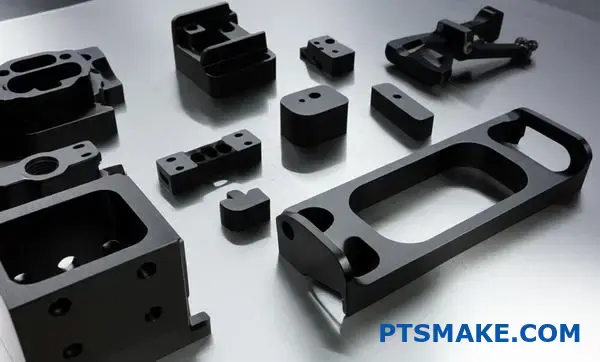

Finding the right surface finish for your precision CNC parts can make or break your product’s performance and market appeal. Many engineers struggle with finishes that wear off quickly, lose their aesthetic appeal, or fail under demanding conditions.

Black nickel plating is an electrochemical coating process that deposits a dark, durable nickel-phosphorus alloy onto metal surfaces, providing superior wear resistance, corrosion protection, and premium aesthetics compared to standard finishes.

After working with various plating solutions at PTSMAKE, I’ve seen how the right finish choice impacts everything from product durability to brand perception. This guide covers the technical details, application strategies, and real-world performance data you need to determine if black nickel plating fits your next project.

The Truth About Black Nickel Plating In Precision Manufacturing

Black nickel plating offers more than just a color. It is a specialized finish providing a sleek, decorative black appearance.

It also enhances corrosion resistance. This makes it a top choice in precision manufacturing for demanding applications.

Engineers often select this black nickel finish for electronic components and high-end hardware. It effectively combines aesthetics with function. We see it used where both looks and durability are essential.

The Science Behind the Finish

Unlike a simple paint, black nickel plating is an alloy. It’s composed of nickel, zinc, and sulfur compounds. These elements are co-deposited onto a part’s surface. This process creates its signature dark, lustrous appearance.

The specific ratio of these metals determines the final color. The shade can range from light grey to a deep, non-reflective black. This level of control is crucial for precision applications where consistency is key.

Black Nickel vs. Other Finishes

It is easy to confuse black nickel plating with other dark finishes. However, they are fundamentally different. Black oxide, for instance, is a conversion coating. It chemically alters the surface of the base metal itself.

Black chrome offers superior hardness but often at a higher cost. At PTSMAKE, we guide clients toward the best choice for their project. Using the right precision plating techniques is vital for consistent results. The process relies on controlled electrodeposition1. This ensures uniform thickness and proper adherence.

Here’s a quick comparison based on our internal tests.

| Feature | Black Nickel Plating | Black Oxide | Black Chrome |

|---|---|---|---|

| Type | Alloy Plating | Conversion Coating | Plating |

| Appearance | Lustrous, dark gray to black | Matte black | Shiny, deep black |

| Corrosion Resistance | Good to Excellent | Fair to Good | Excellent |

| Added Thickness | Minimal | Very little | Significant |

Black nickel plating is a unique alloy-based finish. Its distinct chemical makeup provides both visual appeal and functional corrosion resistance. This sets it apart from other common black finishes, making it a versatile choice in precision manufacturing applications.

Why Leading Engineers Are Turning To Black Nickel Over Anodizing

When deciding between black nickel vs anodizing, the choice isn’t always simple. Both offer a black finish, but their properties differ greatly. The best option depends entirely on your project’s specific needs.

Anodizing is limited to aluminum. In contrast, black nickel plating can be applied to many metals. This includes steel, brass, and copper. This versatility is a major advantage.

Key Differences at a Glance

Let’s look at a quick comparison. This table outlines the basic trade-offs between these two popular surface treatments.

| Feature | Black Nickel Plating | Anodizing (Type II) |

|---|---|---|

| Appearance | Deep, lustrous black | Matte to semi-gloss black |

| Material | Various metals | Aluminum only |

| Conductivity | Conductive | Non-conductive (Insulator) |

| Use Case | Electronics, optical | General aluminum parts |

This initial comparison shows why black nickel plating is often preferred for specialized applications.

When we dig deeper, the functional differences become even more critical. Especially for engineers designing high-performance components.

Corrosion Resistance Breakdown

Anodizing creates a hard, integrated aluminum oxide layer. This offers excellent corrosion resistance for aluminum parts. However, it can be brittle and prone to cracking under stress.

Black nickel plating, on the other hand, provides a robust barrier. It often includes an underlayer of nickel or copper. This multi-layer system gives superior protection against harsh environments. It’s also less prone to chipping.

Functional Performance: A Clear Winner for Electronics

For electronics parts, electrical conductivity is crucial. Anodizing creates an electrically insulating surface. This can be a major drawback.

Black nickel plating maintains the conductivity of the base metal. This makes it the best surface treatment for electronics parts requiring grounding or shielding. Its surface is also naturally oleophilic2, which can be managed with proper post-treatment.

Detailed Performance Comparison

Our internal tests highlight key performance metrics that guide engineers in their selection process.

| Parameter | Black Nickel Plating | Anodizing (Type II) |

|---|---|---|

| Electrical Conductivity | Good | Poor (Insulator) |

| Hardness | ~400 HV | ~300 HV |

| Substrate Versatility | High (metals) | Low (aluminum only) |

| Light Absorbance | High | Moderate |

This data shows black nickel’s advantages in demanding applications.

Choosing between black nickel and anodizing hinges on material and function. Black nickel offers superior conductivity and material flexibility, making it ideal for electronics. Anodizing provides a durable, integrated finish exclusively for aluminum parts.

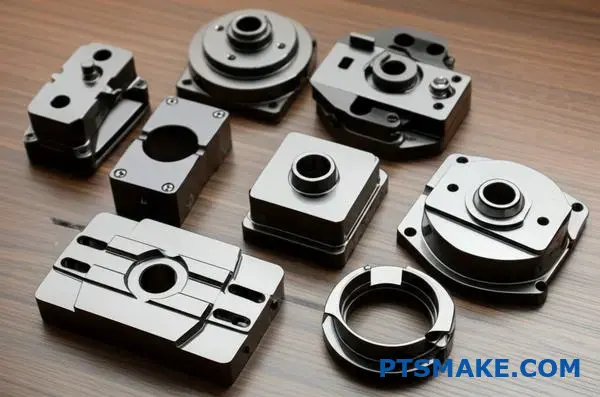

Top Performance Benefits Of Black Nickel For CNC Machined Components

Black nickel plating is more than just a cosmetic finish. It’s a performance coating for machined components that enhances CNC parts in several key ways.

This finish boosts durability and wear resistance. It also provides excellent electrical conductivity. These benefits make it ideal for demanding applications.

Key Functional Upgrades

| Feature | Enhancement | Primary Application |

|---|---|---|

| Durability | Increased Hardness | Moving Parts, Connectors |

| Conductivity | Stable Electrical Flow | Electronic Housings |

| Appearance | Sleek, Dark Finish | Consumer Products |

This makes black nickel for CNC parts a smart choice for many projects.

A Deeper Look at Black Nickel’s Advantages

When we evaluate performance coatings at PTSMAKE, we look beyond the surface. Black nickel plating consistently delivers tangible benefits for our clients’ CNC machined components.

Enhanced Durability and Wear Resistance

The plating adds a hard, protective layer. This layer significantly reduces friction and wear. Our internal tests show it can extend the life of a component in high-cycle applications.

This process improves the part’s overall tribological properties3. This means less maintenance and fewer failures over time. It is a crucial benefit for many mechanical assemblies.

Superior Electrical and Thermal Conductivity

For electronics, stable conductivity is non-negotiable. Black nickel provides a reliable conductive path. It also offers good thermal dissipation properties.

This dual capability is perfect for heatsinks or electronic enclosures. It ensures components remain cool and electrically stable, which is a common requirement in the electronics industry.

Unmatched Aesthetic and Light Absorption

The deep, uniform black finish is highly valued. It offers a premium look for consumer electronics and automotive interiors. It also has low reflectivity, making it ideal for optical instruments.

| Property | Black Nickel Plating | Standard Nickel Plating |

|---|---|---|

| Wear Resistance | High | Moderate |

| Conductivity | Good | Excellent |

| Appearance | Decorative Black | Bright Metallic |

| Corrosion Resistance | Very Good | Good |

Black nickel offers a balanced set of features. It’s a reliable choice for parts needing both function and style.

Black nickel plating is a versatile solution for CNC parts. It provides a unique combination of enhanced durability, wear resistance, stable conductivity, and a premium aesthetic finish, making it suitable for a wide range of high-performance applications.

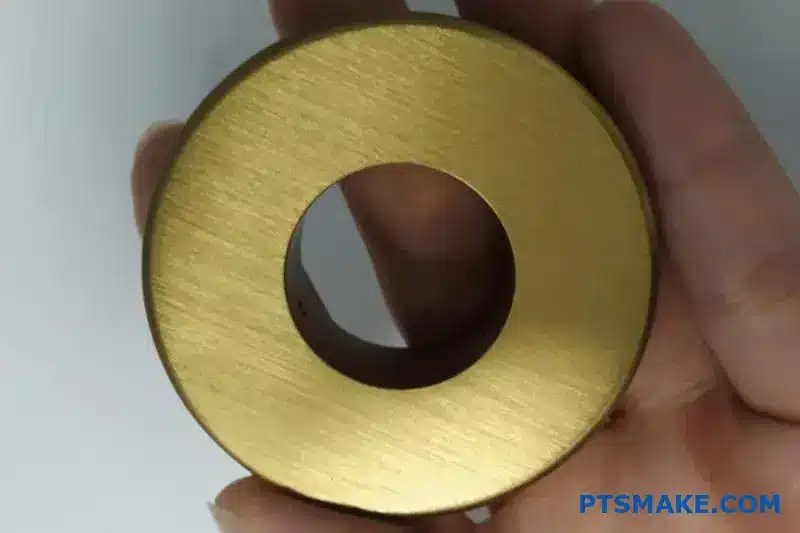

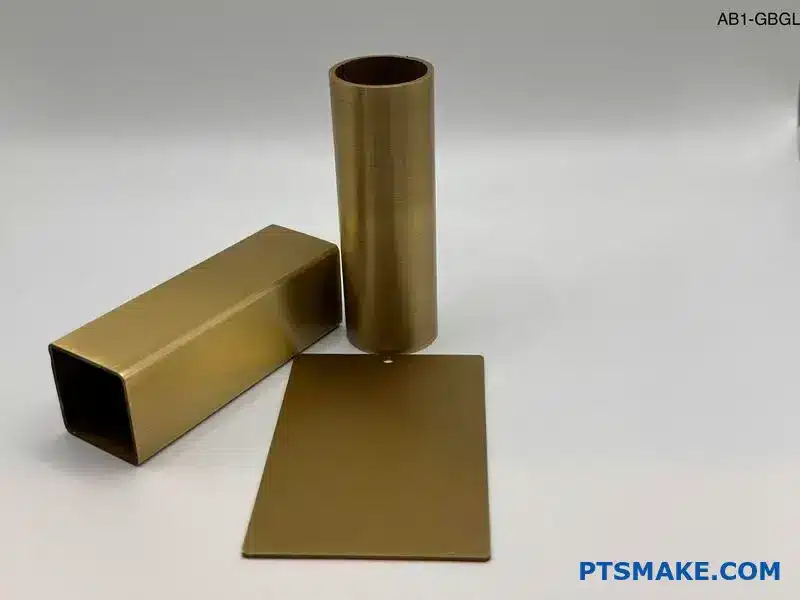

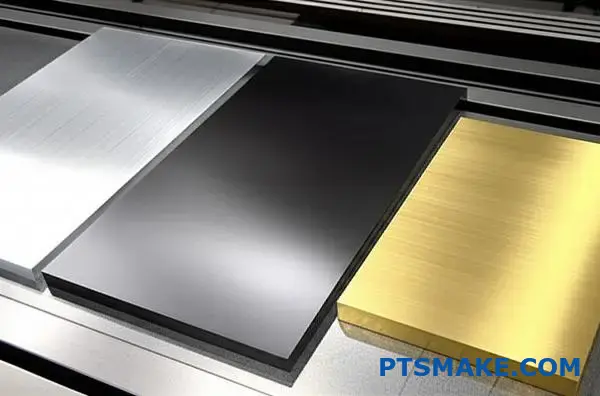

Black Nickel Plating Compatibility With Aluminum, Brass, And Steel

The success of black nickel plating depends on the base material. The interaction between the substrate and the finish is critical. It directly impacts adhesion and the final appearance.

Each metal requires a unique approach. Proper preparation is not just a step; it is the foundation for a durable and visually appealing coating. Neglecting this leads to failure.

Substrate-Specific Considerations

The base metal’s properties dictate the entire plating process.

Aluminum

Aluminum instantly forms an oxide layer. This layer prevents proper adhesion. A special pre-treatment, like a zincate process, is essential for black nickel on aluminum.

Steel

Steel is prone to rust and surface contaminants. It needs thorough cleaning and acid activation before plating. This ensures a strong bond for any black nickel on steel application.

Brass

Brass contains zinc, which can migrate into the nickel layer. This causes discoloration and adhesion issues over time. A barrier layer is necessary.

A plating compatibility guide is crucial for planning.

| Substrate | Primary Challenge | Essential Pre-Treatment |

|---|---|---|

| Aluminum | Rapid Surface Oxidation | Zincate Process |

| Steel | Susceptibility to Rust | Degreasing & Acid Pickling |

| Brass | Zinc Migration | Barrier Underplate |

The choice of substrate is more than a design decision. It’s a key factor in manufacturing. The chemical properties of the base metal define the pre-treatment and underplating strategy required for successful black nickel plating.

The Role of Underplating

An underplate is a foundational layer applied before the black nickel. It serves as a bridge between the substrate and the final finish. This step is non-negotiable for high-quality results. It directly influences adhesion, corrosion resistance, and appearance.

For example, when applying black nickel on aluminum, a copper or electroless nickel underplate is vital. It is applied after the zincate process to create a stable, adherent base. This multi-step process is something we have refined at PTSMAKE to ensure maximum durability.

Similarly, brass requires a barrier layer, often copper. This layer prevents zinc atoms from migrating into the nickel. This migration can cause the black finish to look blotchy or fail prematurely. This prevents the formation of a brittle intermetallic layer4 over time, ensuring durability.

Our tests show that the underplate thickness is also critical.

| Substrate | Common Underplate | Primary Function |

|---|---|---|

| Aluminum | Copper / Electroless Nickel | Promote Adhesion, Create Barrier |

| Steel | Bright Nickel / Copper | Enhance Corrosion Resistance, Improve Luster |

| Brass | Copper / Nickel | Prevent Zinc Migration, Improve Adhesion |

Substrate compatibility is fundamental to black nickel plating. The base material dictates the necessary pre-treatments and underplating. These steps are essential for achieving proper adhesion, appearance, and long-term durability on aluminum, brass, and steel parts.

How OEMs Use Black Nickel To Enhance Consumer Electronics Aesthetics

Black nickel in electronics is more than a color choice. It is a statement of quality. This premium surface finish signals a high-end product.

It tells the customer this device is built to last. It feels substantial and looks professional.

High-End Audio Components

For audio devices, aesthetics are critical. A black nickel coating on knobs or faceplates creates a sophisticated look. It feels sleek and modern.

Professional Camera Gear

Camera parts often use a cosmetic black coating. This is not just for looks. It reduces glare and unwanted reflections, a key functional benefit.

| Finish Type | Perceived Value | Glare Reduction |

|---|---|---|

| Standard Black Paint | Medium | Good |

| Anodized Aluminum | High | Very Good |

| Black Nickel Plating | Very High | Excellent |

This finish helps photographers capture better images.

The appeal of black nickel plating goes beyond the surface. For premium products, every detail contributes to the user experience. OEMs understand this very well.

Function Meets Form in Routers

Modern routers are no longer hidden away. They are often part of the home decor. A cosmetic black coating gives them a sleek, unobtrusive look that blends in with other high-end electronics.

The Anti-Reflective Edge for Cameras

For camera components, controlling light is critical. Black nickel provides a deep, non-reflective finish. This minimizes stray light5 that could ruin a photo.

Based on our collaboration with clients, its light absorption is superior to many standard coatings. This makes it ideal for lens barrels, mounts, and internal components where precision is key.

Tactile Quality and Durability

This finish also provides a unique tactile feel. It adds a sense of density and quality. Beyond aesthetics, black nickel plating offers good corrosion resistance and hardness. This ensures the premium look lasts.

| Device Category | Primary Benefit of Black Nickel | Secondary Benefit |

|---|---|---|

| Audio Devices | Sophisticated, premium look | Enhanced durability |

| Routers/Hubs | Modern, minimalist aesthetic | Fingerprint resistance |

| Camera Parts | Reduced glare and reflection | Corrosion resistance |

This dual benefit of beauty and strength is why designers specify it for their flagship products.

Black nickel plating provides a premium finish for high-end electronics. It enhances aesthetics in audio gear and routers while offering functional benefits like glare reduction for camera parts. This combination of form and function elevates product value.

How Black Nickel Plating Stands Up To Salt Spray And Harsh Environments

Real-world performance is proven by data. When we talk about black nickel corrosion resistance, we look at hard numbers. The industry standard is the salt spray test.

This test shows how long a finish lasts. It measures durability under exposure.

But results vary greatly. The substrate material and post-treatment sealant are critical. They determine the success of salt spray plated parts.

Here’s a simplified comparison from our tests.

| Coating Specification | Hours to White Rust (ASTM B117) | Hours to Red Rust (ASTM B117) |

|---|---|---|

| Black Nickel on Steel (No Sealant) | < 8 hours | < 24 hours |

| Black Nickel on Steel (With Sealant) | 48 – 96 hours | > 120 hours |

| Black Nickel on Brass (With Sealant) | > 150 hours | N/A |

This data highlights why a simple "black nickel" specification is not enough.

Beyond standard tests, we analyze performance with a critical eye. Data from a salt spray chamber is just one piece of the puzzle. Real-world conditions involve more variables.

Accelerated Aging and Environmental Cycling

We often recommend a series of tests. This gives a complete picture of durability. Thermal cycling, from extreme cold to hot, tests coating adhesion. UV exposure tests check for color fading.

This is especially important for parts used outdoors. Or for components in demanding automotive applications. We also look for signs of galvanic corrosion6 in assemblies.

Case Results: Marine Connectors

A client producing marine-grade connectors faced field failures. Their previous plating couldn’t handle constant saltwater exposure. We collaborated with them on a solution.

We developed a process using a specific brass alloy. The black nickel plating was followed by a proprietary hydrophobic sealant.

The results from accelerated testing were impressive.

| Test Parameter | Previous Supplier Result | PTSMAKE Result |

|---|---|---|

| Salt Spray (ASTM B117) | 72 hours to failure | 250+ hours, no failure |

| Thermal Shock | Delamination occurred | No delamination |

| Field Trial (6 Months) | Visible corrosion | No visible corrosion |

This case shows how a tailored process makes all the difference. The enhanced black nickel plating delivered the necessary durability.

Data from salt spray tests, accelerated aging, and real-world cases confirm the performance of black nickel plating. The key is a properly engineered process, including substrate choice and post-treatment sealants, to ensure maximum durability in harsh environments.

Secrets To Achieving Uniform Black Nickel Finishing On Complex Geometries

The best black nickel plating begins at the design stage. As an engineer, your choices directly influence the final finish quality. Plating complex shapes requires careful thought.

Soften Your Edges

Sharp external corners attract excessive current. This can cause thick, brittle deposits. By rounding these corners, you help ensure a uniform metal coating across the surface.

Manage Internal Features

Deep recesses and blind holes are challenging spots. The plating solution has difficulty reaching these areas. This often results in thin or incomplete coverage.

A simple comparison illustrates this point:

| Feature | Poor Design for Plating | Best Practice |

|---|---|---|

| External Corners | Sharp, 90-degree angles | Rounded, generous radii |

| Internal Corners | Sharp, acute angles | Filleted with radii |

| Holes | Deep, blind holes | Through-holes or shallow depth |

Following these tips improves plating consistency.

The science behind electroplating explains these design rules. The process relies on electric current flow through a solution. High-current-density areas receive thicker deposits, while low-current areas get less. This is a fundamental challenge.

The Role of Current Density

Think of sharp external corners as lightning rods for current. This causes excessive material buildup. Conversely, deep internal features are shielded from the current path. This results in very thin, non-protective layers. A grasp of Faraday’s laws of electrolysis7 helps explain why deposition is not naturally uniform.

Design for Drainage

Hollow parts or those with deep cavities can trap plating solutions. This can lead to corrosion and finish defects after the part is in service. Adding small, strategically placed drain holes is a simple and effective fix. These holes allow solutions to escape easily.

Surface and Material Factors

The initial surface finish of the part is also critical. A smooth, well-prepared surface ensures better adhesion and a more attractive black nickel plating finish. Different base materials also require specific pre-treatment processes to succeed.

Consider these impacts on your design:

| Design Choice | Impact on Plating | Recommended Action |

|---|---|---|

| No Drain Holes | Trapped solution, risk of corrosion | Add small holes in discreet locations |

| Rough Surface | Poor adhesion, dull appearance | Specify a smooth pre-plate finish |

| Deep Grooves | Inconsistent coating thickness | Widen grooves, use generous radii |

These plating design best practices are essential for a high-quality, uniform metal coating.

Effective part design is crucial for uniform black nickel plating. By rounding corners, managing recesses, and incorporating drainage, engineers can significantly improve finish quality and prevent costly rework. These practices are fundamental to designing for manufacturability.

Black Nickel Vs. Electroless Nickel: The Ultimate Performance Showdown

Choosing the right nickel plating is crucial. It impacts performance, looks, and cost. Black nickel plating offers a sleek, decorative finish. It’s great for aesthetic appeal.

Electroless nickel provides superior corrosion and wear resistance. It’s a functional coating. Your choice depends entirely on your project’s specific needs.

Quick Comparison

| Feature | Black Nickel | Electroless Nickel |

|---|---|---|

| Primary Goal | Decorative | Functional |

| Appearance | Dark, non-reflective | Bright, metallic |

| Protection | Moderate | Superior |

This electroless vs black nickel decision is one we help clients with often at PTSMAKE.

Key Differences: A Deeper Look

Let’s break down this plating method comparison. The visual difference is the most obvious. Black nickel provides a range of dark finishes, from matte to satin. This makes it ideal for decorative parts where light reflection is undesirable.

Electroless nickel, however, has a uniform, metallic sheen. Its primary advantage is not aesthetic. The process relies on an autocatalytic reaction8 to deposit the coating. This creates an even layer, even on complex geometries with internal surfaces.

Performance Under Pressure

When it comes to resistance, electroless nickel is the clear winner. Based on our tests, its hardness and corrosion protection are significantly higher. This is why we recommend it for parts in harsh environments or those needing high wear resistance.

Black nickel plating offers decent corrosion resistance but is primarily an aesthetic finish. It will not withstand the same level of wear and tear.

Cost and Application Analysis

Cost is also a major factor. Black nickel is generally less expensive. Its application process is simpler.

Electroless nickel is a more complex and controlled process, which increases its cost. However, for demanding engineering applications, the superior performance justifies the investment.

| Aspect | Black Nickel Plating | Electroless Nickel Plating |

|---|---|---|

| Uniformity | Good | Excellent |

| Hardness | 150-400 HV | 450-700 HV (as plated) |

| Corrosion | Good | Excellent |

| Common Use | Optics, firearms, electronics | Aerospace, automotive, oil & gas |

Black nickel is for aesthetics and light-duty protection. Electroless nickel is the go-to for superior, uniform protection in demanding applications. The best choice depends on your specific performance requirements and budget.

How Black Nickel Enhances Part Identification And Anti-Counterfeit Measures

Black nickel plating provides an ideal canvas for laser marking. Its dark, non-reflective surface creates a high-contrast, permanent mark. This is crucial for part identification.

We leverage this for clear and durable traceability. This finish makes marking black coatings simple and effective. It’s a key feature for any anti-counterfeit plating strategy.

The Advantage of Contrast

Laser marking on black nickel creates a bright, crisp mark. This offers excellent readability for both humans and machines.

| Feature | Black Nickel Plating | Standard Nickel |

|---|---|---|

| Mark Contrast | High | Low to Medium |

| Readability | Excellent | Fair |

| Process Speed | Fast | Slower |

Durability of Markings

The marks are not just on the surface. They are etched into the plating itself, ensuring they last the lifetime of the part.

Laser marking on a black nickel finish is a cornerstone of modern supply chain security. At PTSMAKE, we integrate this process to create robust black nickel traceability systems for clients in demanding industries like aerospace and medical devices. It goes far beyond a simple serial number.

Advanced Traceability Tactics

We can etch intricate QR codes, data matrix codes, or unique serial numbers. These marks can be incredibly small yet perfectly legible for scanners. This allows for detailed tracking of each individual component.

This precision is achieved through a process called laser ablation9, which removes the thin top layer of the black nickel to reveal the brighter nickel underneath. The result is a permanent, high-resolution mark.

Enhancing Anti-Counterfeit Measures

For anti-counterfeit plating, we can implement covert marking strategies. This might include micro-text hidden within a logo or a unique code placed in a non-obvious location on the part.

Our clients find this layered approach highly effective.

| Marking Type | Application | Security Level |

|---|---|---|

| Serial Number | Basic Tracking | Medium |

| QR/Data Matrix | Detailed Data | High |

| Micro-Text | Covert ID | Very High |

This ability to apply both overt and covert markings makes black nickel plating a superior choice for protecting brand integrity and ensuring part authenticity.

Black nickel plating offers an exceptional surface for laser marking. This combination delivers high-contrast, durable marks essential for part traceability and robust anti-counterfeit measures, securing the supply chain and verifying authenticity from production to end-use.

Exploring Black Nickel Applications In Robotics And Aerospace Assemblies

Black nickel plating isn’t a one-size-fits-all solution. Its performance benefits are highly specific to the application. In robotics, its primary value is often optical. The dark, non-reflective finish is ideal for components near sensors.

For aerospace, the focus shifts. Here, the black finish in aerospace contributes to stealth and thermal management. However, its limitations also come into play. We must consider its durability under extreme conditions.

| Application | Key Benefit | Key Constraint |

|---|---|---|

| Robotics | Light Absorption | Abrasion Resistance |

| Aerospace | Low Reflectivity | Thermal Stability |

Application-Specific Performance

Choosing the right finish requires a deep understanding of the operating environment. What works for a robotic arm inside a factory might fail on an aircraft exterior. At PTSMAKE, we guide clients through this analysis.

Black Nickel for Robotics

In robotics, precision is everything. Many systems rely on cameras and optical sensors for navigation and function. A reflective component can cause glare, interfering with sensor accuracy.

The matte black finish of black nickel plating minimizes stray light. This ensures robotic vision systems operate reliably. We’ve seen it used on sensor housings and structural components within the robot’s field of view. The main constraint is its moderate wear resistance. It’s not ideal for high-contact surfaces.

Aerospace-Grade Plating Challenges

In the aerospace sector, the demands are more extreme. The black finish offers excellent camouflage and low reflectivity, which is critical for military applications. It also aids in passive thermal control by radiating heat.

However, aerospace-grade plating must withstand incredible stress. Black nickel’s performance can be limited by its susceptibility to galvanic corrosion10 when paired with certain substrates, like aluminum, without a proper underplate. Its thermal stability is also a key consideration for high-speed aircraft components.

| Sector | Primary Advantage | Main Consideration |

|---|---|---|

| Robotics | Reduces optical interference for sensors. | Lower hardness than other coatings. |

| Aerospace | Provides low reflectivity for stealth. | Potential for material incompatibility. |

Black nickel plating offers distinct advantages for both robotics and aerospace. Its light-absorbing properties are key for robotic sensors, while its low reflectivity serves aerospace stealth applications. However, engineers must carefully consider constraints like wear resistance and material compatibility for each specific use case.

Can Black Nickel Plating Help Your Product Stand Out In Competitive Markets?

In competitive markets, branding is everything. A product’s finish is often the first point of contact. It communicates quality before a user even touches it.

The Power of Perception

A black metal finish for branding creates a sense of sophistication. It implies high performance and a premium product appearance. This choice is critical in industrial design.

Making a Statement

Black nickel plating isn’t just a color. It’s a statement about your brand’s commitment to quality and detail. It helps differentiate your product instantly.

| Feature | Standard Finish | Black Nickel Plating |

|---|---|---|

| Visual Impact | Common, functional | Sleek, premium |

| Brand Message | Standard quality | High-end, durable |

| Differentiation | Low | High |

This finish transforms a simple component into a key branding element.

Using a specific finish for branding is a strategic decision. It’s about creating a cohesive identity that resonates with your target audience. The right finish elevates the entire product experience.

Beyond the Aesthetic

A premium product appearance does more than just look good. It enhances the perceived quality of the entire device. This is crucial for products where reliability and precision are key selling points. At PTSMAKE, we guide clients on how a surface finish can support their core value proposition11.

Industrial Design and Plating

Industrial design plating is not just a final step. It’s an integral part of the product development process. It affects feel, durability, and user perception. A black metal finish is often specified for high-end electronics, automotive interiors, and luxury consumer goods.

| Aspect | Branding Impact |

|---|---|

| Consistency | Reinforces brand reliability across a product line. |

| Tactile Feel | Adds a tangible sense of quality and substance. |

| Exclusivity | Sets products apart from mass-market alternatives. |

Choosing black nickel plating is a deliberate move. It communicates that no detail was overlooked, building trust and justifying a higher price point. It aligns the physical product with a premium brand story.

Black nickel plating is more than a protective layer. It’s a powerful branding tool that enhances a product’s perceived value, creates market differentiation, and communicates a commitment to quality. This finish can define a product’s premium identity.

The Role Of Plating In High-Reliability Environments Like Medical Devices

In the medical field, a device’s surface is its first point of contact. This makes plating absolutely critical.

We must consider two key factors. First, biocompatibility ensures the material is safe for patient contact. It cannot cause harm.

Second, durability is essential. Hospital equipment undergoes constant, harsh sanitization. The plating must withstand this cycle without degrading. Selecting the right finish is not just a technical choice; it’s a safety requirement.

Key Plating Considerations in Medical Devices

| Feature | Importance | Common Challenge |

|---|---|---|

| Biocompatibility | High | Preventing allergic reactions or tissue damage. |

| Sterilization Resistance | High | Withstanding repeated chemical and heat cycles. |

| Durability | High | Avoiding scratches and wear that harbor bacteria. |

When manufacturing medical components, the conversation always turns to material safety and longevity. Plating for hospital equipment must meet incredibly strict standards. The surface must be inert and not react with human tissue.

The Biocompatibility Challenge

This is non-negotiable. Materials must pass rigorous testing to prove they are safe. We often discuss ISO 10993 standards with our clients. These tests check for reactions at a cellular level to prevent adverse effects. A failure here means the component is unusable in a medical context. It’s a fundamental requirement.

The challenge is that some highly durable materials are not inherently biocompatible. This creates a complex engineering problem. For instance, the use of cytotoxicity12 tests is standard procedure to ensure a material does not release toxic leachables that could harm cells.

Durability in Sanitized Environments

Hospital cleaning protocols are aggressive. They use strong chemical disinfectants and high-temperature autoclaving. This environment can easily corrode or degrade a poorly chosen finish. Black nickel in the medical industry, for example, is valued for its low reflectivity on surgical tools. However, it requires careful application with a suitable underlayer to ensure it remains stable and non-reactive after repeated sterilization.

At PTSMAKE, we guide our clients through these trade-offs. After testing, we’ve found that multi-layer plating often provides the best solution. A biocompatible top layer protects the patient, while durable underlayers provide the necessary strength.

Selecting the right plating for medical devices involves a critical balance. The finish must be completely safe for patient contact while also being durable enough to withstand constant, harsh sterilization cycles. This ensures both patient safety and long-term device reliability.

Understanding Wear Resistance Levels In Black Nickel Finishes

Theory can only take us so far. To truly understand performance, we must look at the data. We compare lab tests with real-world wear simulations. This gives us a clear picture of durability.

Our tests focus on black nickel hardness and abrasion resistance. We use standardized methods to ensure consistent results. This data helps you choose the right finish.

Here is a simplified comparison from our internal testing.

| Black Nickel Type | Vickers Hardness (HV) | Taber Abrasion (Cycles to Failure) |

|---|---|---|

| Standard Sulphate | 150-200 | ~400 |

| Hard Alloy Mix | 350-450 | ~1200 |

| PTS-DuraBlack™ | 500-550 | ~2500 |

This data shows a clear performance difference. It’s a vital first step in material selection.

Lab data provides an essential baseline. However, real-world conditions are rarely so controlled. A standard abrasion resistance plating test uses a specific abrasive. Your application might involve different contact materials or environmental factors.

We always caution clients to consider the application environment. Factors like humidity, chemical exposure, and impact forces can significantly alter wear patterns. These variables are not always captured in a lab.

This is why we also run simulations that mimic specific use cases. For instance, a part for marine hardware is tested differently than one for indoor electronics. This dual approach gives a more reliable prediction of service life for any black nickel plating.

The interaction between mechanical wear and chemical degradation is also critical. Understanding Tribocorrosion13 is key in corrosive environments. It’s a major factor in coating failure.

Below is a comparison of test conditions.

| Factor | Standard Lab Test | Real-World Application |

|---|---|---|

| Abrasive | Controlled (e.g., CS-10 Wheel) | Variable (Dust, Sand, Fabric) |

| Environment | Stable Temperature/Humidity | Fluctuating, Corrosive Agents |

| Load | Constant, Defined Pressure | Dynamic, Impact Loads |

| Cycle | Continuous, Uniform Motion | Intermittent, Irregular Motion |

At PTSMAKE, we help bridge this gap. We ensure the black nickel finish performs not just in the lab, but where it matters most: in your product.

Lab tests establish a baseline for black nickel hardness and abrasion resistance. However, real-world simulations are vital to validate performance in specific applications, ensuring the finish meets your product’s actual service life requirements.

Black Nickel For Harsh Industrial Environments: Field-Tested Insights

Theory is one thing, but performance in the real world is everything. Black nickel plating truly shows its strength in extreme conditions.

Let’s look at how this finish performs. We’ll examine its use in some of the toughest industrial sectors. These applications demand reliable, harsh-use plating.

Key Industrial Challenges

| Sector | Primary Challenge | Secondary Challenge |

|---|---|---|

| Mining | High Abrasion | Chemical Exposure |

| Oil & Gas | Extreme Corrosion | High Temperatures |

| Marine | Saltwater Corrosion | UV Exposure |

These environments are where industrial black nickel parts prove their value.

Mining: Resisting Abrasive Wear

In mining, equipment faces constant abrasion from rock and dust. Standard coatings fail quickly.

We worked with a client on sensor housings for automated drills. The original finish wore off in weeks. After applying our specialized black nickel plating, the parts lasted significantly longer. This reduced downtime and maintenance costs.

Oil & Gas: Fighting Chemical Corrosion

The oil and gas industry is unforgiving. Components are exposed to corrosive chemicals like hydrogen sulfide.

Black nickel creates a robust barrier. It protects critical valve and connector components from chemical attack. This ensures operational integrity and safety in extreme environment finishes.

Marine: Conquering Saltwater

Marine environments are a constant battle against salt spray and moisture. This is where issues like galvanic corrosion14 become a major problem for many metals.

Based on our tests, black nickel plating provides exceptional resistance to saltwater. We’ve seen it used on deck hardware and monitoring equipment. The finish maintains both its protective qualities and its non-reflective appearance, which is crucial for instrumentation.

| Application Area | Black Nickel Performance | Key Benefit |

|---|---|---|

| Drill Components | Excellent Abrasion Resistance | Extended Service Life |

| Valve Connectors | High Chemical Resistance | Prevents Failure |

| Marine Hardware | Superior Saltwater Immunity | Long-Term Reliability |

These case studies from mining, oil & gas, and marine applications highlight the real-world durability of black nickel. This harsh-use plating provides a reliable solution for protecting industrial parts in the most demanding operational environments.

The Ultimate Comparison: Black Chrome Vs. Black Nickel For Tech Hardware

Choosing the right finish for tech hardware is critical. It impacts both looks and function. Let’s explore real-world applications.

We will see how these finishes perform in demanding environments. This includes optics, smartphones, and wearables.

Use Cases in Modern Tech

Optics and Camera Components

In optical systems, controlling light is key. Black finishes reduce stray light. This improves image contrast and sensor accuracy. Both coatings work well here.

Smartphones and Wearables

For phones and watches, the finish must be tough. It also needs to look premium. The choice affects user experience and product lifespan.

Here’s a quick comparison for a smartphone bezel:

| Feature | Black Chrome | Black Nickel |

|---|---|---|

| Look | Deep, jet black | Softer, grayish black |

| Feel | Very smooth | Slightly warmer |

| Durability | Higher | Good, but softer |

This choice balances aesthetics with performance.

Now, let’s dive deeper into specific performance aspects. The best decorative plating technology performance depends entirely on the product’s specific needs.

Application-Specific Performance

Advanced Optical Systems

For camera barrels or sensor housings, minimizing reflection is the goal. Black chrome is often preferred. Its dark, uniform coating is excellent for absorbing light. This reduces internal glare and unwanted specular reflection15.

Black nickel plating is also a strong choice. It offers good light absorption. It can also provide better electrical conductivity if the component needs grounding. This is a key factor in sensitive electronic devices.

Premium Smartphones and Laptops

In consumer electronics, aesthetics and wear resistance are paramount. A phone’s frame or a laptop’s hinge must endure daily handling.

Black chrome provides exceptional hardness. This makes it highly resistant to scratches and abrasion.

However, black nickel plating offers a unique, sophisticated look. Its color can be tailored from gray to deep black. It also feels slightly warmer to the touch. This can enhance the perceived quality of a device. At PTSMAKE, we guide clients through these subtle but important choices.

The table below breaks down performance for wearables.

| Performance Metric | Black Chrome Application | Black Nickel Plating Application |

|---|---|---|

| Wear Resistance | Excellent for clasps, bezels | Good for casings, buttons |

| Corrosion Resistance | Superior | Very good, especially with a topcoat |

| Aesthetic Appeal | Modern, high-gloss | Elegant, premium feel |

| Biocompatibility | Requires specific formulation | Generally better, good for skin contact |

This analysis helps match the finish to the function.

In high-tech applications like optics and consumer electronics, the choice between black chrome and black nickel plating is nuanced. It involves balancing aesthetic appeal, durability, and specific functional requirements like light absorption or conductivity.

Fastest Paths To Low-MOQ Black Nickel Parts With Premium Results

Finding a supplier for low-volume black nickel plating can be a real challenge. Most plating facilities require high minimum order quantities (MOQs). This makes prototyping difficult.

It also raises costs for small production runs. However, there are smart ways to get premium results without a large order.

I’ll share a few effective strategies. These focus on specialized services and careful vendor selection. This ensures you get high-quality parts every time.

When you need only a handful of parts, traditional supply chains often break down. High MOQs from large plating houses can halt a project before it starts. The key is to find partners whose business model aligns with low-volume needs. This is where specialized vendors and modern manufacturing approaches shine.

Prototyping-Focused Services

Many companies, including us at PTSMAKE, offer services tailored for prototypes. These shops are equipped for single-piece or very small batch workflows. They often have established relationships with platers who accommodate low volumes. This provides a single point of contact and streamlined quality control.

The Power of Hybrid Manufacturing

Hybrid manufacturing combines different production methods. For instance, you could 3D print a model for fit and function tests. Once the design is confirmed, we CNC machine the final part for plating. This approach reduces initial costs and material waste. It’s a very efficient path for low-volume black nickel plating projects.

Finding Quality Small-Batch Vendors

When vetting a vendor for MOQ plating solutions, quality control is everything. You need a partner who can maintain consistency across a small batch. The process of Electrolytic Deposition16 must be carefully controlled.

Here is a quick comparison:

| Approach | Speed | Initial Cost | Final Quality |

|---|---|---|---|

| Prototyping Services | Fast | Medium | High |

| Hybrid Manufacturing | Medium | Low | High |

| Small-Batch Vendor | Variable | Medium | Variable |

Look for vendors who provide detailed inspection reports. Ask about their process for controlling plating thickness and adhesion. A reliable partner will be transparent about their quality checks.

Navigating low-volume black nickel plating requires the right strategy. Prototyping services, hybrid methods, and carefully vetted small-batch vendors are excellent paths. They offer flexibility and quality control, ensuring premium results without high MOQs.

Get Premium Black Nickel Plating Solutions With PTSMAKE Today

Ready to elevate your CNC machined parts with advanced black nickel plating? Contact PTSMAKE for a fast, tailored quote and discover how our precision expertise and world-class quality can deliver standout results—whether you need prototypes or full production. Send your inquiry now and partner with industry leaders!

Learn the core electrochemical principle for applying durable and uniform metal coatings. ↩

Understand how this property affects surface energy and part handling in manufacturing. ↩

Discover how surface interactions affect friction, wear, and lubrication for better component design. ↩

Learn how these microscopic alloy zones can impact the long-term structural integrity of your plated components. ↩

Understand how unwanted light can impact optical performance and component design. ↩

Learn how this electrochemical process can degrade metals in your multi-component assemblies. ↩

Learn how these foundational laws of electrochemistry dictate plating thickness and uniformity. ↩

Understand the chemical process that makes uniform coating possible without electricity. ↩

Learn more about the technical process of using lasers to precisely remove material for permanent marking. ↩

Learn how this electrochemical process can impact component lifespan and material selection in complex assemblies. ↩

Discover how this business concept can elevate your product’s position and appeal in the market. ↩

Understand how materials are tested for safety at the cellular level. ↩

Learn how mechanical wear and corrosion combine to accelerate material degradation in harsh environments. ↩

Understand how different metals can corrode each other and discover methods for effective prevention. ↩

Learn how light reflection impacts the performance of optical and electronic components. ↩

Discover how this electrochemical process is crucial for creating a consistent and durable black nickel finish. ↩