Finding the right CNC machining partner in Birmingham feels impossible when every supplier promises precision but delivers headaches. You’re stuck juggling multiple vendors, dealing with delays, and constantly worrying about quality issues that could derail your entire project.

Birmingham businesses need CNC machining services that deliver precision parts on time, but success requires looking beyond just local suppliers to find partners who combine advanced technology, proven quality systems, and reliable communication for complex manufacturing projects.

I’ve worked with engineering teams across Birmingham’s automotive, aerospace, and tech sectors, and I see the same pattern. Companies start with good intentions but get trapped by limited local options. This guide shows you how to break free from that cycle and find a manufacturing partner who actually delivers on their promises.

The Core Challenge: Finding Precision CNC Machining in Birmingham

If you’re an engineer or procurement manager in Birmingham, your search for reliable partners is constant. You’re likely looking for top-tier cnc machining services birmingham that can meet demanding specifications.

なぜ精度が重要なのか

Birmingham’s key industries—automotive, aerospace, and tech—thrive on precision. A single component failure can have significant consequences. This makes your choice of supplier critical.

Local vs. Global Sourcing

| ファクター | Local CNC Suppliers | Global Partners |

|---|---|---|

| コミュニケーション | Easier, same time zone | Potential time delays |

| 物流 | Faster, simpler | より複雑 |

| 能力 | Can be limited | Often wider range |

This post will explore how to navigate these manufacturing challenges to find the best fit.

Navigating Birmingham’s Manufacturing Landscape

Finding the right partner for precision CNC machining in Birmingham goes beyond a simple search. It’s about aligning capabilities with your project’s specific needs. Local CNC suppliers offer undeniable advantages in communication and logistics. Face-to-face meetings can resolve complex issues quickly.

However, local capacity might not always match the scale or complexity your project requires. This is a common manufacturing challenge. You might need specialized materials or advanced 5-axis machining that isn’t available down the road. This forces a broader perspective.

The Global Alternative

Looking globally opens up a vast pool of expertise and technology. At PTSMAKE, we often work with clients who initially sought local partners but needed our specific capabilities for tight tolerances. The key is finding a global supplier who mitigates the distance with excellent communication and proven logistics.

A partner’s ability to interpret complex technical drawings using systems like 幾何学的寸法と公差1 is non-negotiable, regardless of their location.

主な決定要因

| 考察 | 重要性 | 共通の課題 |

|---|---|---|

| テクニカル・スキル | 高い | Inconsistent quality |

| リードタイム | 高い | Production delays |

| 費用対効果 | ミディアム | Hidden costs |

| コミュニケーション | 高い | Slow responses |

Ultimately, the goal is a partnership that feels local but delivers global-standard quality and reliability.

Finding the right CNC machining partner in Birmingham means balancing local convenience with global capabilities. This decision is crucial for overcoming manufacturing challenges and ensuring your project’s components meet exact specifications, on time and within budget.

Your Definitive Checklist for Vetting Any CNC Machining Partner

Finding the right partner is crucial. A simple checklist helps you compare potential suppliers objectively. This isn’t just about price; it’s about reliability.

A structured approach saves time. It also prevents costly mistakes down the line.

Key Areas for Your Checklist

Use this as your starting point when vetting CNC suppliers. It covers the essentials for any serious evaluation. This CNC quality control checklist is your first line of defense.

| チェックリスト項目 | What to Ask For |

|---|---|

| 認証 | Current ISO 9001 certificate |

| 機材リスト | Full list with machine ages/models |

| Team Experience | Resumes of key technical staff |

| 品質システム | A copy of their quality manual |

This framework ensures you cover all critical aspects.

Digging Deeper Than the Paperwork

An ISO certified machining partner is a baseline, not the finish line. Ask how they apply their quality management system daily. A proactive partner integrates quality into every step, from quoting to shipping.

When you get an equipment list, look for diversity and modernity. A mix of 3, 4, and 5-axis machines indicates versatility. Well-maintained, late-model equipment often means better precision and reliability. This is vital for complex parts.

Verifying Materials and Processes

Material verification is a critical checkpoint. Your partner must have a robust process for material traceability. Ask them to walk you through how they confirm a material’s grade and origin. They should readily provide material certifications.

Their quality control system should involve more than just a final check. In-process inspections are key to catching errors early. The use of advanced 計測2 equipment like CMMs shows a serious commitment to precision. Whether you’re sourcing cnc machining services in Birmingham or across the globe, these standards are universal.

| Quality System Element | 何を見るべきか | Potential Red Flag |

|---|---|---|

| 第一条検査(FAI) | A detailed FAI report is standard | FAI is an extra charge or not offered |

| 工程内検査 | Documented checks at key stages | Inspections are informal or undocumented |

| 材料のトレーサビリティ | Can provide certs for all raw materials | Hesitation or inability to provide certs |

| Final Inspection Tools | Calibrated CMMs, micrometers, gauges | Relies only on basic calipers |

This structured approach to vetting CNC suppliers helps build a foundation for a successful partnership. It ensures your parts are made right the first time.

This checklist provides a clear framework. Focusing on certifications, equipment, team expertise, and robust quality control systems helps you identify a truly reliable partner and avoid costly production issues down the road.

The Hidden Costs of Sticking to Local Birmingham CNC Shops

Sticking exclusively to local suppliers feels secure. But it can introduce hidden business risks. We must think strategically about sourcing.

This means looking beyond convenience. It’s about evaluating the total cost and capability.

Evaluating Local Supplier Limitations

Higher overheads in the UK can increase your final price. This directly impacts the cnc machining cost birmingham for your project.

Also, smaller shops often have limited production capacity. This can lead to unexpected delays when they get busy.

| Sourcing Factor | Local Birmingham Shop | Global Partner |

|---|---|---|

| オーバーヘッド | より高い可能性 | しばしば低い |

| リードタイムズ | Variable; risk of delays | より予測可能 |

| テクノロジー | May use older equipment | Access to latest tech |

These are critical points to consider. A purely local strategy might not always be the most competitive one.

Relying solely on local shops requires careful thought. Many businesses I’ve worked with find that a blended sourcing model offers more resilience and value. It’s not about abandoning local, but understanding its place in a larger strategy.

A Deeper Look at Strategic Sourcing

Local suppliers often face unique pressures. These can inadvertently affect your project’s timeline and budget. These are key local supplier limitations to assess.

Overhead and Cost Structures

A Birmingham-based shop has higher property and labor costs. These costs are passed on to you. It’s a simple business reality. A global partner often benefits from different Economies of scale3. This allows for more competitive pricing on high-quality cnc machining services birmingham.

Technology and Material Access

Furthermore, smaller local shops may not have the capital for the latest 5-axis machines or advanced automation. This can limit part complexity and efficiency. They might also have a smaller network for sourcing specialized materials, potentially causing delays.

| Limitation Category | Specific Impact on Your Project |

|---|---|

| コスト | Higher per-unit price due to local overhead. |

| 定員 | A single large order can create a bottleneck, delaying all jobs. |

| テクノロジー | Less access to advanced machinery may limit design possibilities. |

| 材料 | Sourcing non-standard alloys or plastics can be slow and costly. |

Strategically evaluating these limitations helps you build a more robust and cost-effective supply chain.

While local sourcing has its place, it’s crucial to weigh its limitations. Higher costs, capacity constraints, and potential technology gaps are real business risks that must be managed for a competitive edge.

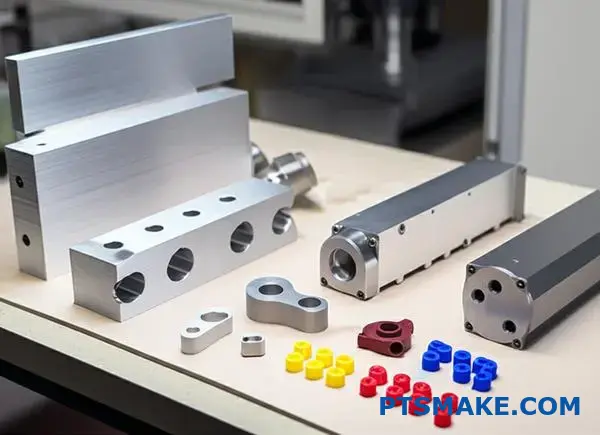

Your Complete Guide to Material Selection for Optimal Performance

Choosing the right material is the foundation of any successful engineering project. The decision impacts performance, cost, and manufacturing. It’s a critical balance.

This guide simplifies your CNC material selection process. We’ll explore common metals and plastics.

Common Material Choices

Engineers often start with these four categories. Each has unique strengths for specific applications.

| 素材グループ | 主な特徴 | 一般的な使用例 |

|---|---|---|

| アルミニウム合金 | Lightweight, good strength-to-weight, corrosion resistant | Aerospace, automotive, consumer electronics |

| ステンレス鋼 | High strength, corrosion/heat resistance | Medical devices, food processing, marine |

| チタン | Excellent strength-to-weight, biocompatible | Aerospace, medical implants, high-performance sports |

| エンジニアリングプラスチック | Lightweight, chemical resistant, can be self-lubricating | Gears, bearings, electronic insulators |

Making the right choice early on prevents costly redesigns later.

The ideal material on paper isn’t always the best for production. You must weigh trade-offs. It’s a constant balancing act between ideal properties and practical constraints.

The Trade-Off Matrix

Every material choice involves compromise. A material with high strength might be heavy and difficult to machine, driving up costs. For example, machining aluminum parts is fast and cost-effective. Titanium offers superior performance but at a much higher price.

This is where experience is key. We help clients navigate these decisions daily. Our extensive material inventory at PTSMAKE gives us the flexibility to find the perfect fit for your budget and performance needs.

Whether you’re sourcing locally, perhaps seeking cnc machining services birmingham, or working with a global partner, these fundamentals remain the same. Some materials also have 異方4 properties, which adds another layer of complexity to the design.

Deeper Comparison

| 素材 | 強さ | 重量 | コスト | 加工性 |

|---|---|---|---|---|

| アルミニウム6061 | ミディアム | 低い | 低い | 素晴らしい |

| ステンレス304 | 高い | 高い | ミディアム | フェア |

| チタン Ti-6Al-4V | 非常に高い | ミディアム | 非常に高い | 貧しい |

| 覗き見 | High (for a plastic) | 非常に低い | 高い | グッド |

Understanding these trade-offs for materials, including various aerospace grade materials, is crucial for project success.

Proper material selection involves balancing performance requirements with manufacturing realities. Understanding the trade-offs between strength, weight, cost, and machinability is essential for optimizing your design for both function and budget.

Unlocking Rapid Prototyping: From Design to Part in Days, Not Weeks

The longest wait in product development is often for the first physical prototype. Traditional methods can leave your team stalled for weeks.

This delay creates a major bottleneck.

With modern CNC machining, this timeline is crushed. We transform your digital design into a tangible part in just days. For companies that need fast turnaround CNC, this is a game-changer. It accelerates everything that follows.

The Old Way vs. The New Way

| Traditional Methods | Rapid CNC Prototyping |

|---|---|

| 週または月 | 日数 |

| High Tooling Costs | No Tooling Needed |

| Slow Iteration | Rapid Design Validation |

This speed allows for real-world testing almost immediately, which is invaluable.

Long lead times are more than just an inconvenience; they are a direct risk to your project’s success. Each week spent waiting is a week you aren’t testing, validating, or improving your design. It’s a week your competitors might be gaining ground.

The CNC Prototyping Workflow

The process is straightforward and built for speed. It begins with your 3D CAD model. We run a Design for Manufacturability (DFM) analysis to ensure the part is optimized for machining. This simple check prevents costly errors down the line.

From there, our CAM software generates the precise toolpaths. A block of production-grade material is then loaded into one of our CNC machines. The process of Subtractive Manufacturing5 begins, carving away material to reveal your final part with incredible precision.

スピードが重要な理由

Getting a physical part quickly allows your engineering team to conduct immediate functional tests. You can verify fit, form, and function right away. When providing cnc prototype machining, this is the value we bring. This is how we provide industry-leading cnc machining services birmingham.

This rapid feedback loop transforms the development cycle.

| Development Stage | Benefit of Speed |

|---|---|

| Initial Concept | Validate core ideas with a real part. |

| 機能テスト | Find and fix design flaws early. |

| プリプロダクション | Finalize design with high confidence. |

This ability to iterate quickly reduces risk and ultimately leads to a better final product, launched sooner.

CNC rapid prototyping collapses the timeline from design to physical part. This speed enables faster testing, validation, and design iteration, directly accelerating your product development cycle and providing a clear competitive advantage.

How a Reliable CNC Supplier Guarantees On-Time Delivery

Delivery delays are a major source of frustration. They can halt your entire Birmingham project.

True on-time CNC delivery isn’t about luck. It results from carefully designed systems.

A reliable partner proves their worth through process, not just promises. They must have robust project management, production planning, and logistics.

These three pillars are what you should look for. They are the backbone of a dependable manufacturing partnership that respects your deadlines.

To guarantee punctuality, a supplier’s internal operations must be seamless. It’s about having a system that anticipates problems before they happen. When we provide cnc machining services birmingham clients can rely on, our process is transparent and structured.

プロアクティブ・プロジェクト・マネジメント

A dedicated project manager is essential. They act as your single point of contact. This prevents miscommunication and ensures accountability. Clear milestones are set and tracked from day one.

Meticulous Production Planning

Effective planning is critical for managing manufacturing lead times. This involves more than just a schedule. It includes early material procurement and strategic machine allocation. We always build in buffer times to account for unexpected issues. This ensures minor setbacks don’t cause a major delay. The Critical Path Method (CPM)6 is one technique we use to map out every task.

| 特徴 | Reliable CNC Supplier | Unreliable Supplier |

|---|---|---|

| Scheduling | Detailed, with buffer times | Vague or overly optimistic |

| コミュニケーション | Proactive updates, single contact | Reactive, multiple contacts |

| Tracking | Transparent, real-time data | Limited or no visibility |

| 問題解決 | Pre-planned contingencies | Ad-hoc and chaotic |

Transparent Logistics Systems

The job isn’t done until parts arrive safely. A robust logistics system includes transparent, real-time tracking. It also means having protocols to manage customs and resolve any shipping issues swiftly. Constant communication keeps you informed every step of the way.

Ultimately, achieving on-time CNC delivery depends on your partner’s internal processes. A truly reliable CNC supplier demonstrates strong project management, detailed production planning, and transparent logistics. These systems are the only real guarantee for meeting your project deadlines.

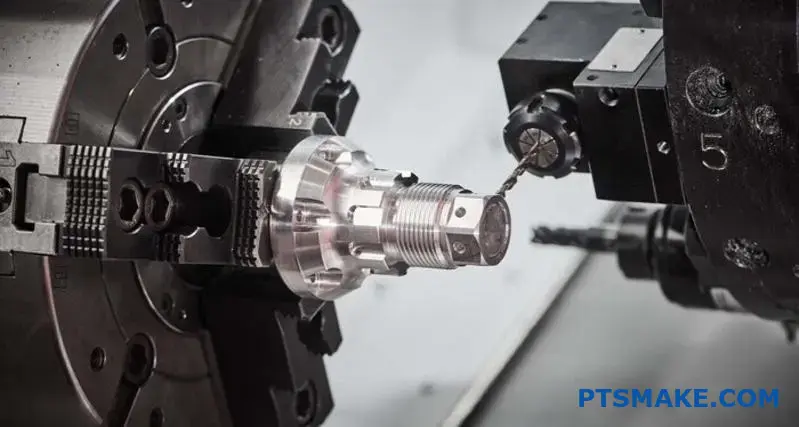

Solving Complex Geometry Challenges: The Power of 5-Axis CNC

For engineers, 5-axis CNC machining isn’t just an upgrade. It’s a fundamentally different approach to creating parts. It moves a tool or part along five axes simultaneously.

This capability is vital for complex geometry machining. It allows us to machine intricate shapes in a single setup. This greatly improves accuracy and reduces lead times for parts.

シングル・セットアップの利点

Fewer setups mean fewer errors. With 5-axis, the workpiece doesn’t need to be manually re-positioned. This maintains tight tolerances, which is critical for aerospace CNC parts.

The efficiency gain is also significant. For businesses seeking 5-axis CNC machining birmingham, this translates directly into faster turnarounds and lower costs.

| 特徴 | 3軸CNC | 5軸CNC |

|---|---|---|

| 必要なセットアップ | 複数 | シングル |

| 部品の複雑さ | 限定 | 高い |

| 精度 | グッド | 素晴らしい |

| リードタイム | 長い | より短い |

When we discuss 5-axis machining, it’s crucial to distinguish between different types. Not all 5-axis capabilities are equal. The real power lies in how the axes work together.

3+2 Axis vs. True 5-Axis

Many machines operate in a "3+2" or "positional" 5-axis mode. Here, the two rotational axes (A and B) lock into position. Then the machine performs a 3-axis operation. This is useful for reducing setups.

However, true 5-axis machining involves the continuous, simultaneous movement of all five axes. This simultaneous interpolation7 is what allows for the creation of complex curved surfaces. It enables undercutting and intricate detailing in one fluid motion.

部品品質への影響

This continuous movement results in a superior surface finish. It eliminates the small marks left when a tool stops and repositions. It also allows the use of shorter, more rigid cutting tools. Shorter tools deflect less, which significantly improves accuracy. This is a key reason why our cnc machining services birmingham are sought after for high-spec components.

| アスペクト | 3+2 Axis Machining | True 5-Axis Machining |

|---|---|---|

| Axis Movement | Sequential | Simultaneous |

| 表面仕上げ | グッド | スーペリア |

| 最適 | Angled Holes/Features | 複雑な輪郭 |

| 工具の長さ | Longer Tools Needed | Shorter Tools Possible |

5-axis CNC machining enables single-setup production for complex geometries. This method enhances precision, shortens lead times, and reduces costs, making it essential for demanding applications like aerospace parts. True simultaneous 5-axis movement offers superior surface finishes and accuracy.

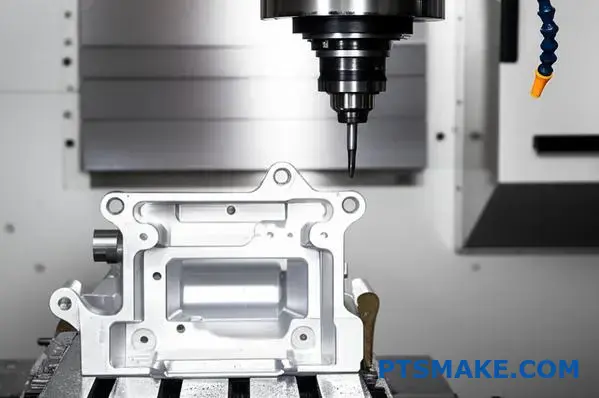

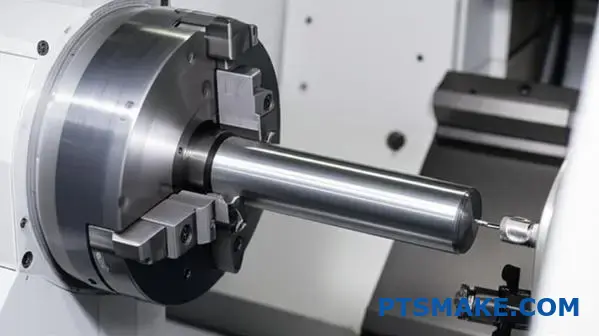

A Definitive Comparison: CNC Milling vs. CNC Turning Services

Choosing between milling and turning can seem complex. But the decision is often simple. It all comes down to your part’s geometry.

Is your part mostly cylindrical, like a pin or shaft? Turning is your answer.

Does it have flat surfaces, pockets, or complex shapes? You need milling.

Let’s look at a quick guide for the key milling vs turning differences.

| 特徴 | CNCフライス加工 | CNC旋盤加工 |

|---|---|---|

| Part Shape | Complex, non-cylindrical | Cylindrical, symmetrical |

| Tool Action | Rotating tool | Rotating workpiece |

| 共通部品 | Brackets, enclosures | Shafts, bolts, pins |

Let’s consider real-world examples. Think of an engine block. It has flat surfaces, holes, and intricate channels. This requires the versatility of CNC milling services in Birmingham. The cutting tool moves around the part to create these features.

Now, picture a simple bolt or a drive shaft. These parts are cylindrical. They are perfect for CNC turning services in Birmingham. The part rotates while a stationary tool removes material. This creates a symmetrical shape very efficiently.

The key takeaway is that many complex products aren’t made with just one process. A single component might need both. It could need turning for a shaft section and milling for adding a keyway or a flat face.

The raw material, or workpiece8, often dictates the initial steps. This is why partnering with a supplier that offers both capabilities is crucial.

At PTSMAKE, we integrate both processes seamlessly. It saves you time and simplifies your supply chain. You avoid coordinating between multiple shops and get a complete solution under one roof.

In short, the choice depends on geometry. Turning creates cylindrical parts, while milling handles complex, non-symmetrical shapes. Working with a partner skilled in both ensures your project is efficient, accurate, and streamlined from start to finish.

The End of Supply Chain Headaches: Your Blueprint for a Single-Source Partner

Managing multiple vendors is a constant balancing act. You’re juggling different timelines, contacts, and quality standards. It adds unnecessary complexity.

What if there was a better way? A single partner for your entire manufacturing process simplifies everything. This is the core of single source manufacturing.

The Multi-Vendor Juggle

Dealing with separate suppliers for CNC machining, injection molding, and assembly is inefficient. It creates communication gaps and logistical nightmares. Delays from one vendor can halt your entire production line.

| チャレンジ | Multi-Vendor Reality | Single-Source Solution |

|---|---|---|

| コミュニケーション | Multiple contacts, delayed replies | One dedicated point of contact |

| 説明責任 | Blame-shifting between suppliers | Full ownership of the process |

| 物流 | Coordinating multiple shipments | One streamlined delivery |

The Power of One Partner

A single-source partner offers a streamlined approach. They manage everything from the initial CNC prototype to the final injection molded parts and assembly. This is the essence of effective OEM manufacturing services. It simplifies procurement immediately.

Your team can focus on innovation. You leave the manufacturing complexities to an expert who understands your project from start to finish. This model is effective globally, whether you need cnc machining services birmingham or an international partner.

Ensuring Perfect Component Harmony

When one company handles both CNC and injection molding, component compatibility is guaranteed. The same team oversees the entire process. This eliminates the risk of parts not fitting together.

We’ve seen projects stall because a CNC part from one supplier didn’t match a molded part from another. This is a costly and avoidable problem. True Supply Chain Integration9 means every component is designed and produced to work together seamlessly.

| サービス | Benefit of Single-Source Partner |

|---|---|

| CNC加工 | Parts are made with final assembly in mind. |

| 射出成形 | Molds are designed to fit machined inserts perfectly. |

| 組立 | All components are tested for fit and function. |

This integrated approach reduces defects and accelerates your time to market. It is the most reliable path from design to a finished product.

A single-source manufacturing partner simplifies your procurement process. It ensures component compatibility and streamlines logistics, saving you time and reducing the risk of costly production delays. This is the blueprint for a headache-free supply chain.

The Ultimate Proof: Real-World Quality Control in a Modern CNC Shop

Saying "we have quality control" is easy. Proving it is what matters. For us, it’s not a single action but a rigorous, multi-stage process. It’s embedded in everything we do.

This system ensures every part meets your exact specifications. It’s how we provide genuine CNC quality assurance.

Our Inspection Framework

We build quality into your parts from start to finish. This isn’t just a final check. It’s a continuous validation process.

| 検査段階 | 主要目標 | Key Method |

|---|---|---|

| 第一条検査(FAI) | Validate the entire setup | Full dimensional report on the first part |

| 工程内検査 | Prevent deviations during production | Scheduled checks by operators & QC |

| 最終検査 | Certify 100% compliance | CMM scans, visual & manual checks |

A Deeper Look at Our Process

A simple checklist isn’t enough for complex components. Our quality system is designed for precision and accountability at every step, a standard that clients seeking reliable cnc machining services in Birmingham have come to expect from a partner.

第一条検査(FAI)

Before we run your full order, we produce one part. This "first article" undergoes a complete inspection against your drawing. This validates our programming, tooling, and setup. It ensures the entire process is correct before mass production begins, saving time and resources.

インプロセス品質管理

During the production run, we don’t just hope for the best. Our machine operators perform regular checks on critical features. This proactive approach catches any potential drift from specifications early. It is a core principle of zero defect manufacturing. We believe in preventing defects, not just finding them.

Final Inspection with CMM Technology

The final step is a comprehensive verification. We use advanced Coordinate Measuring Machines (CMMs) for this. Our CMM inspection services provide highly accurate data on complex geometries that are impossible to measure by hand. The reports often detail complex 幾何学的寸法および公差(GD&T)10 コールアウト

Every shipment from PTSMAKE is accompanied by a full inspection report. This document is your proof that every part you receive has been verified and meets your standards.

Our structured quality process, from FAI to final CMM verification and comprehensive reporting, is our ultimate proof. It’s our tangible commitment to delivering precise, reliable parts that you can trust without question, every single time.

Unveiling the Truth About Communication with a Global CNC Partner

A common fear with global partners is communication. Will they understand my needs? Will time zones create delays? These are valid concerns.

However, modern manufacturing communication has systems to erase these barriers. It’s about structure, not just language.

Dedicated Project Management

You get one point of contact. This person understands your project deeply. They manage all internal communication for you.

Our Communication Channels

We use platforms you already know. This makes collaboration easy and efficient.

| Platform | Usage | 応答時間 |

|---|---|---|

| 電子メール | Formal Documentation, POs | Within 24 Hours |

| WeChat/WhatsApp | Quick Updates, Photos | Near-Instant |

| Video Calls | Project Kick-offs, Reviews | Scheduled |

This structured approach ensures clarity. It provides reliable supplier communication from start to finish.

Many businesses start by looking for local options. They might search for cnc machining services birmingham, for example. They believe proximity equals better communication. This is often a misconception. A well-structured global partner can offer superior communication.

Breaking Down the Barriers

Language is the first hurdle people imagine. At PTSMAKE, our project managers and engineers are fluent in English. This is a non-negotiable requirement. It ensures technical specifications and subtle design details are never lost in translation. We eliminate ambiguity from day one.

The 24-Hour Response Policy

Our commitment is a response within 24 hours. This policy addresses timezone differences directly. Your query is addressed while you sleep. This method of Asynchronous Communication11 keeps projects moving forward continuously.

| Client Time Zone | 私たちの行動 | 成果 |

|---|---|---|

| End of Day (USA) | We start our day, review email | Progress is made overnight |

| Morning (Europe) | We are mid-day, ready for calls | Real-time collaboration |

| Start of Day (USA) | We provide end-of-day summary | You wake up to updates |

This system transforms a potential weakness into a strength. We leverage global time zones to create a 24-hour work cycle on your project. This level of global project management ensures constant progress and transparency.

Effective communication with a global partner is not about luck; it is about design. With dedicated managers, clear policies, and modern tools, collaboration becomes seamless, turning distance into a strategic advantage for your project’s timeline.

Case Study Confidential: How Top Automotive & Aerospace Firms Optimize Parts

Theory is one thing; results are another. Let’s look at real-world examples. These show how strategic changes create major wins. These stories are from projects similar to what you’d find in the UK’s industrial heartland.

Automotive: The Aluminum Bracket Redesign

A Tier 1 supplier needed to cut weight. We focused on an aluminum bracket. Using DFM principles, we found key areas for optimization. This approach delivered impressive results.

The table below shows the impact.

| メートル | Before DFM | After DFM |

|---|---|---|

| 部品重量 | 450g | 382g |

| 加工時間 | 25 mins | 18 mins |

| 単位当たりのコスト | Index 100 | Index 82 |

This project highlights the value of expert automotive cnc machining birmingham partners.

Aerospace: Enhancing Component Durability

アン aerospace parts manufacturer faced fatigue issues with a structural component. The original material choice was adequate but not optimal for new, higher stress requirements. The challenge was finding a new alloy that offered better performance without significantly increasing costs or machining complexity.

Our analysis pointed to a different grade of titanium. While initially more expensive, its superior strength-to-weight ratio was a game-changer. We adjusted the machining strategy to handle the new material’s properties effectively. The material needed to provide uniform strength regardless of the direction of the load. This is crucial for parts under variable stress, as non-uniformity can create weak points. These materials exhibit consistent 等方12 の特性を持つ。

This principle is also critical in medical device machining, where performance is non-negotiable.

Material Property Comparison

| プロパティ | Original Alloy (Al 7075) | New Alloy (Ti-6Al-4V) |

|---|---|---|

| 密度 | 2.81 g/cm³ | 4.43 g/cm³ |

| 引張強度 | 572 MPa | 950 MPa |

| 疲労寿命 | Index 100 | Index 250+ |

By partnering with us for cnc machining services birmingham, the client not only solved the fatigue problem but also extended the part’s service life, reducing long-term maintenance costs.

These cases show how applying Design for Manufacturability and material science solves real engineering challenges. It leads to lighter, stronger, and more cost-effective parts for automotive and aerospace applications, directly improving performance and reducing operational costs.

Get Your CNC Machining Quote with PTSMAKE Today

Ready to solve your Birmingham CNC machining challenges? Contact PTSMAKE for a fast, precision-driven quote—whether you need rapid prototyping, complex geometries, or reliable on-time delivery. Experience our expert support and next-generation capabilities from prototype to production. Send your inquiry now!

この記号化された言語が、どのようにして設計意図を物理的な部品に完璧に変換するのかを学びましょう。 ↩

Learn how advanced measurement science ensures your parts meet exact specifications and why it’s crucial for quality control. ↩

Learn how larger production volumes can significantly lower the per-unit cost of your machined parts. ↩

Understand how a material’s directional properties can impact your component’s strength and performance. ↩

Learn how this core machining process creates parts by removing material from a solid block. ↩

Learn how this method identifies critical tasks to prevent delays and shorten manufacturing lead times. ↩

Learn the mechanics of how a 5-axis machine coordinates movements for superior precision and finish. ↩

Understand the technical term for the raw material used in any machining process. ↩

Discover how integrating your supply chain can boost efficiency and cut operational costs. ↩

この記号化された言語が、どのようにして設計意図を物理的な部品に完璧に変換するのかを学びましょう。 ↩

Learn how this communication style can boost project efficiency across different time zones. ↩

Learn how material properties influence design and machining choices in our comprehensive engineering guide. ↩