Your precision components need flawless performance for years, but standard finishes often fail when exposed to corrosion, wear, or electrical interference. This leads to costly part replacements, system failures, and unhappy customers who expect reliability.

Gold plating provides superior corrosion resistance, excellent electrical conductivity, and long-term durability for precision components. It offers the most reliable surface finish for critical applications in aerospace, medical devices, electronics, and robotics where performance cannot be compromised.

I’ll walk you through everything you need to know about gold plating for precision manufacturing. You’ll learn optimal thickness specifications, material compatibility requirements, cost analysis methods, and industry compliance standards that ensure your components perform exactly as designed.

Why Gold Plating Is The Secret To Long-Term Performance

When we talk about gold, luxury often comes to mind. But in precision manufacturing, gold plating is all about performance. It’s a critical finish for components that must function flawlessly for years.

The secret lies in two key gold plating benefits.

Unbeatable Corrosion Resistance

Gold is exceptionally non-reactive. This property creates a durable barrier against oxidation and environmental corrosion. Components last longer, even in harsh conditions.

Superior Electrical Conductivity

For electronics, consistent signal integrity is key. Gold plating provides a stable and reliable surface for electrical connections, preventing signal loss over time.

| Plating Material | Corrosion Resistance | Electrical Conductivity |

|---|---|---|

| Gold (Au) | Excellent | Excellent |

| Nickel (Ni) | Good | Moderate |

| Tin (Sn) | Moderate | Good |

The long-term performance benefits of gold plating are rooted in its fundamental chemical properties. Gold is a noble metal, meaning it strongly resists chemical action, corrosion, and oxidation. This inertness is a significant advantage over other materials.

The Science of Durability

Unlike metals that form an oxide layer, gold remains pure and unblemished. This prevents the gradual degradation that plagues many components. At PTSMAKE, we often recommend it for parts exposed to moisture or corrosive agents. This ensures the component’s integrity is maintained.

This is especially vital in sensitive electronic and medical devices. A stable, clean connection surface is non-negotiable. The process of electrolytic deposition1 ensures a uniform and durable gold layer is applied.

Why Conductivity Matters Long-Term

While other metals are conductive, they can tarnish over time. This tarnish increases electrical resistance, leading to performance issues or even failure. Gold plating benefits components by maintaining low contact resistance for the product’s entire lifecycle. This reliability is why it’s a standard in high-end connectors and contacts.

| Application Environment | Key Gold Plating Benefit | Impact on Performance |

|---|---|---|

| High-Humidity | Prevents moisture damage | Ensures consistent operation |

| Marine / Salty Air | Resists salt corrosion | Extends component lifespan |

| High-Frequency Electronics | Maintains signal integrity | Reduces data loss and errors |

Gold plating offers unmatched long-term performance through its dual advantages. It provides a superior barrier against corrosion and ensures stable, reliable electrical conductivity. These qualities make it an essential finish for critical components where failure is not an option.

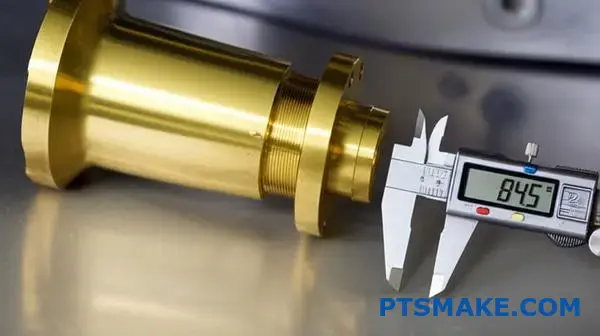

Critical Tolerances: How Gold Plating Affects Dimensional Accuracy

When we talk about CNC machined parts, precision is everything. A few microns can make all the difference. Gold plating adds a new layer to this equation.

It’s not just a coating; it’s added material. This material directly impacts the final dimensions of your part.

The Impact of Plating Thickness

Even a thin layer of gold changes a part’s size. For tight-tolerance parts, this change must be accounted for in the initial design. Otherwise, the final product won’t fit or function correctly.

| Plating Spec | Thickness Added (Per Side) | Impact on a 10.000 mm Shaft |

|---|---|---|

| Commercial Grade | 0.8 µm | 10.0016 mm |

| Precision Grade | 0.2 µm | 10.0004 mm |

Understanding these plating thickness tolerances is the first step toward success.

Gold plating adds significant value, but it also introduces variability. The thickness of the gold layer is not just a single number; it’s a range. This is a critical factor for gold plating on tight-tolerance parts.

The Challenge of Uniformity

Achieving a perfectly uniform coating is difficult. Sharp corners might attract more plating, while internal features may receive less. This is a natural result of the electrochemical deposition2 process.

This unevenness can cause a part that was within tolerance before plating to fall out of spec afterward. It requires careful process control. At PTSMAKE, we work with our plating partners to develop specific strategies for complex geometries.

Managing Plating Variables

Controlling thickness requires managing multiple factors. Current density, solution chemistry, and plating time all play a role. We account for these variables during the design for manufacturing (DFM) stage.

| Control Factor | Standard Process | Precision Process |

|---|---|---|

| Current Density | +/- 10% | +/- 2% |

| Solution Analysis | Daily | Hourly |

| Plating Time | Automated | Monitored |

By tightly controlling these inputs, we can ensure the final part, after gold plating, meets the required dimensional accuracy.

Gold plating directly adds material to a part’s surface. This added thickness, though small, is a critical variable. It must be precisely controlled, especially for high-precision components, to ensure the final product meets its dimensional specifications without fail.

The Ultimate Gold Plating Thickness Guide For Different Industries

Choosing the right gold plating thickness is critical. A one-size-fits-all approach simply doesn’t work. The demands of aerospace are vastly different from consumer electronics.

Getting this wrong can lead to premature failure. Or, it could mean over-engineering and adding unnecessary costs to your project.

Industry-Specific Gold Coatings Reference

This gold plating thickness chart offers a general guide. It’s a great starting point for understanding common industry-specific gold coatings and their applications.

| Industry | Typical Thickness (µin) | Primary Function |

|---|---|---|

| Electronics | 10 – 50 | Conductivity, Solderability |

| Aerospace | 50 – 100 | Corrosion Resistance, Reliability |

| Medical | 20 – 100 | Biocompatibility, Corrosion |

| Decorative | 5 – 10 | Appearance, Tarnish Resistance |

Decoding Gold Plating Specs

The numbers in the chart are just a starting point. The real work is in understanding the why. Gold plating specs are defined by performance needs, not arbitrary numbers. We often help clients navigate these technical details.

Aerospace & Defense Applications

For aerospace, reliability is non-negotiable. Parts are exposed to extreme temperatures and corrosive elements. A thicker coating of 50-100 microinches is standard. This ensures complete coverage and low porosity3. It prevents base metal corrosion.

This thicker layer also provides durability for components that may experience friction or wear over long service lives. It’s a crucial part of meeting stringent military and aerospace gold plating specs.

Electronics & Connectors

In electronics, the goals are different. Conductivity and contact resistance are key. For a high-cycle connector, you need a hard gold layer. This provides excellent wear resistance. For a solderable surface, a thin, pure gold layer is better.

Thickness can range from a flash of 10 microinches to over 50 microinches. This depends on the product’s expected life and operating environment. Balancing cost and performance is crucial here.

Selecting the right gold plating thickness is a key engineering decision. It balances cost against performance. These requirements vary significantly across industries, making a universal standard impossible. Following the correct gold plating specs ensures reliability and longevity for your parts.

Gold Plating Vs. Alternatives: What Should Engineers Specify?

Choosing the right finish isn’t just about performance. It’s a critical balance of cost, durability, and the specific application environment. Gold plating is often the default choice for reliability.

However, engineers must consider other options. Nickel, silver, and tin all have their place. The best conductive plating depends entirely on the component’s function and expected lifespan.

Key Plating Options Comparison

Let’s break down the most common choices. Each has distinct advantages and disadvantages that you need to weigh carefully for your project.

| Feature | Gold | Silver | Nickel |

|---|---|---|---|

| Conductivity | Excellent | Highest | Good |

| Corrosion Resistance | Excellent | Poor (Tarnishes) | Good |

| Wear Resistance | Fair | Poor | Excellent |

| Cost | High | Medium | Low |

This table provides a quick reference. But the real decision-making happens when we look at specific use cases and how these properties interact.

Gold vs. Nickel Coating and Other Finishes

When I work with engineering teams at PTSMAKE, the conversation often moves beyond a simple chart. We have to consider the complete system. A single component’s finish can affect the entire assembly.

For high-reliability connectors that require repeated mating cycles, gold is unbeatable. Its corrosion resistance ensures a stable, low-resistance connection over time. Nothing else quite compares in critical applications.

However, for a simple grounding point or a component requiring high durability, a gold vs nickel coating comparison clearly favors nickel. It’s tough and affordable. Its primary job is protection, not just conductivity.

Silver is an interesting middle ground. It’s the most conductive metal. This makes it ideal for certain high-frequency applications. But it tarnishes, which can increase contact resistance over time. You must plan for this. When dissimilar metals are in contact, the risk of galvanic corrosion4 becomes a serious design consideration.

Based on our client studies, we often recommend a nickel underplate for gold plating. This barrier layer improves adhesion and wear resistance, giving you the best of both worlds.

| Use Case | Recommended Finish | Key Reason |

|---|---|---|

| Medical Device Contacts | Gold | Biocompatibility, reliability |

| RF Connectors | Silver / Gold | Highest conductivity |

| Bus Bars | Tin / Silver | Cost-effective conductivity |

| Shielding Cans | Nickel / Tin | Durability and cost |

Ultimately, the best choice depends on a thorough analysis of your product’s requirements.

Selecting the right plating requires balancing cost, performance, and environment. Gold offers unmatched reliability for critical connections, but alternatives like nickel and silver provide strong, cost-effective solutions for specific mechanical and electrical needs. Your application dictates the optimal choice.

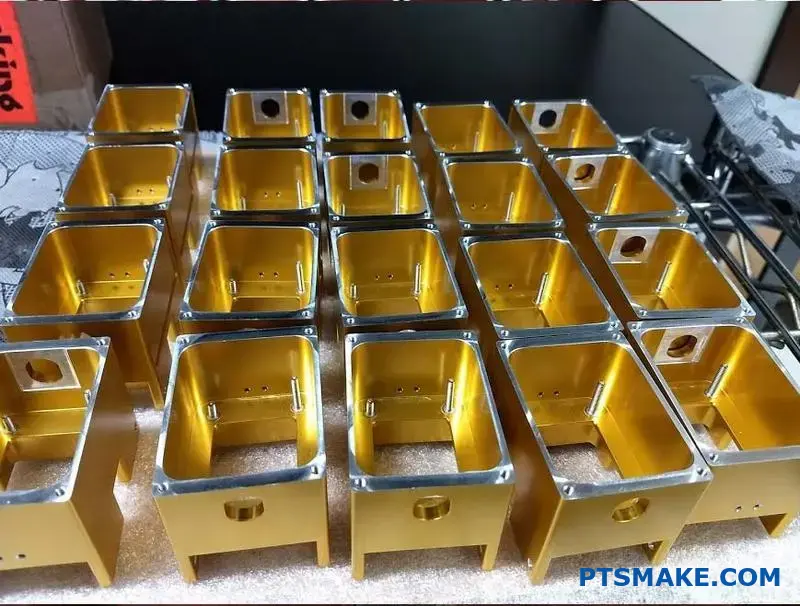

Gold Plating On CNC Machined Parts: Everything You Need To Know

Choosing the right base material is a critical first step. Not all metals are equally suited for direct gold plating. The compatibility directly impacts adhesion, durability, and final appearance.

Understanding this relationship is key for successful gold plating CNC parts.

Material Compatibility for Gold Finishes

Each metal requires a specific preparation process. For instance, active metals like aluminum and steel need intermediate layers. This ensures the gold adheres properly and doesn’t diffuse.

Brass is more compatible, but still benefits from an underplate.

| Base Material | Direct Plating Feasible? | Recommended Underplate |

|---|---|---|

| Aluminum | No | Zincate + Nickel/Copper |

| Steel | No | Nickel or Copper |

| Brass | Yes, but not recommended | Nickel |

Properly preparing the substrate is essential for all post-machining coatings.

The Science Behind Substrate Preparation

Gold plating is more than just a single layer. For many CNC parts, a successful outcome depends on the post-machining coatings applied before the gold. Direct plating on reactive metals is a recipe for failure.

An underplate, usually nickel or copper, acts as a crucial barrier. This layer prevents diffusion between the base metal and the gold. Diffusion can tarnish the gold finish over time, especially with copper or zinc alloys like brass.

Why Underplating is Non-Negotiable

For aluminum parts, the process is even more involved. We first apply a zincate coating to displace the oxide layer. Following this, an electroless nickel5 underplate provides an ideal, non-porous surface for the gold to bond with. This multi-step process is vital.

Steel parts require a nickel strike. This thin, dense layer prevents iron from migrating into the gold, which would cause rust spots and adhesion failure. At PTSMAKE, we tailor this process precisely to the base material. This ensures our CNC gold finishes meet the highest standards for both appearance and performance.

The right underplate sequence is what distinguishes a durable, high-quality finish from one that flakes or corrodes prematurely.

| Metal | Step 1 | Step 2 | Step 3 |

|---|---|---|---|

| Aluminum | Degrease & Etch | Zincate Treatment | Nickel & Gold Plate |

| Steel | Degrease & Acid Dip | Nickel Strike | Gold Plate |

| Brass | Degrease & Clean | Nickel Barrier (Opt.) | Gold Plate |

Successful gold plating on CNC parts hinges on material compatibility and correct underplating. The post-machining process must be specifically tailored to the base metal—aluminum, steel, or brass—to ensure a durable and high-quality finish.

Prototyping With Gold Plating: When Should You Apply It?

Deciding when to add gold plating to your prototypes is a critical question. It’s not always needed in the very first iteration. The timing depends entirely on your testing goals.

For initial form and fit checks, plating is often unnecessary. However, for functional prototypes, it can be essential.

Key Decision Factors for Early-Stage Plating

Consider these points before committing to rapid prototyping plating. Gold plating prototypes helps validate performance early on.

| Testing Goal | Include Plating? | Rationale |

|---|---|---|

| Form & Fit Validation | No | Plating adds minimal thickness but increases cost. |

| Electrical Conductivity | Yes | Essential for testing circuit performance accurately. |

| Corrosion Resistance | Yes | To simulate real-world environmental exposure. |

| Wear & Durability | Yes | To evaluate the lifespan of contact surfaces. |

This approach ensures you only invest in plating when it provides valuable data.

A strategic approach to prototyping with plating can save you significant time and money later. Delaying plating might seem cost-effective initially. But it can mask critical design flaws.

For instance, a part might function perfectly without plating. Add the finish, and suddenly tolerances are off, or performance changes. We’ve seen this happen.

A Phased Plating Strategy

At PTSMAKE, we guide clients on when to introduce finishes. Plating during development should be a deliberate choice, not an afterthought.

A key factor we always examine is the Substrate Adhesion6, as a poor bond can ruin a component’s functionality. Testing this early prevents production-level failures.

Consider a multi-stage prototype plan:

| Prototype Stage | Plating Focus | Purpose |

|---|---|---|

| Alpha | None or selective | Validate core mechanics and fit. |

| Beta | Full specification | Test electrical, wear, and environmental performance. |

| Pre-production | Production-intent | Final validation of all manufacturing processes. |

This phased method ensures that by the time you reach production, you have high confidence in the design. It aligns investment with the maturity of the product. This avoids costly surprises during the final stages of a project.

Deciding on gold plating for prototypes hinges on your testing needs. Early plating validates performance criteria like conductivity and corrosion resistance. A strategic, phased approach helps manage costs and development timelines effectively, preventing late-stage issues.

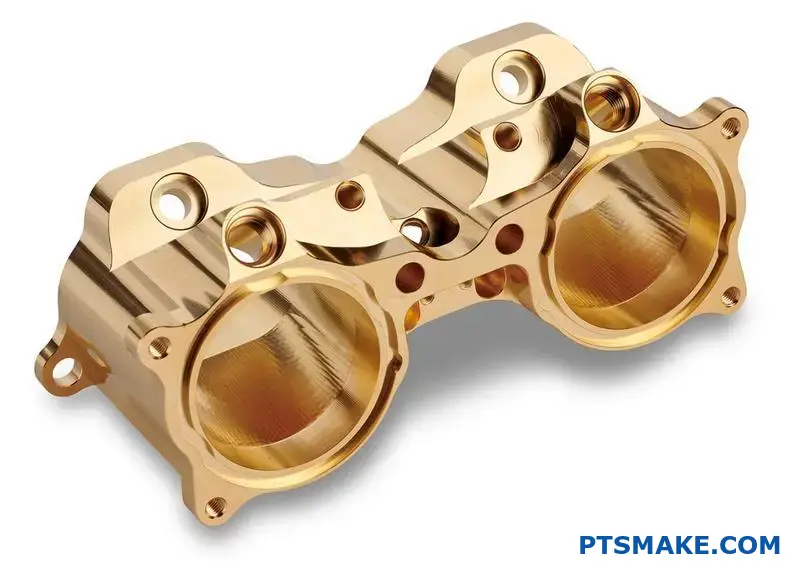

Top Applications Where Gold Plating Gives You A Competitive Edge

Gold plating offers more than a premium finish. It provides critical functional benefits. This makes it essential in high-stakes industries.

In sectors like medical, aerospace, and electronics, performance is non-negotiable. Here, the unique properties of gold provide a significant competitive advantage. Reliability and safety are paramount.

Core Sectors for Gold Plating

Let’s explore where gold coating application benefits truly shine. These industries rely on its unique properties for mission-critical functions.

| Industry | Primary Benefit | Key Application |

|---|---|---|

| Medical | Biocompatibility | Implants, Surgical Tools |

| Aerospace | Reliability | Connectors, Circuitry |

| Electronics | Conductivity | Contacts, Semiconductors |

These applications demand the highest performance standards.

The value of gold plating becomes clear when you examine the specific use-cases. Each industry leverages its properties to solve unique engineering challenges and enhance product value.

Medical Device Applications

For medical devices, biocompatibility is crucial. Gold is inert and non-toxic, preventing reactions with the human body. This is why you see gold plating in medical devices like pacemakers, stents, and dental implants. It ensures patient safety and device longevity.

Aerospace and Defense Sector

In aerospace, components face extreme conditions. Gold’s corrosion resistance and stable electrical conductivity are vital. Connectors and critical circuit components are plated with gold. This prevents failure from oxidation or extreme temperatures, which is essential for flight safety. Poor plating can lead to issues like galvanic corrosion7 when different metals are in contact.

The Electronics Industry

Electronics demand flawless signal transmission. Gold plating on connectors, switches, and PCB contact points ensures low contact resistance. It also prevents corrosion, which can disrupt signals over time. This enhances product reliability and lifespan.

| Feature | Medical Benefit | Aerospace Benefit | Electronics Benefit |

|---|---|---|---|

| Corrosion Resistance | Prevents degradation in the body | Protects against harsh environments | Extends component lifespan |

| Conductivity | Stable electrical signals for implants | Reliable connections for avionics | Ensures clear signal integrity |

| Biocompatibility | Ensures patient safety | Not applicable | Not applicable |

| Ductility | Easy to apply on complex shapes | Withstands vibration and stress | Reliable for small, intricate parts |

At PTSMAKE, we guide our clients to select the right plating thickness for their specific application, balancing cost with performance.

Gold plating is a strategic choice for industries where failure is not an option. From life-saving medical devices to mission-critical aerospace systems and reliable electronics, it provides a distinct performance and safety advantage, ultimately protecting your brand’s reputation.

MITI Vs. MIL-G-45204: Decoding Gold Plating Specs For Compliance

When evaluating suppliers, specification codes can seem like a foreign language. Misunderstanding them is a fast track to non-compliant parts. This is especially true for gold plating.

Decoding these specs is key. It ensures you compare suppliers accurately. It also guarantees your final product performs as designed. Let’s clarify what these codes mean for you. A clear grasp of gold coating grade comparison is crucial.

| Spec Code Element | What It Defines |

|---|---|

| Type | Purity Level |

| Grade | Hardness |

| Class | Thickness |

Demystifying Codes for Supplier Evaluation

Choosing a supplier isn’t just about matching codes on a quote. You must confirm their process control and understanding. A low-cost quote might hide a misunderstanding of a spec, leading to poor quality parts that fail in the field. This is where asking the right questions becomes essential.

Type and Grade in Practice

The interaction between Type (purity) and Grade (hardness) is critical. For instance, MIL-G-45204 Type I is soft (Grade A) and ideal for soldering. But for a high-wear connector, you’d need Type III, which allows for hardening agents through a process of codeposition8. Selecting the wrong combination will compromise the part’s function.

This gold coating grade comparison table simplifies it:

| Grade | Hardness (Knoop) | Common Application |

|---|---|---|

| A | 90 max | Solderability, wire bonding |

| B | 91-129 | General purpose, connectors |

| C | 130-200 | High wear resistance |

Verifying Supplier Compliance

When we handle projects at PTSMAKE, we don’t just take the spec code at face value. We discuss the part’s end-use with you. This ensures the chosen gold plating spec truly fits the application. Adhering to plating compliance specs is a partnership, not just a line item.

Decoding gold plating specs is vital for supplier evaluation. Understanding Type, Grade, and Class ensures the final coating meets your performance needs for purity, hardness, and durability. This diligence prevents costly part failures and project delays.

Mill Thickness Decisions: How To Choose The Right Gold Layer

Choosing the right gold plating thickness is crucial. It directly impacts your component’s performance and cost. It is not a one-size-fits-all decision.

The primary factor is the part’s application. Is it a wear-critical component or a non-wear-critical one? Answering this question is the first step. It guides all subsequent gold thickness recommendations.

For parts with frequent contact, durability is key. For static parts, protection against the environment matters more. Let’s look at the basic guidelines.

| Component Type | Primary Goal | Typical Thickness (Microns) |

|---|---|---|

| Non-Wear Critical | Solderability, Corrosion Resistance | 0.2 – 0.8 µm |

| Wear-Critical | Durability, Low Contact Resistance | 1.0 – 2.5 µm+ |

This simple breakdown helps set a baseline for your project.

Deeper Dive into Wear-Critical Components

For wear-critical parts, like electrical connectors, we must consider mating cycles. How many times will the parts be connected and disconnected? More cycles demand thicker gold.

Our client studies show that a thin layer wears away quickly. This exposes the underlayer, often nickel, leading to increased contact resistance and eventual failure. This is why understanding the expected coating life spans is vital.

Here is a more detailed view.

| Mating Cycles | Environment | Recommended Thickness (Microns) |

|---|---|---|

| < 100 | Mild | 0.8 – 1.0 µm |

| 100 – 500 | Mild | 1.0 – 1.3 µm |

| 500 – 1000 | Harsh | 1.3 – 2.0 µm |

| > 1000 | Harsh | 2.5 µm+ |

Understanding Non-Wear-Critical Needs

For non-wear parts, the goal shifts to corrosion resistance and solderability. The gold layer acts as a protective barrier. Here, even a thin layer can be effective.

However, the layer must be thick enough to cover the surface without significant porosity9. Thinner coatings are more susceptible to this issue. It can allow corrosive agents to reach the substrate.

For these applications, a hard gold plating process is often chosen to ensure a dense, protective layer even at minimal thickness. This balances cost and protection effectively.

Choosing the right gold plating thickness balances wear resistance and corrosion protection against cost. Wear-critical parts need thicker layers for durability, while non-wear components can use thinner coatings for basic protection and solderability. This strategic decision impacts long-term performance.

Key Material Compatibility Considerations Before Gold Plating

Choosing the right base metal is crucial for successful gold plating. The foundation material dictates the entire process. Poor base metal compatibility leads to adhesion failure and poor performance.

Aluminum and Stainless Steel Challenges

Aluminum oxidizes instantly in air. This oxide layer prevents gold from adhering properly. It requires a special zincate process before plating can even begin.

Stainless steel is passive. Its chromium oxide layer also hinders adhesion. It needs a specific activation step, like a Wood’s nickel strike, to ensure a strong bond.

This initial preparation is non-negotiable for quality.

| Base Metal | Primary Challenge | Required Pre-treatment |

|---|---|---|

| Aluminum | Rapid Oxidation | Zincate Process |

| Stainless Steel | Passivity (Oxide Layer) | Nickel Strike Activation |

Copper and Plating Stacks

Copper is a common choice for gold plating. It offers excellent conductivity. However, gold on copper directly is a problem. Copper atoms can migrate through the thin gold layer. This process, called diffusion, tarnishes the surface and degrades performance.

To prevent this, we use a barrier layer. This is a core concept in dissimilar metal plating. A layer of nickel is typically plated between the copper and gold. This nickel barrier stops the migration. It also adds hardness and corrosion resistance. At PTSMAKE, we often recommend this multi-layer approach for long-term reliability. This plating stack ensures the gold finish remains pure and functional. It’s a critical step that prevents future field failures. This can happen due to issues like Galvanic corrosion10 between dissimilar metals.

A typical plating stack looks like this:

| Layer | Material | Purpose |

|---|---|---|

| 3 (Top) | Gold | Final finish, conductivity, corrosion resistance |

| 2 (Middle) | Nickel | Barrier layer, prevents diffusion, adds hardness |

| 1 (Base) | Copper | Substrate material |

This structured approach is essential for high-performance components. It ensures each material performs its role without compromising the others. Base metal compatibility is about the entire system.

The success of gold plating relies heavily on the base material. Aluminum and stainless steel need special pre-treatments. For copper, a nickel barrier layer is essential to prevent diffusion and ensure long-term performance and reliability of the final plated part.

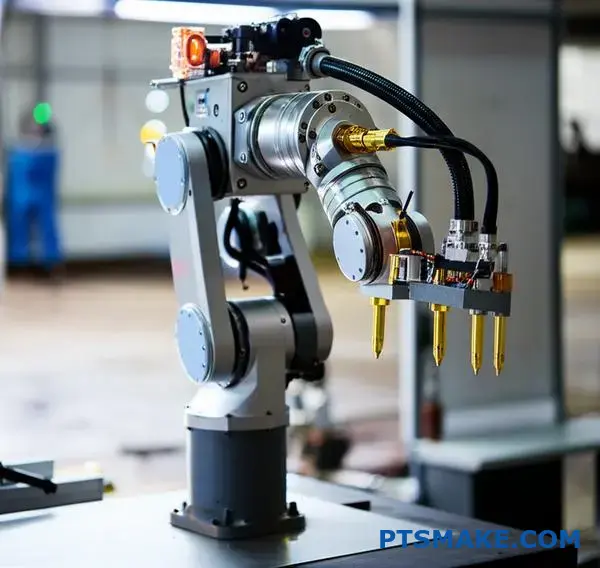

Gold Plating For Robotics: Precision That Enables High-Speed Performance

Let’s look at real-world examples. Theory is important, but practical application shows true value. I’ve seen how gold plating solves critical issues in robotic assemblies.

It’s not just about corrosion resistance. It’s about enabling performance that would otherwise be impossible.

Case Study 1: High-Speed Robotic Arms

In pick-and-place robots, every millisecond counts. Connectors in the joints face constant motion and vibration. We worked on a project where standard connectors caused signal drops. This led to positioning errors.

Gold plating on the connector pins solved this. It ensured a stable, low-resistance connection. This is a clear example of plating for movement accuracy.

| Feature | Standard Connector | Gold-Plated Connector |

|---|---|---|

| Signal Integrity | Variable | Highly Stable |

| Positional Errors | Frequent | Eliminated |

| Maintenance Cycle | 3 months | > 12 months |

| Downtime | High | Minimal |

This small change drastically improved the robot’s reliability and speed.

The impact of gold in robotics extends beyond just connectors. We see its critical role in sensory systems, where data accuracy is paramount. Without reliable data, a robot’s high-speed movements are useless.

Case Study 2: Optical and Proximity Sensors

Robot sensor coatings are vital. A client’s robotic system used infrared sensors for parts detection. These sensors are highly sensitive to surface degradation. Even minor oxidation could alter reflectivity and cause false readings.

Applying a thin, uniform layer of gold plating to the sensor’s reflective surfaces provided a stable, non-oxidizing face. This coating ensured consistent sensor performance over millions of cycles. The improved signal-to-noise ratio was immediately apparent in our tests. This enhancement is crucial in environments where dust or humidity can affect unprotected surfaces.

The process prevents gradual signal decay from environmental factors like tribocorrosion11, which can occur on parts under load and in motion.

Sensor Performance Comparison

| Metric | Uncoated Sensor | Gold-Coated Sensor |

|---|---|---|

| Signal Consistency | Degraded by 5% in 1000 hrs | <0.5% degradation |

| Reading Errors | 1 in 10,000 cycles | 1 in 1,000,000 cycles |

| Environmental Resistance | Low | High |

| Service Life | 1 Year | > 5 Years |

Our collaboration on this project proved that strategic gold plating is an investment in long-term reliability and precision for robotic sensors.

Case studies show gold plating is a practical solution. It enhances robotic joint connectors for movement accuracy and stabilizes sensor surfaces for reliable data. This small detail provides significant gains in performance and longevity.

How To Calculate Plating Costs For Your Next Project

Estimating coating budgets requires a clear view of all variables. It’s not just about the precious metal’s market price.

Key factors directly influence your final cost. These include coverage area, base metal type, and part complexity. Quality requirements also play a huge role. Understanding these helps create accurate gold plating pricing.

Primary Cost Drivers

Let’s break down the main components.

| Factor | Cost Impact | Why It Matters |

|---|---|---|

| Coverage Area | High | Larger surfaces require more material and tank time. |

| Base Metal | Medium | Some materials need extra prep or underlayers. |

| Complexity | High | Intricate shapes require special handling and masking. |

| Quality Specs | Varies | Tighter tolerances mean more process control and inspection. |

A total cost analysis goes deeper than surface area. For precise estimating, you must consider the technical details behind each factor. A simple calculation of cost per square inch plated can be misleading.

Deeper Dive into Cost Factors

Base Metal Preparation

Some metals, like aluminum or stainless steel, need special underplating. This ensures the gold plating adheres properly. This extra step adds both material and labor costs to the project.

Part Complexity and Racking

Complex geometries with deep recesses or blind holes are challenging. They require custom racking fixtures to ensure even coating. The additional labor for masking specific areas also increases the price significantly. The Current Density12 must be carefully managed in these cases.

Quality and Thickness Requirements

The required thickness of the gold plating is a major cost driver. Thicker coatings use more gold and take longer to apply. Specification requirements, like adhesion or corrosion resistance tests, also add to the final cost. At PTSMAKE, we work with clients to find the optimal thickness that meets performance needs without over-engineering.

| Specification | Typical Impact on Gold Plating Cost |

|---|---|

| Thickness (microns) | Direct increase with thickness |

| Masking Requirements | Significant labor cost increase |

| Adhesion Testing | Minor cost for testing procedure |

| Salt Spray Testing | Moderate cost for equipment and time |

Calculating plating costs involves more than material price. A thorough analysis of coverage area, base metal, part complexity, and quality specifications is crucial for an accurate budget. These factors collectively determine the final investment for your project.

Future Trends In Gold Plating You Need To Watch In 2026

The world of gold plating is on the verge of a major transformation. Looking ahead to 2026, we are not just talking about minor adjustments. We are seeing fundamental shifts.

Innovations are driving this change. These new methods promise higher performance and greater sustainability. The future of the coating industry is smart and green.

Key Innovations on the Horizon

Here are the top trends I’m tracking:

| Technology Trend | Primary Benefit | Target Industry |

|---|---|---|

| Nanogold Plating | Enhanced Durability | Electronics, Medical |

| AI-Controlled Baths | Unmatched Consistency | Aerospace, Automotive |

| Eco-Friendly Processes | Reduced Environmental Impact | All Industries |

This advanced gold plating technology is set to redefine our standards for quality and responsibility.

The push toward 2026 plating technology is driven by demand for better, more reliable components. It’s not just about a shiny finish anymore. It’s about performance under extreme conditions.

Deeper Look into Emerging Technologies

Nanogold Plating

Nanogold plating uses gold particles on a nanometer scale. This creates a harder, more wear-resistant surface. It also allows for thinner coatings without sacrificing performance. This means less gold is needed, which can help manage costs for complex projects.

AI and Automation

AI is moving into the plating bath. Sensors will monitor chemical levels, temperature, and current in real-time. The system will make micro-adjustments automatically. This reduces human error and ensures every single part meets exact specifications. This level of control is crucial for high-stakes applications.

Sustainable Plating Solutions

The industry is finally moving away from cyanide-based solutions. New, eco-friendly processes are becoming viable. These alternatives reduce toxic waste and create a safer work environment. This shift is essential for meeting stricter global regulations. Based on our tests, these new methods maintain the required quality for electrodeposition13 while being much safer.

Here is a comparison of old versus new:

| Feature | Traditional Plating | 2026 Plating Technology |

|---|---|---|

| Process Control | Manual Adjustments | AI-Driven, Automated |

| Material Usage | Standard Thickness | Optimized, Thinner Layers |

| Environmental Impact | High (Cyanide) | Low (Non-toxic) |

| Consistency | Variable | Highly Repeatable |

At PTSMAKE, we believe these advancements will be standard practice soon.

The future of gold plating is here, driven by nanotechnology, AI, and green chemistry. These innovations are creating stronger, more reliable, and environmentally responsible coatings. The industry is preparing for a new standard of excellence and precision by 2026.

Get Expert Gold Plating Solutions with PTSMAKE Now!

Ready to achieve the ultimate precision and reliability for your critical components? Contact PTSMAKE for a fast, no-obligation quote on gold plating and precision manufacturing. Our team delivers industry-leading quality, technical expertise, and on-time results every time—let’s make your next project a success!

Discover the technical process of applying metal coatings for superior component protection. ↩

Understand the science of how metal ions are deposited onto a surface during plating. ↩

Understand how microscopic voids can affect your component’s corrosion resistance and overall performance. ↩

Understand how this process causes component failure and what to specify in your designs to prevent it. ↩

Discover how this chemical deposition process creates a uniform barrier essential for plating complex parts. ↩

Learn how the bond between plating and base materials impacts part reliability. ↩

Understand this electrochemical process to prevent material degradation and premature component failure. ↩

Discover how hardening agents are integrated into gold plating to enhance durability and performance for specific applications. ↩

Discover how microscopic gaps in gold plating affect component reliability and performance. ↩

Understand how this electrochemical process can impact your component’s lifespan. ↩

Explore how mechanical wear and corrosion can degrade moving components and affect robotic precision. ↩

Understand how this electrical parameter impacts finish quality, plating speed, and your total project cost. ↩

Click to understand the fundamental science of how metal coatings are precisely applied to parts. ↩