Finding the right aluminum CNC machining service feels overwhelming when your project deadlines are tight and quality can’t be compromised. Every delay or defective part puts your entire production schedule at risk.

Aluminum CNC machining service uses computer-controlled machines to precisely cut and shape aluminum into custom parts, offering superior accuracy, fast turnaround times, and consistent quality for industries requiring lightweight, corrosion-resistant components.

I’ve worked with hundreds of engineering teams who struggle with the same challenges you face. They need parts that meet exact specifications, arrive on schedule, and fit their budget constraints. The right machining partner makes all the difference between a successful product launch and costly delays. Let me share what I’ve learned about getting aluminum CNC machining right the first time.

What Is Aluminum CNC Machining Service?

Ever struggled to find a material that’s both lightweight for performance and strong enough for your application? It’s a common challenge when balancing design requirements with manufacturability.

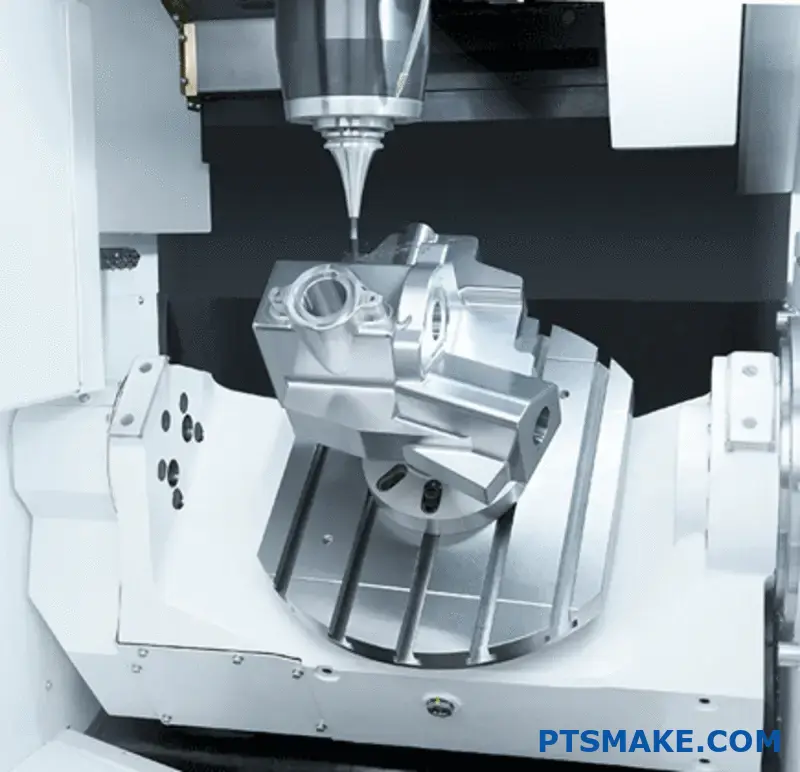

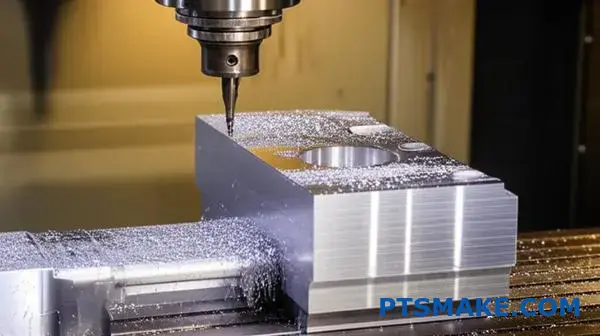

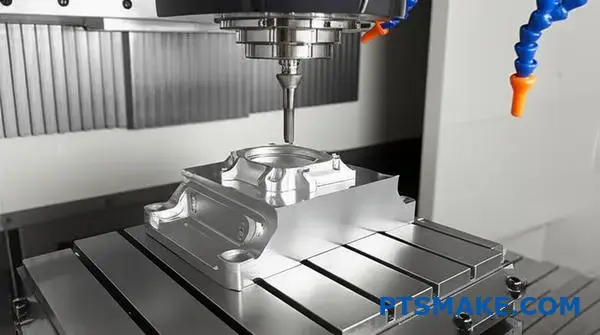

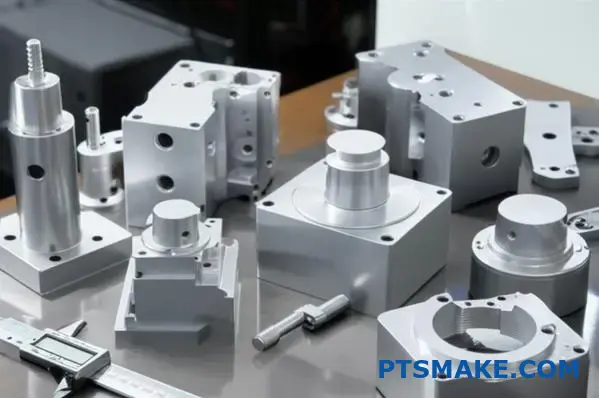

Aluminum CNC machining service is a high-precision manufacturing process that uses computer-controlled machines to cut, drill, and shape blocks of aluminum into custom-designed parts. This subtractive method is ideal for creating complex geometries with tight tolerances for prototypes and production runs.

At its core, this service translates a digital design file (like a CAD model) into physical instructions for a machine. The CNC machine then meticulously carves away material from a solid aluminum block to create the final component. This process, known as subtractive manufacturing1, is incredibly precise.

Why Aluminum is a Go-To Material

Aluminum isn’t just popular by chance; its properties make it an ideal candidate for CNC machining. It offers a fantastic strength-to-weight ratio, making parts durable without being heavy. Its natural corrosion resistance and excellent machinability mean we can produce complex parts faster and more efficiently at PTSMAKE, which ultimately benefits project timelines and costs.

| Property | Benefit for Machining |

|---|---|

| Lightweight | Reduces tool wear and machine load |

| High Strength-to-Weight Ratio | Creates durable yet light parts |

| Corrosion Resistance | Parts last longer without secondary finishing |

| Excellent Machinability | Faster cutting speeds, better surface finish |

An "aluminum CNC machining service" isn’t just about owning the machines. It’s about providing a complete solution. This includes design feedback, material selection guidance, and rigorous quality control to ensure every part meets exact specifications. In past projects at PTSMAKE, we’ve found that this partnership approach is what truly separates a simple supplier from a next-generation manufacturing partner.

Key Industries We Serve

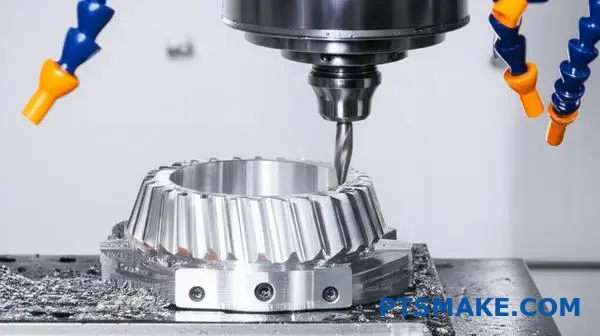

The versatility of CNC machined aluminum makes it essential across many high-tech fields. From aerospace to consumer electronics, the demand for precise, lightweight, and durable components is constant. Each industry leverages aluminum’s unique benefits for different critical applications.

| Industry | Common Aluminum CNC Applications |

|---|---|

| Aerospace | Brackets, housings, structural components |

| Automotive | Engine parts, suspension components, chassis parts |

| Medical | Surgical instruments, device enclosures |

| Electronics | Heat sinks, casings for phones and laptops |

In short, an aluminum CNC machining service uses computer-controlled processes to shape this versatile metal into precise components. Its unique properties, like being lightweight and strong, make it indispensable for critical industries ranging from aerospace to medical, delivering reliable and high-performance parts.

Key Advantages for OEMs and Engineers?

Struggling with parts that don’t meet spec or suppliers who can’t handle complex prototypes? Are long lead times and inconsistent quality derailing your projects and inflating your costs?

Aluminum CNC machining services provide unmatched precision, tight tolerances, and rapid turnaround for both prototypes and full-scale production. These benefits empower OEMs and engineers to reduce lead times, improve product quality, and seamlessly scale from initial concept to market-ready products.

Achieving Unmatched Precision and Quality

The primary advantage of an aluminum CNC machining service is its incredible precision. For engineers, this means parts consistently meet design specifications, which is critical for the performance and reliability of the final product. At PTSMAKE, we frequently work with components where even a micron’s deviation can affect functionality. The process ensures that every part, from the first to the thousandth, is virtually identical. This level of repeatability is difficult to achieve with other methods. Communicating precise requirements through a system like Geometric Dimensioning and Tolerancing2 is key to a successful outcome.

Impact on Assembly and Function

| Manufacturing Method | Typical Tolerance Range | Best For |

|---|---|---|

| CNC Machining | ±0.005 mm to ±0.1 mm | High-precision, functional parts |

| Die Casting | ±0.1 mm to ±0.5 mm | High-volume, less critical parts |

| Sand Casting | ±0.8 mm to ±2 mm | Large parts, non-critical surfaces |

From Complex Prototypes to Full-Scale Production

Speed is another cornerstone. The ability to go from a CAD file to a physical part in days, not weeks, accelerates the entire product development cycle. This is invaluable for rapid prototyping, allowing engineers to test and iterate on designs quickly.

Handling Intricate Geometries with Ease

In our past projects, we’ve seen how CNC machining handles complex geometries and intricate features that are impossible for other methods. This capability gives designers immense freedom. Furthermore, the process is inherently scalable. The same setup used to create a single high-fidelity prototype can be optimized for a production run of thousands of units. This eliminates the need to find a new supplier when scaling up, ensuring consistency in quality and a smoother transition from prototype to production.

For engineers and OEMs, aluminum CNC machining delivers a powerful combination of precision, speed, and scalability. This translates directly into higher-quality products, shorter development cycles, and a more streamlined manufacturing process, from a single complex prototype to full-scale production runs.

Ensuring Consistent Quality and Tolerances?

Ever receive a batch of aluminum parts only to find that half don’t meet your specs? The frustration of production delays and wasted budget due to inconsistent quality is all too real.

Ensuring consistent quality and tolerances in an aluminum CNC machining service relies on a robust quality management system (QMS), combining in-process inspections, final checks with advanced metrology tools, and adherence to certifications like ISO 9001. This systematic approach guarantees every part meets precise specifications.

Quality in aluminum CNC machining isn’t just about a final check; it’s a continuous process woven into every production stage. At PTSMAKE, we integrate quality control from the very beginning to prevent deviations rather than just catching them at the end.

In-Process Quality Control (IPQC)

During manufacturing, operators perform regular checks on critical dimensions. This proactive approach allows for immediate adjustments to machine settings, ensuring consistency across the entire batch. It’s the first line of defense against tolerance creep.

Final Inspection and Reporting

Before shipment, every part undergoes a final, rigorous inspection using advanced metrology3 equipment. We use CMMs, digital calipers, and micrometers to verify that all features conform to the original CAD model and drawing specifications.

| Inspection Stage | Purpose | Key Tools |

|---|---|---|

| First Article Insp. | Verify setup and programming | CMM, Calipers, Height Gauge |

| In-Process Insp. | Monitor and maintain consistency | Calipers, Micrometers |

| Final Quality Insp. | Ensure 100% compliance to spec | CMM, Optical Comparators |

Beyond the physical checks, formal certifications provide a framework for reliable quality. They are a promise of consistency. Many engineers I speak with are rightly concerned about reliability when outsourcing, but a certified partner mitigates these risks significantly.

The Power of ISO 9001

Our ISO 9001 certification isn’t just a badge. It mandates a comprehensive Quality Management System (QMS) that governs everything from raw material verification to employee training and equipment calibration. This system ensures our processes are repeatable and traceable.

Building Trust Through Transparency

To address outsourcing concerns, we provide detailed inspection reports, including FAI (First Article Inspection) and material certificates. Transparency is key. You see the data that proves your parts meet spec, building confidence in your aluminum cnc machining service partner with every order.

Consistent quality in aluminum CNC machining is achieved not by chance, but through a structured system. A combination of in-process controls, final inspections with advanced tools, and adherence to certifications like ISO 9001 ensures every part reliably meets your exact specifications.

What Key Factors Define a Reliable Aluminum CNC Machining Supplier Checklist?

Have you ever created a supplier checklist, only to realize later you missed a critical detail? This oversight can risk your project’s quality, timeline, and budget, causing major headaches down the line.

A robust checklist for vetting an aluminum CNC machining service must assess four key areas: technical capabilities, communication standards, experience with international clients, and a proven track record of delivering on time and within budget.

When creating your checklist, start with the technical fundamentals. You need to verify that the supplier can actually produce your parts to the required specifications. This goes beyond just owning the right machines. It’s about their team’s expertise and their quality control processes. For any specialized aluminum cnc machining service, assessing their experience with specific alloys and finishing processes is vital. For example, some partners excel with 6061 aluminum, while others are masters of the more challenging 7075 alloy. Their approach to quality assurance, such as their CMM inspection4 process, reveals a lot about their commitment to precision.

Technical & Experience Evaluation

| Category | Question to Ask |

|---|---|

| Machinery | What types of 3, 4, and 5-axis CNC machines do you operate? |

| Tolerances | What are your standard and tightest achievable tolerances for aluminum? |

| Materials | Can you provide material certifications for all aluminum alloys? |

| Case Studies | Can you share examples of past projects similar to mine? |

Beyond the technical aspects, your checklist must cover operational excellence. How a partner communicates and manages logistics is just as important as their machining skill. This is especially true for international collaborations. Clear, responsive communication prevents misunderstandings and keeps projects on track. You should also probe their ability to stick to schedules and budgets. Ask for their on-time delivery rate and how they handle unforeseen issues that could impact costs or deadlines. A reliable partner will have transparent processes in place. At PTSMAKE, we assign a dedicated project manager to ensure communication is seamless from quoting to delivery.

Communication & Logistics Evaluation

| Category | Question to Ask |

|---|---|

| Communication | What is your standard response time for emails and calls? |

| Project Management | Who will be my primary point of contact? |

| On-Time Delivery | What is your historical on-time delivery percentage? |

| Budgeting | How do you manage and communicate potential cost overruns? |

A thorough supplier checklist is crucial. It should confirm a partner’s technical ability to meet specs and their operational capacity for clear communication and on-time, on-budget delivery. This balanced evaluation ensures a successful partnership.

How Can You Slash Production Costs Without Compromising on Quality?

Feeling trapped between a tight budget and the high-quality parts your project demands? It’s a frustrating tightrope walk that can jeopardize project timelines and outcomes.

Implementing strategies like Design for Manufacturability (DFM), optimizing batch sizes, and closely collaborating with your supplier are key. These approaches directly reduce costs while upholding the highest quality standards for your aluminum parts.

True cost optimization begins long before a machine starts cutting metal. It starts with smart design.

Design for Manufacturability (DFM)

This is your first and best defense against unnecessary costs. Simple design choices, like standardizing corner radii or avoiding unnecessarily tight tolerances, can dramatically reduce machining time. At PTSMAKE, we often collaborate with clients on DFM reviews, finding opportunities to simplify geometry without affecting the part’s function. Understanding principles like Geometric Dimensioning and Tolerancing5 is crucial here, as it provides a clear language for defining what is truly critical for a part’s function, preventing over-engineering.

Smart Batch Size Optimization

Ordering one part at a time is expensive. Ordering too many ties up capital. Finding the sweet spot is essential. We help clients analyze their needs to determine the most cost-effective batch size, balancing unit price against inventory holding costs.

Beyond design and quantity, your relationship with your manufacturing partner is a powerful lever for cost control. A great partner for an aluminum cnc machining service acts as an extension of your team.

Leverage Supplier Expertise

Don’t just send a purchase order; start a conversation. In our experience at PTSMAKE, a brief discussion can uncover significant savings. We might suggest a slightly different aluminum alloy that meets performance specs but machines faster, or a minor tweak that simplifies workholding. This collaborative approach turns a simple transaction into a strategic partnership.

The Power of Transparent Workflows

A clear process eliminates costly surprises. Knowing where your parts are in the production cycle helps you manage your project timeline and budget effectively.

| Opaque Workflow | Transparent Workflow |

|---|---|

| Unclear Timelines | Real-Time Status Updates |

| Hidden Costs | Itemized Quoting |

| Limited Communication | Proactive Consultation |

Effective cost control is not about cutting corners. It’s about smart strategy. By focusing on Design for Manufacturability, optimizing your order quantities, and building a transparent, collaborative relationship with your supplier, you can lower costs while ensuring top-quality results.

What Surface Finishes and Post-Processing Options Are Available?

Have you ever specified a "finished" aluminum part, only for the final product to fail on durability or appearance? The wrong finish can compromise an otherwise perfect component.

A range of surface finishes are available for CNC machined aluminum parts, including anodizing, sandblasting, and polishing. These processes not only improve the part’s look but also enhance critical properties like corrosion resistance, wear resistance, and surface hardness.

The finish on an aluminum part is more than just cosmetic; it’s a functional feature that dictates performance. At PTSMAKE, we guide clients through the best options for their specific application. Anodizing, for instance, is an Electrolytic passivation6 process that creates a durable, corrosion-resistant oxide layer. Type II is great for color and moderate protection, while Type III (hard-coat) offers superior wear resistance. Sandblasting creates a uniform, non-reflective matte finish, ideal for hiding tool marks and reducing glare. Polishing achieves a smooth, mirror-like surface, which can be crucial for optical or aesthetic applications. Choosing the right finish is a key step in any professional aluminum cnc machining service.

| Finish | Primary Benefit | Best For |

|---|---|---|

| Anodizing | Corrosion/Wear Resistance | External parts, functional components |

| Sandblasting | Uniform Matte Texture | Hiding imperfections, reducing glare |

| Polishing | Smooth, Reflective Surface | Aesthetic parts, optical components |

How do you ensure you get the finish you need? It starts with clear communication. Simply asking for "anodizing" isn’t enough. You must specify the type (e.g., Type II or Type III), the color, and the required thickness of the oxide layer. For sandblasting, specify the media type and desired surface roughness (Ra). For polishing, define the level of reflectivity or provide a sample standard. In past projects at PTSMAKE, providing a control sample or a detailed specification sheet prevents misunderstandings and ensures the final parts match the design intent perfectly. This level of detail is crucial for achieving consistent quality across a production run.

Choosing the right surface finish is critical for both appearance and function. Options like anodizing and sandblasting offer distinct benefits. Clearly specifying your requirements for type, color, and texture is essential to ensure your supplier delivers parts that meet your exact standards.

How Can You Effectively Manage Lead Times and Ensure On-Time Delivery?

Have you ever watched a well-planned project spiral out of control due to unexpected production delays? That sinking feeling when a critical deadline is missed can jeopardize lancement dates and budgets.

Effectively managing lead times hinges on robust project planning, transparent supplier communication, and diligent real-time tracking. Setting realistic timelines from the outset for both prototypes and production is crucial to hitting every critical deadline and ensuring a smooth manufacturing process from start to finish.

The foundation of on-time delivery is built long before machining begins. It starts with a realistic and detailed project plan. Unforeseen issues will always arise, but a solid plan provides the structure to handle them efficiently.

Deconstructing the Timeline

Breaking a project down into smaller, manageable phases is key. Instead of one large deadline, set milestones for design finalization, material procurement, machining, finishing, and quality inspection. This approach makes progress easier to track. We often use a Gantt chart7 in our projects at PTSMAKE to visualize these phases and their dependencies, which helps identify potential bottlenecks early. For any high-quality aluminum cnc machining service, understanding material availability is a critical input for this planning stage.

Material Procurement Buffer

Factoring in a buffer for material sourcing is a lesson learned from past project experiences.

| Material Type | Typical Lead Time | Risk Factor |

|---|---|---|

| Standard Aluminum (6061) | 1-3 Days | Low |

| Specialized Alloys (7075) | 5-10 Days | Medium |

| Imported Materials | 2-4 Weeks | High |

While a solid plan is essential, it’s static without dynamic communication and tracking. Delays often happen in the silent gaps between status updates. Proactive communication turns a supplier into a true partner.

The Role of a Communication Cadence

Establishing a regular communication schedule prevents surprises. A simple weekly check-in can make all the difference. This isn’t about micromanagement; it’s about alignment. At PTSMAKE, we assign a dedicated project manager to ensure there’s a single point of contact, making communication streamlined and effective. This proactive approach is vital, especially when dealing with complex parts that require precise custom machining.

Real-Time Order Tracking

Modern manufacturing shouldn’t be a black box. Ask your supplier about their tracking capabilities.

| Tracking Method | Update Frequency | Transparency Level |

|---|---|---|

| Email Updates | Ad-hoc | Low |

| Online Portal | Daily | Medium |

| Real-Time Dashboard | Instant | High |

To ensure on-time delivery, combine detailed project planning with a proactive communication strategy. Breaking down timelines into clear milestones and utilizing real-time tracking tools transforms your supplier relationship into a transparent partnership, preventing costly delays and keeping your project on schedule.

Case Studies: Solving Real-World Challenges with Aluminum CNC Machining?

Have you ever faced a project where standard components just don’t meet your design’s complex needs, especially with a demanding deadline looming? This is a frequent hurdle in high-stakes industries.

An aluminum CNC machining service directly solves these issues by manufacturing custom parts with intricate geometries and tight tolerances. This empowers companies in aerospace, robotics, and medical sectors to meet strict quality standards and aggressive timelines, transforming complex designs into functional, real-world components.

Theory is one thing, but results are what matter. In past projects at PTSMAKE, we’ve seen how the right manufacturing approach can make or break a project, especially in demanding fields.

Aerospace: The Quest for Lighter, Stronger Components

A common challenge in aerospace is achieving the highest strength-to-weight ratio. A client needed a structural bracket for a communications satellite with an incredibly complex design—full of thin walls and deep pockets to shave off every possible gram. Using our 5-axis aluminum CNC machining service, we manufactured the part from 7075 aluminum in a single setup. This not only preserved the part’s Geometric Dimensioning and Tolerancing8 but also its structural integrity, a critical factor for launch and deployment stresses.

| Challenge | Solution | Outcome |

|---|---|---|

| Complex geometry & low weight | 5-axis CNC machining of 7075 aluminum | 25% weight reduction vs. previous design |

| High precision requirements | Single-setup machining process | Exceeded tolerance and strength specifications |

The lessons learned from one industry often provide innovative solutions for another. For instance, the precision required in aerospace directly translates to the reliability needed in medical devices.

Medical Devices: Precision Meets Biocompatibility

For a medical client developing a handheld surgical tool, the challenge was twofold: the components needed to be flawlessly precise for assembly and the material had to be biocompatible and easily sterilized. We selected 6061-T6 aluminum for its excellent properties. The real key was in the post-processing. After machining, we managed a specialized anodizing process that created a non-porous, durable surface. This ensured the part met the strict cleanliness and biocompatibility standards required for surgical instruments, demonstrating how a full-service approach is vital.

| Challenge | Solution | Outcome |

|---|---|---|

| Biocompatibility & Sterilization | 6061-T6 Aluminum with specific anodizing | Part met all FDA surface requirements |

| Tight assembly tolerances | Precision machining and quality control | Achieved flawless fit and function |

These real-world examples from aerospace and medical industries highlight a core truth. An expert aluminum CNC machining service provides critical, tailored solutions for complex designs, tight deadlines, and stringent quality demands, succeeding where off-the-shelf parts simply cannot.

Click to understand how this core manufacturing principle differs from additive methods like 3D printing. ↩

Master GD&T to perfectly communicate your design intent, ensuring parts are manufactured exactly as you envisioned them. ↩

Click to understand how the science of measurement ensures your CNC machined parts meet the tightest tolerances. ↩

Understand how Coordinate Measuring Machine (CMM) inspections verify part accuracy against your original CAD model. ↩

Click to understand how this engineering language can prevent costly manufacturing errors and improve part functionality. ↩

Discover the science behind how this electrochemical process enhances the natural oxide layer, boosting durability and corrosion resistance. ↩

Learn how this project management tool helps visualize timelines and manage complex manufacturing tasks effectively. ↩

Discover how GD&T ensures your parts fit and function perfectly every time. ↩