads and surfaces, ensuring the final part meets all specifications without costly rework or part failure.

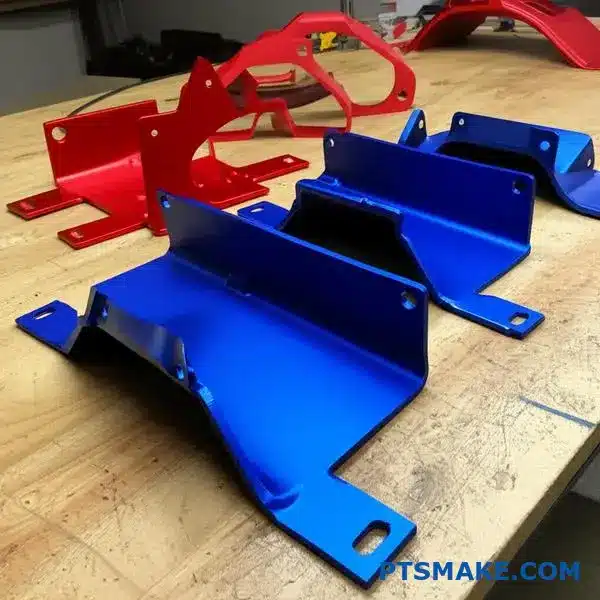

Choosing Powder Coat Finishes That Impress In Consumer Products

The right finish transforms a product. It’s not just about color; it’s about texture and feel. A product’s surface is the first point of contact with a user.

This interaction defines their initial impression. A premium product surface texture can elevate a device from functional to desirable. It’s a key part of brand identity.

Matte and Gloss Applications

Matte finishes are popular for high-end electronics. They minimize fingerprints and reduce glare, creating a sleek, modern look. Think of premium headphones or robotic casings.

Glossy finishes, however, create a vibrant, eye-catching effect. This makes them ideal for sports equipment or products that need to stand out on a shelf.

Tactile and Visual Appeal

The texture of a finish communicates quality. A smooth matte surface feels sophisticated. A high-gloss finish looks energetic and clean. Metallic textures suggest durability and precision.

Here’s a quick comparison:

| Finish Type | Visual Appeal | Tactile Feel | Best For |

|---|---|---|---|

| Matte | Understated, modern | Soft, smooth | Electronics, Robotics |

| Gloss | Vibrant, reflective | Sleek, hard | Sports Gear, Appliances |

| Metallic | Premium, durable | Varies | Automotive, High-tech |

This aesthetic powder coating choice directly impacts user perception.

The choice between finishes goes beyond simple aesthetics. It impacts manufacturing consistency and perceived value. Our work with robotics clients shows that a textured matte finish can hide minor surface imperfections, which simplifies the production process. This is a practical benefit of a well-chosen consumer finish powder coat.

Finishes for Specific Industries

For consumer electronics, a soft-touch matte finish offers a premium feel. It also provides a better grip, improving user experience. We often recommend this for handheld devices.

In contrast, sports gear requires durability. A high-gloss powder coat not only looks dynamic but also provides a tough, easy-to-clean surface. It must resist scratches and impacts effectively.

Metallic finishes bring a sense of high-tech precision. We apply these to drone components and automation hardware. The finish implies advanced technology and robust construction, which is crucial in these fields. The way light interacts with the surface, involving principles like specular reflection6, is key to this effect.

At PTSMAKE, our powder coating services focus on matching the finish to the product’s function and market position.

| Industry | Recommended Finish | Key Benefit |

|---|---|---|

| Robotics | Textured Matte | Hides imperfections, modern look |

| Electronics | Soft-Touch Matte | Premium feel, reduces fingerprints |

| Sports Gear | High-Gloss | Durability, vibrant appearance |

Choosing the correct premium product surface texture is a strategic decision that combines art with engineering.

Selecting the right finish is critical. Matte, gloss, or metallic textures define a product’s visual identity and tactile feel. This choice directly influences how consumers perceive its quality and value in competitive markets like robotics, electronics, and sports gear.

Understanding Curing: The Heart Of Powder Coating Success

The curing stage is where powder coating transforms. It’s not just about heat. It’s a precise chemical reaction. This is a critical step in the powder coating curing process.

We focus on mastering oven dynamics. Getting the bake cycles perfect is key.

Why Timing and Temperature Matter

Even small deviations can impact the final finish. Consistent oven temperature control for coating is non-negotiable for durability and appearance. It prevents defects and ensures a high-quality product.

| Curing State | Adhesion | Durability |

|---|---|---|

| Under-Cured | Poor | Brittle |

| Properly Cured | Excellent | Strong & Flexible |

| Over-Cured | Good | Brittle & Discolored |

The success of any powder coating service hinges on the curing oven. The choice between oven types significantly impacts the outcome. It’s a decision based on the part’s geometry and material.

Oven Technologies: Convection vs. Infrared

Convection ovens circulate hot air. They are great for complex shapes, ensuring even heat distribution. This method allows for a uniform cure across all surfaces.

Infrared (IR) ovens use electromagnetic waves. They transfer heat directly to the part’s surface. This is much faster but works best for flat, line-of-sight parts. The part’s Thermal mass7 plays a huge role in how quickly it heats.

| Oven Type | Heating Method | Best For | Speed |

|---|---|---|---|

| Convection | Hot Air Circulation | Complex Geometries | Slower |

| Infrared (IR) | Direct Radiation | Flat Surfaces | Faster |

The Risks of Improper Curing

An incorrect bake cycle leads to failure. Under-curing results in a soft, brittle finish with poor adhesion. It will easily chip or peel away.

Over-curing is just as bad. It can cause discoloration, especially with lighter colors. The coating also becomes brittle and loses its flexibility, leading to cracks under stress. Perfect oven temperature control for coating is essential.

Proper curing is a precise science. The choice between convection and infrared ovens, combined with carefully managed bake cycles, determines the final coating’s durability and finish. Under or over-curing will compromise the product’s performance and appearance.

Coating Galvanized, Aluminum, Stainless? Know This First

A great powder coat finish isn’t just about the powder. It’s about what happens before. Proper pretreatment is the key to durability.

You can’t use the same process for every metal. Galvanized steel, aluminum, and stainless steel all have unique needs.

Pretreatment Basics

Understanding the right method is crucial. This step ensures the powder adheres correctly. It also prevents future corrosion and failure. We will look at three common methods.

| Metal Type | Common Pretreatment |

|---|---|

| Galvanized Steel | Zinc Phosphating |

| Aluminum | Chromate Conversion |

| Stainless Steel | Abrasive Blasting |

The success of any of our powder coating services hinges on surface preparation. Skipping this step or choosing the wrong method is a recipe for failure. The coating will peel, chip, or rust underneath.

Chemical Pretreatments

For galvanized steel, we often use zinc phosphating. This process creates a micro-crystalline layer on the surface. This layer acts like a perfect primer, giving the powder something strong to bond with. It dramatically boosts corrosion resistance.

For aluminum, a chromate conversion coating is standard. Aluminum naturally forms a passive oxide layer. A chromate treatment cleans this off and replaces it with a new protective layer that also promotes excellent adhesion.

Mechanical Pretreatment

Abrasive blasting, like sandblasting, is a mechanical method. We use it to clean and profile surfaces, especially for stainless steel. It removes contaminants and creates a consistent roughness, or surface profile8. This texture gives the powder coating a much better mechanical grip on the part.

Here’s a quick comparison:

| Pretreatment | Process Type | Primary Use | Key Benefit |

|---|---|---|---|

| Zinc Phosphating | Chemical | Steel, Galvanized | Superior adhesion, corrosion resistance |

| Chromate Conversion | Chemical | Aluminum | Prevents oxidation, promotes adhesion |

| Abrasive Blasting | Mechanical | Stainless Steel, Rework | Creates anchor pattern for grip |

Choosing the right pretreatment for powder coating is critical. Zinc phosphating for steel, chromate for aluminum, and blasting for stainless steel are not optional steps. This proper surface prep before coating ensures a durable, long-lasting finish for your components.

Should You Pre- or Post-Machine Powder Coated Parts?

Deciding your machining sequence is a critical step. Do you machine the part before or after applying the powder coat? This choice impacts cost, precision, and lead time.

Each method has specific advantages. Understanding these trade-offs ensures your project’s success. This guide compares the pros and cons to help you make an informed decision.

| Factor | Machining Before Coating | Machining After Coating |

|---|---|---|

| Finish Integrity | Coating can be damaged | Pristine finish on critical areas |

| Masking | Simple or not required | Complex and often costly |

| Tolerances | Harder to maintain precisely | Excellent dimensional control |

The Case for Machining Before Coating

Machining parts before applying a finish is typically the default workflow. It consolidates all cutting operations into a single phase. This streamlines production and can reduce overall manufacturing time.

However, this approach introduces challenges. The thickness of the powder coating (usually 0.002" to 0.006") adds to the final dimensions. This can affect features with tight tolerances. There is also a risk of damaging the finish during final handling or assembly.

The Advantages of Machining After Coating

Post-machining coated parts gives you the best dimensional accuracy. It allows you to create precise features like tapped holes, bores, or mating surfaces after the coating is applied. This ensures the final part meets exact specifications without any coating buildup.

At PTSMAKE, we often suggest this for aerospace or medical parts where precision is non-negotiable. This process requires careful planning. Masking and extra setups can increase costs, but the quality gain is significant. Good design for finishing considers the material’s dimensional stability9 throughout these thermal and mechanical processes. Our powder coating services are tailored to support both sequences.

| Aspect | Machining Before Coating | Machining After Coating |

|---|---|---|

| Cost | Generally more economical | Higher due to extra setups/masking |

| Accuracy | Lower for tight tolerance features | Highest possible precision |

| Lead Time | Often shorter and simpler | Can be longer due to extra steps |

| Finish Quality | Risk of handling damage | Protected finish on non-machined areas |

The decision balances cost, accuracy, and finish quality. Post-machining offers superior precision for critical features, while pre-machining is more efficient for parts with less stringent tolerance requirements. Both are valid manufacturing strategies depending on the application.

Protecting Edges And Corners In High-Stress Applications

Sharp edges are a primary challenge for durable coatings. Powder coating struggles to adhere properly to them. This is because of a principle where the coating thins out as it flows over a sharp corner.

This leaves the edge exposed and vulnerable. Poor edge coverage powder coat is a common point of failure. It directly compromises the part’s lifespan, especially in high-stress environments. The table below shows the difference.

| Edge Type | Coating Thickness | Protection Level |

|---|---|---|

| Sharp Edge (<0.5mm) | Very Thin | Poor |

| Rounded Edge (>1mm) | Consistent | Excellent |

Addressing Poor Coverage in Design

The most effective solution begins at the design stage. I always recommend clients specify a minimum radius for all external and internal edges. This simple adjustment greatly improves coating durability.

For reliable stress protection powder coating, a radius of just 1mm is far superior to a sharp corner. It allows the powder to flow and cure uniformly. This ensures consistent thickness and maximum protection against corrosion and wear.

Improving the Application Process

In the application stage, choosing the right powder is critical. Certain formulations offer better flow properties, which minimizes the pull-back from edges. We often suggest specific materials based on the part’s geometry.

Technique is also vital, especially when coating corners and cutouts. The electrostatic process can create a Faraday cage effect10, making it difficult for powder to penetrate deep corners.

Our technicians at PTSMAKE carefully adjust voltage and powder flow to counteract this. This expertise ensures even coverage everywhere. Our professional powder coating services focus on these details to deliver reliable results.

| Solution Phase | Key Action | Expected Outcome |

|---|---|---|

| Design | Specify minimum edge radius | Improved powder flow and adhesion |

| Application | Select appropriate powder | Reduced pull-back effect |

| Application | Adjust sprayer settings | Overcome electrostatic challenges |

Sharp edges result in thin, weak coatings due to surface tension. The best fix is rounding edges during design and refining application techniques, a key focus of our expert powder coating services, to ensure consistent, protective coverage.

Color Matching Your Powder Coated Parts To Global Standards

Achieving the perfect color is crucial. It defines your brand and ensures product quality. That’s why global standards are so important in our work.

Using Standard Color Systems

We rely on established color charts. These systems provide a common language for color. This removes guesswork and guarantees consistency across all your parts.

The two most common systems are RAL and Pantone. Each serves a different primary purpose, but both are useful in manufacturing.

| System | Primary Use | Color Range |

|---|---|---|

| RAL | Industrial Coatings & Plastics | Over 2,500 colors |

| Pantone | Printing & Graphic Design | Over 3,000 colors |

Using these standards ensures the color you specify is the color you get. Our powder coating services are built around this principle of precision.

While standards like RAL and Pantone are essential, they are just the starting point for true color consistency finishing. Several real-world factors can still cause variations. Understanding these challenges is key.

Dealing with Lot Variation

Powder coating materials are produced in batches, or lots. Minor variations in pigment or base material between lots can cause slight color shifts. We always request certificates of analysis for each lot.

The Impact of Lighting

How we perceive color is highly dependent on the light source. A part might look perfect under factory lighting but different outdoors. This phenomenon, known as metamerism11, can be a major issue.

We use controlled lighting booths to inspect parts. These booths can simulate different light conditions, like daylight or retail store lighting. This ensures your part’s color holds up in its end-use environment.

Here’s how we address these common challenges:

| Challenge | Our Solution at PTSMAKE |

|---|---|

| Lot-to-Lot Shifts | Verify each new batch against a master sample. |

| Lighting Inconsistency | Use a light booth for quality control checks. |

| Supplier Variance | Maintain a single, trusted powder supplier. |

Managing these factors is a core part of our powder coating services. It is how we deliver consistent results every time.

Achieving perfect color consistency requires using global standards like RAL and Pantone. It also means actively managing challenges like lot-to-lot variation and lighting inconsistencies to ensure the final finish on your parts is exactly what you specified.

How To Work With A Turnkey Supplier Offering Coating + CNC

Working with an all-in-one manufacturing partner simplifies everything. When your CNC and finishing supplier is the same company, you eliminate major headaches.

This integrated approach means one point of contact. One team is responsible for the final part. It streamlines communication and ensures accountability.

Integrated vs. Separate Suppliers

| Feature | Integrated Supplier | Separate Suppliers |

|---|---|---|

| Accountability | Single Point | Multiple, potential blame |

| Communication | Streamlined & Direct | Complex & Delayed |

| Logistics | Simplified (In-House) | Complex (Shipping) |

| Lead Time | Shorter | Longer |

Choosing a full-service powder coating provider that also handles machining is a strategic move. It saves you time and reduces project risks significantly.

Choosing an integrated CNC and finishing supplier has clear advantages beyond simple convenience. It creates a seamless workflow that directly impacts quality and speed.

Enhanced Quality Control

When one team manages both machining and coating, they understand the entire process. They know how the machined surface finish affects powder adhesion. This expertise prevents common finishing defects. At PTSMAKE, our teams collaborate to ensure every part is perfect. This internal loop is key for providing superior powder coating services.

Substrate Preparation12 is handled by experts who understand the part’s final application. This ensures a durable and visually flawless finish.

Streamlined Project Timeline

An all-in-one partner eliminates the time lost shipping parts between different facilities. It also cuts down on administrative delays. This integration can shorten your overall lead time by a significant margin, getting your product to market faster.

| Advantage | Impact on Your Project |

|---|---|

| Unified Quality Checks | Fewer rejections and defects. |

| No Transit Delays | Faster turnaround from raw material to finished part. |

| Reduced Admin | Less time spent managing multiple purchase orders. |

| Cost Efficiency | Lower shipping and handling costs. |

Ultimately, a single-source supplier provides a more reliable and efficient manufacturing experience. It transforms a complex process into a simple, manageable one.

Choosing an all-in-one manufacturing partner for CNC machining and full-service powder coating simplifies logistics. This integration enhances quality control, reduces lead times, and streamlines your entire supply chain, delivering a superior final product with less management effort.

Eco-Friendly Powder Coating: What Buyers Need To Know

Choosing sustainable powder coating is a key step. It helps meet environmental regulations. This finish offers significant green advantages for modern manufacturing.

Zero VOCs for Cleaner Air

Powder coatings contain no solvents. They release virtually zero Volatile Organic Compounds (VOCs). This greatly improves air quality.

High Material Efficiency

A key benefit is reclaiming overspray. This minimizes waste compared to liquid paint. Our powder coating services focus on maximizing this efficiency.

| Feature | Environmental Benefit |

|---|---|

| VOC-Free | No harmful air emissions |

| Recyclable Overspray | Reduces material waste by up to 98% |

| Low Energy Curing | Lower carbon footprint |

The Reality of "Green Manufacturing Finishes"

Eco powder paint is more than just a marketing term. It represents a fundamental shift in finishing technology. The absence of solvents is the most celebrated feature. This directly impacts compliance with environmental laws.

However, the green benefits extend further. Consider the curing process. Traditional methods required high temperatures. Now, low-temperature cure powders are available. This reduces energy consumption significantly. It lowers the carbon footprint of each part.

Maximizing Sustainability

Recycling overspray is a game-changer. An efficient reclamation system can achieve over 95% material utilization. This is nearly impossible with liquid paints. At PTSMAKE, we work with clients to optimize this process. It cuts costs and waste.

The choice of powder also matters. Some are formulated with more sustainable raw materials. When selecting a provider for powder coating services, ask about their material sourcing. This ensures true end-to-end sustainability. The lack of Volatile Organic Compounds13 is a primary health and environmental benefit.

| Curing Method | Energy Impact | Suitable For |

|---|---|---|

| Standard Thermal Cure | High | Most Metals |

| Low-Temp Thermal Cure | Medium | Heat-Sensitive Metals, MDF |

| UV Cure | Low | Heat-Sensitive Substrates |

Powder coating provides a truly green solution. Its VOC-free nature, high material reclaim rate, and energy-efficient curing options make it a top choice for sustainable manufacturing. It’s a finish that benefits both your product and the planet.

Powder Coating On 3D Printed Parts: Yes, It’s Possible

Not all 3D printed parts are created equal. Their material and printing method dictate the prep work.

Polyamide parts, often from SLS printers, require special attention. Their porous nature needs sealing before coating.

This ensures a smooth, durable finish. Ignoring this step leads to poor adhesion and a flawed surface. Proper preparation is the key to a professional outcome for any finish for additive components.

| Print Technology | Material Example | Key Prep Step |

|---|---|---|

| SLS | Polyamide (Nylon) | Surface Sealing |

| SLA | Epoxy Resins | Conductive Primer |

| FDM | ABS, PLA | Layer Smoothing |

This tailored approach is crucial for high-quality powder coating 3D prints.

Let’s dive deeper into specific preparation needs. For coating SLS parts, which are typically made of polyamide (Nylon), the main challenge is their inherent porosity14. These microscopic voids can trap air. This trapped air can cause bubbles in the finish during the curing process.

At PTSMAKE, we use a specialized sealing process. This fills the surface pores, creating a smooth, non-absorbent base. It’s a vital step before applying any powder. This ensures the powder coat adheres uniformly and cures without defects.

SLA prints, on the other hand, have a very smooth, non-porous surface. However, they are not naturally conductive. For the electrostatic process of powder coating to work, the part must be conductive. We apply a thin, conductive primer to the SLA part first. This allows the powder particles to attract and stick to the surface evenly.

These preparation methods are critical in demanding fields. In aerospace, coated prototypes must withstand harsh tests. In medical prototyping, a sealed, non-porous surface is essential for sterilization and biocompatibility. Our comprehensive powder coating services are designed to meet these exact specifications.

| Application | Key Requirement | Our Solution |

|---|---|---|

| Aerospace | Durability, Uniformity | Sealing & Conductive Priming |

| Medical | Biocompatibility, Sterilizability | Pore-sealing & Smooth Finish |

Proper prep is non-negotiable for powder coating 3D prints. Sealing porous SLS parts and applying conductive primers to SLA parts are essential steps. These techniques ensure a durable, high-quality finish suitable for aerospace and medical applications.

Get Your Powder Coating Quote With PTSMAKE Today!

Ready to transform your parts with precision powder coating services? Contact PTSMAKE now for a custom quote! Our engineering expertise and turnkey solutions deliver durability, tight tolerances, and flawless finishes—no surprises, just results. Send your inquiry and discover why professionals trust PTSMAKE!

Discover how this polymer science leads to a more durable and protective coating. ↩

Learn how invisible residues can cause total coating failure and see how to prevent it. ↩

Learn how this electrostatic principle impacts coating uniformity in recessed areas and sharp corners. ↩

Understand the chemistry behind the durability and resistance of modern industrial coatings. ↩

Learn how material hardness affects masking plug performance and reusability in high-temperature applications. ↩

Understand how light reflection properties impact the perceived quality and color of your product’s surface finish. ↩

Learn how a part’s thermal properties affect the required cure time and final coating quality. ↩

Discover how surface texture is measured and why it’s vital for coating performance and durability. ↩

Understand how a material’s reaction to heat and stress affects its final dimensions and performance. ↩

Learn how this electrostatic principle impacts coating quality and how experts overcome it. ↩

Understand how two colors can match under one light but not another with this clear explanation. ↩

Learn how proper surface treatment is critical for coating adhesion and a flawless finish. ↩

Understand what VOCs are and why their elimination is critical for environmental and workplace safety. ↩

Learn how surface characteristics impact coating adhesion and how to properly manage it for superior results. ↩