Brushed metal finishes look appealing in product catalogs, but many engineers discover too late that their "premium" surface treatment creates unexpected manufacturing headaches. Your tight tolerance requirements clash with material removal during brushing, production costs spiral beyond budget projections, and what seemed like a simple aesthetic choice turns into a complex engineering challenge.

Brushed metal finish is a mechanical surface treatment that creates parallel lines or grain patterns through abrasive processes, offering both functional benefits like improved grip and wear resistance, plus the aesthetic appeal that enhances product perception in consumer and industrial applications.

This guide covers the complete engineering perspective on brushed finishes – from material selection and tolerance considerations to industry-specific applications. You’ll learn when brushed treatments solve real problems versus when they create new ones, plus practical insights for maintaining consistency from prototype through production.

Why Engineers Prefer Brushed Finishes For Functional And Aesthetic Balance

In engineering, every choice is a trade-off. This is especially true for surface finishes, where we constantly balance performance with appearance.

A polished finish looks premium but shows every scratch. A matte finish hides wear but can feel plain.

The brushed metal finish often hits the sweet spot. It provides a sophisticated look while offering practical durability. This makes the brushed metal aesthetic a key choice in functional metal finishes.

| Finish Type | Primary Benefit | Common Drawback |

|---|---|---|

| Polished | High-Gloss Look | Shows Fingerprints |

| Matte | Hides Wear | Can Look Dull |

| Brushed | Balanced | Directional Pattern |

This balance makes it a go-to solution for many teams.

The Decision Beyond the Surface

When I consult on a project, the surface finish is a critical decision point. We move beyond just how it looks. We discuss how it will be used, handled, and maintained. This is where engineering surface finish choices become strategic.

When Polished Isn’t Practical

A mirror-like polished surface is stunning on a prototype. However, in a high-touch product or an industrial setting, it’s a maintenance issue. Fingerprints and minor scuffs quickly degrade its appearance. The cost to maintain that perfection is often too high.

The Functional Advantage of Brushed Finishes

This is where a brushed metal finish excels. The fine, parallel lines are not just for show. They create a texture that effectively conceals minor imperfections like fingerprints, smudges, and small scratches. This texture gives the surface an anisotropic1 quality, meaning its properties differ along different axes.

This inherent durability reduces long-term maintenance needs, making the product look newer for longer.

| Feature | Polished Finish | Brushed Finish |

|---|---|---|

| Scratch Visibility | High | Low |

| Fingerprint Resistance | Low | High |

| Light Reflection | Specular | Diffuse |

| Perceived Durability | Low | High |

This practicality, combined with a modern aesthetic, makes it a preferred functional metal finish for everything from kitchen appliances to automotive interiors.

Choosing a surface finish means weighing aesthetics against real-world performance. A brushed metal finish offers a superior balance, delivering a refined look with practical durability that hides everyday wear. This makes it a smart engineering choice for many demanding applications.

How Brushed Metal Finish Enhances Product Durability And Wear Resistance

A brushed metal finish is more than just a visual choice. It’s a strategic decision for enhancing long-term durability.

This process introduces a fine, unidirectional texture. This texture is key to its resilience.

It effectively conceals minor scratches and fingerprints. This keeps products looking new for longer, especially in high-touch applications.

The Durability Advantage

The grain pattern isn’t just for show. It helps mask the wear and tear of daily use.

Unlike polished surfaces that highlight every flaw, a brushed finish provides a practical advantage.

| Feature | Polished Finish | Brushed Metal Finish |

|---|---|---|

| Scratch Visibility | High | Low |

| Fingerprint Marks | High | Low |

| Maintenance | High | Low |

This makes it one of the most practical wear resistant metal finishes available.

The secret to brushed metal longevity lies in the controlled abrasion process. This method removes the original surface layer, eliminating minor imperfections like pits or casting marks that could become stress points. By creating a uniform, textured surface, the finish distributes impacts and friction more evenly. This prevents localized wear.

Impact on High-Wear Environments

In applications with frequent contact, durable brushed parts truly excel. The parallel grooves help to channel away small debris and reduce the effective contact area, which lowers friction. This physical characteristic makes the surface inherently more robust. Our internal tests show that brushed aluminum panels resist visible scratching up to 30% longer than their polished counterparts. The finish is not just hiding damage; it’s actively helping to prevent it. This makes the surface’s properties anisotropic2, providing different strengths along different axes.

Brushing Grit and Durability

The choice of abrasive grit also plays a crucial role. A coarser grit creates deeper grooves, offering better scratch concealment, while a finer grit provides a smoother feel with more subtle protection.

| Grit Level | Scratch Hiding | Wear Resistance |

|---|---|---|

| Coarse | Excellent | Good |

| Medium | Good | Very Good |

| Fine | Fair | Excellent |

At PTSMAKE, we guide clients to select the optimal grit based on their product’s specific wear environment. This ensures the finish is both aesthetically pleasing and functionally sound for its intended lifespan.

The controlled abrasion of a brushed metal finish strengthens a part’s surface. It hides minor scratches and distributes wear, making it a superior choice for durable products in high-contact environments, which enhances brushed metal longevity.

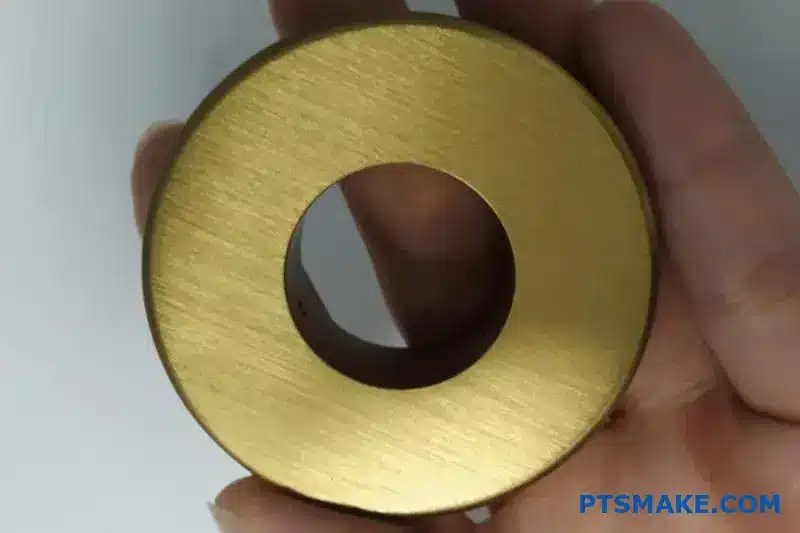

The Complete Breakdown Of Brushed Metal Types And Finishing Techniques

Different metals require unique approaches. A technique that works for steel might not be ideal for aluminum. The alloy’s hardness and composition dictate the process.

Metal-Specific Brushing

Applying the right technique is key. You can’t treat every metal the same. Understanding these differences is crucial for a quality brushed metal finish.

Below is a quick comparison. It shows how steel and aluminum respond differently to brushing.

| Metal Type | Hardness | Common Brushing Challenges | Best For |

|---|---|---|---|

| Steel | High | Heat generation, deep scratches | Durable, industrial look |

| Aluminum | Low | Gouging, smearing, softness | Decorative, clean lines |

Choosing the right abrasive and pressure is essential for achieving a consistent brushed look on any alloy.

Key Brushing Techniques Explained

The method you choose directly impacts the final appearance and texture. Each technique offers distinct advantages depending on the project goals. I’ve seen these methods applied to various parts, and the results vary significantly.

Belt Sanding

This is often the first step for aggressive material removal. It creates a coarse, linear grain. Belt sanding is great for establishing a basic directional pattern but lacks fine control for cosmetic surfaces. It’s a workhorse, not a finishing artist.

Abrasive Brushing

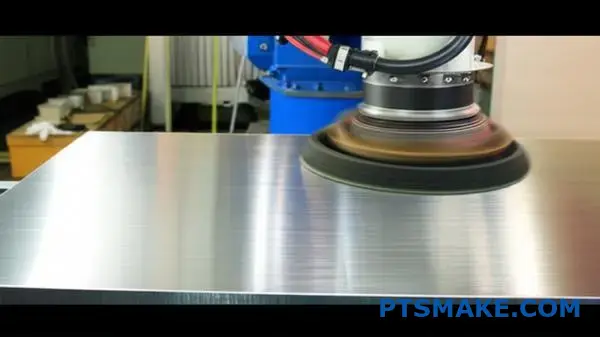

This technique uses rotating brushes with abrasive filaments. It produces a softer, more uniform brushed texture than belts. The flexibility of the bristles allows them to conform to irregular shapes, creating a consistent finish.

CNC Brushing

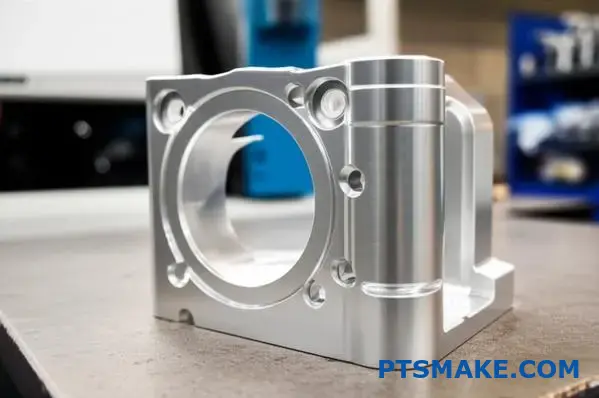

For ultimate precision, we turn to CNC brushing. At PTSMAKE, we integrate this into our machining centers. This method provides unmatched control over brush pressure, speed, and path. The result is a perfectly repeatable brushed aluminum finish or complex brushed steel techniques for high-end components. It ensures every part is identical. The process creates a distinct surface with anisotropy3.

| Technique | Precision | Speed | Common Use |

|---|---|---|---|

| Belt Sanding | Low | Fast | Initial surface prep |

| Abrasive Brushing | Medium | Medium | General purpose finishes |

| CNC Brushing | High | Varies | High-spec cosmetic parts |

The choice between these techniques depends entirely on your design intent and quality requirements.

Choosing the right metal and brushing technique is critical. Steel requires a robust approach, while aluminum needs a delicate touch. Methods like belt sanding, abrasive brushing, and CNC brushing offer different levels of precision for your desired brushed metal finish.

When Brushed Metal Makes Or Breaks A Consumer Product’s Perception

External mechanical parts are your product’s handshake. For consumer electronics or robot frames, this first impression is critical. A brushed metal finish communicates quality long before the device is even turned on.

The Visual Promise

A brushed shell visual impact suggests precision. The fine, parallel lines guide the eye and reflect light in a controlled, sophisticated way. This isn’t just decoration; it’s a statement of quality.

| Feature | Standard Plastic | Brushed Metal Finish |

|---|---|---|

| Light Reflection | Diffuse, often cheap-looking | Linear, highlights form |

| Perceived Value | Low to moderate | High, premium |

| Durability Signal | Varies, can seem fragile | Strong, resilient |

This brushed metal design choice immediately elevates a product above its competitors.

Beyond the initial visual appeal, the tactile experience of a premium metal finish is equally important. How a product feels in the hand can solidify a customer’s perception of its quality and engineering.

Tactile Quality and Perceived Durability

When a user picks up a device with a brushed metal shell, they feel its coolness and rigidity. This sensation implies a solid internal structure and durable components. It’s a subconscious signal of reliability that a plastic shell often struggles to replicate. This is a form of passive Haptic feedback4 that enhances user confidence.

This is especially true for products like high-end laptops or robotic arms. The finish must be perfect. Any inconsistency in the brushing can make the entire product feel cheap or poorly made.

Consistency is Key

We’ve learned through client projects that maintaining uniform grain direction and depth across separate parts is a major challenge. A slight deviation can disrupt the visual flow.

| Aspect | Impact on Perception | Manufacturing Note |

|---|---|---|

| Grain Consistency | Unifies the product’s design | Requires precise CNC control |

| Surface Feel | Communicates precision and care | Depends on the abrasive used |

| Edge Treatment | Prevents sharp, cheap feel | Deburring and chamfering are vital |

A well-executed brushed metal finish feels intentional and meticulously crafted, justifying a premium price point.

The look and feel of external parts define a product’s perceived value. A premium metal finish, like a brushed shell, creates a powerful visual and tactile impression that signals quality and durability to the user from their very first interaction.

Brushed Versus Polished Finish: Which One Solves Your Engineering Problem?

Choosing between a brushed and polished finish is more than an aesthetic choice. For an engineer, this decision is critical. It directly impacts performance, durability, and maintenance.

Your choice affects how a part withstands daily use.

Key Specification Criteria

A brushed metal finish offers a distinct, textured look. But its functional properties are key. The same is true for a polished metal surface comparison. Let’s break them down.

| Feature | Brushed Finish | Polished Finish |

|---|---|---|

| Hides Scratches | Good | Poor |

| Glare | Low | High |

| Maintenance | Low | High |

This simple chart helps guide initial design thoughts.

A common mistake I see is selecting a finish based on a CAD rendering. This view often overlooks real-world conditions. What looks perfect on screen can fail quickly in the field. The brushed vs polished metal debate is really about application performance.

Common Application Misalignments

Engineers must consider the product’s entire lifecycle. A poor choice at this stage can lead to customer issues and costly warranty claims down the line.

Overlooking Wear and Tear

A high-gloss polished finish on a frequently handled product looks premium at first. But it shows every fingerprint and scratch. A brushed metal finish is far more forgiving. It effectively hides minor imperfections from daily use.

Ignoring Environmental Factors

In marine or corrosive settings, a polished surface can be superior. Its smooth, non-porous nature better resists contaminants. A brushed finish has fine grooves. These can trap moisture, potentially accelerating corrosion if not specified correctly.

The directional grain of a brushed surface creates a unique visual effect. This property, known as anisotropy5, also affects how light reflects and how the part is perceived.

Here is a look at typical application matches:

| Application Area | Recommended Finish | Rationale |

|---|---|---|

| Architectural Panels | Brushed | Hides dust, low glare |

| Medical Instruments | Polished | Easy to sterilize, non-porous |

| Kitchen Appliances | Brushed | Resists fingerprints, hides wear |

| Luxury Automotive Trim | Polished | High-gloss, premium appearance |

The choice between a brushed and polished metal finish is a technical one, not just cosmetic. It requires analyzing wear patterns, environmental exposure, and long-term maintenance to ensure the part performs as specified throughout its intended service life.

Understanding Brushing Direction: Vertical, Horizontal, And Cross Patterns

Directional brushing is a fundamental technique in achieving a classic brushed metal finish. It involves creating fine, parallel lines across a metal surface in a single, consistent direction.

This process defines the surface texture orientation. It’s a simple concept with a significant visual impact.

The Visual Effect of Direction

The direction of the brush lines controls how light reflects. This creates a sense of movement and dimension. A vertical pattern can make a part seem taller, while a horizontal one can make it appear wider.

| Brushing Direction | Primary Visual Effect | Common Perception |

|---|---|---|

| Vertical | Elongates the surface | Height, Strength |

| Horizontal | Widens the surface | Stability, Breadth |

This control over light and perception is why the linear brushing direction is so important in product design.

The choice of brushing direction is rarely just about looks. It’s a deliberate decision that balances aesthetics with functional requirements, a conversation I often have with clients at PTSMAKE. Different industries prioritize different outcomes.

Functional vs. Aesthetic Applications

A directional brushed metal finish serves distinct purposes depending on the product’s final use. The application dictates the best path for the brushing.

Aerospace and Industrial Parts

In aerospace, function is paramount. The surface texture orientation can influence factors like fluid dynamics or the adhesion of coatings. A specific grain direction may be required to align with structural stresses, ensuring maximum component integrity and performance under demanding conditions.

Consumer Electronics and Appliances

For consumer products, aesthetics often drive the decision. The goal is to create a premium feel. Directional lines guide the user’s eye, highlight features, and give the product a sleek, modern appearance. This controlled reflection creates visual anisotropy6, making the finish appear different from various angles.

| Industry | Primary Goal | Brushing Direction Driver |

|---|---|---|

| Aerospace | Performance, Durability | Engineering specifications |

| Consumer Devices | Aesthetics, Perceived Value | Industrial design intent |

Directional brushing creates a uniform grain that manipulates light for specific visual effects. The chosen path—vertical or horizontal—depends heavily on the industry, balancing functional needs in aerospace with aesthetic goals in consumer electronics to achieve the desired brushed metal finish.

Designing For Manufacturability With Brushed Metal Requirements

A great brushed metal finish begins at the design stage. Simple DFM choices are crucial. They determine if the final part looks premium or flawed. We’ll focus on a few key areas.

Designing Brush-Friendly Edges

Edge treatment is critical for a uniform finish. Sharp internal corners are difficult to brush consistently. Always consider how the abrasive tool will access surfaces.

| Feature | Recommended | Avoid |

|---|---|---|

| Internal Corners | Generous Radius | Sharp 90° Angle |

| External Edges | Slight Chamfer/Radius | Sharp, Burr-Prone Edge |

A well-planned design makes manufacturing smoother. It directly improves the final brushed metal finish quality.

Achieving a flawless brushed finish requires thinking like a machinist. The process relies on direct, consistent contact with an abrasive. If a tool cannot reach a feature, that feature cannot be brushed properly. This is a core principle of DFM for brushed metal.

Managing Deep Pockets and Cavities

Deep, narrow pockets are challenging. The brushing wheel or belt often cannot reach the bottom corners. This results in an inconsistent finish inside the pocket. A wider, shallower pocket is always a more manufacturable design choice.

Raised and Recessed Features

Raised lettering or logos can be tricky. Sharp vertical walls are difficult to brush evenly. The top surface gets a good finish, but the sides are often missed. This creates a visual disconnect. The material’s anisotropy7 becomes very apparent with poor brushing.

DFM Tips for Lettering

| Feature Type | Best Practice | Rationale |

|---|---|---|

| Raised Text | Use angled sides (draft) | Allows abrasive tools better access |

| Recessed Text | Wide and shallow engraving | Ensures the tool can reach the base |

| Font Choice | Sans-serif, simple fonts | Complex serifs are hard to finish uniformly |

These small adjustments create a truly brushed friendly design. They ensure the final part matches your aesthetic intent. We’ve found that collaborating on these details early on prevents costly rework later.

Effective DFM for brushed finishes focuses on tool access. Designing with generous radii, shallow pockets, and accessible lettering is key. This approach ensures a consistent, high-quality, and manufacturable metal finish that meets both aesthetic and functional requirements.

How Tolerance And Brushed Finish Interact During CNC Fabrication

A brushed metal finish is more than just a cosmetic touch. It’s a subtractive process. It actively removes a thin layer of surface material.

Understanding Surface Material Removal

This might seem minor. But for parts with tight tolerances, this removal is critical. Medical and aerospace components often demand precision that can be affected by finishing.

The Balancing Act

The key is to account for this material loss. We must factor it into the initial CNC machining dimensions. This ensures the final part is within spec after the brushed metal finish is applied.

| Brush Grit | Typical Material Removal (per side) |

|---|---|

| Coarse (80-120) | 0.0005" – 0.001" |

| Medium (150-180) | 0.0002" – 0.0005" |

| Fine (220-320) | 0.0001" – 0.0002" |

For industries like aerospace and medical, every micron matters. The interaction between a brushed finish and CNC tolerance isn’t just a detail; it’s a core manufacturing challenge. Overlooking it leads to parts that fail inspection.

Pre-Compensation in Machining

At PTSMAKE, we address this head-on. Our strategy is to pre-compensate during the CNC machining stage. We machine the part slightly oversized. The amount depends on the specific brushed metal finish required.

This deliberate step ensures that after the brushing process removes material, the component’s final dimensions are perfectly within the specified tolerance range. It requires close collaboration between our machining and finishing departments. The type of abrasive media8 used in the brushing process also plays a significant role in determining the amount of material removed.

Finish vs. Tight Tolerance: A Critical Choice

In some cases, a brushed finish might not be suitable for features with extremely tight tolerances. We work with clients to analyze these trade-offs.

| Finishing Method | Tolerance Impact | Best For |

|---|---|---|

| Brushing | Low to Medium | Aesthetics, non-critical surfaces |

| Polishing | Low | High-gloss, smooth surfaces |

| Anodizing (Type II) | Very Low | Corrosion resistance, color |

| Electropolishing | Very Low | Medical-grade smoothness, deburring |

Understanding these nuances is crucial for success in precision manufacturing.

A brushed metal finish removes surface material, which directly impacts final part tolerances. This effect is especially critical in precision industries and must be accounted for by adjusting initial machining dimensions to ensure the part remains within specification.

Discover Which Industries Rely Heavily On Brushed Metal For Performance And Prestige

A brushed metal finish offers more than just aesthetic appeal. For many high-tech industries, it is a critical performance feature.

It provides enhanced durability and reduces glare. These are vital characteristics in demanding operational environments. Let’s explore the key sectors where this functional finish is indispensable.

Performance-Driven Applications

Industries such as aerospace and medical devices prioritize function. The practical benefits of a brushed metal finish often outweigh its visual style. This makes it a crucial factor during material selection.

Key Sector Benefits

| Industry | Primary Benefit |

|---|---|

| Aerospace | Glare Reduction |

| Medical | Sterilizability & Grip |

| Robotics | Sensor Compatibility |

| Electric Vehicles | Durability & Weight |

This shows how function, not fashion, drives the decision.

The brushed metal markets extend far beyond consumer products. These advanced applications are governed by strict engineering requirements. My work often involves providing solutions for these demanding sectors.

Aerospace and Defense

In an aircraft cockpit, glare is a serious safety hazard. That’s why aerospace brushed aluminum is standard for control panels and instruments. Its non-reflective surface prevents reflections that could distract pilots. The finish also effectively hides minor scratches from daily use.

Medical Technology

Surgical instruments must be easy to clean and handle. A brushed stainless steel finish provides a secure grip for surgeons, even with gloves. The surface texture resists bacterial adhesion and withstands repeated, harsh sterilization cycles much better than polished alternatives.

Robotics and Automation

Many robotic systems rely on optical sensors for navigation and function. Highly polished surfaces can create specular reflections that confuse these sensors. A brushed metal finish diffuses light, a property related to Anisotropic Reflectance9, ensuring sensor data remains accurate and reliable.

Electric Vehicles (EVs)

EV interiors must blend a premium feel with efficiency. Brushed automotive panels on dashboards and consoles achieve a luxury look without adding significant weight. They are also incredibly durable, resisting wear in high-touch areas. At PTSMAKE, we machine these components to precise client specifications for both performance and fit.

| Sector | Specific Example | Performance Advantage |

|---|---|---|

| Aerospace | Cockpit instrument panels | Reduces pilot-distracting glare |

| Medical | Scalpels and forceps | Enhances grip and simplifies sterilization |

| Robotics | Sensor mounting brackets | Minimizes light scatter for accurate readings |

| EVs | Interior trim and handles | Provides durability with a lightweight, premium look |

For these leading industries, a brushed metal finish is an engineered solution. It directly enhances safety, reliability, and functionality. Performance, not just prestige, drives its adoption in critical applications from aerospace cockpits to the operating room.

Does Brushing Ruin Surface Tolerance in Precision Parts?

A common fear I encounter is that a brushed metal finish will ruin tight tolerances. This is a major concern for parts in aerospace or automotive sectors. People believe the process is too aggressive for high-precision components.

This is a myth rooted in a misunderstanding of the process. It’s not about aggression; it’s about control.

The Myth vs. Reality

Uncontrolled brushing can indeed alter dimensions. However, modern techniques are incredibly precise. They are designed to enhance appearance without compromising function, especially for brushed metal precision components.

| Aspect | Uncontrolled Brushing (Myth) | Controlled Brushing (Reality) |

|---|---|---|

| Material Removal | Significant, unpredictable | Minimal, highly controlled |

| Tolerance Impact | Negative, ruins fit | Negligible, within spec |

| Process Goal | Aggressive cleaning | Aesthetic refinement |

Proper brushing is a finishing touch, not a machining operation. It doesn’t lead to flaws in tight-fit parts.

Let’s break down why this myth about tight tolerance brushing persists. The issue isn’t the brushing itself, but the application of the technique. When done incorrectly, it can be detrimental. But when it’s part of a controlled manufacturing plan, it’s perfectly safe.

Key Control Factors in Brushing

At PTSMAKE, we manage several variables to ensure a perfect brushed metal finish without affecting component integrity. We focus on consistency. The goal is to maintain the part’s dimensional stability10 while achieving the desired look.

Parameter Management

Success depends on precise control over the brushing parameters. Based on our internal testing, even minor changes can have a significant impact. We’ve refined these settings for different materials.

| Parameter | Low Impact Setting | High Impact Setting |

|---|---|---|

| Abrasive Grit | Fine (e.g., 240+) | Coarse (e.g., 80) |

| Contact Pressure | Light | Heavy |

| Speed | High | Low |

| Duration | Short | Long |

By mastering these elements, we can apply a beautiful brushed finish. This is true even for parts with tolerances measured in microns. For aerospace and automotive clients, this precision is non-negotiable. They need parts that fit perfectly every time. Controlled brushing delivers on that need.

The idea that brushing compromises tight tolerances is outdated. With modern, controlled techniques, a brushed metal finish can be safely applied to high-precision components without affecting their critical dimensions or fit. It is a matter of expertise, not a limitation of the process itself.

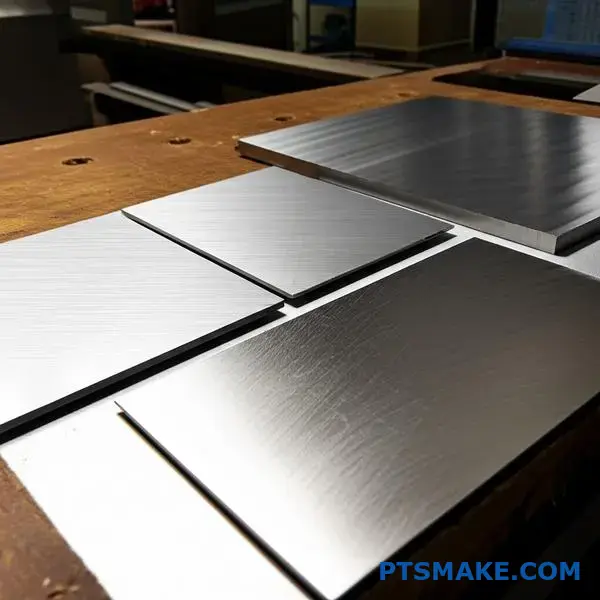

Choosing The Right Grit Level For Your Brushed Finish Application

Selecting the right grit is crucial for your brushed finish. The grit number defines the coarseness of the abrasive used. A lower number means fewer, larger abrasive particles. This creates a rougher texture.

A higher number indicates more, smaller particles. This results in a finer, smoother finish. Understanding this relationship is the first step. It directly impacts the final look and feel of your part.

Understanding Grit Numbers

The number corresponds to the number of abrasive particles per square inch.

| Grit Level | Texture Description | Common Use Case |

|---|---|---|

| 80 Grit | Coarse, very visible lines | Hiding surface defects, industrial look |

| 120 Grit | Medium, distinct lines | General purpose, appliances |

| 240 Grit | Fine, soft, subtle lines | Decorative, consumer electronics |

| 320+ Grit | Very Fine, satin-like | High-end architectural, luxury goods |

This choice affects everything from reflectivity to how the part handles daily wear.

The metal surface grit level you choose is a balance of aesthetics and function. It’s not just about looks. The texture influences how light reflects and how the surface resists fingerprints or scratches.

Impact on Texture and Reflectivity

A low grit, like 80, creates deep grooves. This gives a rugged, industrial brushed aluminum texture. The surface scatters light significantly, resulting in a very matte, non-reflective appearance. This can be great for hiding imperfections from prior manufacturing steps.

As you move to a higher grit, the lines become shallower and closer together. A brushed grit 240 finish, for instance, offers a much softer, more refined look. The surface is smoother to the touch and has a gentle, satin-like sheen. This is a popular choice for consumer electronics and decorative panels.

Matching Grit to Product Context

The final application is key. A heavy-duty tool might benefit from a coarse 80-grit finish. An elegant kitchen appliance might require a smoother 180 or 240-grit finish. We often guide clients at PTSMAKE on this choice. We consider how the product will be seen and used. The right Surface Roughness11 ensures the brushed metal finish meets both design intent and performance needs.

| Grit | Visual Texture | Reflectivity | Ideal For |

|---|---|---|---|

| Low (e.g., 80) | Deep, aggressive lines | Low (Matte) | Industrial parts, hiding flaws |

| Medium (e.g., 120) | Clear, defined lines | Medium (Dull) | Appliances, architectural trim |

| High (e.g., 240) | Fine, subtle lines | Higher (Satin) | Electronics, luxury goods |

Choosing the correct grit level is a critical design decision. It balances the desired texture, reflectivity, and practical application of the final product. Lower grits offer a coarse look, while higher grits like 240 provide a refined, satin finish.

Comparing Manual Vs Machine Brushing: Precision, Cost, And Scalability

Choosing the right brushing method is critical. It directly impacts your product’s final look, cost, and production speed. The debate often centers on manual versus machine finishing.

Hand-brushed metal offers an artistic touch. It’s ideal for complex parts where a machine might struggle. Robotic brushing, however, delivers unmatched consistency for high-volume orders. Your choice depends entirely on project specifics.

Key Decision Factors

| Factor | Manual Brushing | Robotic Brushing |

|---|---|---|

| Volume | Low to medium | High |

| Uniformity | Varies by operator | High |

| Part Geometry | Complex, intricate | Simple to moderate |

Deciding between these methods requires a close look at your project’s goals. Neither is universally better; they simply serve different purposes for achieving a quality brushed metal finish.

Hand Finishing: The Artisan’s Touch

Hand brushing is perfect for prototypes or small batches. It avoids the high setup costs of automation. An experienced technician can navigate intricate curves and unique geometries that would challenge a robotic arm. This method allows for a custom, non-uniform finish that can be highly desirable for certain products. The main drawback is its limited scalability and operator-dependent consistency.

Robotic Brushing: The Power of Automation

When you need thousands of identical parts, robotic brushing is the clear winner. The initial investment is higher due to programming and equipment costs. However, the per-unit cost drops significantly at scale. Robots provide excellent process repeatability12, ensuring every single part has the exact same brushed metal finish.

Method Comparison

| Aspect | Hand Finishing | Robotic Brushing |

|---|---|---|

| Precision | High skill required | Consistently high |

| Speed | Slow | Fast |

| Scalability | Poor | Excellent |

| Labor Cost | High per piece | Low per piece |

At PTSMAKE, we guide clients through this decision. We analyze part design, production volume, and budget to recommend the most effective brushing method comparison.

The right choice between manual and robotic brushing is a strategic decision. It balances the need for artisanal detail against the demands of volume production, consistency, and cost-effectiveness for your final brushed metal finish.

Brushed Metal In Robotics: Where Grip, Form, And Function Meet

In robotics, every surface matters. A brushed metal finish isn’t just about looks. It offers real functional advantages for critical components.

Enhanced Grip on Joint Casings

The fine grooves of a brushed finish provide a tactile surface. This is vital for robotic joints that need manual adjustment or handling during maintenance.

Functional Control Surfaces

Control panels and interactive surfaces on robots benefit greatly. The non-reflective nature of a brushed finish reduces glare, making displays and buttons easier to read.

| Finish Type | Grip Level | Glare Reduction |

|---|---|---|

| Polished | Low | Poor |

| Matte | Medium | Excellent |

| Brushed | High | Good |

The texture also provides a secure grip for operators, which improves safety and precision.

The application of a brushed metal finish extends beyond user-facing parts. We see it used on internal components where durability and performance are key.

The Role of Brushed Motor Housing

A brushed motor housing is a perfect example. The increased surface area from the brushing process can subtly aid in heat dissipation. While not its primary purpose, this small thermal benefit adds up in high-performance robots. After some tests with clients, we found it can improve cooling efficiency by a small margin.

The finish also helps mask minor scratches from assembly or maintenance. This preserves the component’s appearance over its lifespan, which is important for our clients at PTSMAKE who value longevity.

Durability in High-Wear Areas

The directional grain of a brushed finish is excellent at hiding wear and tear. This is crucial for robotic components that are frequently handled or exposed to contact. It ensures the robot looks professional even after extensive use. This functional durability is a key reason many designers choose this finish over others. The finish introduces a controlled texture, which can influence the anisotropic reflection13 of light, reducing distracting glare.

| Robotic Component | Primary Benefit of Brushed Finish |

|---|---|

| Joint Casings | Improved Manual Grip |

| Control Surfaces | Reduced Glare, Enhanced Tactility |

| Motor Housings | Minor Heat Dissipation, Wear Masking |

Brushed metal finishes provide critical functional advantages in robotics. They improve grip on joint casings, reduce glare on control surfaces, and enhance durability and thermal performance on housings. This makes them more than just an aesthetic choice; they are a practical engineering solution.

Brushed Vs Bead Blasted: A Strategic Surface Decision For Engineered Parts

When it comes to cosmetic parts, the finish is everything. It’s the first thing your customer sees and touches. The debate of brushed vs blasted finish is common.

This choice directly impacts user perception. It can make a product feel premium or purely functional.

Aesthetic & Tactile Differences

A brushed metal finish offers a distinct, linear grain. This look is often associated with luxury and high-end electronics.

Bead blasting creates a uniform, matte texture. It feels smooth and non-reflective. This finish is subtle and modern.

| Feature | Brushed Finish | Bead Blasted Finish |

|---|---|---|

| Look | Directional, metallic sheen | Uniform, matte, non-glare |

| Feel | Textured along the grain | Smooth, slightly frosted |

| Fingerprints | Can show smudges | Resists fingerprints well |

| Perception | Premium, decorative | Modern, utilitarian, clean |

Choosing the right brushing vs blasting texture is key for brand identity. It’s a strategic decision we help clients make at PTSMAKE.

Industry-Specific Applications

The best finish depends on the product’s environment and intended use. Different industries have different priorities. What works for a consumer gadget may not suit a medical device.

Tech and Consumer Electronics

In the tech world, aesthetics are paramount. A brushed metal finish on a laptop or speaker conveys a premium feel. It’s a classic choice for high-value items.

However, bead blasting is gaining ground. It offers a clean, minimalist look that aligns with many modern tech brands. It also hides minor scratches and fingerprints better.

Medical Devices

For medical components, function often trumps form. A bead-blasted surface is ideal. Its non-reflective texture reduces glare under bright operating room lights.

This finish is also easier to clean and sterilize effectively. The uniform texture leaves fewer microscopic crevices for bacteria to hide compared to a brushed finish. The principles of Tribology14 also suggest its wear resistance is more uniform.

Electric Vehicles (EV) and Automotive

The EV industry uses both finishes strategically.

| Application Area | Preferred Finish | Rationale |

|---|---|---|

| Interior Trim | Brushed Metal | Creates a luxurious, high-end cabin feel. |

| Dashboard Panels | Bead Blasted | Reduces glare for driver safety. |

| Exterior Accents | Both | Depends on the desired brand aesthetic. |

| Functional Parts | Bead Blasted | Provides a durable, clean, and modern look. |

The brushing vs blasting texture decision here balances luxury with safety and durability.

The choice between a brushed and bead blasted finish is crucial for cosmetic parts. A brushed metal finish often signals premium quality, while bead blasting provides a modern, functional, and durable surface ideal for specific industrial applications.

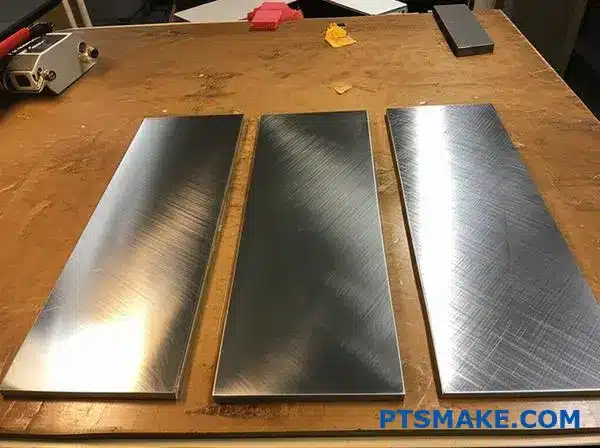

From Prototype To Production: How To Maintain Brushed Consistency At Scale

Scaling a brushed metal finish from a single approved prototype is a common challenge. What works for one part might not work for a thousand. The key is a scalable process plan.

This plan ensures every part matches the original standard.

Developing Your Brushing Process

First, we must document every variable. This creates a repeatable recipe for the desired brushed finish. We treat this as the foundation for mass production.

Key Process Parameters

| Parameter | Specification | Control Method |

|---|---|---|

| Abrasive Grit | 240 Grit | Visual Check & Labeling |

| Tool Speed | 1,800 RPM | Digital Tachometer |

| Feed Rate | 15 mm/sec | CNC Programmed |

| Pressure | 2.5 kg | Calibrated Force Gauge |

This documentation removes guesswork. It is the first step toward achieving brushed finish consistency across thousands of parts.

To truly scale, you need more than just a recipe. You need a system for verification and ongoing control. This is where a formal quality control plan becomes essential for any serious production run.

The First Article Inspection (FAI)

The FAI is critical. We produce the first part using the documented process plan. This part is then rigorously inspected against all specifications. It becomes the "golden sample" or the benchmark for all subsequent production.

Once the first article is approved, its finish characteristics are quantified. We use surface roughness testers and visual guides to set clear, objective standards. This avoids subjective judgments later on.

Maintaining Quality at Volume

With a standard set, we maintain it using quality control checkpoints. We implement methods like Statistical Process Control15 to monitor the process. This helps us spot any deviation from the standard before it becomes a major issue.

Regular checks ensure the brushed finish consistency remains high throughout the entire production batch.

QC Stages for Scaling

| Stage | Action | Purpose |

|---|---|---|

| First Article | Full inspection against spec | Set the quality benchmark |

| In-Process | Periodic checks (e.g., every 50th part) | Catch deviations early |

| Final Inspection | Random sampling of the batch | Verify overall batch quality |

At PTSMAKE, this structured approach ensures the parts our clients receive in the final shipment look just as good as the first one they approved.

A documented process, verified by a first article inspection and maintained with ongoing quality control, is the only way to ensure consistent brushed finishes at scale. This systematic approach removes variability and guarantees a predictable, high-quality outcome.

When Should You Avoid Brushed Metal? Use Cases That Backfire

A brushed metal finish looks fantastic. It offers a premium, textured appearance. But it’s not a one-size-fits-all solution. In some cases, choosing it is a waste of money and can even cause problems.

So, when does it backfire?

For Unseen Internal Components

Why pay for a cosmetic finish on a part no one will ever see? It adds unnecessary cost without providing any functional benefit.

In Harsh Chemical Environments

The fine grooves of a brushed finish can trap corrosive substances. This makes the part harder to clean and can accelerate degradation.

When Another Coating is Applied

If you plan to paint or powder coat the part, the brushed texture will be hidden. A simpler, more cost-effective surface preparation is better.

Here’s a quick guide:

| Situation | Why Avoid Brushed Finish? | Better Alternative |

|---|---|---|

| Hidden Parts | Adds unnecessary cost | As-machined or bead blast |

| Chemical Exposure | Traps contaminants | Electropolishing or passivation |

| Pre-Coating | Visuals are obscured | Sandblasting |

Let’s dig deeper into these poor use cases. Making the right finishing choice is crucial for both budget and performance. It’s a conversation I often have with clients at PTSMAKE.

The Problem with Hidden Parts

Cost is always a factor in manufacturing. Adding a brushed finish to an internal bracket or a hidden support is pure waste. The function isn’t improved, and the aesthetic is lost. We always advise clients to use an "as-machined" finish for such parts to optimize their budget.

Aggressive Environments and Corrosion Risks

The very texture that makes a brushed finish appealing becomes its biggest weakness in certain settings. The microscopic grooves, or striations, increase the surface area.

When exposed to salt, acids, or harsh cleaning agents, these grooves trap the chemicals. This can lead to localized corrosion that’s difficult to see and clean. Over time, it compromises the part’s integrity. This is a classic example of brushed finish disadvantages.

For parts in these environments, a smoother finish like electropolishing is a far safer and more durable choice. It creates a passive layer that resists attack.

Redundancy Before Coating

Applying a coating like paint or powder coat requires a clean, properly prepared surface for good bonding. However, a brushed finish is an aesthetic choice, not a preparatory one.

The final coating will completely cover the brushed lines. A less expensive process, like sandblasting, creates a better profile for Substrate Adhesion16 and costs less. Don’t pay for a look that will just get covered up.

A brushed finish is a great cosmetic choice, but it’s not a universal solution. Avoid it for internal components, in corrosive environments, or on parts destined for another coating. Choosing the right finish saves money and improves part longevity.

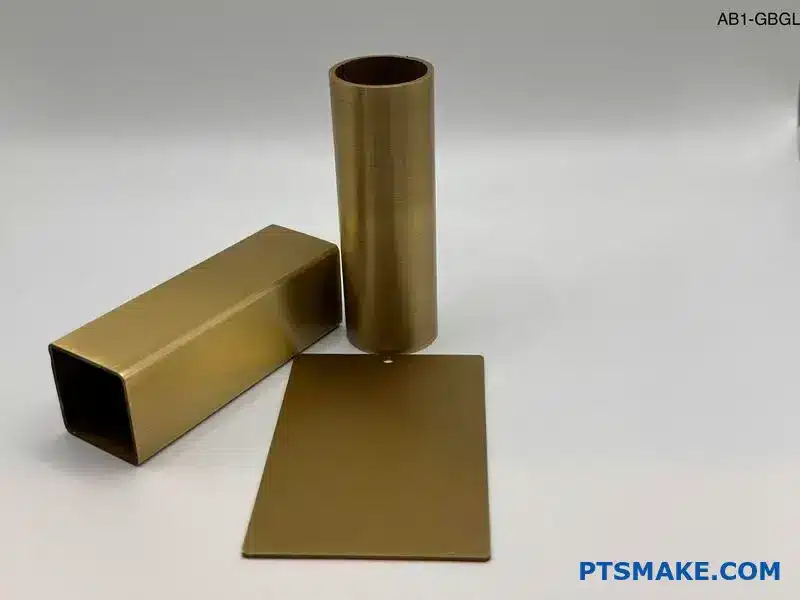

Metal Type Matters: Best Base Materials For High-Quality Brushed Looks

Choosing the right base metal is critical. The final appearance and durability of a brushed metal finish depend heavily on the material’s properties. Not all metals can hold a brushed look equally well.

Top Metal Contenders

Aluminum and stainless steel are top choices. They offer a great balance of aesthetics, performance, and workability. Each has unique benefits for different applications.

Key Material Attributes

A good base material must hold the fine lines of a brushed finish consistently. It should also resist corrosion and wear over time.

| Metal | Finish Consistency | Corrosion Resistance |

|---|---|---|

| Aluminum | Excellent | Good (with anodizing) |

| Stainless Steel | Excellent | Superior |

This decision directly impacts the product’s longevity and visual appeal.

When we dive into a brushed aluminum and brushed stainless steel comparison, the differences become clear. Each material serves distinct purposes based on its inherent characteristics. The choice isn’t just about looks; it’s about long-term performance.

Aluminum: Lightweight and Versatile

Brushed aluminum is prized for its low weight and excellent machinability. It’s a cost-effective option for many consumer electronics and decorative parts. However, it requires an anodized layer for optimal corrosion and scratch resistance. This adds a step to the process.

Stainless Steel: The Durable Champion

Brushed stainless steel offers superior strength and corrosion resistance. This is due to the chromium content, which enables Passivation17. It’s ideal for harsh environments like kitchens or medical devices. It is heavier and typically more expensive to machine than aluminum. Our tests show its finish is exceptionally resilient.

Detailed Comparison

| Feature | Brushed Aluminum | Brushed Stainless Steel |

|---|---|---|

| Weight | Lightweight | Heavy |

| Durability | Good (when anodized) | Excellent |

| Cost | Lower | Higher |

| Best For | Electronics, automotive trim | Appliances, medical gear |

The best material depends on your project’s specific needs for weight, durability, and budget.

Choosing the right metal is key for a lasting brushed metal finish. Aluminum offers a lightweight, cost-effective solution, while stainless steel provides unmatched durability and corrosion resistance. Your project’s specific application and environment should guide your final decision.

Bring Your Brushed Metal Projects to Life with PTSMAKE

Ready to achieve flawless brushed metal finishes for your next industrial application? Contact PTSMAKE now for a fast, precision-driven quote and discover how our CNC machining and injection molding expertise can elevate your product’s durability, aesthetics, and performance—from prototype to production!

Learn how this optical property impacts light reflection and material appearance. ↩

Understand how directional finishing affects material durability and performance in our guide. ↩

Learn how this property affects the visual and mechanical qualities of your brushed parts. ↩

Explore how the science of touch influences product design and user satisfaction. ↩

Learn how this directional property affects both visual appearance and functional performance. ↩

Learn how directional properties impact both the look and performance of your parts. ↩

Learn how this property influences the visual consistency of your brushed metal finish. ↩

Understand the different abrasive materials and how they influence the final surface and dimensional accuracy. ↩

Understand how this light-scattering property impacts material choice in optical and robotic systems. ↩

Discover why this property ensures your components perform reliably under operational stress and maintain their form. ↩

Learn the technical standards for measuring and specifying the texture of a brushed metal finish. ↩

Understand how robotic consistency impacts your product quality and bottom line. ↩

Discover how this light-scattering property impacts the visual quality and inspection of robotic components. ↩

Understand how surface science influences part durability, friction, and long-term performance. ↩

Learn how this data-driven methodology ensures consistent quality in mass production. ↩

Learn how surface preparation impacts the bonding strength between a metal and its coating. ↩

Learn how this chemical process naturally protects stainless steel and extends product life. ↩