Finding reliable CNC machining solutions in Las Vegas can feel overwhelming when your project demands precision and tight deadlines. Many procurement managers struggle with local suppliers who either lack advanced capabilities or can’t meet the strict tolerances required for aerospace, medical, or robotics applications.

Las Vegas offers several precision CNC machining providers specializing in tight-tolerance parts, rapid prototyping, and production runs for industries like aerospace, medical devices, and electronics, with capabilities ranging from aluminum and stainless steel to advanced plastics.

The key is knowing what to look for in a machining partner and understanding how Las Vegas shops compare to other options. I’ll walk you through the essential factors that matter most when selecting a supplier, from material capabilities to quality certifications.

The Ultimate Guide To CNC Machining Suppliers In Las Vegas

Las Vegas is known for entertainment, but it also has a growing industrial backbone. This city’s demand for high-quality components is rising.

Finding the right partner for CNC machining in Las Vegas is crucial. The local market serves very specific and demanding sectors.

Nøgleindustrier, der driver efterspørgslen

The needs of local businesses shape the landscape for CNC shops in Las Vegas.

| Industri | Component Examples | Materielle behov |

|---|---|---|

| Luft- og rumfart og forsvar | Fixtures, prototypes, engine parts | Titanium, Aluminum 7075 |

| Gaming & Hospitality | Slot machine parts, custom fixtures | Stainless Steel, Brass, Plastics |

| Elektronik | Housings, connectors, heat sinks | Aluminum 6061, Copper |

This focus requires specialized expertise from local suppliers.

Understanding Local Capabilities

While Las Vegas offers convenient options, it’s important to assess their full capabilities. Many local CNC shops excel at quick-turnaround jobs and prototyping for nearby industries. This is a significant advantage for projects needing rapid iteration.

However, the scale can sometimes be a limiting factor. Businesses must consider if a local shop can handle high-volume production runs without sacrificing quality or extending lead times. This is where a global partner like PTSMAKE can provide a different kind of value.

Specializations vs. Broad Expertise

Most precision machining companies in Las Vegas specialize in materials and processes that are common in the aerospace and gaming industries. Their expertise is deep but can be narrow. This is perfect for specific projects.

For complex assemblies requiring multiple processes, you might need a partner with broader experience. Understanding the nuances of Geometrisk dimensionering og tolerance1 across various materials and applications is key. It ensures every part fits and functions perfectly.

| Leverandørtype | Styrker | Potential Limitations |

|---|---|---|

| Local Las Vegas Shops | Proximity, fast prototypes | Limited capacity, narrow specialty |

| Global Partners (PTSMAKE) | Scalability, broad expertise | Longer shipping times |

| Niche Specialists | Deep material knowledge | High cost for general parts |

Choosing the right supplier depends entirely on your project’s specific requirements for speed, scale, and technical complexity.

The Las Vegas CNC machining market is vibrant, serving high-tech industries like aerospace and gaming. Assessing local shops’ capabilities, specializations, and scalability against your project’s specific needs is the first step to finding the perfect manufacturing partner for your project.

How To Choose The Right CNC Machine Shop In Las Vegas

Choosing a partner for CNC machining in Las Vegas goes beyond a simple quote. You need a reliable supplier who understands your project’s specific needs. It’s about building a partnership.

To find the best CNC machine shop Las Vegas offers, focus on four key areas. These pillars will help you evaluate potential shops effectively and avoid costly mistakes down the line.

Core Evaluation Criteria

Your decision should rest on a balanced assessment of these factors.

| Kriterier | Hvorfor det er vigtigt |

|---|---|

| Ekspertise | Ensures they can handle your material and complexity. |

| Ledetider | Directly impacts your project timeline and launch date. |

| Certificeringer | Proves commitment to quality and process control. |

| Kommunikation | Prevents errors and keeps your project on track. |

When you begin your search for trusted machining vendors, these criteria act as your guide. Don’t let price be the only factor. A cheap part that fails inspection or arrives late is far more expensive in the long run.

Diving Deeper into Supplier Selection

Assessing Technical Expertise

A shop’s expertise is visible in its work. Ask to see samples of similar projects. Discuss their experience with your specific materials. Do they understand the nuances of working with aluminum versus stainless steel or titanium? This is how to choose a CNC supplier that won’t learn on your dime.

Understanding Certifications and Quality

Certifications like ISO 9001 are a great starting point. They show a commitment to standardized processes. However, you should also inquire about their quality control measures. Ask about their inspection equipment and processes. Proper Sporbarhed af materialer2 is critical, especially for regulated industries.

Evaluating Communication and Lead Times

Clear, consistent communication is non-negotiable. Your contact should be responsive and knowledgeable. When discussing lead times, ask for a detailed production schedule. This transparency helps you plan effectively and builds confidence in your partnership.

| Aspekt | Hvad skal man kigge efter? | Det røde flag |

|---|---|---|

| Ekspertise | Industry-specific examples, material knowledge. | Vague answers, no relevant portfolio. |

| Kvalitet | ISO 9001, CMM inspection reports. | No formal quality system. |

| Kommunikation | Proactive updates, clear technical answers. | Slow responses, communication breakdowns. |

| Gennemløbstid | Realistic and detailed schedules. | Overly optimistic promises without a plan. |

Selecting the right partner for CNC machining in Las Vegas requires careful evaluation of expertise, quality systems, communication, and realistic lead times. These factors ensure you find a reliable vendor who can meet your project’s specific demands and deliver consistent results.

The Complete Cost Breakdown Of CNC Machining In Las Vegas

Understanding the cost drivers in CNC machining is key. When you request a quote, several factors combine to create the final price. It’s not just about the machine’s time.

The final CNC machining cost in Las Vegas depends on four core elements. These are the material selected, the part’s complexity, tooling needs, and the order quantity. Each one plays a distinct role.

Key Pricing Factors

Let’s break down these factors. Thinking about them early helps you design for manufacturability. This saves both time and money.

| Faktor | Low Cost Impact | High Cost Impact |

|---|---|---|

| Materiale | Aluminium 6061 | Titanium, Inconel |

| Kompleksitet | Simple shapes, loose tolerances | Tight tolerances, complex curves |

| Værktøj | Standardværktøj | Custom fixtures, specialized bits |

| Mængde | 1000+ units | 1-10 units (Prototypes) |

Getting accurate machining quotes requires a deep look into these variables. Let’s explore how each one influences your budget. This knowledge forms the basis of any good CNC pricing guide.

Valg af materiale

The material is often the largest single cost component. Common metals like Aluminum 6061 are affordable and easy to machine. Harder or exotic materials like titanium increase costs due to higher raw material prices and slower machining speeds.

Delkompleksitet og tolerancer

A part with intricate geometries, multiple features, and undercuts requires more programming and machine time. Tight tolerances also demand more precise setups and quality control checks, which adds to the cost.

Tooling and Setup

Every job needs a unique setup. This includes creating fixtures to hold the part and selecting the right cutting tools. Custom tooling can be a significant one-time expense, especially for complex parts. This initial cost is spread across the entire order, a concept known as tooling afskrivning3.

Bestillingsmængde

Volume has a huge impact. Larger quantities reduce the per-unit cost. The initial setup and programming costs are distributed over more parts. At PTSMAKE, we can handle both low-volume prototypes and high-volume production runs efficiently.

Understanding these factors is key to navigating the CNC machining cost landscape in Las Vegas.

Mastering the interplay of material, complexity, tooling, and quantity is crucial. It helps optimize your CNC machining budget in Las Vegas and ensures your project’s financial success from the start.

Why Part Consistency Is Non-Negotiable In CNC Manufacturing

For engineering teams, CNC part consistency is the bedrock of success. This is especially true in demanding sectors like robotics and aerospace.

Here, there’s simply no margin for error. A single part that is out of spec can compromise an entire system. It can halt production or, far worse, cause a critical failure.

The Standard for High-Tech

Repeatability ensures every component performs exactly as intended. This isn’t just a quality goal; it’s a fundamental necessity for complex assemblies.

Impact Across Key Industries

| Industri | Core Need | Konsekvens af fejl |

|---|---|---|

| Luft- og rumfart | Absolut pålidelighed | Catastrophic System Failure |

| Robotteknologi | Perfect Interchangeability | Assembly Halts, Malfunction |

| Medicinsk | Patientsikkerhed | Device Failure, Health Risk |

For engineers, consistent parts mean reliable and safe final products.

When I work with engineering teams, the conversation always centers on reliability. For a robotic arm, every gear and actuator must be identical for smooth, predictable movement.

A slight deviation in a single component can throw off the entire machine’s calibration. This can lead to costly downtime and rework. The principle of perfect interchangeability is key.

Aerospace: Consistency Under Pressure

In aerospace, the demands are even more extreme. Parts must withstand incredible stress, pressure, and temperature changes. In this field, tight machining tolerances are a matter of safety.

We’ve worked on projects where even a micron-level deviation could impact structural integrity. That’s why a full grasp of Geometrisk dimensionering og tolerance (GD&T)4 is essential.

Finding a Reliable Partner

This is why choosing the right manufacturing partner is so critical. For companies seeking partners for CNC machining in Las Vegas or globally, demonstrated process control is non-negotiable.

Critical Elements of Consistency

| Element | Beskrivelse | Hvorfor det er vigtigt |

|---|---|---|

| Repeterbarhed | Producing identical parts every time. | Guarantees interchangeability. |

| Processtyring | Actively monitoring and adjusting machining. | Prevents quality drift. |

| Verifikation af materiale | Using certified, consistent raw materials. | Ensures predictable performance. |

Ultimately, this focus on consistency prevents costly delays and ensures the final product is safe and dependable.

For engineering teams in sectors like robotics and aerospace, CNC part consistency is non-negotiable. Repeatability ensures system integrity, operational safety, and predictable performance, making it a foundational requirement for any successful project that demands precision.

How Las Vegas CNC Shops Handle Tight Tolerances With Precision

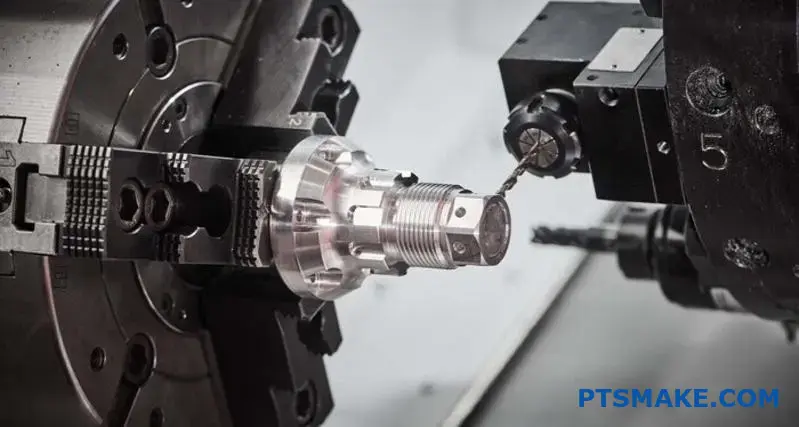

Achieving sub-millimeter precision isn’t guesswork. It’s a calculated process. Top-tier CNC shops master this through a trio of critical elements.

This involves advanced machinery, meticulous inspection technology, and expert programming. These three pillars support all tight tolerance CNC machining. Without one, the others falter. True precision machining in Las Vegas depends on this synergy.

The Pillars of Precision

| Pillar | Funktion | Indvirkning på tolerance |

|---|---|---|

| Maskinens kapacitet | Executes the cut with sub-millimeter accuracy. | Directly sets the physical limits of precision. |

| Inspection Tech | Verifies part dimensions against the CAD model. | Guarantees compliance and process control. |

| Skilled Programming | Translates design intent into machine instructions. | Optimizes toolpaths for complex geometry CNC. |

Beyond the Machine: Technology and Expertise

A high-end CNC machine is only the starting point. The real differentiator in precision machining Las Vegas shops is how they leverage technology and human skill. This combination turns a capable machine into a precision powerhouse.

The Role of CMM Inspection

Coordinate Measuring Machines (CMMs) are fundamental. They provide non-contact, automated measurements with incredible accuracy. This removes human error and provides comprehensive data on every feature. The data ensures the part meets specs. This is far beyond what manual calipers can offer. The machine’s volumetrisk nøjagtighed5 is a critical factor here.

| Inspektionsmetode | Fordele | Ulemper |

|---|---|---|

| Manual (Calipers/Micrometers) | Quick for simple checks | Prone to error, limited on complex shapes |

| CMM (koordinatmålemaskine) | Highly accurate, repeatable, automated | Slower setup, higher initial investment |

The Programmer’s Crucial Touch

Finally, skilled programming is indispensable for complex geometry CNC. CAM software generates good toolpaths. But an expert programmer refines them. They adjust feeds, speeds, and tool entry points to minimize tool deflection and thermal expansion. This ensures the final part is perfect. This human touch is what separates acceptable parts from exceptional ones. At PTSMAKE, our programmers work closely with machinists to optimize every single job.

Achieving tight tolerances relies on a system. It’s the combination of advanced machine capability, precise CMM inspection for verification, and the nuanced skill of expert programmers that guarantees consistent, high-quality results for any precision machining project.

What Every Engineer Needs To Know About Las Vegas Machining Materials

Selecting the right material is a critical first step. This choice affects performance, budget, and project timelines. For any engineer, understanding the options is foundational. It dictates the entire manufacturing strategy.

We often guide clients on popular CNC materials Las Vegas projects demand. This includes a range of metals and plastics. Making an informed decision early prevents costly downstream issues.

Metals vs. Plastics: The Initial Decision

Your application’s needs determine the best material family. Each has distinct advantages.

| Funktion | Metaller | Plast |

|---|---|---|

| Styrke | Høj | Moderat |

| Vægt | Tungt | Letvægt |

| Omkostninger | Generelt højere | Generelt lavere |

| Korrosion | Varies (e.g., SS good) | Fremragende modstandsdygtighed |

At PTSMAKE, we handle a wide array of materials daily. The specifics of your design will point toward the ideal candidate. The choice between metal and plastic often comes down to balancing strength, weight, and environmental exposure.

A Closer Look at Common CNC Materials

Let’s dive into the most frequently requested materials. Each has a unique profile that suits different engineering challenges.

Versatile Metals

Aluminum, especially 6061, is a workhorse. Its strength-to-weight ratio is fantastic, and it machines beautifully. We find that machining aluminum is perfect for prototypes and structural components where weight is a concern.

Stainless Steel (like 304 or 316) offers robust strength and excellent corrosion resistance. This makes it a go-to for medical devices and food-processing equipment.

Titanium stands out for its high strength and low density. It performs well in extreme temperatures, making it essential for aerospace and high-performance automotive parts.

Engineering-Grade Plastics

On the polymer side, ABS is a cost-effective choice. It provides good toughness and impact resistance for enclosures and fixtures. Our plastic machining services handle ABS projects frequently.

PEEK is a high-performance thermoplastic. It excels in harsh chemical and high-temperature environments. When metal parts are not suitable, PEEK is a top contender. The internal stresses from machining can be significant. A process like udglødning6 can relieve these stresses post-machining. This improves dimensional stability.

| Materiale | Nøgleegenskab | Almindelig brug |

|---|---|---|

| Aluminium 6061 | Høj styrke i forhold til vægt | Prototypes, Frames |

| Rustfrit stål 304 | Modstandsdygtighed over for korrosion | Medical, Food-Grade |

| Titanium | Extreme Strength, Low Density | Aerospace, Implants |

| ABS | Impact Resistance, Low Cost | Enclosures, Fixtures |

| PEEK | High Temp/Chemical Resistance | Bearings, Seals |

Choosing between materials like aluminum, titanium, or PEEK is a critical design decision. The material’s inherent properties will directly influence the final part’s performance, durability, and overall cost. A thoughtful selection ensures your component meets every specification for its intended application.

Top Questions To Ask Your Las Vegas CNC Vendor Before A PO

Choosing the right partner for CNC machining in Las Vegas is critical. Before you issue a purchase order, asking the right questions is key. This helps avoid future headaches.

Your goal is to verify their capabilities and processes. Focus on four key areas.

Kvalitetssikring og certificeringer

First, ask about their quality management system. Are they ISO 9001 certified? This shows a commitment to consistent quality.

Lead Time and Delivery

Next, clarify their standard lead times. How do they handle rush orders? On-time delivery is non-negotiable. It protects your own production schedules.

Vendor Checklist: Key Areas

| Kategori | Essential Question | Hvorfor det er vigtigt |

|---|---|---|

| Kvalitet | What is your inspection process? | Ensures parts meet spec. |

| Gennemløbstid | What is your on-time delivery rate? | Predicts reliability. |

Digging deeper helps build a complete picture of a potential supplier. Don’t just accept surface-level answers. Ask for specifics on their equipment and workflow. This shows you’re a serious buyer.

Production Capabilities

Inquire about their machine fleet. What types of CNC machines do they run? Ask about their 3-axis, 4-axis, and 5-axis capabilities. This determines the complexity of parts they can produce.

Also, ask about the materials they commonly work with. If you need a specialty alloy, ensure they have experience with it.

A vendor’s understanding of Geometrisk dimensionering og tolerance (GD&T)7 is also vital. Based on our client feedback, a vendor’s fluency in GD&T directly impacts final part accuracy. A clear CAD to part workflow should be explained.

Kundeservice og kommunikation

Finally, assess their communication process. Who will be your primary point of contact? How quickly do they respond to inquiries or design changes? A responsive partner is invaluable.

Key Questions for Your Las Vegas Vendor

| Topic | Question | Ideal Answer |

|---|---|---|

| Capabilities | Can you describe your CAD to part workflow? | A clear, documented process. |

| Kommunikation | What is your typical response time? | Within a few business hours. |

| Erfaring | Can you provide relevant case studies? | Shows proof of past success. |

A reliable provider of cnc machining las vegas services, like us at PTSMAKE, will welcome these detailed questions.

Asking detailed questions about quality control, lead times, and production workflow is crucial. This diligence ensures you select a reliable partner, preventing costly delays and errors. A thorough Las Vegas vendor checklist is your best tool for success.

How Las Vegas CNC Manufacturers Support Prototyping To Production

The journey from a single concept to mass production is a defining challenge. It requires a clear strategy. Success depends on moving from prototype to scaled manufacturing efficiently.

This transition minimizes risk and validates your design.

Rapid Prototyping Strategies

Effective prototyping tests form, fit, and function. For this, prototype CNC machining Las Vegas offers unmatched speed and precision. It allows for quick adjustments based on real-world feedback.

Transitioning to Production

Moving from one to many involves several key steps. It’s about more than just making more units. It’s about ensuring consistency and quality at scale.

| Scene | Fokus | Vigtige fordele |

|---|---|---|

| Prototype | Validering af design | Fast, accurate feedback |

| Lille parti | Market Testing | Validates demand, refines process |

| Full Production | Skalerbarhed | Cost-effective mass manufacturing |

This structured approach ensures a smooth and successful product launch.

From Small Batches to Full Scale

After validating your prototype, small batch machining is the logical next step. This process allows you to produce a limited quantity of parts. It’s perfect for initial market testing or for fulfilling early orders.

This stage provides crucial data. You learn about manufacturability and potential assembly issues. It bridges the gap between a one-off model and thousands of units. It’s a vital risk-reduction step I always recommend.

Smart Scaling with Bridge Tooling

When you’re not ready for high-volume tooling, bridge tooling options are invaluable. This approach uses less durable, lower-cost molds or fixtures. They are designed to produce parts in the hundreds or low thousands.

This method helps you get to market faster. It also delays the significant capital expense of production tooling. We’ve seen this strategy help many clients test market reception. This process of Iterative Design8 is fundamental to modern product development, allowing for continuous improvement before committing to final tooling.

| Tooling Option | Produktionsvolumen | Gennemløbstid | Omkostninger |

|---|---|---|---|

| Prototype Tooling | 1-100 | Kort | Lav |

| Broværktøj | 100-5,000 | Medium | Moderat |

| Produktionsværktøj | 5,000+ | Lang | Høj |

This tiered approach manages investment and scales with your success.

A planned transition from prototyping to production is key. Using strategies like small batch machining and bridge tooling helps manage costs, reduce risks, and ensure a product is truly ready for the market before full-scale manufacturing begins.

What Las Vegas CNC Buyers Need To Know About Quality Certifications

When you’re sourcing CNC machining services in Las Vegas, quality certifications are your first line of defense. They are more than just logos on a supplier’s website. They signify a deep commitment to proven, documented, and repeatable processes.

Understanding Key Industry Standards

A certified CNC shop Las Vegas provides a baseline of trust. An ISO 9001 certified supplier, for example, adheres to a globally recognized quality management system.

For more demanding sectors, you’ll see specific credentials.

Branchespecifikke certificeringer

| Certificering | Primært fokus | Key Benefit for Buyers |

|---|---|---|

| ISO 9001 | Kvalitetsstyringssystem | Consistency and reliability |

| AS9100 | Aerospace & Defense Quality | Stricter process controls |

| ITAR | U.S. Defense Articles | Legal compliance for defense projects |

This framework helps you quickly identify a capable and compliant machining partner.

A certificate on the wall is a good start, but it’s the culture behind it that truly matters. A piece of paper doesn’t guarantee a perfect part every time. It guarantees a system for achieving quality and a procedure for correcting things when they go wrong.

The Value of an Audit-Ready Partner

The most reliable suppliers are those that are always audit-ready. This means their quality control isn’t a special event. It’s embedded in their daily operations. An audit-ready machining partner lives and breathes their quality system, ensuring consistency.

This operational discipline is built on a process approach9. Every action, from material receiving to final inspection, is a controlled step in a larger system. This minimizes variability and ensures that the final product meets your exact specifications. For any cnc machining las vegas project, this level of dependability is non-negotiable.

As an ISO CNC supplier, we at PTSMAKE have built our reputation on this principle. We ensure that every component has full traceability and conforms to the required standards, providing our clients with peace of mind.

Hvad det betyder for dit projekt

| Certification Benefit | Practical Impact |

|---|---|

| Processtyring | Reduces the likelihood of defects and delays. |

| Dokumentation | Provides a clear record for traceability and accountability. |

| Kontinuerlig forbedring | The supplier is actively working to refine their processes. |

| Risikostyring | Identifies potential failures before they happen. |

For Las Vegas buyers, certifications like ISO 9001 signal a supplier’s robust quality system. Choosing an audit-ready machining partner is the best way to ensure consistent, high-quality results and protect your supply chain from costly errors and delays.

B2B Use Cases: How Las Vegas CNC Helps Aerospace, Medical & Electronics

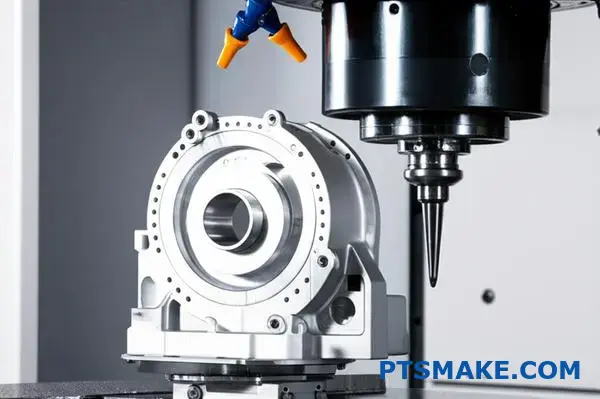

In highly regulated industries, there is no margin for error. Precision is not just a goal; it’s a strict requirement. This is where CNC machining truly shines.

It provides the consistency and accuracy needed for critical parts.

Key Sector Applications

From aerospace to medical devices, each sector has unique demands. Aerospace CNC Las Vegas services focus on strength and lightweight properties. Medical device machining prioritizes biocompatibility. Electronics manufacturing needs precision for miniaturization.

| Sektor | Primary CNC Requirement | Almindelige materialer |

|---|---|---|

| Luft- og rumfart | Højt styrke-til-vægt-forhold | Titanium, Inconel |

| Medicinsk | Biokompatibilitet og steriliserbarhed | Stainless Steel, PEEK |

| Elektronik | Thermal & Electrical Conductivity | Aluminium, kobber |

Now, let’s look closer at these B2B applications. Each industry presents distinct challenges that CNC machining expertly solves, making services like cnc machining las vegas essential for innovation.

CNC-bearbejdning til rumfart

In aerospace, failure can be catastrophic. We manufacture components like turbine blades and structural brackets. These parts demand incredibly tight tolerances and must withstand extreme temperatures and stress.

Working with materials like Titanium and Inconel requires specialized tooling and expertise. The focus of aerospace CNC Las Vegas suppliers is absolute reliability.

Medical Device Machining

For medical devices, patient safety is paramount. We produce surgical instruments, custom implants, and parts for diagnostic machines.

Every component must have a flawless surface finish to prevent contamination. Materials must be biocompatible. This means they won’t cause harm inside the human body. Precision here ensures a device functions exactly as intended. The process is governed by stringent quality control and documentation.

Electronics Parts Manufacturing

In electronics, parts are getting smaller and more complex. We create custom enclosures, heat sinks, and intricate connectors. These components are vital for device performance and longevity.

Proper thermal management prevents overheating. Precise dimensions ensure perfect fits in compact assemblies. This level of detail requires an understanding of Geometrisk dimensionering og tolerance10 to translate design intent perfectly.

| Eksempel på anvendelse | Industri | Kritisk faktor |

|---|---|---|

| Engine Brackets | Luft- og rumfart | Modstandsdygtighed over for udmattelse |

| Bone Screws | Medicinsk | Biokompatibilitet |

| Kølelegemer | Elektronik | Thermal Dissipation |

CNC machining is indispensable for regulated sectors. It delivers the required precision, material compatibility, and repeatability for critical applications in aerospace, medical, and electronics, ensuring safety and performance where stakes are highest.

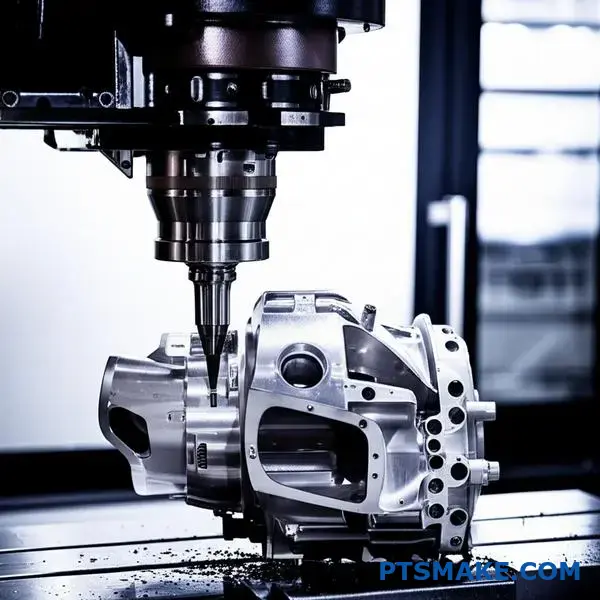

How CNC Machining Supports Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a crucial engineering philosophy. It focuses on designing parts for easy manufacturing. The goal is to optimize for cost, quality, and speed.

This proactive approach prevents many downstream issues. It bridges the gap between a great design and a producible product.

The DFM Advantage

CNC machining’s precision aligns perfectly with DFM. Early engineering decisions, guided by CNC capabilities, lead to superior outcomes. This is key for CNC product optimization.

Below is a simple comparison. It shows how DFM changes the project outcome.

| Aspekt | Without DFM | With DFM |

|---|---|---|

| Omkostninger | Higher, due to rework | Lower, optimized process |

| Tidslinje | Longer, unexpected delays | Shorter, predictable flow |

| Kvalitet | Inkonsekvent | Konsekvent høj |

| Revisions | Hyppig | Minimal |

Thinking about manufacturability from day one is essential. It’s a core principle for modern engineers.

Aligning CNC Capabilities with Design

DFM for engineers isn’t just theory. It’s about practical choices informed by manufacturing realities. CNC machining offers direct feedback for these choices. It ensures that a design is not only possible but also efficient to produce.

Materialevalg og egenskaber

CNC machines handle a vast range of materials. From aluminum alloys to robust plastics. However, each material has unique properties. Some materials are Anisotropisk11, impacting how they respond to cutting forces. An experienced machining partner helps select the optimal material for both function and manufacturability. This avoids unnecessary costs and potential part failure.

Tolerance og overfladefinish

Engineers often specify tight tolerances. While CNC can achieve incredible precision, over-tolerancing adds significant cost. We work with clients to identify critical features. This ensures tight tolerances are applied only where necessary. A reliable machining partner, whether you’re in a tech hub or need a Las Vegas machining partner, makes this process seamless.

Common DFM Oversights and CNC Solutions

Smart design choices can drastically reduce machining time and complexity. Here are some examples we frequently address.

| DFM Oversight | CNC Solution/Recommendation |

|---|---|

| Skarpe indvendige hjørner | Use corner radii ≥ 1/8 inch to allow standard tool use. |

| Tynde vægge | Design walls with adequate thickness to prevent vibration. |

| Dybe, smalle lommer | Keep pocket depth-to-width ratio low for tool stability. |

| Komplekse geometrier | Simplify where possible; consider multi-axis CNC for necessary complexity. |

These small adjustments have a huge impact on the final product.

Integrating DFM principles with an understanding of CNC capabilities is fundamental. This synergy allows engineers to create innovative, reliable, and cost-effective products. It transforms the design process from a siloed activity into a collaborative success.

Unlock Precision CNC Machining Success With PTSMAKE Today!

Ready to tackle your CNC machining Las Vegas challenges with confidence? Partner with PTSMAKE for reliable, consistent, and certified precision machining solutions. Request your custom quote now—discover how our expertise can accelerate your project from prototype to production, all with zero compromise on quality!

Learn how this symbolic language ensures your design intent is perfectly manufactured for optimal part function. ↩

Understand how this guarantees material integrity and compliance for your critical components. ↩

Learn how this cost distribution method impacts your per-part price and long-term project budget. ↩

Learn how GD&T defines engineering tolerances to ensure parts fit and function perfectly. ↩

Discover how this metric ensures measurement accuracy across a machine’s entire working envelope. ↩

Discover how this heat treatment process alters material properties. ↩

Learn how GD&T ensures your parts meet exact design specifications for function and fit. ↩

Understand how this cyclical process of prototyping, testing, and refining can accelerate your product’s success. ↩

Discover how this core quality principle leads to more reliable and consistent manufacturing outcomes. ↩

Understand how this system ensures your design intent is perfectly translated into a physical part. ↩

Understand how material directionality impacts machining strength and performance. ↩