Fingerprint smudges and oil marks on manufactured parts create constant maintenance headaches and make even premium products look cheap and unprofessional. Every touch leaves visible traces that compromise product aesthetics and user experience.

Anti-fingerprint coating solutions use oleophobic nano-technologies and specialized surface treatments to create invisible barriers that repel oils and fingerprints, maintaining clean appearances on metal and plastic surfaces throughout product lifecycles.

This comprehensive guide covers everything from basic coating science to advanced application techniques. You’ll discover which coatings work best for different materials, how to specify finishes for CNC machined parts, and practical sourcing advice for working with coating suppliers.

The Ultimate Breakdown: What Is Anti-Fingerprint Coating Technology?

Ever wonder why your new phone stays so clean? The secret is an anti-fingerprint coating. This isn’t magic. It’s advanced surface science.

This technology creates a barrier. It stops oils from your fingers from sticking.

The Science in Simple Terms

Think of it as an invisible shield. This shield makes the surface slippery to oils. So, fingerprints wipe away easily. This results in fingerprint-resistant surfaces that stay pristine.

| Feature | Standard Surface | Coated Surface |

|---|---|---|

| Fingerprint Visibility | High | Low / None |

| Ease of Cleaning | Difficult | Very Easy |

| Oil Adhesion | Strong | Weak |

Let’s dive deeper into how this works. The magic lies in creating a surface with very low surface energy. This makes it difficult for oils and water to spread out and stick.

The Power of Nano-Coatings

At its core, an anti-fingerprint coating is a nano-scale layer. It’s incredibly thin, often just a few molecules thick. This layer changes the chemical properties of the surface without altering its appearance or feel. The goal is to create a perfect oleophobic treatment.

Key Application Methods

There are a few advanced ways to apply these coatings. The method depends on the product’s needs.

Oleophobic Surface Treatments

This process involves applying a chemical solution. The solution bonds to the surface. It creates a durable, oil-repellent monolayer1. It’s a common and effective method we’ve used in projects at PTSMAKE for consumer electronics.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

PECVD is a more complex process. It uses a plasma to deposit a very thin film from a gas state onto a surface. This method creates an extremely durable and uniform coating. It’s ideal for high-performance applications where reliability is critical.

This technology isn’t magic; it’s advanced science. By creating ultra-thin, oil-repelling layers, we make surfaces resistant to fingerprints. Key methods like oleophobic treatments and PECVD are crucial for achieving these high-performance, fingerprint-resistant surfaces.

Why Top Engineers Swear By Anti-Fingerprint Coatings For Product Durability

An anti-fingerprint coating is not just about looks. It is a crucial layer of defense for products.

Surfaces touched daily face constant exposure to oils and acids from our skin. Over time, this can degrade materials.

A Shield Against Wear

Durable coatings create a protective barrier. This barrier is often fingerprint-resistant. It prevents corrosive substances from reaching the surface material. This simple addition significantly extends a product’s functional and aesthetic life.

| Feature | Uncoated Surface | Anti-Smudge Coated Surface |

|---|---|---|

| Wear Resistance | Low | High |

| Chemical Exposure | Vulnerable | Protected |

| Lifespan | Shorter | Extended |

This protection ensures the product looks and feels new for much longer.

These coatings are essential in many high-stakes industries. Their value goes far beyond just preventing smudges. In our projects at PTSMAKE, we see how they are a non-negotiable feature for top-tier products.

Critical Use in Key Sectors

Consumer Electronics

Think about your smartphone or laptop. These devices are handled constantly. An anti-fingerprint coating ensures the screen remains clear and responsive. It also preserves the premium feel of the device’s casing.

Medical Devices

Here, cleanliness is paramount. A fingerprint-resistant coating on a medical monitor or diagnostic tool ensures displays remain readable. It also creates a smooth, easy-to-sterilize surface. The coating is often oleophobic2, repelling oils and preventing contaminant buildup.

Automotive Interiors

Modern cars rely on touchscreens for navigation and controls. A durable coating reduces distracting glare and smudges. This improves safety and maintains the clean, luxurious feel of the vehicle’s interior.

| Industry | Primary Application | Core Benefit |

|---|---|---|

| Electronics | Touchscreens, Casings | Clarity, Aesthetics |

| Medical | Monitors, Equipment | Hygiene, Readability |

| Automotive | Infotainment Displays | Safety, Premium Feel |

Anti-fingerprint coatings are more than a cosmetic touch-up. They are a functional necessity. They provide a protective layer that boosts product durability and user experience in electronics, medical devices, and automotive applications, ensuring longevity under constant daily use.

Complete Comparison: Anti-Fingerprint Coatings vs Traditional Surface Treatments

Choosing the right surface finish is critical. It impacts both appearance and function. While traditional methods are well-known, specialized fingerprint prevention coatings offer unique benefits.

Let’s look at their primary goals. Each treatment serves a distinct purpose. This quick surface finish comparison highlights their core strengths.

| Treatment Type | Primary Function |

|---|---|

| Anti-Fingerprint Coating | Smudge & Fingerprint Resistance |

| Anodizing | Corrosion & Wear Resistance |

| Painting | Aesthetics & Basic Protection |

| Physical Vapor Deposition (PVD) | Durability & Premium Finish |

This initial look shows a clear difference in intent.

When we dig deeper, the differences become even clearer. Traditional treatments aren’t designed to resist fingerprints. An anti-fingerprint coating, however, is engineered specifically for this.

Anodizing and Painting

Anodizing is great for aluminum durability. But it does little to prevent smudges. Painting offers color variety but often shows fingerprints easily, especially with glossy finishes. Both are applied through established industrial processes.

Anti-Fingerprint vs PVD

This is a common comparison we discuss with clients at PTSMAKE. PVD offers incredible hardness and a premium look. Some PVD finishes even have decent smudge resistance.

However, a dedicated anti-fingerprint coating is superior for cleanliness. It creates a special oleophobic3 surface that actively repels oils from human skin. The application is typically simpler and more cost-effective than PVD.

Here is a more detailed breakdown:

| Feature | Anti-Fingerprint Coating | Anodizing | Painting | PVD |

|---|---|---|---|---|

| Fingerprint Prevention | Excellent | Poor | Fair | Good |

| Application Method | Spray / Dip | Electrolytic Bath | Spray / Powder | Vacuum Deposition |

| Primary Benefit | Cleanliness | Durability | Color Options | Extreme Hardness |

| Relative Cost | Low to Medium | Medium | Low to Medium | High |

Ultimately, the best choice depends on your product’s main priority.

While traditional finishes like anodizing, painting, and PVD provide durability and color, they fall short in smudge prevention. A dedicated anti-fingerprint coating is the most effective solution for maintaining a clean, pristine surface appearance, often at a competitive cost.

The Expert Guide To Choosing Anti-Fingerprint Finishes For CNC Machined Parts

Applying an anti-fingerprint coating isn’t just a final step. Success depends on the technical groundwork. It starts with the part’s surface right after CNC machining.

Engineers must specify the correct surface finish. A surface that is too rough or too smooth can prevent the coating from adhering properly. It’s a delicate balance.

Surface Roughness Targets

For a metal anti-fingerprint coating, achieving the right surface roughness (Ra) is key. We’ve found that different coatings perform best within specific Ra ranges.

| Coating Type | Recommended Ra (μm) | Notes |

|---|---|---|

| PVD Coatings | 0.2 – 0.8 | Requires a smooth but not polished surface. |

| Clear Coats (AF) | 0.4 – 1.6 | Can tolerate slightly rougher surfaces. |

| Nano Coatings | < 0.4 | Needs a very smooth substrate for best results. |

Getting this right ensures the CNC finish has both looks and longevity.

After machining, the part isn’t ready for its CNC surface coating yet. Post-machining treatments are crucial for ensuring the finish lasts. This is a step we never skip at PTSMAKE.

Pre-Coating Preparation

The most important step is cleaning. Any residual cutting fluid, oils, or micro-debris will ruin the coating adhesion. This can lead to peeling or bubbling down the line. We use a multi-stage ultrasonic cleaning process for this.

The goal is to create a perfect foundation for the coating. This enhances the molecular bond, also known as interfacial adhesion4. A strong bond is everything for a durable finish.

Based on our tests, certain pre-treatments can significantly improve results. This is especially true for materials like aluminum or stainless steel.

Essential Post-Machining Steps

| Treatment | Purpose | Benefit |

|---|---|---|

| Degreasing | Removes oils and grease. | Prevents coating defects. |

| Etching | Creates a micro-profile. | Increases surface area for adhesion. |

| Priming | Adds an intermediate layer. | Promotes bonding with specific coatings. |

These steps ensure that the anti fingerprint coating performs as expected, protecting the part and maintaining its appearance for years.

Proper surface preparation, including roughness control and specific post-machining treatments, is critical. These steps ensure strong coating adhesion and the long-term performance of the anti-fingerprint CNC finish.

Top Anti-Fingerprint Coating Applications In Medical Device Design

In medical design, aesthetics and function are linked. A clean device inspires confidence.

This is especially true for surfaces. Fingerprints can suggest contamination.

That’s why an anti fingerprint coating is so important. It maintains a pristine appearance on critical equipment.

Key Application Areas

We see these coatings in three main areas. Each has unique benefits. They improve hygiene and user experience.

| Application Area | Primary Benefit | User Impact |

|---|---|---|

| Surgical Tools | Maintained Sterility | Higher Surgeon Confidence |

| Diagnostic Equipment | Uninterrupted Operation | Increased Accuracy & Reliability |

| Consumer Devices | Enhanced User Trust | Better Patient Compliance |

The need for fingerprint-free surfaces goes much deeper than just looking clean. It’s about safety and performance.

In an operating room, a surgeon relies on clear visuals. A smudge on an endoscope lens can be a serious problem. It could obstruct the view at a critical moment.

Healthcare-grade coatings are designed to be extremely repellent. They have high oleophobicity5, which means they resist oils from skin. This makes surfaces much easier to clean and sterilize.

This isn’t just a feature; it’s a crucial safety layer. In past projects at PTSMAKE, we’ve helped clients select finishes that improve device safety and reduce maintenance.

Enhancing Performance and Trust

For diagnostic tools with touchscreens, smudges can cause input errors. This can compromise test results. An anti fingerprint coating ensures the interface is always clear and responsive.

This same principle applies to home-use devices. A clean, premium feel builds patient trust.

| Device Type | Challenge without Coating | Solution with Coating |

|---|---|---|

| Surgical Endoscope | Obscured vision, difficult to clean | Clear optics, easier sterilization |

| Lab Analyzer | Touchscreen errors, cross-contamination | Accurate inputs, improved hygiene |

| Home Health Monitor | Perceived as unhygienic, low quality | Builds user trust, feels premium |

Anti-fingerprint coatings are a vital component in modern medical device design. They ensure surgical and diagnostic tools remain clean and accurate, while also building user trust in consumer-facing products. These medical coatings directly enhance both functionality and safety.

Secrets To Fingerprint-Free Appearance In High-End Electronics

As a product designer, you focus on the user experience. An anti-fingerprint finish is not just a feature; it’s a promise of lasting beauty and a clean feel. Your design’s success depends on it.

Aesthetic Consistency is Key

Maintaining a consistent look is crucial. The chosen finish must not alter the original color or gloss level of your device. It needs to look perfect from every angle.

Gloss Level and Feel

The tactile response is as important as the visual. A smudge-proof finish should feel premium, not slippery or sticky.

| Finish Type | Gloss Retention | Tactile Feel |

|---|---|---|

| Matte AF Coating | High | Smooth, silky |

| Gloss AF Coating | Medium | Clean, slick |

| Textured Finish | Excellent | Varies |

This balance ensures your product looks and feels high-end throughout its life.

For premium devices, the user’s first touch sets the tone. An anti-fingerprint coating directly impacts this crucial interaction, defining the product’s perceived quality. It’s about more than just preventing smudges.

Retaining Surface Clarity

The primary goal is maintaining pristine surface clarity. The coating must be optically clear, especially for displays and camera lenses. Any haze or distortion ruins the user experience. The chemistry of the coating is designed for this.

We’ve seen that a coating’s oleophobicity6 is a key factor. It’s the surface’s ability to repel oil. A higher rating means fingerprints bead up and wipe away easily, rather than smearing.

Long-Term Durability

Aesthetic consistency must last. The anti-fingerprint coating needs to withstand daily wear, cleaning agents, and environmental factors. In our client projects at PTSMAKE, we test for abrasion resistance to ensure the finish doesn’t wear off prematurely.

| Durability Test | Target Metric | Importance |

|---|---|---|

| Steel Wool Abrasion | > 5,000 cycles | High |

| Chemical Resistance | No change after 24hr | Critical |

| UV Exposure | Minimal color shift | High |

This level of testing ensures the smudge-proof finish performs from day one to the end of the product’s lifecycle.

Achieving a flawless, fingerprint-free surface requires a careful balance of aesthetic consistency, durable surface clarity, and a premium tactile response. The right anti-fingerprint coating, paired with rigorous testing, is essential for a high-end electronic device’s success and long-term user satisfaction.

How To Eliminate Fingerprint Issues On Brushed Aluminum And Stainless Steel

Fingerprints on brushed aluminum and stainless steel are a constant battle. This is especially true for appliances, automotive parts, and electronic enclosures.

The good news is that we can solve this problem. Specialized coatings offer a lasting metal anti-smudge solution. They create a protective barrier.

Choosing the Right Method

Simple cleaning offers a temporary fix. But a professional brushed aluminum coating provides permanent stainless fingerprint prevention. It preserves the premium look without constant wiping.

| Method | Effectiveness | Duration |

|---|---|---|

| Regular Cleaning | Low | Short-Term |

| Wax/Polish | Medium | Medium-Term |

| Professional Coating | High | Long-Term |

Fighting smudges goes beyond simple cleaning. The real, long-term solution lies in advanced surface treatments. At PTSMAKE, we often guide clients toward an effective anti fingerprint coating. This is crucial for high-touch products.

Advanced Coating Technologies

Two primary options stand out for their effectiveness. Each has unique benefits depending on the application and budget.

Physical Vapor Deposition (PVD)

PVD is a process that applies a very thin, durable film. This method is excellent for automotive parts that need to withstand harsh conditions. It changes the surface properties to resist oils and dirt effectively.

Clear Coat Solutions

A more common approach is applying a specialized clear coat. An Oleophobic coating7 is a fantastic example. It actively repels the oils found in fingerprints. Our tests show this can reduce smudge visibility by over 80%.

| Coating Type | Key Benefit | Ideal Application |

|---|---|---|

| PVD Coating | Extreme Durability | High-Wear Automotive Parts |

| Clear Anti-Smudge | High Repellency | Consumer Electronics, Appliances |

For high-end consumer electronics and appliances, a specialized clear anti fingerprint coating provides a practical and lasting solution. It maintains the original aesthetic of the brushed metal while making it easy to clean and resistant to smudges.

Specialized coatings offer a superior, long-term fix for fingerprints on metal surfaces. Moving beyond temporary cleaning to advanced solutions like PVD or clear coats ensures a lasting pristine appearance for appliances and automotive parts.

The Role Of Anti-Fingerprint Coatings In UI/UX Hardware Design

A device’s first touch is critical. It shapes the user’s perception of quality. An anti-fingerprint coating directly impacts this moment.

The First Impression: Usability and Perceived Quality

Smudges make a product feel cheap and neglected. A clean surface, however, signals premium quality and careful design. This is key for any hardware UX surface.

This coating isn’t just about aesthetics. It improves how a user interacts with the screen.

Impact on Different Devices

| Device Type | Without Coating | With Anti-Fingerprint Coating |

|---|---|---|

| Touchscreen | Greasy, poor glide | Clean, smooth swipe |

| HMI Panel | Hard to read, dirty | Clear visibility, professional |

| Portable Device | Looks worn out quickly | Maintains new look |

A better user interface coating leads to a better product experience.

Beyond Cleanliness: The Tactile and Functional Impact

The feel of a surface is a core part of anti-fingerprint tactile design. It’s not just what you see, but what you feel. The right user interface coating reduces friction, making every swipe smoother and more precise.

This is vital for Human-Machine Interface (HMI) panels. In industrial or medical settings, a mis-tap can be a serious issue. A low-friction surface helps ensure accurate input.

Durability Meets Design

A great coating also needs to last. We focus on solutions that withstand repeated use. The coating’s oleophobicity8 must remain high throughout the product’s lifecycle. A worn-out coating degrades the entire user experience.

At PTSMAKE, we help clients select coatings that balance feel, durability, and cost. It’s a key decision in product development.

Coating Properties and Their UX Benefit

| Property | User Experience Benefit |

|---|---|

| Low Friction | Effortless swipes and gestures. |

| High Durability | Consistent feel over time. |

| Smudge Resistance | Enhanced visual clarity. |

| Easy to Clean | Low maintenance for the user. |

Choosing the right anti fingerprint coating is an investment in user satisfaction. It directly impacts hardware UX surface performance.

In short, anti-fingerprint coatings are essential for modern hardware design. They elevate a product’s usability and perceived quality by improving visual clarity and tactile feedback, ensuring a premium user experience from the very first touch.

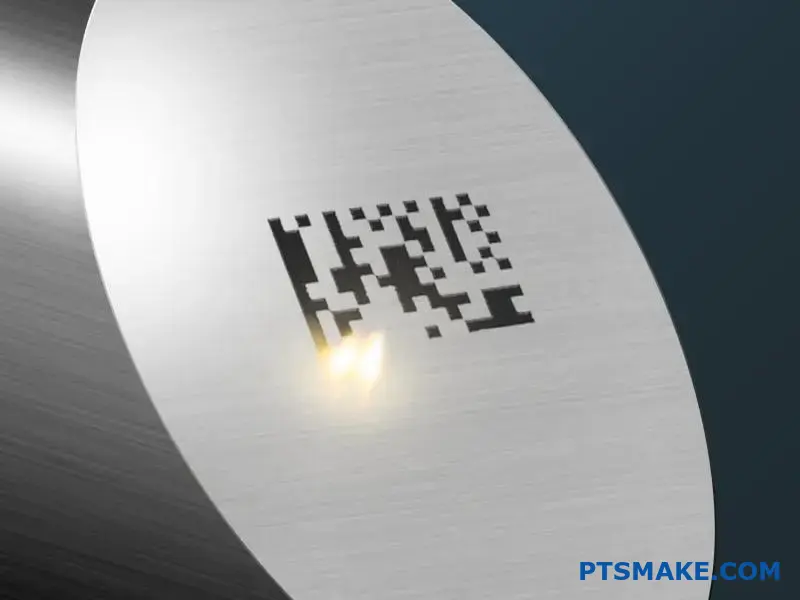

Laser Marking On Anti-Fingerprint Surfaces: What You Need To Know

Not all anti-fingerprint coatings are compatible with laser marking. The wrong combination can lead to poor results. This affects your branding and traceability efforts.

We need durable, high-contrast marks. The key is understanding how the laser interacts with the specific coating. Some vaporize cleanly, while others melt or discolor. This choice impacts the final quality of your laser engraved anti-smudge surface.

Coating Compatibility Overview

| Coating Type | Laser Compatibility | Marking Quality |

|---|---|---|

| PVD Coating | Excellent | High Contrast, Clean Edges |

| AF Spray Coating | Variable | Requires Testing |

| Nano-coating | Good | Consistent, Sharp Marks |

Achieving durable laser marking on these surfaces is a precise science. The laser must cleanly remove the anti-fingerprint layer without damaging the substrate. The goal is a permanent mark for branding or coated surface ID marking.

Optimizing for Different Coatings

PVD (Physical Vapor Deposition) Coatings

These coatings are thin, hard, and uniform. They are ideal for laser marking. The laser energy causes a clean ablation9 of the coating. This exposes the metal underneath for a sharp, high-contrast mark.

Sprayed-On Oleophobic Coatings

These can be more challenging. Their thickness and chemical makeup vary greatly. In some of our past projects at PTSMAKE, we found that improper laser settings can cause these coatings to melt. This creates a blurry or raised edge instead of a clean engraving.

We always recommend testing. Fine-tuning the laser’s power, speed, and frequency is critical. This ensures the mark is clear and permanent, which is essential for QR codes or serial numbers.

| Parameter | PVD Coating Effect | Sprayed Coating Effect |

|---|---|---|

| High Power | Fast, clean removal | Risk of melting, burning |

| High Speed | Sharper detail | May not fully remove coating |

| Frequency | Controls heat input | Crucial for avoiding damage |

The compatibility between your anti fingerprint coating and the laser process is critical. PVD coatings offer reliable, high-quality results. Sprayed coatings demand precise parameter control to achieve the clean, durable marks necessary for branding and long-term traceability.

Plastic Vs Metal Surfaces: Which Benefit More From Fingerprint Protection?

When comparing plastic and metal, the question isn’t which is better, but which is right for the job. Both materials gain significant advantages from an anti fingerprint coating.

The choice often depends on the product’s end-use and desired aesthetic. Each material interacts with coatings differently.

Coating Performance on Different Substrates

We’ve observed distinct results in our tests. Metal often shows smudges more prominently, especially when polished. Plastic can hide them better, but a coating elevates its look and feel.

| Feature | Plastic Casings | Metal Housings |

|---|---|---|

| Smudge Visibility | Lower on textured surfaces | Higher on smooth, polished finishes |

| Coating Goal | Enhance feel, add durability | Maintain premium look, prevent tarnish |

| Cost-Effectiveness | Generally a lower-cost upgrade | Adds significant value to high-end products |

The effectiveness of an anti-smudge coating is deeply tied to the material underneath. The surface energy and texture of plastic versus metal create different challenges and opportunities for coating application.

Use-Cases and Substrate Sensitivity

The interaction between the coating and the surface is critical. This is where substrate sensitivity10 comes into play. Metals are non-porous and require excellent chemical bonding for the coating to adhere properly.

Plastics, however, can vary widely. Some grades are more porous, which can aid mechanical adhesion. In past projects at PTSMAKE, we’ve guided clients toward specific plastic composites that are optimized for coating.

This choice directly impacts the product’s longevity and user experience.

Real-World Applications

Consider a high-end aluminum laptop versus a durable plastic TV remote. The laptop’s metal housing needs a robust anti fingerprint coating to maintain its sleek look under constant handling.

The remote benefits from a coating that improves grip and resists oils from hands over years of use. Each application leverages the plastic coating benefit or minimizes metal surface smudging based on its unique needs.

| Product Example | Primary Material | Key Coating Benefit |

|---|---|---|

| Smartphone Frame | Anodized Aluminum | Resists smudging and corrosion |

| Gaming Controller | ABS Plastic | Improves tactile feel and wear resistance |

| Kitchen Appliance | Stainless Steel | Hides fingerprints and simplifies cleaning |

| Medical Device | Polycarbonate | Ensures cleanliness and chemical resistance |

Both plastics and metals see huge improvements with the right anti fingerprint coating. The best choice depends entirely on the product’s specific requirements, from aesthetic goals to functional demands. The key is matching the coating technology to the substrate.

Design Secrets: Optimal Surface Finishes For Fingerprint Resistance

A pristine product can be ruined by a single touch. Fingerprints instantly cheapen a high-end feel. This is a constant battle in product design.

The secret isn’t just cleaning. It’s choosing the right surface finish from the start. This decision balances looks with daily use.

Gloss Level and Smudge Visibility

A finish’s gloss level is the main factor. High-gloss surfaces reflect light uniformly. This makes oil from fingerprints very obvious. Matte finishes scatter light, hiding smudges effectively.

| Finish Type | Fingerprint Visibility | Common Use Case |

|---|---|---|

| High Gloss | Very High | Decorative panels, display screens |

| Semi-Gloss | Moderate | Consumer electronics, car interiors |

| Matte | Very Low | Handheld devices, high-touch tools |

Selecting the right finish ensures a lasting visual clean design.

The choice between matte and gloss is just the beginning. The real magic happens at a microscopic level. An anti-smudge surface texture is key.

The Power of Micro-Textures

Micro-textures create an uneven surface. These tiny peaks and valleys scatter light in multiple directions. This diffusion makes it difficult for the eye to see the uniform oil deposit of a fingerprint.

In our work at PTSMAKE, we often recommend textures from the SPI (Society of the Plastics Industry) scale. A light bead-blast texture (like an SPI-C1) is far better at hiding prints than a mirror-smooth SPI-A1 finish. The texture breaks up the specular reflection11 that makes smudges stand out.

Aligning Look with Usability

Designers often want a sleek, glossy look. But for a handheld device, that can be a usability nightmare. We must find a balance.

Sometimes, a targeted approach works best. Use a glossy finish on low-touch areas for visual pop. Then, apply a matte or textured finish on areas where users interact most. This creates a practical yet beautiful product. Some advanced textures can even mimic the performance of an anti fingerprint coating.

Here’s how different textures compare based on our test results:

| Texture Type | Smudge Resistance | Tactile Feel | Cost Impact |

|---|---|---|---|

| Smooth (SPI-A) | Poor | Slick | High (polishing) |

| Light Bead-Blast (SPI-C) | Good | Grippy | Low |

| Heavy Etch (SPI-B) | Excellent | Rough | Moderate |

By considering these factors early, you create a product that looks great on day one and day one hundred.

Choosing the right surface finish is a critical design step for fingerprint resistance. Matte and micro-textured surfaces effectively hide smudges by scattering light, unlike glossy finishes that highlight them. This choice directly impacts long-term product appearance and user satisfaction.

How To Avoid Yellowing Or Degradation In Fingerprint-Resistant Finishes

A pristine finish that yellows or degrades over time is a product failure. The long-term appearance is just as critical as its initial look.

Long-Term Environmental Threats

Your product’s finish faces constant attack. The primary culprits are often invisible until the damage is done.

UV Radiation and Oxidation

Sunlight and even indoor lighting emit UV rays. These, combined with oxygen, can break down a coating’s chemical structure. This process leads to coating discoloration and a loss of protective properties. A durable cosmetic finish must be formulated to resist these elements effectively.

| Feature | Standard Coating | UV-Resistant AFP Coating |

|---|---|---|

| Color Stability | Low (Yellows over time) | High (Maintains original color) |

| Surface Integrity | Prone to cracking/peeling | Resists environmental degradation |

| Expected Lifespan | 1-2 Years | 5+ Years |

Ensuring a durable cosmetic finish goes beyond the coating itself. It requires a holistic approach, starting from material selection and continuing through to final maintenance.

Proactive Strategies for Longevity

The best defense is a good offense. We must plan for environmental exposure from the very beginning of a project.

Selecting the Right UV-Resistant Anti-Fingerprint Coating

At PTSMAKE, we guide clients in choosing the correct formulation. We ask: Will the part be used outdoors? Will it sit under direct office lighting? The answers determine the level of UV resistance needed. This is crucial because photo-oxidation12 is a key factor in coating failure. This chemical reaction breaks down the polymer chains in the finish, leading to visible degradation. A superior anti fingerprint coating contains UV inhibitors and stabilizers to neutralize this effect.

The Importance of Maintenance

Even the most robust coatings benefit from proper care. Simple guidelines can dramatically extend the life and appearance of the finish. Harsh chemicals or abrasive cleaners can strip away the protective top layer, accelerating wear.

| Maintenance Task | Frequency | Best Practice |

|---|---|---|

| Routine Wiping | Weekly | Use a dry, soft microfiber cloth. |

| Spot Cleaning | As needed | Damp cloth with a pH-neutral cleaner. |

| Chemicals to Avoid | Always | Solvents, ammonia-based cleaners, abrasives. |

Preventing coating discoloration requires selecting a robust UV-resistant anti-fingerprint coating and implementing a simple maintenance routine. This dual strategy effectively combats long-term risks like oxidation, ensuring a durable cosmetic finish that lasts for years.

Are Anti-Fingerprint Coatings Eco-Friendly? Here’s The Truth

When you choose an anti-fingerprint coating, you are also making an environmental choice. Not all coatings are created equal. The key is to look at their formulation.

Many older coatings release harmful compounds. Today, conscious buyers demand better options.

Sustainable Coating Formulations

We always push for greener solutions at PTSMAKE. This means focusing on coatings with minimal environmental impact. Water-based formulas are a great step forward. They replace harsh chemical solvents.

The VOC Concern

Volatile Organic Compounds (VOCs) are a major issue. They are gases emitted from certain solids or liquids. Low-VOC coatings are essential for a safer workplace and a healthier planet.

Here’s a quick comparison:

| Coating Type | VOC Content | Environmental Impact |

|---|---|---|

| Traditional Solvent-Based | High | Significant |

| Modern Low-VOC | Low to None | Minimal |

This shift towards green fingerprint protection is not just a trend; it’s a responsibility.

The eco-friendliness of an anti fingerprint coating goes beyond its application. We must consider its entire lifecycle, from production to disposal. At PTSMAKE, we guide clients through these important details for sustainable product design.

Low-VOC Coating Options

The biggest move towards an eco-friendly surface treatment is reducing Volatile Organic Compounds13. These compounds contribute to air pollution. In past projects, we have successfully switched clients to low-VOC or zero-VOC alternatives.

These options perform just as well without the negative side effects. They are safer for our teams and for the end-user. It’s a win-win situation.

Recyclability and Removal

What happens at the end of a product’s life? This is a question we must ask. An eco-friendly coating shouldn’t complicate recycling. The ideal coating can be removed without using harsh chemicals.

This ensures the substrate material, like metal or plastic, can be easily reclaimed. We factor this into our recommendations.

| Aspect | Traditional Coating | Eco-Friendly Coating |

|---|---|---|

| Formulation Base | Solvent-based | Water-based or high-solids |

| VOC Level | High | Low or Zero |

| End-of-Life | Difficult to remove/recycle | Easier removal, aids recycling |

Choosing a truly green fingerprint protection means looking at the full picture. It’s about making choices that align with long-term sustainability goals.

Choosing an eco-friendly anti-fingerprint coating means looking at its formulation, VOC content, and end-of-life recyclability. These factors are critical for any company committed to sustainability and responsible manufacturing.

Understanding MOQ And Lead Times For Custom Coated Parts

Planning for custom coated parts requires understanding two key factors. These are Minimum Order Quantity (MOQ) and lead times. They directly impact your project’s budget and timeline.

MOQs exist because of initial setup costs. Every new batch needs machine calibration and material preparation. These fixed costs make very small runs impractical.

Realistic Timelines

Custom-coating lead times vary. Simple projects might take a few weeks. Complex jobs with special requirements, like a new anti-fingerprint coating, will take longer. Good coating production planning is essential.

Below is a general idea of batch sizes.

| Batch Size | Unit Cost Impact | Best For |

|---|---|---|

| Small (e.g., <500) | Highest | Prototypes, testing |

| Medium (e.g., 500-5,000) | Moderate | Early production |

| Large (e.g., >5,000) | Lowest | Mass production |

Always discuss your specific needs with your partner.

Let’s dive deeper into what drives these numbers. A significant part of the cost for any custom coating job is the initial setup. This isn’t just about flipping a switch.

Breaking Down Setup Costs

Setup involves several steps. First, we clean and prepare the equipment for the specific coating chemistry. This prevents contamination. Second, we mix and quality-check the coating material itself. Finally, we calibrate the application machinery for your part’s geometry.

These steps create a fixed cost. This cost is the same whether we coat 100 parts or 10,000 parts. This is why the anti-fingerprint MOQ is important. A higher quantity allows the setup cost amortization14 to be spread across more units. This drastically lowers the price per part.

Factors Influencing Lead Times

Lead time isn’t just production time. It’s the entire process from order to delivery. At PTSMAKE, we map this out clearly for our clients to ensure there are no surprises.

Here’s a typical breakdown of custom-coating lead times:

| Stage | Typical Duration | Notes |

|---|---|---|

| Quoting & Approval | 1-3 Business Days | Depends on project complexity. |

| Material Prep | 3-5 Business Days | Ordering and preparing substrates and coatings. |

| Production Run | 5-10 Business Days | Includes coating, curing, and finishing. |

| Quality Control | 1-2 Business Days | Thorough inspection and testing. |

| Packing & Shipping | 2-5 Business Days | Varies based on location and method. |

This timeline is a guide. Complex geometries or multi-layer coatings can add time.

Understanding MOQs and lead times is crucial for successful project management. Factoring in setup costs and production stages prevents budget overruns and delays, ensuring your custom coated parts arrive on time and within your financial plan.

Optimizing Anti-Fingerprint Coating Adhesion On 3D Curves

Applying an anti-fingerprint coating to a flat surface is one thing. But achieving flawless fingerprint curve adhesion on 3D surfaces is a different game entirely.

Ergonomic parts, with their complex curves, present unique challenges. The goal is a uniform layer. One that resists peeling and distortion.

This requires precision at every step.

The Curved Part Challenge

On contoured surfaces, liquid coatings can pool in valleys. They can also become too thin on peaks. This inconsistency is a primary cause of failure. It creates stress points, leading to cracks or peeling.

Best Practices for Application

Achieving a durable 3D surface coating relies on technique. Controlling the spray angle, distance, and speed is critical. Automation often provides the consistency that manual application cannot. This ensures a uniform film thickness across the entire part.

| Parameter | Best Practice on Curves | Impact of Error |

|---|---|---|

| Spray Angle | Perpendicular to surface tangent | Uneven thickness, runs |

| Speed | Consistent robotic motion | Thin spots or pooling |

| Distance | Maintained uniformly | "Orange peel" or dry spray |

Mastering coating on complex geometries separates the experts from the amateurs. The curved part challenges go beyond just applying the coating. It’s about understanding the physics at play.

Surface Dynamics and Coating Stress

The success of an anti-fingerprint coating on a curve is dictated by material science. Factors like the coating’s viscosity and the substrate’s surface energy15 are crucial. If the surface energy is too low, the coating won’t wet the surface properly. This leads to poor adhesion from the start.

Another major issue is internal stress. As the coating cures, it shrinks slightly. On a flat surface, this stress is distributed evenly. On a curve, stress concentrates at the sharpest points. This can cause the coating to pull away or delaminate over time.

At PTSMAKE, we address this through a multi-step process.

Our Approach

First, we carefully select a coating formulation. It must be compatible with the substrate material. Then, we optimize the application parameters using robotic arms. This ensures an even layer, minimizing stress concentration. The curing process is also tightly controlled. We use specific temperature and humidity profiles. This reduces shrinkage-induced stress.

| Technique | Advantage for 3D Surfaces | Common Pitfall |

|---|---|---|

| Automated Spraying | High consistency and repeatability | Requires complex programming |

| Dip Coating | Excellent for complex internals | Can lead to drips or uneven thickness |

| Flow Coating | Good for large, gentle curves | Less precise for sharp angles |

This methodical approach is how we ensure robust fingerprint curve adhesion. It prevents field failures and maintains the aesthetic quality of the final product.

Proper surface preparation and precise application are key to durable 3D surface coating. Understanding material interactions prevents peeling and ensures the anti-fingerprint coating performs flawlessly on ergonomic and contoured parts.

How To Communicate Coating Expectations With Your China-Based Supplier

Sourcing an anti-fingerprint coating from China requires more than a simple request. Clear communication is your most critical tool. Misunderstandings can lead to delays and quality issues.

Why Precision Matters

Vague language creates risk. Your supplier might interpret your needs differently. This can affect the final product’s performance and appearance. Specificity is essential from the start.

The Role of Documentation

Your Request for Quotation (RFQ) sets the stage. It must be detailed. Include all technical specifications for the coating. This helps avoid confusion.

A clear RFQ should contain:

| RFQ Element | Description |

|---|---|

| Coating Type | Specify "Anti-Fingerprint (AF) Coating" |

| Performance | Contact Angle, Hardness (e.g., 9H) |

| Thickness | Target thickness in micrometers (µm) |

| Testing Method | How performance will be verified |

This clarity in your initial communication, especially in the anti-smudge RFQ language, is crucial.

Working with China-based suppliers is about building a partnership. This partnership relies on mutual understanding, which goes beyond technical documents. You need to account for cultural and communication differences.

Bridging the Communication Gap

Written specifications are vital, but they are not everything. What seems obvious to you might not be to your supplier. Nuances can get lost in translation.

That’s why we always emphasize visual aids and physical standards. In our experience at PTSMAKE, sending a "golden sample" that meets your exact expectations is invaluable. This becomes the benchmark for quality.

From Theory to Reality

A spec sheet can define technical properties like Oleophobicity16, but it can’t fully capture the desired look and feel. Your supplier needs to see and touch what you want.

Here’s how to provide better instructions in your China supplier coating spec:

| Vague Instruction | Specific Instruction |

|---|---|

| "Good anti-fingerprint" | "Water contact angle >110°, steel wool test pass" |

| "Durable coating" | "9H pencil hardness, 5000 cycles abrasion test" |

| "Nice smooth feel" | "Provide a physical ‘limit sample’ for texture" |

This level of detail, combined with sampling, removes ambiguity. It ensures your supplier understands exactly what to deliver for your anti-fingerprint coating needs. Good sourcing communication tips always start with clarity.

Clear documentation, cross-cultural awareness, and physical samples are non-negotiable. They are the three pillars for successfully communicating your coating expectations and ensuring your supplier in China delivers exactly what you need for your project.

Your Blueprint for Success

Effective communication is the foundation of any successful manufacturing partnership. It’s not just about sending a PO; it’s about building a shared understanding of the final goal. When you define your anti-fingerprint coating specs clearly, provide visual standards, and approve physical samples, you create a clear path to success. This proactive approach minimizes risks and builds trust.

At PTSMAKE, we manage this entire process for you. We bridge the communication gap, ensuring your specifications are perfectly understood and executed. We believe that trust makes everything simple, and clear communication is how we build that trust from day one.

Frequently Asked Questions

What is the most common mistake when specifying coatings to a China supplier?

The most common mistake is being too vague. Using subjective terms like "good" or "durable" without providing measurable data or physical samples is a recipe for misunderstanding. Always provide quantifiable metrics and approved samples.

How many samples should I request before mass production?

We recommend a multi-stage sampling process. First, request initial engineering samples (T1) to verify the process. After adjustments, get a final pre-production "golden sample" for approval. This sample becomes the quality standard for the entire production run.

Can I specify a certain brand of coating material?

Yes, absolutely. If you have a preferred material or brand for your anti-fingerprint coating, include it in your RFQ. This is one of the best ways to ensure consistency and performance, leaving no room for interpretation.

Real-World Case Studies: Anti-Fingerprint Coating Success Stories

Theory is one thing. Seeing results is another. Let’s look at a real fingerprint problem fix.

A client developing a premium audio player faced a major issue. Their device’s sleek, matte black finish was a fingerprint magnet.

This ruined the high-end feel right out of the box. Our anti-smudge solution story began here. We applied a thin anti-fingerprint coating. The difference was immediate.

| Challenge | Solution | Outcome |

|---|---|---|

| Constant smudges | Anti-fingerprint coating | Pristine, premium appearance |

| Negative user perception | Easy-to-clean surface | Increased customer satisfaction |

A Focus on Functionality: Medical Devices

Another case study involves a medical diagnostics tablet. Here, function was more critical than aesthetics.

Nurses and doctors needed a clear view of vital data at all times. Smudges from constant handling were a serious problem.

They obscured the screen and raised hygiene concerns. The challenge was finding a durable coating. It needed to withstand frequent cleaning with harsh chemicals.

We worked with the client to select a robust anti fingerprint coating. This coating provided excellent oleophobic17 properties. The result was a screen that stayed clear longer.

It was also much easier to sanitize between uses. This fingerprint problem fix directly improved usability and safety in a clinical setting. This is a perfect anti-smudge solution story.

| Sector | Initial Problem | Coating Solution | Key Improvement |

|---|---|---|---|

| Medical | Obscured screen, hygiene risk | Durable, chemical-resistant AF | Enhanced clarity & safety |

| Public Kiosk | Poor user experience, wear | High-endurance AF coating | Maintained look, reduced wear |

These case studies show how an anti-fingerprint coating is a versatile fix. It enhances luxury consumer products and improves safety on critical medical devices. The right application solves both aesthetic and functional challenges, providing a real anti-smudge solution.

Discover PTSMAKE’s Anti-Fingerprint Expertise for Your Next Project

Ready to enhance your CNC or injection molded parts with premium anti fingerprint coating solutions? Contact PTSMAKE today for a fast, no-obligation quote and leverage our expertise to achieve flawless, durable, and fingerprint-resistant finishes on your next precision hardware project. Send your RFQ now!

Explore how these single-molecule layers are engineered for maximum performance and durability. ↩

Discover the science behind how this property repels oils and keeps surfaces pristine. ↩

Understand the science of how these advanced surfaces repel oils and fingerprints. ↩

Learn the science behind how coatings bond to metal surfaces for better finish specification. ↩

Discover the science behind how surfaces can repel oil and fingerprints for superior performance. ↩

Learn the science of how surfaces repel oils to perfect your anti-fingerprint electronics design. ↩

Learn more about how this oil-repelling technology keeps surfaces clean. ↩

Discover the science of oil-repellent surfaces and their role in creating a flawless user experience. ↩

Understand the technical process of how lasers remove material for precise marking and engraving. ↩

See how a material’s surface properties impact coating performance and durability. ↩

Learn the science of how light reflection makes fingerprints so visible on smooth surfaces. ↩

Understand the science of how light and oxygen can break down materials. ↩

Understand the specific impact of VOCs on air quality and how to select safer materials for your projects. ↩

Learn how spreading costs over larger volumes can significantly reduce your per-unit price. ↩

Discover how this critical property influences coating adhesion on any surface. ↩

Learn how this key metric defines a coating’s resistance to oils and fingerprints. ↩

Learn the science behind how this property repels oils and keeps surfaces clean. ↩