Selecting the right material for high-wear applications can make or break your project. Many engineers struggle with material failures, unexpected downtime, and costly replacements when they don’t fully understand their options.

UHMWPE (Ultra-High Molecular Weight Polyethylene) is a specialized engineering plastic with molecular chains 10-15 times longer than standard polyethylene, creating exceptional wear resistance, impact strength, and chemical resistance that outperforms many metals in specific applications.

This guide covers everything from molecular structure to real-world applications. You’ll learn how to select the right grade, avoid common design mistakes, and make informed decisions that save time and money on your next project.

What makes UHMWPE’s molecular structure fundamentally unique?

The secret to UHMWPE’s strength isn’t complex chemistry. It’s about length. This material has extremely long polymer chains.

Think of it like spaghetti. Cooked spaghetti strands, when tangled, are hard to pull apart. This entanglement is the key.

Chain Length Comparison

The molecular chains in this UHMWPE material are exceptionally long. This physical characteristic is more important than its chemical bonds.

| Polymer Type | Average Chain Length | Primary Strength Source |

|---|---|---|

| Standard PE | Shorter | Chemical Bonds |

| UHMWPE | Extremely Long | Physical Entanglement |

This length creates a unique and robust structure.

Beyond Chemical Bonds: The Power of Entanglement

Most plastics get their strength from strong chemical bonds. But UHMWPE is different. Its strength comes from the sheer length and physical entanglement of its molecular chains. Imagine a massive, tangled knot of fishing line.

You can’t easily pull one strand out. The friction and interlinking between strands create immense resistance. This is how UHMWPE works on a molecular level.

How Entanglement Translates to Performance

This structure is why UHMWPE excels in high-stress applications. When an impact occurs, the energy spreads across these tangled chains. Instead of a single bond breaking, the force is distributed. This dissipation prevents catastrophic failure.

The long chains also slide past each other smoothly. This is what gives the UHMWPE material its incredibly low coefficient of friction. These chains are held together by weak Van der Waals forces1, allowing for movement without breaking apart.

At PTSMAKE, we leverage these properties. We create parts for high-wear environments where durability is critical.

| Property | Cause | Application Example |

|---|---|---|

| High Impact Strength | Energy dissipation via chain network | Medical implants, armor |

| Low Friction | Smooth sliding of long chains | Gears, wear strips |

| Abrasion Resistance | Chains resist being pulled apart | Conveyor components |

This physical structure is the foundation of its superior performance.

The uniqueness of UHMWPE lies not in its chemistry but its physics. Its ultra-long, entangled polymer chains create a structure that is incredibly tough and slick, providing exceptional impact strength and a very low coefficient of friction.

What is the practical meaning of ‘molecular weight’?

Molecular weight is more than a number on a spec sheet. It directly tells us about a material’s practical performance. Think of it as a blueprint for toughness and durability.

A Direct Link to Performance

For materials like UHMWPE, a higher molecular weight means longer polymer chains. These long chains create a stronger, more entangled structure. This directly improves key properties.

| Property | Lower Molecular Weight | Higher Molecular Weight |

|---|---|---|

| Toughness | Good | Excellent |

| Wear Resistance | High | Exceptional |

| Processing | Easier | More Difficult |

This relationship is crucial. It dictates how a part will perform in the real world. It also affects how we approach manufacturing it.

The UHMWPE Molecular Weight Spectrum

The typical range for UHMWPE material is vast. It spans from 3.5 to 7.5 million g/mol. This isn’t a minor variation. It represents a significant shift in material behavior and processing needs.

At PTSMAKE, we handle this full spectrum. We know that choosing the right grade is critical for success. The selection depends entirely on the application’s demands.

Low vs. High End of the Spectrum

Lower-end UHMWPE is easier to process. It flows better during molding. However, it offers less resistance to abrasion and impact. This makes it suitable for less demanding applications.

Higher-end UHMWPE is a different challenge. Its extremely long chains increase material viscosity2. This makes it difficult to mold or machine. But the payoff is immense. You get superior wear resistance and impact strength. It’s ideal for high-stress components. Our experience shows that specialized tooling and techniques are necessary to machine these high-grade materials effectively.

| Molecular Weight (million g/mol) | Key Characteristics | Common Applications |

|---|---|---|

| 3.5 – 5.0 | Easier to process, good wear resistance. | Guide rails, chain guides, general-purpose parts. |

| 5.0 – 7.5 | Exceptional toughness, superior abrasion resistance. | Medical implants, high-wear conveyor parts, bearings. |

Choosing between them involves a trade-off. You balance performance needs against manufacturing complexity and cost.

Molecular weight is a key performance indicator. For UHMWPE material, a higher value means superior toughness and wear resistance. However, it also significantly increases the difficulty and cost of processing, requiring specialized manufacturing expertise to achieve desired results.

Why is UHMWPE more abrasion-resistant than steel?

It’s a common question we get at PTSMAKE. How can a plastic be tougher than steel? The answer isn’t about hardness. It’s about a smarter way of handling friction and wear.

Steel is hard, but it can be brittle on a micro-level. UHMWPE is different.

The Low-Friction Advantage

The surface of this material is incredibly slick. Its low coefficient of friction means abrasive particles often just slide over it. They don’t get a chance to dig in and cause damage.

The Role of High Toughness

If a sharp particle does apply force, UHMWPE’s toughness comes into play. Instead of cracking, the material can deform slightly, absorbing the impact without gouging.

Here’s a simple comparison based on our test results:

| Property | UHMWPE | Carbon Steel |

|---|---|---|

| Abrasion Resistance | Excellent | Good |

| Coefficient of Friction | Extremely Low | Moderate |

| Impact Strength | Very High | Moderate to Low |

This unique combination makes the UHMWPE material incredibly resilient.

A Deeper Look at the Mechanism

The secret lies in its molecular structure. UHMWPE is made of extremely long polymer chains. These chains are not chemically cross-linked, giving them a unique ability to move and absorb energy. This is a core reason we often recommend it for high-wear applications.

When an abrasive force is applied, these long chains can shift and stretch. This dissipates the energy across the material’s structure rather than concentrating it at one point. The material’s viscoelasticity3 plays a huge role here, allowing it to deform under stress and then slowly return to its original shape.

How Steel Responds Differently

Steel, on the other hand, has a rigid crystalline lattice. While very strong, this structure is less forgiving. When a sharp particle strikes its surface, the energy has nowhere to go. This concentration of force can cause microscopic cracks and fractures, leading to material loss.

Think of it this way:

| Interaction | UHMWPE | Steel |

|---|---|---|

| Energy Response | Dissipates energy by chain movement | Concentrates energy, causing fractures |

| Primary Failure Mode | Gradual, smooth wear | Chipping and micro-pitting |

This fundamental difference is why UHMWPE can often outlast steel in sliding abrasion scenarios.

UHMWPE’s true strength lies in its combination of slipperiness and toughness. Its molecular structure allows it to absorb and dissipate energy that would cause harder materials like steel to chip and fracture on a microscopic level, leading to superior abrasion resistance.

What are its primary weaknesses or application limitations?

While UHMWPE is an incredible performer in many areas, it’s not suitable for every job. Understanding its weaknesses is key to avoiding costly design failures.

Every material choice involves trade-offs. We must look beyond the highlights to see the full picture. Let’s explore the practical constraints of using this polymer.

Key Limiting Factors

Here is a quick overview of the main challenges associated with UHMWPE material.

| Limitation | Impact on Application |

|---|---|

| Low Service Temperature | Unsuitable for high-heat environments |

| High Thermal Expansion | Can cause tolerance issues with temperature shifts |

| Low Surface Hardness | Prone to scratching and abrasion |

| Low Stiffness (Creep) | Deforms over time under constant load |

| Difficult to Bond | Its waxy surface resists adhesives |

A Deeper Look at the Constraints

To make the right choice, you need to understand why these limitations matter. In past projects at PTSMAKE, we’ve seen these issues firsthand.

Thermal Instability

UHMWPE has a very low melting point, around 135°C (275°F). This limits its use to low-temperature applications. Anything approaching this temperature will cause it to soften and fail.

Furthermore, its coefficient of thermal expansion4 is very high. It expands and contracts significantly with temperature changes. This can be a major problem for parts requiring tight tolerances.

Here’s a comparison based on our lab tests:

| Material | Thermal Expansion (x10⁻⁶ /°C) |

|---|---|

| UHMWPE | ~130-200 |

| Aluminum | ~23 |

| Steel | ~12 |

As you can see, the difference is substantial.

Mechanical Deficiencies

While tough, UHMWPE is a relatively soft material. It has low surface hardness, making it susceptible to scratches.

It also has low stiffness and is prone to creep. This means under a constant load, the material will slowly deform over time. This makes it unsuitable for high-load structural components.

Processing and Assembly Hurdles

One of the biggest challenges is its incredibly low coefficient of friction. This "non-stick" quality makes it nearly impossible to bond with adhesives. Special surface treatments are required, which adds complexity and cost to the assembly process.

In summary, UHMWPE’s main drawbacks are its poor performance in high heat, its tendency to deform under load, and its significant expansion with temperature. Its non-stick surface also makes bonding a major challenge for multi-part assemblies.

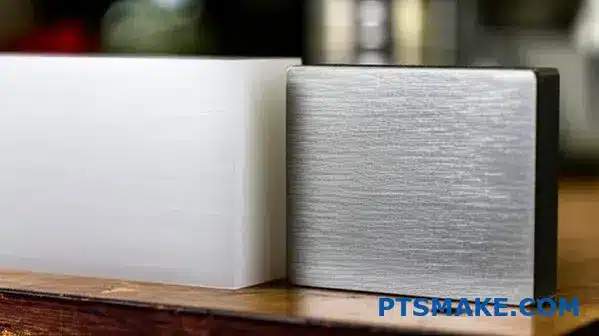

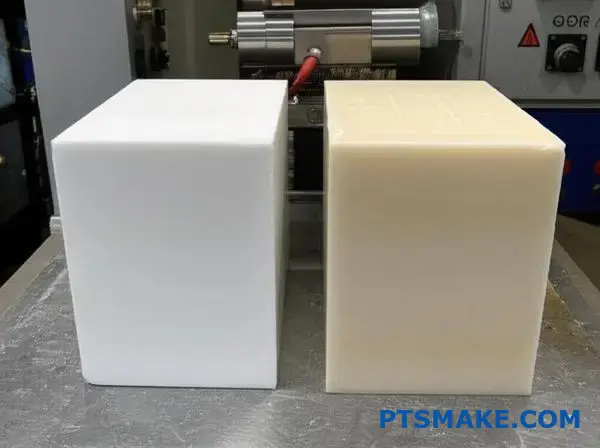

How does virgin UHMWPE differ from reprocessed grades?

When choosing a UHMWPE material, the biggest question is often virgin versus reprocessed. The decision boils down to a trade-off. It’s a balance between performance and cost.

Reprocessed grades offer a significant cost saving. However, this comes at the price of performance. Virgin material guarantees purity and optimal properties.

Quick Comparison

| Feature | Virgin UHMWPE | Reprocessed UHMWPE |

|---|---|---|

| Cost | Higher | Lower |

| Purity | 100% Pure Resin | Contains Recycled Material |

| Performance | Maximum | Reduced |

| Consistency | High | Variable |

This choice directly impacts your final part’s reliability.

The reprocessing cycle involves melting and reforming the material. This process exposes the UHMWPE to heat and mechanical stress. It inevitably shortens its ultra-long molecular chains. These chains are the source of its exceptional strength.

Molecular Chain Degradation

Shorter chains mean weaker material. Based on collaborative research with our clients, we’ve seen this directly affect two key properties. Impact strength is reduced, making the material more brittle. It also lowers the material’s stress crack resistance5, a critical factor in many applications.

This doesn’t mean reprocessed grades are useless. It’s about matching the material to the job. At PTSMAKE, we help clients make the right call. We analyze the specific needs of each part.

When to Use Each Grade

| Application Requirement | Recommended Grade | Rationale |

|---|---|---|

| High Wear & Impact | Virgin | Essential for durability and safety. |

| Medical Devices | Virgin | Purity and biocompatibility are non-negotiable. |

| Food Contact | Virgin | Required for compliance and safety. |

| Non-Critical Spacers | Reprocessed | Cost-effective for low-stress roles. |

| General Purpose Bumpers | Reprocessed | Acceptable where peak performance isn’t needed. |

Choosing wisely prevents premature failure. It also ensures you aren’t overspending on non-critical components.

Virgin UHMWPE guarantees peak performance due to its intact molecular structure, making it essential for critical applications. Reprocessed grades provide a cost-effective alternative for less demanding roles, but with compromised strength and consistency. The choice depends entirely on application requirements.

How does UHMWPE compare to other common engineering plastics?

Choosing the right material is critical. It determines your part’s performance and lifespan. Let’s compare UHMWPE material with other common plastics.

We’ll look at Nylon, Acetal (POM), and PTFE. These are all excellent materials. But they serve different purposes. Understanding their key differences is essential for success.

Quick Look: UHMWPE vs. Alternatives

Here’s a quick comparison to get us started. It shows where UHMWPE truly shines against others.

| Material | Wear Resistance | Impact Strength |

|---|---|---|

| UHMWPE | Highest | Highest |

| Nylon (PA) | Good | High |

| Acetal (POM) | Very Good | Good |

| PTFE | Fair | Low |

This gives you a starting point for selection.

A Deeper Dive into Material Properties

In past projects at PTSMAKE, we’ve guided many clients through this selection process. The best choice always depends on the specific application’s demands.

Factors like friction, moisture, and budget play huge roles. For instance, Nylon is strong but absorbs water. This can change its dimensions, making it unsuitable for high-precision, wet applications.

PTFE has the lowest coefficient of friction6. It’s incredibly slick. However, it’s softer and not as durable as UHMWPE. It cannot handle high loads or abrasive wear nearly as well.

Acetal (POM) offers a great balance. It has good mechanical strength, low moisture absorption, and excellent machinability. It’s a reliable workhorse for many applications where UHMWPE might be overkill. But it lacks UHMWPE’s top-tier impact and abrasion resistance.

Below is a more detailed comparison based on our test results and project experience.

| Property | UHMWPE | Nylon (PA66) | Acetal (POM) | PTFE |

|---|---|---|---|---|

| Wear Resistance | Excellent | Good | Very Good | Fair |

| Impact Strength | Excellent | High | Good | Low |

| Coefficient of Friction | Very Low | Moderate | Low | Lowest |

| Moisture Absorption | Very Low | High | Low | Very Low |

| Relative Cost | Moderate | Low | Moderate | High |

This chart helps build a mental matrix. It simplifies choosing the right engineering plastic for your specific needs, balancing performance with cost.

This comparison shows there’s no single "best" material. UHMWPE is superior for abrasion and impact. However, POM, Nylon, or PTFE might be more suitable depending on chemical exposure, dimensional stability needs, or friction requirements.

What are the main commercial grades of UHMWPE material?

Not all UHMWPE material is created equal. Choosing the right grade is critical for your project’s success. Different additives create materials tailored for specific challenges.

Understanding these families is the first step. It ensures you select a material that performs reliably. The main categories are designed for distinct operational needs.

| Grade Family | Primary Function |

|---|---|

| Standard Virgin | General-purpose applications |

| Enhanced Wear | Low friction, high wear resistance |

| Antistatic | Static electricity dissipation |

| High-Temperature | Improved thermal stability |

This structure helps us at PTSMAKE guide clients to the best-fit material. It avoids over-engineering and manages costs effectively.

Standard Virgin Grades

This is your baseline UHMWPE. It is unmodified and often compliant with FDA and USDA regulations. It is perfect for food processing equipment and general-purpose components where extreme conditions are not a factor. It offers a great balance of impact strength and a low coefficient of friction.

Enhanced Bearing & Wear Grades

When parts face constant friction, virgin UHMWPE may not be enough. Enhanced grades include lubricants like oil, wax, or silicone. These additives are integrated directly into the material matrix.

This results in a lower coefficient of friction and superior wear life. In past projects at PTSMAKE, we’ve used these for bearings, sprockets, and wear strips, extending part longevity significantly.

Antistatic Grades

Standard plastics can build up a static charge. This is a major risk in electronics manufacturing or explosive environments. Antistatic grades solve this by including carbon or other conductive fillers.

These fillers safely dissipate static charge. This prevents damage to sensitive components and reduces ignition risks. This grade is essential for applications requiring control over triboelectric charging7.

High-Temperature Grades

Cross-linked UHMWPE is engineered for thermal stability. The cross-linking process creates stronger bonds between molecules. This allows the material to retain its mechanical properties at elevated temperatures where standard UHMWPE would fail.

| Property | Virgin Grade | Enhanced Wear | Antistatic | High-Temp |

|---|---|---|---|---|

| Wear Resistance | Good | Excellent | Good | Very Good |

| Temp Limit | ~80°C | ~80°C | ~80°C | ~130°C |

| Static Control | Poor | Poor | Excellent | Poor |

Choosing the correct UHMWPE grade is key. Additives create specialized versions for specific needs, from reducing static buildup to improving wear resistance in demanding applications. This ensures optimal performance and a longer service life for your components.

How do fillers like glass or carbon change properties?

Fillers are not just for cost-cutting. In high-performance plastics, they are powerful tools. We use them to engineer specific material properties.

This enhances a base polymer for a unique application. Think of it like adding rebar to concrete.

Tailoring Plastic Performance

Fillers like glass or carbon fibers transform standard plastics. They turn them into high-strength composites. This allows for more demanding uses.

The choice of filler depends entirely on the final goal.

| Property | Base Nylon 66 | 30% Glass-Filled Nylon 66 |

|---|---|---|

| Tensile Strength | Lower | Significantly Higher |

| Stiffness | Flexible | Very Stiff |

| Cost | Lower | Higher |

This simple change unlocks new possibilities for parts.

Glass Fiber Reinforcement

Adding glass fibers is a common strategy. We do this to boost mechanical strength and stiffness. This makes the plastic much more rigid.

It also increases compressive strength and heat deflection temperature. This is great for parts under constant load or in hot environments.

However, there are trade-offs. The material becomes more brittle. This means its impact strength often decreases.

The glass fibers also make the material abrasive. This can cause faster wear on injection molds and any mating parts. During the design phase, we always account for this.

The final properties can also be highly anisotropic8. This means the part is stronger in the direction the fibers are aligned.

Carbon-Based Fillers

Carbon fillers serve very different functions. They are not always for mechanical strength.

Static Dissipation

One key use is for electrical conductivity. Adding carbon black or carbon fibers makes a plastic conductive.

This is critical for electronics enclosures. It helps to safely dissipate static electricity, protecting sensitive components.

Thermal Conductivity

Carbon can also improve thermal conductivity. It helps pull heat away from a source.

In projects at PTSMAKE, we’ve used carbon-filled plastics for components that act like heat sinks. This is a clever way to manage heat without using metal. These fillers are effective in many polymers, including specialized ones like UHMWPE Material.

Fillers like glass and carbon are essential for modern manufacturing. They allow us to precisely tailor a polymer’s properties. However, these enhancements come with trade-offs, like reduced impact strength or increased mold wear, which must be carefully managed.

What distinguishes medical-grade from industrial-grade UHMWPE?

The core difference isn’t just a label. It’s about patient safety. Industrial-grade UHMWPE is a robust material for machinery. But it is not made for the human body.

Medical-grade UHMWPE is fundamentally different. It starts with purer raw materials. The manufacturing process involves much stricter controls to ensure safety and performance inside a patient.

Here is a simple breakdown of the primary differences.

| Feature | Medical-Grade UHMWPE | Industrial-Grade UHMWPE |

|---|---|---|

| Purity | Extremely high, no additives | Standard purity, may contain additives |

| Controls | Rigorous process & quality control | General industrial standards |

| Testing | Extensive biocompatibility tests | Mechanical property tests only |

These distinctions are not minor. They are critical for any medical application.

While mechanical specs can look similar on paper, the unseen factors are what truly matter. Choosing the wrong grade is a risk no one in the medical field can afford to take. At PTSMAKE, we strictly adhere to material specifications for our medical clients.

Traceability from Start to Finish

For medical devices, every single component must be traceable. This means we can track the material from its raw resin form to the final machined part. This complete chain of custody is a non-negotiable requirement. It ensures accountability if an issue ever arises. Industrial grades simply do not have this level of documentation.

The Biocompatibility Standard

A material used inside the body must be safe. It cannot cause a toxic reaction or be rejected. This is known as biocompatibility9. Medical-grade UHMWPE material undergoes rigorous testing according to standards like ISO 10993. This extensive process validates that the material is safe for long-term implantation. Industrial grades are not subjected to this vital testing.

Stricter Manufacturing Controls

The environment where parts are made matters. Medical-grade UHMWPE components are often produced in controlled environments. This prevents contamination from dust, oils, or other foreign particles. Industrial manufacturing doesn’t require these stringent protocols, making the final product unsuitable for sterile medical applications.

The differences are profound. Medical-grade UHMWPE is defined by its purity, traceability, and biocompatibility testing. These factors are absent in industrial grades, making them completely unsafe for any medical device or implant, regardless of their mechanical strength.

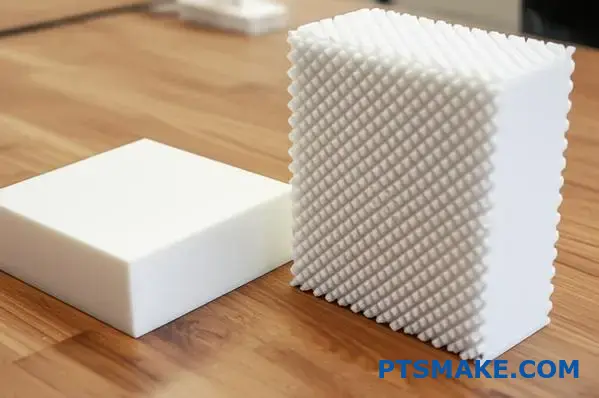

What is the purpose of cross-linking in UHMWPE?

Cross-linking is a crucial process. It enhances the properties of standard UHMWPE. We use it to prepare the material for more demanding applications.

The most common method is irradiation. This process forges chemical bonds between the long polymer chains.

This structural change dramatically boosts wear resistance. It also increases the material’s service temperature, making it more durable under stress.

| Property | Before Cross-Linking | After Cross-Linking |

|---|---|---|

| Wear Resistance | Good | Excellent |

| Toughness | Excellent | Good |

The cross-linking process is quite fascinating. Typically, we expose the UHMWPE material to controlled doses of gamma or electron beam radiation.

This energy breaks some carbon-hydrogen bonds along the polymer chains. This action creates highly reactive sites known as free radicals10.

These unstable sites quickly seek stability. They do this by forming strong, new covalent bonds with neighboring chains. This transforms the separate strands into a robust, three-dimensional network.

This interconnected structure is the secret to its enhanced performance. It restricts molecular movement, making it much harder for material to be worn away from the surface.

In past projects, we’ve seen this directly translate to parts that last significantly longer in high-friction environments. However, this increased rigidity comes at a cost.

The material becomes less ductile. This means its toughness and impact strength are reduced. The choice to use cross-linked UHMWPE is an engineering trade-off.

| Feature Comparison | Standard UHMWPE | Cross-Linked UHMWPE |

|---|---|---|

| Molecular Structure | Independent Chains | 3D Network |

| Wear Resistance | High | Extremely High |

| Max Service Temp | Lower | Higher |

| Impact Strength | Very High | Moderate |

Cross-linking transforms UHMWPE by creating a robust molecular network. This significantly improves wear and heat resistance but reduces toughness and impact strength, a critical trade-off for specialized applications where durability is paramount.

How are UHMWPE materials categorized by molecular weight ranges?

Understanding UHMWPE starts with its molecular weight. This isn’t just a technical number. It’s the primary factor that defines the material’s grade and performance.

Different molecular weight ranges create distinct grades. Each grade offers a unique balance of properties. This categorization helps engineers select the perfect material for a specific application.

Here is a simplified breakdown of common categories:

| Molecular Weight (g/mol) | Common Designation | Key Characteristic |

|---|---|---|

| 3.1 – 4.5 Million | Standard / High-Grade | Good all-around performance |

| 5.0 – 6.0 Million | Premium-Grade | Enhanced wear resistance |

| > 6.0 Million | Ultra-Premium / Medical | Maximum impact & wear resistance |

Choosing the right grade is crucial for project success.

The Link Between Molecular Weight and Performance

So, why does a higher molecular weight result in a tougher material? It’s about the length of the polymer chains. Longer chains create more connections and overlap within the material’s structure.

Think of it like a bowl of spaghetti. Short strands are easy to pull apart. But very long strands get tangled together. This creates a much stronger, more cohesive mass. This is the core principle behind UHMWPE’s strength.

This increased chain entanglement11 directly improves key mechanical properties. The tightly bound molecules are much more effective at dissipating energy from impacts and resisting abrasive forces.

Performance Improvements with Higher Molecular Weight

From our internal testing at PTSMAKE, we’ve consistently seen a direct correlation. As molecular weight increases, performance in critical areas improves significantly. This is especially true for wear and impact applications.

| Molecular Weight Range | Impact Strength | Abrasion Resistance | Typical Use Cases |

|---|---|---|---|

| 3-6 Million | High | Very Good | Chute liners, guide rails |

| >6 Million | Extremely High | Excellent | Medical implants, high-load gears |

For demanding projects, we often guide clients toward premium grades. The higher molecular weight UHMWPE material ensures longevity and reliability, even under severe stress.

In essence, categorizing UHMWPE by molecular weight provides a clear roadmap. It allows engineers and designers to match a specific grade to the performance demands of their application, ensuring optimal results from the start.

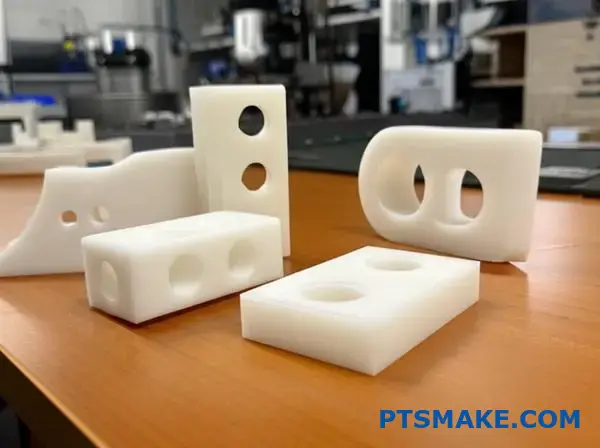

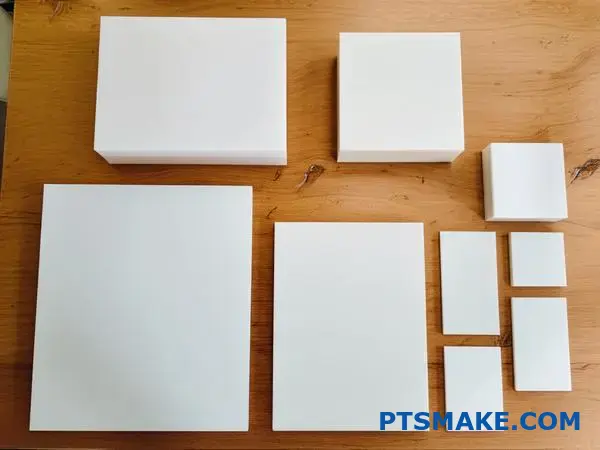

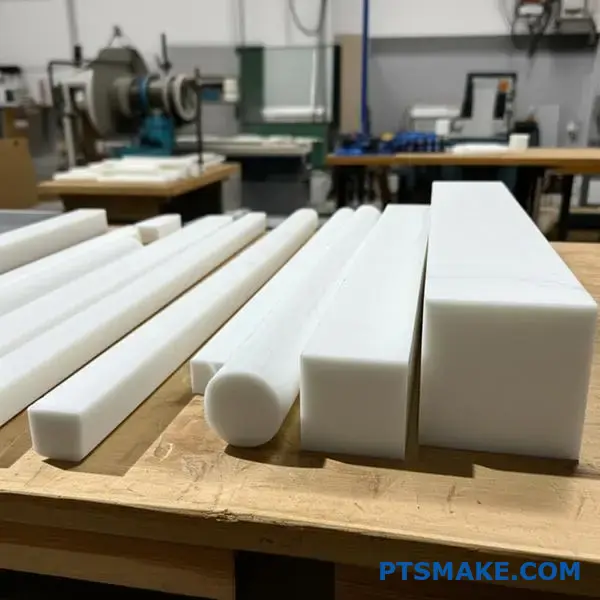

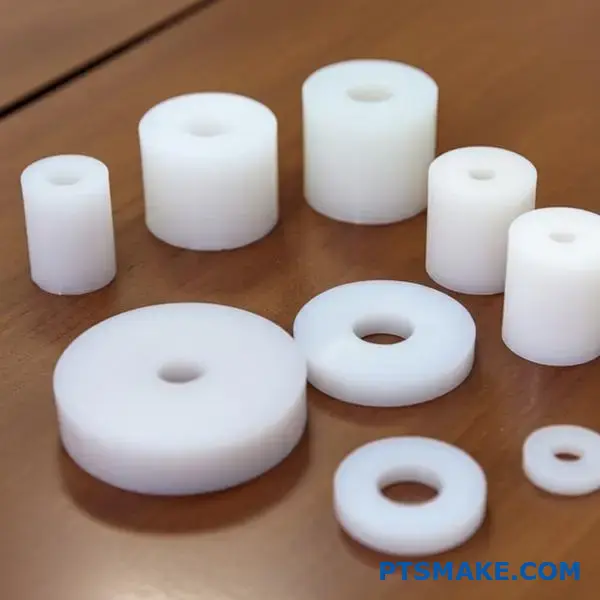

What common forms is UHMWPE available in for practice?

UHMWPE is incredibly versatile. It’s not a one-size-fits-all material. You’ll find it in several standard forms, ready for machining or integration. This makes it adaptable for many different projects.

The most common shapes are sheets, rods, and tubes. These are the workhorses for industrial applications. From these basic forms, we can create countless custom parts.

Primary Stock Shapes

Practitioners will most often encounter these basic forms. They serve as the starting point for custom fabrication.

| Shape | Common Use Case |

|---|---|

| Sheets | Hopper liners, wear strips |

| Rods | Gears, bushings, rollers |

| Tubes | Bearings, sleeves |

Specialized Forms

Beyond standard stock, UHMWPE material is also available in advanced forms. These include high-strength fibers and unique porous sheets for very specific applications.

Understanding the available forms of UHMWPE helps in selecting the right starting point for your project. This choice directly impacts manufacturing efficiency and final part performance. At PTSMAKE, we guide clients through this selection process.

A Closer Look at Each Form

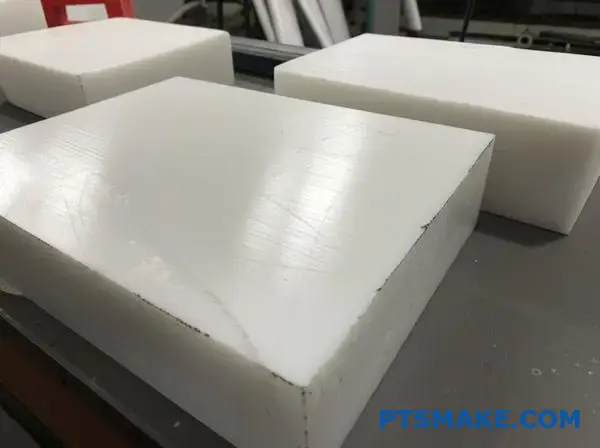

Sheets and Plates

These are produced through compressive molding12 or ram extrusion. They are ideal for lining chutes and creating large wear-resistant surfaces. Their availability in various thicknesses provides great design flexibility.

Rods and Tubes

Rods are perfect for CNC machining parts like gears, bearings, and rollers. Tubes are excellent for creating bushings or sleeves. We often work with these forms to produce high-precision components for our clients in the automotive and robotics industries.

Custom Profiles

Extruded profiles are made to specific cross-sections. These are common for creating custom guide rails, chain guides, and other uniquely shaped wear components. They minimize machining waste.

Advanced Applications

Specialty forms unlock new possibilities.

| Specialized Form | Key Characteristic | Industry |

|---|---|---|

| Fibers (Dyneema®, Spectra®) | High tensile strength | Aerospace, Medical |

| Sintered Porous Sheets | Controlled porosity | Filtration, Fluidics |

These advanced forms show the true range of UHMWPE material. From bulletproof vests to medical implants, its potential is vast.

In short, UHMWPE is available in standard stock shapes like sheets and rods for general machining. It also comes in specialized forms, such as high-strength fibers and porous sheets, for highly specific and demanding applications.

Which industry standards (ASTM/ISO) govern UHMWPE specification?

When sourcing UHMWPE material, standards are non-negotiable. They are your quality guarantee. The two main bodies setting these rules are ASTM International and ISO.

For general industrial uses, ASTM D4020 is the key document. It covers everything from raw resin to finished shapes like sheets and rods.

In the medical field, the requirements are far stricter. ISO 5834 is the specific standard for UHMWPE used in surgical implants. Knowing which standard applies is the first step to success.

Understanding these standards helps you verify material quality and avoid costly mistakes. They remove the guesswork and provide a clear benchmark for performance. At PTSMAKE, we always verify material certificates against these standards.

ASTM D4020: Standard for Industrial UHMWPE

This is the foundational standard for most non-medical applications. It defines the property requirements for UHMWPE plastics.

This includes specifying the molecular weight, density, and other physical properties. Adherence to ASTM D4020 ensures the material has the expected durability and low friction.

ISO 5834: Standard for Medical-Grade UHMWPE

When a part is designed for the human body, ISO 5834 takes precedence. This standard is for UHMWPE used in surgical implants, like hip or knee replacements.

It has much stricter controls on material purity, additives, and the polymerization13 process. This guarantees the material is biocompatible and safe for long-term use inside the body. Based on our work with medical clients, there is no room for compromise here.

A quick comparison highlights their different focuses:

| Standard | Primary Application | Key Focus Areas |

|---|---|---|

| ASTM D4020 | Industrial & General Use | Mechanical Performance, Consistency |

| ISO 5834 | Medical Implants | Biocompatibility, Purity, Safety |

Selecting the correct standard is critical. It aligns the material’s properties with the application’s demands, ensuring both safety and functionality.

To ensure quality, ASTM D4020 is the benchmark for industrial UHMWPE material. For medical devices, ISO 5834 is the non-negotiable standard. Following these guidelines is crucial for verifying material performance and safety, protecting your project from failure.

What are the different manufacturing methods for stock shapes?

Understanding how stock shapes are made is key. It helps predict material behavior. The primary conversion processes are crucial here.

Compression Molding

This method is for creating large, thick sheets. It involves heat and immense pressure. It is ideal for big, blocky components.

Ram Extrusion

This process produces continuous profiles. Think of rods, tubes, and other long shapes. It is a very different approach.

| Method | Primary Output | Common Use |

|---|---|---|

| Compression Molding | Sheets, Blocks | Large flat parts |

| Ram Extrusion | Rods, Tubes | Continuous profiles |

A Deeper Look: Compression Molding

In this process, we place polymer resin or powder into a mold cavity. The mold is then heated and closed.

This applies high pressure. It forces the material to fill the cavity. The material undergoes a process called sintering14 where particles fuse together without fully melting. This method is common for materials like UHMWPE material.

A Deeper Look: Ram Extrusion

Ram extrusion is a semi-continuous process. A hydraulic ram pushes a compacted mass of material, often called a billet, through a heated die.

This force shapes the material into a continuous profile. The process is repeated with new billets to create long lengths of rods or tubes. It’s a slower, more deliberate method.

How Method Affects Properties

The manufacturing method directly impacts the final part. Compression-molded sheets can have some internal stress. This is something we always account for during machining at PTSMAKE.

Ram-extruded parts might show directional properties. Their strength can vary along their length versus across their diameter.

| Feature | Compression Molding | Ram Extrusion |

|---|---|---|

| Process Type | Batch | Semi-Continuous |

| Internal Stress | Can be high | Generally lower |

| Shape Complexity | Limited to simpler blocks | Continuous complex profiles |

| Best For | Large sheets, thick parts | Long rods, tubes |

Compression molding and ram extrusion are fundamental for stock shapes. One creates large sheets, while the other forms continuous profiles. The chosen method defines the material’s internal stresses and directional properties, impacting final part performance and machinability.

When should one choose a modified UHMWPE over a standard grade?

Deciding on the right UHMWPE material doesn’t have to be complex. The choice hinges on one question: does your application face a challenge that standard UHMWPE cannot handle?

Start with the Standard

Standard UHMWPE is a fantastic, versatile material. It’s often the default choice for many applications due to its excellent balance of properties and cost-effectiveness.

Identify the Limiting Factor

A modified grade becomes necessary only when a specific limitation of the standard version compromises performance or safety. Think of it as a targeted upgrade.

| Feature | Standard UHMWPE | Modified UHMWPE Example |

|---|---|---|

| Max Temperature | ~80°C | ~130°C (Cross-linked) |

| Static Buildup | High | Low (Antistatic) |

This approach ensures you get the performance you need without over-engineering.

To make the right call, I suggest a simple decision-making framework. We use a similar process at PTSMAKE to guide our clients, ensuring they get the best possible material for their parts.

A Practical Framework

This framework breaks the decision down into logical steps. It moves from general requirements to a specific material choice.

1. Define Your Operating Environment

First, list all environmental and operational challenges. Will the part be exposed to high temperatures? Does it operate in an environment with flammable dust or gases? Is it subject to extreme abrasive forces?

2. Assess Standard UHMWPE

Next, see if standard UHMWPE meets these demands. In many cases, it will. But sometimes a critical gap appears. For instance, in mining, conveying certain materials can generate static electricity, creating a safety hazard.

3. Pinpoint the Performance Gap

This is the crucial step. If standard UHMWPE falls short, identify exactly why. The issue isn’t the material itself, but a specific property. For explosive environments, the problem is its inability to safely discharge static. The material needs specific dissipative properties15 to be viable.

4. Match the Modification to the Need

Once the gap is clear, the solution is straightforward. You choose a modification designed to solve that one problem.

| Problem Scenario | Limiting Property of Standard Grade | Recommended Modified Grade |

|---|---|---|

| High Heat & Load | Low thermal stability | Cross-linked UHMWPE |

| Explosive Atmosphere | High surface resistivity | Antistatic UHMWPE |

| High Friction/Stick-Slip | Standard coefficient of friction | Internally lubricated UHMWPE |

| UV Exposure (Outdoor) | Poor UV resistance | UV-stabilized UHMWPE |

This structured process prevents guesswork and leads to reliable, safe, and effective components.

The takeaway is simple: start with standard UHMWPE as your baseline. Only upgrade to a modified grade when you identify a specific performance gap—like heat resistance or static control—that your application cannot tolerate. This ensures both performance and cost-efficiency.

How can thermal expansion be managed in UHMWPE design?

UHMWPE has a very high rate of thermal expansion. It can expand and contract about ten times more than steel with temperature changes.

This is a critical factor in design. Ignoring it can lead to parts binding, warping, or failing entirely. Proper design accounts for this movement.

Quantifying the Challenge

Understanding the numbers helps. The coefficient of thermal expansion for UHMWPE is significant.

| Material | Coefficient of Thermal Expansion (per °C) |

|---|---|

| UHMWPE | ~1.3 x 10⁻⁴ |

| Steel | ~1.2 x 10⁻⁵ |

| Aluminum | ~2.3 x 10⁻⁵ |

This table clearly shows why this UHMWPE material needs special attention.

Practical Design Rules for UHMWPE

Managing this expansion is straightforward with the right design rules. At PTSMAKE, we apply these principles to ensure part performance across different operating temperatures. It’s about giving the material room to move.

Rule 1: Increase Running Clearances

For any moving parts, such as bearings or sliding components, clearances must be larger than you’d use for metals. This prevents parts from seizing up as temperatures rise.

The part needs space to expand without creating excessive friction or stress. The high Coefficient of Thermal Expansion16 is the direct reason for this. We often advise clients to factor this in early.

Rule 2: Use Oversized Holes for Fasteners

When fastening UHMWPE sheets or blocks, never use a tight-fitting bolt. The material needs to expand and contract around the fastener.

Using oversized or slotted holes is a simple solution. This allows the material to move freely, preventing stress buildup and potential cracking around the fastener location. Washers help distribute the load evenly.

| Fastener Strategy | Purpose |

|---|---|

| Oversized Holes | Allows radial expansion |

| Slotted Holes | Allows linear expansion |

| Shoulder Bolts | Provides a fixed pivot point |

Rule 3: Avoid Long, Constrained Sections

Long, thin sections of UHMWPE are prone to buckling or warping if they are constrained at both ends. As the material expands, it has nowhere to go but sideways.

It is better to secure the part at one central point. Let the ends float freely with guides if needed. This design approach prevents thermally-induced stress and deformation.

To manage UHMWPE’s thermal expansion, designers must incorporate larger running clearances for moving parts, use oversized holes for fasteners, and avoid constraining long sections. These simple rules prevent binding, warping, and premature failure in finished components.

What are the most effective methods for joining UHMWPE?

Joining UHMWPE presents a unique challenge. Its waxy, low-friction surface makes traditional bonding methods ineffective. Choosing the right approach is vital for structural integrity.

Mechanical Fastening: The Top Choice

For reliability, mechanical fasteners are usually the best option. Bolts, screws, and rivets create strong, predictable joints without complex surface treatments.

Adhesives and Welding

These methods are possible but require expertise. Adhesives need extensive surface prep to work. Welding demands precise control to avoid material degradation.

Here is a quick overview of the options.

| Method | Reliability | Ease of Use |

|---|---|---|

| Mechanical | High | High |

| Adhesive | Low-Medium | Low |

| Welding | Medium-High | Medium |

Based on our tests, mechanical fastening consistently provides the most dependable results for joining UHMWPE parts. It bypasses the chemical inertness of the material.

A Closer Look at Mechanical Fasteners

Using bolts or screws is straightforward. This method physically clamps the parts together. This ensures a robust connection for demanding applications. Care must be taken to manage stress concentrations around the holes to prevent potential cracking over time.

The Adhesive Bonding Hurdle

Adhesives face a major obstacle. UHMWPE has an extremely low surface energy17, which prevents glues from wetting the surface and forming a strong bond. It’s like trying to glue a non-stick pan.

Overcoming the Challenge

To bond this UHMWPE material, you must first modify its surface. Techniques like plasma treatment, flame treatment, or chemical etching can raise the surface energy. These processes, however, are specialized and add significant complexity and cost to the project.

The Nuances of Plastic Welding

Welding can create seamless, strong joints. Methods like hot gas welding and extrusion welding are effective if done correctly. But this requires skilled technicians and specialized equipment. Precise temperature control is crucial, as overheating can compromise the material’s properties.

| Feature | Mechanical Fastening | Adhesive Bonding | Plastic Welding |

|---|---|---|---|

| Joint Strength | Very High | Variable | High |

| Equipment Cost | Low | High (for treatment) | High |

| Expertise Needed | Low | High | High |

| Best For | Structural Assemblies | Light-Duty Sealing | Continuous Seams |

To summarize, mechanical fastening is the most reliable method for joining UHMWPE. Adhesives and welding are viable alternatives, but they require specialized surface treatments and expert execution to overcome the material’s inherent resistance to bonding.

What surface finishes are achievable and how?

When machining UHMWPE, the surface finish is unique. It’s unlike metal. You typically achieve a smooth, almost waxy texture.

This finish is a natural characteristic of the material. However, the quality of this "as-machined" surface is critical for performance.

Achieving the best possible finish requires specific tooling and expertise. Let’s explore what’s practical and why.

| Finish Type | Achievability | Common Use Cases |

|---|---|---|

| Standard Smooth | High | Wear Strips, Bearings |

| Optically Clear | Very Difficult | Not a practical goal |

Clients often ask if we can polish UHMWPE to a mirror shine. The simple answer is that achieving an optical-quality surface is extremely difficult. It’s generally not a practical manufacturing goal.

The reason lies in the material’s properties. UHMWPE is soft and has a low melting point. Aggressive polishing generates heat, causing the surface to smear rather than become smoother. The material’s structure, containing both crystalline and amorphous18 regions, resists uniform polishing.

However, a smooth "as-machined" finish is vital. For applications demanding low friction and high wear resistance, surface quality is everything. A smoother surface ensures minimal resistance and extends the component’s service life significantly.

At PTSMAKE, we focus on perfecting this initial finish. Using incredibly sharp tools and refined cutting parameters is how we deliver parts that perform reliably.

| Surface Quality | Friction Impact | Part Lifespan |

|---|---|---|

| Smooth | Low | Extended |

| Rough | High | Reduced |

In summary, UHMWPE material yields a smooth, waxy finish. While optical polishing is impractical, a high-quality machined surface is crucial. This smoothness directly enhances the material’s low-friction and wear-resistant properties, which are key for performance.

What are the fundamentals of designing wear pads using UHMWPE?

Designing wear pads with UHMWPE material seems straightforward. However, the real success is in the details. Getting them right ensures long life and top performance.

We must consider four key areas. These are thickness, surface finish, fasteners, and the mating surface. Each plays a vital role.

Here’s a quick look at the design fundamentals.

| Design Fundamental | Key Consideration |

|---|---|

| Thickness | Must support the load and impact |

| Surface Finish | Needs to be smooth to reduce friction |

| Fastening | Use correct hardware to avoid stress |

| Mating Surface | Material choice impacts system life |

Neglecting any of these can lead to premature failure.

Let’s dive deeper into these design principles. In our experience at PTSMAKE, these details separate a good design from a great one. Getting them right is crucial for reliability.

Calculating Required Thickness

The thickness depends on load and impact. A pad must resist deformation under static load. It also needs to absorb energy from dynamic impacts. Thicker isn’t always better. Overly thick pads can trap heat, which affects performance. Calculating the pressure-velocity (PV) rating helps guide this decision.

Ensuring a Smooth Sliding Surface

A smooth finish on the UHMWPE wear pad is non-negotiable. It minimizes the initial coefficient of friction. This reduces break-in wear on both the pad and the mating component. A rough surface can act like an abrasive, accelerating wear.

Using Mechanical Fasteners Correctly

Never bolt directly onto the UHMWPE surface. Always use large-diameter washers. Washers distribute the clamping force evenly. This prevents localized stress that causes cracking. For a flush surface, use counterbored holes for the bolt heads and washers. This is a common practice in our CNC machining projects. The entire interaction between these surfaces forms a complete Tribological System19.

Mating Surface Considerations

The material your UHMWPE pad slides against is critical.

| Mating Material | Hardness | Finish | Performance |

|---|---|---|---|

| 304 Stainless Steel | Medium | Polished | Excellent |

| Hard Chrome Plated | High | Polished | Very Good |

| Anodized Aluminum | Medium | Smooth | Good |

| Mild Steel | Low | Rough | Poor (can cause abrasion) |

A hard, smooth, and corrosion-resistant surface works best. It extends the life of the entire assembly.

Proper design of UHMWPE wear pads requires balancing four elements: calculating thickness for load and impact, ensuring surface smoothness, using correct fastening with washers, and selecting a compatible mating surface. These fundamentals ensure optimal system performance and longevity.

How would you select a UHMWPE grade for a high-wear conveyor guide?

Selecting the right UHMWPE is a practical process. It’s about matching the material’s properties to the job’s demands. Let’s walk through a real-world scenario together.

Starting with the Standard

We always begin with a baseline. For most conveyor guides, a standard virgin grade of UHMWPE material is a great starting point.

It offers a low coefficient of friction. It also provides excellent general wear resistance for many common applications.

| Grade | Key Feature | Best For |

|---|---|---|

| Virgin UHMWPE | Low Friction | General Purpose |

| Antistatic | ESD Control | Electronics, Powders |

| Wear-Enhanced | Abrasion Resistance | Abrasive Materials |

This initial selection sets the stage for further refinement based on performance feedback.

A Practical Decision-Making Flow

Let’s imagine a project we handled at PTSMAKE. A client needed a new guide system for a high-speed packaging line. We started by machining guides from virgin UHMWPE.

Identifying a Specific Challenge: Static

Initially, the guides worked well. However, the client reported an issue. Fine powder from their product was clinging to the guides due to static electricity. This was causing blockages.

Our solution was simple. We moved to an antistatic UHMWPE grade. This material includes additives that safely dissipate static charges. The powder-clinging problem was solved immediately.

Addressing Another Challenge: Abrasion

Now, consider a different application. A client was conveying coarse, abrasive minerals. The standard virgin UHMWPE guide wore down much faster than acceptable.

This required a different approach, focusing on the material’s tribological properties20. We needed something tougher.

Our recommendation was a wear-enhanced grade. These advanced formulas contain solid lubricants or reinforcing agents. They significantly increase resistance to abrasive wear.

| Scenario | Initial Grade | Problem Identified | Recommended Upgrade |

|---|---|---|---|

| Powder Packaging | Virgin UHMWPE | Static Buildup | Antistatic UHMWPE |

| Mineral Conveying | Virgin UHMWPE | High Abrasion | Wear-Enhanced UHMWPE |

This methodical process ensures the final selection is perfectly suited to the application.

Selecting the best UHMWPE involves a logical process. Start with a standard grade, observe its performance, and then upgrade based on specific challenges like static or high abrasion. This iterative approach ensures the part performs optimally and lasts longer.

Analyze a case study of UHMWPE failure in a bearing application.

Let’s examine a common failure scenario. A UHMWPE bushing in a high-load conveyor system failed prematurely. This caused unexpected downtime.

Understanding why parts fail is key. It helps prevent future issues. It also guides better material selection. This case study highlights critical design factors.

Initial Problem Overview

We received a call about a catastrophic bushing failure. The client’s conveyor line was completely stopped. Here is what we knew initially.

| Parameter | Description |

|---|---|

| Component | UHMWPE Conveyor Roller Bushing |

| Application | Heavy-duty industrial conveyor |

| Problem | Severe deformation and seizure after 3 months |

| Expected Life | 24+ months |

This failure was costly. We needed to find the root cause quickly.

A Deeper Dive into the Failure

In a past project at PTSMAKE, a similar issue occurred. We found that failures are rarely from a single cause. It is usually a combination of factors. A systematic investigation is always the first step.

Root Cause Investigation

We began by analyzing the operating environment. We compared the design specifications with the actual working conditions. This is where we often find discrepancies. The environment can change over time.

The investigation revealed several contributing factors. The original design did not account for recent increases in production speed and load.

Analyzing Key Factors

The failure was traced to a few key areas. Heat, pressure, and the wrong material grade played a part. The interaction between these elements caused the failure. Poor initial design clearance was the final blow.

| Factor | Specified | Actual Operation | Impact |

|---|---|---|---|

| Load (MPa) | 2.5 | 4.0 | Exceeded creep limit |

| Speed (m/s) | 0.5 | 1.0 | Increased frictional heat |

| Temp (°C) | 40 | 65 | Accelerated wear |

| Clearance (mm) | 0.25 | 0.25 | Insufficient for thermal expansion |

The high temperature caused the UHMWPE material to expand. With insufficient clearance, this led to seizure. The material’s tribological21 properties were not suitable for these elevated stresses and temperatures.

Material Grade Matters

Furthermore, a standard grade of UHMWPE was used. A specialized, thermally-stabilized grade would have performed better. It would have handled the higher temperatures and loads more effectively.

This case shows why a detailed application analysis is vital. At PTSMAKE, we work with clients to understand every operational detail. This ensures the right material is chosen from the start.

This analysis shows that bushing failure was caused by multiple issues. Overloading, excessive heat from higher speeds, and insufficient clearance created a perfect storm. The wrong UHMWPE material grade couldn’t handle these compounded stresses, leading to rapid wear and seizure.

How would you justify using UHMWPE over bronze in a bushing?

Choosing the right material for a bushing is a critical decision. It goes beyond the initial price tag. You must consider the entire lifecycle of the part.

Why choose UHMWPE over traditional bronze? The justification lies in a superior value proposition. We’ll compare them on key metrics. These include weight, corrosion resistance, lubrication, noise, and total cost of ownership. This analysis reveals a clear winner for many modern applications.

Deciding between these materials requires a shift in perspective. You’re not just buying a component. You are investing in long-term operational efficiency. The true value emerges when you look beyond the initial purchase price.

The Full Comparison

We need to analyze how each material performs in the real world. In past projects at PTSMAKE, we’ve helped clients evaluate these trade-offs carefully. The performance differences are often significant.

This direct comparison highlights the advantages of using a modern polymer like UHMWPE.

| Metric | Bronze Bushing | UHMWPE Bushing |

|---|---|---|

| Weight | Heavy, increases overall system mass | Very lightweight (1/8th of bronze) |

| Corrosion Resistance | Susceptible to corrosion and oxidation | Excellent, inert to most chemicals and moisture |

| Lubrication | Requires regular greasing and maintenance | Self-lubricating, no external lubricant needed |

| Noise Level | Can be noisy, metal-on-metal contact | Dampens noise and vibration effectively |

| Maintenance | High; requires cleaning and re-greasing | Virtually zero maintenance required |

The self-lubricating nature of the UHMWPE Material is due to its very low coefficient of friction22. This property eliminates the need for grease. It reduces maintenance schedules and creates a cleaner operating environment, a huge benefit in industries like food processing or medical devices.

Total Cost of Ownership (TCO)

Bronze may have a familiar feel, but UHMWPE often delivers a lower TCO. This accounts for material cost, easier installation due to low weight, and dramatically reduced maintenance costs over the bushing’s life.

Ultimately, UHMWPE offers a compelling value proposition. It reduces maintenance, lowers operational costs, and enhances performance through weight and noise reduction. This makes it a smart, long-term investment over traditional bronze for many applications.

What are the emerging applications for UHMWPE materials?

UHMWPE material is not just for industrial gears anymore. Its unique properties are pushing it into new, exciting frontiers. We are seeing it transform industries.

The Innovation Frontier

Next-Gen Protection

This material creates incredibly strong yet lightweight textiles. These are used for personal armor, offering better protection for law enforcement and military personnel.

Powering the Future

In electric vehicles, UHMWPE is becoming crucial. It’s used in battery separators, enhancing safety and performance. This is a rapidly growing area.

| Emerging Sector | Key Application | Core Advantage |

|---|---|---|

| Defense & Security | Advanced Ballistic Textiles | Superior strength-to-weight ratio |

| Automotive (EV) | Battery Separators | Increased safety & efficiency |

| Marine Operations | High-Performance Ropes | Stronger than steel, yet buoyant |

| Advanced Medical | Novel Orthopedic Implants | High wear resistance & biocompatibility |

A Deeper Look at Groundbreaking Uses

The true potential of UHMWPE material shines in these new applications. Each leverages its core strengths in a unique way, demanding new manufacturing precision.

Advanced Textiles in Personal Armor

UHMWPE fibers are woven into advanced fabrics. These fabrics stop projectiles more effectively than traditional materials like Kevlar, but at a fraction of the weight. This innovation significantly reduces the load on the user.

Revolutionizing Electric Vehicle Batteries

In EVs, safety is paramount. UHMWPE is used to create a thin, durable separator between the anode and cathode. This prevents short circuits. The material is processed into a microporous membrane23 that allows ions to pass through freely. In our work at PTSMAKE, we recognize that controlling the porosity and thickness of such films requires immense precision.

| Feature Comparison | UHMWPE Separator | Traditional Polyolefin Separator |

|---|---|---|

| Puncture Resistance | Exceptional | Good |

| Chemical Stability | Very High | High |

| Thickness for Performance | Can be made thinner | Standard thickness |

| Safety Shutdown | Excellent | Good |

New Horizons in Marine and Medical

For marine applications, UHMWPE ropes are replacing steel cables. They are stronger, lighter, and they float. In the medical field, its biocompatibility and low-friction surface make it ideal for the next generation of joint replacements and surgical cables.

UHMWPE material is driving significant advancements across diverse, high-tech sectors. From lightweight personal armor to safer EV batteries and durable medical implants, its unique combination of properties is enabling next-generation products that were previously impossible to create.

How do you calculate the cost-effectiveness of a UHMWPE solution?

Beyond the Initial Price Tag

Focusing only on the upfront cost of UHMWPE material is a common mistake. This approach gives you an incomplete picture.

The true value of a material solution is revealed over its entire service life. To understand this, we need a broader perspective.

The Total Cost of Ownership (TCO)

At PTSMAKE, we guide clients using a Total Cost of Ownership (TCO) model. This considers all expenses from day one to replacement.

| Factor | Initial Cost View | TCO View |

|---|---|---|

| Material | The only focus | One part of the equation |

| Maintenance | Not considered | A major saving |

| Lifespan | Ignored | Key to long-term value |

Building a Simple TCO Model

Let’s break down the TCO model to see how it works. It’s about balancing the initial investment with the operational gains over the long run. This is a practical approach we’ve refined through many client projects.

Initial Investment

This part is straightforward. It includes the price of the raw UHMWPE material. It also covers the fabrication, like CNC machining, to produce the final component. However, this is just the starting point of your calculation.

Long-Term Savings Unlocked

Here is where a UHMWPE solution truly proves its worth. The savings accumulate significantly over years of operation. The material’s low Coefficient of Friction24 is a key factor in these savings.

Maintenance costs plummet. Because UHMWPE is self-lubricating, you eliminate expenses for grease, oil, and the labor required to apply them. This also means cleaner operating environments.

Our tests show part life is substantially longer. In high-wear applications, UHMWPE parts can outlast metals and other plastics, leading to fewer replacements and less operational downtime.

| Cost Category | Traditional Material (e.g., Steel) | UHMWPE Solution |

|---|---|---|

| Initial Cost | Lower to Moderate | Moderate |

| Lubrication | Required Regularly | Not Required |

| Maintenance Labor | High | Very Low |

| Replacement Frequency | Higher | Lower |

| Damage to Mating Parts | Possible | Minimal |

Finally, it protects your other equipment. Its smooth, non-abrasive surface reduces wear on mating parts, preventing costly collateral damage to your larger assembly.

A true cost-effectiveness analysis relies on a Total Cost of Ownership model. While the initial investment for a UHMWPE material solution might be higher, it delivers significant long-term savings in maintenance, lubrication, and replacement costs, proving its superior value.

Unlock the Full Potential of UHMWPE with PTSMAKE Expertise

Ready to optimize your next project with UHMWPE Material? Contact PTSMAKE for a fast, accurate quote on precision CNC machining or injection molding. Let our 20+ years of experience deliver high-quality, custom UHMWPE parts that meet your toughest demands—reach out now for a competitive inquiry!

Discover how these weak intermolecular forces significantly influence a material’s physical properties. ↩

Learn how this property affects material flow and processing during manufacturing. ↩

Explore how this unique property helps materials absorb impact without permanent damage. ↩

Learn how this property impacts material selection for precision parts and applications. ↩

Learn more about how this property affects part longevity in demanding environments. ↩

Learn how this value affects energy loss and material wear in moving components. ↩

Learn how static electricity builds up and why it matters in material selection. ↩

Learn how fiber orientation impacts a part’s strength and performance in different directions. ↩

Understand why a material’s interaction with human tissue is critical for medical device safety. ↩

Click to understand how these highly reactive atoms are key to creating stronger polymer networks. ↩

Learn the microscopic principle that gives UHMWPE its remarkable toughness. ↩

Learn more about this crucial process for producing robust polymer stock shapes and parts. ↩

Learn how this chemical process creates the long molecular chains that give UHMWPE its exceptional properties. ↩

Click to understand the science behind how polymer particles bond together. ↩

Explore how these properties are critical for safety in sensitive industrial applications. ↩

Learn how this property impacts material selection and your design process. ↩

Discover why this property makes materials slick and resistant to adhesion. ↩

Learn how a material’s internal structure dictates its surface finish capabilities and machining challenges. ↩

Learn how interacting surfaces, lubricant, and environment affect wear and friction in mechanical systems. ↩

Learn how material surface interactions affect wear, friction, and lubrication in our detailed guide. ↩

Explore how friction, wear, and lubrication influence material selection for moving parts. ↩

Learn how this property directly impacts wear, energy efficiency, and operational cleanliness in your designs. ↩

Understand the complex engineering behind these essential EV battery components and their impact on safety. ↩

Learn how this key property impacts wear, energy consumption, and overall part performance. ↩