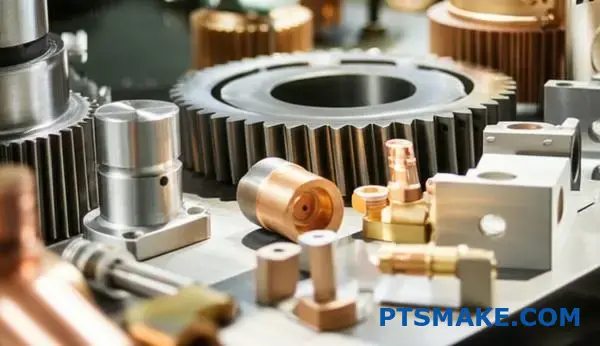

Manufacturing precision parts demands flawless surface treatments. Yet many engineers struggle with choosing the right coating process that delivers both exceptional durability and maintains critical tolerances. Poor plating decisions lead to premature part failure, costly rework, and production delays that can derail entire projects.

Hard chrome plating is an electrochemical coating process that deposits a thin layer of chromium onto metal surfaces, providing superior wear resistance, corrosion protection, and dimensional restoration for precision components across aerospace, automotive, and industrial applications.

After working with chrome plating processes for precision manufacturing at PTSMAKE, I’ve seen how the right surface treatment transforms ordinary components into high-performance parts. This guide reveals the specific techniques and considerations that separate successful plating operations from costly failures.

The Ultimate Guide To Hard Chrome Plating Applications In Manufacturing

Hard chrome plating is more than just a shiny finish. It’s a critical engineering solution that enhances durability and performance. I often see its impact on parts we process.

This process is a cornerstone of modern manufacturing. Industrial hard chrome plating protects components from wear, friction, and corrosion. This significantly extends the service life of critical machinery parts. The applications of hard chrome are incredibly diverse.

Key Industry Applications

| Industry | Common Parts | Primary Benefit |

|---|---|---|

| Aerospace | Landing gear, actuators | Extreme wear resistance |

| Automotive | Pistons, crankshafts | Reduced friction |

| Medical | Surgical tools | Biocompatibility, corrosion resistance |

| Manufacturing | Molds, dies, rollers | Hardness, release properties |

Why Different Industries Rely on Hard Chrome

The specific benefits of a chrome coating for machinery are tailored to each sector’s unique demands. In aerospace, absolute reliability is non-negotiable. A coating failure on landing gear or actuator components is not an option. Here, the plating must endure extreme stress and temperature fluctuations.

For the automotive industry, efficiency is the main driver. Applying hard chrome to engine components like pistons and rings reduces friction. This directly translates to improved fuel economy and a longer operational life for the engine. It’s a small detail that delivers a major performance impact.

The medical field prioritizes safety and purity above all else. Hard chrome provides a non-porous and highly corrosion-resistant surface. This ensures that surgical instruments can be sterilized effectively and repeatedly without degradation. The success of any plating job hinges on the bond with the base material. A proper electro-deposition1 process is crucial for achieving the required performance and longevity.

Application-Specific Demands

| Requirement | Aerospace & Defense | Automotive | Medical Devices |

|---|---|---|---|

| Wear Resistance | Very High | High | Moderate |

| Corrosion Resistance | High | High | Very High |

| Friction Reduction | Moderate | Very High | Low |

| Precision Tolerances | Critical | Important | Critical |

Hard chrome plating provides essential performance enhancements across many industries. From aerospace to medical, this coating improves durability, lowers friction, and ensures reliability. The key is adapting the process to meet the specific demands of each application for optimal results and longevity.

The Truth About Chrome Plating Adhesion And Base Metal Compatibility

Choosing the right base metal is the first critical step. Strong adhesion in hard chrome plating depends entirely on this choice. Not all metals are equally suited for this process.

Base Metal Suitability

Steels are generally excellent candidates. They provide a stable foundation for chrome. Copper and its alloys also bond very well with hard chrome.

Aluminum and titanium are more challenging. They require special intermediate layers to ensure a reliable bond. The metal compatibility for plating is key.

| Base Metal | Compatibility | Key Consideration |

|---|---|---|

| Carbon & Alloy Steels | Excellent | Requires thorough cleaning and activation. |

| Stainless Steel | Good | Must remove the passive oxide layer first. |

| Copper & Brass | Excellent | Often used as an underlayer for other metals. |

| Aluminum | Poor (Directly) | Needs a zincate and/or nickel strike layer. |

| Titanium | Poor (Directly) | Requires specialized and complex etching processes. |

A perfect chrome finish starts long before the part enters the plating tank. The secret to unbeatable adhesion lies in meticulous surface preparation. This process is tailored to each base metal.

It’s more than just cleaning. It’s about creating a chemically active surface that will form a strong metallurgical bond with the chrome.

Preparing Steel Substrates

For common steels, the process is straightforward. It involves alkaline cleaning to remove oils, followed by an acid etch. This etch removes oxides and slightly roughens the surface, giving the chrome a better grip.

The Challenge of Stainless Steel

MARKDOWN_HASH03e8eb698ed784e21be797412adf5becMARKDOWNHASH requires an extra step. Stainless steel has a thin, invisible [passivation layer](https://en.wikipedia.org/wiki/Passivation(chemistry))2 that prevents corrosion. This same layer also blocks adhesion. We must remove it using a specific activator, often a Wood’s nickel strike, just before plating.

Plating on Aluminum

Aluminum is even trickier. It oxidizes instantly in air. To plate it, we first apply a zincate coating. This is followed by a copper or nickel strike layer. The hard chrome is then applied over this foundation.

| Metal | Primary Cleaning | Surface Activation | Underlayer Requirement |

|---|---|---|---|

| Carbon Steel | Degreasing | Acid Etching | None (usually) |

| Stainless Steel | Degreasing | Wood’s Nickel Strike | Required (Nickel) |

| Aluminum | Degreasing | Zincate Process | Required (Zinc & Ni/Cu) |

In summary, achieving strong hard chrome plating adhesion is a science. It demands careful selection of the base metal and a precise, material-specific surface preparation protocol. Skipping these steps guarantees poor results and part failure.

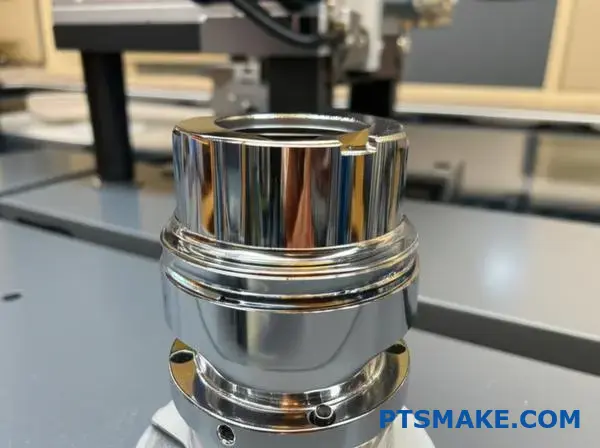

Hard Chrome Plating For Cylindrical Components: Secrets For Long-Term Performance

When dealing with cylindrical components, precision is everything. Shafts, pistons, and rollers are the workhorses of many machines. Their performance depends heavily on the quality of their surface finish.

Plating for Specific Applications

Hard chrome plating for shafts is not the same as for pistons. Each part has unique operational demands. Understanding these differences is key to achieving long-term reliability. A proper cylindrical part chrome coat must be tailored.

Here’s a quick breakdown of their primary needs.

| Component | Primary Requirement | Common Challenge |

|---|---|---|

| Shafts | Wear Resistance | Maintaining balance |

| Pistons | Low Friction | Sealing integrity |

| Rollers | Hardness & Finish | Uniform surface |

This tailored approach prevents premature failure. It ensures each component functions optimally within its system.

The real challenge in rotating parts plating lies beyond surface hardness. It’s about maintaining the component’s geometric integrity. This is where diameter tolerances and concentricity come into play. A deviation of just a few microns can cause significant issues.

Mastering Tolerances and Concentricity

For high-speed rotating shafts, any imbalance can lead to vibration and catastrophic failure. The chrome layer must be perfectly uniform. An uneven coating throws off the part’s balance. This is a critical detail in chrome plating for shafts.

The Challenge of Uniform Deposition

Achieving a perfectly even coat is difficult. The electrochemical process naturally deposits more chrome on edges and ends. This can compromise the precise diameter required for the part.

We use specific techniques, like anode conforming3, to control plating distribution. This ensures the coating thickness is consistent along the entire length of the component. It is a non-negotiable step for high-performance parts. After plating, precision grinding is often necessary to achieve the final, exacting tolerances.

Here are some common issues and our solutions.

| Challenge | Solution | Outcome |

|---|---|---|

| Uneven Plating Thickness | Custom Anode Configuration | Consistent Diameter |

| Loss of Concentricity | Precision Racking & Rotation | Balanced, Vibration-Free Part |

| Out-of-Spec Tolerances | Post-Plating Precision Grinding | Meets Exact Specifications |

At PTSMAKE, our process control ensures every cylindrical part chrome coat meets or exceeds the required geometric specifications for optimal performance.

Precision hard chrome plating is essential for cylindrical parts. Tailoring the process for shafts, pistons, and rollers is crucial. Mastering diameter tolerances and concentricity ensures the long-term performance and reliability of these critical components.

Enhancing Durability and Wear Resistance

The primary reason we apply hard chrome plating is to boost durability. This process adds an incredibly hard outer layer to a finished component.

Applying chrome over CNC parts creates a barrier against abrasion and wear. It is an essential step in post-machining plating for components under constant stress. This protective layer significantly extends the part’s operational life.

Surface Hardness Comparison

A harder surface directly translates to better wear resistance. This is a key advantage of hard chrome plating.

| Component Type | Surface Hardness (HRC) |

|---|---|

| Unplated Steel Part | 30-40 HRC |

| Hard Chrome Plated Part | 68-72 HRC |

This plating makes parts much more resilient. It’s a crucial finish for high-performance applications.

The Science Behind Enhanced Wear Resistance

The exceptional hardness of hard chrome plating is just one part of the story. Its low coefficient of friction4 is equally important. This property means less resistance when parts slide against each other.

This reduction in friction minimizes heat generation and material loss over time. It’s a critical factor for moving parts like pistons, shafts, and hydraulic cylinders. For these applications, smooth operation is just as vital as raw strength.

Impact on Milled Components

When considering chrome for milled components, we often focus on parts with dynamic contact surfaces. The plating ensures these surfaces remain smooth and within tolerance for much longer.

| Benefit | Impact on Performance |

|---|---|

| Reduced Friction | Smoother operation, less heat |

| Increased Hardness | Prevents scratches and gouges |

| Corrosion Resistance | Protects the base material |

At PTSMAKE, we have found that this dual benefit of hardness and low friction is key. It transforms a standard machined part into a high-endurance component. This post-machining plating process provides measurable improvements in product lifespan and reliability.

Hard chrome plating dramatically improves the durability and wear resistance of CNC parts. By adding a hard, low-friction surface, this post-machining plating process extends component life, reduces maintenance, and enhances overall performance, especially for parts subject to constant motion.

Machining After Hard Chrome Plating: What’s Possible And What’s Not

Hard chrome plating offers incredible surface hardness. But it’s often not the final step for precision parts.

Achieving the tightest tolerances requires post-processing. This is where precision finishing techniques come into play. These methods refine the surface and dimensions.

Precision Finishing Methods

Let’s look at the most common practices. Grinding, lapping, and polishing each serve a distinct purpose. They are essential for chrome dimensional post-processing. Proper execution is key to a perfect final part.

| Process | Primary Goal | Surface Finish (Ra) |

|---|---|---|

| Grinding | Dimensional Accuracy | 0.2 – 0.8 µm |

| Lapping | Extreme Flatness | 0.05 – 0.2 µm |

| Polishing | Mirror-like Shine | < 0.05 µm |

These techniques ensure the plated part meets exact specifications.

The real challenge in machining after chrome is control. The hard chrome layer is strong but brittle. Incorrect methods can introduce stress, cracks, or delamination. It’s not just about removing material; it’s about refining it without damage.

Grinding Chrome-Plated Parts

Grinding chrome-plated parts is the most common step. The goal is to correct any dimensional inconsistencies from the plating process. We must use the right grinding wheel. Vitrified-bond silicon carbide or diamond wheels are standard choices.

The choice of abrasive is critical. Its friability5 determines how it breaks down, exposing new sharp edges. This is vital for clean cuts on the hard surface. Our tests at PTSMAKE show that controlling wheel speed and using proper coolant is non-negotiable. It prevents overheating, which is a primary cause of cracking in hard chrome plating.

Lapping and Polishing

Lapping and polishing are for achieving superior surface finishes. Lapping uses a fine abrasive slurry to create ultra-flat surfaces. Polishing uses even finer compounds to achieve a mirror-like appearance.

| Technique | Key Challenge | Our Solution |

|---|---|---|

| Grinding | Heat generation, cracking | Controlled parameters, proper coolant |

| Lapping | Maintaining uniform flatness | Precision lapping plates, consistent slurry |

| Polishing | Avoiding surface contamination | Clean environment, specific polishing pads |

Each step requires specialized knowledge and equipment.

Post-plating grinding, lapping, and polishing are crucial for achieving final tolerances and surface finishes on hard chrome parts. Success depends entirely on using the correct techniques, tools, and process controls to avoid damaging the brittle chrome layer.

Hard Chrome Plating And Lubrication: A Friction Management Strategy

Hard chrome plating offers more than just hardness. Its true value emerges when paired with proper lubrication. This combination creates an exceptional friction management system.

The unique micro-cracked surface of hard chrome plating is key. These tiny fissures act as reservoirs. They hold lubricants, ensuring consistent plated surface lubrication.

This turns the surface into a true chrome low-friction coating. It prevents lubricant starvation under high pressure, drastically reducing wear and extending the life of components.

| Condition | Coefficient of Friction | Wear Rate |

|---|---|---|

| Dry Chrome | 0.20 – 0.40 | Moderate |

| Lubricated Chrome | < 0.10 | Very Low |

This synergy is vital for high-performance applications.

The interaction between hard chrome and lubricants is a fascinating area of study. This field is a core part of the science of tribology with chrome. It’s not just about applying any oil; it’s about a calculated pairing.

The Role of Surface Texture

The micro-cracked structure is not a defect. It is a feature we leverage at PTSMAKE. This texture ensures a boundary layer of lubricant is always present, even under extreme loads. This prevents direct metal-to-metal contact, which is the primary cause of catastrophic wear.

This consistent oil film helps maintain a state of hydrodynamic lubrication6, where surfaces are fully separated.

Matching Lubricant to Application

Choosing the right lubricant is critical. Factors like viscosity, additives, and operating temperature play a huge role. A high-viscosity oil might be perfect for slow, high-load systems. A lower-viscosity fluid works better for high-speed applications.

We often work with clients to test different combinations. This ensures the final system achieves optimal performance and longevity. The goal is to create a stable, low-friction environment tailored to the specific mechanical demands.

| Lubricant Property | Impact on Chrome Surface Performance |

|---|---|

| Viscosity | Affects film thickness and load-bearing capacity. |

| Additives (EP/AW) | Provide chemical protection during boundary lubrication. |

| Operating Temp. | Influences lubricant viscosity and degradation rate. |

The synergy between hard chrome’s micro-structure and a carefully selected lubricant is crucial. This engineered relationship transforms a simple coating into a high-performance system for friction and wear management, maximizing the component’s operational life.

Hard Chrome Vs Thin Dense Chrome: Choosing The Right Process

Choosing the right coating is critical. Hard chrome and thin dense chrome often cause confusion. While both offer protection, they are not interchangeable.

Their differences directly impact component performance and lifespan. Understanding this comparison is key for any engineer. It ensures you select the best precision plating solutions for your needs.

Key Distinctions at a Glance

Let’s break down the core differences between these chrome types.

| Feature | Standard Hard Chrome | Thin Dense Chrome |

|---|---|---|

| Thickness | Thicker (25-500 µm) | Thinner (1-10 µm) |

| Primary Use | Heavy wear, repair | High precision, friction reduction |

| Tolerance | Can alter dimensions | Minimal dimensional change |

The main difference comes from the plating process itself. Standard hard chrome plating builds up thick layers. This is great for rebuilding worn parts or for heavy-duty applications where material loss is a concern.

Thin dense chrome (TDC), however, is a more controlled process. It deposits a less porous and more uniform layer. This precision is vital for components with very tight tolerances. You cannot afford significant dimensional changes on these parts.

Performance and Structural Impact

The TDC process creates a surface with higher nodularity. This results in a smoother, more consistent finish right out of the tank. This is ideal for reducing friction and preventing galling in moving parts.

The internal stress and micro-cracking7 patterns are also different. Based on our client collaborations, TDC often has a denser, finer crack pattern. This structure is excellent at retaining lubricants, which improves performance under high-pressure contact. This is a clear example of thin dense chrome vs standard hard chrome application differences.

Application Suitability Comparison

| Aspect | Standard Hard Chrome | Thin Dense Chrome |

|---|---|---|

| Surface Finish | Good, can be ground/polished | Excellent, smoother as-plated |

| Adhesion | Strong | Exceptionally strong |

| Application Control | Less precise | Highly precise deposition |

| Best For | Salvage work, high wear areas | Molds, precision tooling, hydraulics |

At PTSMAKE, we help clients analyze their specific wear patterns and tolerance requirements. This ensures the selected hard chrome plating provides the longest and most effective service life for their components.

The choice is not about which is "better," but about fitness for purpose. Standard hard chrome excels in heavy wear and salvage roles. Thin dense chrome is the superior choice for high-precision applications where dimensional accuracy and lubricity are absolutely critical.

Secrets To Masking Precision Features During Chrome Plating

Protecting precision features during hard chrome plating is not optional. It is the core of a successful project. Threads, tight bores, and critical tolerances demand meticulous masking strategies.

Simple tapes won’t work here. One small error can lead to a scrapped part. This increases costs and causes delays.

The Challenge of Precision Areas

These areas are the most difficult to protect. They often have sharp edges or complex internal geometries. The right chrome plating masking techniques are essential for success.

| Feature Type | Common Masking Challenge | Recommended Solution |

|---|---|---|

| Threads | Plating buildup in roots | Custom-fit plugs or wraps |

| Tight Bores | Uneven coating inside | Tapered plugs, custom shields |

| Critical Flatness | Edge buildup ("dog-boning") | Lacquer with precise trim lines |

At PTSMAKE, we treat masking as a critical engineering step. It receives the same attention to detail as the CNC machining process itself.

When dealing with precision plating, a one-size-fits-all approach fails. Protecting critical areas requires a toolkit of specialized methods. The choice depends on the part’s geometry and the specific requirements of the hard chrome plating process.

Advanced Masking Strategies

For internal threads, we often use custom-molded silicone plugs. These provide a perfect seal. They prevent any process solution from seeping in and compromising the thread profile. This is much more reliable than simply wrapping threads with tape.

Bores and Internal Diameters

Protecting tight bores is a significant challenge. A slight plating buildup can render a part useless. Here, we use a combination of tapered plugs and specialized lacquers. This ensures the bore remains untouched. In some cases, proper Anodic Shielding8 is used to divert the electrical current away from the bore’s entrance, preventing buildup.

Managing Critical Tolerances

For flat surfaces with tight tolerances, the biggest risk is buildup along the edges. We apply high-temperature lacquers and then precisely trim the masking line. This creates a sharp, clean edge after plating, with no overflow.

| Masking Method | Best For… | Key Advantage |

|---|---|---|

| Custom Plugs | Threads, Bores | Reusable, perfect seal |

| High-Temp Lacquer | Flat Surfaces, Complex Shapes | Sharp, precise mask lines |

| Specialty Tapes | Non-critical external areas | Fast application |

These advanced masking strategies are fundamental to achieving the precision our clients at PTSMAKE expect. It is a non-negotiable part of our quality process.

Effective masking for precision features like threads and bores is critical. It requires specialized materials and strategic application to protect part integrity during the hard chrome plating process, ensuring final components meet exact specifications.

Advanced Plating Techniques For High-Precision Aerospace Components

In aerospace, plating is not just a finish. It’s a critical process governed by strict standards. We focus on coatings that meet the highest specifications.

This ensures components can withstand extreme operational stresses.

The Role of Certification

FAA certified plating is non-negotiable for flight-critical parts. This certification guarantees process control and traceability. It’s about safety and reliability.

Enhancing Fatigue Resistance

Aerospace chrome plating must enhance, not hinder, a part’s fatigue life. The wrong process can introduce stress and lead to premature failure.

A look at key requirements shows the difference.

| Feature | Standard Plating | Aerospace Plating |

|---|---|---|

| Certification | Optional | Mandatory (e.g., FAA) |

| Fatigue Test | Not Always Required | Required |

| Process Control | Standard | Highly Documented |

| Material Specs | General | Strict Aerospace Grade |

Proper techniques for precision aero components coating are essential.

The demands of aerospace manufacturing go far beyond a shiny surface. Every coating process must be rigorously validated. This validation ensures it meets extreme performance criteria.

Navigating High-Specification Requirements

Meeting specs like those from Boeing or Airbus is complex. It involves precise control over plating thickness, adhesion, and hardness. At PTSMAKE, we guide our clients through these demanding specifications. We ensure their designs are manufacturable from the start.

This early collaboration prevents costly redesigns later.

The Challenge of Hydrogen Embrittlement

A major risk in hard chrome plating is hydrogen embrittlement9. This phenomenon can cause high-strength steel parts to fail unexpectedly under load. It’s a silent killer of components.

Preventing this requires specialized pre-plating and post-plating treatments. Baking the components in an oven is a critical step. This step drives out trapped hydrogen.

We have found that a carefully controlled process is key.

| Mitigation Step | Purpose | Criticality |

|---|---|---|

| Stress Relief Bake | Removes residual stress before plating. | High |

| Controlled Plating | Minimizes hydrogen absorption during the process. | High |

| Embrittlement Relief Bake | Removes absorbed hydrogen after plating. | Critical |

Following these certified procedures is the only way to ensure the structural integrity of precision aero components after coating. It’s a fundamental part of reliable manufacturing.

Aerospace plating is a science of precision and safety. It demands strict adherence to certifications, careful management of fatigue properties, and meeting the highest specifications to ensure component reliability in extreme environments.

How Chrome Plating Enhances Robotic And Automation System Components

In robotics, precision is everything. Unwanted friction can cause jerky movements and positioning errors. This compromises the entire system’s reliability.

Hard chrome plating provides a solution. It creates an ultra-smooth, low-friction surface. This is essential for components that require fluid motion.

The Impact of Surface Friction

Better surface finish directly translates to better performance. Using chrome for robotic movement ensures components glide seamlessly. This enhances accuracy and reduces wear over time.

| Feature | Uncoated Steel | Chrome Plated Steel |

|---|---|---|

| Friction | High | Very Low |

| Wear | Fast | Slow |

| Movement | Can be jerky | Consistently smooth |

This simple upgrade makes coated automation parts far more dependable.

Smooth motion is critical for robotic arms and linear guides. Even microscopic surface imperfections can lead to inconsistent performance. Hard chrome plating addresses this issue at its core by creating a uniform and slick surface.

The Advantage in Actuators

Actuators are the muscles of automated systems. They need to move without hesitation or sticking. Plating for actuators with hard chrome is a common practice at PTSMAKE. It prevents the "stick-slip" effect, where static friction causes a component to jerk into motion.

This process ensures that the force applied results in immediate and smooth movement. It significantly lowers the coefficient of friction10, a key factor in mechanical efficiency. Our internal tests show a dramatic reduction in friction on treated parts.

Benefits of Low-Friction Surfaces

A lower friction surface brings multiple advantages to any automated system.

| Benefit | Impact on Robotic System |

|---|---|

| Reduced Energy Use | Motors work less, saving power. |

| Higher Accuracy | Predictable, repeatable movements. |

| Less Heat Generation | Prevents overheating in fast cycles. |

| Longer Part Life | Minimal wear on moving components. |

Ultimately, using chrome for robotic movement is not just about smoothness. It is about building more efficient, reliable, and durable machines. This is a core principle we apply to the components we manufacture.

In short, hard chrome plating is vital for robotic precision. It creates a smooth, low-friction surface on key components like actuators. This ensures reliable, accurate, and efficient movement in any automation system.

Unlock Precision: Partner with PTSMAKE for Superior Hard Chrome Solutions

Ready to take your manufacturing project to the next level with expert hard chrome plating? Contact PTSMAKE now for a quote and let our precision CNC machining and plating expertise deliver unmatched durability, reliability, and performance—no matter your industry or part complexity.

Explore the technical process of creating a strong, lasting bond. ↩

Learn about this invisible protective film and how it impacts metal finishing and adhesion. ↩

Explore how specialized anode setups enhance coating uniformity on critical parts. ↩

Understand how this key property reduces operational wear and boosts mechanical efficiency. ↩

Understand how abrasive properties influence the quality of your finished part. ↩

Learn how fluid-film lubrication separates surfaces to minimize friction and wear in high-load mechanical systems. ↩

Learn how these tiny crack patterns can greatly affect lubrication and component lifespan. ↩

Understand how this technique controls current to prevent edge buildup and ensure plating uniformity. ↩

Understand this critical failure mode and see the certified post-plating steps required to prevent it. ↩

Understand how this key metric quantifies surface friction and impacts engineering design. ↩