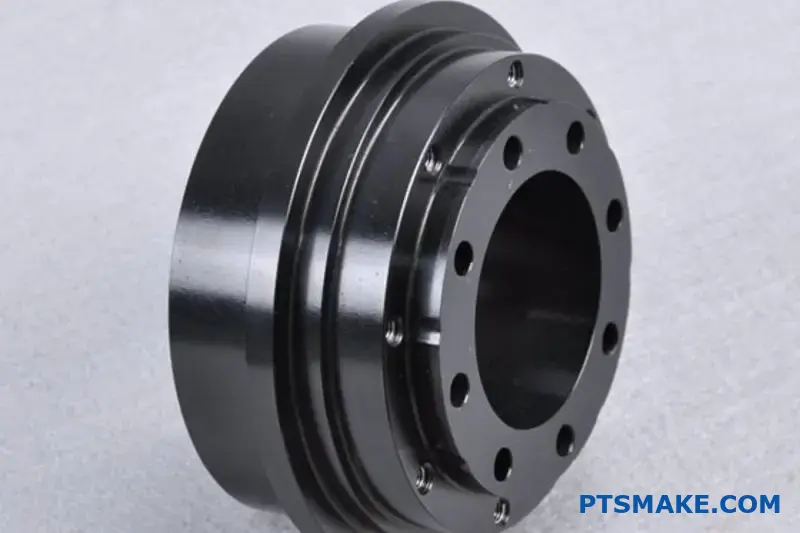

You’re sourcing CNC machined steel parts, but standard finishes keep falling short of your performance requirements. Your components face corrosion issues, aesthetic inconsistencies, or fail to meet the demanding standards your applications require.

Black oxide is a conversion coating that transforms the surface of steel parts into a thin, protective magnetite layer, providing enhanced corrosion resistance, improved aesthetics, and dimensional stability without adding significant thickness to your precision components.

I’ve worked with engineering teams who struggled with finish selection for critical steel components. This guide covers everything from cost analysis and tolerance considerations to regulatory compliance and real-world performance data. You’ll discover when black oxide outperforms other finishes and when it might not be the right choice for your specific application.

Why Technical Leaders Choose Black Oxide For Steel Components

Technical leaders often ask why use black oxide for steel. The answer is simple. It provides reliable performance without altering part dimensions.

This finish is a go-to for precision components. It offers a unique blend of protection, stability, and appearance. Let’s break down these key benefits.

Core Black Oxide Benefits

| Feature | Advantage for CNC Parts |

|---|---|

| Corrosion Resistance | Protects steel from rust and corrosion. |

| Dimensional Stability | Adds no significant thickness to parts. |

| Aesthetics | Provides a clean, professional black finish. |

This balance makes it a smart, cost-effective choice for many applications.

How Black Oxide Achieves Superiority

Black oxide is not a paint or plating. It’s a chemical process that creates a conversion coating1 on the steel’s surface. This means it becomes part of the metal itself. This is why it doesn’t chip, peel, or flake.

The Dimensional Stability Advantage

For high-precision CNC machining, every micron matters. Black oxide adds no significant thickness—typically less than one micron. It preserves the part’s original dimensions and tight tolerances. This is a critical benefit for CNC parts we produce at PTSMAKE, ensuring perfect fit and function.

Practical Corrosion Resistance

The black oxide layer itself offers mild corrosion resistance. Its true strength comes when combined with a supplementary oil or wax. This post-treatment seals the porous surface. It significantly improves its ability to repel moisture and prevent rust. We advise this for almost all applications.

| Feature | Black Oxide | Painting / Plating |

|---|---|---|

| Thickness Added | Negligible (<1µm) | Significant (5-25µm+) |

| Chipping Risk | Very Low | High |

| Hydrogen Embrittlement | No Risk | Potential Risk |

This process also provides a sleek, uniform black finish. It reduces light glare, which is useful for optical components or machine parts. The aesthetic is professional and clean.

In short, black oxide offers a balanced solution for steel components. It provides essential corrosion protection and a professional finish while critically maintaining the part’s precise dimensions. This makes it a top choice for high-tolerance CNC machined parts and other precision applications.

The Hidden Cost Savings Of Black Oxide Finishing In Large-Scale Production

Many see black oxide as just for looks. But it’s a key tool for cutting costs in large-scale manufacturing. It’s a truly black oxide cost-effective finish.

This finish directly impacts your operational budget. It reduces both long-term maintenance needs and initial material expenses. This means real, measurable savings.

Let’s look at the breakdown.

| Cost Factor | Direct Impact of Black Oxide |

|---|---|

| Maintenance | Reduced friction and wear |

| Material | Avoids need for expensive alloys |

| Rework | Minimal dimensional change |

The financial benefits of black oxide become clear when you examine the entire part lifecycle. We are not just talking about the initial coating cost.

Lowering Long-Term Maintenance Costs

Black oxide creates a porous surface that holds lubricants exceptionally well. This simple property significantly reduces friction between moving components.

This improved lubricity means less wear and tear. Your parts last longer, which reduces spending on replacements and minimizes costly operational downtime.

A Practical Example: Mating Components

Consider threaded fasteners or sliding parts. Black oxide helps prevent galling, a common failure mode where surfaces seize up under pressure, leading to expensive repairs.

Reducing Upfront Material & Production Costs

Here’s a clear way to reduce CNC part cost black oxide. You can often specify a more affordable steel for your part. The black oxide provides the necessary corrosion resistance.

This strategy avoids the higher cost of stainless steel or other specialized alloys. These material savings add up quickly on high-volume production runs.

Because black oxide is a conversion coating2, it adds virtually no thickness. This means you avoid expensive post-machining adjustments, as the part’s original tight tolerances are maintained.

| Finishing Method | Dimensional Change | Post-Processing Need |

|---|---|---|

| Black Oxide | Negligible (<1 micron) | None |

| Zinc Plating | 5-25 microns | Potential rework |

| Powder Coating | 25-125 microns | Definite rework |

Black oxide offers significant savings beyond its initial application. By cutting long-term maintenance and allowing for more affordable materials, it proves to be a highly strategic and cost-effective finish for large-scale production of CNC parts.

Black Oxide Vs Other Finishes: What B2B Buyers Must Know

Choosing the right finish is critical. It impacts performance, cost, and appearance. Black oxide is an excellent choice for many applications. But it’s not always the best one.

How does it stack up against others? Let’s compare it directly. Each finish has unique strengths.

Black Oxide vs. Plating

Plating adds a layer of metal. Black oxide does not. This is a key difference for tight tolerance parts. Zinc plating is common for corrosion resistance.

Here is a quick comparison based on our tests.

| Feature | Black Oxide | Zinc Plating |

|---|---|---|

| Dimensional Change | Negligible | Adds Thickness |

| Corrosion Resistance | Moderate (with oil) | Good to Excellent |

| Application | Ferrous Metals | Various Metals |

| Appearance | Matte Black | Varies (clear, yellow, black) |

This makes black oxide ideal when dimensions are critical. It’s often the best finish for steel CNC parts requiring precision.

When clients ask for comparisons, I break it down by material and primary function. It simplifies the decision-making process.

Black Oxide vs. Anodize

The ‘black oxide vs anodize’ question is common. But they serve different materials. Black oxide is for ferrous alloys. Anodizing is an electrochemical process for non-ferrous metals like aluminum. Anodizing creates a durable, corrosion-resistant oxide layer that is much harder than the base metal.

Black Oxide vs. Powder Coating

Powder coating applies a thick, durable polymer layer. It offers superior corrosion, chemical, and impact resistance. However, this thickness makes it unsuitable for parts with tight tolerances. Black oxide, with its minimal buildup, preserves the original part dimensions perfectly.

A Broader Comparison

Let’s look at these finishes side-by-side. This helps clarify the best use case for each one. Zinc plating, for example, offers great protection. It works as a sacrificial coating3, corroding before the steel underneath is affected. This is a major advantage for parts exposed to harsh environments.

| Finish | Primary Material | Dimensional Change | Corrosion Resistance |

|---|---|---|---|

| Black Oxide | Steel, Stainless, Copper | < 1 µm | Moderate |

| Zinc Plating | Steel | 5-25 µm | Good |

| Anodizing | Aluminum, Titanium | 5-50 µm | Excellent |

| Powder Coating | Most Metals | 50-150 µm | Excellent |

At PTSMAKE, we guide our clients to select the finish that provides the required protection without compromising the part’s function.

Black oxide maintains tight tolerances, making it ideal for precision parts. Other finishes like plating or powder coating offer superior corrosion resistance but add significant thickness. The best choice depends entirely on your material, environment, and dimensional requirements.

How Black Oxide Boosts Corrosion Resistance Without Compromising Tolerances

Black oxide is a conversion coating. It doesn’t add a layer of material. Instead, it transforms the surface iron into magnetite. This creates a thin, protective barrier.

This finish offers strong corrosion protection. Especially when a sealant like oil or wax is applied. It’s a fantastic choice for many precision parts.

As a true ‘tolerance safe coating,’ its impact on dimensions is minimal. The change is typically less than one micron.

| Coating Type | Typical Thickness Added | Impact on Tolerance |

|---|---|---|

| Black Oxide | < 1 micron (0.00004") | Negligible |

| Zinc Plating | 5-25 microns | Significant |

| Anodizing (Type II) | 5-25 microns | Significant |

How Does Black Oxide Achieve This?

The process uses a hot bath of alkaline solution. This starts a chemical reaction on the surface of ferrous metals. It is a subtractive, not an additive, process. This is key to its precision.

The Conversion Process in Detail

The reaction forms a stable layer of black iron oxide, or magnetite4. Because this layer is integral to the part, it won’t chip, flake, or peel. It becomes one with the base metal.

At PTSMAKE, we manage this process carefully. This ensures every high-precision component receives a uniform finish. The part’s original dimensions are fully preserved.

Sealing: The Final Step for Corrosion Protection

The sealant is what boosts the corrosion protection of black oxide. The porous oxide layer readily absorbs the rust-preventative oil or wax. This creates a durable shield.

The sealant displaces moisture. It blocks corrosive elements from the base metal. This combination delivers reliable protection without altering a part’s fit.

| Step | Purpose | Key Consideration |

|---|---|---|

| 1. Cleaning | Remove oils and contaminants | Critical for a uniform finish |

| 2. Rinsing | Remove cleaning solution | Prevents bath contamination |

| 3. Blackening | Convert surface to magnetite | Temperature and time control |

| 4. Rinsing | Remove blackening salts | Stops chemical reaction |

| 5. Sealing | Apply oil or wax | Enhances corrosion resistance |

Black oxide creates a thin, integral protective layer offering solid corrosion resistance when sealed. Crucially, it achieves this with negligible dimensional change, preserving the tight tolerances essential for precision parts and making it an ideal surface treatment.

Black Oxide For CNC Machined Parts: When And Why To Specify It

So, when is black oxide the right choice? I recommend it for specific jobs. It’s perfect for CNC parts that need mild corrosion resistance. Crucially, it does this without changing part dimensions.

This makes it ideal for precision components. For example, threaded parts or close-tolerance assemblies benefit greatly. This is one of the most practical CNC part finishing options available.

Here are some common scenarios where a black oxide CNC machined part excels.

| Industry | Typical Application | Primary Benefit |

|---|---|---|

| Automotive | Fasteners, Brackets | Anti-galling, mild protection |

| Medical Devices | Surgical Instruments | Reduced light glare |

| Industrial Tools | Jigs, Fixtures, Gauges | Wear resistance, stability |

| Firearms | Barrels, Components | Glare reduction, aesthetics |

Black oxide is a conversion coating. This means it chemically alters the surface of a part. It doesn’t add a new layer on top. The process creates a thin layer of magnetite5 on the surface of ferrous metals.

This is a key advantage. The finish becomes part of the metal itself. Unlike paint or plating, it cannot chip, peel, or flake off. We see this as a major benefit at PTSMAKE for moving parts.

This process is why it’s a superior choice for maintaining tight tolerances. For a black oxide CNC machined part, you can be confident the dimensions will remain exactly as designed. After the treatment, a wax or oil is often applied. This step enhances the corrosion resistance significantly. It also gives the part a final, deep black appearance.

Here’s how it compares to other common CNC part finishing options.

| Finishing Option | Dimensional Change | Best Suited For | Main Weakness |

|---|---|---|---|

| Black Oxide | None | Ferrous Metals | Limited corrosion resistance |

| Anodizing | Minimal | Aluminum, Titanium | Not for steel |

| Zinc Plating | Adds a layer | Steel | Can be uneven |

| Powder Coating | Adds a thick layer | Most Metals | Can chip, hides details |

Black oxide is a valuable finish for ferrous CNC parts. It provides mild corrosion protection and anti-galling properties. Critically, it does this without affecting part dimensions, making it perfect for high-precision applications.

Top Quality Concerns Engineers Should Vet When Ordering Black Oxide Finishes

When verifying a black oxide finish, quality control is paramount. You must look beyond a simple black color.

True quality lies in the finish’s uniformity, adhesion, and overall performance. A poor finish can lead to premature failure.

This chapter outlines a practical black oxide inspection checklist. It ensures your parts meet stringent specifications.

Visual and Physical Inspection

A consistent, deep black appearance is the first sign of quality. Any streaks, stains, or rainbow sheens are red flags. The finish must also adhere properly to the part’s surface.

A simple inspection can reveal a lot.

| Inspection Point | What to Look For |

|---|---|

| Color Uniformity | Even, non-streaky black color across all surfaces. |

| Adhesion | No flaking or chipping when lightly handled. |

| Surface Texture | Should match the underlying metal’s texture. |

| Residue | No loose black powder (smut) on the surface. |

Establishing a Testing Protocol

Visual checks are just the start. For critical applications, a formal testing protocol is essential for effective black oxide quality control. This protocol provides objective data, removing guesswork from the inspection process. It helps validate the finish’s protective properties.

Substrate6 preparation is crucial before the black oxide process. Improper cleaning or pre-treatment will always result in a failed finish, no matter how good the blackening bath is.

At PTSMAKE, we work with clients to define these standards. This ensures the final parts perform as expected in their specific environments. This alignment prevents costly rework later.

Key Surface Finish Testing Methods

Standardized tests confirm the finish’s corrosion resistance and durability. The specific tests depend on the application’s demands.

Here are common methods we use:

| Test Method | Purpose | Acceptance Criteria |

|---|---|---|

| Smut Test | Checks for loose, powdery residue. | A clean white cloth shows no significant black transfer. |

| Humidity Test | Evaluates corrosion resistance in a moist environment. | No signs of red rust after a specified time (e.g., 24-96 hours). |

| Salt Spray Test | Assesses performance in a highly corrosive environment. | Part meets ASTM B117 standards for a set duration. |

A robust black oxide inspection checklist combines visual checks with these quantitative tests. This comprehensive approach guarantees that every batch meets your engineering requirements and ensures long-term reliability for your components.

A thorough quality control plan is crucial. It should combine visual inspections with standardized surface finish testing methods. This ensures the black oxide coating provides both the desired appearance and the necessary corrosion protection, preventing field failures and ensuring part longevity.

Engineering Tolerances And Black Oxide: What B2B Engineers Must Understand

A common question I hear is: does black oxide change a part’s dimensions? The short answer is yes. While the change is minimal, it is crucial for parts with tight tolerances.

This finish is not just a layer of paint. It’s a chemical conversion. For high-precision components, this tiny change can matter a great deal.

The Myth of Zero Impact

Many assume the black oxide dimension change is zero. This is a risky assumption in precision engineering. Even a microscopic addition can affect assembly and function.

| Assumption | Reality |

|---|---|

| No dimensional change | A slight, measurable increase |

| Fits are unaffected | Tight fits can become interference |

| Tolerances are safe | May push parts out of spec |

Why It Matters for CNC Parts

For finishing tolerances in CNC machining, every micron counts. Ignoring the finish can lead to costly rework or scrap. It’s something we plan for from the start.

Black oxide is a conversion coating7, not an additive one like plating. The process converts the surface iron into magnetite (Fe3O4). This reaction grows the layer both into and out of the material’s surface.

This unique process results in a very thin dimensional change. Our tests confirm the buildup is typically between 0.00004 and 0.00006 inches (about 1 to 1.5 microns).

Impact on Critical Features

This slight increase seems negligible. But for high-tolerance CNC parts, it can be the difference between a perfect fit and a failed assembly. Consider how this affects different features.

| Feature Type | Potential Impact of Black Oxide |

|---|---|

| External Diameters | Diameter increases slightly |

| Internal Diameters (Holes) | Diameter decreases slightly |

| Threads (External) | Pitch diameter increases |

| Threads (Internal) | Pitch diameter decreases |

Accounting for the Change

At PTSMAKE, we factor this into our CAM programming. For a shaft requiring a tight fit, we machine it slightly undersized before the black oxide process. This ensures the final part is perfectly within spec after coating. This foresight is key for finishing tolerances on CNC parts.

Black oxide does cause a minimal but critical dimensional change. This buildup, typically around 1-1.5 microns, must be accounted for during the CNC machining stage to ensure parts with tight tolerances meet final specifications after finishing.

The Secret Role Of Black Oxide In Improving Part Aesthetics And Usability

A great finish is more than just eye candy. It directly impacts how a part performs in the real world. A black oxide cosmetic finish is a prime example of function meeting form.

It changes the part’s tactile properties. This can improve grip for tools or components that are handled frequently.

Grip and Usability

A raw machined surface can be slippery, especially when oil is present. Black oxide creates a micro-porous surface. This texture subtly increases friction, ensuring a more secure hold.

| Feature | Smooth Metal | Black Oxide Finish |

|---|---|---|

| Grip | Low | High |

| Feel | Cold, Slippery | Textured, Secure |

| Oil Retention | Poor | Excellent |

This small change makes a big difference in daily use.

Functional Aesthetics in Action

The concept of functional aesthetics with black oxide is key. It’s not just about making a part look good. It’s about using aesthetics to improve its job. For example, a consistent, non-reflective finish is crucial for optical equipment.

A shiny part can cause glare. This distracts users and can interfere with sensitive instruments. A uniform black oxide finish eliminates this problem. It creates a visually quiet component that lets the user focus.

The Impact of Consistency

In complex assemblies, visual consistency is important. Mismatched finishes can make a high-quality product look cheap. Black oxide provides a uniform appearance across different batches of parts.

This finish subtly influences the coefficient of friction8 on the part’s surface. When we add a post-treatment oil or wax, we can fine-tune this property. This allows us to control both the corrosion resistance and the final feel of the part. Our tests at PTSMAKE show how different oils affect handling.

| Post-Treatment | Feel | Usability Impact |

|---|---|---|

| Light Oil | Slightly Oily | Good for internal parts |

| Dry Wax | Non-greasy, Matte | Ideal for hand tools |

| Heavy Wax | Tacky | Maximum grip |

This level of control is why the black oxide cosmetic finish is so valuable.

A black oxide finish does more than just enhance appearance. It improves grip, ensures visual consistency across assemblies, and reduces glare. This makes it a smart choice for functional aesthetics, where looks and performance are equally important.

Fastest Turnaround Tactics For Black Oxide Services Without Sacrificing Quality

Everyone wants parts coated yesterday. But how fast is realistic for black oxide? The black oxide lead time is a common question I get. It’s not just about the chemical process.

It depends on part quantity, size, and current shop workload. Speed is achievable, but it requires planning. Rushing blindly often leads to rework, which costs more time.

Typical Turnaround Expectations

Here’s a general idea of what to expect for quick coating CNC parts.

| Batch Size | Standard Lead Time | Expedited Lead Time |

|---|---|---|

| Small (1-50 pcs) | 2-3 Business Days | 24 Hours |

| Medium (51-500 pcs) | 3-5 Business Days | 1-2 Business Days |

| Large (500+ pcs) | 5-7 Business Days | 2-3 Business Days |

This table provides a baseline. Complex geometries or masking requirements will add time.

Getting quick, high-quality results is a partnership. It’s not just about pushing your supplier. The client’s preparation plays a huge role in achieving a faster black oxide lead time.

Your Checklist for Faster Service

Providing clear and complete information upfront is the single best way to speed things up. Any ambiguity causes delays. We always send our parts to our partners with precise instructions.

The parts must be completely free of oils, grease, and debris. The first step in any black oxide line is cleaning. If parts arrive dirty, they require extra pre-treatment, adding hours to the job. This starts with a process like alkaline cleaning9 to strip away any residual machining fluids or contaminants.

After collaboration with our coating partners, we’ve found that pre-cleaned parts can cut turnaround by up to 30%.

Preparation Impact on Lead Time

| Client Preparation | Standard Process (Client does nothing) | Optimized Process (Client prepares) |

|---|---|---|

| Documentation | Vague specs, verbal requests | Detailed drawings, PO with all info |

| Part Condition | Arrives with oils/coolant | Arrives clean and dry |

| Resulting Delay | 1-2 days for clarification/cleaning | 0 days, process starts immediately |

At PTSMAKE, we ensure our CNC parts are properly deburred and cleaned before they even leave our facility. This simple step helps our partners start immediately, keeping projects on schedule.

Achieving a fast turnaround for black oxide without losing quality is about preparation and communication. When you provide clean parts and clear instructions, your supplier can move much faster. It transforms the process from a simple service into a collaborative success.

The Truth About Black Oxide Durability In Real-World Applications

How durable is black oxide, really? This is a question I get often. The answer isn’t a simple yes or no. Its durability is tied directly to its application.

Understanding Wear Resistance

Black oxide wear resistance is moderate. The finish itself is very thin. It’s the post-treatment sealant, like oil or wax, that provides most of the lubricity and protection.

Real-World Scenarios

For high-use parts not subject to harsh scratching, it performs well. Think about internal engine components or fasteners.

| Application | Wear Expectation | Recommended Sealant |

|---|---|---|

| Fasteners | Low-to-Moderate | Wax or Oil |

| Hand Tools | Moderate | Heavy Oil |

| Firearm Parts | Moderate | Specialized Gun Oil |

| Gears | High | Heavy Oil |

This finish is not ideal for parts that see constant abrasive contact.

Black oxide is a conversion coating. This means it doesn’t add a layer on top of the metal. Instead, it converts the surface iron into magnetite. This distinction is crucial for its durability profile.

Abrasion Resistance in Detail

The finish itself has minimal inherent abrasion resistance. If you scratch a black oxide part with a sharp tool, it will come off. Its real strength comes from the supplementary treatment.

The oil impregnation significantly reduces the Coefficient of Friction10. This allows parts to move against each other with less wear. This makes it a great choice for certain black oxide for high-use parts, like precision fixtures or threaded components we produce at PTSMAKE.

Factors Affecting Longevity

Several factors determine how long the finish lasts:

- The quality of the post-treatment oil or wax.

- The operating environment (e.g., dry vs. humid).

- The frequency of contact and friction.

Based on our internal testing, reapplying the protective oil periodically can extend the service life of a component by up to 50% in moderately corrosive environments.

| Factor | High Impact | Low Impact |

|---|---|---|

| Abrasive Contact | High Wear | Low Wear |

| Regular Oiling | Low Wear | High Wear |

| Humid Environment | Corrosion Risk | Low Risk |

Black oxide’s durability excels in applications requiring dimensional stability and moderate wear resistance. Its strength lies in its oil-holding capacity and non-depositional nature, not in resisting direct, abrasive forces.

Black oxide offers moderate durability, primarily through its oil-holding properties. It is not suitable for high-abrasion environments but performs well for high-use parts where lubricity and dimensional integrity are key. The post-treatment sealant is critical for its longevity.

How Black Oxide Helps Meet Regulatory And Safety Standards

Meeting global standards isn’t just a goal. It’s a requirement for market access. Black oxide finishing is a practical solution here. It helps you achieve compliance with key regulations.

Key Regulatory Frameworks

These standards govern material safety and quality. They include ISO 9001, RoHS, and REACH.

How Black Oxide Fits In

Black oxide avoids many restricted materials. This makes it a preferred finish in industries that export globally. Its simple chemistry streamlines the compliance process.

| Standard | Primary Focus | Black Oxide’s Contribution |

|---|---|---|

| ISO 9001 | Quality Management | Ensures process consistency and traceability. |

| RoHS | Hazardous Substances | Inherently free of lead, cadmium, mercury. |

| REACH | Chemical Safety | Does not contain Substances of Very High Concern. |

Navigating regulatory landscapes can be complex. Choosing the right surface finish simplifies this task significantly. Black oxide stands out for its straightforward compliance profile across major international standards.

Ensuring Quality with ISO 9001

ISO 9001 focuses on quality management systems. It requires consistent, repeatable processes. At PTSMAKE, we exclusively work with ‘ISO9001 black oxide suppliers’. This ensures that every batch meets the same documented quality standards, providing the traceability our clients need for their own audits.

Meeting RoHS Substance Restrictions

The Restriction of Hazardous Substances (RoHS) directive is crucial for electronics. It limits the use of materials like lead and mercury. A key benefit of ‘RoHS black oxide’ is that the finish is an integral part of the metal itself. This conversion coating11 process adds no prohibited substances, making it a compliant-by-default option.

Adhering to REACH Chemical Standards

REACH is the EU’s regulation for chemical safety. It scrutinizes Substances of Very High Concern (SVHCs). The chemicals used in standard black oxide processes are well-established and do not contain SVHCs. This allows parts to enter the European market without risk of non-compliance.

| Regulation | Compliance Check | Black Oxide Result |

|---|---|---|

| ISO 9001 | Process Control | Pass (with certified suppliers) |

| RoHS | Prohibited Materials | Pass (inherently compliant) |

| REACH | SVHC Content | Pass (formulation is SVHC-free) |

Black oxide offers a clear path to compliance. It aligns with ISO 9001 quality systems when using certified suppliers. The coating’s inherent chemistry satisfies both RoHS and REACH material restrictions, streamlining global market access and reducing supply chain risks.

Using Black Oxide On Moving Components: What Engineers Must Know

When we discuss black oxide for moving parts, we must focus on performance. It’s not just about aesthetics. The finish must support the component’s function.

Application in Hinges and Sliders

Hinges and sliders require smooth, consistent action. A proper black oxide finish, paired with a sealant, provides essential lubricity. This greatly reduces friction.

Use on Pistons

For components like pistons, the porous nature of black oxide helps retain oil. This improves lubrication under pressure. It’s an effective surface finish on mechanical assemblies that balances cost and function.

| Component | Primary Benefit | Secondary Benefit |

|---|---|---|

| Hinges | Reduced Friction | Corrosion Resistance |

| Sliders | Smooth Action | Anti-Galling |

| Pistons | Oil Retention | Wear Resistance |

Let’s look closer at the mechanics. The performance of black oxide relies heavily on its interaction with post-treatment lubricants. The coating itself has minimal lubricity.

The Critical Role of Post-Treatment

The real benefit comes from the supplementary sealant. Without a proper wax or oil, the black oxide layer offers very little friction reduction. This is a crucial detail that engineers sometimes overlook, leading to premature wear. The choice of sealant directly impacts the component’s life and performance.

Selecting the Right Sealant

For high-load sliders or pistons, a heavy-duty oil is essential. For hinges exposed to dust, a dry-to-touch wax is a better choice to avoid attracting contaminants. The sealant choice directly influences the tribological12 properties of the surface.

Performance Limitations

Remember, black oxide is not a high-performance wear coating. It cannot compete with finishes like nitriding. It provides a base level of protection and lubricity. Our client studies show it excels in low-to-moderate load applications where cost is a driving factor.

| Application | Recommended Sealant | Key Advantage |

|---|---|---|

| High-Speed Piston | Heavy Oil | Superior Lubrication |

| Exposed Hinge | Dry Wax Sealant | Resists Debris |

| Internal Slider | Light Oil | Smooth, Clean Action |

Black oxide enhances moving parts like hinges and pistons by reducing friction and retaining lubricants. However, its performance is dependent on the correct post-treatment sealant, making it ideal for low-to-moderate load applications where cost-effectiveness is important.

Real-World Case Studies: How Engineers Solved Problems With Black Oxide

Theory is one thing, but results are what matter. Let’s look at a common problem-solving surface finish scenario I’ve seen.

An engineer needed a durable, non-reflective finish. It was for steel components in an automated assembly jig.

These parts were precision CNC machined. Any added thickness from plating was unacceptable for their design.

This is a perfect black oxide case study. The finish solved the core issues without altering critical part dimensions.

Here’s a simple breakdown of the challenge and solution.

| Problem | Black Oxide Solution |

|---|---|

| Glare affecting sensors | Matte black, non-reflective finish |

| Minor corrosion risk | Added layer of corrosion resistance |

| Tight tolerances | No dimensional change |

Let’s dive into a specific project we handled at PTSMAKE. A client in the robotics industry was developing an optical sorting machine.

Their CNC-machined steel sensor mounts were causing issues. Reflections from the bare metal interfered with the camera’s accuracy. This led to unacceptable sorting errors. They needed a solution fast.

The Challenge: Precision and Performance

The key challenge was finding a finish that was completely non-reflective. It also could not change the part’s critical dimensions.

The mounting holes and surfaces had tolerances within a few microns. Traditional coatings like paint or powder coating were simply too thick and would have required design modifications.

The Black Oxide Solution

We recommended a hot black oxide finish. This process creates a conversion coating of magnetite13 directly on the material’s surface. It is not an additive layer, so it doesn’t build up.

The result was a uniform, matte black finish. It completely eliminated the reflection problem. After treatment, the parts passed all dimensional checks perfectly. Our client confirmed that their machine’s performance improved significantly.

| Requirement | How Black Oxide Met It |

|---|---|

| Non-Reflective Surface | Provided a deep, matte black finish |

| Maintain Tight Tolerances | Zero dimensional impact |

| Corrosion Resistance | Offered mild protection for handling |

| Cost-Effectiveness | More affordable than complex plating |

This problem solving surface finish case shows how a simple treatment can solve a complex engineering problem effectively.

This case demonstrates how black oxide is an ideal solution for CNC machined parts. It enhances functionality, like reducing glare and adding corrosion resistance, without compromising the precise tolerances essential for high-performance applications.

When Not To Use Black Oxide: Critical Engineering Exceptions

Black oxide is a fantastic finish, but it’s not a universal solution. Knowing its limitations is key to preventing part failure. This is a crucial part of any surface finish selection guide.

Certain applications demand more than what black oxide can offer. I’ve seen projects run into issues when the wrong finish was specified. Here are some clear exceptions.

| Part Type / Use Case | Reason Black Oxide is Not Ideal |

|---|---|

| High-Wear Components | Thin layer offers minimal abrasion resistance. |

| Electrical Connectors | The oxide layer is an electrical insulator. |

| Extreme Corrosion Environments | Provides only mild corrosion protection. |

| Parts Requiring Welding | The coating must be removed before welding. |

Understanding these black oxide limitations helps in making better design choices. Let’s look deeper into why these exceptions are so critical for engineers to consider.

For components experiencing high friction, like gears or sliding shafts, the black oxide layer wears away quickly. This exposes the base metal, defeating the purpose of the coating. The finish is simply too thin to provide meaningful wear resistance.

Another major issue is electrical conductivity. The conversion coating creates an insulating barrier. This makes it unsuitable for grounding lugs, connector shells, or any part where a reliable electrical path is necessary. We always guide our clients at PTSMAKE toward conductive finishes for such applications.

When you assemble parts made of different metals, you risk Galvanic corrosion14. Black oxide does not prevent this electrochemical reaction. In fact, it can sometimes trap moisture, making the problem worse over time.

For these specific cases, alternative finishes are far superior.

| Limitation | Recommended Alternative | Key Benefit |

|---|---|---|

| Low Wear Resistance | Hard Chrome Plating, Nitriding | Superior hardness and durability |

| Electrical Insulation | Electroless Nickel, Zinc Plating | Excellent conductivity |

| Mild Corrosion Resistance | Zinc-Nickel Plating, Anodizing (Al) | Robust protection in harsh settings |

Choosing the right surface finish is critical. Black oxide is excellent for aesthetics and mild corrosion resistance, but its limitations in wear, conductivity, and severe environments make other options necessary for demanding applications.

Black Oxide For Medical And Aerospace Components: Are You Cleared?

When dealing with medical or aerospace parts, a black oxide finish is more than just a coating. It’s a critical process. It must meet stringent industry regulations.

Certifications are not optional here. They are your proof of compliance. They ensure safety and reliability for every component.

Key Industry Standards

For these sectors, specific standards are foundational. They dictate every step of the process. This guarantees quality control from start to finish.

A simple checklist shows what’s at stake.

| Standard | Industry Focus | Key Requirement |

|---|---|---|

| ISO 13485 | Medical Devices | Process Validation & Traceability |

| AS9100 | Aerospace | Risk Management & Quality |

| MIL-DTL-13924 | Military Spec | Coating Performance |

Following these isn’t just about paperwork. It’s about patient and passenger safety.

Navigating Regulatory Oversight

Having a certificate is just the first step. True compliance is about consistent, documented processes. It’s about building a system that guarantees quality every single time. This is essential for both black oxide aerospace parts and medical devices.

We’ve found that robust internal systems are crucial. They must go beyond the minimum requirements of the standards. This ensures that every batch meets the exact specifications demanded by clients in regulated fields.

The Importance of Documentation

Documentation is the backbone of compliance. Every step, from material sourcing to final inspection, must be recorded. This creates a complete history for each part. Full traceability is not a luxury; it’s a requirement. This is especially true for black oxide ISO13485 compliance, where every detail matters.

This level of detail ensures that if a problem ever arises, we can trace it to its source. The manufacturing process needs comprehensive oversight, including detailed Process validation15 to confirm consistent results.

Here’s a look at the essential documentation trail.

| Document Type | Purpose |

|---|---|

| Material Certifications | Confirms raw material meets spec |

| Process Logs | Records all parameters during coating |

| Inspection Reports | Verifies final part dimensions & finish |

| Certificates of Conformance | Declares compliance with all standards |

At PTSMAKE, we manage this entire documentation chain for our clients. This provides peace of mind and a clear audit trail. It proves that every component is cleared for its critical application.

In regulated industries like medical and aerospace, black oxide requires proof of compliance. Certifications such as ISO 13485 and robust documentation are essential. They ensure every component is safe, reliable, and fully traceable from start to finish.

Surface Roughness and Its Impact on Performance

When discussing black oxide, we must look at surface roughness. This is a critical factor. It affects not just appearance but also performance.

Let’s explore the key metrics. We’ll focus on Ra and Rz values. These numbers tell a story about the part’s surface texture.

Key Roughness Parameters

Ra (Roughness Average): This is the most common parameter. It measures the average deviation of the surface profile from a mean line.

Rz (Mean Roughness Depth): This metric averages the height of the five highest peaks and the depth of the five deepest valleys. It is more sensitive to occasional high peaks or deep scratches.

| Parameter | Description | Common Use |

|---|---|---|

| Ra | Arithmetic average of profile heights | General quality control |

| Rz | Average of highest peaks and lowest valleys | Detecting surface defects |

Understanding these helps define the surface roughness black oxide will have.

Black oxide is a conversion coating. This means it doesn’t add significant thickness to a part. Typically, it adds less than 1 micron.

Therefore, the final surface roughness is almost entirely determined by the substrate’s initial finish. A smooth part going in results in a smooth part coming out. A rough part remains rough.

The Substrate’s Critical Role

At PTSMAKE, we always emphasize pre-finish preparation. The Ra values oxide finish will have are locked in before the part even enters the black oxide bath. The process will not hide or smooth over existing imperfections like scratches or tool marks.

This is why specifying the desired surface finish before coating is essential. It directly impacts the final part’s functional properties. Small asperities16 on the surface can affect everything.

How Roughness Influences Performance

A slightly rougher surface can hold post-treatment oils or waxes better. This significantly enhances corrosion resistance.

Conversely, for parts requiring smooth, sliding contact, a lower Ra value is necessary to reduce friction and wear. The right balance is key.

| Initial Ra Value | Post-Black Oxide Ra | Performance Impact |

|---|---|---|

| Low (e.g., <0.4 µm) | Remains Low | Better for aesthetics, low friction |

| Medium (e.g., 0.8 µm) | Remains Medium | Good oil retention, balanced performance |

| High (e.g., >1.6 µm) | Remains High | Maximum oil retention, may increase wear |

We’ve covered average Ra and Rz values for black oxide. The key takeaway is that the original material’s texture dictates the final finish. This surface profile directly impacts corrosion resistance and lubrication, making it a critical design parameter.

Can Black Oxide Be Combined With Other Coatings Or Plating?

Can you combine black oxide with other coatings? The short answer is yes. But the process is not straightforward. It opens up possibilities for enhanced properties. However, it also introduces significant risks.

Multi-layer coating for metal parts is a delicate balancing act. You might gain corrosion resistance from one layer. You could add the aesthetic appeal of black oxide with another. But success depends on perfect compatibility and process control.

Layering Considerations

| Aspect | Potential Benefit | Potential Risk |

|---|---|---|

| Adhesion | Combined properties | Delamination or peeling |

| Corrosion | Enhanced protection | Galvanic corrosion |

| Appearance | Unique finish | Inconsistent color |

This approach requires deep material and chemical knowledge. It is not a standard procedure.

Combining finishes requires careful planning. Applying black oxide over plating is more common than the reverse. For example, a layer of zinc or nickel plating can provide excellent corrosion protection. Then, a black oxide finish is applied on top.

This creates a part with strong rust defense and a non-reflective black surface. However, the black oxide conversion coating must properly react with the underlying plating material, not the base metal. This can be a challenge.

Key Technical Challenges

The biggest hurdle is ensuring the layers stick together. Poor interfacial adhesion17 is a common failure point. The surface of the plating must be perfectly prepared before the black oxide process. Any contamination will cause the top layer to flake off.

We have found that the type of plating matters greatly. Some materials are simply not suitable for this multi-layer approach.

| Plating Type | Compatibility with Black Oxide | Key Consideration |

|---|---|---|

| Zinc Plating | Moderate | Requires specific post-treatment |

| Nickel Plating | Good | Electroless nickel works best |

| Chrome Plating | Poor | Surface is too inert for conversion |

| Cadmium Plating | Moderate | Environmental concerns |

Ultimately, the intended application dictates if this complex process is worthwhile. For most projects, choosing a single, high-performance finish is a more reliable and cost-effective path. We always analyze the trade-offs before proceeding.

Layering black oxide with other coatings offers unique benefits but poses significant risks. Success hinges on material compatibility, surface preparation, and precise process control, with adhesion being the primary technical challenge.

Reworking Or Recoating Black Oxide Parts—Myths And Methods

As a procurement manager, the cost to reapply a surface finish can seem small. But the true cost is often hidden. The black oxide rework process isn’t just about re-coating.

It involves logistics, stripping, and re-inspection. Each step adds time and risk. What looks like a simple fix can quickly become a complex problem. Let’s look at the real impact.

| Factor | Initial Perception | Rework Reality |

|---|---|---|

| Cost | Low re-coating fee | Fee + Logistics + Labor |

| Time | Quick turnaround | Days or weeks of delay |

| Risk | Minimal | High risk of scrap |

Let’s break down why reapplying a surface finish on CNC parts is more complex than it appears. The decision goes far beyond the supplier’s quote for the rework itself.

The True Cost of Rework

The initial quote for a black oxide rework process is just the beginning. You must account for round-trip shipping, internal handling, and additional quality control man-hours.

Our analysis shows these hidden costs can add 50-100% to the initial rework quote. A scrapped part means a total loss of the initial manufacturing cost, not just the finish.

| Cost Component | Description |

|---|---|

| Direct Rework Fee | The supplier’s charge to strip and re-coat. |

| Logistics | Shipping costs to and from the finisher. |

| Internal Handling | Labor for packing, unpacking, and inspection. |

| Scrap Risk | The cost of replacing a part damaged in rework. |

The Time Delay Cascade

Time is a critical factor. Rework doesn’t happen in a vacuum. It disrupts your entire production schedule. A "two-day" re-coating job can easily become a two-week delay for your assembly line once you factor in transit and inspection.

The Unseen Risks

The biggest risk is compromising the part itself. Chemical stripping can affect the material’s surface and its dimensional stability18. This is especially critical for parts with tight tolerances. At PTSMAKE, we focus on process control to avoid these issues entirely, ensuring parts are right the first time.

Reworking black oxide parts involves significant hidden costs, time delays, and quality risks. Procurement teams should evaluate the total cost of the black oxide rework process, not just the supplier’s quote, to avoid unexpected budget and schedule overruns.

Black Oxide Shelf Life And Long-Term Part Storage Concerns

How long can you store a black oxide coated part? This is a common question. There isn’t one simple answer. The shelf life depends heavily on several factors.

The post-treatment sealant, like oil or wax, is crucial. The storage environment also plays a big role. High humidity can cause problems. Proper black oxide part storage is essential to prevent issues.

Key Storage Factors

The primary concern is oxidation degradation. The black oxide finish itself offers minimal corrosion resistance. It’s the supplementary coating that does the work.

| Environment | Expected Shelf Life |

|---|---|

| High Humidity (>75%) | Months |

| Controlled Indoor (40-60%) | 1-2 Years |

| Dry, Sealed Packaging | Several Years+ |

This shows why controlled storage is so important for coated part corrosion over time.

The longevity of a black oxide finish is not infinite. It’s a common misconception. The finish is porous, designed to hold a rust-preventative sealant. The sealant’s breakdown is the real issue. This leads to coated part corrosion over time.

Understanding Oxidation Degradation

The process begins when the sealant (oil or wax) degrades. This can be due to time, temperature fluctuations, or exposure to contaminants. Once the sealant is compromised, moisture can reach the steel underneath. The iron oxide conversion coating offers very little protection on its own.

Packaging for Long-Term Storage

Proper packaging is your best defense. It shields parts from humidity and contaminants. We have seen significant differences in outcomes based on packaging choices.

| Packaging Method | Protection Level | Best For |

|---|---|---|

| Standard Poly Bag | Low | Short-term, dry rooms |

| Sealed VCI Bag | High | Long-term, humid areas |

| Desiccant Packs | Medium-High | Sealed containers |

Using Vapor Corrosion Inhibitor (VCI) bags is a smart move for black oxide part storage. These bags release a chemical that prevents corrosion. The black oxide coating is oleophilic19, meaning it readily absorbs and holds the protective oil. This property is what makes the post-treatment so effective initially. Protecting that oil layer is key.

The shelf life of black oxide parts depends on the post-treatment sealant and storage conditions. Proper packaging, like VCI bags, is crucial to prevent oxidation and ensure long-term integrity, mitigating coated part corrosion over time.

CNC Machine Shop Questions That Reveal If They Truly Understand Black Oxide

Choosing a CNC partner involves more than just machining. Their surface treatment expertise is critical. Black oxide, for example, is often misunderstood.

A simple "Do you offer black oxide?" isn’t enough. You need to dig deeper. This helps you assess their knowledge properly.

Asking the right questions helps you avoid inconsistent finishes and part failures. A partner’s true expertise lies in the details of the process.

Initial vs. Expert Questions

| Basic Inquiry | In-Depth Assessment |

|---|---|

| Can you do black oxide? | What is your process for pre-cleaning? |

| What’s the cost? | How do you control bath temperature? |

This approach helps vet a partner’s true understanding.

A real partner’s black oxide knowledge assessment goes beyond a simple "yes." You should ask about their specific processes. Do they use hot black oxide or cold black oxide? Each has distinct advantages and applications.

Hot vs. Cold Black Oxide

A shop should explain why one is better for your specific material and needs. For instance, hot black oxide provides a more durable and corrosion-resistant finish. It is a true conversion coating.

| Feature | Hot Black Oxide | Cold Black Oxide |

|---|---|---|

| Process Type | Conversion Coating | Deposition Coating |

| Temperature | ~285°F (141°C) | Room Temperature |

| Durability | High | Moderate |

| Abrasion Resistance | Good | Fair |

| Appearance | True Black | Grayish-Black |

The process involves converting the iron on the metal’s surface into magnetite20, a key detail an expert should know. We also discuss post-treatment options. A supplementary oil or wax is crucial for maximizing corrosion protection. Without this step, the black oxide finish offers minimal rust prevention. A knowledgeable shop, like us at PTSMAKE, will always present these options upfront to ensure part longevity.

Vetting a CNC shop’s surface treatment expertise requires specific questions. Inquiring about their black oxide process, pre-treatment steps, and post-finish sealing methods reveals their true depth of knowledge and ensures you receive high-quality, durable parts.

Prevent Compliance Problems By Understanding The Chemistry Of Black Oxide

You don’t need a degree in chemistry. But knowing the basics helps avoid compliance issues. The black oxide chemical process is not a paint or plating. It is a conversion coating. We are changing the surface of the steel itself.

The Core Reaction

This process involves a chemical reaction. It transforms the iron on the metal’s surface into black iron oxide. This creates the protective layer.

Key Components in the Bath

| Component | Role |

|---|---|

| Oxidizing Salts | Drives the conversion reaction |

| Caustic Soda | Creates the high-temperature alkaline environment |

| Water | Controls bath concentration and temperature |

This simple insight helps you select the right process. It is crucial for avoiding future regulatory headaches.

The black oxide chemical process primarily creates a layer of Magnetite21. This is a stable form of iron oxide. It provides the corrosion resistance that parts need. The specific method used to create this layer directly impacts safety and compliance.

Hot vs. Cold Process: A Chemical Safety View

The traditional hot black oxide process uses a boiling caustic salt solution. It operates at around 285°F (140°C). This method is very effective but involves hazardous materials. Proper handling and ventilation are critical for safety.

The cold black oxide process is an alternative. It uses a room-temperature solution, often containing selenium compounds. While it avoids high heat, these compounds are also toxic. They require specialized and careful disposal procedures.

Chemical Safety of Coatings

| Aspect | Hot Black Oxide | Cold Black Oxide |

|---|---|---|

| Primary Hazard | High-temperature caustic solution | Selenium compounds |

| Environmental Concern | Waste bath disposal | Heavy metal contamination |

| Worker Safety | Risk of severe chemical burns | Risk of toxic exposure |

At PTSMAKE, we manage these chemical processes carefully. Our team ensures that our methods meet stringent safety and environmental standards. This protects our workers and guarantees your product’s compliance. Understanding the chemical safety of coatings is not optional; it’s a core manufacturing responsibility.

Understanding the black oxide chemical process is key. It’s a conversion coating, not an additive layer. This knowledge helps you evaluate hot and cold methods, ensuring both part performance and regulatory compliance for your project.

Unlock Precision Results: Request a PTSMAKE Black Oxide Quote Today!

Ready to elevate your CNC machined parts with premium Black Oxide finishing? Partner with PTSMAKE—your next-generation solution for reliable, cost-effective, and precision-manufactured components. Send your inquiry now for a tailored quote and discover how PTSMAKE outperforms the competition in quality and service!

Learn more about the chemical process that distinguishes this coating from paints and platings for superior performance. ↩

Understand how this process protects parts without altering their dimensions, saving you from costly rework. ↩

Learn more about how different coatings protect metal parts from corrosion. ↩

Understand the chemical composition and protective properties of this key iron oxide for better material selection. ↩

Understand the chemical process that forms the durable, non-dimensional black oxide layer on your parts. ↩

Learn how the base material’s condition critically impacts the final black oxide finish quality. ↩

Understand the science behind how this chemical process alters a metal’s surface for enhanced properties. ↩

Learn how this physical property is crucial for designing parts with optimal handling and safety characteristics. ↩

Discover how this vital cleaning method prevents coating defects and ensures a flawless finish. ↩

Understand how this key metric influences the wear and performance of your components. ↩

Learn how this chemical process differs from plating and why it improves component durability. ↩

Understand the science of friction, wear, and lubrication in mechanical systems. ↩

Discover the chemical process that gives black oxide its unique protective and non-reflective properties. ↩

Learn how to prevent part failure caused by electrochemical reactions between dissimilar metals. ↩

Understand how this systematic protocol ensures consistent quality and performance in every batch. ↩

Learn how these microscopic peaks and valleys are measured and why they matter in manufacturing. ↩

Learn more about the science of how different coating layers bond together. ↩

Learn how surface treatments can alter part dimensions and why it’s critical for high-precision components. ↩

Understand how this oil-attracting property is key to maximizing corrosion resistance. ↩

Learn the chemical science behind this protective conversion coating for enhanced technical understanding. ↩

Learn more about this specific iron oxide and its crucial role in creating a durable, protective finish. ↩