Are you struggling to find reliable information about brushed copper for your industrial manufacturing needs? Most online resources focus on decorative applications, leaving engineers and procurement managers without the technical depth required for precision industrial projects.

Brushed copper offers superior conductivity, antimicrobial properties, and aesthetic appeal for industrial applications, but requires specific knowledge of alloy selection, finishing techniques, and protective coatings to achieve optimal performance in demanding environments.

This comprehensive guide covers everything from alloy selection and finishing techniques to cost optimization and design considerations. You’ll discover practical insights from real manufacturing projects and learn how to avoid common pitfalls that can delay your timeline or compromise quality.

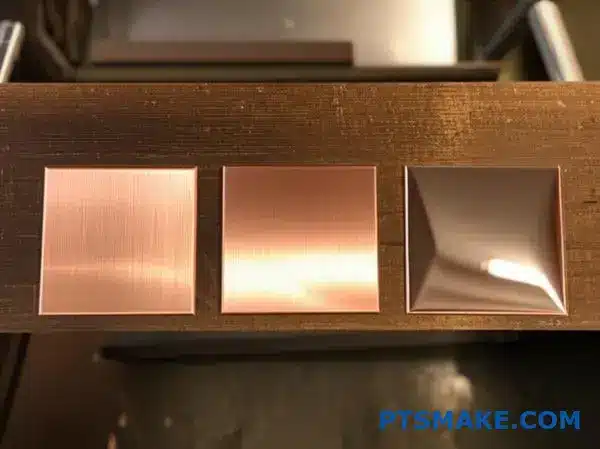

Brushed Copper Vs. Satin And Polished: What’s The Difference?

Choosing the right copper finish is critical. It impacts both appearance and performance. Each finish offers a unique look and specific functional benefits.

Understanding these differences is key for any project. Let’s compare copper finishes directly. This will help you select the best option for your application.

Quick Finish Comparison

| Finish Type | Key Characteristic | Common Use |

|---|---|---|

| Brushed Copper | Fine, parallel lines | Decorative hardware |

| Satin Copper | Smooth, matte look | High-touch surfaces |

| Polished Copper | Shiny, reflective | Architectural details |

This guide will break down everything you need to know.

A Deeper Look at Copper Finishes

When we discuss brushed copper vs satin copper, the difference lies in the texture. Brushed copper has visible lines from a wire brush. This gives it a distinct, handcrafted appearance. It also hides fingerprints and minor scratches well.

Satin copper, however, has a softer, diffused finish. It’s achieved through blasting or chemical treatment. It provides a low-gloss, smooth feel that is very uniform. This makes it ideal for components requiring a modern, clean aesthetic.

Polished copper is the most traditional. It’s buffed to a mirror-like shine. This high reflectivity makes it a great choice for statement pieces. However, it requires frequent cleaning to maintain its appearance. Finding good polished copper alternatives often leads designers to brushed or satin finishes for better durability.

Comparing Key Properties

| Property | Brushed Copper | Satin Copper | Polished Copper |

|---|---|---|---|

| Reflectivity | Low, directional | Low, diffused | High, mirror-like |

| Maintenance | Low | Low | High |

| Scratch Hiding | Excellent | Good | Poor |

| Corrosion Resistance | Good | Good | Moderate |

When selecting a finish, you also have to consider how it will interact with other materials in an assembly to avoid issues like galvanic corrosion1.

Choosing between brushed, satin, and polished copper depends on your project’s aesthetic, functional, and maintenance requirements. Each finish offers a distinct balance of visual appeal and practical performance, directly impacting the final product’s durability and look.

How To Prevent Oxidation In Brushed Copper Assemblies

Understanding how to prevent copper oxidation is crucial. Brushed copper’s beauty is its warm, lustrous finish. However, air and moisture quickly tarnish this surface. This process is called oxidation.

It creates a greenish layer, or patina. While some seek this aged look, most industrial applications require a pristine appearance and function. Protecting the material is essential.

Why Copper Oxidizes

Copper is a reactive metal. It readily reacts with oxygen in the atmosphere. This reaction forms copper oxide, which darkens the surface. Humidity and pollutants accelerate this process significantly.

First Line of Defense

Simple coatings are often the first step. These create a physical barrier between the copper and the environment. This directly improves brushed copper corrosion resistance.

| Treatment | Effectiveness | Appearance |

|---|---|---|

| Untreated | Low | Tarnishes quickly |

| Clear Lacquer | High | Glossy, preserves color |

| Wax Coating | Medium | Natural, semi-gloss |

For robust protection, we must look beyond basic coatings. The right method depends entirely on the assembly’s final use and environment. At PTSMAKE, we guide clients to the best solution.

Protective Coatings for Copper

Clear lacquers and acrylic sprays offer excellent barriers. They seal the brushed copper surface from air and moisture. We’ve found that applying multiple thin layers provides a more durable finish than one thick coat. This method is great for decorative parts.

However, for components requiring electrical conductivity or high wear resistance, these coatings can be unsuitable. They act as insulators and can scratch off.

Chemical Conversion Coatings

This is where chemical treatments come in. These processes alter the surface of the copper itself. They create a more stable, non-reactive layer. This is a far more integrated solution than a simple surface coating.

One effective method is passivation2. This chemical process forms a microscopic protective layer. It greatly enhances the brushed copper’s natural resistance to environmental corrosion without adding significant thickness or altering its metallic properties.

| Coating Type | Best For | Durability |

|---|---|---|

| Clear Lacquer | Decorative Parts | Medium |

| Wax | Low-contact items | Low |

| Passivation | Functional/Industrial Parts | High |

Preventing oxidation in brushed copper assemblies involves understanding the material’s behavior. Choosing the right protective coatings, from simple lacquers to advanced chemical treatments like passivation, is key to maintaining both appearance and function. This ensures long-term performance and reliability for your components.

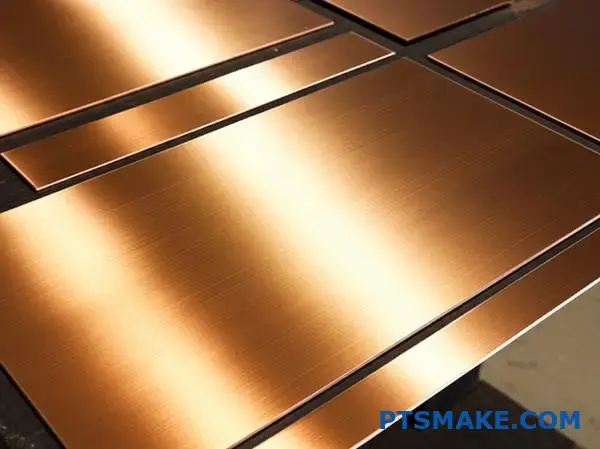

Choosing The Right Copper Grade For Brushed Finishing

Selecting the right copper grade is critical. The alloy you choose directly impacts the final look and feel of the brushed finish. Not all coppers are created equal for this process.

Your choice affects both aesthetics and manufacturability. Let’s compare some common options for your brushed copper alloy selection.

Popular Copper Grades

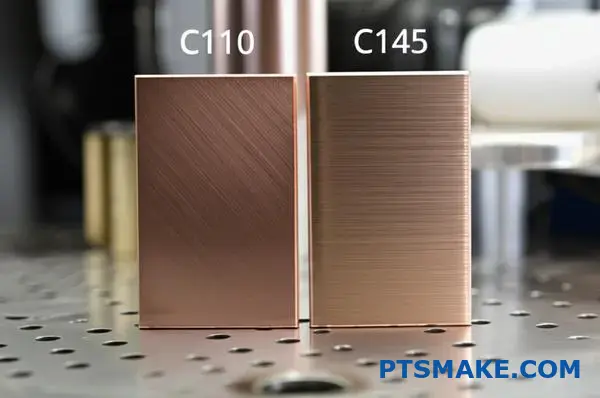

C110 (ETP Copper)

C110 is very pure. This makes it soft, which can sometimes lead to an inconsistent finish if not handled carefully. It’s often chosen for electrical applications.

C145 (Tellurium Copper)

C145 contains tellurium. This small addition dramatically improves its machinability. This makes achieving a clean, uniform brushed texture much easier.

Here is a quick comparison:

| Feature | C110 Copper | C145 Copper |

|---|---|---|

| Purity | 99.90% Cu | 99.5% Cu, 0.5% Te |

| Machinability | Poor (20%) | Excellent (85%) |

| Brushed Finish | Good, but requires skill | Excellent, very consistent |

This makes C145 a strong candidate for the best copper for brushed finish projects.

The choice between alloys often comes down to balancing machinability with other requirements like conductivity. For purely aesthetic parts, machinability is king.

Why Machinability Matters for Brushing

A material that machines well produces cleaner cuts. This creates a smoother base surface before the brushing even begins. It prevents metal from smearing or galling during the process.

This is why C145 is a favorite at PTSMAKE for C110 brushed copper parts. The tellurium acts as an internal lubricant. It creates small, easily broken chips. This results in a superior surface ready for a perfect brushed texture. The process is more controlled and repeatable.

The material’s grain structure also plays a role. Brushing applies fine, parallel scratches. If the material has significant anisotropy3, the finish might look different depending on the brushing direction relative to the grain.

Diving Deeper into Alloy Selection

| Alloy | Key Advantage for Brushing | Main Consideration |

|---|---|---|

| C110 | High purity, excellent conductivity | Softness can lead to inconsistent finish |

| C145 | Superior machinability for clean lines | Slightly lower conductivity than C110 |

| C101 | Highest purity (Oxygen-Free) | Even softer than C110, challenging |

Based on our tests, C145 consistently delivers the most uniform and visually appealing brushed finish. It simplifies the manufacturing process, reducing the risk of defects and ensuring a high-quality result every time.

Choosing the right copper alloy is crucial for a high-quality brushed finish. C145’s superior machinability often makes it the best choice for achieving a clean, consistent texture, outperforming softer grades like C110 that require more careful handling.

Expert Guide To Brushed Copper Tolerances In CNC Machining

Achieving precise brushed copper machining tolerances is a common goal. It requires a deep understanding of the material’s unique properties. Copper’s softness isn’t a barrier, but a factor to manage.

With the right approach, tight tolerances are entirely feasible. Success hinges on a carefully planned CNC setup. It’s about balancing precision with the material’s nature.

General Tolerance Guidelines

We often work with clients on tight tolerance copper fabrication. Here are some typical achievable tolerances based on our experience.

| Feature | Standard Tolerance | Tight Tolerance |

|---|---|---|

| General Dimensions | ±0.1 mm (±0.004") | ±0.025 mm (±0.001") |

| Hole Diameters | ±0.05 mm (±0.002") | ±0.01 mm (±0.0004") |

| Surface Flatness | 0.1 mm/100mm | 0.05 mm/100mm |

These values demonstrate what is possible with expert setup.

The Impact of Copper’s Malleability on CNC Setups

Copper’s softness presents unique challenges. The material can easily deform under pressure or heat. This directly impacts the final part’s accuracy. A robust CNC setup is therefore non-negotiable for any serious brushed copper project.

At PTSMAKE, we focus on controlling every variable. This ensures the part we deliver matches the design specifications perfectly. It starts with the right tools and machine parameters.

Tooling and Speed Adjustments

Sharp, specialized tooling is essential. We use carbide tools, often with a TiB2 coating. This coating is extremely slick, reducing friction and material buildup on the cutting edge.

Heat management is also critical. We often reduce cutting speeds. This prevents the copper from getting too hot and gummy. Higher feed rates help clear chips quickly, further reducing heat transfer into the workpiece. This prevents issues like galling4, where material welds to the tool.

Managing Heat and Fixturing

Proper workholding is vital. Fixtures must secure the part without marring the soft surface or causing distortion. High-pressure flood coolant is also a must. It serves two purposes: it cools the part and tool, and it forcefully flushes away chips that could otherwise get stuck and ruin the surface finish or dimensional accuracy.

| Parameter | Recommendation for Brushed Copper | Rationale |

|---|---|---|

| Tool Material | TiB2-Coated Carbide | Minimizes friction and material buildup |

| Cutting Speed | Lower than steel | Prevents excessive heat and material gumming |

| Feed Rate | Higher than usual | Ensures effective chip evacuation |

| Coolant Use | High-pressure flood | Manages heat and flushes away chips |

Achieving tight tolerance copper fabrication relies on a specialized setup. Copper’s softness requires sharp tools, specific speeds, and robust cooling. These controls are essential to prevent deformation and ensure the final part meets precise specifications.

High-Purity Brushed Copper: When Specs Really Matter

In some industries, "good enough" is never an option. Standard copper works for many applications. But for the most critical sectors, purity levels above 99.9% are non-negotiable.

This is where specs truly matter.

High-purity brushed copper isn’t just a material choice. It is a fundamental requirement for performance and safety. Let’s look at where it’s essential.

Critical Industry Applications

For sectors like aerospace and medical, even tiny impurities can lead to catastrophic failures. Ultra-pure copper parts ensure reliability.

| Application Tier | Typical Purity | Key Requirement |

|---|---|---|

| General Use | 99.90% (C11000) | Cost-Effectiveness |

| Critical Systems | >99.99% (OFC) | Absolute Reliability |

These demands drive the need for specialized materials.

When a client specifies oxygen-free copper (OFC) with 99.99% purity, they have a clear reason. In my experience, this isn’t about over-engineering. It’s about mitigating risk in environments where failure has severe consequences.

Aerospace & Defense Systems

In satellites and avionics, electrical conductivity must be perfect. Impurities create resistance, generating heat and distorting signals. For sensitive guidance systems or communication arrays, this is unacceptable. High-purity brushed copper ensures clean signal transmission.

It also prevents issues like outgassing5 in a vacuum. Trapped gases from impure metals can degrade sensitive optical and electronic components over time, compromising a mission.

Medical & Scientific Instruments

In MRI machines, the powerful magnetic coils require ultra-pure copper parts. This maximizes magnetic field efficiency and imaging clarity. Any variance could lead to misdiagnosis.

For particle accelerators or lab equipment, material purity guarantees predictable and repeatable results. It’s about precision at a microscopic level.

| Purity Level | Electrical Conductivity (% IACS) | Key Advantage |

|---|---|---|

| 99.90% ETP | 100% | Good for general wiring |

| 99.95% OF | 101% | Better for audio/video |

| 99.99% OFHC | >101% | Essential for vacuum electronics |

Our internal tests show that moving from 99.95% to 99.99% purity can significantly improve performance under extreme thermal stress.

For critical industries like aerospace and medical, high-purity brushed copper is essential. It guarantees the reliability, signal integrity, and safety required for systems where failure is not an option. The choice of material directly impacts performance and prevents catastrophic outcomes.

Smart Budgeting For Custom Brushed Copper Part Orders

When you receive a quote for CNC copper machining, it’s more than just a final number. To truly manage your budget, you must see inside the quote.

The price is a mix of fixed and variable costs. Understanding this difference is key. It helps you make smart decisions. This is crucial for a successful ‘budget brushed copper’ project.

Here’s a simple breakdown:

| Cost Type | Description |

|---|---|

| Fixed Costs | One-time charges per order |

| Variable Costs | Costs that change with quantity |

This separation helps you identify where your money is really going.

Let’s dig deeper into what these costs mean for your custom brushed copper parts. A clear understanding helps you negotiate better and plan your production runs more effectively. It turns a simple quote into a strategic tool.

Unpacking Fixed Costs in Your Quote

Fixed costs are the upfront, one-time expenses for each production batch. They don’t change whether you order 10 parts or 1,000. These include CNC programming, machine setup, and any custom tooling or fixtures required for your specific design.

Spreading these initial expenses across the total number of parts produced is a form of Amortization6. A larger order volume significantly reduces the fixed cost portion of each part’s final price.

Analyzing Variable Costs

Variable costs are directly tied to the quantity of parts you order. The more you produce, the higher the total variable cost, but the cost per part often remains steady or decreases slightly with scale.

Key variable costs include:

| Variable Cost | Details |

|---|---|

| Raw Material | The price of the copper itself. |

| Machine Time | The time each part spends being cut. |

| Labor | Manual work like inspection or handling. |

| Finishing | The specific process for the brushed finish. |

At PTSMAKE, we provide a clear breakdown in our quotes to help you see these factors.

Understanding the difference between fixed and variable costs in your quote is critical. It empowers you to see how order quantity affects your per-part price, allowing for smarter decisions when planning your budget for brushed copper components.

Brushed Copper For Outdoor Use: What Buyers Must Know

When you take brushed copper outdoors, it begins a natural transformation. This isn’t a sign of poor quality; it’s the metal interacting with its environment. Understanding this process is key.

How Copper Responds to the Elements

Atmospheric corrosion is the main driver of change. It dictates the surface appearance and the material’s long-term performance. The formation of a patina is a direct result of this.

This natural green or blue layer is a hallmark of copper’s endurance. It provides a unique aesthetic and a protective shield. Alternatively, lacquer coatings can be applied. This preserves the original brushed finish, but it comes with its own set of considerations.

| Feature | Untreated Brushed Copper | Lacquered Brushed Copper |

|---|---|---|

| Appearance | Evolves over time (patina) | Stays consistent initially |

| Maintenance | Very low (self-protecting) | Periodic re-coating needed |

| Durability | Excellent (natural shield) | Depends on coating integrity |

The Science Behind Outdoor Copper Durability

Let’s look closer at atmospheric corrosion. It’s more than just water and oxygen. Airborne pollutants, especially sulfur compounds found in urban or industrial air, accelerate this process significantly. This explains why copper fixtures might darken faster in a city.

This reaction is fundamental to understanding brushed copper outdoor durability. It’s a predictable and well-documented chemical behavior.

The Protective Patina Process

The initial darkening is the first stage of patina formation. This oxide-sulfide layer is tightly adhered to the surface. Over years, it gradually converts into the well-known blue-green layer of copper sulfates and carbonates.

This patina is not like rust on steel. It’s a dense, stable barrier that effectively stops deeper corrosion. This self-protection makes copper one of the best choices for long-lasting, weather-proof copper parts.

The Role of Lacquer Coatings

A clear lacquer creates a physical barrier. It seals the brushed surface from atmospheric elements, preserving the original look. This is often an acrylic or urethane coating designed for exterior use.

However, this protection isn’t permanent. Scratches, abrasions, or UV degradation can create weak points. Moisture can then creep under the coating, causing localized corrosion. The process of sulfidation7 can still occur if the seal is broken. We advise clients that regular inspection and reapplication are necessary to maintain the coating’s integrity.

| Stage | Timeframe (Approx.) | Color/Appearance |

|---|---|---|

| 1 | 1-6 months | Light brown to dark brown/black |

| 2 | 1-5 years | Darkening, with initial green flecks |

| 3 | 5-20+ years | Stable blue-green or green patina |

Untreated brushed copper develops a protective patina, which enhances its durability for outdoor use. Lacquered finishes preserve the initial appearance but demand regular maintenance to prevent coating failure. The choice depends on your project’s aesthetic goals versus its maintenance schedule.

Common CNC Design Mistakes With Brushed Copper And How To Avoid Them

Designing parts for brushed copper requires special attention. Some common copper part design flaws can easily ruin an otherwise great design. We often see issues with poor feature placement.

Placing features like holes or pockets too close to an edge weakens the material. Similarly, walls that are too thin can cause major problems during machining.

These brushed copper DFM errors often result in higher costs. They can also compromise the part’s final quality and performance.

| Common Flaw | Consequence |

|---|---|

| Poor Feature Placement | Weakened Edges, Stress Points |

| Thin Walls | Deformation, Machining Vibration |

| Burr-Prone Tolerances | Poor Finish, Assembly Issues |

Understanding these points is the first step to avoiding them.

Let’s explore these brushed copper DFM errors more closely. Poor feature placement is a primary concern. When features are clustered together or near edges, the material’s internal structure is compromised. This creates points of stress concentration8, raising the risk of cracks or failure.

Tool access is another practical problem. Cramped features can make it impossible for the correct tool to reach the surface. This forces compromises that affect both efficiency and finish quality.

Thin walls are especially problematic with a soft material like brushed copper. During CNC machining, thin sections vibrate excessively. This makes it very difficult to maintain tight tolerances and achieve a smooth surface.

Heat also builds up in thin areas. Since it cannot dissipate quickly, it can affect the copper’s temper and structural properties.

Finally, we must address burrs. Copper’s ductility means it tends to push and deform rather than shear cleanly. Setting tight tolerances without planning for specific de-burring steps often leads to a poor-quality finish.

| Design Parameter | Recommended Guideline (Copper) | Reason |

|---|---|---|

| Wall Thickness | > 0.8mm (0.031") | Avoids vibration and deformation |

| Feature Spacing | > 1.5x hole diameter | Maintains structural integrity |

| Edge Distance | > 2x wall thickness | Prevents edge breakout |

At PTSMAKE, our DFM process flags these issues early. We work with our clients to optimize their designs for manufacturing before any metal is cut.

Effective Design for Manufacturability (DFM) is critical for brushed copper. Paying close attention to feature placement, wall thickness, and realistic tolerances helps avoid common copper part design flaws. This ensures a smoother production process and a higher-quality final component.

Industrial Case Studies: High-Performance Brushed Copper Parts In Action

Theoretical benefits are one thing. Seeing parts perform in the field is what truly matters. We’ve worked on many projects where brushed copper was the key to success.

These real-world brushed copper success stories show its practical advantages. Let’s look at two specific industrial use cases.

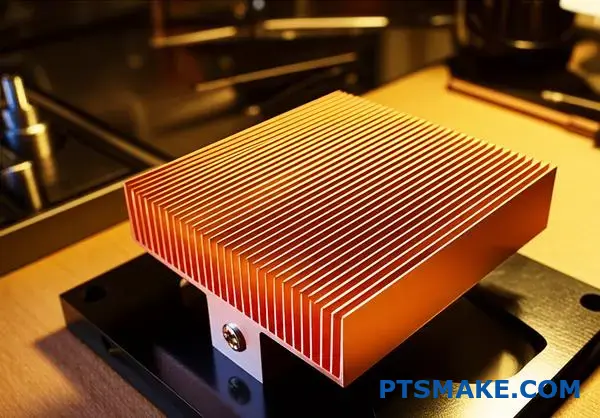

Electronics: Advanced Heatsinks

A client needed better thermal management for a high-power server. Their previous aluminum heatsinks were not enough. We manufactured a brushed copper alternative.

The results from our joint testing were significant.

| Metric | Previous (Aluminum) | New (Brushed Copper) |

|---|---|---|

| Peak Temperature | 95°C | 78°C |

| Heat Dissipation | Baseline | +35% |

| System Stability | Occasional Throttling | Stable |

Robotics: High-Current Connectors

In a robotic arm application, reliable power delivery was critical. The original connectors showed wear and resistance over time. Brushed copper parts provided a more durable solution.

Exploring these brushed copper industrial use cases reveals clear engineering advantages. It’s not just about looks; it’s about performance under pressure.

Deep Dive: Electronics Application

The server client’s primary issue was thermal throttling. This limited the processor’s performance during heavy workloads. Standard solutions were failing.

The high thermal conductivity of brushed copper was the answer. By switching, they not only lowered peak temperatures but also improved overall system efficiency. This extended the hardware’s lifespan.

Deep Dive: Robotics Application

The robotics client faced connection failures. These failures caused costly downtime on their assembly line. The issue was electrical resistance increasing due to surface oxidation and wear.

We recommended brushed copper for its superior conductivity and durability. We also carefully considered the mating components to prevent issues like galvanic corrosion9. The new connectors maintained a low-resistance connection through many cycles.

This table highlights the improvements we confirmed with the client.

| Feature | Old Connector | Brushed Copper Connector |

|---|---|---|

| Electrical Resistance | Increased over time | Consistently low |

| Lifespan (Cycles) | ~5,000 | >20,000 |

| Downtime Impact | Frequent | Minimal |

These projects show how a material choice directly solves complex operational problems.

These brushed copper success stories in electronics and robotics prove its value. The material delivers measurable performance improvements, from thermal management to electrical conductivity, solving critical engineering challenges and enhancing system reliability in demanding industrial applications.

Glossary Of Brushed Copper Manufacturing Terms Buyers Should Know

To get the best results for your brushed copper parts, you need to speak the language. This short manufacturing copper glossary will help.

Understanding these key terms ensures clarity between you and your supplier. It prevents costly misunderstandings. Let’s define four common but crucial terms.

Key Terminology Overview

| Term | Relates To | Primary Impact |

|---|---|---|

| Grain Direction | Aesthetics | Visual consistency of the brush lines |

| RA Finish | Surface Quality | Smoothness and texture of the surface |

| Passivation | Durability | Corrosion and tarnish resistance |

| Yield Strength | Mechanical Property | Resistance to permanent bending |

This brushed copper terminology list is a great starting point for any buyer.

Navigating technical specifications is a core part of my job at PTSMAKE. Let’s break down these terms further so you can specify your parts with confidence.

Grain Direction

This term refers to the primary direction of the brushed pattern on the copper surface. It’s purely an aesthetic choice. But it’s a critical one. Inconsistent grain direction across multiple parts can make a final assembly look unprofessional. Always specify the desired direction on your drawings.

RA Finish (Roughness Average)

RA finish is a measure of surface texture. It quantifies the average roughness of a surface. A lower RA number means a smoother, more reflective surface. A higher RA indicates a rougher texture.

| RA Value | Surface Feel | Common Application |

|---|---|---|

| Low (e.g., 16 µin) | Very Smooth | Decorative panels, high-end electronics |

| High (e.g., 125 µin) | Coarse / Textured | Industrial components, non-visible parts |

Passivation

Passivation is a chemical treatment. It creates a protective oxide layer on the copper’s surface. This layer significantly improves corrosion and tarnish resistance. For brushed copper, this step is essential for maintaining its appearance over time, especially in humid environments.

Yield Strength

This is a critical mechanical property. It defines the maximum stress a material can withstand before it starts to deform permanently. Knowing the Yield Strength10 is vital for any copper part that will be under load. It ensures the component won’t bend or fail in its application.

These terms—covering aesthetics, surface quality, durability, and structural integrity—are fundamental for specifying brushed copper parts. Mastering them ensures you get exactly what you designed, avoiding costly remakes and delays.

Top 5 CNC Finishing Techniques That Improve Brushed Copper Aesthetics

While a standard brushed copper finish is classic, we can elevate it. Advanced techniques add unique character and functionality. These methods enhance the copper CNC visual quality.

They allow for branding, texturing, or creating unique patterns. It’s about moving beyond the basic surface treatment. This customization can truly set a product apart. Let’s explore some powerful options for brushed copper finish enhancement.

| Technique | Primary Effect | Best For |

|---|---|---|

| Laser Marking | High-contrast surface marks | Logos, serials, patterns |

| Matte Brushing | Fine, non-reflective texture | Modern, subtle aesthetics |

| Patination | Controlled chemical aging | Antique, colored finishes |

To truly enhance a brushed copper part, we must understand the material’s properties. This knowledge guides our choice of finishing techniques, ensuring both beauty and durability.

Laser Marking for Precision

Laser marking is excellent for adding permanent details. It creates precise, high-contrast graphics or text without removing material. This is perfect for branding or adding serial numbers cleanly. The heat from the laser alters the surface, creating a mark that won’t wear off.

The Anodizing Misconception

Many clients ask about anodizing copper. It’s important to clarify: anodizing is an electrochemical process for metals like aluminum and titanium. It doesn’t work on pure copper because copper oxide is not a stable, protective layer. Applying this process would lead to poor results. This is a key technical detail we always discuss at PTSMAKE to ensure the right finish is selected. Some surface treatments can create similar colored effects through a different chemical patination11 process.

Matte Brushing for a Subdued Look

A matte brushed finish offers a sophisticated alternative. It uses a finer abrasive than standard brushing. The result is a soft, non-reflective surface. This finish hides fingerprints well and gives the brushed copper a modern, high-end feel.

Here’s a quick comparison of these advanced options:

| Feature | Laser Marking | Patination (Coloring) | Matte Brushing |

|---|---|---|---|

| Durability | Excellent | Varies, needs sealing | Good |

| Aesthetic | High-tech, precise | Artistic, aged | Modern, soft |

| Complexity | Moderate | High | Low |

| Use Case | Branding, identification | Decorative components | Architectural, consumer products |

These advanced techniques provide powerful ways to customize brushed copper parts. By understanding material limitations and aesthetic goals, we can select the perfect finish to enhance visual quality and add distinct character to any CNC-machined component.

Your Step-By-Step Guide To Partnering With A Trusted Brushed Copper Manufacturer

A true manufacturing partnership is built on more than just purchase orders. It requires a solid foundation of mutual understanding and clear expectations.

This is especially true for specialized work like brushed copper components.

Before you commit, it’s vital to define what a successful collaboration looks like for you. This clarity helps you ask the right questions and find a partner who aligns with your goals.

| Partnership Pillar | Key Expectation |

|---|---|

| Communication | Proactive & regular updates |

| Transparency | Clear cost and process visibility |

| Quality | Agreed-upon standards |

| Reliability | Consistent on-time delivery |

Setting these expectations early prevents misunderstandings down the road.

Laying the Groundwork for a Strong Partnership

When you’re ready to discuss specifics, your questions should be targeted. They help you gauge a manufacturer’s true capabilities beyond their sales pitch. This is a critical step in finding a trusted copper manufacturer China.

Probing Technical and Process Capabilities

Don’t just ask if they can make your part. Ask how. What specific equipment do they use for the brushing process? How do they ensure uniformity across a large batch of parts? Their answers reveal their expertise. This is where you separate general machine shops from specialists in brushed copper contract manufacturing.

A potential partner should be able to explain their entire process, from material sourcing to final inspection. For us at PTSMAKE, our process transparency is key. We operate a documented Quality Management System12 that ensures every step is controlled and repeatable.

Key Questions to Ask

Here are some questions I always recommend asking to get a clearer picture of a potential partner.

| Area of Inquiry | Sample Question |

|---|---|

| Material Control | "How do you verify the grade and purity of your copper stock?" |

| Finish Consistency | "What are your specific QC checks for the brushed finish texture and color?" |

| Project Management | "Who will be my single point of contact for project updates?" |

| Logistics & Shipping | "What are your standard procedures for packaging and international freight?" |

Their ability to answer these questions confidently is a strong indicator of their reliability.

Establishing clear expectations and asking detailed questions are crucial first steps. This initial diligence helps you select a reliable brushed copper manufacturing partner and builds a strong foundation for long-term success, preventing costly delays and quality issues.

Get Your Brushed Copper Parts Quote with PTSMAKE Today

Ready to elevate your next industrial project with premium brushed copper solutions? Contact PTSMAKE for a fast, precise quote on custom CNC machined brushed copper parts. Trust our expertise, reliability, and commitment to exceeding your specifications—from prototype to mass production. Send your RFQ now!

Learn how this electrochemical process can degrade metals and how to prevent it. ↩

Learn more about this chemical treatment and how it creates a protective, non-reactive surface. ↩

Understand how a material’s internal structure can influence the final surface finish of your parts. ↩

Learn about this common machining issue with soft metals and how to prevent it effectively. ↩

Understand how trapped gases can degrade sensitive components in vacuum or high-purity environments. ↩

Learn how this financial principle directly impacts your per-part cost and budget planning. ↩

Learn how specific pollutants chemically alter copper surfaces and impact long-term durability. ↩

Understand how stress points can cause unexpected part failure and learn how to design against them. ↩

Understand how this electrochemical process can impact your multi-metal designs. ↩

Learn more about how this critical material property influences part design and durability. ↩

Discover how chemical processes can create a range of unique, aged colors on copper surfaces. ↩

Learn how a certified QMS guarantees consistent quality and minimizes supply chain risks for your project. ↩