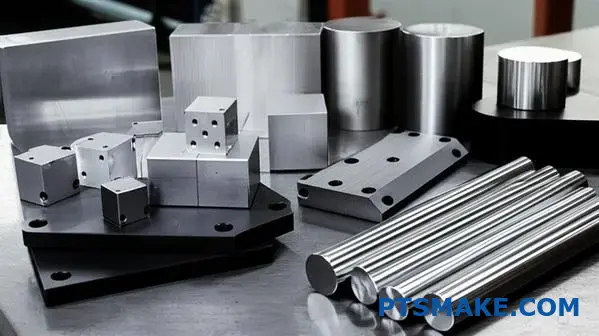

Finding the right aluminum forging solution for your critical components shouldn’t feel like navigating a maze of technical specifications and supplier promises. Yet many engineers and procurement managers struggle with inconsistent quality, unexpected costs, and suppliers who can’t deliver the precision their applications demand.

Forged aluminum offers superior mechanical properties through controlled plastic deformation that refines grain structure, eliminates porosity, and creates directional grain flow – resulting in parts with exceptional strength-to-weight ratios, fatigue resistance, and reliability for demanding aerospace, automotive, and industrial applications.

I’ve worked with hundreds of clients at PTSMAKE who needed to make smart decisions about forged aluminum – from startup engineers designing their first critical component to seasoned procurement managers optimizing existing supply chains. This guide breaks down everything you need to know about forged aluminum, from material selection and process optimization to cost estimation and quality control, giving you the practical knowledge to specify, source, and manufacture forged aluminum parts with confidence.

What defines forged aluminum’s superior mechanical properties?

Ever wonder why some aluminum parts outperform others? The secret isn’t just the alloy; it’s the process. Forged aluminum offers incredible strength.

This strength comes from its internal structure.

The Forging Transformation

The forging process applies immense pressure. This refines the metal’s grain structure. It also eliminates tiny internal defects found in other methods. This creates a denser, more uniform material.

Key Property Improvements

Here is a simple comparison between forged and cast parts.

| Feature | Forged Aluminum | Cast Aluminum |

|---|---|---|

| Tensile Strength | Very High | Moderate |

| Fatigue Life | Excellent | Fair to Poor |

| Impact Toughness | Superior | Good |

This is why forging is preferred for critical applications.

Grain Flow: The Path to Strength

In cast or machined parts, the grain structure is either random or abruptly cut. These interruptions act as stress points. They can lead to cracks under load.

Forging avoids this completely. The process directs the grain to flow along the part’s contours. It creates an unbroken, continuous internal structure. This is a huge advantage.

Why Continuous Grain Flow Matters

This aligned grain flow significantly boosts fatigue resistance. Think of it like wood grain. A long plank is strongest along its grain, not against it. Forged aluminum follows the same principle, enhancing its durability. This is achieved through a process known as plastic deformation1, which reshapes the metal on a microscopic level.

Eliminating Hidden Weaknesses

Casting often traps small pockets of gas, creating porosity. These tiny voids are weak spots. Under impact or stress, they can easily become failure points. Forging’s intense pressure forces these voids closed.

A Denser, Tougher Material

This results in a denser, non-porous structure. Based on our testing, this directly increases impact toughness and tensile strength. It provides a level of reliability that casting simply cannot match. At PTSMAKE, we rely on this for high-performance components.

In short, forging transforms aluminum’s internal structure. It refines grains, creates continuous grain flow, and eliminates porosity. This directly enhances tensile strength, fatigue resistance, and impact toughness, making it a superior choice for demanding applications.

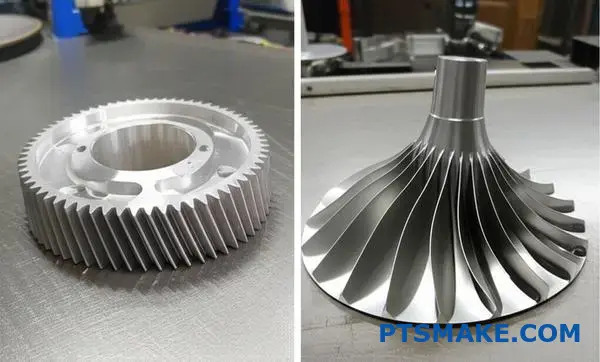

What are the main types of aluminum forging processes?

Aluminum forging isn’t a one-size-fits-all process. The method we choose depends on your part’s complexity and final use.

We can break it down into three main categories. Each offers unique benefits for different applications.

Open-Die Forging

This is the simplest form. A workpiece is shaped between two flat dies that don’t fully enclose it. It’s like a blacksmith shaping metal with a hammer and anvil. This is ideal for large, simple shapes.

Closed-Die Forging

Also called impression-die forging, this method uses dies that contain a cavity or impression. This impression is the shape of the desired part. It offers better dimensional accuracy.

Precision Forging

This is an advanced form of closed-die forging. It produces parts with much tighter tolerances and minimal need for finishing.

Here’s a quick comparison:

| Forging Type | Tooling Complexity | Geometric Complexity |

|---|---|---|

| Open-Die | Low | Simple |

| Closed-Die | Medium | Moderate to High |

| Precision | High | Very High |

This structure helps us select the best process for your forged aluminum components.

Let’s dive deeper into how these processes differ. The choice directly impacts the final part’s properties and cost.

From Impression to Precision

In closed-die forging, heated aluminum is pressed into the die cavity. The immense pressure forces the metal to fill the impression completely.

This process creates a strong, durable part. Excess material is squeezed out between the die halves. This material, called flash2, is trimmed off later. Managing this is key to quality.

Precision forging takes this a step further. It aims to produce a "net-shape" or "near-net-shape" part. This means the component comes out of the die very close to its final dimensions. It drastically reduces or eliminates the need for costly secondary machining.

At PTSMAKE, we often guide clients toward precision forging for complex parts. It is perfect for aerospace or automotive applications where every gram matters.

The table below shows the achievable tolerances.

| Feature | Open-Die Tolerance | Closed-Die Tolerance | Precision Forging Tolerance |

|---|---|---|---|

| Length/Width | ± 1.5 mm | ± 0.5 mm | ± 0.1 mm |

| Thickness | ± 1.0 mm | ± 0.4 mm | ± 0.05 mm |

| Surface Finish (Ra) | > 6.3 µm | 3.2 – 6.3 µm | < 1.6 µm |

Choosing the right aluminum forging process is a balance. It involves weighing part complexity against production costs and desired precision. Each method offers distinct advantages for specific manufacturing needs.

How are wrought aluminum alloys systematically classified for forging?

The Aluminum Association’s four-digit system is the key. It neatly categorizes alloys based on their main alloying elements. This code tells you a lot about the material’s potential performance.

Understanding the First Digit

The first digit is the most important. It identifies the principal alloying element. This determines the alloy’s core characteristics, which is crucial for selecting the right material for your forging project.

| Series | Primary Alloying Element |

|---|---|

| 2xxx | Copper (Cu) |

| 6xxx | Magnesium (Mg) & Silicon (Si) |

| 7xxx | Zinc (Zn) |

This simple system makes choosing a forged aluminum alloy much more predictable and straightforward.

The High-Strength Contenders: 2xxx and 7xxx Series

When strength is your top priority, the 2xxx and 7xxx series are the primary choices. At PTSMAKE, we work with these alloys for applications where failure is not an option.

2xxx Series: The Aerospace Classic

Alloys like 2014 and 2024 get their impressive strength from copper. Their strength-to-weight ratio is exceptional after heat treatment. This makes them ideal for aircraft structures and high-performance automotive components. Their corrosion resistance is lower, so protective coatings are often needed.

7xxx Series: The Strength Kings

The 7xxx series, with zinc as the main element, offers the highest strength available in forged aluminum. Alloys like 7075 are essential for parts under extreme stress. The ultimate strength comes from a process of precipitation hardening3, which we carefully control during manufacturing.

The All-Rounder: 6xxx Series

For projects needing a balance of properties, I often recommend the 6xxx series.

6xxx Series: Versatility and Forgeability

With magnesium and silicon, alloys like 6061 offer good strength, excellent corrosion resistance, and superior forgeability. They are generally easier to work with than the high-strength series. This balance makes them a cost-effective choice for a wide range of forged aluminum parts.

| Feature | 2xxx Series | 6xxx Series | 7xxx Series |

|---|---|---|---|

| Strength | High | Medium-High | Very High |

| Forgeability | Good | Excellent | Fair-Good |

| Corrosion Resistance | Fair | Excellent | Good |

| Primary Use | Aerospace | General, Automotive | High-Stress Aerospace |

The Aluminum Association’s system classifies alloys by their main alloying element. This directly links the 2xxx, 6xxx, and 7xxx series to distinct properties like high strength or excellent forgeability, simplifying material selection for specific forging applications.

Which aluminum alloy series are for structural applications?

When selecting an aluminum alloy for forging, the series number tells you everything. Not all aluminum is created equal for high-stress jobs. The choice is critical for performance.

We primarily focus on three families for structural applications. These are the 2xxx, 6xxx, and 7xxx series. Each has a distinct purpose.

The Go-To Forging Alloys

| Alloy Series | Primary Alloying Element | Key Characteristic |

|---|---|---|

| 2xxx | Copper | High Strength |

| 6xxx | Magnesium & Silicon | Versatility, Corrosion Resistance |

| 7xxx | Zinc | Highest Strength |

These heat-treatable alloys provide the strength needed for demanding structural parts.

The right forged aluminum alloy depends entirely on the application’s demands. In past projects at PTSMAKE, we’ve seen how a mismatch can lead to failure. It’s about balancing strength, weight, corrosion resistance, and cost.

Aerospace Titans: 2xxx and 7xxx Series

For aerospace components, there’s no room for compromise. This is where the 2xxx and 7xxx series shine. They offer some of the highest strength-to-weight ratios available.

The 2xxx series, alloyed with copper, provides excellent strength at elevated temperatures. The 7xxx series, using zinc, achieves the highest strengths of all aluminum alloys through a process called precipitation hardening4. This makes it ideal for critical airframe structures.

The Versatile Workhorse: 6xxx Series

The 6xxx series is the most common choice for automotive and general engineering. It offers a great blend of good strength, excellent corrosion resistance, and good formability. It’s the practical, cost-effective solution for many structural parts that don’t face the extreme stresses of aerospace.

Why Some Series Don’t Make the Cut

You won’t often see 1xxx or 3xxx series in structural forgings.

| Alloy Series | Reason for Unsuitability |

|---|---|

| 1xxx | Too soft; it’s commercially pure aluminum. |

| 3xxx | Lacks the high mechanical strength needed. |

These alloys have their uses, but they lack the robustness required for load-bearing forged components.

Choosing the right alloy series is critical for structural forging. The high-strength 2xxx and 7xxx series are for aerospace, while the versatile 6xxx series serves automotive and general use. Others, like 1xxx and 3xxx, lack the necessary strength.

What forging features are critical for aerospace components?

The aerospace industry has no room for error. Every component must be incredibly strong and reliable. It also needs to be as light as possible.

This is why forging is so critical. It creates parts that can withstand immense stress.

The Non-Negotiables for Aerospace Parts

We focus on four key areas. Each one is a non-negotiable requirement for safety and performance. These features are vital for components made from materials like high-strength forged aluminum.

| Critical Feature | Why It Matters in Aerospace |

|---|---|

| Superior Fatigue Life | Resists failure from repeated stress cycles. |

| Fracture Toughness | Prevents small cracks from growing. |

| Strength-to-Weight Ratio | Maximizes performance and fuel efficiency. |

| Absolute Reliability | Ensures parts perform without failure. |

Achieving Excellence Through Forging

How does forging achieve these exceptional properties? It comes down to controlling the material at a microscopic level. It is a process we have perfected at PTSMAKE through numerous aerospace projects.

Precise Grain Flow Control

Unlike other methods, forging directs the internal grain structure of the metal. Imagine the grain of wood. It is strongest along its length.

Forging aligns the metal’s grain to follow the shape of the part. This concentrates strength precisely where it is needed most. This drastically improves resistance to fatigue and impact.

Eliminating Internal Defects

Casting can leave behind tiny, hidden voids or porosity. These are weak spots that can lead to catastrophic failure under stress.

The immense pressure used in forging eliminates these defects. It creates a dense, uniform material structure, ensuring the part is solid and reliable through and through. Rigorous Non-Destructive Testing5 then verifies that the component is flawless before it ever leaves our facility.

| Property Enhancement | Forging’s Impact |

|---|---|

| Grain Structure | Aligned and refined for directional strength. |

| Material Density | Consolidated, eliminating voids and porosity. |

| Part Integrity | Superior toughness and fatigue resistance. |

Forging is essential for aerospace because it directly manipulates the metal’s internal structure. This achieves the unparalleled strength, low weight, and absolute reliability demanded by the industry. The process ensures components are free from defects and built for extreme performance.

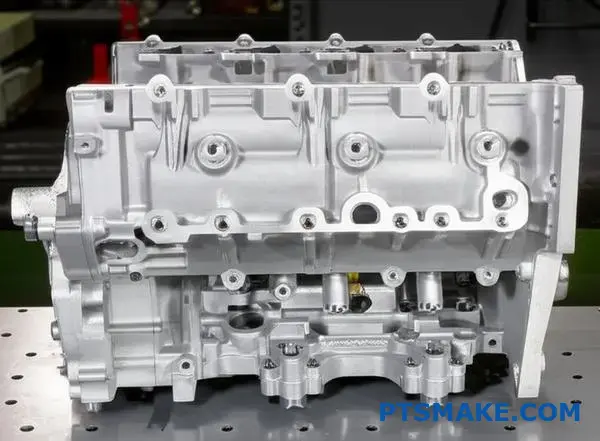

How do automotive forging requirements differ from aerospace?

The core difference is simple. Automotive prioritizes cost-efficiency for high volumes. Aerospace demands peak performance, regardless of cost.

This fundamental split influences every decision. It affects material choices, precision levels, and documentation needs.

Core Philosophy Contrast

Automotive forging must be economical. It’s about producing millions of reliable parts.

Aerospace forging focuses on safety and performance. Failure is not an option at 30,000 feet. This drives different engineering choices.

| Feature | Automotive Forging | Aerospace Forging |

|---|---|---|

| Primary Driver | Cost-Effectiveness | Performance & Safety |

| Production Volume | High to Very High | Low to Medium |

| Material Focus | Good Strength, Malleability | Maximum Strength-to-Weight |

| Inspection Level | Statistical Sampling | 100% Inspection, NDT |

This philosophical divide creates very different practical requirements. At PTSMAKE, we navigate these distinct needs for our clients in both sectors. The approach for a suspension component is worlds apart from that for a landing gear part.

Alloy Selection: Cost vs. Ultimate Strength

Material choice highlights the contrast perfectly. The automotive industry often uses 6xxx series forged aluminum. It offers good formability, corrosion resistance, and strength. It is also more economical for mass production.

Aerospace, however, leans heavily on 7xxx series aluminum alloys. These alloys provide exceptional strength-to-weight ratios after a specific heat treatment6. This performance comes at a higher material and processing cost.

| Alloy Series | Typical Industry | Key Advantages | Considerations |

|---|---|---|---|

| 6xxx Aluminum | Automotive | Excellent formability, good strength, cost-effective | Lower ultimate strength than 7xxx |

| 7xxx Aluminum | Aerospace | Highest strength-to-weight ratio, superior fatigue resistance | Higher cost, more complex processing |

Tolerances and Traceability

Aerospace demands incredibly tight tolerances. Parts must fit perfectly and perform under extreme stress.

Furthermore, aerospace requires complete traceability. We must document every step, from the raw material billet to the final inspection report. This ensures accountability and safety. Automotive requirements, while strict, are generally less exhaustive.

Automotive forging balances cost and performance for mass production. In contrast, aerospace forging prioritizes absolute material integrity, tight tolerances, and complete traceability. The end-use application dictates every single manufacturing decision, from alloy choice to final documentation.

How do you design a heat treatment cycle for 7075 aluminum?

Let’s get practical. Designing a heat treatment cycle isn’t guesswork. It’s a precise recipe. At PTSMAKE, we follow standards like AMS 2770. This ensures repeatable, high-quality results for 7075 aluminum parts.

The process has three main steps. Each one is critical for the final properties.

The Core Three-Step Process

- Solution Treatment: Heating the alloy.

- Quenching: Rapidly cooling it.

- Artificial Aging: A final, controlled heating.

Here are the details for the first step.

Solution Treatment Parameters

| Material Thickness | Soak Time at Temperature |

|---|---|

| Up to 0.250 inch | 1 Hour |

| 0.251-0.500 inch | 2 Hours |

| 0.501-1.000 inch | 4 Hours |

| Over 1.000 inch | 6 Hours |

This table is a great starting point. The goal is uniformity.

Solution treatment prepares the material’s microstructure. We heat the 7075 aluminum to a specific temperature, usually between 870-900°F (465-482°C). This allows the alloying elements like zinc, magnesium, and copper to dissolve evenly into the aluminum.

The part "soaks" at this temperature. The soak time depends on thickness, as shown earlier. Thicker parts, including some complex forged aluminum geometries, need more time for heat to penetrate fully.

After soaking, we quench. This is a rapid cooling process, typically in water. The speed is crucial. The goal is to trap the dissolved elements in place, creating a supersaturated solid solution7. Delaying the quench, even by seconds, allows these elements to precipitate out prematurely, which harms the final mechanical properties. The maximum quench delay is typically 5 to 15 seconds.

Finally, we have artificial aging. This step determines the final temper.

Aging: T6 vs. T73 Temper

| Temper | Aging Temperature | Aging Time | Primary Benefit |

|---|---|---|---|

| T6 | 250°F (121°C) | 24 Hours | Maximum Strength and Hardness |

| T73 | 225°F (107°C) then 325°F (163°C) | 6-8 hrs then 24-30 hrs | Excellent Stress Corrosion Cracking Resistance |

The T6 temper gives you peak strength. However, it can be more susceptible to stress corrosion cracking. The T73 temper involves a two-step aging process. This slightly reduces the ultimate strength but vastly improves its resistance to corrosion, which is a critical trade-off in many aerospace applications.

This chapter provides a detailed, step-by-step recipe for heat treating 7075 aluminum based on industry standards. It covers solution treatment, quenching, and the critical differences between T6 and T73 artificial aging, explaining the "why" behind each parameter.

How do you estimate the cost of a forged aluminum part?

Estimating the cost of a forged aluminum part goes beyond its final weight. You must consider the entire process.

The total cost is a sum of several distinct factors. We break it down into four main categories.

Key Cost Components

Raw Material Input

The initial billet is always heavier than the finished part. This difference, including scrap and flash, is part of the material cost you pay for.

| Cost Factor | Description |

|---|---|

| Input Weight | The weight of the raw aluminum billet. |

| Finished Weight | The weight of the final part. |

| Scrap/Flash | Excess material removed during forging. |

This initial calculation is fundamental to an accurate estimate.

Beyond the Billet: Tooling and Operations

The raw material is just the starting point. The tools and the energy required to shape the metal are significant cost drivers.

Tooling Investment

Forging dies are a major upfront expense. This cost is typically amortized, or spread, across the total number of parts in the production run.

A higher production volume means a lower tooling cost per individual part. At PTSMAKE, we help clients plan this to optimize their budget.

Operational Expenses

This category covers the direct manufacturing costs. It includes the forging press time, the energy consumed, and the skilled labor needed to operate the machinery. These are often bundled into an hourly rate.

The Final Touches: Secondary Operations

After forging, parts often require additional steps to meet final specifications. These are not optional for high-performance applications.

These processes ensure the part meets tight tolerances and has the right mechanical properties. This is where we verify the integrity of the internal grain flow8 that gives forgings their strength.

| Operation | Purpose |

|---|---|

| Trimming | Removes excess flash from the part. |

| Heat Treatment | Enhances strength and hardness. |

| NDT | Non-Destructive Testing to check for flaws. |

| Finishing | Surface treatments like anodizing. |

Each step adds to the final cost but is crucial for quality.

A true cost estimate for a forged aluminum part must account for raw materials (input weight), amortized tooling, operational costs like press time, and all necessary secondary operations. Overlooking any of these leads to inaccurate projections.

How could you modify a process for a thin-walled forging?

Creating thin-walled forgings presents unique challenges. The primary issues are rapid heat loss and high friction.

Thin sections cool down very quickly. This makes the material harder to shape. High friction also restricts metal flow into the die cavity.

Key Advanced Strategies

We must use advanced methods to succeed. These methods tackle heat and friction directly. Our goal is to ensure complete die filling and maintain material integrity.

| Challenge | Primary Effect |

|---|---|

| Rapid Heat Loss | Increased flow stress |

| High Friction | Incomplete die filling |

Thin-walled components, especially in materials like forged aluminum, demand precise process control. In our past projects at PTSMAKE, we’ve found that standard forging methods often fail. The material cools before it can fill the intricate details of the die. This leads to defects and failed parts.

Managing Temperature and Metal Flow

The solution lies in maintaining the workpiece temperature. This is where advanced techniques become critical. Processes like isothermal forging9 keep the die and workpiece at the same high temperature. This completely eliminates heat loss from the part to the tooling.

Another approach is hot-die forging. Here, the dies are heated to a temperature slightly below the workpiece. This slows down heat loss significantly, giving the material more time to flow.

Optimizing the Forging Sequence

Beyond temperature, we must manage the physical process.

Lubrication and Speed

Specialized lubricants are crucial. They create a thermal barrier and reduce friction. Glass-based lubricants are excellent for high temperatures.

Using faster presses also helps. A quick press stroke shapes the part before it has a chance to cool down.

Multi-Stage Forging

For complex parts, a multi-stage approach is best. We gradually shape the material over several steps. This reduces the stress on the material in any single stage. It allows for a more controlled formation of thin features.

| Technique | Primary Benefit |

|---|---|

| Isothermal/Hot-Die Forging | Minimizes heat loss |

| Specialized Lubricants | Reduces friction, acts as thermal barrier |

| Faster Presses | Reduces time for cooling |

| Multi-Stage Forging | Forms features gradually and safely |

For thin-walled forgings, success depends on managing heat loss and friction. Advanced solutions like isothermal forging, specialized lubricants, and multi-stage sequences are not just optional; they are essential for achieving the required precision and preventing defects.

What are the trade-offs between strength and cost for 6061 vs 7075?

Let’s use a specific application: a high-stress aerospace bracket. Here, the choice between 6061 and 7075 is not straightforward.

7075 aluminum is significantly stronger. Our tests show it can be 60-80% stronger than 6061.

This strength is highly desirable for critical parts. However, the true cost extends far beyond the raw material price.

We must look at the total manufacturing cost. This includes forging, heat treatment, and finishing.

| Feature | 6061 Aluminum | 7075 Aluminum |

|---|---|---|

| Relative Strength | Baseline | +60-80% |

| Raw Material Cost | Lower | Higher |

| Manufacturing Cost | Standard | Significantly Higher |

Beyond the Price Tag: The Hidden Costs of 7075

The true cost of using 7075 aluminum appears during manufacturing. It is a much more demanding material to work with compared to its 6061 counterpart.

Forging and Machinability Challenges

7075 is notoriously difficult to work with. This is especially true when creating a forged aluminum part with complex geometry. The material is less forgiving, which increases the risk of defects and scrap. This drives up the cost. Machining also requires slower speeds, increasing cycle times.

Heat Treatment Complexity

Heat treatment for 7075 is a very delicate process. The material has high Quench Sensitivity10. This means the cooling rate after heating must be perfectly controlled. Even small deviations can cause internal stresses or prevent the part from reaching its full strength. This requires specialized equipment and expertise, adding to the cost.

Corrosion and Finishing Needs

Unlike 6061, 7075 has poor corrosion resistance. This is a critical design factor, not a minor detail. Parts almost always need a protective coating, such as anodizing or painting. This adds another mandatory and costly step to the production line.

| Manufacturing Step | 6061 Process | 7075 Process |

|---|---|---|

| Forging | Relatively straightforward | Difficult, higher scrap rate |

| Heat Treatment | Less sensitive | Highly sensitive, precise control needed |

| Finishing | Coating is optional | Mandatory protective coating |

Choosing 7075 provides a major strength advantage. This performance comes with significant hidden costs from complex forging, precise heat treatment, and mandatory protective coatings. The final decision must weigh performance requirements against the total manufacturing budget.

Develop a plan to produce a complex automotive suspension knuckle.

This is where theory meets practice. We will outline a complete manufacturing plan for a suspension knuckle. This plan is a capstone, combining material science with process engineering.

Choosing the Right Alloy

We start with a 6xxx series aluminum. Its balance of strength, corrosion resistance, and formability makes it ideal for this critical automotive component.

Manufacturing Blueprint

Our plan covers every critical step. From the initial forging to the final inspection, each stage is carefully defined to ensure quality and safety.

| Stage | Key Objective |

|---|---|

| 1. Material Selection | Choose optimal 6xxx series alloy |

| 2. Forging Process | Shape the knuckle’s complex geometry |

| 3. Heat Treatment | Achieve required mechanical properties |

| 4. Inspection & QA | Verify part integrity and dimensions |

Multi-Stage Forging Strategy

A complex knuckle cannot be formed in one step. We use a multi-stage forging process. This involves blocker dies to pre-shape the metal, followed by finisher dies for the final intricate geometry.

Die Design Considerations

Die design is critical. We focus on proper draft angles to ensure the part releases easily. We also design precise flash gutters. These control material flow and help fill the die completely. This avoids defects in the final part.

The T6 Heat Treatment Cycle

To achieve peak performance from the forged aluminum, a T6 temper is necessary. This process involves three key steps. First, solution heat treatment dissolves alloying elements.

Next is the quenching11 process. The part is rapidly cooled to lock these elements in place. Finally, artificial aging heats the part at a lower temperature. This precipitates the alloys, creating immense strength.

Quality Assurance: NDT and Dimensional Checks

Safety is non-negotiable. Our quality plan includes both Non-Destructive Testing (NDT) and precise dimensional verification to guarantee every knuckle meets specification.

| Inspection Type | Method | Purpose |

|---|---|---|

| NDT | Ultrasonic Testing | Detects internal cracks or voids |

| NDT | Dye Penetrant | Reveals surface-level imperfections |

| Dimensional | CMM Scan | Verifies all critical dimensions and GD&T |

Our plan covers alloy selection, multi-stage forging, T6 heat treatment, and rigorous NDT/dimensional inspections. This comprehensive approach ensures the final suspension knuckle is safe, durable, and performs exactly as designed, a process we’ve refined at PTSMAKE.

How will additive manufacturing impact the future of aluminum forging?

It’s not about competition. It’s about collaboration. Additive manufacturing (AM) and forging aren’t rivals. Instead, they are becoming powerful partners. This partnership blends the best of both worlds.

AM offers design freedom for complex parts. Forging delivers unmatched strength and reliability. By combining them, we unlock new levels of performance and efficiency for manufacturing forged aluminum parts.

| Technology | Primary Strength | Best Use Case |

|---|---|---|

| Additive Manufacturing | Geometric Complexity | Prototypes, custom parts |

| Aluminum Forging | Mechanical Strength | High-stress applications |

The Power of Hybrid Manufacturing

The true innovation lies in hybrid approaches. Instead of choosing one over the other, we can use them together. This creates a smarter, more efficient workflow. We are seeing this firsthand at PTSMAKE as we explore these new methods for our clients.

Additive Manufacturing for Preforms

One powerful strategy is using AM to create near-net-shape preforms. An AM machine prints a part that is very close to the final design. This preform is then forged.

This process drastically reduces material waste. It also shortens the forging and final machining time. It’s perfect for creating complex forged aluminum components that were once too difficult or costly.

Optimized Dies with AM

AM is also changing how we make the tools for forging. We can now 3D print forging dies with advanced features. For example, we can build dies with internal conformal cooling channels12 that follow the shape of the tool surface.

This allows for faster, more uniform cooling. The result is a longer tool life and higher quality parts.

| Hybrid Approach | Traditional Method Benefit | New AM Benefit |

|---|---|---|

| AM Preform + Forging | High strength | Reduced waste, complex shapes |

| AM-Made Forging Dies | Durability | Longer tool life, faster cycles |

Where Forging Remains King

Even with these advancements, traditional forging will remain dominant. For high-volume production of simpler parts, nothing beats its speed and cost-effectiveness. Industries requiring immense durability, like aerospace and automotive, will continue to rely on forging’s superior material properties.

AM and forging are not competitors but collaborators. Hybrid approaches, like using AM for preforms and optimized dies, combine design freedom with mechanical strength. This synergy enhances the future of high-performance aluminum component manufacturing while traditional forging retains its dominance in specific areas.

Unlock Your Forged Aluminum Success with PTSMAKE

Ready to optimize your next forged aluminum project? Contact PTSMAKE now for a fast, precision-driven quotation. Trust our expertise in high-quality, complex forgings—engineered for aerospace, automotive, and beyond. Let’s deliver superior, reliable, and cost-effective solutions—starting with your inquiry!

Explore how materials are permanently reshaped under force to achieve desired engineering properties. ↩

Learn how managing flash is crucial for part quality and cost-effectiveness in forging. ↩

Discover how this heat treatment process creates high-strength properties in advanced aluminum alloys. ↩

Learn how this heat treatment process dramatically increases the strength of aluminum alloys. ↩

Discover how these advanced inspection techniques ensure flawless components without causing any physical damage. ↩

Learn how specific thermal cycles alter metal properties to meet extreme performance standards. ↩

Understand the science behind this microstructural state and why it’s essential for high-strength aluminum alloys. ↩

Learn how controlling grain flow is critical for achieving superior part strength and fatigue resistance. ↩

Learn more about how this high-temperature process enables the creation of complex, near-net-shape parts. ↩

Learn more about how quench rates impact the final properties and integrity of aluminum alloys. ↩

Discover how different rapid cooling methods affect material grain structure and overall part integrity. ↩

Discover how this AM-enabled tooling technology can dramatically improve cycle times and part quality. ↩