Výber nesprávneho výrobcu CNC obrábacích strojov môže narušiť celý časový plán projektu a rozpočet. Sledoval som, ako sa technické tímy boria s nekonzistentnou kvalitou, nedodržiavaním termínov a dodávateľmi, ktorí sa vytratia, keď sa objavia technické otázky.

Správny výrobca CNC obrábacích strojov kombinuje osvedčené schopnosti, certifikáty kvality, spoľahlivé harmonogramy dodávok a ústretovú komunikáciu, aby zabezpečil, že vaše diely budú spĺňať špecifikácie načas a v rámci rozpočtu.

V spoločnosti PTSMAKE pracujem s inžinierskymi tímami, ktoré pravidelne čelia tomuto rozhodnutiu. Výrobcovia, ktorých si vyberiete, priamo ovplyvňujú kvalitu vašich produktov, časový harmonogram projektu a celkový úspech. Táto príručka vás prevedie ôsmimi kľúčovými faktormi, ktoré oddeľujú spoľahlivých partnerov v oblasti CNC obrábania od tých, ktorí spôsobujú bolesti hlavy. Dozviete sa, ako vyhodnotiť možnosti, posúdiť štandardy kvality a vytvoriť partnerstvá, ktoré podporia vaše projekty od prototypu až po výrobu.

Pochopenie možností CNC obrábania

Už ste niekedy navrhli zložitú súčiastku, ale zistili ste, že jej výroba je oveľa náročnejšia alebo nákladnejšia, ako ste predpokladali? Tento nesúlad často pramení z nedostatkov v chápaní výrobných možností.

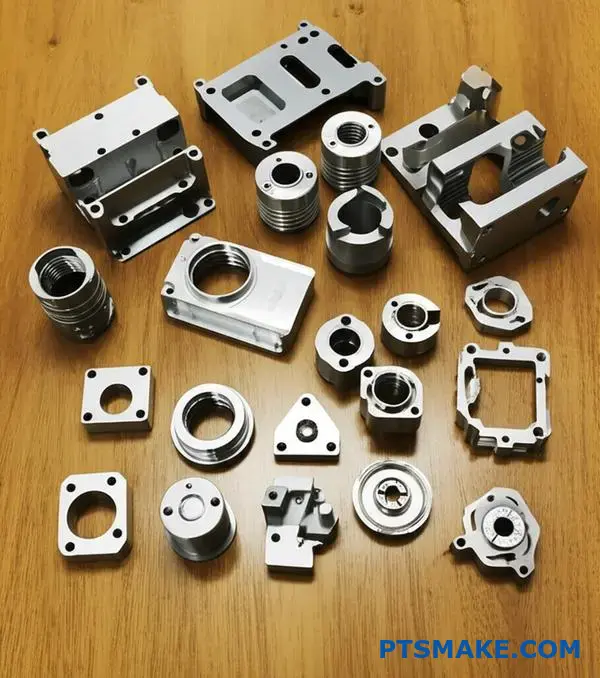

Pochopenie možností CNC obrábania zahŕňa znalosť základných procesov, ako je frézovanie a sústruženie, pokročilých možností, ako sú viacosové a hybridné systémy, a spôsobu, akým umožňujú dosiahnuť prísne tolerancie a komplexné geometrie. Tieto znalosti pomáhajú preklenúť priepasť medzi konštrukčným zámerom a vyrobiteľnosťou, čím sa zabezpečí kvalita a inovácia.

Nadácia: Frézovanie vs. sústruženie

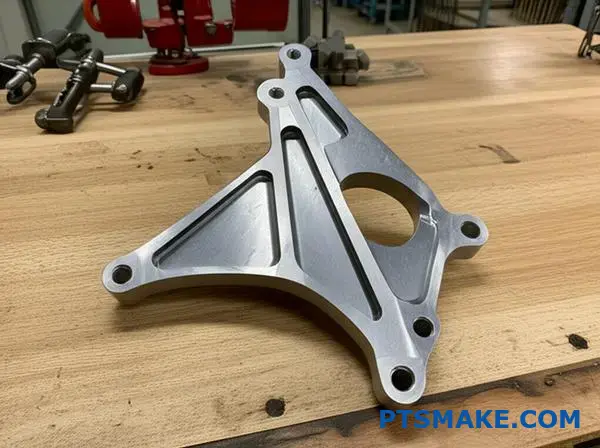

CNC obrábanie je vo svojej podstate subtraktívny proces. Začíname s pevným blokom materiálu a presne odrezávame materiál, aby sme vytvorili hotový diel. Dve základné metódy na tento účel sú frézovanie a sústruženie. Hoci obe rezajú materiál, ich prístup je úplne odlišný a výber tej správnej je prvým krokom k efektívnemu výrobnému plánu. V našich projektoch v spoločnosti PTSMAKE často začíname rozhovor tým, že si ujasníme, či je diel "dominantný pre frézovanie" alebo "dominantný pre sústruženie", aby sme hneď na začiatku stanovili správnu stratégiu.

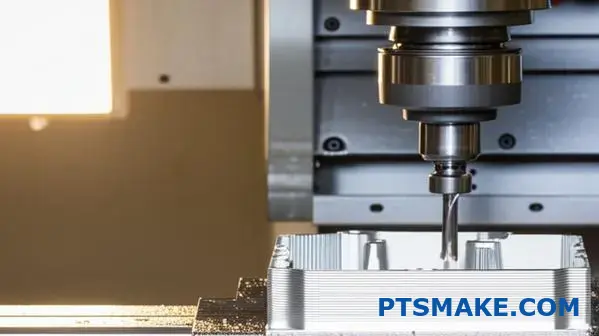

CNC frézovanie: Tvarovanie pomocou rotačného nástroja

Pri CNC frézovaní sa obrobok drží v pokoji, zatiaľ čo rotujúci rezný nástroj sa pohybuje pozdĺž viacerých osí a odoberá materiál. Táto metóda je neuveriteľne všestranná a je ideálna na vytváranie rovných povrchov, vreciek, drážok a zložitých 3D kontúr.

- 3-osové frézovanie: Ide o najbežnejšiu formu, pri ktorej sa nástroj pohybuje v smeroch X, Y a Z. Je ideálna pre jednoduchšie diely, ako sú konzoly, puzdrá a dosky.

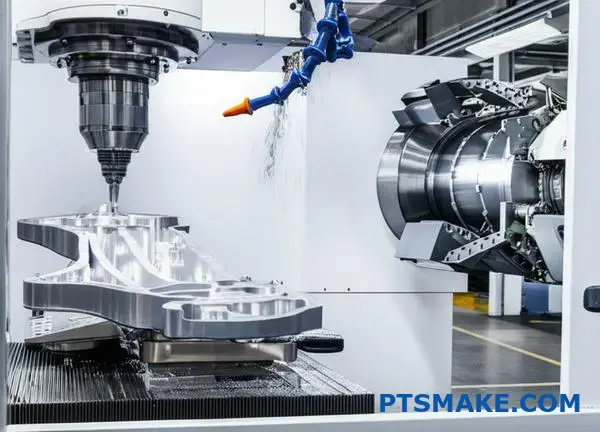

- 5-osové frézovanie: Tu sa veci stávajú zaujímavými. Pridaním dvoch rotačných osí sa môže rezný nástroj priblížiť k obrobku prakticky z akéhokoľvek uhla. To umožňuje zručnému

výrobca CNC obrábaniana vytváranie veľmi zložitých geometrií v rámci jedného nastavenia, čo výrazne zvyšuje presnosť, pretože znižuje chyby, ktoré sa môžu vyskytnúť pri ručnom prefixovaní súčiastky. Zlepšuje tiež čas cyklu a dokáže vytvárať hladšie a organickejšie povrchy.

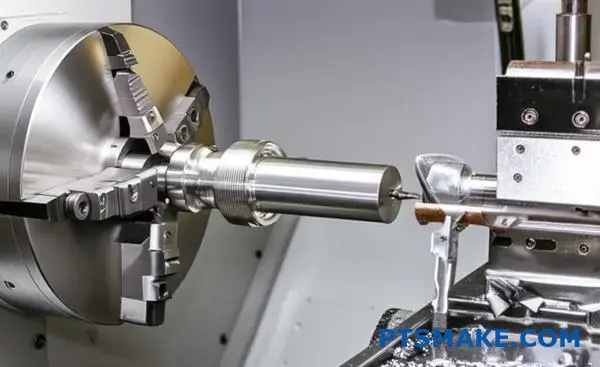

CNC sústruženie: Presnosť otáčania

Pri CNC sústružení sa obrobok otáča vysokou rýchlosťou, zatiaľ čo nehybný rezný nástroj odoberá materiál. Tento proces sa používa na vytváranie valcových alebo kužeľových dielov. Predstavte si hriadele, čapy, dýzy a spojovacie prvky. Sústruh CNC dokáže efektívne vyrábať prvky, ako sú drážky, závity a kužele, s mimoriadnou presnosťou. Princípy Geometrické dimenzovanie a tolerovanie1 sú tu rozhodujúce na definovanie sústrednosti a hádzania prvkov vzhľadom na stredovú os súčiastky.

Tu je jednoduché rozdelenie, ktoré vám pomôže ich rozlíšiť:

| Funkcia | CNC frézovanie | CNC sústruženie |

|---|---|---|

| Primárny pohyb | Rotujúci nástroj, stacionárny obrobok | Stacionárny nástroj, rotujúci obrobok |

| Typické geometrie | Štvorcové/ploché prvky, vrecká, komplexné 3D povrchy | Valcové, kužeľové, závitové prvky |

| Spoločné časti | Skrine, konzoly, rozdeľovače, jadrá foriem | Hriadele, čapy, puzdrá, armatúry, dýzy |

| Obrábacie stroje | Obrábacie centrum | Sústruh |

Výber medzi nimi nie je vždy exkluzívny. Mnohé komponenty si na dokončenie vyžadujú frézovanie aj sústruženie, a práve tu prichádzajú na rad multifunkčné stroje a starostlivé plánovanie procesov.

Posúvanie hraníc: Pokročilé schopnosti

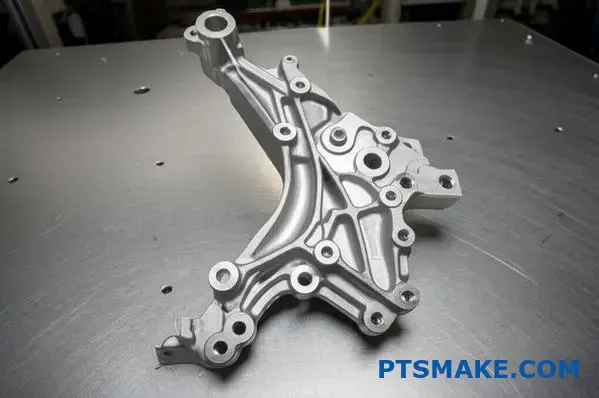

Samotné poznanie rozdielu medzi frézovaním a sústružením je len začiatok. Skutočná hodnota moderného výrobca CNC obrábania spočíva v jeho schopnosti využiť pokročilé technológie na premenu náročného návrhu na fyzickú realitu. Tu prechádzame od základnej výroby k vysoko presnej výrobe, čo umožňuje väčšiu slobodu pri navrhovaní a vynikajúci výkon výrobku. Pri predchádzajúcich prieskumoch s klientmi sme videli, ako môže posunutie týchto hraníc uvoľniť inovácie, ktoré sa predtým považovali za nemožné vyrobiť.

Výkon viacosového a hybridného obrábania

Dotkli sme sa päťosového frézovania, ale jeho vplyv je potrebné zdôrazniť. Schopnosť obrábať komplexné diely v rámci jedného nastavenia - často nazývaná výroba "done-in-one" - mení pravidlá hry. Nielenže eliminuje možnosť ľudskej chyby pri opakovanom nastavovaní, ale tiež zabezpečuje, že všetky prvky sú navzájom dokonale zarovnané. To má zásadný význam pre aplikácie v leteckom priemysle a zdravotníckych zariadeniach, kde je presnosť nevyhnutná.

Hybridná výroba ide ešte ďalej tým, že kombinuje aditívne procesy (napríklad 3D tlač kovov) a subtraktívne procesy (CNC obrábanie) v jednom stroji. To umožňuje vytvárať diely s vnútornými chladiacimi kanálmi alebo zložitými mriežkovými štruktúrami, ktoré nie je možné obrábať tradičným spôsobom.

Dosahovanie presných tolerancií a vynikajúcej povrchovej úpravy

"Tolerancia" sa vzťahuje na prípustnú odchýlku pre daný rozmer. "Tesná" tolerancia môže byť len ±0,005 mm (alebo 0,0002 palca). Dosiahnutie tohto cieľa si vyžaduje viac než len moderný stroj; vyžaduje si to holistický prístup.

- Stabilita stroja: Samotný stroj musí byť neuveriteľne tuhý a tepelne stabilný, aby sa zabránilo drobným odchýlkam počas prevádzky.

- Nástroje a stratégia: Výber rezného nástroja, jeho povlak a naprogramovaná dráha nástroja majú obrovský vplyv na konečnú presnosť a povrchovú úpravu.

- Životné prostredie: Dokonca aj výkyvy okolitej teploty v dielni môžu ovplyvniť tolerancie citlivých dielov. Aby sme to zmiernili, pracujeme v klimatizovanom prostredí.

Povrchová úprava (meraná v Ra) je rovnako dôležitá, najmä v prípade dielov, ktoré sa utesňujú, kĺžu alebo majú špecifické estetické požiadavky. Rôzne procesy poskytujú rôzne povrchové úpravy.

| Schopnosti | Typická špecifikácia | Vplyv na dizajn | Najvhodnejšie pre |

|---|---|---|---|

| Štandardná tolerancia | ±0,1 mm (±0,004") | Dobré pre všeobecné diely, skrinky | Spotrebné výrobky, konštrukčné konzoly |

| Prísna tolerancia | ±0,01 mm (±0,0004") | Umožňuje presné uloženie, zarovnanie a rozhrania | Zdravotnícke pomôcky, letecké a vesmírne komponenty, motory |

| Štandardná povrchová úprava | 3,2 μm Ra | Obrábané, viditeľné stopy po nástrojoch | Nekritické povrchy, vnútorné komponenty |

| Jemná povrchová úprava | 0,8 μm Ra | Hladký, reflexný povrch | Tesniace plochy, uloženie ložísk, estetické časti |

Pochopenie týchto pokročilých možností vám ako konštruktérovi umožňuje s istotou špecifikovať požiadavky, pretože viete, že ich možno splniť. Otvára to dvere k vytváraniu kompaktnejších, účinnejších a spoľahlivejších výrobkov.

Kľúčové sú hlboké znalosti možností CNC, od základného frézovania a sústruženia až po pokročilé viacosé obrábanie. Tieto znalosti umožňujú inžinierom navrhovať s ohľadom na vyrobiteľnosť, dosahovať prísne tolerancie a zložité geometrie a v konečnom dôsledku vytvárať kvalitnejšie a inovatívnejšie výrobky.

Ako hodnotiť normy kontroly kvality?

Už sa vám niekedy stalo, že ste schválili cenovú ponuku na základe pôsobivých tvrdení o kvalite, ale dostali ste diely, ktoré sa jednoducho minuli účinkom? Táto malá odchýlka môže zastaviť celú vašu výrobnú linku.

Ak chcete správne vyhodnotiť kontrolu kvality, musíte sa pozrieť ďalej ako len na certifikát na stene. Spoľahlivý výrobca CNC obrábacích strojov preukazuje kvalitu prostredníctvom overiteľného súladu s normou ISO 9001, zdokumentovaných vnútroprocesných kontrol v kritických fázach a aktívneho využívania štatistickej kontroly procesov (SPC) na predchádzanie odchýlkam skôr, ako sa vyskytnú.

Základ dôvery: Certifikáty a inšpekcie

Keď preverujete nového výrobného partnera, certifikáty sú pravdepodobne prvou vecou, ktorú skontrolujete. Slúžia ako základný ukazovateľ záväzku spoločnosti voči kvalite. Nie všetky certifikáty sú však rovnaké a samotný papier je menej dôležitý ako systémy, ktoré reprezentuje.

ISO 9001: viac ako len odznak

Takmer každý seriózny výrobca má certifikát ISO 9001. Čo to však znamená pre váš projekt? Znamená to, že spoločnosť má systém riadenia kvality (QMS). Nie je to len dokument, je to rámec pre ich činnosť. Znamená to, že majú definované postupy pre všetko od manipulácie s prichádzajúcimi surovinami až po konečnú kontrolu a expedíciu dielov. Kľúčovou súčasťou normy ISO 9001 je požiadavka na neustále zlepšovanie. To núti výrobcu sledovať nezhody, nájsť ich hlavnú príčinu a zaviesť nápravné opatrenia, aby sa zabránilo ich opakovaniu. Keď spolupracujeme s klientmi v leteckom alebo automobilovom priemysle, často musíme dodržiavať ešte prísnejšie normy, ako sú AS9100 alebo IATF 16949, ktoré vychádzajú zo základov normy ISO 9001 a obsahujú špecifické požiadavky pre dané odvetvie. Existencia týchto systémov je silným ukazovateľom vyspelosti a spoľahlivosti dodávateľa. Ukazuje, že má opakovateľný proces na zabezpečenie kvality. Veda Metrológia2 je základom všetkých týchto systémov kvality a zabezpečuje presnosť a spoľahlivosť každého merania.

Kontrolné body: Včasné zachytenie chýb

Kvalitný plán je len taký dobrý, ako je jeho realizácia. Tu prichádzajú na rad inšpekcie. Spoliehať sa len na záverečnú kontrolu pred expedíciou je obrovské riziko. Ak sa dovtedy zistí problém, celá dávka môže byť zošrotovaná, čo vedie k obrovským oneskoreniam a nákladom. Preto sú kontroly v priebehu procesu neoddiskutovateľné.

| Typ kontroly | Kľúčový účel | Keď sa vyskytne |

|---|---|---|

| Kontrola prvého článku (FAI) | Overenie, či je výrobný proces schopný vyrobiť diel, ktorý spĺňa všetky špecifikácie. | Pred spustením hlavnej výrobnej série. |

| In-Process Inspection (IPI) | Monitorovať proces a zachytiť odchýlky alebo opotrebovanie nástrojov skôr, ako sa prejaví v chybných dieloch. | V plánovaných intervaloch alebo kritických krokoch počas výroby. |

| Konečná kontrola kvality (FQC) | Vykonanie konečného overenia dokončených dielov podľa technických výkresov a požiadaviek. | Po ukončení výroby, pred zabalením. |

V minulých projektoch sme v spoločnosti PTSMAKE zistili, že zavedenie kľúčovej kontroly v procese po dlhom cykle CNC frézovania zložitého komponentu zdravotníckeho zariadenia znížilo konečnú mieru zamietnutia o viac ako 70%. Zachytila jemné opotrebenie nástroja, ktoré nebolo zjavné, kým sa neobrobilo niekoľko prvkov. Toto včasné odhalenie je to, čo odlišuje reaktívneho dodávateľa od proaktívneho partnera.

Kvalita založená na údajoch: Prechod od detekcie k prevencii

Najpokročilejší výrobcovia nekontrolujú len kvalitu, ale zapracúvajú ju do procesu pomocou údajov. Tento proaktívny prístup skutočne minimalizuje chyby a zabezpečuje konzistenciu od prvého dielu po desaťtisíci.

Štatistická kontrola procesov (SPC)

Štatistická kontrola procesov (SPC) je výkonná metodika založená na údajoch. Namiesto jednoduchej kontroly, či je diel "dobrý" alebo "zlý" (v rámci tolerancie alebo mimo nej), SPC monitoruje výkonnosť samotného procesu v reálnom čase. Na vykreslenie meraní z výrobných vzoriek používame regulačné diagramy. Tieto grafy majú horné a dolné kontrolné limity vypočítané z vlastných historických údajov procesu. Pokiaľ sa dátové body náhodne nachádzajú v týchto medziach, proces sa považuje za "riadený" a stabilný. Ak sa body začnú približovať k limitu alebo vykazujú iný ako náhodný vzor, signalizuje to, že sa niečo mení - možno sa opotrebúva nástroj alebo sa zmenila vlastnosť materiálu. To nám umožňuje zasiahnuť a problém odstrániť pred sa nikdy nevyrobili žiadne diely, ktoré by boli mimo špecifikácie. Je to najvyššia forma preventívneho zabezpečenia kvality a charakteristický znak špičkového výrobcu CNC obrábania.

Správne nástroje na prácu

Účinná kontrola kvality závisí od toho, či máte správne meracie zariadenia a viete, ako ich používať. Investície dodávateľa do laboratória kvality vypovedajú o jeho schopnostiach.

| Nástroj na meranie | Najlepšia aplikácia | Typická dosiahnuteľná presnosť |

|---|---|---|

| Súradnicový merací stroj (CMM) | Komplexné 3D diely, overovanie GD&T | Do 0,001 mm |

| Systém merania zraku | Malé, zložité 2D prvky, dávkové kontroly | Do 0,003 mm |

| Digitálny mikrometer | Vysoko presné priemery a hrúbky | Do 0,001 mm |

| Kalibrované meradlá kolíkov a závitov | Kontrola priemerov otvorov a závitov Go/No-Go | Vyhovel/nevyhovel na základe stanovenej normy |

Dôležité je, že všetky tieto nástroje musia byť súčasťou prísneho plánu kalibrácie. Nekalibrovaný mikrometer môže poskytovať falošný pocit bezpečia a je pravdepodobne nebezpečnejší ako žiadne meranie. V spoločnosti PTSMAKE sú naše kalibračné záznamy základnou súčasťou nášho systému riadenia kvality a pravidelne sa kontrolujú. Zabezpečujeme, aby každé meranie, ktoré poskytujeme našim klientom, bolo spätne sledovateľné na známy štandard, čo poskytuje úplnú dôveru vo výsledky. Tento disciplinovaný prístup je základom pre dodávanie dielov, ktoré spĺňajú najnáročnejšie špecifikácie.

Hodnotenie noriem kvality výrobcu presahuje rámec jeho certifikátu ISO. Zahŕňa potvrdenie používania vnútroprocesných kontrol na včasné zachytenie chýb a nástrojov založených na údajoch, ako je SPC, na ich úplné predchádzanie. Záväzok používať kalibrované, vysoko presné meracie zariadenia je poslednou časťou skladačky.

Dodacie lehoty a včasné dodanie.

Už sa vám niekedy stalo, že vám časový harmonogram projektu úplne zničil jeden oneskorený komponent? Frustrácia z toho, že sa termín spustenia posunul, pretože dodávateľ nemohol dodať načas, je riziko, ktoré nechce podstúpiť žiadny inžinier.

Spoľahlivý výrobca CNC obrábacích strojov zabezpečuje včasné dodávky tým, že ovláda plánovanie výroby, urýchľuje výrobu prototypov a efektívne riadi veľkoobjemové objednávky. To sa dosahuje prostredníctvom pokročilých systémov plánovania, špecializovaných tímov rýchlej reakcie a transparentnej komunikácie, ktoré menia sľuby na spoľahlivé termíny pre zákazkové aj výrobné diely.

Pri hodnotení výrobného partnera je jeho prístup k plánovaniu jedným z najdôležitejších ukazovateľov jeho spoľahlivosti. Je to oveľa viac ako len zapísanie dátumov do kalendára. Skutočne spoľahlivý harmonogram je dynamický systém, ktorý vyvažuje kapacitu strojov, dostupnosť materiálu, pracovnú silu a kontrolné body kontroly kvality. V spoločnosti PTSMAKE považujeme výrobný plán za centrálny nervový systém našich operácií, za živú mapu, ktorá vedie každú časť od surovín až po hotový výrobok.

Dekódovanie zložitosti výrobných plánov

Častým omylom je, že čas prípravy je jednoducho súčet hodín obrábania. V skutočnosti sa proces začína oveľa skôr. Zahŕňa podrobné preskúmanie návrhu pre vyrobiteľnosť (DFM) s cieľom zachytiť potenciálne problémy, po ktorom nasleduje programovanie CAM, nastavenie nástrojov a obstaranie materiálu. Každý z týchto krokov má svoj vlastný časový harmonogram, ktorý musí byť dokonale synchronizovaný. Na vytvorenie uceleného plánu využívame integrované systémy ERP, ktoré zabezpečujú, že suroviny sa dostanú presne načas na plánované miesto na stroji a že potrebné nástroje sú pripravené vopred. Tým sa predchádza bežným úzkym miestam, keď stroj stojí a čaká na materiál alebo pokyny. Táto metóda vyrovnávania výroby, niekedy známa ako Heijunka3, je kľúčom k vytvoreniu plynulého a predvídateľného pracovného postupu, minimalizácii času nečinnosti a maximalizácii efektívnosti všetkých projektov, nielen toho jedného.

Rýchlosť prototypovania: prvý test spoľahlivosti

Schopnosť výrobcu vyrábať prototypy rýchlo a presne je často silným ukazovateľom jeho celkovej efektívnosti. Rýchle a vysokokvalitné prototypy vám umožnia overiť váš návrh a s istotou prejsť do výroby. Pomalý proces výroby prototypov však môže spôsobiť kaskádové oneskorenia, ktoré ovplyvnia celý váš vývojový cyklus. Náš proces sme štruktúrovali tak, aby sme oddelili rýchle prototypovanie od hlavných výrobných sérií. To zahŕňa špecializované vybavenie a špecializovaný tím zameraný výlučne na rýchle otáčanie prototypov bez toho, aby bola ohrozená presnosť. Tento zjednodušený prístup výrazne skracuje počiatočnú fázu každého projektu.

Tu je porovnanie štandardného a optimalizovaného pracovného postupu:

| Funkcia | Štandardné prototypovanie | Optimalizované prototypovanie (náš prístup) |

|---|---|---|

| Úvodné preskúmanie | 24-48 hodín | Do 12 hodín, so spätnou väzbou DFM |

| Programovanie | Sekvenčný proces | Paralelné programovanie počas revízie |

| Prideľovanie strojov | Všeobecná výrobná fronta | Špecializovaná bunka na rýchlu výrobu prototypov |

| Typický obrat | 7-14 pracovných dní | 3-5 pracovných dní |

Tento optimalizovaný tok ukazuje, ako proaktívne výrobca CNC obrábania môže hneď na začiatku poskytnúť významnú výhodu.

Okrem rýchlych prototypov je skutočným testom partnera jeho schopnosť rozšíriť sa na veľké objemy objednávok pri zachovaní termínov a kvality. Prechod od výroby desiatich súčiastok k výrobe desiatich tisícok súčiastok prináša úplne iné logistické výzvy. Výrobca, ktorý pri tomto prechode vyniká, dokazuje svoje schopnosti a stáva sa dlhodobým strategickým prínosom. Nejde len o to, aby mal viac strojov, ale aj o to, aby mal procesy, dodávateľský reťazec a systémy kvality na podporu tohto rozsahu.

Stratégie na rozšírenie a zabezpečenie včasnosti

Úspešné riadenie veľkých objednávok si vyžaduje proaktívny, nie reaktívny prístup. To znamená plánovať kapacity, dôsledne riadiť dodávateľský reťazec a zavádzať systémy, ktoré predvídajú problémy skôr, ako nastanú. Naučili sme sa, že transparentnosť a spoľahlivé interné procesy sú kľúčom k predchádzaniu takým prekvapeniam, ktoré vedú k oneskoreniam. Spoľahlivý partner vás nikdy nenechá hádať o stave vašej objednávky.

Z jedného na tisíc: proces zväčšovania

Keď projekt prejde z prototypu do výroby, vytvoríme podrobný plán výroby. To zahŕňa hromadné obstarávanie surovín, aby sa zabezpečila lepšia cena a dostupnosť, vyhradenie konkrétnych strojov alebo výrobných buniek pre projekt, aby sa dosiahla konzistentnosť, a vývoj vlastných prípravkov alebo prípravkov na urýchlenie času nastavenia pri opakovaných objednávkach. Okrem toho náš plán preventívnej údržby zabezpečuje, aby boli stroje vždy v špičkovom stave, čím sa minimalizuje riziko neočakávaných prestojov, ktoré by mohli zastaviť veľkú sériovú výrobu. Práve tento typ myslenia do budúcnosti odlišuje priemerného dodávateľa od skutočného výrobného partnera.

Zmiernenie bežných rizík pri dodávkach

Aj tie najlepšie plány sa môžu stretnúť s problémami. Rozdiel spočíva v tom, ako sa na ne výrobca pripraví a ako na ne reaguje. V priebehu rokov sme vyvinuli jasné stratégie na zmiernenie najčastejších príčin oneskorení.

| Bežná príčina oneskorenia | Proaktívna stratégia zmierňovania |

|---|---|

| Nedostatok surovín | Vytvorenie vopred preverenej siete viacerých dodávateľov materiálu. |

| Neočakávané prestoje stroja | Zavedenie prísneho programu preventívnej údržby založeného na údajoch. |

| Problémy s kvalitou v polovici výroby | Používanie kontroly kvality v procese (IPQC) na včasné zachytenie odchýlok. |

| Zlyhania komunikácie | Pridelenie špecializovaného projektového manažéra ako jediného kontaktného miesta. |

Riešením týchto potenciálnych problémov sme do nášho procesu zakomponovali spoľahlivosť, vďaka ktorej sa môžeme bez obáv zaviazať a dodržať termíny dodania, na ktorých naši klienti závisia.

Dodávka načas nie je náhoda, ale výsledok dôsledného plánovania a aktívneho riadenia. Spoľahlivý výrobca CNC obrábacích strojov ovláda plánovanie výroby, od rýchlej výroby prototypov až po veľkosériovú výrobu, pomocou pokročilých systémov, jasnej komunikácie a dôsledného zmierňovania rizík, aby zabezpečil, že vaše diely budú dodané tak, ako bolo sľúbené.

Komunikácia s dodávateľmi a schopnosť reagovať

Mali ste niekedy pocit, že naliehavosť vášho projektu sa stráca v prázdnote pomalých e-mailových odpovedí a nejasných aktualizácií? Ste unavení z naháňania dodávateľov kvôli základným informáciám, ktoré by mali byť ľahko dostupné?

Efektívna komunikácia s dodávateľmi je založená na zrozumiteľnosti, rýchlom stanovení cien a proaktívnych aktualizáciách. Operatívny výrobca CNC obrábacích strojov okamžite rieši zmeny v návrhu, technické otázky a naliehavé požiadavky, čo buduje dôveru a udržiava váš projekt v súlade s harmonogramom a rozpočtom.

Základ dôvery: Jasná a aktívna komunikácia

Vo výrobe nie je komunikácia len o výmene informácií, ale je základom úspešného partnerstva. Keď dodávateľ komunikuje jasne a aktívne, signalizuje to rešpektovanie vášho času, rozpočtu a cieľov projektu. Nie je to len "príjemné mať" - je to kritická zložka, ktorá odlišuje priemerného dodávateľa od skutočného výrobného partnera. Bez nej môže aj technologicky najvyspelejšie zariadenie spôsobiť nákladné oneskorenia a frustráciu.

Od nejednoznačnosti k jasnosti

Jasná komunikácia sa začína počúvaním. Skvelý dodávateľ si len neprečíta objednávku, ale snaží sa pochopiť zámer za dizajnom. Kladú objasňujúce otázky týkajúce sa kritických vlastností, tolerancií a konečného použitia. Tým sa zabezpečí, že obe strany budú mať rovnakú predstavu o konečnom diele, čím sa predíde nedorozumeniam, ktoré by mohli viesť k vyradeniu alebo prepracovaniu. Tento proces dosiahnutia spoločného porozumenia je pre úspech projektu kľúčový. V našich projektoch v spoločnosti PTSMAKE vytvárame pre každý projekt jedno kontaktné miesto, aby sme tento proces zefektívnili a zabezpečili, že sa nič nestratí pri preklade. Toto zosúladenie, resp. izomorfizmus4, medzi vaším návrhom a naším výrobným plánom je neoddiskutovateľný.

Sila rýchlej citácie

Cenová ponuka je často prvou skutočnou interakciou s potenciálnym výrobca CNC obrábania. Pomalá, neúplná alebo nepresná citácia je hlavným varovným signálom. Naznačuje neorganizované interné procesy alebo nedostatočný záujem o váš projekt. Naopak, rýchla, podrobná a presná cenová ponuka svedčí o efektívnosti a rešpekte. Ukazuje, že dodávateľ má odborné znalosti na to, aby rýchlo analyzoval váš návrh, posúdil výrobné požiadavky a poskytol jasný rozpis nákladov. Táto počiatočná ústretovosť udáva tón celému vzťahu a dodáva vám istotu, že môžete napredovať.

Proaktívne aktualizácie verzus reaktívne odpovede

Najlepší dodávatelia nečakajú, kým ich požiadate o aktualizáciu. Poskytujú proaktívne informácie v kľúčových míľnikoch projektu. To buduje obrovskú dôveru a odstraňuje obavy z neznámeho.

| Komunikačný štýl | Reaktívny dodávateľ | Proaktívny dodávateľ (náš prístup) |

|---|---|---|

| Začiatok projektu | Potvrdzuje prijatie PO. | Potvrdzuje PO, poskytuje odhadovaný časový harmonogram s kľúčovými míľnikmi. |

| Počas výroby | Ticho, pokiaľ sa nevyskytne problém. | Odosiela aktualizácie pri míľnikoch (napr. prijatý materiál, ukončená kontrola prvého výrobku). |

| Potenciálny problém | Informuje vás po probléme, ktorý spôsobí oneskorenie. | Upozorní vás na potenciálny problém a navrhne riešenie skôr, ako ovplyvní harmonogram. |

| Preprava | Na požiadanie zašle číslo zásielky. | Odošle sledovacie číslo a automaticky potvrdí odoslanie. |

Udržiavanie projektov na správnej ceste: Reakcia v praxi

Dôvera sa buduje prostredníctvom proaktívnej komunikácie, ale je testovaná, keď sa objavia problémy. Projekt zriedkakedy prebieha presne podľa plánu. Návrhové súbory sa revidujú, objavujú sa technické otázky a vyskytujú sa neočakávané naliehavé situácie. To, ako dodávateľ reaguje v týchto kritických momentoch, definuje jeho hodnotu ako partnera. Reagujúci dodávateľ nereaguje len tak, ale má zavedené systémy na efektívne riadenie týchto udalostí, ktoré zabraňujú tomu, aby sa malé problémy rozrástli do veľkých oneskorení.

Agilné spracovanie zmien návrhu

Revízie dizajnu sú pri vývoji produktov realitou. Citlivý dodávateľ si to uvedomuje a má jasný proces ich riadenia. Keď predložíte revidovaný súbor CAD, nemali by ste čakať niekoľko dní na potvrdenie. Dodávateľ by mal zmenu rýchlo potvrdiť, posúdiť jej vplyv na náklady a časový plán a poskytnúť vám jasnú spätnú väzbu na schválenie. V minulosti sme sa u klientov stretli s tým, že pomalá reakcia na jednoduchú zmenu návrhu môže spôsobiť oneskorenie výroby o týždeň, čo následne ovplyvní celý harmonogram uvedenia výrobku na trh. Aby sme tomu zabránili, používame formálny proces ECN (Engineering Change Notice), ktorý zabezpečuje, že každá revízia je zdokumentovaná, skontrolovaná našimi inžiniermi a pred realizáciou potvrdená klientom.

Poskytovanie odborných technických odpovedí

Keď máte technickú otázku - či už ide o výber materiálu, možnosti povrchovej úpravy alebo návrh DFM (Design for Manufacturability) - musíte sa obrátiť na odborníka. Dodávateľ, ktorý reaguje, umožňuje svojim inžinierom prístup. Nemali by ste uviaznuť v slučke s predajcom, ktorý musí otázky prenášať sem a tam. Priamy prístup k inžinierskym odborníkom poskytuje okamžité a presné odpovede, ktoré vám pomôžu rýchlo prijať informované rozhodnutia. Tento prístup založený na spolupráci zaručuje, že konečný diel bude nielen správne vyrobený, ale aj optimalizovaný z hľadiska výkonu a nákladov.

Správa naliehavých požiadaviek

Niekedy potrebujete diel včera. Hoci to nie je vždy možné, dodávateľ, ktorý reaguje na požiadavky, má jasný protokol na vyhodnotenie naliehavých požiadaviek. Nebude jednoducho hovoriť "nie". Posúdi svoj aktuálny výrobný plán, preskúma možnosti urýchlenia a poskytne vám realistickú a úprimnú odpoveď o tom, čo je možné dosiahnuť.

| Fáza žiadosti | Nereagujúci dodávateľ | Citlivý dodávateľ |

|---|---|---|

| Prvotný kontakt | Odpoveď trvá 24-48 hodín. | Reaguje do niekoľkých hodín a potvrdí žiadosť. |

| Kontrola uskutočniteľnosti | Nejasná odpoveď: "Uvidíme, čo sa dá robiť." | Do jedného pracovného dňa poskytne konkrétnu odpoveď o uskutočniteľnosti a potenciálnom časovom pláne. |

| Kalkulácia nákladov | Poskytuje nadhodnotený "poplatok za urýchlenie" bez odôvodnenia. | Poskytuje jasnú cenovú ponuku s podrobnými informáciami o všetkých nákladoch na expedíciu (napr. nadčasy, špeciálna doprava). |

| Záväzok | Dá sľub, ktorý nemôže dodržať, čo vedie k oneskoreniu. | Dodržiava realistický časový plán a poskytuje časté aktualizácie. |

Jasná a aktívna komunikácia buduje základnú dôveru. Skutočne ústretový dodávateľ to dokazuje tým, že efektívne rieši zmeny návrhu, technické otázky a naliehavé požiadavky, čím udržiava váš projekt v pohybe bez nákladných oneskorení a posilňuje partnerstvo pri každej interakcii.

Výber materiálu a sledovateľnosť: Čo môžete očakávať od výrobcu CNC strojov?

Schválili ste niekedy prototyp, ktorý vyzeral perfektne, len aby ste videli, že v reálnom prostredí nečakane zlyhal? Problém sa často skrýva v neoverenej histórii materiálu.

Špičkový výrobca CNC obrábacích strojov overuje kvalitu materiálu prostredníctvom prísnej vstupnej kontroly a testovania, udržiava neprerušený reťazec sledovateľnosti od valcovne surovín až po finálny diel a poskytuje komplexnú dokumentáciu, ako sú protokoly o skúškach materiálu (MTR) a certifikáty zhody (CoC), ktoré zaručujú zhodu.

Základom každého vysokokvalitného obrábaného dielu je samotná surovina. Tvrdenie o použití konkrétnej triedy hliníka alebo nehrdzavejúcej ocele je bez spoľahlivého overovacieho procesu bezvýznamné. V spoločnosti PTSMAKE nepovažujeme overenie materiálu za posledné kontrolné políčko, ale za prvý kritický krok vo výrobnom procese. Ide o budovanie dôvery od základov.

Kontrola prichádzajúceho materiálu: Prvá línia obrany

Pred prijatím akéhokoľvek materiálu do našich zásob sa podrobí prísnej vstupnej kontrole. Nejde len o rýchly pohľad. Náš tím kvality starostlivo kontroluje dodávku na základe objednávky a dokumentácie dodávateľa. Overujeme rozmery, hľadáme akékoľvek povrchové chyby a uisťujeme sa, že materiál je riadne označený tepelným číslom alebo číslom šarže. Tento úvodný krok je kľúčový, pretože zachytí zjavné nezrovnalosti skôr, ako sa dostanú do výrobného procesu, čím sa ušetrí značný čas a zdroje. Každý materiál, ktorý nevyhovie tejto úvodnej kontrole, sa okamžite umiestni do karantény a vráti dodávateľovi.

Pokročilé testovanie pre nespochybniteľnú kvalitu

Vizuálne kontroly sú dôležité, ale nevypovedajú o všetkom. Na skutočné overenie integrity materiálu sa spoliehame na pokročilé testovacie metódy. Konkrétne testy závisia od materiálu a požiadaviek zákazníka, najmä v prípade dielov používaných v citlivých aplikáciách.

Overovanie chemického zloženia

V prípade kovových zliatin je potvrdenie presného chemického zloženia neoddiskutovateľné. Používame analyzátory pozitívnej identifikácie materiálu (PMI), ktoré využívajú technológiu tzv. spektrometria5, aby sa potvrdilo, že prvkové zloženie materiálu zodpovedá špecifikovanej triede. Napríklad zabezpečenie správneho percenta molybdénu v nehrdzavejúcej oceli 316 je rozhodujúce pre jej odolnosť voči korózii. Malá odchýlka môže viesť ku katastrofickému zlyhaniu v morskom alebo chemickom spracovateľskom prostredí.

Potvrdenie mechanických vlastností

V technickom liste materiálu sú uvedené jeho mechanické vlastnosti, ale často vykonávame vlastné testy na overenie týchto tvrdení. Patrí sem testovanie tvrdosti (metódami Rockwell alebo Brinell) a testovanie v ťahu. Ťahové skúšky sú deštruktívne, pretože ťaháme kus vzorky, kým sa neroztrhne, ale poskytujú neoceniteľné údaje o jeho pevnosti v ťahu, medze klzu a predĺžení. Tieto údaje potvrdzujú, že materiál bude pri mechanickom namáhaní fungovať tak, ako sa očakáva.

| Testovacia metóda | Primárny účel | Bežné aplikačné scenáre |

|---|---|---|

| Pozitívna identifikácia materiálu (PMI) | Overenie chemického zloženia zliatiny | Letecké komponenty, lekárske implantáty, vysokotlakové nádoby |

| Testovanie tvrdosti (Rockwell) | Meranie odolnosti voči lokalizovanej plastickej deformácii | Tepelne spracované diely, povrchy odolné proti opotrebovaniu, kontroly kvality |

| Ťahové skúšky (deštruktívne) | Určenie pevnosti a ťažnosti v ťahu | Kritické konštrukčné časti, nosné komponenty, overovanie nových materiálov |

| Ultrazvukové testovanie (UT) | na zisťovanie vnútorných chýb, ako sú praskliny alebo dutiny | Komponenty dôležité z hľadiska bezpečnosti, hrubé surové polotovary, kontroly zvarov |

Overenie je len polovica úspechu; udržanie tohto overenia počas celého výrobného procesu je to, čo definuje skutočne spoľahlivého partnera. Tu prichádza na rad vysledovateľnosť. Vysledovateľnosť je schopnosť sledovať cestu konkrétnej dávky materiálu od jej zdroja, cez každú operáciu obrábania až po konečný zabalený diel. Pre odvetvia, ako je letecký, zdravotnícky a automobilový priemysel, to nie je "pekné mať", ale povinná požiadavka.

Neprerušená reťaz: Vysledovateľnosť šarží a dávok

Od okamihu prijatia surového materiálu, tyče alebo plechu, je mu pridelené jedinečné interné číslo šarže. Toto číslo ju priamo spája s tepelným číslom dodávateľa a príslušným protokolom o skúške materiálu. Toto interné ID sa potom zaznamenáva a sleduje materiál v každom kroku: rezanie, CNC frézovanie, sústruženie, sekundárne operácie, ako je tepelné spracovanie alebo eloxovanie, a záverečná kontrola. V každej pracovnej objednávke je uvedená presná šarža materiálu, ktorá sa má použiť. Tým sa vytvára neprerušený reťazec dokumentácie. V nepravdepodobnom prípade, že sa neskôr objaví chyba materiálu, môžeme okamžite identifikovať každý jednotlivý diel vyrobený z danej šarže, aj keď boli súčasťou rôznych objednávok. Táto schopnosť je veľmi dôležitá pri cielenom sťahovaní výrobkov z trhu, čím sa minimalizuje riziko a zodpovednosť našich klientov.

Dokumentácia: Váš dôkaz o zhode

Ako inžinier alebo manažér obstarávania by ste nemali veriť slovu výrobcu. Dôkazom je dokumentácia. Profesionálny výrobca CNC obrábacích strojov bude aktívne poskytovať jasnú a komplexnú dokumentáciu.

Správy o skúškach materiálov (MTR)

Tento dokument, známy aj ako protokol o skúške vo valcovni alebo certifikovaný protokol o skúške vo valcovni (CMTR), pochádza priamo od výrobcu materiálu. Je to "rodný list" materiálu. Podrobne uvádza výsledky skúšok vykonaných na špecifickom tepelnom čísle materiálu vrátane jeho presnej chemickej analýzy a mechanických vlastností. Vždy sa ubezpečujeme, že MTR, ktoré sme dostali, zodpovedá materiálu, ktorý používame pre váš projekt.

Certifikáty zhody (CoC)

Zatiaľ čo MTR certifikuje suroviny, certifikát zhody (CoC) je dokument vydaný nami, výrobcom súčiastky. CoC je naše oficiálne vyhlásenie, že hotové diely, ktoré sme vyrobili, spĺňajú všetky vaše špecifikácie - od použitého materiálu až po rozmerové tolerancie, povrchovú úpravu a všetky ostatné požiadavky uvedené vo vašich výkresoch a objednávke. Je to posledná záruka, že to, čo dostanete, je presne to, čo ste si objednali.

| Typ dokumentu | Poskytuje | Čo certifikuje |

|---|---|---|

| Správa o skúške materiálu (MTR) | Materiálový mlyn | Chemické a fyzikálne vlastnosti dávky surovín (tepelné číslo). |

| Certifikát o zhode (CoC) | Výrobca dielu (PTSMAKE) | Hotový diel zodpovedá všetkým špecifikáciám a požiadavkám výkresu. |

| Záverečná správa z inšpekcie | Výrobca dielu (PTSMAKE) | Namerané rozmerové údaje pre špecifické prvky na hotových dieloch. |

Spoľahlivosť súčiastky sa začína jej materiálom. Dôveryhodný výrobca CNC obrábacích strojov zabezpečuje kvalitu prostredníctvom prísnych overovacích testov a udržiava úplný, neprerušený záznam o sledovateľnosti. Tento proces podporený jasnou dokumentáciou, ako sú MTR a CoC, zaručuje, že konečné komponenty spĺňajú prísne požiadavky akéhokoľvek odvetvia.

Efektívnosť nákladov a hodnotové inžinierstvo

Neviete pochopiť, prečo sa cenové ponuky CNC obrábania tak líšia? Obávate sa, že najnižšia cena môže byť spojená so skrytými nákladmi, ako sú oneskorenia alebo nízka kvalita, čo v konečnom dôsledku zničí rozpočet vášho projektu?

Skutočná hospodárnosť od popredného výrobcu CNC obrábacích strojov nie je o obetovaní kvality za nižšiu cenu. Dosahuje sa prostredníctvom strategickej kombinácie efektívnych procesov, inteligentnej automatizácie a spolupráce pri navrhovaní pre vyrobiteľnosť (DFM) s cieľom maximalizovať hodnotu od prototypu až po výrobu.

Častým omylom je, že nákladová efektívnosť znamená len nájdenie najlacnejšej ponuky. Skutočné náklady na obrábaný diel však ďaleko presahujú počiatočnú cenu. Zahŕňa potenciálne náklady na oneskorenia, zmetky a poruchy v teréne. Strategický partner pre CNC obrábanie sa zameriava na poskytovanie dlhodobej hodnoty optimalizáciou každého kroku výrobného procesu. To sa začína dlho predtým, ako stroj začne rezať.

Sila dizajnu pre vyrobiteľnosť (DFM)

Jednou z najvýznamnejších oblastí optimalizácie nákladov je DFM. Ide o proces spolupráce, pri ktorom spolupracujeme s vaším konštrukčným tímom na drobných úpravách, ktoré môžu viesť k veľkým úsporám. Napríklad v minulom projekte spoločnosti PTSMAKE obsahoval návrh klienta niekoľko hlbokých vreciek s veľmi ostrými vnútornými rohmi. Hoci to bolo možné dosiahnuť, vyžadovalo si to špecializované nástroje a výrazne dlhší čas obrábania. Navrhnutím o niečo väčšieho polomeru rohov sme zachovali plnú funkčnosť súčiastky a zároveň skrátili čas obrábania o viac ako 30%. Táto jednoduchá zmena, vykonaná pred začatím výroby, ušetrila klientovi značnú sumu na jeho veľkoobjemovej zákazke.

Efektívne procesy a optimalizácia dráhy nástroja

V dielni je kľúčová efektivita. Pokročilý softvér CAM nám umožňuje vytvárať vysoko optimalizované dráhy nástrojov, ktoré minimalizujú pohyb stroja a skracujú časy cyklov. Každá sekunda ušetrená na jednom diele znamená výrazné zníženie nákladov počas celej výrobnej série. Zameriavame sa aj na minimalizáciu času nastavenia prostredníctvom modulárnych prípravkov a štandardizovaných postupov. Táto pružnosť nám umožňuje rýchlo prepínať medzi jednotlivými úlohami, čím sa znižujú režijné náklady a zvyšuje sa naša konkurencieschopnosť pri malých aj veľkých sériách. Táto prevádzková dokonalosť je charakteristickým znakom špičkového výrobca CNC obrábania. Kľúčovým ukazovateľom, ktorý sledujeme, je Čas taktu6, čo nám pomáha prispôsobiť mieru výroby priamo dopytu zákazníkov, čím sa predchádza nadprodukcii a plytvaniu.

Výber a využitie materiálu

Náklady na materiál môžu tvoriť veľkú časť konečnej ceny súčiastky. Naša úloha zahŕňa viac než len objednávanie určených zásob. Analyzujeme geometriu dielu, aby sme vybrali najvhodnejšiu veľkosť suroviny a minimalizovali odpad. Pri nedávnej výrobe leteckej súčiastky sme zistili, že miernym preorientovaním súčiastky na skladový materiál sme mohli znížiť odpad o 15%, pričom sme tieto úspory preniesli priamo na zákazníka.

| Taktika optimalizácie | Štandardný prístup | Optimalizovaný prístup | Potenciálny vplyv na náklady |

|---|---|---|---|

| Vnútorné rohy | Ostré 90° rohy | Rádiusové rohy (napr. 3 mm) | 20-40% skrátenie času obrábania |

| Použitie materiálu | Predvolená veľkosť zásob | Optimalizovaná veľkosť hniezda/zásob | 5-15% zníženie materiálových nákladov |

| Hrúbka steny | Veľmi tenké steny (<0,5 mm) | Rovnomerné, hrubšie steny (>1 mm) | Znižuje vibrácie, zlepšuje povrchovú úpravu |

| Tolerancie | Všade príliš tesné | Len kritické tolerancie | Skracuje čas kontroly a znižuje počet vyradených výrobkov |

Vyváženie "železného trojuholníka" ceny, kvality a škálovateľnosti je neustálou výzvou, najmä pri prechode z jedného prototypu na celú sériovú výrobu. To, čo funguje v jednej fáze, nemusí byť optimálne v druhej. Kľúčom k úspechu je spolupracovať s výrobným partnerom, ktorý rozumie tomu, ako sa pohybovať v týchto kompromisoch, a môže poskytnúť jasnú cestu rastu.

Vytváranie prototypov: Rýchlosť a spätná väzba pred jednotkovými nákladmi

Počas fázy prototypovania sú hlavnými cieľmi rýchlosť a overenie návrhu. Náklady na jeden diel budú prirodzene vyššie, pretože náklady na nastavenie sa amortizujú len na jeden alebo niekoľko kusov. V tejto fáze sa hodnota nenachádza v najnižšej cene. Nachádza sa v rýchlom čase realizácie, ktorý umožňuje vášmu inžinierskemu tímu rýchlejšie iterovať. Taktiež sa nachádza v kvalite spätnej väzby. V spoločnosti PTSMAKE pri výrobe prototypu nedodávame len diel, ale poskytujeme správu DFM, ktorá poukazuje na potenciálne možnosti úspory nákladov pre budúce výrobné série. Táto investícia do spolupráce v počiatočnej fáze sa oplatí, keď príde čas na rozšírenie.

Výroba: Presun pozornosti na škálovateľnosť a konzistenciu

Pri prechode na malosériovú alebo hromadnú výrobu sa ekonomický model mení. Zameranie sa presúva na zníženie nákladov na jeden diel pri zachovaní absolútnej konzistencie. Práve tu sa počiatočná práca DFM stáva rozhodujúcou. Väčšiu úlohu zohráva aj automatizácia. Pri väčších sériách môžeme zaviesť robotické ramená na nakladanie a vykladanie dielov alebo použiť sondy v procese na automatizáciu kontroly kvality. Tieto investície znižujú náklady na pracovnú silu a ľudskú chybu a zabezpečujú, aby každý diel, od prvého po desaťtisíci, spĺňal presne rovnaké špecifikácie.

Skutočný význam škálovateľnosti

Skutočne škálovateľný výrobca CNC obrábania nemá len viac strojov, ale aj škálovateľné procesy. To znamená mať spoľahlivé systémy kvality, ktoré zvládnu zvýšený objem, zavedené dodávateľské reťazce materiálov a kontroly procesov potrebné na zabezpečenie konzistentnosti. Pri preverovaní partnera sa pýtajte, ako by zvládol 10-násobné zvýšenie objemu vašich objednávok. Ich odpoveď odhalí ich skutočnú škálovateľnosť.

| Fáza projektu | Primárny cieľ | Kľúčový faktor nákladov | Zameranie ideálneho partnera |

|---|---|---|---|

| Prototyp | Overovanie rýchlosti a dizajnu | Čas nastavenia a spätná väzba od inžinierov | Rýchle spracovanie, odborné znalosti DFM |

| Nízkoobjemové | Overenie procesu a prispôsobenie trhu | Čas obrábania a materiál | Flexibilné nastavenia, riadenie procesov |

| Veľkoobjemové | Náklady na jeden diel a konzistentnosť | Automatizácia a získavanie materiálov | Optimalizácia časov cyklu, dodávateľského reťazca |

Efektívne riadenie nákladov pri CNC obrábaní presahuje cenovú kategóriu. Zahŕňa partnerstvo zamerané na hodnotové inžinierstvo prostredníctvom inteligentného DFM, efektívnych procesov a jasnej stratégie na vyváženie ceny, kvality a škálovateľnosti, keď sa váš projekt vyvíja od jedného prototypu až po plnú výrobu.

Riadenie zložitosti viacerých dodávateľov

Už vás nebaví žonglovať s viacerými tabuľkami dodávateľov, zháňať aktualizácie od rôznych kontaktov a vyrovnávať sa s nekonzistentnou kvalitou? Spôsobuje táto zložitosť oneskorenia a prečerpáva váš rozpočet?

Riešením je konsolidácia dodávateľského reťazca s jedným integrovaným partnerom. Spolupráca s jedným odborným výrobcom CNC obrábacích strojov zefektívňuje komunikáciu, zjednocuje zabezpečenie kvality a zjednodušuje logistiku, čím vám ušetrí značný čas, peniaze a stres.

Skrytá záťaž roztriešteného dodávateľského reťazca

Riadenie viacerých dodávateľov sa môže zdať ako dobrý spôsob diverzifikácie rizika alebo hľadania najnižšej ceny pre každý komponent, ale často prináša skryté náklady a neefektívnosť, ktoré môžu projekt ochromiť. Zložitosť ďaleko presahuje správu niekoľkých faktúr navyše. Podľa mojich skúseností sa tieto problémy rýchlo nabaľujú a vytvárajú značné trenie v životnom cykle vývoja produktu.

Zlyhania komunikácie

Ak spolupracujete so samostatnými dodávateľmi pre CNC obrábanie, vstrekovanie a konečnú úpravu, vytvárate viacero nesúvislých komunikačných liniek. Každý dodávateľ má iné kontaktné miesto, iný štýl podávania správ a prípadne aj iné časové pásmo. Jednoduchá aktualizácia návrhu si vyžaduje koordináciu s každým jedným dodávateľom a zabezpečenie, aby všetci pochopili zmenu a jej vplyv na ich proces. To vytvára príležitosti na nesprávnu interpretáciu, čo vedie k chybám, prepracovaniu a oneskoreniam. To, čo by malo byť jednoduchou aktualizáciou, sa stáva zložitou logistickou úlohou, ktorá odčerpáva cenný čas inžinierov.

Nedôsledná kontrola kvality

Každý výrobný partner má svoje vlastné normy a procesy zabezpečenia kvality (QA). Jeden dodávateľ môže mať neuveriteľne prísne tolerancie pre svoje obrábané diely, zatiaľ čo lisované komponenty iného dodávateľa majú väčšiu prijateľnú odchýlku. Keď sa tieto diely musia bez problémov integrovať, aj malé rozdiely môžu viesť k veľkým montážnym problémom. Videl som projekty, ktoré sa oneskorili o niekoľko týždňov, pretože CNC obrábaný diel od jedného dodávateľa dokonale nesedel so vstrekovaným puzdrom od iného dodávateľa. Z hľadania príčiny sa stáva hra na obviňovanie, pričom vy sa ocitnete uprostred. Tento problém Fragmentácia dodávateľského reťazca7 je častým zdrojom zlyhania projektu.

Logistické nočné mory

Koordinácia logistiky z viacerých miest je práca na plný úväzok. Musíte riadiť rozložené harmonogramy dodávok, sledovať jednotlivé zásielky a vybavovať odlišné colné dokumenty pre každý dovoz. Oneskorenie jedného dodávateľa môže spôsobiť domino efekt a zastaviť celú výrobnú linku, pretože čakáte na kritický komponent. To má vplyv nielen na váš časový plán, ale zvyšuje aj náklady na prepravu a skladovanie zásob, pretože diely prichádzajú v rôznom čase a musia sa skladovať, kým nie sú všetky komponenty pripravené na montáž.

Tu je jednoduché rozdelenie pridanej zložitosti:

| Aspekt | Scenár s viacerými dodávateľmi | Partner z jedného zdroja |

|---|---|---|

| Komunikácia | Viacero kontaktov, časových pásiem a štýlov hlásení. | Jediný kontaktný bod pre celý projekt. |

| Kontrola kvality | Rozdielne normy, riziko problémov s integráciou. | Jednotný systém kontroly kvality, ktorý zabezpečuje, aby všetky diely sedeli a fungovali. |

| Logistika | Viacnásobné zásielky, colné formuláre a časové harmonogramy. | Jedna konsolidovaná zásielka, zjednodušené papierovanie. |

| Zodpovednosť | Rozptýlená zodpovednosť, možnosť obviňovania. | Plná zodpovednosť za konečný výsledok. |

Strategická výhoda integrovaného výrobného partnera

Prechod od prístupu viacerých dodávateľov k partnerovi z jedného zdroja nie je len o pohodlí, ale je to strategický krok, ktorý poskytuje silnú konkurenčnú výhodu. Integrovaný výrobca CNC obrábania ktorá poskytuje aj služby, ako je vstrekovanie plastov, pôsobí ako skutočná nadstavba vášho tímu a od začiatku až do konca zosúlaďuje svoje procesy s cieľmi vášho projektu. Táto synergia mení proces obstarávania zo série transakcií na partnerskú spoluprácu.

Jediný zdroj pravdy

Najbezprostrednejšou výhodou je, že máte jediné kontaktné miesto. V spoločnosti PTSMAKE naši projektoví manažéri dohliadajú na každú fázu výroby, od počiatočnej analýzy DFM pre CNC frézovaný prototyp až po záverečnú kontrolu kvality veľkej série lisovaných dielov. Keď máte otázku alebo potrebujete vykonať zmenu, máte jednu osobu, ktorej môžete zavolať. Táto osoba rozumie celému rozsahu vášho projektu a zabezpečuje, aby sa všetky úpravy bez problémov komunikovali vo všetkých interných oddeleniach. Tým sa eliminuje riziko nesprávnej komunikácie a zabezpečí sa, že všetci budú pracovať podľa rovnakého návodu.

Jednotná a nekompromisná kvalita

Ak je jeden partner zodpovedný za všetky komponenty, je plne zodpovedný za konečnú zhodu a funkčnosť. Neexistuje žiadne ukazovanie prstom. Integrovaný partner zaručuje, že povrchová úprava obrábaného hliníkového dielu je dokonalá pre proces pretláčania, ktorý bude tiež spracovávať. Zaručujú, že CNC sústružený kolík bude presne pasovať do vstrekovaného ozubeného kolesa, pretože kontrolujú tolerancie oboch. Náš systém kvality v spoločnosti PTSMAKE je navrhnutý tak, aby zvládal tieto vzájomné závislosti a vykonával skúšky lícovania a kontroly funkčnosti pred tým, ako sa čokoľvek dodá. Tento jednotný proces kontroly kvality odbúrava riziko pre montážnu linku a zabezpečuje, že konečný výrobok bude presne zodpovedať vašim špecifikáciám.

Zrýchlenie časového harmonogramu a zjednodušenie logistiky

Integrovaný partner dokáže optimalizovať celý výrobný proces. Napríklad môžeme začať obrábať kritické kovové vložky na CNC, zatiaľ čo sa vstrekovacia forma ešte vyrába. Toto paralelné spracovanie riadené pod jednou strechou môže výrazne skrátiť celkový čas realizácie v porovnaní s čakaním na dokončenie jedného dodávateľa pred odoslaním dielov ďalšiemu. Po dokončení výroby sa všetko skonsoliduje do jednej zásielky. To znamená jednu faktúru, jednu sadu colných dokumentov a jednu dodávku, ktorú treba sledovať. Toto zjednodušenie nielenže znižuje administratívnu záťaž, ale znižuje aj náklady na prepravu a dostáva váš výrobok na trh rýchlejšie.

Žonglovanie s viacerými dodávateľmi prináša skryté náklady v dôsledku porúch komunikácie, nezrovnalostí v kvalite a logistickej zložitosti. Spolupráca s jedným integrovaným výrobca CNC obrábania zefektívňuje prevádzku tým, že poskytuje jedno kontaktné miesto, jednotnú kontrolu kvality a zjednodušenú logistiku, čím zabezpečuje efektívnejší a spoľahlivejší výrobný proces.

Budovanie dlhodobých partnerstiev

Už vás nebaví nekonečný cyklus tvorby ponúk a preverovania nových dodávateľov pre každý projekt? Obávate sa, že ďalší nový dodávateľ by nemusel pochopiť vaše štandardy kvality, čo by viedlo k nákladným oneskoreniam?

Silné a dlhodobé partnerstvo s výrobcom CNC obrábacích strojov je strategickou výhodou. Buduje základ dôvery, zabezpečuje konzistentnú kvalitu, neochvejnú spoľahlivosť a inovácie založené na spolupráci, ktoré sú hnacím motorom udržateľného úspechu ďaleko za hranicou jednej objednávky.

Nadácia: Prechod od transakcie k dôvere

Výber výrobcu CNC obrábacích strojov nie je len o hľadaní najnižšej ceny, ale aj o hľadaní partnera, ktorý dokáže dôsledne plniť vaše špecifikácie. Na začiatku je každý vzťah transakčný. Vy pošlete objednávku, oni dodajú diely. Skutočné partnerstvo sa však začína formovať, keď sa táto transakcia vyvinie do hlbšieho porozumenia.

Dôslednosť je kráľ

S novým dodávateľom musíte zakaždým znovu vysvetľovať svoje normy kvality, požiadavky na povrchovú úpravu a kritické tolerancie. Dlhodobý partner sa však naučí vaše preferencie. Vie, ktoré povrchy sú kozmetické, ktoré rozmery sú pre funkciu kritické a ako musia vyzerať vaše kontrolné správy. Tieto spoločné znalosti eliminujú trenie a výrazne znižujú možnosť nesprávnej interpretácie. Pri našej práci v spoločnosti PTSMAKE sme videli, že to Vzájomné zosúladenie procesov8 je kľúčom k zníženiu počtu nezhôd a zrýchleniu časového harmonogramu projektu. Výrobca sa stáva rozšírením vášho vlastného tímu kvality, ktorý predvída vaše potreby a nereaguje len na vaše výkresy.

Skutočný význam spoľahlivosti

Spoľahlivosť je viac ako len včasné dodanie. Ide o komunikáciu, transparentnosť a riešenie problémov. Spoľahlivý partner vás informuje o potenciálnom probléme vo výrobe pred ovplyvňuje váš termín, nie po ňom. V spolupráci s vami nájdu riešenie, či už ide o úpravu tolerancie alebo návrh alternatívnych materiálov. Táto proaktívna komunikácia buduje úroveň dôvery, ktorú jednorazový transakčný vzťah nikdy nemôže dosiahnuť. Časom sa prestanete obávať, či sa diely objavia; viete, že sa objavia, a viete, že budú správne.

Táto tabuľka znázorňuje rozdiel v časových investíciách pri práci s novým dodávateľom v porovnaní so zavedeným partnerom na typickom projekte:

| Úloha | Čas s novým dodávateľom | Čas so zavedeným partnerom |

|---|---|---|

| Nástup na palubu a overovanie | 8-16 hodín | 0 hodín |

| Technické objasnenie | 2-5 hodín | <1 hodina |

| Preskúmanie normy kvality | 3-6 hodín | 0 hodín |

| Riadenie projektu | Vysoká | Nízka |

Ako vidíte, skryté náklady na neustálu zmenu dodávateľa sa rýchlo sčítajú, a to nielen v peniazoch, ale aj vo vašom drahocennom inžinierskom čase.

Výplata: Spolupráca a strategická výhoda

Po vytvorení základov dôvery a spoľahlivosti sa začnú prejavovať skutočné výhody dlhodobého partnerstva. Váš výrobca CNC obrábacích strojov sa zmení z jednoduchého dodávateľa na strategického spolupracovníka, ktorý aktívne prispieva k vášmu úspechu.

Uvoľnenie spolupráce v oblasti inovácií

Jednou z najsilnejších výhod je prístup k proaktívnej spätnej väzbe v oblasti DFM (Design for Manufacturability). Partner, ktorý rozumie konečnému použitiu vášho výrobku, môže ponúknuť poznatky, ktoré ďaleko presahujú rámec tlače. V minulom projekte s klientom z automobilového sektora im naše včasné vstupy DFM na komplexný hliníkový kryt pomohli zlúčiť dva komponenty do jedného. Táto zmena navrhnutá našimi inžiniermi, ktorí rozumeli ich dlhodobým cieľom, nielenže znížila náklady na diel o 30%, ale tiež zlepšila štrukturálnu integritu komponentu. Nový dodávateľ, zameraný len na aktuálnu zákazku, by jednoducho opracoval dve samostatné časti podľa návrhu. Takáto spolupráca v oblasti inovácií je možná len vtedy, keď obe strany investujú do dlhodobého výsledku.

Získanie konkurenčnej výhody

Strategické partnerstvo poskytuje významnú konkurenčnú výhodu, najmä na nestabilnom trhu. Keď sa vyskytne nedostatok materiálu alebo sa obmedzí kapacita strojov, koho si myslíte, že výrobca uprednostní? Jednorazovému zákazníkovi, ktorý hľadá najlacnejšiu cenu, alebo lojálnemu partnerovi, s ktorým spolupracuje už roky? Tento prioritný prístup zabezpečuje, že vaše výrobné linky budú bežať aj vtedy, keď sa vaša konkurencia môže zastaviť. Poskytuje takú úroveň odolnosti dodávateľského reťazca, ktorú nie je možné dosiahnuť prostredníctvom čisto transakčných vzťahov.

Tu je porovnanie toho, čo môžete očakávať od transakčného dodávateľa v porovnaní so strategickým partnerom:

| Atribút | Transakčný dodávateľ | Strategický partner |

|---|---|---|

| Komunikácia | Reaktívne | Proaktívny a kolaboratívny |

| Vstup DFM | Žiadne alebo na požiadanie | Ponúka sa skoro a často |

| Riešenie problémov | Hlásenie problémov | Navrhuje riešenia |

| Priorita | Nízka | Vysoká |

| Zameranie | Cena za diel | Celkové náklady a dlhodobá hodnota |

Investícia do partnerstva s výrobcom CNC obrábacích strojov v konečnom dôsledku znamená, že nekupujete len súčiastky, ale zabezpečujete si kapacitu, odborné znalosti a oddaného spojenca, ktorý vám pomáha pri inováciách a raste.

Výber výrobcu CNC obrábacích strojov by sa mal považovať za dlhodobé strategické rozhodnutie. Partnerstvo založené na dôvere prináša konzistentnú kvalitu, spoľahlivosť a inovácie založené na spolupráci, čím sa váš dodávateľ mení z položky v tabuľke na skutočnú konkurenčnú výhodu pre vašu firmu.

Zistite, ako môže ovládanie GD&T výrazne zlepšiť komunikáciu s výrobcom a zabezpečiť, aby boli vaše diely vyrobené správne hneď na prvýkrát. ↩

Zistite viac o vede o meraní a o tom, prečo je rozhodujúca pre dosiahnutie vysoko presných výrobných výsledkov. ↩

Zistite, ako táto technika vyrovnávania výroby pomáha výrobcom zabezpečiť stabilné a predvídateľné časy dodania pre všetkých zákazníkov. ↩

Zistite, ako tento princíp štrukturálnej podobnosti zaručuje, že sa váš návrhový zámer dokonale odzrkadlí vo finálnej časti. ↩

Objavte vedecké poznatky o tom, ako spektrometria zabezpečuje, aby chemické zloženie vášho materiálu zodpovedalo technickým špecifikáciám. ↩

Zistite, ako tento princíp štíhlej výroby pomáha optimalizovať výrobný tok a znižovať náklady pri CNC obrábaní. ↩

Kliknutím sa dozviete, ako môže prekonanie roztrieštenosti dodávateľského reťazca priamo zvýšiť efektívnosť vášho projektu a znížiť nákladné riziká. ↩

Zistite, ako môže zosúladenie výrobných procesov s vaším partnerom znížiť množstvo odpadu a skrátiť cyklus vývoja produktu. ↩