Selecting the wrong heat sink material can destroy your entire thermal management system. Your components overheat, performance drops, and reliability plummets – turning what should be a simple cooling solution into an expensive engineering nightmare.

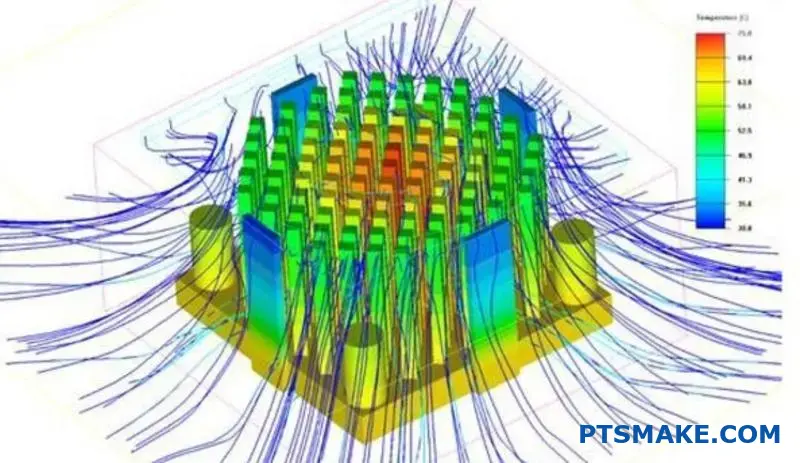

Heat sink material selection depends on four critical factors: thermal conductivity for heat transfer efficiency, material density for weight constraints, manufacturing compatibility for cost-effective production, and environmental resistance for long-term reliability in your specific application.

This guide breaks down 20 practical material selection scenarios that I encounter regularly at PTSMAKE. You’ll discover when copper justifies its higher cost over aluminum, why ceramics excel in high-voltage applications, and how advanced composites solve problems that traditional materials can’t handle.

Why is material density a key practical parameter?

When selecting materials, density is often overlooked. But it’s a critical factor that directly impacts performance. It’s not just about how heavy something is.

It’s about how much strength you get for that weight. This balance is key.

The Strength-to-Weight Ratio

This ratio is a simple measure of a material’s efficiency. High strength with low weight is the ideal goal in many engineering applications. This is where material choice becomes a strategic decision.

| Material Feature | Importance |

|---|---|

| High Strength | Resists breaking under load |

| Low Density | Reduces overall product weight |

| High Ratio | Optimal performance & efficiency |

This balance helps create better, more efficient products.

Understanding density goes beyond a simple number on a spec sheet. It’s about practical application and achieving the best possible outcome for a product’s specific needs.

Applications Where Weight is Critical

In aerospace and automotive industries, every gram counts. Lighter components mean better fuel efficiency and higher performance. A lower density material can make a huge difference in an airplane’s payload capacity or a car’s acceleration.

The same principle applies to portable electronics. A lighter phone or laptop is more convenient for the user. For components like a heat sink material, density affects both thermal mass and overall device weight, a crucial balance we often manage at PTSMAKE.

Density’s Impact on Cost and Design

Material density also has direct financial implications. Less dense materials can sometimes mean lower shipping costs. More importantly, it can influence the amount of structural support a part requires.

Lighter parts might need a less robust frame, saving material and complexity. This is a key consideration in our CNC machining projects. We always analyze how material choice affects the entire assembly, not just the single part. The material’s tensile strength1 is just one part of a bigger picture.

| Factor | Impact of Lower Density |

|---|---|

| Material Cost | Can be lower if sold by weight |

| Shipping Costs | Reduced due to lighter loads |

| Structural Needs | Requires less support |

| Machining Time | Can vary based on material type |

Material density is a vital parameter that influences performance, cost, and design. The strength-to-weight ratio is especially crucial in weight-sensitive industries like aerospace and electronics, directly impacting efficiency and usability.

How do machinability and formability constrain material choice?

Choosing the right heat sink material isn’t just about thermal performance. How easily can we shape it? This question directly impacts your final cost and design possibilities.

Easier manufacturing means lower costs.

Linking Process to Economics

Materials that are simple to extrude, stamp, or machine require less time and specialized tooling. This translates directly into savings. For example, aluminum is often favored for its excellent machinability.

Here is a quick comparison:

| Feature | Aluminum 6061 | Copper C110 |

|---|---|---|

| Machinability | Excellent | Fair |

| Formability | Good | Excellent |

| Relative Cost | Lower | Higher |

This balance is key to project success.

The choice of manufacturing method is a critical decision. It defines the boundaries of your design complexity and budget from the very beginning.

Manufacturing Method vs. Design Freedom

Extrusion is cost-effective for simple, linear heat sink profiles. It’s perfect for aluminum. However, it limits complex geometries. Stamping is great for high-volume, thin-finned parts, but tooling can be expensive upfront.

CNC machining, our specialty at PTSMAKE, offers maximum design freedom. We can create highly complex shapes with tight tolerances. But this process can be more expensive, especially for materials that are difficult to cut.

The Challenge of Material Behavior

Some materials change during manufacturing. This process, known as Work hardening2, can make a material stronger but also more brittle and harder to process further. This adds complexity and cost.

Consider this breakdown:

| Manufacturing Method | Typical Material | Design Complexity | Cost Impact |

|---|---|---|---|

| Extrusion | Aluminum Alloys | Low | Low |

| Stamping | Copper, Aluminum | Medium | High Initial, Low per unit |

| CNC Machining | Any (e.g., Copper) | High | High |

At PTSMAKE, we guide clients through these choices. We help select a heat sink material and process that aligns with both performance needs and budget constraints, ensuring a practical and effective final product.

The manufacturing process is not an afterthought. It directly influences project cost, timeline, and design complexity. Your choice of heat sink material must be compatible with a feasible and economical manufacturing method to ensure success.

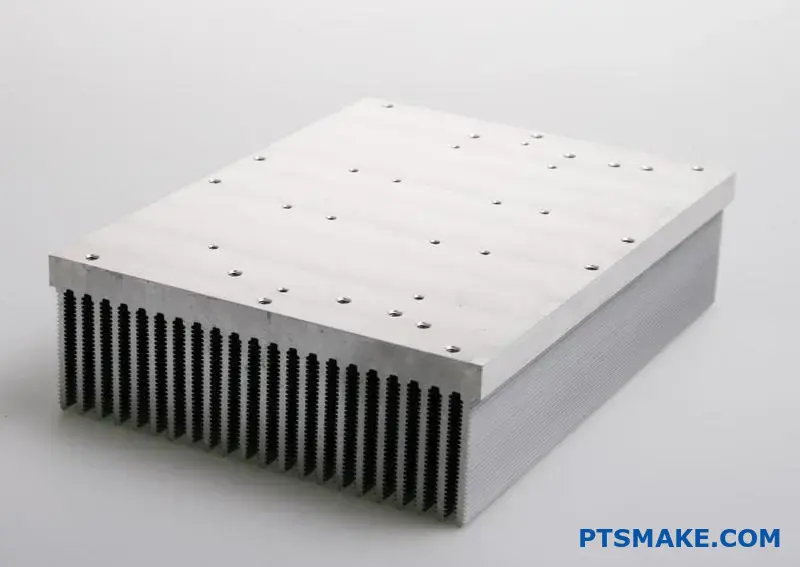

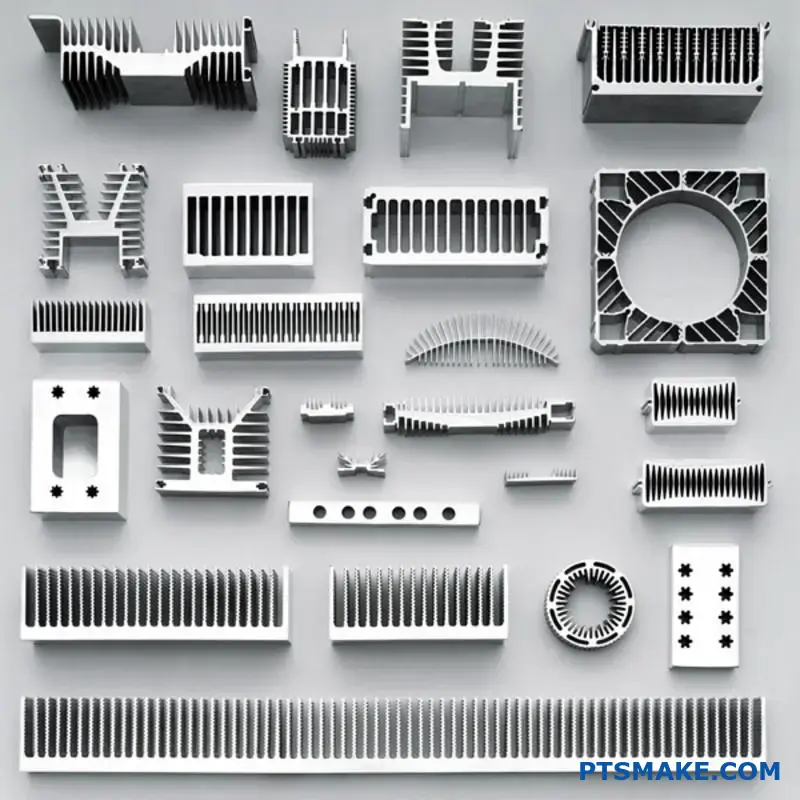

What are the primary categories of heat sink materials?

Choosing the right heat sink material is critical. It’s a balance of thermal performance, weight, and cost. At PTSMAKE, we guide clients through this decision daily.

The options are usually grouped into four main families. Each has distinct advantages for specific applications.

Material Classification Overview

We can break down materials into four primary types. This helps simplify the initial selection process for any project.

| Material Category | Key Advantage | Common Use Case |

|---|---|---|

| Metals | High Thermal Conductivity | CPUs, Power Electronics |

| Ceramics | Electrical Insulation | High-Voltage ICs |

| Composites | Tailored Properties | Aerospace, High-End GPUs |

| Polymers | Low Cost & Weight | Low-Power LEDs |

This framework provides a solid starting point for design engineers.

A Deeper Dive into Material Properties

Let’s explore these categories more closely. The nuances determine a project’s success. In our experience, overlooking these details can lead to costly redesigns.

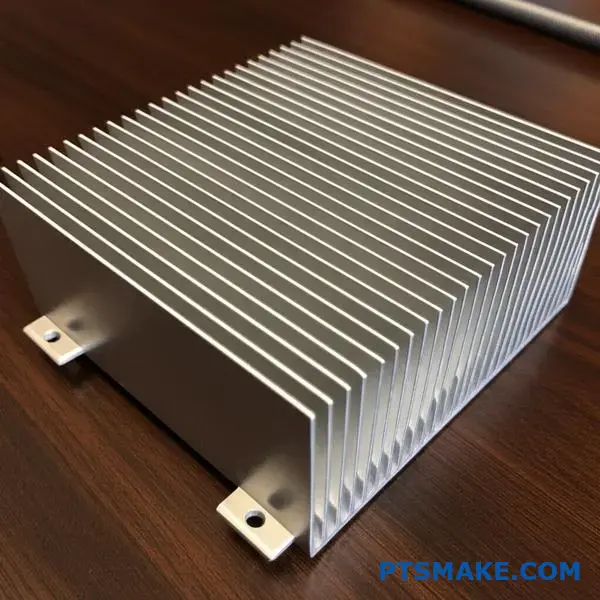

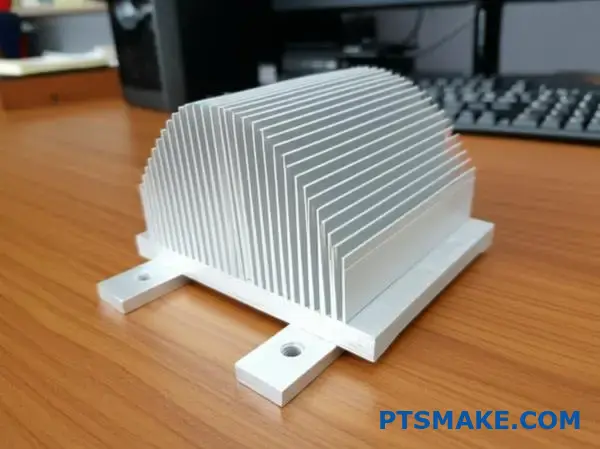

Metals: The Industry Standard

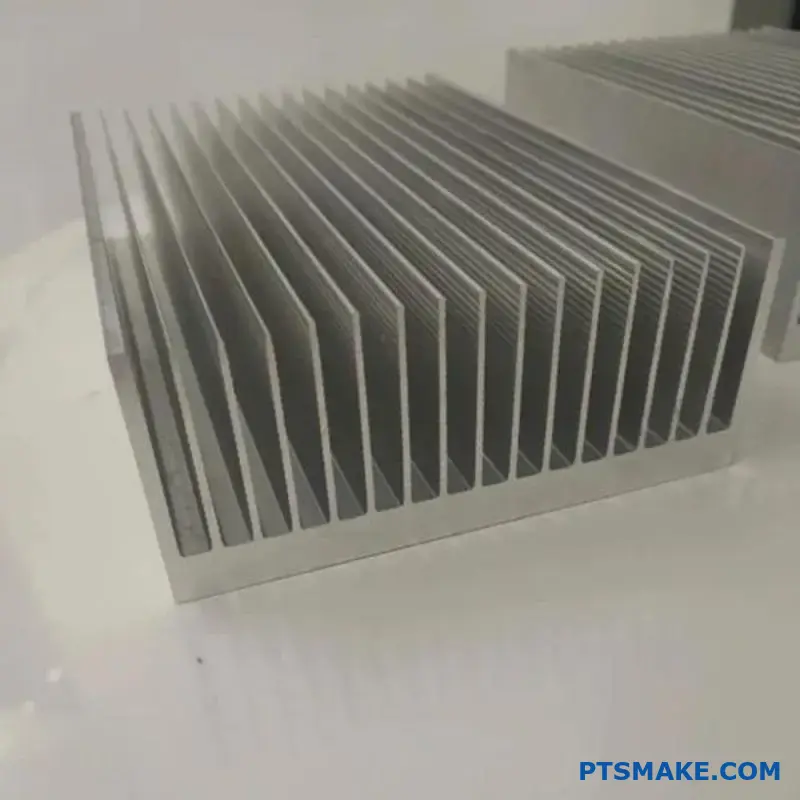

Aluminum alloys like 6061 and 6063 are popular. They offer a great mix of cost, weight, and machinability. They are the go-to for many general applications.

Copper is the choice for maximum performance. Its thermal conductivity is nearly double that of aluminum. However, it is heavier and more expensive.

Ceramics & Composites: Specialized Solutions

Ceramic heat sinks are perfect when you need electrical insulation. Materials like Aluminum Nitride prevent short circuits while still managing heat.

Composites are at the cutting edge. Graphite, for example, has excellent anisotropic3 thermal conductivity. This allows us to direct heat in very specific ways, a huge advantage in compact electronics. Metal Matrix Composites (MMCs) offer custom-blended properties but come at a higher cost.

| Material | Thermal Conductivity (W/mK) | Key Feature |

|---|---|---|

| Aluminum (6061) | ~167 | Balanced cost & performance |

| Copper (C110) | ~391 | Highest performance |

| Aluminum Nitride | ~170 | Electrical insulator |

| Graphite | 25-1500 | Directional heat transfer |

Thermally Conductive Polymers

These plastics are ideal for low-power devices. They are lightweight, easily molded into complex shapes, and cost-effective for high-volume production. They don’t match metal performance but are perfect for the right job.

Selecting the right heat sink material involves balancing thermal needs, cost, and manufacturing methods. From common aluminum to advanced graphite composites, each category offers unique solutions for specific engineering challenges, ensuring optimal device performance and reliability.

When is copper practically chosen over aluminum?

Choosing between copper and aluminum often boils down to a classic trade-off. It’s about balancing cost against performance. Aluminum is the default for many applications.

But what happens when "good enough" isn’t an option?

The Cost vs. Performance Equation

In some cases, the higher upfront cost of copper is a smart investment. This is especially true for demanding thermal management challenges. Think of high-power electronics where failure is not an option.

Here’s a simplified look at the trade-off:

| Feature | Copper | Aluminum (6061) |

|---|---|---|

| Thermal Conductivity | ~385 W/mK | ~167 W/mK |

| Relative Cost | Higher | Lower |

| Machinability | More Difficult | Easier |

When heat dissipation is critical, copper’s superiority is clear.

The decision becomes clearer when we look at specific high-stakes applications. It’s not just about better numbers on a spec sheet. It’s about enabling technology that would otherwise be impossible or unreliable.

High-Stakes Thermal Management

In past projects at PTSMAKE, we have handled designs where thermal performance directly impacts product viability. Choosing the right heat sink material is a critical first step.

High Heat Flux Environments

This is where a large amount of heat is generated in a very small area. Think of powerful laser diodes or the core of a server CPU. Aluminum might not draw heat away fast enough.

This leads to overheating and component failure. Copper, with its superior conductivity, excels here. It pulls heat away quickly, keeping temperatures stable and ensuring reliability. Its lower thermal resistance4 is a key advantage.

Space-Constrained Designs

Modern devices are getting smaller. From medical instruments to robotics, space is a premium. You can’t just use a bigger aluminum heat sink.

Here, copper’s efficiency shines. A smaller copper heat sink can dissipate the same amount of heat as a much larger aluminum one. This allows for smaller, lighter, and more powerful product designs. We often machine complex copper parts for these exact scenarios.

| Scenario | Aluminum Solution | Copper Solution |

|---|---|---|

| Cooling 100W CPU | Large heat sink with fan | Compact heat sink, possibly fanless |

| High-Power LED | Requires active cooling | Can use passive cooling |

This shows how copper enables designs that aluminum cannot support.

While aluminum is often the cost-effective choice, copper is essential for high-performance needs. Its superior thermal conductivity is non-negotiable in applications with high heat flux or severe space constraints, justifying the investment for reliability and performance.

What are advanced materials like graphite and diamond?

Now we reach the high-performance end of materials. Here, cost takes a backseat to extreme performance.

Meet Annealed Pyrolytic Graphite (APG) and synthetic diamond. These are not your everyday choices. They are solutions for the most demanding thermal challenges.

Unmatched Thermal Conductivity

Their ability to dissipate heat is truly remarkable. Our tests show their performance dwarfs traditional metals. They are a top-tier heat sink material.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Synthetic Diamond | ~2200 |

| APG | ~1700 |

| Copper | ~400 |

| Aluminum | ~200 |

These materials are reserved for applications where failure is not an option.

Niche Applications for Elite Materials

Why choose such expensive materials? It’s about solving problems that other materials simply can’t. These are for niche, cost-insensitive applications.

Annealed Pyrolytic Graphite (APG) in Aerospace

In aerospace, every gram counts. APG is not only an excellent thermal conductor but also incredibly lightweight.

This makes it ideal for satellite thermal management systems. It helps sensitive electronics survive the extreme temperatures of space. Its unique layered structure allows heat to spread efficiently across a plane. This is due to its highly ordered structure, which creates a pronounced anisotropy5 in its properties.

At PTSMAKE, we’ve machined graphite for various high-tech uses. We understand how its properties influence the design and manufacturing process.

Synthetic Diamond in High-Power Electronics

When it comes to raw thermal conductivity, nothing beats diamond. Synthetic diamond is crucial for high-power electronics.

Think of advanced radar systems or high-frequency communication devices. These generate immense heat in a very small area. Synthetic diamond acts as a heat spreader. It pulls heat away from critical components instantly. This prevents overheating and ensures reliability.

| Application | Key Material Property |

|---|---|

| Satellite Electronics | Lightweight & High In-Plane Conductivity (APG) |

| High-Power Lasers | Extreme Thermal Conductivity (Diamond) |

| Avionics | Durability & Heat Spreading (APG) |

| Advanced Radar | Maximum Heat Dissipation (Diamond) |

APG and synthetic diamond represent the pinnacle of thermal management. They offer unparalleled performance for critical aerospace and high-power electronic applications where standard materials fall short. Cost is secondary when ensuring system reliability and function in extreme environments.

What is the practical application for ceramic heat sinks?

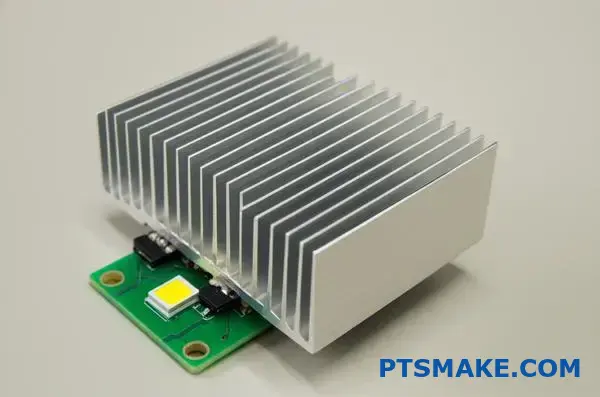

Ceramic heat sinks have a game-changing advantage. They combine good thermal conductivity with excellent electrical insulation. This is a rare and valuable combination.

It means they can directly touch live electronic components. There’s no need for an extra insulating layer. This simplifies design and assembly.

Where Direct Contact Matters

Consider high-power electronics or LEDs. These components get very hot and carry voltage. A standard metal heat sink would cause a short circuit if it touched them directly.

This is where a ceramic heat sink material shines. It pulls heat away while preventing electrical shorts.

Traditional vs. Ceramic Heat Sinks

This table shows the difference in assembly.

| Component Stack (Metal) | Component Stack (Ceramic) |

|---|---|

| Heat Sink (Metal) | Heat Sink (Ceramic) |

| Insulating Pad (TIM) | Electronic Component |

| Electronic Component | N/A |

As you can see, the ceramic solution is simpler.

The dual role of ceramic heat sinks offers more than just simplicity. It fundamentally improves thermal management in specific scenarios. By removing the need for a separate thermal interface pad, we eliminate a layer of thermal resistance.

Every layer in a thermal stack adds resistance. Even the best thermal pads impede heat flow to some extent. Removing this layer means heat transfers more directly from the component to the heat sink.

The Impact on Performance and Reliability

This direct contact approach leads to lower operating temperatures. In our work at PTSMAKE, we’ve seen this result in better performance and longer component life. The high dielectric strength6 of materials like Alumina or Aluminum Nitride ensures safety.

This is critical in compact and power-dense applications. Think of power converters, solid-state relays, and advanced motor drives. Fewer parts also mean fewer potential points of failure.

Assembly Benefits

Here’s how it simplifies the manufacturing process:

| Aspect | Metal Sink + Insulator | Ceramic Sink |

|---|---|---|

| Part Count | Higher (3+ parts) | Lower (2 parts) |

| Assembly Time | Longer | Shorter |

| Potential for Error | Higher | Lower |

| Long-term Reliability | Good | Excellent |

This streamlined approach can reduce assembly costs and improve product consistency, a key goal for any manufacturing manager.

Ceramic heat sinks excel by providing both thermal conductivity and electrical insulation. This unique dual-functionality allows direct contact with live components, simplifying design, removing failure points, and boosting thermal performance in compact power electronics.

How do metal matrix composites (MMCs) solve specific problems?

Metal Matrix Composites (MMCs) are smartly engineered materials. They combine a base metal with a reinforcing element. This creates a powerful and unique hybrid.

A great example is Aluminum Silicon Carbide (AlSiC). It blends aluminum’s lightness with silicon carbide’s low expansion properties.

This mix gives us properties that are impossible to find in a single material. You get high thermal conductivity and a low expansion rate. It is an excellent heat sink material. This solves specific challenges, especially in advanced electronics.

| Property | Monolithic Aluminum | Silicon Carbide | AlSiC Composite |

|---|---|---|---|

| Thermal Conductivity | High | Moderate | Very High |

| CTE (Expansion) | High | Low | Very Low (Tailorable) |

| Density | Low | Low | Very Low |

The Engineering Behind MMCs

MMCs are not just simple mixtures. They are carefully designed materials. The main goal is to create a product with a very specific set of properties. We can tailor them for unique and demanding applications.

Understanding the Components

The metal matrix, like aluminum, provides ductility. It also gives good thermal and electrical conductivity. The reinforcement, like silicon carbide particles, adds stiffness. It also greatly lowers thermal expansion.

In our past projects focusing on thermal management, this customization is critical. Standard materials often force a tough compromise. You might get high conductivity but also high expansion. MMCs remove this difficult trade-off.

Solving the Electronics Packaging Puzzle

Think about high-power electronics. Silicon chips have a very low coefficient of thermal expansion (CTE). If you mount them on a standard aluminum heat sink, problems will occur.

The different expansion rates create huge stress. This can lead to component failure over time. AlSiC solves this problem perfectly. We can engineer its CTE to closely match silicon. This reduces mechanical stress. The material’s high thermal conductivity also pulls heat away efficiently. The quality of the matrix-reinforcement interface7 is vital here for consistent performance.

This table shows the separate roles:

| Component | Primary Role | Key Contribution |

|---|---|---|

| Metal Matrix (e.g., Al) | Host Material | Ductility, Thermal Conductivity |

| Reinforcement (e.g., SiC) | Property Modifier | Stiffness, Low CTE |

This targeted approach makes MMCs so valuable. They provide real solutions where traditional metals simply cannot keep up.

MMCs like AlSiC are engineered, not just mixed. They combine properties like low CTE and high thermal conductivity to solve specific problems, such as thermal stress in electronics, that monolithic materials cannot address alone. This makes them highly effective.

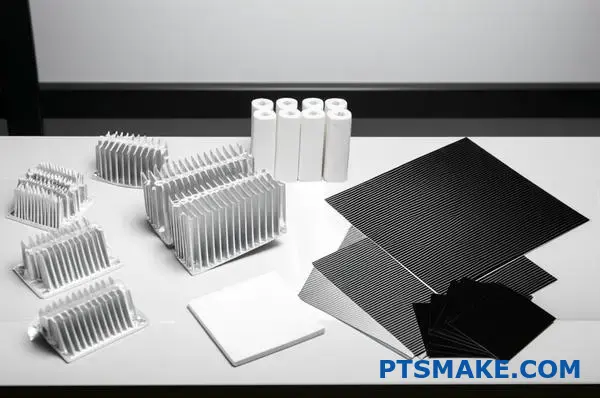

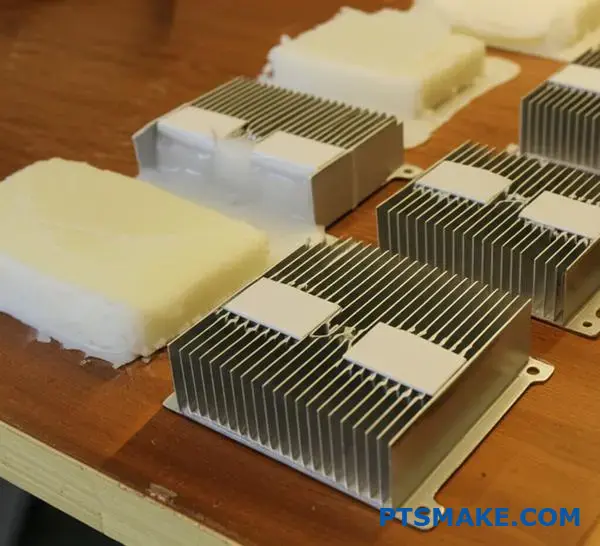

What are the types of Thermal Interface Materials (TIMs)?

Choosing the right Thermal Interface Material (TIM) is critical. It is not just about picking the highest thermal conductivity.

The form factor of the TIM matters just as much. It impacts manufacturing, reliability, and overall cost.

Let’s explore the primary types available. Each offers a unique balance of properties for different thermal challenges.

A Quick Comparison

We often help clients choose based on their specific assembly and performance goals. Here is a simple breakdown.

| TIM Type | Primary Advantage | Common Use |

|---|---|---|

| Thermal Grease | High Performance | CPUs, GPUs |

| Thermal Pads | Ease of Use | Chipsets, Memory |

| Phase Change | Reliability | High-power servers |

| Adhesive Tapes | Structural Bonding | LED lighting |

This variety ensures a tailored solution for almost any application.

Let’s break down these options further. Each has specific trade-offs that I’ve seen play out in past projects at PTSMAKE.

Thermal Grease (Pastes)

Greases typically offer the best thermal performance. They conform perfectly to microscopic surface gaps. This achieves a very thin bond line thickness.

However, they can be messy and difficult to apply consistently. They also risk "pump-out" over time, where the material is squeezed out, degrading performance.

Thermal Pads

Pads are the simplest to use. They are pre-cut, solid sheets that are easy to handle and apply. This makes them great for high-volume automated assembly.

The trade-off is lower thermal performance than grease. They are thicker and conform less perfectly to surfaces. This increases the overall Thermal Impedance8 of the interface.

Phase Change Materials (PCMs)

PCMs offer a clever hybrid approach. They are solid at room temperature, making them as easy to handle as a pad.

When the device heats up, they melt and flow like grease. This provides excellent surface wetting. They then re-solidify when cooled, locking them in place.

Thermal Adhesive Tapes

These tapes provide both thermal transfer and mechanical bonding. This can simplify the design and reduce component count, removing the need for clips or screws on a heat sink material assembly.

Their thermal performance is generally the lowest of the group. However, their convenience makes them ideal for certain applications.

| Feature | Grease | Pad | PCM | Tape |

|---|---|---|---|---|

| Performance | Highest | Moderate | High | Lowest |

| Application | Manual/Dispensed | Manual/Automated | Manual/Automated | Manual |

| Reworkable? | Yes | Yes | Difficult | No |

| Bonding? | No | No | No | Yes |

Selecting the right TIM involves balancing thermal needs, manufacturing processes, and reliability. Each type has clear advantages and disadvantages. The ideal choice is always specific to your product’s design, use case, and production volume.

How are thermally conductive polymers used in practice?

When you think of a heat sink material, metal is the traditional choice. However, thermally conductive polymers are creating new possibilities. They offer a powerful combination of benefits.

These materials are lightweight and cost-effective. They also allow for incredible design freedom through injection molding, a process we specialize in at PTSMAKE.

The Rise of Polymer Heat Sinks

Polymers are not just for housings anymore. They are now a viable option for thermal management, especially in specific applications where metals are over-engineered.

Key Advantages Over Metals

Consider these benefits when choosing your next heat sink material. They can dramatically impact your final product’s cost and performance.

| Feature | Conductive Polymer | Traditional Metal (e.g., Aluminum) |

|---|---|---|

| Weight | Lightweight | Heavier |

| Cost | Often lower | Higher material cost |

| Manufacturing | Injection moldable | Machining, extrusion, die-casting |

| Design | High complexity possible | Limited by process |

These factors make them perfect for low-power electronics.

Polymers challenge the "metal-only" mindset for thermal management. But it’s crucial to understand their ideal use cases. They are not a universal replacement for aluminum or copper, especially in high-power scenarios.

The key difference is thermal conductivity. Metals are still far more effective at conducting heat. So, where do polymers fit in?

Matching Material to Application

The secret lies in balancing material properties with design. Injection molding allows us to create complex geometries. Think of intricate fins and pins that maximize surface area for heat dissipation.

This design flexibility helps compensate for the polymer’s lower conductivity. Based on our tests, a well-designed polymer heat sink can outperform a poorly designed metal one in low-power applications. The process allows for the integration of features, reducing assembly steps and costs. This is something we’ve seen in past projects with clients moving from machined aluminum to molded polymers.

It’s not just about the material’s raw performance but also about how that material enables smarter design. We often find that this approach leads to a better overall product, especially in consumer electronics where weight and cost are critical. Not all polymers exhibit isotropic thermal conductivity9, which is a key design consideration.

Application Sweet Spots

| Application | Why Polymers Work Well |

|---|---|

| LED Lighting | Low heat output, complex shapes needed. |

| Consumer Electronics | Weight reduction is critical. |

| Automotive Sensors | Corrosion resistance and lower weight. |

Thermally conductive polymers provide an excellent alternative to metal heat sinks in specific low-power applications. Their light weight, lower cost, and immense design flexibility through injection molding make them ideal for modern electronics and LED lighting systems where efficiency is key.

What are phase change materials (PCMs) for thermal management?

Phase change materials offer a unique way to manage heat. They absorb and release thermal energy without a significant change in their own temperature. This happens during their phase transition, like melting from solid to liquid.

This property makes them excellent for handling sudden heat spikes. They act like a thermal sponge, soaking up excess energy. This keeps sensitive components cool and stable. Think of it as a better heat sink material for certain jobs.

Latent Heat vs. Sensible Heat

| Heat Type | Temperature Change | Mechanism |

|---|---|---|

| Sensible Heat | Temperature Rises | Material absorbs energy, gets hotter. |

| Latent Heat | Stays Constant | Material absorbs energy to change phase. |

How PCMs Act as a Thermal Buffer

The real power of PCMs is their ability to act as a temporary thermal buffer. They absorb heat when a device experiences a peak load. This prevents the system from overheating.

Once the peak load passes, the PCM slowly releases the stored heat. This heat can then be dissipated by a traditional cooling system. This process relies on the material’s latent heat of fusion10.

This buffering is critical in modern electronics. Processors, for example, have very intermittent workloads. A PCM can absorb the heat from a short, intense calculation burst. In past projects at PTSMAKE, we’ve designed enclosures that integrate PCMs to protect sensitive electronics from such thermal spikes.

Applications with Intermittent Loads

PCMs are not a one-size-fits-all solution. They excel where heat loads are inconsistent.

| Application | Peak Load Source | PCM Function |

|---|---|---|

| Consumer Electronics | CPU/GPU processing bursts | Absorbs burst heat, prevents throttling. |

| Electric Vehicles | Fast charging/discharging | Manages battery temperature spikes. |

| Solar Energy | Daytime sun exposure | Stores solar energy as heat for later use. |

| Medical Devices | Active operation cycles | Maintains stable operating temperature. |

This approach provides passive and reliable thermal control. It avoids the need for larger, more complex active cooling systems.

PCMs absorb and release heat at a constant temperature using latent heat. This makes them ideal thermal buffers for applications with intermittent peak loads, protecting components from thermal damage and ensuring stable performance.

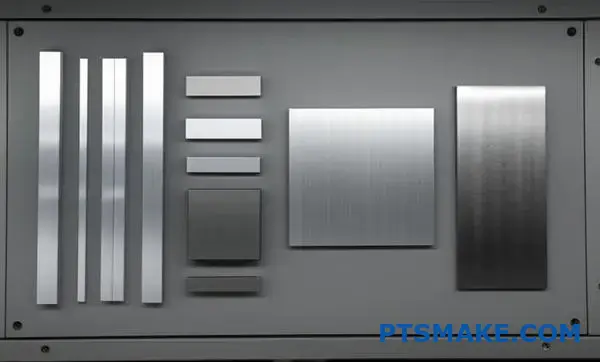

How do manufacturing processes dictate material classification?

Choosing the right material isn’t just about its final properties. It’s also about how you can shape it. The manufacturing process itself creates a practical classification system.

Thinking about the production method first often simplifies material selection. It helps avoid costly design changes later.

Process-Driven Material Selection

Each manufacturing method has materials that work best with it. You wouldn’t try to stamp a material that’s perfect for casting.

Here is a quick guide linking process to material.

| Manufacturing Process | Suitable Material Example | Key Characteristic |

|---|---|---|

| Extrusion | Aluminum 6063 | Excellent formability |

| Die Casting | Aluminum A380 | Great fluidity, castability |

| Stamping | Aluminum 1100 | High ductility |

| CNC Machining | Aluminum 6061-T6 | Good machinability |

This approach helps align your design with real-world production from the start.

A Deeper Look at Manufacturability

The link between process and material is rooted in physics. A material’s internal structure dictates how it responds to force, heat, and pressure. This is why we can group them by how they are best formed.

Extrusion Favorites

For extrusion, you need materials that can be pushed through a die without cracking. Aluminum 6063 is a classic example. Its properties allow for complex shapes, making it a top choice for a custom heat sink material. Copper also extrudes well but is more costly.

Die Casting Alloys

Die casting requires materials with excellent fluidity when molten. They must fill intricate mold cavities completely. Alloys like Zamak and Aluminum A380 are designed for this. They solidify into strong, near-net-shape parts.

Stamping and Forming Sheets

Stamping uses materials with high ductility, like steel 1018 or aluminum 1100. These materials can be bent, drawn, and stretched without fracturing. Their crystalline structure allows for this plastic deformation. The material’s grain direction can also affect forming, a property related to anisotropy11.

CNC Machining Champions

For CNC machining, the key is "machinability." This refers to how easily a material can be cut. Materials like Aluminum 6061 and PEEK have predictable cutting behavior. They produce good surface finishes and don’t cause excessive tool wear. At PTSMAKE, we analyze these properties to optimize tool paths and cutting speeds.

| Process | Primary Advantage | Common Challenge |

|---|---|---|

| Extrusion | Cost-effective for constant cross-sections | Limited to 2D complexity |

| Die Casting | High-speed production of complex parts | High initial tooling cost |

| Stamping | Excellent for high-volume sheet parts | Material thinning and springback |

| CNC Machining | High precision and design flexibility | Slower cycle times per part |

Choosing the right combination is a critical step. It ensures both performance and manufacturability for your project.

The manufacturing process fundamentally classifies materials by their workability. Selecting a material well-suited to extrusion, casting, stamping, or machining is crucial for an efficient and cost-effective production cycle, ensuring the final part meets all specifications.

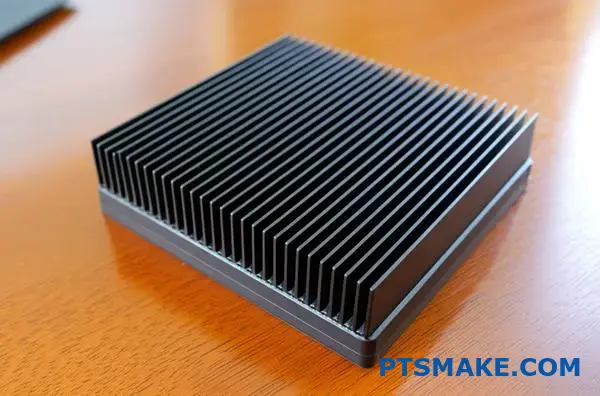

What surface finishes are used and how are they chosen?

Choosing a surface finish for a heat sink is crucial. It’s not just about aesthetics. The right finish enhances performance and longevity.

The Functional Role of Finishes

A finish can protect the heat sink from corrosion. It can also improve its ability to radiate heat.

Sometimes, the best choice is no finish at all. This saves on cost. At PTSMAKE, we weigh these factors carefully for every project.

| Factor | Key Consideration |

|---|---|

| Performance | Does it improve heat transfer? |

| Protection | Will it prevent corrosion? |

| Cost | Is the added expense justified? |

Making the Right Choice: A Breakdown

The decision comes down to balancing three key factors. These are performance needs, the operating environment, and the project budget. Each finish offers a unique trade-off.

Anodizing: The Performance Enhancer

Anodizing is a top choice for aluminum heat sinks. It creates a durable, corrosion-resistant layer. More importantly, it significantly increases the surface’s emissivity12. This helps the heat sink radiate heat more effectively. This is a huge plus for passive cooling systems.

Chromate Conversion Coating: The Protector

If corrosion is the main concern, chromate is the way to go. But it is also important to maintain electrical conductivity. It offers excellent corrosion protection and is less expensive than anodizing. This makes it a great middle-ground solution.

Unfinished: The Economic Option

Leaving the heat sink material unfinished is the most cost-effective choice. It works well in controlled, non-corrosive environments. If the budget is tight and the application allows, this is a very practical option.

Here’s a quick comparison to guide your decision.

| Finish | Primary Benefit | Best For | Key Trade-off |

|---|---|---|---|

| Anodizing | Enhanced thermal radiation | High-performance passive cooling | Higher cost |

| Chromate Coating | Corrosion resistance | Corrosive environments | Lower thermal benefit |

| Unfinished | Low cost | Controlled environments | No extra protection |

The choice of finish—anodizing, chromate, or none—is a strategic decision. It hinges on the specific balance between thermal performance requirements, environmental exposure, and the project’s budget. It’s a critical step in heat sink design and manufacturing.

How do you design for manufacturability (DFM) with different materials?

Designing for manufacturability means following the rules of your chosen process. Each method has unique requirements. Ignoring them leads to delays and higher costs.

Let’s look at three common processes.

DFM for Extrusion

For extruded parts, like those using a common heat sink material like aluminum, the fin aspect ratio is key. It is the ratio of fin height to its thickness.

DFM for Die Casting

With die casting, draft angles are critical. These are small tapers on vertical walls. They help eject the part from the mold cleanly.

DFM for CNC Machining

Tool access is everything in CNC machining. If the cutting tool can’t reach a surface, it can’t be machined. This simple rule shapes complex parts.

| Process | Key DFM Guideline | Why It Matters |

|---|---|---|

| Extrusion | Fin Aspect Ratio | Prevents tool breakage, ensures material flow |

| Die Casting | Draft Angles | Eases part ejection, avoids surface damage |

| CNC Machining | Tool Access | Determines feature feasibility, affects cost |

Understanding process-specific rules is non-negotiable for successful manufacturing. Let’s dive deeper into why these guidelines are so important for designers and engineers.

Understanding Aspect Ratios

In aluminum extrusion, a high aspect ratio (tall, thin fins) is difficult to produce. The die tongue can break under pressure. Our work with clients on heat sink designs often involves balancing thermal performance with a manufacturable aspect ratio, typically keeping it under 6:1 for best results.

The Importance of Draft Angles

In die casting, a lack of sufficient draft angle is a common design flaw. Without it, the part scrapes against the mold during ejection. This causes cosmetic defects and can damage the mold itself. In past projects at PTSMAKE, adding even a 1-2 degree draft has solved major production issues, reducing cycle times and preventing porosity13.

Thinking About Tool Access

For CNC machining, designers must visualize the cutting tool’s path. Internal corners need a radius matching the tool. Deep pockets require long, slender tools. These tools are less rigid and can vibrate, affecting surface finish and accuracy.

| Design Feature | Tool Access Challenge | DFM Solution |

|---|---|---|

| Deep Pockets | Tool length and rigidity | Widen pocket, reduce depth if possible |

| Sharp Internal Corners | Tool cannot create a sharp corner | Add an internal radius (fillet) |

| Undercuts | Standard tools cannot reach | Redesign the feature or use special tooling |

Adhering to DFM guidelines for extrusion, die casting, and CNC machining is crucial. Understanding concepts like aspect ratios, draft angles, and tool access connects your material choice directly to a successful, cost-effective manufacturing outcome.

How would you select a material for a high-power LED?

Selecting a heat sink material for high-power LEDs is a critical task. It’s a balance between managing intense heat and ensuring long-term reliability. A poor choice can lead to premature failure.

The main challenge is the high heat flux. But another, often overlooked, issue is the material’s expansion. This can damage the delicate LED substrate over time.

The Application Problem

Let’s consider a high-power industrial lighting fixture. It needs to run for thousands of hours without failure. This is where material choice becomes everything.

| Feature | Importance | Consequence of Failure |

|---|---|---|

| Heat Dissipation | Very High | LED burnout, reduced lifespan |

| Low CTE Match | Very High | Substrate cracking, failure |

| Durability | High | Physical damage, unreliability |

High-power applications demand more than just good thermal conductivity. The real challenge is managing the stress caused by heating and cooling cycles over many years. This is where we need to look closely at material properties.

The Critical Role of Low CTE

The Coefficient of Thermal Expansion (CTE) is key. A significant mismatch between the heat sink material and the LED substrate creates immense stress. This stress can cause micro-cracks or even lead to delamination14. These issues will ultimately cause the LED to fail.

Evaluating Advanced Materials

At PTSMAKE, we often guide clients through this choice. It’s about finding the right balance for their specific application and budget.

Die-Cast Aluminum

Die-cast aluminum alloys, like A380, are a common starting point. They offer good thermal performance and are cost-effective for mass production. However, their CTE is not always low enough for the most demanding applications.

Metal Matrix Composites (MMCs)

For ultimate reliability, we look at MMCs. These are engineered materials, like aluminum reinforced with silicon carbide (AlSiC). They offer an exceptional combination of high thermal conductivity and a very low, tailorable CTE. Our CNC machining capabilities allow us to create complex heat sink geometries from these advanced materials.

| Material | Thermal Conductivity (W/mK) | CTE (ppm/°C) | Relative Cost |

|---|---|---|---|

| Die-Cast Aluminum (A380) | ~96 | ~22 | Low |

| MMC (e.g., AlSiC) | 180-200 | 7-12 | High |

The choice often comes down to the required lifespan and operating environment.

For high-power LEDs, material selection must address both heat dissipation and thermal expansion stress. Advanced materials like MMCs offer superior long-term reliability by matching the LED substrate’s CTE, preventing critical failures, although at a higher initial cost than die-cast aluminum.

Propose a material solution for a fanless,sealed enclosure.

Designing a fanless, sealed enclosure presents a major thermal challenge. You need to protect sensitive electronics from dust and moisture. But this also traps heat.

The Casing as the Cooler

The solution is to turn the entire enclosure into a passive heat sink. This requires a material with excellent thermal properties. It also needs to be easily shaped.

Material Selection

Extruded aluminum is often the best choice for this heat sink material. Its properties make it ideal for dissipating heat effectively without using any fans.

| Property | Benefit for Enclosure |

|---|---|

| High Thermal Conductivity | Quickly moves heat away |

| Malleability | Allows for integrated fins |

| Lightweight | Reduces overall product weight |

This clever design ensures your device stays cool and protected from the elements.

Extruded aluminum is my go-to recommendation for these demanding applications. At PTSMAKE, we leverage CNC machining to create complex enclosure geometries from extrusions. This allows us to integrate cooling fins directly into the casing’s structure.

Maximizing Surface Area

These fins dramatically increase the surface area available for heat dissipation. More surface area means faster and more efficient cooling. This is the core principle of passive thermal management. You are using the product’s own body to do the work.

Beyond Conductivity

While aluminum’s thermal conductivity is high, that is only half the story. The surface finish plays a vital role. Its ability to radiate heat is measured by its emissivity15. A shiny, raw aluminum surface is surprisingly poor at radiating heat away.

In our collaboration with clients, we found that applying a surface treatment significantly improves thermal performance. Anodizing is a popular and effective choice for this.

| Surface Finish | Relative Heat Radiation |

|---|---|

| Polished Aluminum | Poor |

| Matte Black Anodized | Excellent |

| Standard Anodized | Good |

This treatment creates a surface that excels at releasing thermal energy into the surrounding environment. It is a critical detail that makes a huge difference in performance.

For a fanless, sealed enclosure, the solution lies in smart design and material choice. Using extruded aluminum to create a casing with integrated fins transforms the entire product into an effective passive heat sink, ensuring reliable thermal management.

How do you manage thermals in an EV battery pack?

Let’s move from theory to application. We’ll look at a core component: the aluminum cooling plate. These plates are integrated directly into the battery pack.

Choosing the right material is a balancing act. It’s about more than just cooling. We must consider weight, corrosion resistance, and structural strength. Aluminum is often the best choice. It is a fantastic heat sink material for this role.

A quick comparison shows why.

| Material | Thermal Conductivity (W/mK) | Density (g/cm³) | Relative Cost |

|---|---|---|---|

| Aluminum | ~205 | 2.7 | Low |

| Copper | ~401 | 8.96 | High |

| Steel | ~50 | 7.85 | Low |

The Four Pillars of Material Choice

When designing cooling plates, we analyze four key factors. Each one is critical for the battery pack’s overall performance and lifespan.

1. Thermal Performance

Aluminum’s thermal conductivity is excellent. While not as high as copper, it’s more than sufficient. It efficiently pulls heat away from the battery cells. This balance is perfect for vehicle applications.

2. Weight

This is where aluminum truly shines. Its low density helps keep the battery pack’s weight down. Lighter packs mean longer range and better vehicle efficiency. This is a non-negotiable benefit in EV design.

3. Corrosion Resistance

Coolants, typically a mix of glycol and water, can be corrosive. The right aluminum alloy, like 6061, is crucial. It naturally forms a protective oxide film, a passivation layer16, that prevents corrosion.

4. Structural Integrity

The cooling plate is not just for cooling. It often serves as a structural part of the battery pack enclosure. At PTSMAKE, our CNC machining creates intricate fluid channels without compromising the plate’s strength and rigidity.

| Aspect | Analysis of Aluminum Cooling Plates |

|---|---|

| Performance | Great heat dissipation, providing an ideal balance for its weight. |

| Weight | Very lightweight, which directly improves the vehicle’s overall range. |

| Corrosion | Requires specific alloys or coatings to prevent issues with coolant. |

| Structure | Strong enough to be integrated as a key structural component. |

Aluminum cooling plates are an excellent solution for EV battery packs. They offer a winning combination of thermal efficiency, low weight, and structural strength. The key is precise material selection and manufacturing to ensure long-term reliability and performance.

How do you mitigate corrosion for a marine environment heat sink?

Marine environments are brutal on electronics. The constant salt spray aggressively attacks metals. Protecting a heat sink here requires a dual strategy. It is not just about one fix.

First, select the right base alloy. Then, add a protective surface treatment. This layered defense is the only way to ensure long-term reliability for your device.

Two-Part Defense Strategy

| Step | Action | Purpose |

|---|---|---|

| 1 | Select Corrosion-Resistant Alloy | Establish a strong, inherently resistant foundation. |

| 2 | Apply Protective Coating | Add an external barrier against direct salt exposure. |

This approach combines material science with finishing techniques for maximum effect.

A complete solution addresses both the core material and its surface. Failing to consider both aspects is a common mistake that leads to premature failure in marine applications. The secret is creating a system where each component supports the other.

Choosing the Right Base Material

Not all aluminum is the same. For marine use, we often recommend 5000-series alloys, like 5052. Its primary alloying element is magnesium, which gives it excellent corrosion resistance, especially in saltwater. It outperforms the more common 6061 aluminum in these conditions. An improper heat sink material can doom a project.

Layering on Protection: Surface Treatments

Once you have the right base, you must add a barrier. This is where a high-quality finish comes in. It shields the aluminum from direct contact with the corrosive salt and moisture. This also prevents issues like galvanic corrosion17 if other metals are nearby. At PTSMAKE, we guide clients through these crucial finishing choices.

Comparing Top Coating Options

| Feature | Marine-Grade Powder Coat | Anodization (Type II/III) |

|---|---|---|

| Protection | Excellent barrier coating | Good, forms a hard oxide layer |

| Thickness | Thicker, can slightly impact heat transfer | Thinner, better thermal performance |

| Durability | Very high impact resistance | High scratch resistance |

| Best Use | When physical toughness is a top priority. | When thermal efficiency is critical. |

Ultimately, the choice depends on your specific thermal and durability requirements.

A dual approach is essential for marine heat sinks. Starting with a corrosion-resistant alloy like 5052 aluminum and adding a protective surface treatment, such as a marine-grade powder coat or anodization, ensures the device’s long-term survival and performance in harsh environments.

What are the material implications for liquid cooling cold plates?

Choosing the right material for a liquid cooling cold plate is crucial. It’s not just about cooling. It’s a balance of performance, longevity, and cost.

The material directly impacts how efficiently heat moves. It also determines how the cold plate resists corrosion from the coolant over time.

Key Material Considerations

The right material ensures your system runs cool and reliably. Three factors are most important: thermal conductivity, coolant compatibility, and how it can be manufactured.

Material Thermal Properties

High thermal conductivity is the top priority. It dictates how quickly the plate absorbs heat. Copper is a very common choice for this reason.

Here is a quick comparison of common materials:

| Material | Thermal Conductivity (W/mK) | Key Benefit |

|---|---|---|

| Copper | ~400 | Excellent Performance |

| Aluminum | ~235 | Lightweight & Lower Cost |

| Stainless Steel | ~16 | High Corrosion Resistance |

Deeper Dive into Material Selection

Material choice goes beyond just a single property. You must consider the entire system. In past projects at PTSMAKE, we’ve seen how a poor choice can cause system-wide failures.

Conductivity vs. Cost

Copper offers the best thermal performance. However, it’s heavier and more expensive than aluminum. For applications where weight and budget are tight, aluminum is a strong contender. We help clients weigh these trade-offs to find the optimal solution. The choice of a cold plate material, much like a traditional heat sink material, is a critical decision.

The Risk of Corrosion

Coolant compatibility is non-negotiable. The material must not react with the fluid. Mixing incompatible metals, like copper and aluminum, in the same loop can lead to galvanic corrosion18. This process degrades the materials, causing leaks and clogs over time. Additives in the coolant can help, but material selection is the first line of defense.

Manufacturing and Internal Channels

The inside of a cold plate is complex. It contains micro-channels to maximize the surface area for heat transfer. Creating these requires advanced manufacturing.

Methods for creating these channels include:

- CNC Machining: Excellent for prototypes and complex geometries.

- Brazing/Welding: Joining multiple pieces to form internal paths.

- Die Casting: Suitable for high-volume production of simpler designs.

At PTSMAKE, our precision CNC machining is ideal for creating intricate and efficient micro-channel designs for custom cold plates.

Material selection for cold plates is a careful balance. You must weigh thermal conductivity against corrosion resistance and manufacturability. The right choice ensures optimal performance, system reliability, and meets budget goals for the entire liquid cooling loop.

How would you select materials for a thermoelectric cooler (TEC) assembly?

Integrating with Thermal Components

A TEC doesn’t work in a vacuum. Its true performance is tied to the components it’s integrated with. Think of it as a team effort.

The most crucial teammates are the heat exchangers. These components are attached to the hot and cold sides of the TEC.

Their job is to move heat. For maximum efficiency, you need a heat sink material with very high thermal conductivity. This ensures heat is pumped effectively across the temperature differential.

Common Heat Exchanger Materials

| Material | Thermal Conductivity (W/m·K) | Key Benefit |

|---|---|---|

| Copper | ~400 | Excellent Performance |

| Aluminum | ~235 | Good Performance, Lightweight |

| Graphite | ~150-1500 | High Performance, Directional |

Maximizing Heat Pumping Efficiency

Let’s break down why high thermal conductivity is so vital for both the hot and cold side heat exchangers. It’s all about minimizing bottlenecks for heat flow.

The Hot Side Exchanger

The hot side’s mission is simple: get rid of heat. It must dissipate the heat pumped by the TEC, plus the electrical heat generated, into the surrounding environment as quickly as possible.

If the heat sink material has low conductivity, heat builds up. This raises the TEC’s hot side temperature, drastically reducing its efficiency and cooling capacity. It creates a thermal traffic jam.

The Cold Side Exchanger

The cold side exchanger has the opposite job. It must efficiently pull heat from the object you want to cool and deliver it to the TEC’s cold face.

Any inefficiency here means the object doesn’t get as cold as it should. Low conductivity creates a barrier, preventing the TEC from doing its job effectively. The entire system’s performance hinges on minimizing the Thermal resistance19 at these interfaces.

In past projects at PTSMAKE, we have observed that switching from a poorly chosen heat sink material to an optimized one like copper can boost overall system efficiency significantly.

Effective TEC assembly depends on high-conductivity heat exchangers. Materials like copper or aluminum are critical for both hot and cold sides to ensure efficient heat transfer, preventing thermal bottlenecks and maximizing the cooler’s performance by enabling effective heat pumping.

Propose a material for a lightweight drone’s power electronics.

When designing a lightweight drone, every gram counts. This is especially true for power electronics. They generate significant heat that must be managed.

Standard aluminum heat sinks are often too heavy. They can reduce flight time and payload capacity. We must look at advanced materials.

The Weight vs. Heat Challenge

The goal is to find the best heat sink material for the job. It needs to be light but also very effective at dissipating heat. This balance is key for drone performance.

Let’s compare a standard choice with an advanced one.

| Material | Relative Density | Thermal Performance |

|---|---|---|

| Aluminum (6061) | 1.0x | Good |

| Magnesium Alloy | 0.65x | Fair |

| APG | 0.8x | Exceptional |

This shows why advanced materials are worth considering. They offer a significant advantage in weight-critical situations.

For high-performance drones, the choice of material for power electronics is crucial. It directly impacts flight efficiency. While aluminum is a reliable default, its weight can be a limiting factor. This is where we need to innovate.

Justifying an Advanced Material

In past projects at PTSMAKE, we have explored several options. For the most demanding applications, Annealed Pyrolytic Graphite (APG) stands out. It’s a game-changer for thermal management in compact spaces.

Performance Per Gram

APG offers exceptional thermal conductivity. It is far superior to aluminum. Its real advantage is its low density. This gives it the best thermal performance per gram. This is the most important metric for a drone. APG’s properties are not uniform in all directions, a characteristic known as anisotropy20.

Our tests show APG can spread heat laterally very effectively. This prevents hot spots on sensitive components.

| Property | Aluminum (6061) | Magnesium (AZ91D) | APG (In-Plane) |

|---|---|---|---|

| Density (g/cm³) | 2.70 | 1.81 | 2.26 |

| Thermal Conductivity (W/m-K) | 167 | 72 | ~1700 |

| Performance/Gram (W/m-K / g/cm³) | 61.8 | 39.8 | ~752.2 |

Manufacturing Considerations

However, APG is not a simple drop-in replacement. Machining it requires specific expertise and tools. Magnesium alloys are easier to process but offer less thermal benefit. At PTSMAKE, we have developed processes to handle these advanced materials effectively.

Choosing advanced materials like APG or magnesium is a strategic decision. It provides a significant performance edge for lightweight drones by offering superior thermal management per gram compared to standard aluminum. This is key for flight time and reliability.

Unlock Superior Heat Sink Solutions with PTSMAKE Expertise

Ready to improve your product’s thermal management or streamline your next heat sink project? Contact PTSMAKE today for a fast, tailored quotation on high-precision, custom-manufactured heat sink materials and components. Our team stands ready to help you achieve unmatched performance and reliability—from prototype to production!

Discover how this property is measured and why it’s critical for your part’s durability. ↩

Understand how this property affects material strength during manufacturing and its impact on your design. ↩

Learn how directional properties can solve complex thermal challenges in your designs. ↩

Learn how this key metric impacts your component’s temperature and lifespan. ↩

Learn how directionally dependent properties can impact material selection for your design. ↩

Learn how this electrical property is measured and why it is critical for component safety and design. ↩

Learn about this critical boundary and how its integrity dictates the composite’s final properties and reliability. ↩

Discover how this critical metric influences the real-world thermal performance of your components. ↩

Discover how heat can conduct differently in various directions within a material. ↩

Understand the specific thermal energy required to change a material from solid to liquid without raising its temperature. ↩

Explore why this material property is critical for predictable results in metal forming. ↩

Learn how this key property directly improves a heat sink’s ability to dissipate heat. ↩

Learn how to identify and prevent this common defect to improve the structural integrity of your parts. ↩

Learn more about how this material separation can compromise your product’s structural integrity and performance. ↩

Discover how this surface property is crucial for radiating heat away from your components. ↩

See how this microscopic layer protects metal from harsh chemicals. ↩

Learn how dissimilar metals can cause accelerated corrosion and how to prevent it in your designs. ↩

Learn how mixing certain metals in a coolant loop can cause electrical currents that destroy your components. ↩

Understand how this property impacts the overall efficiency of your thermal management system. ↩

Understand how a material’s directional properties can unlock superior performance in your designs. ↩