You’re designing precision components, but your finish choices might be sabotaging your project’s success. Many engineers overlook how surface treatments impact both functionality and manufacturing costs, leading to expensive redesigns and missed deadlines.

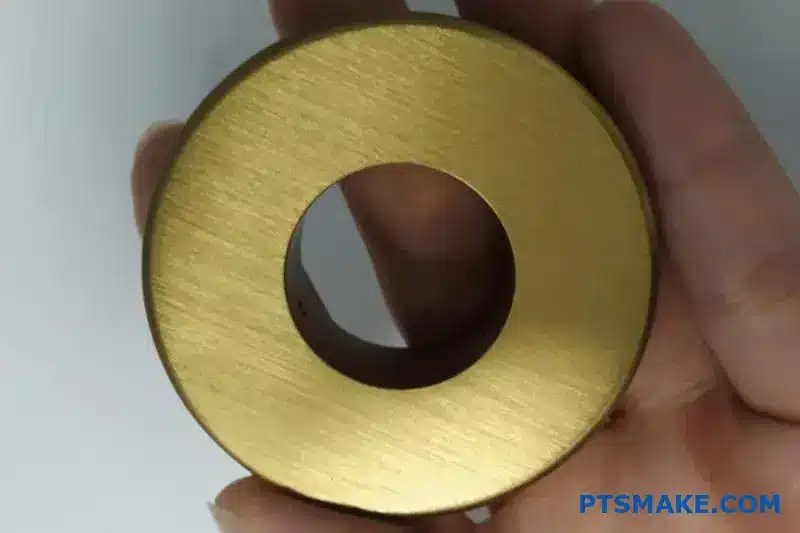

Brushed bronze finish is a premium metallic surface treatment that combines aesthetic appeal with functional durability, achieved through controlled abrasive processes that create directional texture patterns while maintaining dimensional precision for high-end manufacturing applications.

This guide breaks down the technical specifications, tolerance considerations, and cost implications that separate successful brushed bronze implementations from costly mistakes. I’ll walk you through the engineering decisions that matter most when specifying this finish for your next project.

The Complete Breakdown Of Brushed Bronze Finish Grades

When clients specify a brushed bronze finish, my first question is always, "Which grade?" Many people don’t realize there are different quality levels.

The choice impacts durability, appearance, and cost. Understanding the types of brushed bronze finish is crucial for any project’s success. It ensures the final part meets expectations.

Primary Brushed Bronze Grades

Here’s a quick overview of the main categories we work with at PTSMAKE.

| Grade Type | Primary Use | Key Feature |

|---|---|---|

| Commercial | Indoor Decorative | Cost-Effective |

| Architectural | High-Traffic Areas | Durability |

| Marine-Grade | Harsh Environments | Corrosion Resistance |

Choosing the correct brushed bronze finish quality level is about matching the material to its environment. The differences are not just cosmetic; they relate directly to the alloy’s composition and protective coating.

Understanding the Composition

Commercial Grade

This is the most common and affordable option. It’s typically a brass or bronze alloy with a thin lacquer topcoat. This finish is perfect for indoor decorative hardware with low wear.

Architectural Grade

This grade offers superior durability. The base alloy often has a higher copper content, providing better wear resistance. It receives a more robust clear coat. This makes it ideal for doors, railings, and fixtures in commercial buildings.

Marine-Grade

For ultimate corrosion resistance, marine-grade is the only choice. It uses specific bronze alloys like silicon bronze or aluminum bronze. These alloys naturally resist saltwater and harsh chemicals. The unique patination1 process also adds a protective layer.

Application Comparison

Here’s a breakdown of how these brushed bronze finish types compare in real-world applications.

| Feature | Commercial Grade | Architectural Grade | Marine-Grade |

|---|---|---|---|

| Corrosion Resistance | Low | Medium | Very High |

| Scratch Resistance | Low | High | Medium-High |

| Typical Cost | $ | $$ | $$$ |

| Best For | Light-use fixtures | Commercial entries | Coastal properties |

Selecting the appropriate brushed bronze finish grade is vital. Commercial grade suits indoor decor, architectural grade handles high traffic, and marine-grade is essential for harsh, corrosive environments. This choice directly impacts the part’s longevity and performance.

Engineering Tolerances And Brushed Bronze Finish: What Changes

A brushed bronze finish isn’t just paint. It’s a layer of material added to your part. This layer, though thin, directly impacts final dimensions.

For parts with tight tolerances, this is critical. A few microns of coating can push a component out of spec.

The Added Thickness Factor

Every finish adds thickness. You must account for this during the design phase. Ignoring it leads to assembly issues later.

Consider this simple example:

| Feature | Original Spec (mm) | Coating Thickness (mm) | Final Dimension (mm) |

|---|---|---|---|

| External Diameter | 20.00 | +0.02 | 20.02 |

| Internal Hole | 10.00 | -0.02 | 9.98 |

This shows how the brushed bronze finish and dimensional tolerance are linked. External features grow, and internal features shrink.

Accounting for the Finish in Tolerance Stackups

Simply knowing the finish adds thickness isn’t enough. The key is to compensate for it before manufacturing. We adjust the pre-finish machining dimensions.

This means machining a part slightly undersized or oversized. The goal is for the final, coated part to meet your exact specifications. This requires close collaboration.

Bronze Coating Tolerance Implications

The brushing process itself adds a variable. Unlike a perfectly uniform plating, brushing creates a textured surface. The thickness can vary slightly across the part.

We’ve found that this variation is often predictable. However, it needs to be factored into your tolerance analysis2. The direction of the brush strokes can even affect measurements.

Here’s how we approach it at PTSMAKE:

| Consideration | Standard Plating | Brushed Bronze Finish |

|---|---|---|

| Uniformity | Highly uniform | Directional texture, minor variance |

| Pre-machining | Standard compensation | Targeted compensation for texture |

| Inspection | Standard calipers/CMM | Profile gauges may be needed |

We work with our clients to define the "before finish" drawing. This document specifies the dimensions needed from the CNC machine. The final drawing shows the dimensions after the brushed bronze finish is applied. This avoids any confusion.

The brushed bronze finish adds a tangible material layer. This directly alters part dimensions and must be included in your tolerance stackup. Proper planning and pre-compensation during machining are essential for ensuring the final assembly fits and functions as designed.

Secrets To Achieving Uniform Brushed Bronze Appearance On Complex Geometries

Achieving a perfect brushed bronze finish on flat surfaces is one thing. But complex geometries present a whole new set of challenges. Consistency is the main goal.

Curved surfaces, small features, and recessed areas are common problem spots. The brushing process can easily become uneven. This results in a finish that looks inconsistent and unprofessional. A uniform bronze coating requires careful technique.

Common Problem Zones

| Geometry Type | Typical Finishing Issue |

|---|---|

| Inner Corners | Brushing tool cannot reach effectively. |

| Curved Surfaces | Uneven pressure creates light/dark patches. |

| Small Holes | Finish appears darker or is missed entirely. |

These areas require specialized approaches beyond standard finishing methods.

Mastering a brushed bronze finish on complex parts is about control. It’s not just about the final brushing motion. It involves adjusting the entire process, from surface preparation to the final sealing. Without this control, achieving a uniform appearance is nearly impossible.

Process Solutions for Consistency

At PTSMAKE, we use a multi-stage approach. We start with a base coating that promotes adhesion. The initial brushing uses softer tools to avoid aggressive material removal on high points. This sets a foundation for the final texture.

We then use custom-shaped tools. These are designed to match the part’s specific curves and recesses. This ensures consistent contact and pressure across the entire surface. This is key for achieving a uniform bronze coating on the most difficult parts.

Our process also involves careful control over the electrochemical deposition3 of the bronze layer itself. We adjust parameters to ensure the coating thickness is consistent before any brushing begins. Our tests show this step is critical.

Comparing Brushing Techniques

| Technique | Best For | Main Advantage |

|---|---|---|

| Manual Brushing | Prototypes, unique shapes | High level of control |

| Automated Brushing | High-volume production | Excellent consistency |

| Multi-Axis CNC | Highly complex geometries | Reaches difficult areas |

Tackling complex geometries for a brushed bronze finish requires specialized tools and multi-stage process controls. Adjusting techniques for curves, corners, and recesses is essential to ensure a consistent, high-quality uniform bronze coating that meets design specifications every time.

Brushed Bronze Finish Vs. Other Metallic Finishes: A Decision-Making Guide

Choosing the right metallic finish is a critical decision. It impacts aesthetics, durability, and cost. How does a brushed bronze finish stack up against the classics?

Let’s compare it directly with chrome, brass, and stainless steel. Each has its place. Your project’s specific needs will determine the best fit.

A Quick Glance Comparison

This initial overview helps frame the discussion. We’ll dive deeper into the specifics for engineers and designers.

| Feature | Brushed Bronze | Polished Chrome |

|---|---|---|

| Aesthetics | Warm, Subdued | Cool, Reflective |

| Maintenance | Hides Prints | Shows Prints |

Understanding these basic differences is the first step in making an informed choice for your components.

When engineers approach a metallic finish comparison, function often leads. However, form is equally important for the final product’s success. A brushed bronze finish offers a unique blend of modern and classic appeal.

Detailed Finish Breakdown

Let’s break down the pros and cons of each primary alternative. This is the kind of analysis we do at PTSMAKE when guiding clients on CNC machined part specifications.

Polished Chrome

Chrome is known for its brilliant shine and hardness. It’s highly resistant to corrosion and easy to clean. However, it easily shows fingerprints and water spots. Its cool, mirror-like appearance can feel too sterile for some designs.

Natural Brass

Brass offers a warm, golden tone that is very similar to bronze. The key difference in the ‘brushed bronze vs brass’ debate is aging. Untreated brass develops a natural patina over time. This can be a desired effect or a maintenance issue. Engineers must also consider potential galvanic corrosion4 when pairing different metals in an assembly.

Stainless Steel

A true workhorse, stainless steel is prized for its strength and corrosion resistance. It is a practical, go-to choice for industrial and functional parts. Its look is clean and modern but lacks the warmth of a brushed bronze finish.

| Finish | Primary Pro | Primary Con | Best Application Fit |

|---|---|---|---|

| Brushed Bronze | Hides fingerprints, warm tone | Higher initial cost | Decorative hardware, luxury fixtures |

| Polished Chrome | Very durable, high shine | Shows smudges easily | High-traffic areas, automotive |

| Natural Brass | Develops unique patina | Requires polishing to maintain shine | Vintage designs, classic hardware |

| Stainless Steel | Excellent corrosion resistance | Can look industrial/cold | Kitchens, medical devices, machinery |

Each finish serves a purpose. The choice depends on balancing visual intent with functional demands.

Choosing between brushed bronze, chrome, brass, and stainless steel requires balancing aesthetics, durability, and project-specific needs. Each finish offers a distinct set of advantages and disadvantages that make it suitable for different applications.

How Brushed Bronze Elevates Product Perceived Value

A brushed bronze finish does more than just color a product. It communicates a story of quality and sophistication. This choice directly impacts how customers perceive your brand.

The Psychology of Bronze

Bronze suggests permanence and value. Its warm, earthy tones feel inviting and authentic. This creates an immediate emotional connection. The ‘brushed’ texture adds a layer of craftsmanship.

Key Brand Attributes

This finish is a shortcut to conveying specific brand values. It helps new products stand out.

| Attribute | Impact on Perception |

|---|---|

| Luxury | Suggests a premium, high-end product. |

| Craftsmanship | The textured finish implies attention to detail. |

| Warmth | Creates an inviting, less industrial feel. |

The right finish enhances the bronze finish product appeal significantly.

A brushed bronze finish taps into deep-seated associations. Historically, bronze was a valuable material. It was used for art and important tools. This history gives it an inherent sense of prestige. It’s a visual cue for durability and quality.

For startups, this is a powerful tool. You can establish a premium market position without a legacy brand history. Enhancing design with bronze helps you compete. It suggests your product is built to last.

Beyond Visuals: The Tactile Experience

The "brushed" aspect is critical. It provides a tactile dimension that smooth finishes lack. This texture invites touch, creating a stronger connection between the user and the product. The subtle lines catch light differently, adding visual depth. It’s a detail that signifies thoughtful Affective Design5 principles.

At PTSMAKE, we guide clients on finish selection. The goal is to align the product’s feel with its intended brand message.

Strategic Application

Consider where this finish makes the most impact. It works well on touchpoints like knobs or casings. These are areas where users physically interact with the product.

| Product Category | Ideal Application Area | Desired Perception |

|---|---|---|

| Consumer Electronics | Control dials, trim, bezels | Premium tech, reliable |

| Kitchen Appliances | Handles, knobs, decorative accents | High-end, durable, warm |

| Home Fixtures | Faucets, light switches, door hardware | Timeless, artisanal |

This careful application maximizes the bronze finish product appeal.

In short, a brushed bronze finish is a strategic branding decision. It elevates perceived value by communicating luxury, detailed craftsmanship, and warmth, making it a powerful choice for products aiming for a premium market position.

How To Request A Sample Swatch For Brushed Bronze Finish

Seeing a brushed bronze finish online is one thing. Holding a sample in your hand is entirely different. It’s a critical step for making the right decision.

A physical swatch confirms the true color, texture, and overall feel. This simple action prevents costly disappointments during production.

Using a Sample Request Template

To streamline the process, a clear request is best. At PTSMAKE, we find that detailed requests help us send the perfect swatch on the first try.

Here is a basic brushed bronze sample request template.

| Field | Your Information |

|---|---|

| Project Name | [e.g., Project Alpha Enclosure] |

| Base Material | [e.g., Aluminum 6061] |

| Quantity | [e.g., 2 Samples] |

| Shipping Address | [Your Full Address] |

| Special Notes | [e.g., Match Pantone 10125 C] |

This simple format ensures clarity.

Once your sample arrives, the real work begins. A structured evaluation is far better than a quick glance. Your goal should be a methodical bronze surface sample evaluation.

Bronze Surface Sample Evaluation Checklist

I always advise clients to assess three main areas. This systematic approach allows for an objective comparison between different suppliers. It’s how we verify quality for every brushed bronze finish we produce.

Visual and Tactile Inspection

First, view the sample under various lighting conditions—office light, daylight, and low light. A high-quality finish maintains its color integrity.

Next, run your fingers across the surface. The brush lines should feel consistent and uniform. Any roughness or inconsistencies can indicate poor process control. The sample’s visual properties are also a result of the underlying substrate6 preparation, which is a key manufacturing step.

Key Evaluation Metrics

A simple checklist can guide your decision.

| Criteria | Pass Condition | Fail Condition |

|---|---|---|

| Color Consistency | Uniform hue under all lights | Obvious shifts, blotches, or spots |

| Texture Uniformity | Straight, even brush lines | Swirls, uneven depth, or gaps |

| Durability Test | Resists light scuffing from a fingernail | Finish easily marks or scratches |

This disciplined evaluation ensures you choose a finish that is not only beautiful but also durable enough for your product’s application.

Requesting a sample using a clear template is the first step. A thorough evaluation of color consistency, texture, and durability is essential. This ensures the final brushed bronze finish meets your project’s quality standards and prevents production delays.

How To Balance Aesthetics And Functionality With Brushed Bronze

Engineers often face a tough choice. You must balance the visual appeal of a brushed bronze finish with strict performance needs. It’s a classic case of beauty versus function.

This isn’t just about looks. The decision impacts durability, cost, and the product’s lifespan. We need to think critically from the start.

Key Decision Factors

When designing with brushed bronze, consider where the part will be used. Is it a high-wear component or purely decorative? The answer changes everything.

| Consideration | Decorative Focus | Functional Focus |

|---|---|---|

| Wear Resistance | Low Priority | High Priority |

| Corrosion | Moderate Concern | Critical Concern |

| Substrate Choice | Flexible (e.g., plastic) | Specific (e.g., brass) |

| Cost Target | Lower | Higher (performance-driven) |

This simple breakdown helps clarify priorities. It ensures that functional vs decorative bronze choices are made deliberately, not by accident.

Making the right trade-offs is crucial. A beautiful finish that fails in six months is a failure for the entire product. The key is understanding the limitations of the finish itself.

A brushed bronze finish is typically a surface treatment. Its performance is heavily tied to the material underneath. This is where many design challenges appear.

Substrate and Environment Impact

For example, applying a finish to an unsuitable base material can lead to problems. This includes issues like poor adhesion or accelerated wear. It’s a common oversight.

Our work at PTSMAKE often involves guiding clients on material selection. We help them avoid long-term issues. A part’s environment is also a major factor. High humidity or salt exposure requires a more robust material and finishing process.

A hidden risk is galvanic corrosion7. This occurs when dissimilar metals are in contact in the presence of an electrolyte. It can destroy a part from the inside out.

Common Substrate Trade-Offs

| Substrate Material | Aesthetic Advantage | Functional Limitation |

|---|---|---|

| Aluminum | Lightweight, easy to finish | Softer, prone to scratching |

| Stainless Steel | Strong, corrosion-resistant | Heavier, more costly to machine |

| Brass (Base) | Authentic color, durable | Higher cost and weight |

| ABS Plastic | Low cost, complex shapes | Lower strength, thermal limits |

Choosing the substrate isn’t just a technical decision. It directly impacts the final balance between the look you want and the performance you need.

Balancing aesthetics and function with a brushed bronze finish requires smart material choices. The substrate material and operating environment are critical. Overlooking these factors can lead to premature failure, compromising both beauty and performance. This is a key part of designing with brushed bronze.

Avoiding Finish Overkill: When Brushed Bronze Isn’t Worth It

A brushed bronze finish offers a premium look. But its appeal can come with a significant cost. The key is knowing when this investment pays off.

Not every part needs a luxury aesthetic. For some applications, it is simply overkill. The goal is to balance appearance with budget and function.

When to Skip the Bronze Aesthetic

Consider the part’s final use. Is it a customer-facing component or a hidden internal part? This simple question often provides the answer. Assessing the brushed bronze finish ROI is crucial.

| Component Type | Brushed Bronze Justification |

|---|---|

| External Housing | High – Directly impacts user perception. |

| Internal Bracket | Low – Adds cost with no functional or visual benefit. |

| Functional Lever | Medium – Depends on visibility and user interaction. |

Choosing a standard finish for non-critical parts can free up budget. You can then allocate those funds to more important aspects of the project.

Deciding against a brushed bronze finish is a strategic move, not a compromise. It’s about optimizing your resources for the best possible product outcome. At PTSMAKE, we guide clients through this cost-benefit analysis daily.

Analyzing the Brushed Bronze Finish ROI

The return on investment for any finish is tied to its purpose. A beautiful finish on a part no one sees provides zero return. It only increases your production cost. We need to think beyond just aesthetics.

High-Wear and Harsh Environments

Think about the operational environment. A brushed bronze finish on a part subject to constant friction or chemical exposure will degrade quickly. In these cases, a more durable, functional coating is a better long-term choice. The Substrate compatibility8 with the finish is also a major factor.

Internal or Non-Visible Components

This is the most common scenario for skipping a premium finish. For parts inside a machine or enclosure, a simple, protective finish like anodizing or powder coating is far more practical. It provides the necessary protection without the added expense.

| Factor | Impact on Decision | Recommended Action |

|---|---|---|

| Part Visibility | High | Consider brushed bronze for aesthetic value. |

| Wear & Tear | High | Prioritize durable, functional finishes. |

| Project Budget | Tight | Opt for standard, cost-effective finishes. |

| Prototyping Stage | N/A | Focus on form and fit, not final aesthetics. |

Making smart choices about finishes is essential. It directly impacts your bottom line and project timeline. We always focus on what adds real value for the end-user.

Choosing a brushed bronze finish should be a deliberate decision. It’s ideal for high-visibility parts where aesthetics drive value. For internal, high-wear, or budget-sensitive applications, skipping it is a smart financial move that optimizes your brushed bronze finish ROI.

How Brushed Bronze Reflectivity Affects Optical Systems

The wrong surface finish can ruin an optical system. A brushed bronze finish is more than just looks; it’s about light control. Its unique properties help manage reflectivity.

Managing Signal Interference

High reflectivity causes stray light. This creates noise in sensitive optical sensors. The controlled ‘bronze finish reflectivity’ of a brushed surface scatters light. This reduces interference significantly.

Reducing Unwanted Glare

Glare can blind cameras and detectors. Effective ‘surface finish and light control’ is critical. A brushed texture diffuses light instead of reflecting it directly.

| Finish Type | Reflectivity | Glare Risk |

|---|---|---|

| Polished Bronze | High | High |

| Brushed Bronze | Low-Medium | Low |

This simple choice improves data accuracy and system reliability.

In optical systems, every photon counts. Uncontrolled light from reflective surfaces can cause serious functional problems. The low-sheen characteristic of a brushed bronze finish is a key design tool. It helps maintain signal integrity in demanding applications.

Functional Impact on Mechatronic Systems

Mechatronic devices combine mechanics and electronics. They often rely on optical sensors for positioning and feedback. Stray light can lead to incorrect readings, causing mechanical misalignment or operational failure. This makes ‘surface finish and light control’ a top priority.

Sensor Accuracy

Consider a robotic arm using an optical encoder. A glint of light from a component could be misread as a positional marker. A brushed bronze finish on surrounding parts minimizes this risk. We often recommend it for internal housing components. It improves the reliability of the entire system. This is because the surface produces primarily diffuse, not specular, reflection. Light scattering is non-uniform due to the brushing direction, an effect known as anisotropic scattering9.

System Calibration and Performance

Proper calibration depends on a stable environment. Reflectivity introduces variables that complicate this process.

| Application | Problem with High Reflectivity | Brushed Bronze Solution |

|---|---|---|

| Barcode Scanners | Glare obscures code | Diffuses light, improves readability |

| Machine Vision | False positives from reflections | Provides a neutral, low-glare background |

| Laser Alignment | Beam scattering, power loss | Minimizes stray reflections |

Choosing the right finish is about building a robust and reliable system from the start.

A brushed bronze finish is an engineering choice, not just a cosmetic one. Its controlled reflectivity reduces signal interference and glare. This directly improves the accuracy and reliability of sensitive optical and mechatronic systems, ensuring consistent performance.

How Designers Use Brushed Bronze To Signal Brand Premiumization

In a market filled with polished chrome and matte black, visual differentiation is key. A product’s finish is a powerful tool for brands. It’s one of the first things a customer notices.

A brushed bronze finish immediately sets a product apart. It communicates a different story. It suggests warmth, heritage, and quality. This is a deliberate choice for brands aiming for a premium feel. It helps them stand out.

| Finish Type | Common Perception | Brand Signal |

|---|---|---|

| Polished Chrome | Modern, Clean, Common | Mass-Market Appeal |

| Matte Black | Sleek, Tech-focused | Minimalist, Modern |

| Brushed Bronze | Warm, Classic, Rich | Premium, Heritage |

Understanding Bronze Finish and User Perception

The choice of a brushed bronze finish goes beyond simple looks. It taps directly into user perception. This finish has a unique visual weight. It feels more substantial and timeless compared to cooler metals like aluminum or stainless steel.

Brands use this to their advantage. They are shaping the customer’s initial affective response10 to the product. The warm, earthy tones of bronze evoke feelings of stability, luxury, and craftsmanship. This isn’t just a color; it’s a message.

At PTSMAKE, we often discuss finishes with clients during the CNC machining design phase. The right material choice can elevate a product from standard to premium. A brushed bronze finish is a perfect example of this principle in action.

| Metal Finish | Key Psychological Impact | Common Application |

|---|---|---|

| Brushed Stainless Steel | Professional, Hygienic, Durable | Kitchen Appliances, Medical |

| Anodized Aluminum | Modern, Lightweight, Techy | Consumer Electronics |

| Brushed Bronze | Luxurious, Warm, Enduring | High-end Fixtures, Audio |

This strategic use of brushed bronze in branding helps create a perception of higher value. It subtly tells the consumer that this product is built to last and designed with care. It’s a silent yet powerful differentiator.

A brushed bronze finish is more than an aesthetic choice. It is a strategic tool for brands to visually differentiate their products, shape user perception, and clearly signal a premium position in the market.

Why Brushed Bronze Adds Value To User-Touch Components

When designing user-touch components, the material choice goes beyond aesthetics. It’s about the entire user experience. A brushed bronze finish offers a unique tactile satisfaction.

The interaction with a knob or button becomes memorable. The slight texture communicates quality and durability. This is something colder, smoother materials often lack. The user interface bronze finish creates an immediate sense of value.

Tactile Feedback Comparison

| Material | Perceived Temperature | Texture Feel | Weight Perception |

|---|---|---|---|

| Brushed Bronze | Warm, substantial | Finely textured | Heavy, solid |

| Anodized Aluminum | Cool, slick | Smooth | Light, modern |

| ABS Plastic | Neutral | Varies, often smooth | Very light |

This subtle feedback enhances the product’s perceived quality.

The Importance of Haptic Design

Haptic design is crucial for user interfaces. It’s how a product communicates through touch. With bronze, this communication is clear and reassuring. The material’s density and thermal conductivity provide a distinct feel that users associate with premium construction.

At PTSMAKE, we often recommend a brushed bronze finish for key interaction points. It provides a better grip and a more satisfying "click" or turn. This isn’t just a feeling; it’s a measurable part of the user experience that builds trust in the device. The interaction reinforces the user’s sense of control and precision.

Functional Benefits

Beyond the feel, bronze offers practical advantages. A key benefit is its natural resistance to showing fingerprints and smudges. This keeps high-touch surfaces looking clean.

| Surface Finish | Fingerprint Visibility | Cleaning Frequency |

|---|---|---|

| Brushed Bronze | Low | Infrequent |

| Polished Chrome | High | Frequent |

| Matte Black Plastic | Medium-High | Moderate |

This functional aspect of haptic design and bronze is critical for products in public spaces or those handled frequently. It improves the user’s perception through both touch and sight, connecting physical sensation with a sense of the object’s position, also known as Proprioception11.

The tactile qualities and anti-fingerprint benefits of a brushed bronze finish create a superior user experience. This choice elevates knobs and buttons from simple inputs to premium components that communicate quality and reliability directly to the user’s hand.

Ultimate Cost-Value Matrix For Brushed Bronze Across Industries

Choosing a finish isn’t just about looks. It’s about return on investment (ROI). The brushed bronze finish offers a unique blend of luxury and durability. Its value, however, varies across different industries. Let’s break down this bronze finish value matrix.

Automotive Interior Accents

In luxury cars, perceived value is everything. A brushed bronze finish on trim pieces elevates the cabin feel. This small touch can justify a higher vehicle price point.

Medical Technology Devices

For medtech, durability and perceived quality are key. This finish suggests reliability to users. It conveys a sense of premium, trustworthy equipment.

| Industry | Initial Cost Impact | Perceived Value Boost |

|---|---|---|

| Automotive | Moderate | High |

| Medtech | Moderate | High |

| Furniture | Low | Very High |

| Electronics | Low | Moderate |

High-End Furniture

Furniture relies heavily on aesthetics. The warm, classic look of brushed bronze can dramatically increase a product’s appeal. This helps drive sales and offers fantastic ROI.

Consumer Electronics

In electronics, differentiation is crucial. A brushed bronze finish on a device makes it a premium lifestyle product, not just another gadget.

The ROI of a brushed bronze finish is not a simple calculation. It involves both tangible gains, like higher sales prices, and intangible benefits, such as brand perception. The industry application of brushed bronze directly shapes this equation.

Tangible vs. Intangible ROI

In the automotive and furniture sectors, the finish directly impacts the final product price. The return is often immediate and measurable. You can simply sell it for more.

For medtech and electronics, the value is more subtle. It’s tied to brand trust and user experience. This builds long-term loyalty, a less direct but powerful return. A product that looks and feels robust inspires more confidence. This is where a detailed Lifecycle Cost Analysis12 becomes valuable.

Comparative ROI Factors

| Industry | Primary ROI Driver | Time to Return | Risk Factor |

|---|---|---|---|

| Automotive | Brand Premium | Medium | Low |

| Medtech | Perceived Reliability | Long | Low |

| Furniture | Aesthetic Appeal | Short | Medium |

| Electronics | Market Differentiation | Short | High |

My team at PTSMAKE often guides clients through this decision. We help them see beyond the initial coating cost. We focus on how a finish like brushed bronze aligns with their product’s market goals and overall value proposition.

Ultimately, the ROI for a brushed bronze finish is industry-specific. It hinges on whether value is driven by luxury perception, aesthetic appeal, or perceived durability. Choosing correctly requires understanding your market’s core desires and your product’s long-term goals.

Discover Brushed Bronze Excellence—Partner With PTSMAKE Today

Trust PTSMAKE for precision brushed bronze finish manufacturing—from tight tolerances to premium-grade aesthetics. Ready to elevate your project or need samples? Send us your RFQ now and experience reliable communication, top-tier quality, and on-time delivery with your next-generation manufacturing partner!

Learn about the chemical process behind this unique surface aging effect. ↩

Understand how to calculate cumulative tolerances for complex assemblies. ↩

Understand the science behind applying metal coatings for a flawless and durable finish. ↩

Click to understand how dissimilar metals can cause accelerated corrosion when in electrical contact. ↩

Learn how specific design elements are used to intentionally evoke positive emotions and user connections. ↩

Learn how the base material’s surface preparation impacts the final appearance of a finish. ↩

Learn how to prevent this electrochemical process in your multi-metal designs. ↩

Learn how material choice affects the durability and cost of your finish. ↩

Understand how directional light scattering affects material performance in our guide on advanced surface finishing techniques. ↩

Learn how customers form emotional connections with products based on material and design cues. ↩

Explore how our sense of body position and movement enhances tactile feedback in product design. ↩

Explore how this method evaluates total ownership cost, not just initial price, for better investment decisions. ↩