A maquinação CNC tradicional de 3 eixos atinge um obstáculo quando são necessárias geometrias complexas, tolerâncias apertadas ou peças intrincadas com várias superfícies. Está preso a múltiplas configurações dispendiosas, tempos de ciclo mais longos e o risco constante de erros de posicionamento que podem arruinar toda uma produção.

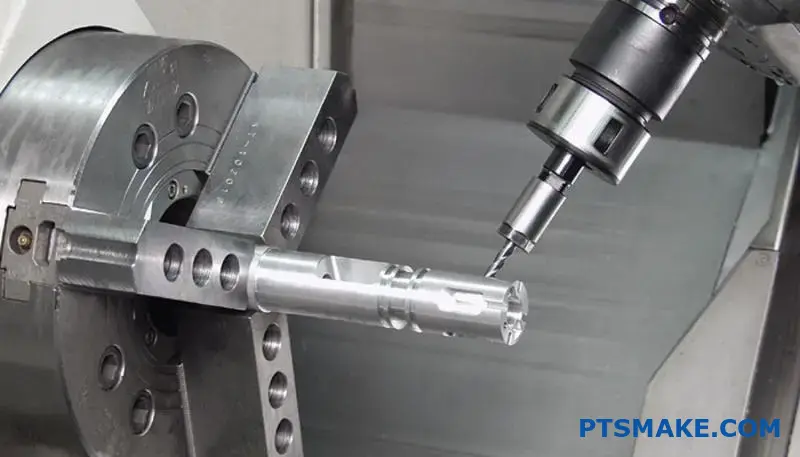

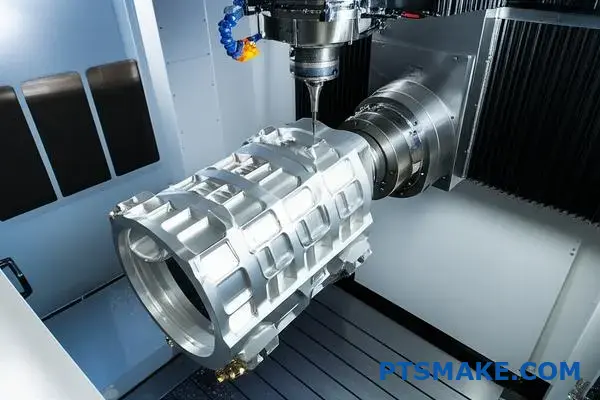

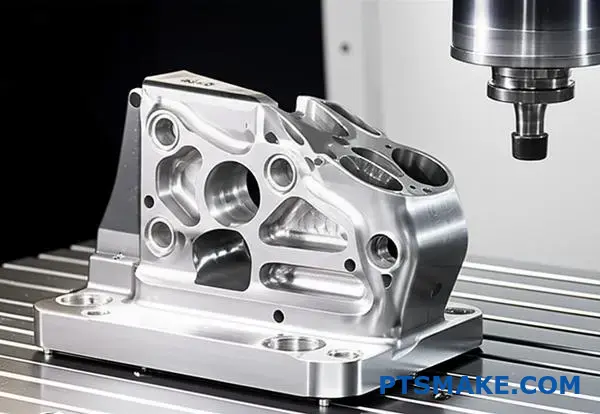

A maquinagem CNC multieixos desbloqueia capacidades de fabrico avançadas ao permitir o movimento simultâneo em 4, 5 ou mais eixos, permitindo a criação de geometrias complexas em configurações únicas, reduzindo drasticamente os tempos de ciclo e melhorando a precisão para indústrias com elevada procura, como a aeroespacial, a automóvel e a de dispositivos médicos.

A mudança da maquinação tradicional para a tecnologia multieixos não é apenas uma atualização - é uma transformação completa do que é possível no fabrico de precisão. Na PTSMAKE, tenho visto os fabricantes a debaterem-se com as limitações dos métodos convencionais, apenas para descobrirem que a maquinação multieixos resolve problemas que nem sequer sabiam que podiam resolver. Este guia irá guiá-lo por tudo o que precisa de saber sobre como tirar partido desta tecnologia para se manter competitivo no exigente mercado atual.

Aplicações específicas do sector da maquinagem CNC multieixos?

Está a ter dificuldades em fabricar geometrias complexas com a precisão exigida pelas indústrias modernas? As múltiplas configurações de máquinas estão a inflacionar os seus custos e a prolongar os prazos de entrega, atrasando o seu projeto?

A maquinagem CNC multieixos é uma solução transformadora para sectores de elevada procura como o aeroespacial, o automóvel e o médico. Permite a produção de peças incrivelmente complexas com uma precisão superior numa única configuração, assegurando que as indústrias podem cumprir normas rigorosas de precisão, fiabilidade e qualidade.

A maquinagem CNC multieixos não é apenas uma atualização; é um requisito fundamental para as indústrias mais inovadoras da atualidade. A capacidade de mover uma ferramenta de corte ou uma peça de trabalho ao longo de quatro, cinco ou mais eixos em simultâneo abre possibilidades de design que são simplesmente impossíveis com as máquinas tradicionais de 3 eixos. Esta tecnologia aborda diretamente os principais desafios do fabrico de peças com curvas intrincadas, bolsos profundos e ângulos complexos, que são comuns em aplicações de elevado desempenho. Na minha experiência no PTSMAKE, a conversa mudou de "Pode ser feito?" para "Como podemos optimizá-lo para a produção de 5 eixos?" Esta mudança é motivada pela necessidade de melhorar o desempenho das peças, reduzir o peso e consolidar as montagens.

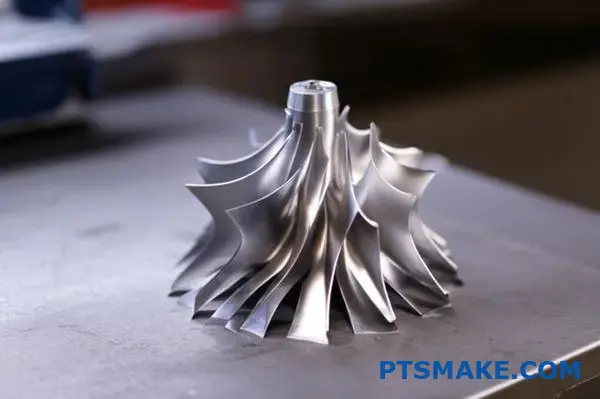

Aeroespacial: Maquinação para ambientes extremos

Na indústria aeroespacial, não há espaço para erros. Os componentes têm de suportar temperaturas, pressões e tensões extremas e, ao mesmo tempo, ser tão leves quanto possível. É aqui que a maquinagem CNC multieixos brilha. É utilizada para criar peças como lâminas de turbinas, impulsores e estruturas complexas a partir de superligas como o Inconel e o titânio. Uma lâmina de turbina de peça única, por exemplo, tem superfícies de aerofólio complexas que devem ser perfeitamente lisas para maximizar a eficiência. A maquinação desta peça a partir de um bloco sólido numa única configuração numa máquina de 5 eixos elimina os erros de empilhamento de tolerância que poderiam ocorrer com várias configurações. Esta abordagem de configuração única é crucial para manter a qualidade da peça. cinemática1 e a integridade estrutural.

Dispositivos médicos: Precisão que salva vidas

O sector médico exige uma precisão absoluta e biocompatibilidade. Os instrumentos cirúrgicos, os implantes ortopédicos, como as próteses de joelho ou anca, e as próteses personalizadas são frequentemente produzidos utilizando a maquinagem multieixos. Estes componentes têm formas orgânicas e ergonómicas que têm de se adaptar perfeitamente ao corpo humano. Além disso, o acabamento da superfície deve ser excecionalmente suave para evitar a contaminação e garantir a biocompatibilidade. As máquinas multieixos podem criar estas superfícies de forma livre com um percurso de ferramenta contínuo, produzindo um acabamento que muitas vezes requer um pós-processamento mínimo.

| Caraterística | Maquinação de 3 eixos | Maquinação CNC multieixos |

|---|---|---|

| Complexidade da peça | Limitado a geometrias mais simples | Lida com curvas e ângulos complexos |

| Tempo de configuração | Elevado (são necessárias várias configurações) | Baixa (frequentemente uma única configuração) |

| Exatidão | Bom, mas com riscos de empilhamento de tolerância | Excelente, alta repetibilidade |

| Ideal para | Suportes, placas, caixas simples | Implantes, lâminas de turbina, impulsores |

Este quadro mostra por que razão a transição para a tecnologia multieixos não é apenas uma tendência, mas uma necessidade para atingir a qualidade e a complexidade exigidas por estes sectores críticos.

Para além das aplicações bem conhecidas nos sectores aeroespacial e médico, a influência da maquinagem CNC multieixos estende-se profundamente a outros sectores avançados. Cada indústria tira partido desta tecnologia para resolver desafios únicos, quer se trate da miniaturização da eletrónica ou da aceleração dos ciclos de desenvolvimento no mundo automóvel. A linha comum é a procura de maior precisão, eficiência e liberdade de design. Em projectos anteriores com clientes, vimos em primeira mão como a adoção de uma estratégia multieixos pode alterar fundamentalmente o desempenho de um produto e o tempo de colocação no mercado. Trata-se de mais do que apenas cortar metal; trata-se de permitir a próxima geração de tecnologia.

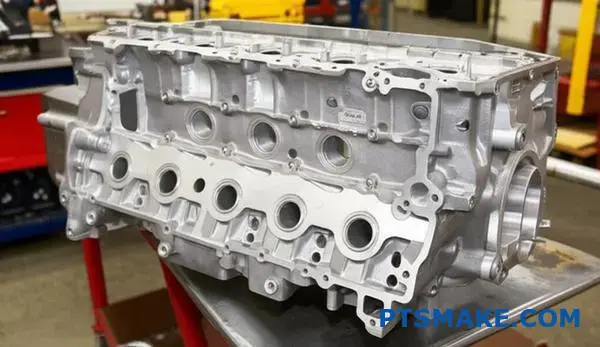

Automóvel: Velocidade e desempenho

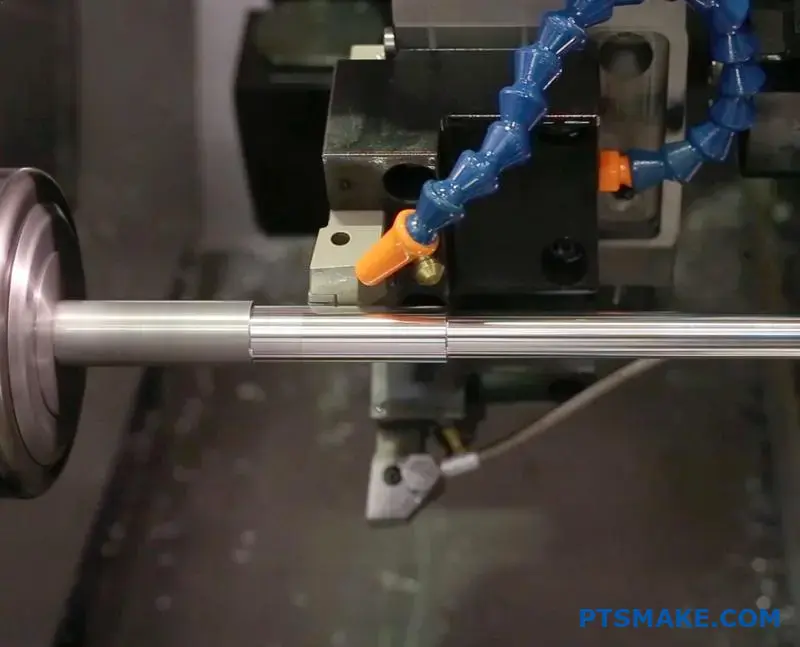

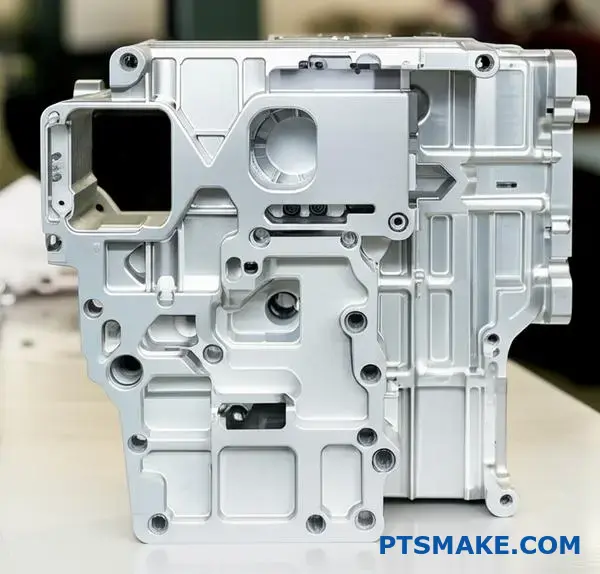

A indústria automóvel funciona com prazos apertados e exige um elevado desempenho, desde os protótipos iniciais até à produção em grande escala. A maquinagem multieixos é fundamental para a criação de componentes complexos do motor, como cabeças de cilindro, pistões e caixas de transmissão. Estas peças apresentam frequentemente canais e portas de refrigeração intrincados e de difícil acesso. Para veículos eléctricos e de alto desempenho, a tecnologia é utilizada para criar protótipos e produzir componentes de chassis leves e caixas de bateria sofisticadas. A capacidade de maquinar um protótipo complexo numa única configuração reduz drasticamente o tempo de iteração, permitindo aos engenheiros testar e aperfeiçoar os designs muito mais rapidamente do que com os métodos tradicionais.

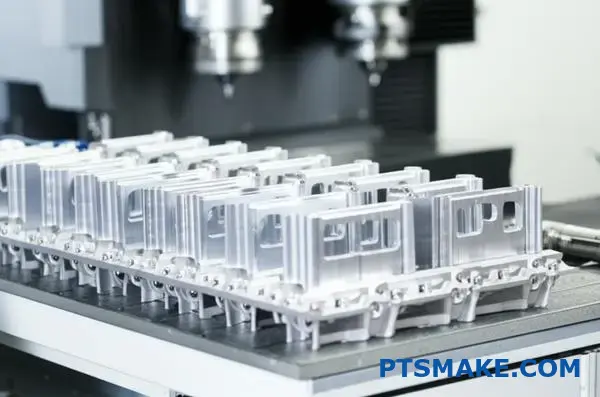

Eletrónica: O desafio da miniaturização

À medida que os dispositivos electrónicos se tornam mais pequenos e mais potentes, os seus componentes tornam-se mais complexos. A maquinagem multieixos é essencial para o fabrico de dissipadores de calor complexos com alhetas de alta densidade, caixas personalizadas para componentes electrónicos bem compactados e conectores duradouros. A precisão de uma máquina de 5 eixos garante que estas peças pequenas e detalhadas cumprem as especificações exactas, o que é vital para a gestão térmica e a fiabilidade do dispositivo. Por exemplo, a maquinação de um dissipador de calor complexo a partir de um único bloco de alumínio ou cobre proporciona um desempenho térmico superior em comparação com a montagem a partir de várias peças.

| Indústria | Aplicação principal | Porque é que o multieixo é essencial |

|---|---|---|

| Automóvel | Blocos de motor, peças do grupo motopropulsor | Acesso a canais internos, prototipagem rápida |

| Defesa | Componentes de mísseis, sistemas de orientação | Materiais de alta resistência, geometrias complexas |

| Eletrónica | Dissipadores de calor complexos, caixas personalizadas | Miniaturização, caraterísticas de alta precisão |

| Robótica | Articulações personalizadas, operadores terminais | Leveza, funcionalidade integrada |

Em última análise, a escalabilidade da maquinagem CNC multieixos permite que empresas como a PTSMAKE apoiem os clientes desde um único protótipo até milhares de peças de produção, garantindo uma qualidade consistente em todas as fases.

Em suma, a maquinagem CNC multieixos não é apenas um processo de fabrico avançado; é um fator crítico para a inovação nas indústrias mais exigentes da atualidade. Desde a indústria aeroespacial e médica à automóvel e eletrónica, proporciona a precisão, a eficiência e a liberdade de conceção necessárias para criar componentes complexos e de elevado desempenho. Ao permitir que as peças sejam maquinadas numa única configuração, reduz os erros, encurta os prazos de entrega e, em última análise, permite que os engenheiros coloquem mais rapidamente no mercado produtos melhores e mais fiáveis.

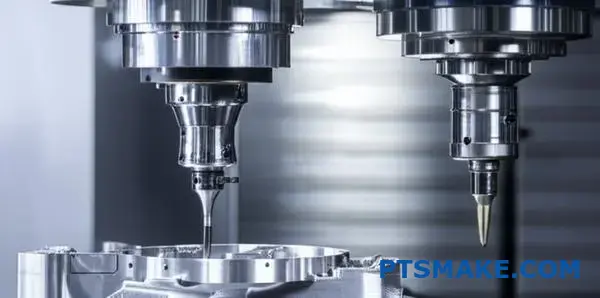

Precisão e complexidade: Obtenção de Geometrias Incomparáveis.

Já alguma vez concebeu uma peça com curvas complexas e cortes inferiores profundos, apenas para ser informado de que são necessárias várias configurações dispendiosas? Essa frustração de comprometer o seu design para a capacidade de fabrico é demasiado comum.

A maquinação CNC multieixos ultrapassa estas limitações. Utiliza o movimento simultâneo de ferramentas ao longo de quatro, cinco ou mais eixos para maquinar geometrias complexas, caraterísticas intrincadas e superfícies lisas numa única configuração. Este método desbloqueia projectos que anteriormente eram considerados impossíveis ou proibitivamente caros.

O salto da maquinagem de 3 eixos para a maquinagem multieixos

A maquinagem tradicional de 3 eixos é poderosa mas limitada. A ferramenta de corte desloca-se ao longo dos eixos lineares X, Y e Z, aproximando-se da peça de trabalho a partir de uma única direção, normalmente a partir de cima. Embora seja eficaz para peças mais simples, tem dificuldades com superfícies complexas e caraterísticas em várias faces de uma peça. Cada nova face que precisa de ser maquinada requer uma nova configuração - um processo manual de desapertar, rodar e voltar a apertar a peça de trabalho. Isto introduz oportunidades de erro e aumenta drasticamente o tempo de produção.

A maquinagem CNC multieixos introduz eixos de rotação, normalmente designados por eixos A e B (ou C). Isto permite que a peça de trabalho ou a cabeça da ferramenta (ou ambas) rodem e se inclinem durante o processo de maquinagem.

A vantagem de uma configuração única

A vantagem mais significativa desta tecnologia é a capacidade de maquinar uma peça complexa numa operação de "configuração única" ou "feito em um". Assim que o bloco de matéria-prima é fixado na máquina, não precisa de ser movido novamente até ser uma peça acabada. Esta abordagem de configuração única é transformadora por várias razões. Em primeiro lugar, reduz drasticamente a acumulação de erros de tolerância que ocorrem com cada reposicionamento manual. Quando se manuseia uma peça várias vezes, os pequenos desalinhamentos acumulam-se, podendo fazer com que o componente final fique fora das especificações. Com a maquinagem multieixos, a precisão da máquina é mantida ao longo de todo o processo. Para tal, é necessário um software avançado para calcular a interpolação do percurso da ferramenta2 necessário para manter um contacto constante. De acordo com a nossa experiência no PTSMAKE, isto é crucial para peças em que mesmo alguns microns de desvio podem causar falhas, como em aplicações aeroespaciais ou de dispositivos médicos.

| Caraterística | Abordagem de maquinagem de 3 eixos | Abordagem de maquinagem multieixos |

|---|---|---|

| Contornos complexos | Curvas aproximadas com muitos cortes pequenos e lineares, resultando em "scalloping". | O movimento contínuo da ferramenta cria uma superfície suave e precisa numa só passagem. |

| Cortes inferiores | Impossível sem ferramentas especiais ou várias configurações e rotação de peças. | A ferramenta pode inclinar-se para alcançar caraterísticas por baixo sem reposicionar a peça. |

| Furos angulares | Requer acessórios personalizados ou a rotação da peça para cada ângulo único. | A peça de trabalho ou a cabeça da ferramenta podem ser inclinadas de acordo com a especificação exacta para perfuração. |

Este processo consolidado não só aumenta a precisão como também simplifica o fluxo de trabalho, reduzindo a mão de obra e o tempo tradicionalmente gastos na configuração e inspeção entre operações.

Desvendar geometrias e caraterísticas complexas

A capacidade de manter sempre um ângulo de corte ótimo entre a ferramenta e a peça de trabalho é o que permite às máquinas multieixos criar caraterísticas que estão simplesmente fora do alcance das suas congéneres de 3 eixos. Esta capacidade abre um novo mundo de liberdade de conceção para engenheiros e projectistas de produtos.

Criação de cortes inferiores e caraterísticas multi-superfície

Os cortes inferiores são caraterísticas que não podem ser maquinadas a partir de uma abordagem de cima para baixo porque uma parte do material a ser removido está bloqueada por outra caraterística da peça. Pense nas aberturas internas num bloco de motor ou na ranhura em cauda de andorinha numa montagem complexa. Numa máquina de 3 eixos, a criação destes elementos exigiria a paragem da máquina e a rotação da peça ou a utilização de ferramentas altamente especializadas, muitas vezes frágeis. Uma máquina de 5 eixos, no entanto, pode simplesmente inclinar a ferramenta ou a peça de trabalho para ter acesso a estas áreas, maquinando-as de forma limpa e eficiente num movimento contínuo. Isto tem sido um fator de mudança em projectos anteriores no PTSMAKE, particularmente nos sectores automóvel e de maquinaria, onde os canais de fluido integrados e as superfícies de acoplamento complexas são comuns.

O impacto na eficiência da produção

As vantagens vão para além da complexidade das peças. Ao consolidar as operações, a maquinagem CNC multieixos reduz drasticamente o tempo de ciclo global.

| Etapa do processo | Tradicional de 3 eixos (várias configurações) | CNC multieixos (configuração única) |

|---|---|---|

| Número de configurações | 3-6+ por peça | 1-2 por peça |

| Tempo de programação | Superior (vários programas) | Inferior (um programa complexo) |

| Tempo de maquinagem | Mais elevado devido a alterações de configuração | Significativamente inferior |

| Risco de erro | Elevado (erro humano nas configurações) | Mínimo (controlado por máquina) |

Por exemplo, um componente que antes exigia cinco configurações separadas numa fresadora de 3 eixos - cada uma envolvendo programação, configuração de fixação, maquinação e verificações de qualidade - pode muitas vezes ser completado numa operação contínua numa máquina de 5 eixos. Com base nos nossos estudos internos de comparação de processos de fabrico, isto pode levar a uma poupança de tempo de 30-50% ou mais, dependendo da complexidade da peça. Esta eficiência não significa apenas uma entrega mais rápida; também se traduz em custos mais baixos, tornando comercialmente viáveis projectos anteriormente dispendiosos. O investimento em tecnologia avançada maquinagem cnc multieixos A tecnologia de ponta paga dividendos através da redução de mão de obra, menos equipamentos e maior produtividade.

A maquinagem CNC multieixos altera fundamentalmente o que é possível fazer no fabrico. Aborda diretamente as limitações dos métodos tradicionais, permitindo a criação de geometrias altamente complexas e tolerâncias apertadas numa única configuração. Ao utilizar movimentos rotativos e lineares simultâneos, pode maquinar cortes inferiores, curvas complexas e peças multifacetadas com uma precisão e eficiência superiores. Esta capacidade não só melhora a qualidade das peças e reduz o tempo de produção, como também permite aos engenheiros conceberem componentes mais inovadores e funcionais sem estarem limitados pelas limitações de fabrico.

Ganhos de eficiência: Redução dos tempos de preparação e de ciclo.

Já alguma vez viu uma peça complexa a saltar entre diferentes máquinas, com configuração após configuração a consumir o seu tempo de execução e orçamento? Esse tempo de inatividade é um assassino silencioso de lucros.

A maquinação CNC multieixos é a solução. Reduz o tempo de produção através da maquinação de geometrias complexas numa única configuração. Isto minimiza a intervenção manual, reduz a possibilidade de erros e reduz diretamente os tempos de ciclo e os custos de mão de obra, aumentando a eficiência global.

A abordagem tradicional a uma peça complexa, utilizando uma máquina de 3 eixos, é como fazer uma corrida de estafetas consigo próprio. Maquina-se um lado, pára-se a máquina, solta-se a peça, desenha-se uma nova fixação, fixa-se a peça numa nova orientação, restabelece-se o zero de trabalho e começa-se de novo. Este processo repete-se para cada face única que precisa de ser maquinada. Não é apenas tedioso; é uma enorme fonte de ineficiência e potencial erro. Na nossa experiência no PTSMAKE, este tempo de preparação pode frequentemente exceder o tempo de corte efetivo.

Os custos ocultos de várias configurações

Sempre que um operador tem de reposicionar manualmente uma peça de trabalho, acontecem várias coisas negativas. Não se trata apenas do tempo perdido, mas também dos riscos e custos que se acumulam e que são frequentemente ignorados até aparecerem no relatório de inspeção final ou no orçamento do projeto.

Consumo de tempo e máquinas inactivas

O custo mais óbvio é o tempo. Cada configuração envolve a limpeza, o carregamento, a fixação e a indicação da peça. A sua dispendiosa máquina CNC fica inativa durante todo este processo. Para uma peça que requer quatro ou cinco configurações, este tempo não produtivo aumenta rapidamente, prolongando os prazos de entrega e criando estrangulamentos na produção.

O risco agravado da imprecisão

A exatidão é fundamental no fabrico de precisão. Sempre que uma peça é desapertada e reapertada, é introduzida uma pequena quantidade de erro de posicionamento. Mesmo com o melhor equipamento e os operadores mais qualificados, estes pequenos desvios podem acumular-se. Depois de várias configurações, a peça final pode ter dificuldade em manter as tolerâncias apertadas exigidas, levando a desperdícios ou retrabalho. É aqui que o conceito de maquinação "done-in-one" brilha verdadeiramente. Compreender as funções da máquina cinemática3 é crucial para os programadores alcançarem esta precisão de configuração única, garantindo que todas as funcionalidades estão perfeitamente relacionadas entre si.

A vantagem da configuração única

A maquinagem CNC multieixos, em particular a de 5 eixos, aborda este problema de frente. Ao rodar a peça de trabalho nos seus eixos A e B/C, a máquina pode apresentar quase todas as faces à ferramenta de corte sem que a peça saia da fixação inicial.

| Tarefa de maquinagem | Processo tradicional de 3 eixos | Processo de configuração simples de 5 eixos |

|---|---|---|

| Maquinação de 5 faces | São necessárias 5 configurações separadas | Todas as 5 faces maquinadas numa única instalação |

| Furos angulares | Requer placas angulares ou acessórios complexos | A mesa/cabeça inclina-se para o ângulo correto |

| Cortes inferiores | Requer ferramentas especiais e várias configurações | A ferramenta aproxima-se de um ângulo para limpar |

| Total de configurações | 4-6+ | 1 |

Esta consolidação das operações é o cerne do ganho de eficiência. Transforma o processo de fabrico de uma série de passos desarticulados numa operação única, contínua e altamente automatizada.

Eliminar as configurações é apenas o começo. A verdadeira magia acontece quando analisamos a forma como essa única alteração se repercute em todo o processo de produção, afectando tudo, desde a atribuição de mão de obra à produção global da fábrica. Não se trata apenas de poupar alguns minutos aqui e ali; trata-se de alterar fundamentalmente a economia do fabrico de componentes complexos.

De ciclos mais rápidos a maior produtividade

A vantagem mais direta de uma configuração única é uma redução drástica no tempo total do ciclo por peça. Não se trata apenas de eliminar o tempo de reposicionamento manual; também permite estratégias de maquinação mais eficientes que não eram possíveis anteriormente.

Otimização do tempo de funcionamento do fuso

Num ambiente com várias configurações, o fuso da máquina está frequentemente parado durante mais tempo do que está a cortar. Com a maquinagem multieixos, o tempo de funcionamento do fuso - a percentagem de tempo em que a ferramenta está realmente a remover material - aumenta significativamente. Após a configuração inicial, a máquina pode funcionar sem interrupções durante toda a peça, por vezes durante horas. É assim que se maximiza o retorno do investimento na máquina.

Percursos de ferramentas e condições de corte superiores

A capacidade multieixos permite a utilização de ferramentas de corte mais curtas e mais rígidas. Como a máquina pode inclinar a ferramenta ou a peça para evitar colisões, não precisamos de ferramentas longas e frágeis que são propensas a vibrações e vibrações. As ferramentas mais curtas podem lidar com velocidades e avanços mais agressivos, removendo o material mais rapidamente e mantendo um acabamento superficial superior. Isto significa que podemos frequentemente combinar passagens de desbaste e acabamento, reduzindo ainda mais o tempo de ciclo.

O impacto financeiro e operacional

Ciclos mais rápidos e menos configurações traduzem-se diretamente em poupanças de custos significativas e vantagens operacionais. É aqui que a maquinagem CNC multieixos prova o seu valor para além das capacidades técnicas.

Reduzir os custos de mão de obra e de fixação

Menos configurações significam que é necessária menos mão de obra direta por peça. Um maquinista experiente pode configurar um trabalho complexo numa máquina de 5 eixos e deixá-lo funcionar, libertando-o para preparar o trabalho seguinte ou gerir outra máquina. Isto permite tirar partido da mão de obra especializada de forma muito mais eficaz. Para além disso, é eliminada a necessidade de fixações múltiplas, complexas e dispendiosas. Muitas vezes, uma única morsa ou mandril de alta qualidade é tudo o que é necessário.

| Fator de custo | Configuração múltipla tradicional | Configuração única Multi-eixos |

|---|---|---|

| Trabalho por peça | Elevado (intervenções múltiplas) | Baixo (uma configuração) |

| Custo de fixação | Alta (vários aparelhos personalizados) | Baixo (uma luminária padrão) |

| Taxa de refugo/trabalho | Mais elevado (erros de composição) | Mínimo (elevada precisão) |

| Tempo de máquina inativa | Significativo | Reduzido drasticamente |

Em última análise, estas eficiências conduzem a um maior rendimento. Ao produzir peças mais rapidamente e de forma mais fiável, uma instalação pode assumir mais trabalho sem necessitar de mais máquinas ou de mais espaço. Para os nossos clientes da PTSMAKE, isto significa que podemos fornecer peças complexas em prazos mais curtos e a um preço mais competitivo.

Em suma, a maquinagem CNC multieixos revoluciona a eficiência da produção ao consolidar as operações numa única configuração. Esta estratégia reduz drasticamente o reposicionamento manual, o que, por sua vez, reduz os tempos de ciclo, minimiza o potencial de erro humano e diminui os custos de mão de obra. Para os fabricantes, o resultado é um aumento significativo da produtividade e do rendimento. Isto permite uma entrega mais rápida de peças complexas e cria um processo de fabrico mais rentável e competitivo.

Qualidade e consistência: Minimizar o desperdício e os erros?

Já se debateu com ciclos de produção em que a primeira peça é perfeita, mas a milésima está ligeiramente desfasada? As pequenas inconsistências e as elevadas taxas de refugo estão a consumir o orçamento e o calendário do seu projeto?

A maquinagem CNC multieixos resolve este problema, tirando partido da automatização e de software avançado para eliminar a variabilidade humana. Este processo assegura que cada peça é um duplicado exato da primeira, reduzindo significativamente o desperdício e garantindo uma qualidade consistente em qualquer volume de produção.

A mecânica da precisão e da repetibilidade

A principal vantagem da maquinagem CNC multieixos é a sua capacidade de criar uma ligação direta e ininterrupta entre um desenho digital e um produto físico. Esta ligação é o que elimina sistematicamente as variáveis que conduzem a erros e desperdícios. Na maquinagem tradicional, um operador pode ter de interpretar desenhos, ajustar manualmente a máquina ou mudar várias vezes as fixações. Cada um destes passos é um potencial ponto de falha. Os sistemas multieixos, guiados por um sofisticado software CAM, eliminam essa adivinhação. A máquina segue um percurso de ferramenta pré-programado com uma precisão ao nível do mícron, executando sempre cortes e ângulos complexos sem falhas.

Configuração única, ganhos múltiplos

Uma das maiores fontes de erro no fabrico de peças complexas é a refixação. De cada vez que uma peça é desprendida, movida e novamente fixada para maquinar uma face diferente, existe o risco de introduzir um pequeno erro de alinhamento. Estes pequenos erros acumulam-se, um fenómeno conhecido como empilhamento de tolerâncias, que pode empurrar uma peça acabada para fora das especificações exigidas. A maquinagem CNC multieixos minimiza este risco ao permitir que a ferramenta se aproxime da peça de trabalho a partir de várias direcções numa única configuração. Uma máquina de 5 eixos pode trabalhar em cinco lados de um cubo sem nunca o libertar da morsa. Este facto preserva a precisão volumétrica4 relativamente ao seu ponto de referência inicial, assegurando que todas as caraterísticas estão perfeitamente posicionadas umas em relação às outras.

Processos automatizados para uma execução sem falhas

Para além do percurso da ferramenta, a automatização estende-se a outros aspectos críticos do processo. Os trocadores de ferramentas automatizados asseguram a utilização da ferramenta correta para cada operação sem intervenção manual. Os sistemas de sondagem durante o processo podem ser utilizados para medir a peça a meio do ciclo, ajustando automaticamente qualquer desgaste minúsculo da ferramenta ou variações térmicas na máquina. Isto cria um ciclo de feedback auto-corretivo que mantém a consistência desde a primeira até à última peça.

| Comparação de caraterísticas | Maquinação tradicional (3 eixos) | Maquinação CNC multieixos (5 eixos) |

|---|---|---|

| Complexidade da configuração | São necessárias várias configurações | Configuração única para a maioria das funcionalidades |

| Entrada do operador | Elevada dependência de competências | Intervenção mínima necessária |

| Potencial de erro | Elevado (refixação, interpretação) | Baixa (automatizada, pré-programada) |

| Consistência de parte a parte | Variável | Extremamente elevado |

Este nível de automatização significa que o processo é repetível, escalável e previsível.

Resultados quantificáveis: Da teoria à realidade da produção

As vantagens de minimizar os erros não são apenas teóricas; traduzem-se em melhorias tangíveis no rendimento e na relação custo-eficácia. Em projectos anteriores no PTSMAKE, vimos em primeira mão como a adoção de uma estratégia multieixos transforma os resultados da produção. Não se trata apenas de fazer algumas peças boas; trata-se de fazer milhares de peças perfeitas com o mínimo de desperdício. A redução do material de refugo e o tempo de máquina poupado têm um impacto direto no preço final da peça, tornando o fabrico de alta precisão mais acessível.

Um estudo de caso sobre a redução de defeitos

Trabalhámos recentemente com um cliente da indústria de dispositivos médicos que necessitava de uma caixa complexa com canais internos intrincados. O seu fornecedor anterior utilizava uma série de operações de 3 eixos e estava a registar uma taxa de refugo de quase 12% devido a inconsistências de tolerância. Depois de reavaliar o processo de fabrico com a nossa equipa, transferimos a produção para um dos nossos centros de maquinação de 5 eixos. Ao completar a peça numa única configuração, eliminámos os erros de refixação que estavam a causar os defeitos. Os resultados dos nossos testes mostraram que a taxa de refugo desceu para menos de 1,5%, o que representa uma poupança de custos significativa e uma cadeia de fornecimento mais fiável para o seu produto crítico.

Melhorar os rendimentos em toda a linha

Este não é um incidente isolado. O princípio de reduzir os pontos de contacto humanos e as etapas do processo conduz consistentemente a melhores rendimentos. Quando um processo é estável e repetível, é possível prever os resultados com um elevado grau de confiança. Isto é crucial para grandes séries de produção, onde mesmo uma pequena percentagem de melhoria no rendimento pode resultar em poupanças substanciais e evitar atrasos dispendiosos na produção.

| Métrica de produção | Antes da implementação multieixos | Após a implementação de vários eixos |

|---|---|---|

| Taxa média de defeitos | 6-8% | < 2% |

| Rendimento por 1.000 unidades | ~930 peças | >980 peças |

| Tempo de configuração da máquina | 3-4 horas (várias configurações) | < 1 hora (configuração única) |

| Falhas de inspeção | Frequente | Raros |

Em última análise, a consistência proporcionada pela maquinagem CNC multieixos gera confiança. Quando os nossos clientes sabem que cada peça que recebem corresponde às suas especificações exactas, isso simplifica o seu processo de aquisição e reforça a nossa parceria.

A maquinagem CNC multieixos proporciona uma qualidade e consistência excepcionais, substituindo a variabilidade manual pela precisão automatizada. Esta abordagem reduz drasticamente o erro humano, enquanto as operações de configuração única evitam a acumulação de tolerância comum nos métodos tradicionais. Como visto em aplicações reais no PTSMAKE, essa tecnologia leva a melhorias quantificáveis, reduzindo significativamente as taxas de refugo e garantindo que cada componente em uma grande produção seja uma combinação perfeita com o projeto original, minimizando tanto o desperdício quanto os erros.

Avanços tecnológicos que moldam a maquinagem CNC multieixos?

Está a ter dificuldades em maquinar peças complexas a partir de materiais duros sem comprometer a velocidade ou a precisão? Os longos tempos de ciclo e o desgaste das ferramentas estão a prejudicar a rentabilidade do seu projeto e a causar atrasos na produção?

Os avanços tecnológicos como o controlo simultâneo de múltiplos eixos, o software CAD/CAM avançado e os sistemas inteligentes estão a revolucionar a maquinagem CNC. Permitem uma produção mais rápida, uma maior precisão e a capacidade de trabalhar com materiais difíceis, aumentando diretamente a competitividade e a inovação do fabrico.

A evolução da maquinagem CNC multieixos é uma história de quebra de limitações físicas. Durante anos, o principal desafio era traduzir um desenho digital complexo para o mundo real sem múltiplas configurações, o que introduzia erros e desperdiçava tempo. Os últimos saltos tecnológicos abordam diretamente este problema fundamental, transformando a forma como abordamos a produção. Não se trata apenas de avançar mais rapidamente; trata-se de avançar de forma mais inteligente.

A base: Controlo e integração de software

No centro da maquinagem moderna de múltiplos eixos está a sinergia entre os sistemas de controlo e o software. Sem uma comunicação perfeita entre o projeto (CAD), a estratégia do percurso da ferramenta (CAM) e o controlador da máquina, mesmo o hardware mais avançado é ineficaz.

Controlo simultâneo de vários eixos

Ao contrário da maquinagem 3+2 ou indexada, em que a peça de trabalho é reposicionada entre operações, o controlo simultâneo de múltiplos eixos envolve a ferramenta de corte e a peça de trabalho que se movem simultaneamente ao longo de quatro ou cinco eixos. Este movimento contínuo permite a criação de superfícies curvas complexas, cortes inferiores e caraterísticas intrincadas numa única configuração. Mantém o contacto ideal da ferramenta com a peça de trabalho, o que melhora o acabamento da superfície e prolonga a vida útil da ferramenta. Esta capacidade é crucial para indústrias como a aeroespacial, onde os componentes apresentam frequentemente formas orgânicas e aerodinâmicas. A capacidade da máquina para executar estes movimentos complexos depende da sua cadeia cinemática5que define a relação entre todas as partes móveis.

Software CAD/CAM avançado

O software CAD/CAM moderno é o cérebro por detrás da operação. Faz mais do que apenas gerar código G. As plataformas actuais incluem poderosas funcionalidades de simulação que nos permitem visualizar todo o processo de maquinação antes de uma única limalha ser cortada. Esta verificação virtual ajuda a identificar potenciais colisões, a estimar os tempos de ciclo e a otimizar os percursos das ferramentas para obter eficiência. Na PTSMAKE, confiamos nestas simulações para reduzir o risco de projectos complexos, assegurando que podemos cumprir tolerâncias apertadas e prazos de entrega para os nossos clientes. Transforma o processo de tentativa e erro num fluxo de trabalho previsível e projetado.

Princípios da maquinagem de alta velocidade (HSM)

A maquinagem de alta velocidade é uma estratégia, não se trata apenas de aumentar as RPM. Centra-se em cortes mais leves e rápidos em vez de cortes lentos e pesados. Esta abordagem tem um impacto profundo no desempenho.

| Caraterística | Maquinação tradicional | Maquinação a alta velocidade (HSM) |

|---|---|---|

| Profundidade de corte | Profundo | Raso |

| Velocidade do fuso | Baixo a moderado | Muito elevado |

| Taxa de alimentação | Moderado | Elevado |

| Transferência de calor | Na peça de trabalho e na ferramenta | No chip |

Esta metodologia, quando aplicada à maquinagem CNC multieixos, reduz as forças de corte, minimiza a transferência de calor para a peça de trabalho e permite taxas de remoção de material mais elevadas. O resultado é uma menor distorção da peça, melhor precisão e tempos de ciclo significativamente mais curtos. É particularmente eficaz para peças de paredes finas e materiais difíceis que são propensos ao endurecimento por trabalho.

Enquanto os sistemas de controlo avançados e o HSM lançam as bases, a próxima vaga de inovação centra-se em tornar o próprio processo de maquinação inteligente e adaptável. Estes avanços estão a alargar os limites do que pode ser alcançado, especialmente quando se trabalha com os materiais e geometrias mais exigentes. Acrescentam uma camada de dados em tempo real e de automatização que eleva as capacidades das máquinas CNC multieixos, passando da simples execução de comandos à otimização ativa do processo.

A ascensão dos sistemas inteligentes e automatizados

A integração de sensores, análise de dados e robótica está a criar um novo paradigma para o fabrico. Trata-se de criar um sistema capaz de se monitorizar a si próprio, de se adaptar às condições em mudança e de funcionar com um mínimo de intervenção humana, impulsionando tanto a eficiência como a qualidade.

Monitorização durante o processo e controlo adaptativo

As máquinas CNC multieixos modernas estão cada vez mais equipadas com sensores sofisticados que monitorizam variáveis-chave como a vibração da ferramenta, as forças de corte e a temperatura em tempo real. Estes dados são enviados para a unidade de controlo da máquina, que pode então efetuar micro-ajustes em tempo real. Por exemplo, se for detectada vibração excessiva - um sinal de potencial vibração da ferramenta que pode arruinar o acabamento da superfície de uma peça - o sistema pode ajustar automaticamente a velocidade do fuso ou a taxa de avanço para estabilizar o corte. Este controlo adaptativo é um fator de mudança para a maquinação de ligas exóticas como o Inconel ou o titânio, onde as condições de corte podem ser imprevisíveis. Em projectos anteriores no PTSMAKE, esta tecnologia ajudou-nos a reduzir as taxas de desperdício em mais de 15% em componentes particularmente difíceis.

Integração robótica para automatização

A verdadeira vantagem competitiva no fabrico moderno advém frequentemente da automatização. A integração de máquinas CNC de múltiplos eixos com braços robóticos cria células de produção automatizadas que podem funcionar 24 horas por dia, 7 dias por semana, um conceito frequentemente designado por fabrico "lights-out". Os robôs podem ser encarregados de carregar biletes de matéria-prima, descarregar peças acabadas, efetuar verificações de qualidade durante o processo e até mudar ferramentas gastas. Isto não só aumenta drasticamente a utilização e o rendimento da máquina, como também liberta os operadores qualificados para se concentrarem em tarefas mais complexas, como a programação e a melhoria do processo. Este nível de automatização permite-nos oferecer preços mais competitivos e prazos de entrega previsíveis, especialmente para séries de produção de grande volume.

Avanços na maquinagem de materiais difíceis

A capacidade de maquinar eficazmente materiais difíceis é uma referência fundamental de uma oficina mecânica de topo. Os recentes avanços nas estratégias de percursos de ferramentas, possibilitados por um poderoso software CAM, estão a tornar este objetivo mais viável.

| Estratégia de maquinagem | Descrição | Benefício chave |

|---|---|---|

| Fresagem trocoidal | Utiliza um percurso de ferramenta circular ou "descascado" com uma profundidade de corte radial baixa mas uma profundidade axial alta. | Evita a sobrecarga da ferramenta e a acumulação de calor, ideal para cortar ranhuras em materiais duros. |

| Compensação adaptativa | Mantém um ângulo de engate da ferramenta constante, ajustando automaticamente o percurso da ferramenta para evitar cantos afiados. | Permite taxas de remoção de material mais elevadas e prolonga a vida útil da ferramenta ao evitar picos súbitos na força de corte. |

| Rebarbação de 5 eixos | Utiliza a versatilidade de uma máquina de 5 eixos para traçar arestas complexas com uma ferramenta de rebarbação, automatizando um processo tipicamente manual. | Garante uma qualidade consistente das arestas e reduz significativamente o trabalho manual e os custos associados. |

Estes percursos de ferramenta inteligentes asseguram que a carga sobre a ferramenta de corte se mantém constante, o que é crucial para evitar quebras e prolongar a sua vida útil quando se trabalha com materiais que endurecem ou geram calor significativo. Ao dominar estas técnicas, podemos enfrentar trabalhos que antes eram considerados proibitivamente difíceis ou demorados.

Os avanços na maquinagem CNC multieixos não são melhorias isoladas, mas sim um ecossistema ligado de hardware, software e sistemas inteligentes. Desde os princípios fundamentais de controlo simultâneo e HSM até à integração de sensores adaptativos e automação robótica, estas tecnologias abordam os principais desafios de fabrico. Fornecem as ferramentas para maquinar geometrias complexas a partir de materiais difíceis com maior velocidade, precisão sem precedentes e maior fiabilidade. Esta evolução traduz-se diretamente numa posição competitiva mais forte para os fabricantes e em melhores produtos para todos.

Versatilidade de materiais e capacidades avançadas na maquinagem multieixos.

Já alguma vez concebeu uma peça complexa, mas foi-lhe dito que o material ideal é demasiado difícil ou dispendioso de maquinar? Já se deparou com limitações que o obrigaram a comprometer a escolha do material?

A maquinação CNC multieixos abre uma vasta gama de materiais, desde metais padrão a compósitos avançados. Ao ajustar dinamicamente os percursos das ferramentas, as velocidades e os avanços, ultrapassa os desafios únicos de cada material, aumentando diretamente a durabilidade, o desempenho e a liberdade de conceção do produto final.

A maquinação CNC multieixos não é apenas uma questão de geometrias complexas; é uma questão de dominar os materiais que dão vida a essas geometrias. A capacidade de abordar uma peça de trabalho a partir de vários ângulos permite estratégias de corte optimizadas que respeitam as propriedades inerentes de cada material, algo com que as máquinas tradicionais de 3 eixos se debatem. Esta adaptabilidade abre a porta à utilização de materiais que anteriormente eram considerados "não maquináveis" ou economicamente inviáveis.

Maquinação de uma vasta gama de metais e ligas

O núcleo de muitas aplicações exigentes reside em metais de alto desempenho. Na nossa experiência no PTSMAKE, vimos como as capacidades multieixos transformam a forma como lidamos com estes materiais.

Metais ferrosos e não ferrosos

Do aço inoxidável ao alumínio e ao titânio, cada metal apresenta um desafio único. Por exemplo, a baixa condutividade térmica do titânio pode levar a uma acumulação excessiva de calor na ferramenta de corte. Uma máquina de 5 eixos pode manter um ângulo de corte ótimo, ajustando constantemente o percurso da ferramenta para gerir o calor e evitar o endurecimento do trabalho. Não se trata apenas de evitar a quebra da ferramenta; trata-se de preservar a integridade do material, o que é crucial para os componentes aeroespaciais e médicos.

Superligas e materiais exóticos

Materiais como o Inconel e o Hastelloy são conhecidos pela sua resistência a altas temperaturas, mas são notoriamente difíceis de maquinar. A sua tendência para endurecer por trabalho pode destruir instantaneamente uma ferramenta de corte. A maquinagem CNC multieixos permite uma técnica designada por fresagem trocoidal, em que a ferramenta efectua cortes contínuos e pouco profundos. Isto mantém uma carga de aparas consistente, minimiza o calor e evita os movimentos de pára-arranca que causam o endurecimento. O resultado é uma peça acabada que cumpre as especificações sem comprometer as propriedades avançadas do material.

O quadro seguinte, baseado no desenvolvimento do nosso processo interno, mostra como adaptamos as estratégias aos diferentes metais:

| Propriedade do material | Desafio de maquinagem | Solução CNC multieixos |

|---|---|---|

| Dureza (por exemplo, aço temperado) | Forças de corte elevadas, desgaste da ferramenta | Ângulo de engate da ferramenta optimizado, configuração rígida |

| Ductilidade (por exemplo, cobre) | Textura gomosa, fraca quebra das aparas | Refrigerante de alta pressão, ferramentas de corte afiadas |

| Baixa condutividade térmica (por exemplo, titânio) | Acumulação de calor na ponta da ferramenta | Movimento constante da ferramenta, jactos de refrigeração direcionados |

| Endurecimento por trabalho (por exemplo, Inconel) | O material endurece durante o corte | Carga de aparas consistente, trajectórias de fresagem trocoidais |

Manuseamento de compósitos e plásticos avançados

A versatilidade da maquinação multieixos vai muito para além dos metais. É também um fator de mudança para os compósitos e plásticos de engenharia. O polímero reforçado com fibra de carbono (CFRP) e outros compósitos têm anisotrópico6 o que significa que a sua resistência varia consoante a direção das fibras. O corte incorreto destes materiais pode causar delaminação e desgaste, arruinando a peça. Uma máquina multieixos pode orientar a ferramenta para cortar ao longo da direção das fibras, assegurando um acabamento limpo sem comprometer a integridade estrutural. Este nível de controlo é essencial para a produção de componentes leves e de elevada resistência para as indústrias automóvel e robótica.

Para além do simples manuseamento de uma gama mais vasta de materiais, o verdadeiro poder da maquinagem CNC multieixos reside na forma como melhora o desempenho e a durabilidade do produto final através da adaptação inteligente do processo. A máquina não está apenas a cortar material; está a responder ao seu comportamento específico em tempo real. Esta capacidade dinâmica conduz a acabamentos de superfície superiores, tolerâncias mais apertadas e propriedades mecânicas melhoradas na peça acabada.

Adaptação de técnicas para um desempenho ótimo do material

A forma como um material é cortado tem um impacto direto no seu estado final. Uma maquinação agressiva ou inadequada pode introduzir tensões internas, microfracturas e danos térmicos que comprometem a fiabilidade a longo prazo de uma peça, mesmo que esta pareça perfeita à superfície.

Minimizar o stress térmico

Muitos plásticos e ligas avançadas são sensíveis ao calor. Temperaturas excessivas durante a maquinação podem alterar a sua estrutura cristalina, reduzindo a resistência ou causando deformações. Os sistemas multieixos são excelentes na gestão térmica. A máquina pode utilizar ferramentas mais curtas, que são mais rígidas e vibram menos, reduzindo o atrito. Também pode criar percursos de ferramentas que movem constantemente a zona de corte, evitando que o calor se concentre numa só área. Combinado com o líquido de arrefecimento de alta pressão através do eixo, isto assegura que o material se mantém dentro do seu intervalo de temperatura ideal, preservando as propriedades pretendidas. Este é um fator crítico que monitorizamos para componentes médicos e electrónicos.

Melhorar o acabamento e a integridade da superfície

Na maquinagem tradicional, o reposicionamento frequente da ferramenta pode deixar pequenas marcas ou linhas na superfície da peça. Para aplicações que requerem superfícies lisas para reduzir o atrito ou por razões estéticas, isto é inaceitável. Com a maquinagem CNC multieixos, a ferramenta pode seguir uma trajetória contínua e fluida através de superfícies complexas sem se retrair. Isto resulta num acabamento superior, de passagem única, que frequentemente elimina a necessidade de operações de polimento secundárias.

Este quadro mostra como as adaptações específicas beneficiam o produto final:

| Adaptação à maquinagem | Desafio material abordado | Benefício para o desempenho do produto |

|---|---|---|

| Envolvimento contínuo com a ferramenta | Marcas de superfície resultantes de mudanças de ferramentas | Acabamento superficial superior, pontos de tensão reduzidos |

| Fornecimento optimizado de líquido de refrigeração | Danos térmicos e expansão | Preserva a integridade do material e a estabilidade dimensional |

| Ferramentas mais curtas e mais rígidas | Desvio e vibração da ferramenta | Tolerâncias mais apertadas, precisão melhorada |

| Ângulos de corte variáveis | Caraterísticas de difícil acesso | Permite concepções complexas sem fragilidade das peças |

Em última análise, o objetivo é criar uma peça que funcione exatamente como o designer pretendia. Em projectos anteriores na PTSMAKE, a adaptação das nossas estratégias multieixos ao material tem sido a chave para alcançar este objetivo. O processo de maquinação passa de uma simples tarefa de remoção de material para uma solução de fabrico refinada que acrescenta valor e fiabilidade ao produto final.

A maquinagem CNC multieixos proporciona a versatilidade necessária para trabalhar com uma vasta gama de materiais, desde superligas resistentes a compósitos delicados. As suas capacidades avançadas permitem uma adaptação dinâmica às propriedades únicas de cada material, como a dureza e a sensibilidade térmica. Esta abordagem inteligente faz mais do que apenas permitir designs complexos; melhora diretamente a durabilidade do produto final, a integridade da superfície e o desempenho geral, minimizando o stress e preservando a resistência inerente do material, garantindo que as peças cumprem os mais elevados padrões de engenharia.

Flexibilidade de design e oportunidades de personalização?

Já se sentiu limitado pelo fabrico tradicional, forçado a simplificar um desenho complexo apenas para o tornar fabricável? Está cansado de comprometer a sua visão de engenharia devido a limitações de produção?

A maquinação CNC multieixos liberta os designers ao permitir a criação de peças complexas e personalizadas diretamente a partir de modelos CAD. Proporciona uma flexibilidade inigualável para prototipagem rápida, produção de baixo volume e soluções personalizadas, tornando-a uma pedra angular da inovação em indústrias exigentes.

A maquinagem CNC multieixos não é apenas uma melhoria incremental; é uma mudança de paradigma no que é possível para o design de produtos. Aborda diretamente as limitações que muitas vezes obrigam os engenheiros a fazer concessões. A capacidade de manipular simultaneamente a ferramenta e a peça de trabalho através de múltiplos eixos abre um mundo de possibilidades geométricas que estão simplesmente fora do alcance das máquinas convencionais de 3 eixos.

Desbloquear a verdadeira liberdade geométrica

Na maquinação tradicional, caraterísticas como cortes inferiores, orifícios angulares e cavidades profundas e estreitas requerem frequentemente várias configurações, dispositivos personalizados ou revisões completas do projeto. Cada configuração adicional introduz o risco de erro, aumenta o tempo de produção e faz subir os custos. A maquinação multieixos resolve este problema de frente. Ao abordar a peça de trabalho a partir de praticamente qualquer ângulo, pode criar contornos complexos e caraterísticas internas numa operação única e contínua. Esta abordagem de configuração única, uma das principais vantagens da tecnologia, é crucial para manter tolerâncias apertadas. Assegura que todas as caraterísticas são maquinadas umas em relação às outras com uma precisão excecional, eliminando o potencial de desalinhamento que pode ocorrer quando uma peça é refixada. O sistema de Cinemática7 definir como estes movimentos complexos são coordenados para obter a forma final.

De protótipos rápidos a peças personalizadas

A velocidade a que um desenho digital pode ser transformado num componente físico é uma enorme vantagem. Esta capacidade é inestimável para a criação rápida de protótipos e ciclos de conceção iterativos. Os engenheiros podem ter um protótipo funcional nas suas mãos em poucos dias, e não semanas, permitindo testes, validação e aperfeiçoamento mais rápidos. Esta agilidade reduz significativamente o tempo de desenvolvimento do produto.

| Caraterística | Maquinação CNC de 3 eixos | Maquinação CNC multieixos |

|---|---|---|

| Cortes inferiores | Requer várias configurações ou ferramentas especiais | Facilmente maquinado numa única configuração |

| Curvas complexas | Aproximado com escalonamento | Percursos de ferramenta suaves e contínuos |

| Furos angulares | Requer placas angulares ou configurações múltiplas | Perfurado diretamente em qualquer ângulo composto |

| Tempo de produção | Mais tempo devido a várias configurações | Reduzido devido à configuração única |

Esta flexibilidade estende-se para além da criação de protótipos. Para as indústrias que requerem uma produção de baixo volume ou peças únicas personalizadas, tais como maquinaria especializada ou robótica, a maquinação multieixos é a solução ideal. Evita a necessidade de moldes ou ferramentas dispendiosas, tornando o fabrico personalizado economicamente viável.

A flexibilidade de design oferecida pela maquinação CNC multieixos permite aos engenheiros criar soluções à medida, adaptadas aos desafios únicos das indústrias de alto risco. Aqui, o desempenho, a fiabilidade e a personalização não são apenas desejáveis - são essenciais. Na PTSMAKE, vimos esta tecnologia impulsionar a inovação em domínios onde o fracasso não é uma opção.

Soluções à medida para sectores exigentes

Diferentes sectores tiram partido desta tecnologia para resolver problemas específicos. A capacidade de produzir peças com formas orgânicas e optimizadas é um fator de mudança.

Aplicações aeroespaciais e médicas

Na indústria aeroespacial, cada grama conta. A maquinação multieixos é utilizada para produzir componentes leves mas incrivelmente fortes, tais como peças estruturais monolíticas, impulsores e pás de turbinas. Estas peças apresentam frequentemente curvas complexas e paredes finas que são impossíveis de criar com outros métodos. Ao maquiná-las a partir de um único bloco de liga de alto desempenho, eliminamos os pontos fracos associados a juntas ou soldaduras.

Do mesmo modo, o sector médico recorre a esta tecnologia para implantes específicos para cada doente e instrumentos cirúrgicos complexos. Um implante de joelho personalizado, por exemplo, pode ser maquinado para corresponder perfeitamente à anatomia de um doente, melhorando o conforto e a longevidade. Os instrumentos cirúrgicos com canais intrincados e não lineares para fluidos ou fios podem ser fabricados como uma peça única, melhorando a sua funcionalidade e esterilização.

O poder da consolidação de peças

Uma das aplicações mais poderosas desta liberdade de conceção é a consolidação de peças. Um conjunto que antes consistia em vários componentes individuais pode muitas vezes ser redesenhado e maquinado como uma peça única e complexa. Isto traz benefícios profundos.

| Vantagem da consolidação | Descrição |

|---|---|

| Aumento da força | Elimina pontos fracos como soldaduras, parafusos ou costuras. |

| Peso reduzido | Uma única peça optimizada é frequentemente mais leve do que um conjunto. |

| Custos de montagem mais baixos | Reduz o tempo de trabalho e a necessidade de fixadores. |

| Cadeia de fornecimento simplificada | Gere um número de peça em vez de vários. |

Num projeto anterior, trabalhámos com um cliente do sector da robótica para consolidar um conjunto de junta articulada de cinco peças maquinadas separadas num componente monolítico. O novo design, possibilitado pela maquinagem de 5 eixos, não só era mais forte e mais leve, como também reduziu o tempo de montagem em mais de 75%, proporcionando uma vantagem competitiva significativa. Este é o tipo de impacto transformador que a verdadeira flexibilidade de conceção proporciona.

A maquinagem CNC multieixos altera fundamentalmente a relação entre o design e o fabrico. Elimina as barreiras tradicionais, permitindo aos engenheiros criar peças complexas e personalizadas sem compromissos. Esta tecnologia é um catalisador para a inovação, permitindo a criação rápida de protótipos, soluções personalizadas e consolidação de peças em indústrias exigentes. Transforma conceitos ambiciosos em componentes físicos de elevado desempenho com uma precisão e flexibilidade inigualáveis, o que a torna uma ferramenta essencial para os desafios da engenharia moderna em que a forma e a função optimizadas são fundamentais.

Avaliação do ROI da maquinagem CNC multieixos: Um quadro prático.

Está a ter dificuldade em justificar o custo inicial mais elevado da maquinagem multieixos para os seus projectos? É um desafio comum quando peças complexas tornam os métodos de fabrico tradicionais ineficientes e dispendiosos.

Escolha a maquinagem CNC multieixos quando as poupanças resultantes de configurações consolidadas, mão de obra reduzida e menos erros superam a taxa horária mais elevada. Proporciona o melhor retorno do investimento para peças complexas, tolerâncias apertadas e produção de volume baixo a médio, melhorando significativamente a qualidade e reduzindo os prazos de entrega.

Decidir entre métodos de fabrico requer mais do que apenas comparar orçamentos. Uma verdadeira análise de custo-benefício envolve a análise de todo o ciclo de vida da produção. Para a maquinagem CNC multieixos, o retorno do investimento (ROI) torna-se claro quando se decompõe o custo total por peça, e não apenas o tempo de máquina. Vamos criar uma estrutura simples para orientar esta decisão.

Factores-chave no cálculo do ROI

Para começar, é necessário quantificar os custos para além do orçamento inicial. A taxa horária mais elevada de uma máquina multieixos pode ser enganadora se eliminar outras despesas mais significativas.

- Custos de instalação e fixação: Uma máquina de 3 eixos pode necessitar de três, quatro ou mesmo mais configurações únicas para completar uma peça complexa. Cada configuração requer acessórios personalizados, tempo de inatividade da máquina e mão de obra especializada. Uma máquina de 5 eixos completa frequentemente a mesma peça numa única configuração, reduzindo drasticamente estes custos cumulativos.

- Tempo de ciclo: Embora o tempo de corte possa ser semelhante, o tempo total desde a matéria-prima até à peça acabada é muito mais curto com a maquinagem multieixos. Eliminar o tempo gasto a mover, refixar e recalibrar a peça entre operações é um enorme ganho de eficiência.

- Custos de mão de obra: Menos configurações traduzem-se diretamente em menos horas de intervenção do operador. Isto não só reduz os custos de mão de obra direta, como também liberta os seus maquinistas especializados para trabalharem noutras tarefas valiosas.

- Risco e taxa de sucata: Sempre que uma peça é deslocada e refixada, existe um risco de erro. As imprecisões de posicionamento podem levar ao desperdício de peças, o que representa uma perda total de material, tempo de máquina e mão de obra. A abordagem de configuração única da maquinagem multieixos minimiza este risco. O processo gradual amortização8 dos custos de ferramentas e dispositivos durante um ciclo de produção também se torna mais previsível.

Comparação de custos: Um exemplo simplificado

Vamos comparar a produção de uma peça moderadamente complexa utilizando dois métodos diferentes.

| Fator de custo | Maquinação de 3 eixos (4 configurações) | Maquinação de 5 eixos (1 configuração) |

|---|---|---|

| Custo do equipamento | Alto (4 luminárias personalizadas) | Baixo (1 aparelho simples) |

| Tempo de configuração | 4 horas | 1 hora |

| Tempo de ciclo (total) | 45 minutos | 30 minutos |

| Intervenção laboral | Elevado (monitorização constante) | Baixo (supervisão mínima) |

| Risco de erro | Moderado a elevado | Muito baixo |

| Custo total por peça | Frequentemente mais elevado para peças complexas | Frequentemente inferior para peças complexas |

Como se pode ver, embora a taxa horária da máquina de 5 eixos possa ser 30-50% mais elevada, o custo total por peça pode acabar por ser significativamente mais baixo, uma vez que se consideram estas outras variáveis críticas.

A análise quantitativa é crucial, mas não conta a história toda. As vantagens "ocultas" da maquinagem CNC multieixos proporcionam frequentemente o valor mais significativo a longo prazo. Estas vantagens qualitativas podem ter um impacto direto no desempenho do seu produto, na reputação da sua marca e na sua eficiência operacional global. Nos projectos que tratámos na PTSMAKE, estes factores são muitas vezes os decisivos para os nossos clientes.

Para além dos números: O custo total de propriedade

O Custo Total de Propriedade (TCO) inclui todos os custos diretos e indirectos associados a uma peça ao longo do seu ciclo de vida. É aqui que a maquinagem multieixos brilha verdadeiramente.

Melhoria da qualidade e da consistência

Uma vez que a peça é maquinada numa única fixação, as relações geométricas entre as caraterísticas são perfeitamente mantidas. Não há risco de erros de empilhamento de tolerância que podem ocorrer quando uma peça é movida entre várias máquinas ou configurações. Isto resulta em:

- Precisão superior: A obtenção de tolerâncias mais rigorosas passa a ser uma norma e não um esforço.

- Melhores acabamentos de superfície: A ferramenta pode manter um ângulo ótimo em relação à superfície da peça, eliminando as pequenas imperfeições que podem resultar de várias configurações.

- Repetibilidade inigualável: Todas as peças do lote são praticamente idênticas, garantindo a consistência da montagem e do desempenho.

Velocidade de colocação no mercado e simplificação da cadeia de fornecimento

A consolidação das operações numa única máquina tem um impacto profundo na sua linha de tempo.

- Prazos de entrega reduzidos: A eliminação de filas de espera para diferentes máquinas e processos manuais reduz drasticamente o tempo entre a encomenda e a entrega. Em alguns dos nossos estudos com clientes, verificámos que os prazos de entrega foram reduzidos em mais de 40%.

- Logística simplificada: Está a gerir um processo e não a coordenar entre vários fornecedores ou departamentos internos. Isto reduz as despesas administrativas e os potenciais pontos de falha na sua cadeia de abastecimento.

Ponderação de factores qualitativos

Ao tomar a sua decisão, considere a forma como estes benefícios menos tangíveis se alinham com os objectivos do seu projeto.

| Fator | Maquinação de 3 eixos | Maquinação CNC multieixos | Impacto no projeto |

|---|---|---|---|

| Liberdade de conceção | Limitada | Quase ilimitado | Permite concepções de produtos mais inovadoras e eficientes. |

| Qualidade da peça | Bom, mas dependente do operador | Excecional e consistente | Reduz os problemas de montagem e melhora a fiabilidade do produto final. |

| Risco de atrasos | Superior (várias etapas) | Mais baixo (processo simplificado) | Aumenta a previsibilidade e cumpre os prazos dos projectos. |

| Gestão de fornecedores | Potencialmente complexo | Simplificado | Liberta recursos de aquisição e engenharia. |

Escolher a maquinagem CNC multieixos não é apenas uma decisão de fabrico; é uma decisão estratégica que pode proporcionar uma vantagem competitiva significativa ao produzir peças de maior qualidade de forma mais rápida e fiável.

Decidir sobre a maquinagem CNC multieixos requer uma mudança da comparação de taxas horárias para a realização de uma análise completa do ROI. Embora o custo inicial pareça mais elevado, revela-se frequentemente mais económico para peças complexas. Ao considerar factores como a redução do tempo de configuração, custos de mão de obra mais baixos e taxas de erro mínimas, é possível ter uma visão mais clara do custo total. A estrutura fornecida ajuda a pesar estes custos quantitativos em relação a benefícios qualitativos críticos como qualidade superior, liberdade de design e entrada mais rápida no mercado.

Desafios e limitações da maquinagem CNC multieixos?

Alguma vez sentiu que a promessa da maquinagem multieixos estava fora do seu alcance? Vê as peças incríveis que pode produzir, mas o caminho para a sua adoção parece cheio de obstáculos assustadores.

Os principais desafios da maquinagem CNC multieixos são o investimento de capital inicial significativo, a complexidade da programação e simulação, o elevado nível de competências exigido aos operadores e as rigorosas exigências de manutenção. Ultrapassar com êxito estes obstáculos é fundamental para libertar todo o potencial de eficiência e precisão da tecnologia.

A maquinagem CNC multieixos é um fator de mudança, mas não é uma simples atualização plug-and-play. Entrar neste mundo requer uma compreensão clara dos obstáculos envolvidos. Na minha experiência, o compromisso financeiro é frequentemente a primeira e mais significativa barreira para muitas lojas.

O elefante na sala: Investimento inicial de capital

Uma máquina de 5 eixos não é apenas uma peça de equipamento; é um sistema completo. O investimento inicial vai muito para além do preço da máquina. É necessário ter em conta um software CAM sofisticado, capaz de lidar com percursos de ferramentas multieixos simultâneos, ferramentas especializadas e, potencialmente, soluções de fixação de trabalho topo de gama. Em alguns dos nossos projectos anteriores no PTSMAKE, descobrimos que a infraestrutura e o software de apoio podem acrescentar uma percentagem significativa ao custo inicial da máquina. É crucial orçamentar todo o ecossistema, e não apenas a máquina em si. Se não o fizer, pode levar a que uma máquina potente seja subutilizada devido a estrangulamentos de software ou de ferramentas.

| Componente de custo | Configuração de 3 eixos (linha de base) | Configuração de 5 eixos (Multiplicador) |

|---|---|---|

| Máquina CNC | 1x | 2,5x - 5x |

| Software CAM | 1x | 2x - 4x |

| Ferramentas | 1x | 1,5x - 3x |

| Formação | 1x | 3x - 5x |

A curva de aprendizagem acentuada da programação

A programação de uma máquina de 3 eixos é relativamente simples. A programação para maquinagem CNC multieixos é uma disciplina completamente diferente. Envolve a gestão da orientação da ferramenta para além da posição, o que acrescenta camadas de complexidade. O programador tem de pensar constantemente no espaço 3D, considerando os ângulos de aproximação da ferramenta, as potenciais colisões entre a ferramenta, o suporte, a peça e os componentes da máquina. É aqui que o software avançado se torna indispensável. Ferramentas para simulação cinemática9 não são um luxo, mas uma necessidade para verificar os percursos das ferramentas e evitar falhas catastróficas e dispendiosas antes mesmo de a máquina começar a cortar. Isto requer um investimento significativo tanto em software como no tempo necessário para formar os programadores para o utilizarem eficazmente. Vimos que um programador bem treinado pode reduzir drasticamente os tempos de configuração e de ciclo, com impacto direto na rentabilidade.

Para além do investimento inicial e da programação, os factores humanos e operacionais apresentam o seu próprio conjunto único de desafios. Uma máquina multieixos é tão boa quanto a pessoa que a gere e os processos implementados para a manter. Estes são compromissos permanentes que requerem atenção e recursos contínuos.

A procura de um "Maestro": Requisitos de competência do operador

O papel de um operador muda significativamente com as máquinas multi-eixo. Passa de um operador de máquinas para um técnico altamente qualificado. Um operador multieixos competente necessita de um conhecimento profundo da cinemática da máquina, do código G e de procedimentos de configuração complexos. Deve ser capaz de resolver problemas que são muito mais complexos do que os de uma máquina de 3 eixos. Encontrar pessoas com esse conjunto de habilidades pode ser difícil e mantê-las é fundamental. Na PTSMAKE, criámos programas de formação interna robustos para melhorar as competências da nossa equipa, garantindo que crescem a par da nossa tecnologia. Investir no seu pessoal é tão importante como investir no hardware. Um operador qualificado pode otimizar os processos em tempo real, minimizar o tempo de inatividade e garantir que todas as peças cumprem as especificações, o que é inestimável.

Manter a máquina saudável: Exigências de manutenção

A complexidade mecânica que confere a uma máquina de 5 eixos a sua capacidade também torna a sua manutenção mais exigente. Com mais peças móveis - mesas rotativas, munhões e cabeças de fuso giratórias - há mais pontos potenciais de falha. O tempo de inatividade de uma máquina tão dispendiosa é incrivelmente caro, não só em termos de perda de produção, mas também em termos de potenciais atrasos para os clientes.

Um calendário rigoroso de manutenção preventiva não é negociável.

| Tarefa de manutenção | Frequência |

|---|---|

| Verificar os níveis de fluido | Diário |

| Limpar o interior da máquina | Diário |

| Inspecionar as ferramentas e os suportes | Semanal |

| Verificar a lubrificação do eixo | Semanal |

| Calibrar eixos | Mensal/trimestral |

| Inspecionar os vedantes e os limpa para-brisas | Mensal |

O cumprimento de um calendário rigoroso como este ajuda a identificar pequenas questões antes de se tornarem problemas graves. É uma disciplina operacional que se paga a si própria muitas vezes, maximizando o tempo de atividade e preservando a precisão da máquina ao longo da sua vida útil.

Embora a maquinagem CNC multieixos apresente desafios como custos iniciais elevados, programação complexa, necessidade de operadores qualificados e manutenção intensiva, estes não são insuperáveis. Os principais obstáculos são o compromisso financeiro inicial e a curva de aprendizagem acentuada tanto para a programação como para a operação. Ao abordar a adoção com uma estratégia clara de investimento, formação e desenvolvimento de processos, qualquer empresa de fabrico pode ultrapassar com êxito estas barreiras e tirar partido do imenso poder desta tecnologia avançada para produzir peças de qualidade superior.

Tendências futuras: Automação, IoT e fabrico inteligente?

Está a sentir-se sobrecarregado com as palavras-chave da Indústria 4.0? Quer saber de que forma a automação e a IoT têm realmente impacto na sua área de maquinação CNC multieixos, ou se são apenas uma moda?

O futuro da maquinagem CNC multieixos reside no fabrico inteligente, onde a automação, a IoT e a análise de dados convergem. Esta integração aumenta a eficiência, permite a manutenção preditiva para evitar períodos de inatividade e permite o controlo de qualidade em tempo real, alterando fundamentalmente a forma como produzimos peças complexas.

A paisagem da indústria transformadora está a mudar debaixo dos nossos pés. O que antes era ficção científica está agora a tornar-se realidade no chão de fábrica. A integração de tecnologias digitais avançadas com processos de maquinação tradicionais não é apenas uma tendência; é uma evolução fundamental. Para a maquinagem CNC multieixos, isto significa passar da simples execução de código G para a criação de ecossistemas de fabrico inteligentes e auto-conscientes.

Os principais componentes de uma oficina mecânica inteligente

No centro desta transformação estão três pilares fundamentais: a automação, a Internet das Coisas (IoT) e a análise de dados. Estes não funcionam isoladamente; o seu poder advém da forma como se ligam e interagem entre si.

Automação para além da robótica

Quando pensamos em automação no CNC, vêm-nos frequentemente à cabeça braços robóticos que carregam e descarregam peças. Mas a verdadeira automação inteligente vai mais longe. Inclui sistemas automatizados de gestão de ferramentas que substituem ferramentas gastas sem intervenção humana, CMMs integradas que efectuam medições durante o processo e trocadores de paletes que permitem que as máquinas funcionem sem supervisão durante horas, mesmo durante a noite. Este nível de automação reduz drasticamente o potencial de erro humano e maximiza a utilização da máquina.

IoT: Dar voz às máquinas

A Internet das Coisas consiste em ligar máquinas e dar-lhes a capacidade de comunicar. Num ambiente de maquinagem CNC multieixos, isto significa incorporar sensores em todo o equipamento. Estes sensores podem monitorizar tudo, desde a vibração do fuso e a temperatura do líquido de refrigeração até ao binário do motor do eixo. Este fluxo constante de dados fornece uma verificação do estado da máquina em tempo real, transformando-a de um cavalo de batalha silencioso num participante ativo no processo de fabrico. Estes são os blocos de construção de sistemas ciber-físicos10onde os controlos digitais e os processos físicos estão profundamente interligados.

| Caraterística | Maquinação tradicional | Maquinação inteligente (activada por IoT) |

|---|---|---|

| Recolha de dados | Manual; controlos periódicos | Automatizado; fluxo contínuo |

| Monitorização de máquinas | Observação do operador | Dados de sensores em tempo real |

| Tomada de decisões | Com base na experiência | Informações baseadas em dados |

| Controlo de processos | Ajustes reactivos | Proactivo e preditivo |

Este ambiente ligado é a base para transformar dados brutos em inteligência acionável, que é onde entra a análise de dados.

Olhando para o futuro, a convergência destas tecnologias promete mudanças ainda mais profundas. A integração atual é apenas o início. O futuro reside na criação de sistemas que não só monitorizam e comunicam, mas também prevêem, aprendem e optimizam-se a si próprios. Esta é a verdadeira promessa do fabrico inteligente para processos complexos como a maquinagem CNC multieixos.

Poder de previsão e sistemas de auto-otimização

O próximo salto em frente será impulsionado pela inteligência artificial (IA) e pela aprendizagem automática (ML). Estas tecnologias transformarão os enormes conjuntos de dados gerados pelos sensores IoT em previsões altamente precisas e acções automatizadas, elevando a eficiência e a qualidade a novos patamares.

Da manutenção preditiva à manutenção prescritiva

A manutenção preditiva, que nos alerta antes de um componente falhar, já é um grande passo. O futuro é prescritivo manutenção. Os algoritmos de IA não dirão apenas que é provável que um rolamento de fuso falhe na próxima semana; eles analisarão os horários de produção, a disponibilidade de material e os horários dos técnicos para recomendar o momento ideal absoluto para realizar a substituição com o mínimo de interrupção. Nas nossas explorações no PTSMAKE, vimos simulações que sugerem que esta abordagem poderia aumentar a eficácia global do equipamento (OEE) em mais 5-10% em relação aos modelos preditivos actuais.

Controlo de qualidade em tempo real que se corrige a si próprio

Imagine uma máquina multieixos que não se limita a detetar um desvio dimensional, mas que o corrige em tempo real. Os sistemas futuros utilizarão dados de metrologia em processo para fornecer um ciclo de feedback em direto ao controlador CNC. Se uma ferramenta começar a desgastar-se e uma dimensão crítica começar a desviar-se, o sistema ajustará automaticamente o desvio da ferramenta para que a peça volte a estar dentro das especificações na passagem seguinte. Este controlo de qualidade em circuito fechado minimiza o desperdício e elimina a necessidade de inspecções pós-produção em muitas caraterísticas.

| Tendência futura | Impacto no KPI de fabrico | Exemplo |

|---|---|---|

| Manutenção prescritiva | Aumento do OEE, redução do tempo de inatividade | A IA programa a substituição dos rolamentos durante a mudança planeada. |

| CQ com autocorreção | Taxa de refugo próxima de zero, Cpk mais elevado | A máquina ajusta a trajetória da ferramenta a meio do corte para manter a tolerância. |

| Simulação de gémeos digitais | Tempo de configuração reduzido, sucesso na primeira peça | Todo o processo é validado virtualmente antes de qualquer metal ser cortado. |

Isto leva ao conceito de "gémeo digital" - uma réplica virtual e dinâmica da máquina física. Antes de uma única peça de stock ser carregada, podemos executar todo o programa de maquinação no gémeo digital, simulando percursos de ferramentas, remoção de material e expansão térmica. Isto permite-nos otimizar o processo e detetar potenciais colisões ou problemas de qualidade no mundo virtual, garantindo que a primeira peça física é perfeita.

O futuro da maquinagem CNC multieixos é inteligente e interligado. A automação, a IoT e a análise de dados não são apenas complementos; são componentes essenciais que estão a moldar uma nova era de fabrico. Esta integração está a gerar ganhos de eficiência sem precedentes, permitindo uma manutenção preditiva que elimina surpresas e criando sistemas de controlo de qualidade em tempo real que garantem que cada peça é perfeita. À medida que avançamos, estas tecnologias inteligentes tornar-se-ão o padrão para alcançar a precisão e a fiabilidade que os nossos clientes esperam.

Desbloqueie o desempenho industrial com a maquinagem CNC multieixos PTSMAKE

Pronto para transformar desafios complexos de engenharia em soluções de alta precisão? Contacte a PTSMAKE agora para obter um orçamento personalizado e descubra como a nossa maquinação CNC multieixos avançada proporciona uma qualidade, eficiência e personalização imbatíveis para os seus projectos mais exigentes - do protótipo à produção. Dê o próximo passo com um parceiro de confiança!

Aprenda os princípios de movimento da máquina que são essenciais para otimizar os seus designs de peças complexas para fabrico. ↩

Saiba como o sistema de controlo traduz códigos complexos em movimentos suaves e coordenados para uma qualidade superior das peças. ↩

Descubra como são calculados os movimentos dos eixos de uma máquina para criar percursos de ferramenta eficientes e sem colisões. ↩

Compreenda como esta métrica crucial define a verdadeira precisão de uma máquina CNC no espaço 3D. ↩

Explore esta ligação para compreender como a estrutura física da máquina afecta a sua precisão e capacidades. ↩

Saiba como as propriedades direcionais podem afetar a resistência do material e as opções de maquinagem. ↩

Clique para compreender os princípios de movimento da máquina que permitem a maquinagem complexa de vários eixos. ↩

Compreender como este conceito financeiro afecta o custo real e a rentabilidade dos seus projectos de fabrico. ↩

Explore como a simulação de máquinas virtuais evita colisões dispendiosas e optimiza os percursos das ferramentas antes de cortar uma única pastilha. ↩

Compreender o conceito central que associa as máquinas físicas à computação digital para ver como funcionam as fábricas inteligentes. ↩