You’re managing a critical rail project in Houston, but your current CNC supplier keeps missing tolerances on brake components. One failed part could derail entire operations and cost thousands in downtime.

PTSMAKE delivers precision CNC machined railroad components in Houston with micron-level tolerances, ensuring reliable performance for brake systems, connectors, and custom rail parts from prototype to full production.

I’ve worked with rail companies across Texas who struggled with similar challenges. The right CNC partner makes the difference between smooth operations and costly failures. Let me walk you through what separates top-tier railroad machining from the rest.

The Ultimate Guide To CNC Machining For Railroad Components

The railroad industry demands extreme reliability. Every component must withstand constant stress and harsh conditions. There is simply no room for error.

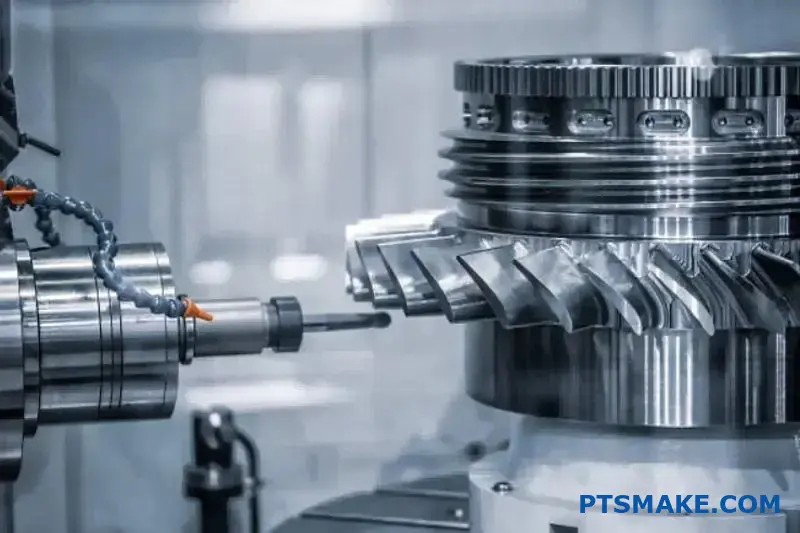

This is where CNC machining plays a vital role. It provides the necessary precision for safety and performance.

Effective CNC machining for railroads isn’t just about cutting metal. It’s about ensuring every part meets exact specifications, every single time. This is fundamental for producing precision railway components.

| Feature | Importance in Railroads |

|---|---|

| Precision | Ensures compatibility and safety |

| Durability | Withstands high stress and wear |

| Reliability | Prevents catastrophic failures |

The Unseen Demands on Railway Components

Think about the forces on a simple axle or wheel. These parts endure massive loads and constant vibration. Failure is not an option.

This is why material selection and machining are so critical. Even a tiny flaw, invisible to the naked eye, can lead to a major problem over time.

Why Precision is Non-Negotiable

Precision railway components must fit together perfectly. CNC machines achieve tolerances that manual methods simply cannot match. This ensures smooth operation and reduces wear.

For businesses looking for reliable railroad parts manufacturing in Houston, finding a partner who understands these demands is key. It’s about more than making a part. It’s about guaranteeing its performance.

We carefully analyze how each part will perform over its expected fatigue life1. This involves understanding material properties and the specific stresses of operation.

| Factor | CNC Machining Contribution |

|---|---|

| Stress Tolerance | Precise geometries distribute load correctly. |

| Reliability | Repeatable accuracy eliminates weak points. |

| Safety | Parts meet or exceed industry standards. |

At PTSMAKE, our process focuses on this from day one. We collaborate with clients to understand the application and its unique challenges. This ensures every part we produce is built for endurance.

CNC machining is essential for creating reliable railroad components. It delivers the precision to handle immense stress and ensure safety, a key focus for any quality railroad parts manufacturer. This process is vital for the industry’s integrity.

Why Houston Is A Strategic Hub For Rail CNC Manufacturing

Houston’s power as a manufacturing hub comes from a powerful trio. It’s not just one factor, but the synergy of three.

We have world-class industrial infrastructure. This is paired with highly efficient transport logistics. Finally, there’s a deep pool of skilled labor.

This combination creates a perfect environment. It’s ideal for rail component production Houston. It makes the city a top choice for finding reliable CNC manufacturers in Houston. This ecosystem provides a clear competitive edge for any project.

When clients look for railroad industry suppliers Texas, I often point to Houston’s complete package. It’s more than just a location; it’s a strategic advantage. Let’s break down why this environment is so effective for a railroads cnc machining manufacturer houston.

Robust Industrial Infrastructure

Houston’s infrastructure is built for heavy industry. The Port of Houston is a major gateway for global trade. It allows easy import of raw materials and export of finished rail components. The city is also a nexus for major railway lines, which simplifies domestic distribution.

This physical network reduces transit times and costs. It’s a foundational element that supports the entire manufacturing process.

Integrated Transport Logistics

Houston is a prime example of a Logistics cluster2. It’s not just about having ports and railways. It’s about how they work together seamlessly. This integration creates massive efficiencies.

Companies benefit from a network of specialized freight forwarders, trucking companies, and warehousing facilities. This ecosystem ensures that materials and parts move quickly.

| Logistical Advantage | Impact on Rail CNC Manufacturing |

|---|---|

| Port Access | Reduced cost for raw materials like steel alloys. |

| Rail Network | Direct, cost-effective shipping of large components. |

| Highway System | Flexible last-mile delivery to clients. |

| Air Cargo | Fast shipping for urgent, high-value parts. |

Access to Specialized Labor

Houston has a unique workforce. Decades of leadership in the energy and aerospace sectors have created a deep talent pool.

These engineers and machinists are experts in high-tolerance work. They understand the demands of manufacturing durable, mission-critical parts. This expertise translates directly to the high standards required in rail component production.

Houston’s integrated infrastructure, advanced logistics, and skilled workforce create a powerful advantage. This synergy lowers operational risks and costs, making it a top-tier location for any railroads cnc machining manufacturer houston seeking to excel in the competitive railroad industry.

The Must-Know CNC Machined Parts Used In Rail Systems

CNC machining is essential for the rail industry. It creates parts that are strong, reliable, and precise. These components form the backbone of safe and efficient rail systems.

We often produce a core set of railroad CNC components. These parts must meet strict standards.

Key Machined Components

Here’s a look at some common parts:

| Component Type | Primary Function | Material Focus |

|---|---|---|

| Brake Components | Safety, Speed Control | High Wear Resistance |

| Connectors | Electrical & Mechanical Links | Durability, Conductivity |

| Brackets | Structural Support | High Strength-to-Weight Ratio |

| Housings | Protection for Electronics | Environmental Resistance |

For the custom rail parts Houston businesses need, we focus on delivering high-precision machined rail parts that guarantee performance.

The demands on rail components are immense. They face constant vibration, extreme temperatures, and heavy loads. This is why material choice and machining precision are not just goals; they are absolute requirements.

Brake Components Unpacked

Brake parts are arguably the most critical. They require extremely tight tolerances to ensure reliable stopping power. We often use hardened steels and specialized alloys. These materials manage heat and wear effectively during braking.

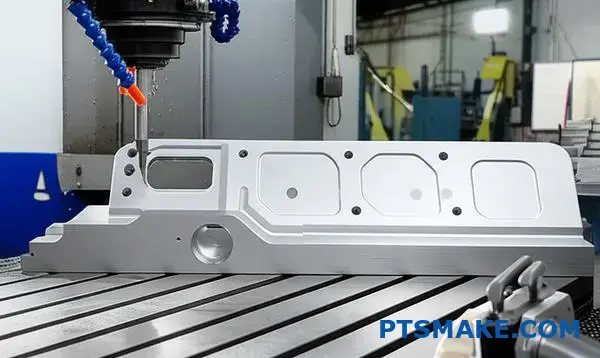

Housings and Structural Parts

Housings protect sensitive electronics from harsh conditions. Brackets must support heavy loads without failing. We use materials like aluminum and stainless steel for these parts. They offer a great balance of strength, weight, and corrosion resistance.

The performance of hydraulic brake systems is also critical. It depends heavily on fluid properties under pressure. Understanding how fluids behave, including their Kinematic Viscosity3, is crucial for designing reliable systems.

As a dedicated railroads cnc machining manufacturer houston, we help clients select the right materials for each specific application.

| Part Category | Common Materials | Key Machining Consideration |

|---|---|---|

| Safety-Critical | Hardened Steel, Titanium | Tight Tolerances, Surface Finish |

| Structural | Aluminum 6061, Stainless Steel 304 | Stress-Bearing Points, Weldability |

| Electrical | Copper, Brass | Conductivity, Corrosion Resistance |

The right material and precise manufacturing process work together. They ensure every part performs its function perfectly, contributing to the overall safety and longevity of the rail system.

CNC machining delivers the precision required for critical rail parts like brake components, connectors, brackets, and housings. Material selection is key to ensuring these high-precision machined rail parts withstand the harsh operating environment and perform reliably for safety and efficiency.

Avoid These Critical CNC Failures In Railroad Applications

In railroad applications, small defects can lead to major failures. The CNC machining risks for railroads are significant if not managed properly. Precision is non-negotiable.

Three common culprits often emerge. These are poor tolerances, incorrect material selection, and overlooked tool wear. Each one introduces a unique threat to system integrity.

The Dangers of Machining Defects

Poor rail part quality control can compromise safety. Imagine a critical switch component failing due to a slight dimensional error. This is why vigilance is key.

Here’s a quick look at the impact:

| Defect Type | Primary Consequence |

|---|---|

| Poor Tolerances | Component Misfit, Premature Wear |

| Material Misselection | Structural Failure, Corrosion |

| Tool Wear | Poor Surface Finish, Inaccuracy |

Let’s break down these CNC machining risks further. It’s not just about getting one part right. It’s about ensuring every single part is right, every time. This is the foundation of failure-free CNC operations Houston providers must guarantee.

Material Selection is Critical

Choosing the wrong material is a frequent but avoidable error. A part might look correct but lack the required strength or corrosion resistance for the harsh railroad environment. Material properties must match the application’s demands exactly.

Some materials exhibit different strengths based on their grain direction. Understanding these anisotropic properties4 is crucial for parts under specific load types. We always verify material certifications to ensure compliance and avoid failures.

Tolerance and Tool Wear

Tolerances that are off by even a fraction of a millimeter can cause cascading failures. This is where diligent quality control becomes essential for any reliable railroads cnc machining manufacturer houston.

Tool wear is a silent threat. As a cutting tool dulls, it creates dimensional inaccuracies and poor surface finishes. Automated tool monitoring and scheduled replacements are vital. This ensures consistent rail part quality control.

| Control Measure | Target Defect |

|---|---|

| Material Certification | Material Misselection |

| CMM Inspection | Poor Tolerances |

| Scheduled Tool Replacement | Tool Wear Defects |

Ultimately, preventing critical CNC failures in railroad parts comes down to meticulous control over tolerances, materials, and tooling. Proactive quality assurance is the only way to mitigate these significant risks and ensure operational safety and reliability on the tracks.

Secrets To Ensuring Long-Term Durability Of Railway Parts

The foundation of any durable part lies in its material and treatment. You can have a perfect design, but it will fail without the right foundation. This is especially true for railway components.

Choosing the right metal and applying the correct hardening process are non-negotiable steps. These decisions directly impact the part’s resistance to wear, fatigue, and environmental factors. They are the first line of defense.

Below is a simple breakdown of common material choices.

| Material | Key Benefit | Ideal Application |

|---|---|---|

| Carbon Steel | Strength & Cost | Structural Components |

| Stainless Steel | Corrosion Resistance | Fasteners, Outdoor Parts |

| Titanium | Strength-to-Weight | High-Stress, Low-Weight |

Deeper into Material Science and Treatments

The right metal selection for CNC rail parts is a balance of performance and cost. For example, stainless steel is an excellent choice for components exposed to moisture. It prevents rust and extends service life significantly.

Titanium, while more expensive, is invaluable for parts needing high strength without adding much weight. This is critical for moving components where inertia is a factor. We see this often in modern, high-speed rail systems.

However, the material is only half the story. Hardening processes are what truly create durable railroad components. These treatments alter the metal’s microstructure. Processes like induction hardening create a tough outer layer while keeping the core ductile. This prevents cracking under shock loads. After heat treatment, which includes controlled heating and cooling after austenitizing5, the part’s surface becomes exceptionally wear-resistant. For any railroad cnc machining manufacturer, mastering these techniques is essential for delivering long-life machined components for railways.

| Hardening Method | Surface Hardness | Core Ductility |

|---|---|---|

| Case Hardening | Very High | High |

| Through Hardening | Uniform High | Low |

| Induction Hardening | High (Localized) | High |

Material selection and subsequent hardening processes are fundamental to creating durable railroad components. The synergy between the base metal’s properties and the surface treatment’s enhancements dictates the final performance and lifespan of the part in demanding railway environments.

Rail-Grade Materials And Their Impact On CNC Performance

Selecting the right material is a critical first step. It dictates the durability and safety of rail components. The choice affects everything from weight to wear resistance.

In rail applications, performance is non-negotiable. We primarily work with three material categories. Each offers unique benefits for specific parts.

Key Material Categories

The material directly impacts machining processes. It influences tool selection, cutting speeds, and cycle times. Below is a quick overview.

| Material | Key Advantage | Common Application |

|---|---|---|

| Carbon Steel | High Strength | Wheels, Axles, Rails |

| Aluminum Alloys | Lightweight | Body Panels, Interior |

| Composites | Design Flexibility | Cabins, Seat Frames |

Understanding these rail CNC materials is essential. It ensures the final product meets strict industry standards.

The discussion of materials often starts with strength. However, other factors like corrosion resistance and weight are equally vital in modern railway design.

High-Strength Metals for Railroad Parts

Carbon steel remains the backbone of the industry. Its exceptional durability makes it ideal for high-stress components like wheels and tracks. We frequently machine high-carbon grades. These high-strength metals for railroad parts ensure maximum safety and longevity under constant load.

Aluminum’s Growing Role

Aluminum alloys, like 6061-T6, offer an excellent strength-to-weight ratio. They are used for car bodies and structural components. This reduces overall train weight, improving energy efficiency. Better efficiency means lower operating costs.

The Rise of Advanced Composites

Composites bring new possibilities. These materials allow for complex shapes that are difficult to achieve with metals. Their properties can exhibit anisotropy6, which must be considered during the design and machining phases. As a specialized railroads cnc machining manufacturer houston, we see composites used more in interiors and non-structural parts.

| Material | Machinability | Weight | Corrosion Resistance |

|---|---|---|---|

| Carbon Steel | Moderate | Heavy | Low |

| Aluminum Alloy | High | Light | High |

| Composites | Varies | Very Light | Excellent |

At PTSMAKE, our experience in material performance rail machining helps clients balance these trade-offs. We guide them toward the optimal choice for their specific application, ensuring both performance and cost-effectiveness.

Choosing the right rail-grade material is a balancing act. High-strength steels offer durability, while aluminum provides lightweight efficiency. Composites add design freedom. This decision is crucial for performance, safety, and manufacturing success in the rail industry.

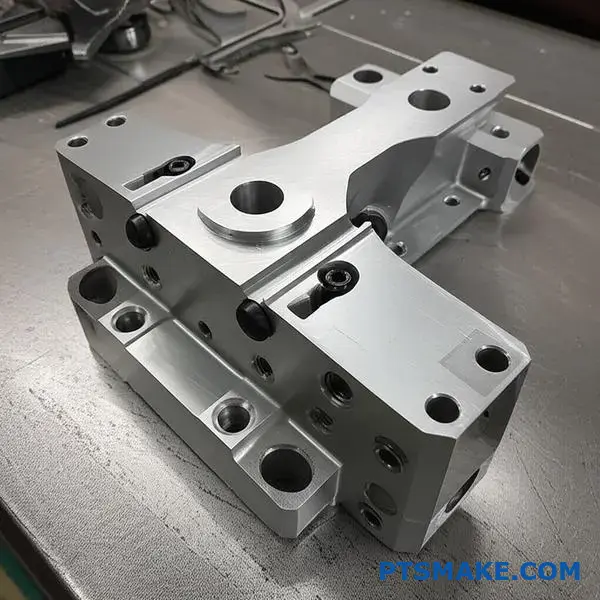

High-Mix, Low-Volume Machining Solutions For Rail Prototypes

For innovation testing, finding the right partner is crucial. Companies need low-volume and custom solutions. This allows for rapid iteration.

The Innovation Partner

Look for manufacturers specializing in prototypes. They understand the need for speed and precision. This is key for effective testing cycles.

Custom Solutions Focus

A partner geared for cnc for low volume rail parts offers flexibility. They can adapt to design changes quickly. This supports a dynamic development process.

| Capability | Benefit for Prototyping |

|---|---|

| Low-Volume Focus | Cost-effective for single or few parts |

| Custom Tooling | Adapts to unique component designs |

| Rapid Turnaround | Accelerates testing and validation |

This approach is essential for rail prototyping Houston and beyond.

Flexible Rail Component Manufacturing

True innovation requires a manufacturing partner who is as agile as your design team. Speed cannot come at the expense of quality. Prototypes must accurately represent the final product’s performance. Otherwise, testing data is unreliable. This is where expertise in flexible rail component manufacturing becomes non-negotiable.

A good partner provides more than just parts. They offer feedback on manufacturability. This helps refine designs early, saving time and cost. We’ve seen how early collaboration improves outcomes significantly.

Evaluating a Potential Partner

When selecting a railroads cnc machining manufacturer houston, consider their technical depth. Do they have experience with the specific materials and tolerances your project demands? The ability to hold tight tolerances is critical for rail components, even in the prototype stage. This ensures that the parts function as intended during rigorous testing. True precision requires a deep understanding of concepts like Geometric Dimensioning and Tolerancing (GD&T).

| Evaluation Criteria | Importance for Low-Volume Rail |

|---|---|

| Material Expertise | Ensures correct material properties for testing |

| Tolerance Capability | Guarantees functional fit and performance |

| DFM Feedback | Optimizes design for eventual production |

| Prototyping Speed | Reduces time from design to physical part |

Choosing the right supplier streamlines your entire innovation pipeline.

Choosing a partner specializing in low-volume, custom rail components is vital. This ensures your innovation testing is backed by speed, precision, and manufacturing expertise, leading to more effective and reliable development cycles for new rail technologies.

Boost Reliability With Tighter Tolerances In Rail Machined Parts

In the rail industry, component wear is a constant challenge. Micron-level precision in manufacturing directly combats this issue.

It ensures that parts fit and function perfectly. This minimizes unwanted movement and friction between components.

Tight tolerance machining in the rail industry is not just a goal. It is essential for creating reliable rail components that last longer and perform better under stress. The difference is clear.

| Tolerance Level | Wear Impact | Component Lifespan |

|---|---|---|

| Standard | Higher friction & vibration | Shorter |

| Micron-Level | Minimal friction & vibration | Significantly Extended |

This precision directly translates to enhanced safety and operational efficiency.

Micron-level precision fundamentally changes how rail components interact. It creates a more stable tribological system7 where parts work in harmony. This is where we see the most significant gains in reliability.

A better fit means less microscopic sliding and rubbing. This directly reduces material loss from friction. At PTSMAKE, we focus on this to achieve superior part performance.

Vibration is also significantly dampened. When components fit perfectly, they move as a single, cohesive unit. This prevents the small, repetitive impacts that cause material fatigue and accelerate wear over time.

This meticulous approach ensures rail part dimensional stability, even under the harshest operating conditions. Every top-tier railroads cnc machining manufacturer recognizes this principle. It is a non-negotiable standard for producing genuinely reliable rail components.

| Wear Factor | Effect of Tight Tolerance | Outcome |

|---|---|---|

| Friction | Smoother surface interaction | Less material abrasion |

| Vibration | Reduced unwanted movement | Lower fatigue stress |

| Load | Even stress distribution | Prevents localized failure |

In short, achieving micron-level tolerances is a direct strategy to minimize wear. It reduces friction and vibration, extending the service life of critical rail components. This ensures greater reliability and safety for the entire system.

Smart Integration: CNC Machining For Rail And IoT Device Housings

The rail industry is rapidly evolving. It’s no longer just about heavy steel. Today, it is integrating smart systems. This includes IoT devices and advanced sensors.

This digital shift creates new needs. Specifically, it demands robust, custom housings. These housings protect delicate electronics from the harsh rail environment. Precision is everything. This is where the value of CNC IoT rail parts becomes clear.

| Smart System | Housing Requirement | Machining Solution |

|---|---|---|

| Trackside Sensors | Weather & Impact Resistance | Precision-Milled Aluminum |

| GPS/Comms Units | Signal Integrity | EMI-Shielded Enclosures |

| Onboard Diagnostics | Vibration Damping | Custom-Fit Mounts |

Proper digital rail component machining ensures these devices function reliably. It is the bridge between traditional rail and its smart future.

Creating effective housings presents unique challenges. The environment is unforgiving. It involves constant vibration, extreme temperatures, and exposure to the elements. A simple off-the-shelf box will not work.

Material selection is the first critical step. For example, we often recommend 6061 aluminum for its strength and thermal conductivity. This helps dissipate heat from sensitive electronics. But the material is only half the story.

The real challenge is in the manufacturing process. Precision is non-negotiable. Digital rail component machining allows us to achieve tight tolerances. This is essential for creating waterproof and dustproof seals, often specified with IP ratings.

We must also consider factors like electromagnetic interference8. This is crucial for ensuring that powerful rail systems do not disrupt sensitive sensor data. A railroads cnc machining manufacturer houston must address these issues.

The requirements for sensor housings rail Houston projects, for instance, must account for high humidity and heat. This directly impacts design and material choices.

| Environmental Factor | CNC Machining Advantage |

|---|---|

| High Vibration | Machining integral mounting points |

| Extreme Temperatures | Milling custom heat sinks |

| Moisture Ingress | Creating precise gasket grooves |

| Electrical Noise | Ensuring tight enclosure seams |

Each feature is designed and machined for a specific purpose. This guarantees the long-term reliability of the entire smart system.

The fusion of rail and IoT demands specialized, durable housings. CNC machining delivers the necessary precision for these components, ensuring sensors and electronics are protected from harsh operational environments and function reliably.

Future-Proofing Your Rail Project With Scalable CNC Solutions

Transitioning from a single prototype to full-scale production is a critical step. This is where scalable rail CNC services make a difference. They ensure consistency and quality across every single part.

The Journey From One to Many

Your project’s success depends on this transition. It must be seamless and reliable. This journey maintains quality from the first part to the last, which is key for volume manufacturing Houston rail projects.

| Stage | Focus | Key Challenge |

|---|---|---|

| Prototype | Proof of Concept | Functionality |

| Low-Volume | Process Validation | Repeatability |

| Full Production | Cost & Efficiency | Scalability |

Scaling With Precision

The path from prototype to rail production involves careful planning. We adjust our entire approach to manufacturing. This ensures quality remains consistently high as the quantity increases for your project.

Material and Tooling Adjustments

For a prototype, we often use a standard material block. For production, we source materials in bulk to optimize costs. We also design specialized fixtures and jigs. These custom tools dramatically speed up setup times and improve accuracy.

Process Optimization

We analyze every step of the machining process. We refine toolpaths and optimize cycle times for maximum efficiency. Applying principles like Design for Manufacturability (DFM)9 at this stage is vital for success. It helps avoid costly changes and delays down the line. As your railroads cnc machining manufacturer houston partner, we guide this process.

| Aspect | Prototyping | Full Production |

|---|---|---|

| Material | Standard stock | Bulk, cost-optimized |

| Tooling | General-purpose | Custom fixtures/jigs |

| QC | Manual inspection | Automated inspection, SPC |

| Goal | Validate design | Maximize efficiency |

We manage this complexity for you. Our goal is to ensure that the ten-thousandth part is identical to the very first one. We focus on delivering repeatable and reliable outcomes.

A successful project relies on scalable CNC services to bridge the gap between concept and mass production. This ensures your rail components maintain strict quality and precision standards at any volume.

Discover Railroads CNC Machining Excellence with PTSMAKE

Ready to achieve flawless reliability and precision in your railroad CNC machined components? Contact PTSMAKE now for a quick, competitive quote tailored to your project’s unique requirements. Experience unmatched expertise and consistent quality—send your RFQ today and accelerate your journey from prototype to production!

Learn how material stress over time can impact component safety and longevity. ↩

Learn how geographic concentrations of logistics firms boost efficiency and cut costs for your manufacturing supply chain. ↩

Learn how this property impacts fluid dynamics and component performance in extreme temperatures. ↩

Learn how material grain direction can impact the strength and durability of your mission-critical CNC machined components. ↩

Learn more about this critical stage in the heat treatment of steel. ↩

Explore how a material’s directional properties can influence its strength and engineering application. ↩

Learn how the science of friction, wear, and lubrication in mechanical systems can optimize your component design. ↩

Discover how proper housing design shields sensitive electronics from signal disruption in critical rail applications. ↩

Discover how applying DFM principles can significantly reduce manufacturing costs and accelerate your project timeline. ↩