Need stronger parts but tired of costly assembly processes and quality issues? Traditional single-material manufacturing often leads to weak joints, complex assembly steps, and parts that fail under stress.

2K injection molding creates stronger, integrated parts by combining two materials in a single molding cycle, eliminating assembly costs while improving durability and performance.

Over my years at PTSMAKE, I’ve worked with engineers who struggled with the same challenges you face today. This guide walks you through everything about 2K injection molding – from the technical process to real applications that solve manufacturing problems and boost product performance.

Unlock Advanced Product Design & Efficiency with 2K Molding!

Are you tired of complex multi-part assemblies? The high labor costs, potential for failure at each joint, and sealing issues can be a constant headache. Many product designers face these challenges daily, seeking a more streamlined and reliable solution. What if you could combine multiple components into one single, robust part?

This is where 2K injection molding changes the game. It’s not just another manufacturing process; it’s a strategic advantage. It allows you to create a single, integrated component with superior performance and aesthetics. Imagine eliminating adhesives, screws, and gaskets entirely.

At PTSMAKE, we’ve helped clients move beyond traditional assembly challenges. By integrating different materials in a single molding cycle, we enhance product functionality, improve tactile feel, and simplify the supply chain. This process is key to creating innovative and durable products.

The Problem with Multi-Part Assembly

Traditional methods often involve assembling multiple, separately molded parts. This approach introduces several points of potential failure and inefficiency.

| Challenge | Traditional Assembly | 2K Injection Molding Solution |

|---|---|---|

| Sealing | Requires gaskets or sealants | Creates a perfect, bonded seal |

| Labor Costs | High due to manual assembly | Drastically reduced or eliminated |

| Durability | Multiple failure points | Single, solid component |

| Complexity | More parts to source and stock | Simplified bill of materials |

This shift in manufacturing thinking unlocks new possibilities. It allows for more complex geometries and integrated features that were once considered too expensive or unreliable to produce.

The magic of 2K injection molding lies in its ability to create a strong, permanent bond between two different materials. This isn’t just about placing one material next to another; it’s about fusing them at a molecular level during the molding process itself. This creates a part that is fundamentally stronger and more reliable.

Achieving a Perfect Bond

The success of a 2K part depends heavily on material compatibility. The first shot, or substrate1, must be engineered to bond perfectly with the second material, the overmold.

There are two primary types of bonds:

- Chemical Bonding: The two materials form a chemical connection, essentially melting into each other. This creates the strongest possible bond and is ideal for parts requiring a perfect seal.

- Mechanical Bonding: The design incorporates undercuts or holes in the first shot. The second material flows into these features, creating a physical interlock.

Design Considerations for Success

Achieving a successful bond requires careful planning. Our engineers at PTSMAKE work closely with clients on these details.

Key Factors for Material Selection:

- Adhesion: Do the materials have natural chemical compatibility?

- Melt Temperature: The second material’s melt temp should not deform the first.

- Shrinkage Rates: Different rates can cause warping or stress in the part.

Based on our testing, selecting polymers from the same family often yields the best results. For example, overmolding a TPE onto a PP substrate typically creates an excellent chemical bond.

Beyond the technical benefits, 2K injection molding offers significant advantages for the user experience and your brand. Creating products with soft-touch grips, integrated seals, or color-coded features enhances their perceived value and functionality. This directly impacts how a customer interacts with and feels about your product.

Enhancing Ergonomics and Aesthetics

Think about a high-quality power tool. The hard, durable plastic housing combined with a soft, non-slip rubber grip is a perfect example. This isn’t just for comfort; it improves safety and control. 2K molding makes this seamless integration possible in a single step.

This process allows for a level of design freedom that is difficult to achieve otherwise. You can create striking visual contrasts and textures without paint or other secondary operations that can chip or wear away over time.

Streamlining Your Supply Chain

By consolidating multiple parts into a single component, you simplify more than just assembly. Your entire supply chain becomes more efficient.

| Area of Impact | Before 2K Molding | After 2K Molding |

|---|---|---|

| Vendor Management | Multiple suppliers for each part | Fewer vendors to manage |

| Inventory | Stocking multiple components | One SKU to track and store |

| Quality Control | Inspecting each individual part | Inspecting one integrated part |

This simplification reduces overhead, minimizes the risk of stockouts for one small component delaying production, and ultimately leads to a more robust and cost-effective manufacturing operation. In past projects, clients have seen a notable reduction in their overall inventory management costs.

In essence, 2K injection molding is a powerful strategy for overcoming common manufacturing hurdles. It moves beyond traditional multi-part assembly by creating a single, integrated component. This enhances product durability through superior material bonding, improves user experience with better ergonomics and aesthetics, and streamlines your entire supply chain. It’s a direct path to creating more advanced, reliable, and efficient products.

The Two-Shot Molding Process: A Visual Step-by-Step.

Have you ever held a product with a soft-grip handle attached to a hard plastic body and wondered how it was made? That seamless fusion of two different materials is often the result of 2k injection molding. It’s a sophisticated process, but the core idea is surprisingly straightforward. It’s like a carefully choreographed dance inside a steel mold.

Instead of trying to glue or assemble two separate parts, we create one integrated component in a single machine cycle. This not only creates a stronger bond but also streamlines production, saving time and cost. The magic happens in a few precise, automated steps. Let’s break down this fascinating process.

The Four Core Stages

The entire cycle is a rapid sequence. From molten plastic to a finished, dual-material part, the process is completed in seconds. Each stage is critical for the final quality.

Here’s a simple overview of what happens inside the machine:

| Stage Number | Action | Result |

|---|---|---|

| 1 | First Shot Injection | The base part (substrate) is formed. |

| 2 | Mold Repositioning | The mold shifts to prepare for the second material. |

| 3 | Second Shot Injection | The second material (overmold) is injected. |

| 4 | Ejection | The completed, dual-material part is removed. |

This integration creates parts that are not only aesthetically pleasing but also functionally superior. Think of a toothbrush with a rubberized grip or a waterproof electronic enclosure. Those are classic examples of 2k injection molding at work.

Now, let’s explore the mechanics a bit further. The way the mold repositions between shots is key. This single action defines the two primary methods used in 2k injection molding. Understanding them helps you see why one approach might be better than another for your specific project.

Method 1: Rotational Molding

In this common technique, the mold features two distinct cavity halves. After the first shot creates the substrate, the side of the mold holding the new part rotates 180 degrees. This rotation aligns the substrate with the second cavity. The second material is then injected into the remaining space, forming the final part. It’s highly efficient for high-volume production. The study of material flow, or rheology2, is critical here to ensure both materials bond correctly without defects.

Method 2: Core-Back Molding

Core-back molding uses a simpler approach. The mold doesn’t rotate. Instead, a section of the mold core, called a slide or insert, retracts after the first shot. This movement creates a new void. The second material is then injected into this newly created space. This method is often used for simpler geometries or when creating seals.

Here is a quick comparison:

| Feature | Rotational Molding | Core-Back Molding |

|---|---|---|

| Mechanism | Mold rotates 180° | Mold core retracts (slide action) |

| Complexity | More complex tool design | Simpler tool design |

| Cycle Time | Generally faster | Can be slightly slower |

| Best For | High-volume, complex parts | Simpler geometries, seals |

At PTSMAKE, we help clients choose the right method based on part design, material choice, and production volume.

Choosing between these methods isn’t just a technical decision; it directly impacts your project’s outcome. The choice influences tooling costs, cycle times, and the final part’s integrity. It’s a balance of design intent and manufacturing practicality.

Practical Application and Decision-Making

For example, a high-volume consumer product like a power tool handle benefits from the speed of rotational molding. The complex tool is a worthwhile investment when spread across millions of units. The consistent cycle time ensures a predictable production schedule.

On the other hand, a medical device with a simple silicone seal might be better suited for core-back molding. The tooling is less complex and therefore less expensive to build. This makes it a more cost-effective choice for lower production volumes where initial investment is a key concern.

The Critical Material Bond

Regardless of the method, the most critical factor is the chemical bond between the two materials. Not all plastics are compatible. We must select a substrate and an overmold material that will form a strong, permanent bond. This often involves choosing materials from the same family or using a substrate that is chemically engineered to adhere to the overmold. In our projects, material compatibility is the first thing we validate to ensure the part will not fail.

In summary, the 2k injection molding process transforms raw pellets into a fused, dual-material part through four key stages: first injection, mold repositioning, second injection, and ejection. The choice between the primary methods, rotational and core-back, depends on part complexity, production volume, and cost considerations. Ultimately, success hinges on proper material selection to ensure a durable bond, resulting in a high-quality, integrated component that meets both functional and aesthetic requirements.

Quantifiable Benefits: Why 2K Injection Molding Pays Off.

Moving beyond the technical process, let’s focus on what matters most: the tangible results. Why should you choose 2K injection molding for your next project? The answer lies in clear, quantifiable advantages that directly impact your budget, product quality, and timeline. It’s about making a smarter manufacturing choice.

This technology isn’t just about combining two plastics. It’s a strategic decision that streamlines your entire production process. By eliminating secondary assembly steps like gluing, screwing, or ultrasonic welding, you immediately cut down on labor costs and potential points of failure. This is part consolidation at its best.

We’ve seen clients achieve significant savings. But the benefits extend far beyond just the initial cost. The superior bond created between materials enhances the structural integrity of the part. This means a more durable, reliable product for your end-user.

Consider the following comparison. It highlights the core advantages that 2K molding offers over traditional methods that require post-molding assembly.

| Feature | Traditional Assembly | 2K Injection Molding |

|---|---|---|

| Assembly Steps | Multiple (e.g., molding, gluing, fastening) | Single, integrated process |

| Labor Cost | Higher due to manual assembly | Significantly reduced |

| Part Integrity | Dependent on adhesive/fastener quality | Superior molecular bond |

| Seal Quality | Separate gasket needed | Integrated, reliable seal |

This integrated approach fundamentally changes how we think about part design and production, unlocking efficiencies that were previously out of reach.

Let’s dig deeper into the structural advantages. The core benefit of 2K injection molding is the robust bond formed between the two materials. Unlike adhesives, which can degrade over time, or mechanical fasteners, which create stress points, 2K molding creates a chemical or molecular bond. This results in a single, cohesive component.

This enhanced integrity is not just a theoretical benefit. In our testing, parts made with 2K molding consistently outperform their assembled counterparts in drop tests, vibration analysis, and cyclical loading scenarios. The seamless transition between a rigid substrate and a flexible overmold eliminates common failure points.

This durability has a direct impact on your product’s lifecycle and brand reputation. Fewer field failures mean lower warranty costs and higher customer satisfaction. It’s about building products that last. The improved substrate adhesion3 ensures that components like soft-touch grips or waterproof seals won’t peel or detach, even under harsh conditions.

Here’s a breakdown of how the bond type affects long-term performance:

| Bonding Method | Bond Strength | Durability under Stress | Failure Risk |

|---|---|---|---|

| Adhesives | Variable | Can degrade with age/exposure | Medium to High |

| Fasteners | Good | Creates stress concentration | Medium |

| 2K Molding | Excellent | Consistent & permanent | Very Low |

Ultimately, choosing 2K injection molding is an investment in quality and reliability from the very first shot. It simplifies production and builds a better, stronger product.

Beyond structural strength, 2K injection molding unlocks incredible design freedom. It empowers designers and engineers to create products that are not only functional but also aesthetically pleasing and ergonomically superior. This is where a product can truly stand out in a crowded market.

Think about the soft-touch grips on power tools or kitchen utensils. By overmolding a thermoplastic elastomer (TPE) onto a rigid polypropylene (PP) handle, you create a comfortable, non-slip surface. This tactile quality significantly improves the user experience and perceived value of the product. This can’t be achieved as effectively with a simple press-fit or glued-on grip.

Another powerful application is creating integrated seals. For electronic devices requiring an IP rating for water and dust resistance, 2K molding is a game-changer. We can mold a flexible seal directly onto the device housing in a single cycle. This eliminates the need for a separate O-ring or gasket, which simplifies the supply chain, reduces assembly time, and creates a more reliable, consistent seal.

This process allows for complex geometries that would be difficult or impossible with other methods. You can combine clear windows with opaque housings or create multi-color designs for branding without resorting to painting or printing. This design flexibility allows for more innovative and integrated product solutions. It opens the door to creating truly unique and competitive products.

In summary, 2K injection molding delivers significant, measurable benefits. It reduces assembly costs and labor by consolidating parts into a single process. The resulting molecular bond enhances part integrity and long-term durability, leading to a more reliable product. This technology also provides immense design freedom, enabling improved aesthetics, superior ergonomics with soft-touch surfaces, and integrated sealing solutions. It is a strategic manufacturing choice for building better products more efficiently.

2K Injection Molding vs. Overmolding: A Clear Comparison.

Are you deciding between 2K injection molding and overmolding? It’s a question we often hear at PTSMAKE. On the surface, both processes create single parts from multiple materials. But they are fundamentally different.

Choosing the wrong one can impact your production speed, labor costs, and even your product’s final quality. The distinction is crucial for scaling up production efficiently.

Overmolding is a two-step process. First, a base part is molded. Then, it’s moved to another mold where a second material is injected over it.

2K injection molding, however, is a highly integrated process. It uses one machine with a rotating mold to inject two different materials in a single, continuous cycle. This seemingly small difference has huge implications for your project.

To make the choice easier, let’s look at a direct comparison. This table breaks down the key factors you need to consider.

Head-to-Head: Key Process Differences

Here is a straightforward comparison to guide your decision. It highlights the main trade-offs between these two powerful manufacturing techniques.

| Feature | 2K Injection Molding | Insert Overmolding |

|---|---|---|

| Process Cycle Time | Faster (Single automated cycle) | Slower (Multi-step, includes part transfer) |

| Labor Cost | Lower (Highly automated) | Higher (Requires manual part handling) |

| Bond Strength | Excellent (Chemical bond) | Good to Very Good (Primarily mechanical bond) |

| Geometric Complexity | High (Allows for intricate, integrated designs) | Moderate (Limited by part transfer) |

| Initial Tooling Investment | Higher | Lower |

This table clearly shows that while 2K molding requires a larger initial investment, it excels in efficiency and bond quality for high-volume production.

Let’s dive deeper into the technical advantages, specifically bond strength and design freedom. The quality of the bond is often the most critical factor for a part’s longevity and performance.

Bond Strength and Design Freedom

In 2K injection molding, the two materials are injected in quick succession while the first material is still hot and molten. This creates a powerful chemical bond at the molecular level. The materials essentially fuse together. This results in a superior, permanent bond that is ideal for creating robust seals or integrated components that will not separate.

Overmolding typically relies on a mechanical bond. The second material flows into holes or around features designed into the first part, the substrate4. While effective for applications like soft-touch grips, it may not offer the same level of permanence or resistance to peel strength as a chemical bond.

Unlocking Complex Geometries

This integrated process also opens up new possibilities for part design. With 2K molding, you can create complex geometries with seamless transitions between hard and soft materials.

Think of integrated gaskets on an electronics housing. These must be perfect to ensure a waterproof seal. Achieving this with a two-step overmolding process is far more challenging and less reliable. The single-cycle nature of 2K molding ensures perfect alignment and bonding every time. In projects at PTSMAKE, we leverage this for creating intricate multi-material parts that are both functional and aesthetically pleasing.

Now, let’s consider the economic and operational side of the equation. Your decision will heavily depend on your production volume and cost-per-part targets. The upfront investment is only one piece of the puzzle.

A Look at Costs and Efficiency

The most significant operational advantage of 2K injection molding is its efficiency. By eliminating the need to transfer a part from one machine or mold to another, you drastically cut down on cycle time and labor. This automation is the key to cost-effective high-volume production.

Overmolding requires manual labor or complex robotics to place the base part into the second mold. This adds time and cost to every single unit produced. While the initial tooling for overmolding is less expensive, the per-part cost can be significantly higher.

Calculating Your Break-Even Point

The higher initial investment for a 2K mold can be intimidating. However, the savings in labor and cycle time create a clear break-even point.

Let’s consider a simplified scenario.

| Production Volume | Overmolding | 2K Injection Molding | Best Choice |

|---|---|---|---|

| 10,000 Units | Lower Tooling Cost, Higher Unit Cost | Higher Tooling Cost, Lower Unit Cost | Overmolding may be cheaper |

| 100,000 Units | High Total Labor & Cycle Cost | Savings from automation multiply | 2K Molding is more cost-effective |

| 1,000,000+ Units | Prohibitively High Labor Costs | Lowest possible cost-per-part | 2K Molding is the clear winner |

As you scale, the efficiency of 2k injection molding provides a massive competitive advantage. It’s an investment in lowering your long-term production costs.

In essence, the choice between 2K injection molding and overmolding comes down to your project’s specific needs. Overmolding offers flexibility with a lower initial investment, making it suitable for smaller runs or simpler designs. In contrast, 2K molding is a highly efficient, automated process. It delivers superior chemical bonds and design freedom, making it the ideal choice for high-volume production where quality and cost-per-part are paramount. Both are great technologies, but they solve different problems.

Innovative Applications Across Key Industries.

Have you ever wondered how your car’s dashboard buttons feel both firm and soft? Or how your smartwatch remains water-resistant after countless uses? The answer often lies in 2k injection molding. This technology is not a futuristic concept; it is a practical solution shaping the products we use daily.

By chemically bonding two different materials in a single process, we create parts with combined properties. This eliminates assembly steps and improves product quality. It’s a game-changer for designers and engineers.

Automotive Advancements

In the automotive world, user experience is paramount. 2k injection molding delivers this by creating components that are both durable and aesthetically pleasing.

Dashboard Components and Soft-Touch Buttons

Think of a climate control knob. It needs a rigid core for structure and a soft, grippy exterior for a premium feel. Two-shot molding makes this possible in one go. A hard plastic like PC or ABS is molded first, followed by a soft TPE or TPU overmold.

This process transforms a simple button into a key part of the vehicle’s perceived quality.

| Feature | Single-Material Button | 2K Molded Button |

|---|---|---|

| User Feel | Hard, basic plastic | Soft-touch, premium grip |

| Durability | Prone to wear and scratches | High wear resistance |

| Assembly | Requires secondary assembly | Single integrated part |

| Sealing | Requires separate gasket | Integrated dust/moisture seal |

Consumer Electronics Revolution

From power tools to wearables, durability and ergonomics are key selling points. This is where multi-material injection molding truly shines, creating robust and user-friendly products.

Water-Resistant Wearables

Your smartwatch band needs to be comfortable, durable, and water-resistant. 2k molding can combine a rigid plastic for the watch interface with a flexible elastomer for the band. This creates a seamless, reliable seal against water and dust ingress.

The medical and industrial fields demand the highest levels of precision and reliability. Here, failure is not an option. That’s why 2k injection molding has become indispensable for creating critical components that perform under pressure. It’s not just about combining hard and soft plastics; it’s about creating functionally superior parts.

Medical Device Innovation

In medical applications, every component must be safe, reliable, and often biocompatible. The ability to create integrated parts reduces potential points of failure, which is crucial for patient safety.

Surgical Instrument Grips

Surgeons need tools with exceptional grip and control, even in demanding situations. By overmolding a hard substrate with a soft, tactile TPE, we create handles that are ergonomic and slip-resistant. This process also ensures the grip is permanently bonded, preventing contamination between layers. The material’s viscoelasticity5 plays a key role here.

| Aspect | Traditional Assembly | 2K Injection Molding |

|---|---|---|

| Contamination Risk | Gaps can harbor bacteria | Hermetically sealed part |

| Durability | Grip can loosen or peel | Permanently bonded materials |

| Ergonomics | Limited design freedom | Optimized for user comfort |

| Sterilization | Materials may react differently | Materials selected for compatibility |

Industrial Durability

Industrial environments are harsh. Components face chemicals, extreme temperatures, and constant vibration. 2k injection molding creates robust parts that can withstand these challenges.

Sealed Sensor Housings

An industrial sensor housing often needs to be rigid to protect electronics but also requires a flexible seal to keep out moisture and dust. Instead of molding a housing and then manually applying a gasket, the two-shot molding process creates the seal directly onto the rigid part. This results in a perfect, repeatable seal every time.

Beyond simply listing applications, it’s crucial to understand the problem-solving power of 2k injection molding. This technology enables a level of functional integration that was previously impossible or prohibitively expensive. It’s about creating smarter, more efficient components from the ground up.

At PTSMAKE, we’ve helped clients move beyond traditional manufacturing limits. We focus on how material synergy can solve core design challenges, not just improve aesthetics.

Solving Complex Challenges with Material Synergy

The magic of 2k molding is in the combination. Choosing the right pair of materials unlocks new possibilities for product performance and durability.

Functional Integration Examples

Consider a diagnostic device casing. It needs to be impact-resistant (Polycarbonate) and have an integrated soft seal (TPE) for drop protection and fluid resistance. 2k molding achieves this in a single part, reducing assembly costs and improving reliability. This is a common challenge we solve for our medical clients.

Another example is a power tool handle. It requires a rigid frame (Glass-filled Nylon) for strength and a vibration-dampening overmold (TPU) for user comfort and safety. This dual-functionality is native to the two-shot molding process.

| Material Combination | Primary Industry | Key Benefit Solved |

|---|---|---|

| PC + TPE | Medical, Electronics | Impact resistance with integrated sealing |

| ABS + TPU | Automotive, Consumer | Aesthetically pleasing with a durable grip |

| PA66 + TPE | Industrial, Automotive | Chemical resistance with ergonomic feel |

| PP + TPV | Consumer Goods | Low cost with a flexible, durable hinge |

By thinking about material pairings first, we can design parts that are inherently more capable and cost-effective over their lifecycle.

Across automotive, consumer electronics, medical, and industrial sectors, 2k injection molding proves its value. It moves beyond simple aesthetics to offer functional integration, creating durable, reliable, and ergonomic components. This technology solves complex design challenges by bonding different materials into a single, high-performance part. By leveraging material synergy, products become more robust and cost-effective, directly addressing the core needs of today’s most demanding industries.

Design for Manufacturing (DFM) for 2K Molded Parts.

A great design on paper can quickly turn into a production headache. This is especially true for 2k injection molding. The interaction between two different materials adds layers of complexity. This is where Design for Manufacturing (DFM) becomes your most critical tool.

DFM is not just about making a part manufacturable. It’s about optimizing it for efficiency, quality, and cost-effectiveness. Ignoring these principles early on leads to costly tool modifications. It can also cause frustrating production delays and parts that fail in the field.

At PTSMAKE, we’ve seen how early DFM collaboration transforms a project. By focusing on a few key areas, you can ensure your design is robust and ready for production. This avoids common pitfalls associated with the 2k molding process.

Let’s explore the core pillars of DFM for two-shot parts.

Key DFM Focus Areas

Proper DFM ensures a smooth transition from your CAD file to a high-quality physical part. It addresses potential issues before they ever reach the molding machine. This proactive approach is fundamental to success in 2k injection molding.

Here are the critical areas we will discuss:

- Wall Thickness: Managing flow and cooling between two materials.

- Gate Location: Its impact on part appearance and bond integrity.

- Shut-off Areas: The secret to crisp, clean material transitions.

- Bonding Interfaces: Creating a part that will never delaminate.

| DFM Principle | Primary Goal | Common Failure if Ignored |

|---|---|---|

| Wall Thickness | Ensure even material flow and cooling. | Warping, sink marks, stress cracks. |

| Gate Location | Control material fill and weld lines. | Weak bonds, cosmetic defects. |

| Shut-off Design | Prevent material leakage (flash). | Material bleed, poor part definition. |

| Interface Design | Create a robust mechanical bond. | Delamination, part failure under stress. |

Getting these four elements right is 90% of the battle. It ensures your innovative two-material design performs as intended.

Managing Wall Thickness in 2K Parts

Uniform wall thickness is a golden rule in all injection molding. For 2k parts, its importance is amplified. You are managing the flow and cooling of two different materials, often with different shrink rates.

Consistency is Key

Ideally, the walls for both the substrate and the overmold material should be as uniform as possible. Drastic variations cause uneven cooling. This creates internal stress, leading to part warpage and sink marks. We aim for smooth, gradual transitions when thickness changes are unavoidable.

Smooth Transitions Are Crucial

If you must change wall thickness, avoid sharp corners. Use generous radii and gentle slopes. This helps the molten plastic flow evenly. It prevents pressure drops and ensures the cavity fills completely. A smooth flow path is vital for a strong chemical bond between the two materials. Poor flow can lead to weak spots.

Strategic Gate Placement

The gate is where molten plastic enters the mold cavity. Its location is a critical decision that affects the part’s final quality. It influences everything from aesthetics to structural integrity. A poorly placed gate can ruin an otherwise perfect design.

The rheology6 of the materials plays a significant role here. Understanding how each material flows under pressure is key.

Impact on Aesthetics and Strength

We try to place gates in non-visible areas to hide any cosmetic blemishes. More importantly, gate location determines the formation of weld lines. These lines appear where two flow fronts meet. In 2k injection molding, a weld line at the material interface can create a significant weak point, compromising the bond.

| Gate Type | Best Use Case | Considerations |

|---|---|---|

| Edge Gate | Simple, flat parts. | Leaves a visible mark after trimming. |

| Tunnel Gate | High-volume production. | Automatically degates parts. |

| Hot Tip Gate | Parts requiring perfect finish. | More complex and costly tooling. |

The right gate strategy ensures a strong, visually appealing part. It requires balancing cosmetic needs with the mechanical requirements of the 2k process.

Designing Critical Shut-Off and Sealing Areas

In 2k injection molding, the shut-off is the area where the two halves of the mold press together. This creates a seal that prevents the second material from bleeding onto the first. A crisp, clean line between your materials depends entirely on this feature.

The ‘Steel-Safe’ Approach

Designing robust shut-offs is non-negotiable. These surfaces must meet perfectly to form a tight seal. Even a tiny gap can lead to flash or material bleed. In our experience, designing these features to be "steel-safe" is a wise precaution. This means we can easily remove steel to tighten the fit if needed. Adding steel back is far more difficult and expensive.

We often recommend angled or stepped shut-off designs. These provide a more reliable seal than simple flat surfaces. They create a more complex path for the plastic to travel, effectively stopping any potential leakage.

Enhancing Bonds with Mechanical Interlocks

While material compatibility provides a chemical bond, you should never rely on it alone. A truly robust 2k part incorporates mechanical interlocks. These design features physically lock the two materials together. This creates a bond that is far stronger and more reliable.

Beyond Chemical Adhesion

Think of it like dovetail joints in woodworking. The interlocking shapes provide strength, not just the glue. In 2k molding, we can design features like holes, grooves, or channels in the first shot (the substrate). The second material then flows into these features, creating a powerful mechanical connection.

| Bonding Method | Strength | Design Complexity | Reliability |

|---|---|---|---|

| Chemical Only | Moderate | Low | Dependent on materials |

| Mechanical Only | High | Moderate | Very High |

| Chemical + Mechanical | Very High | Moderate | Highest |

This combined approach is the gold standard for parts subjected to stress, torsion, or peeling forces. It ensures the overmold will never separate from the substrate. For a deeper dive into these techniques and more, I encourage you to download our comprehensive DFM guide. It’s a resource our team at PTSMAKE has developed to help engineers like you succeed.

Successful Design for Manufacturing in 2k injection molding hinges on four key pillars. Consistent wall thickness and smooth transitions ensure proper material flow and prevent defects. Strategic gate placement is crucial for both aesthetic quality and structural integrity. Furthermore, precise shut-off areas are essential for creating clean separations between materials. Finally, incorporating mechanical interlocks alongside chemical adhesion provides the most robust and reliable bond, ensuring the long-term performance and durability of the final part.

Material Compatibility: Your Guide to Perfect Bonding.

Choosing the right materials is the single most critical decision in 2k injection molding. Get it right, and you create a seamless, durable, multi-material part. Get it wrong, and you’re left with peeling, delamination, and product failure. It’s a costly mistake.

Many believe it’s as simple as picking two plastics. But the reality is a complex science. A strong, permanent bond doesn’t happen by chance. It relies on the deep, molecular compatibility between the substrate and the overmolding material.

What makes one plastic stick to another? The secret lies in their chemical makeup. Certain polymer families are naturally attracted to each other, forming powerful chemical bonds. Others repel each other, requiring clever design tricks to hold them together.

This guide is your starting point. We’ll give you a clear compatibility chart. Use it to navigate the complex world of material selection. It will help you avoid common pitfalls and design parts that last. Think of it as your cheat sheet for perfect bonding.

To truly master material selection, you need to understand the "why." Why do some materials bond perfectly while others fall apart? It all comes down to two main mechanisms: chemical bonding and mechanical interlocking.

Chemical Bonding: The Molecular Handshake

The ideal bond in 2k injection molding is a chemical one. This happens when the molten overmold material comes into contact with the substrate. The polymer chains from both materials intermingle and form a true molecular weld at the interface.

This type of bond is incredibly strong and reliable. It depends heavily on the materials having similar chemical properties. Factors like polarity and surface energy7 play a huge role. When these properties align, the materials are naturally attracted to one another.

Mechanical Interlocking: A Physical Grip

What if your chosen materials aren’t chemically compatible? You can still achieve a strong bond through mechanical interlocking. This method relies on the part’s physical design rather than chemical attraction.

We design the substrate with features like undercuts, holes, or a rough texture. The overmolding material then flows into these features and solidifies. This creates a powerful physical grip, much like how Velcro works. It’s a robust solution, especially for materials like nylon.

Here’s a quick comparison:

| Feature | Chemical Bonding | Mechanical Interlocking |

|---|---|---|

| Bond Strength | Very High | Moderate to High |

| Mechanism | Molecular Adhesion | Physical Entanglement |

| Requirement | Material Compatibility | Substrate Design Features |

| Example | TPE on ABS | LSR on PA66 with undercuts |

Knowing the theory is one thing, but applying it is what matters. To make your job easier, I’ve put together a material compatibility chart based on projects we’ve handled at PTSMAKE. This chart covers some of the most common material combinations in the industry.

Use this as your starting point. It will help you quickly narrow down your options for your next 2k injection molding project.

General Material Compatibility Chart

| Substrate Material | TPE (SEBS-based) | TPU (Ester-based) | LSR (Silicone) |

|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Good | Good | Poor* |

| PC (Polycarbonate) | Good | Good | Poor* |

| PA66 (Polyamide 66) | Poor | Fair | Good (with primer) |

| PBT (Polybutylene Terephthalate) | Fair | Good | Poor* |

Note: LSR often requires a primer or mechanical interlocks for a strong bond with most thermoplastics.

Beyond the Chart

Remember, this chart is a guideline. The exact grade of material, additives like colorants or flame retardants, and even molding process parameters can affect bond strength. For instance, a TPU overmolded onto PC can create an excellent bond. This is because both materials share polar characteristics.

However, a TPE overmolded onto PA66 will likely fail without mechanical features. Their chemistries are simply too different. In our work, we always recommend creating sample plaques to test the specific material grades you intend to use. This validation step removes any guesswork.

Successful 2k injection molding hinges on material compatibility. The strongest bonds are chemical, formed when polymers are naturally attracted to each other. When materials are incompatible, a robust mechanical interlock can provide the necessary strength. This guide and chart offer a solid foundation, but remember that real-world testing with your specific material grades is essential for guaranteeing a perfect, lasting bond. Consulting with experts can prevent costly failures down the line.

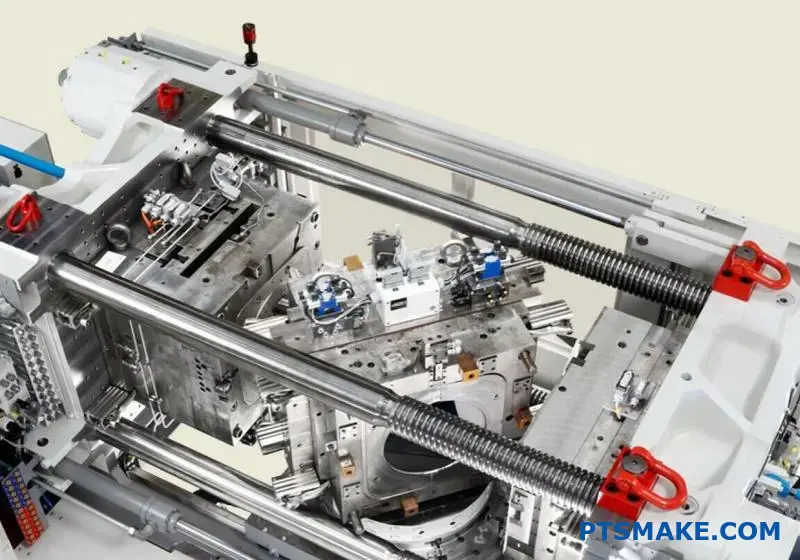

Our Advanced 2K Molding Capabilities & Technology.

Having the right idea is one thing. Having the right partner with the right technology to bring it to life is everything. At PTSMAKE, we’ve invested heavily in the specific technology and expertise required for high-precision 2k injection molding. It’s not just about having machines; it’s about having a complete, integrated system.

This system ensures your design intent is perfectly translated into a final product. We combine state-of-the-art equipment with deep engineering knowledge. This synergy allows us to tackle complex geometries and material combinations that others might turn away.

Our capabilities are built on a foundation of powerful, reliable machinery. We operate a range of specialized 2K injection molding presses. This gives us the flexibility to handle various part sizes and production volumes.

Our Core 2K Molding Equipment

We utilize industry-leading machines from manufacturers like Engel and Arburg. This choice isn’t accidental. Their precision and reliability are crucial for the tight tolerances required in 2k molding.

| Machine Feature | Specification / Capability | Impact on Your Project |

|---|---|---|

| Tonnage Range | 80T – 450T | Versatility for small intricate parts to larger components. |

| Injection Units | Dual, independent control | Precise material delivery for perfect layer bonding. |

| Control Systems | Advanced CNC programming | High repeatability and process stability. |

| Mold Technology | Rotary Platen, Index Plate | Supports efficient and complex multi-shot molding. |

Our modern, clean facility houses this advanced equipment. We maintain a controlled environment to ensure process consistency. This is key for delivering quality parts, batch after batch.

Great machines are only half the story. The real magic happens in the tooling. Unlike many molders, we have a fully-equipped, in-house tool room. This is a significant advantage for our clients.

Having our own mold design and manufacturing capabilities changes the game. It means we control the entire process from the very start. We aren’t waiting on a third-party toolmaker. This vertical integration streamlines communication and shortens lead times.

In-House Tooling and Engineering Expertise

Our engineers design the mold specifically for your part and our machines. This synergy is critical for successful 2k injection molding. They use advanced software to simulate the molding process. This helps us predict and solve potential issues before cutting any steel.

We consider every detail, from gate location to cooling channels. The material’s rheology8 is carefully analyzed to ensure a perfect chemical bond between the two plastics. This proactive approach minimizes costly trial-and-error cycles.

Our team has a deep understanding of how different materials behave together. This knowledge is crucial for creating a durable, seamless bond.

| Engineering Stage | Our Focus | Client Benefit |

|---|---|---|

| Design for Manufacturability (DFM) | Optimizing part design for the 2k process. | Reduced costs and improved part quality. |

| Mold Flow Analysis | Simulating plastic flow and bonding. | Prevents defects like voids or weak bonds. |

| Tool Design & Build | Precision engineering and machining. | A robust mold that delivers consistent parts. |

| Prototyping & Validation | Testing and refining the process. | Guarantees the final product meets specifications. |

This expertise ensures your project moves smoothly from concept to production. We manage every step, giving you a single point of contact and total accountability.

Our process is built around collaboration. We see ourselves as an extension of your team. From the initial quote request, our engineers are involved. They work with you to understand your goals and challenges.

This collaborative approach is essential for complex 2k injection molding projects. We believe open communication and shared expertise lead to the best outcomes. Your product knowledge combined with our manufacturing experience creates a powerful partnership.

A Collaborative Path to Production

We don’t just take your CAD file and press a button. We engage in a detailed review process. We might suggest small design tweaks that can lead to big improvements in manufacturability or cost-effectiveness. Our goal is to set the project up for success from day one.

This partnership continues throughout the project lifecycle. We provide regular updates and are always available to discuss progress. Transparency is a core part of how we operate at PTSMAKE.

Our structured process ensures nothing is left to chance. Every step is planned, executed, and verified.

| Process Step | Our Action | Your Involvement |

|---|---|---|

| 1. Initial Consultation | Our engineers review your design and goals. | You provide project requirements and specifications. |

| 2. DFM & Quote | We provide a detailed analysis and transparent quote. | You review and approve the design direction. |

| 3. Mold Manufacturing | Our team builds the high-precision 2k mold. | You receive regular progress updates. |

| 4. Part Production | We run first articles and then full production. | You approve samples and receive final parts. |

This systematic approach minimizes risk and ensures on-time delivery. We handle the manufacturing complexity so you can focus on your core business.

Our advanced 2k molding capability is a complete system. It combines top-tier machinery like Engel and Arburg presses with deep, in-house tooling expertise. This integration, guided by our collaborative engineering team, ensures your complex components are manufactured to the highest standards. We control the entire process, from DFM analysis to final production, providing a reliable and streamlined path for your project’s success. We are your partner in manufacturing innovation.

Success Stories: Real-World 2K Molding Case Studies.

Theory is one thing, but results are what truly matter. Talk is cheap, but seeing how a technology solves real-world problems is priceless. That’s why I want to walk you through some actual projects we’ve handled at PTSMAKE. These aren’t just hypotheticals; they are tangible examples of how 2K injection molding delivered incredible value.

We’ll look at challenges our clients faced and how we turned them into successes. Each case follows a simple structure: Problem, Solution, and Result. This format clearly shows the impact of our approach. You’ll see how we moved from a complex issue to a streamlined, cost-effective outcome.

These examples come from different industries. They showcase the versatility of the 2K molding process. Whether it’s for rugged automotive parts or ergonomic consumer goods, the principles are the same. We combine materials to create a better, more integrated product.

Let’s dive into the specifics.

Case Study 1: Automotive Sensor Housing

The Problem

A client in the automotive sector needed a robust housing for a critical sensor. The part had to withstand harsh engine bay conditions. This meant extreme temperatures, vibrations, and exposure to fluids. More importantly, it required an IP67 rating, meaning it had to be completely dust-tight and waterproof. Their previous design used a separate gasket, which was costly to assemble and prone to failure over time.

Our 2K Molding Solution

We proposed a single-part solution using 2K injection molding. The process involved molding a rigid, heat-resistant Polybutylene Terephthalate (PBT) for the main body. Then, in the same mold, we overmolded a Thermoplastic Elastomer (TPE) seal directly onto the housing. This created a perfect, permanent bond.

The Quantified Result

The outcome was a game-changer for the client. The integrated seal eliminated the need for a separate gasket and the manual assembly step.

| Metric | Before 2K Molding | After 2K Molding | Improvement |

|---|---|---|---|

| Part Count | 2 (Housing + Gasket) | 1 (Integrated Part) | 50% Reduction |

| Assembly Time | ~30 seconds/part | 0 seconds/part | 100% Elimination |

| Waterproof Rating | IP65 (at best) | IP67 (Certified) | Exceeded Requirement |

| Unit Cost | Baseline | Reduced by 18% | Significant Savings |

The final part was not only more reliable but also cheaper to produce. It passed all validation tests with flying colors, enhancing the overall product quality.

Deep Dive: Achieving the Perfect Bond

Creating a durable bond between two different materials is the heart of 2K injection molding. It’s not just about pressing them together. The success hinges on material compatibility, mold design, and precise process control. In the automotive sensor project, the choice of PBT and TPE was critical.

These materials are engineered to have excellent Chemical Bonding9 properties. During the overmolding stage, the molten TPE flows onto the still-warm PBT substrate. At the interface, the polymer chains from both materials intermingle and form a strong, permanent connection. It’s a molecular-level fusion, not just a mechanical lock.

Our team at PTSMAKE ran multiple mold flow simulations. This helped us optimize the gate location and injection parameters. We needed to ensure the TPE material filled the seal channel perfectly without causing any defects or stress in the PBT housing.

Here is a simplified look at the key factors we control:

| Process Parameter | Importance | Why It Matters |

|---|---|---|

| Substrate Temperature | High | Ensures the surface is receptive for a strong chemical bond. |

| Overmold Injection Speed | Medium | Fills the cavity without degrading the material or damaging the substrate. |

| Holding Pressure | High | Prevents sink marks and ensures proper part density. |

| Cooling Time | Critical | Allows the bond to set properly before part ejection. |

By fine-tuning these elements, we create a single, seamless component that performs as one. This attention to detail is what separates a standard part from a high-performance one.

Case Study 2: Ergonomic Power Tool Grip

The Problem

A leading consumer brand wanted to launch a new line of cordless drills. A key design goal was superior ergonomics. They wanted a handle that was comfortable, non-slip, and durable enough to handle job site abuse. Their initial prototypes used a standard plastic handle with a rubber sleeve slid over it. This felt cheap and the sleeve could twist or peel off with heavy use.

Our 2K Molding Solution

We worked with their design team to develop a fully integrated handle grip. The solution was a 2K injection molding process. We used a tough, glass-filled Polypropylene (PP) for the structural core of the handle. For the outer layer, we overmolded a soft-touch TPE with a custom-designed texture. This provided both a comfortable cushion and a secure grip.

"PTSMAKE didn’t just make our part; they improved our product. The 2K molded handle is now a key selling feature, and our customer feedback on comfort has been overwhelmingly positive." – Product Manager

The Quantified Result

The new handle design transformed the user experience and improved manufacturing efficiency. It helped the product stand out in a crowded market.

| Metric | Before 2K Molding | After 2K Molding | Improvement |

|---|---|---|---|

| Manufacturing Steps | 2 (Mold handle + Assemble grip) | 1 (Integrated molding) | Streamlined Process |

| Product Durability | Grip peel issues in tests | Passed 2-meter drop test | 100% Pass Rate |

| User Comfort Score | 6.5 / 10 | 9.2 / 10 | 41.5% Increase |

| Perceived Value | Standard | Premium | Enhanced Brand Image |

This project demonstrates how 2K molding can be used not just for technical function, but also to significantly enhance a product’s look, feel, and overall market appeal.

These real-world case studies show that 2K injection molding is more than just a manufacturing process. It’s a powerful problem-solving tool. By intelligently combining materials into a single component, we help clients like you reduce costs, improve product performance, and create superior designs. The results, as seen in the automotive and power tool examples, are tangible, measurable, and impactful. This process turns complex challenges into elegant, efficient solutions.

Ensuring Quality and Precision in Every Part.

Quality isn’t just a final check. It’s the foundation of everything we do, especially in complex processes like 2k injection molding. For engineers and procurement managers, receiving a part that’s out of spec is more than an inconvenience; it can halt an entire production line. That’s a risk we are not willing to take.

At PTSMAKE, our commitment to quality is built into our operational DNA. We understand that trust is earned through consistent, reliable results. This is why we maintain rigorous standards and certifications, ensuring every component we produce meets your exact specifications. Our approach is not just about catching defects; it’s about preventing them from ever happening.

Our Core Quality Commitment

We start with a certified framework. Our ISO 9001:2015 certification isn’t just a badge; it’s a system we live by. It governs every step, from the moment we receive your CAD file to the final shipment. This structured process provides the traceability and control that our B2B clients demand for critical applications.

The Inspection Journey

Each part undergoes a multi-stage inspection process. This ensures that quality is monitored and verified continuously, not just at the end. It’s a systematic approach designed to build confidence and guarantee precision.

| Stage | Key Actions | Purpose |

|---|---|---|

| Incoming Raw Material | Material Certificate Verification, Hardness & Composition Testing | To ensure the material meets project specifications from the start. |

| In-Process Quality Control | First Article Inspection (FAI), Regular dimensional checks | To catch any deviations early and maintain process stability. |

| Final Part Approval | Full dimensional inspection, Visual check, Functional testing | To confirm the finished part meets all design requirements before shipping. |

This meticulous journey is how we ensure that every part, whether simple or complex, is a perfect match for your design.

To deliver on our promise of precision, we invest in state-of-the-art metrology equipment. Technology is a critical partner in our quality control process. It allows us to measure with a level of accuracy and repeatability that manual methods simply cannot match. This is especially vital for parts with tight tolerances or complex geometries.

Our inspection lab is equipped with advanced tools that provide objective, data-driven feedback. This data is not only used to approve parts but also to refine our manufacturing processes continually. It’s about creating a loop of constant improvement. We believe that good data leads to better parts.

Advanced Metrology at PTSMAKE

Our tools are selected to handle the diverse needs of our clients. From aerospace components to medical devices, we have the right equipment for the job. This capability allows us to provide comprehensive inspection reports that give you full confidence in our work. We use Statistical Process Control10 to monitor and control our processes.

Our Key Inspection Technologies

Below is a look at some of the core technologies we employ and what they help us achieve. Each one plays a specific role in our comprehensive quality assurance strategy.

| Equipment | Primary Use | Key Benefit |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Verifying complex 3D geometries and tight tolerances. | Provides highly accurate, repeatable measurements down to the micron level. |

| Optical Scanners | Capturing detailed surface data and comparing to CAD models. | Ideal for freeform surfaces and ensuring cosmetic perfection. |

| Digital Calipers & Micrometers | Quick and precise checks of critical dimensions during production. | Enables real-time feedback and process adjustments on the shop floor. |

| Hardness Testers | Confirming material properties after heat treatment. | Ensures parts meet strength and durability requirements. |

This investment in technology is a direct investment in your project’s success. It’s how we transform your designs into tangible, high-quality parts.

Our quality philosophy extends beyond the inspection lab. We believe in a proactive approach focused on risk mitigation. This starts long before the first piece of material is cut. It begins with a thorough Design for Manufacturability (DFM) analysis. For 2k injection molding projects, this step is absolutely critical.

We analyze your design to identify potential challenges in the molding process. This could involve issues with wall thickness, draft angles, or the bonding between the two materials. By addressing these potential problems upfront, we prevent costly tool modifications and production delays down the line.

Proactive vs. Reactive Quality Control

Many suppliers focus only on final inspection, which is a reactive approach. They find problems after they’ve already occurred. At PTSMAKE, we integrate quality checks throughout the entire lifecycle of your project. This proactive mindset is a key differentiator. It saves you time, reduces costs, and eliminates surprises.

Our engineers work closely with your team. We provide feedback and suggestions to optimize your design for both performance and manufacturability. This collaborative process ensures a smoother production run and a better final product.

| Approach | Proactive QC (PTSMAKE Method) | Reactive QC (Traditional Method) |

|---|---|---|

| Timing | Before and during production | After production is complete |

| Focus | Prevention of defects | Detection of defects |

| Key Activity | DFM analysis, process simulation | Final part inspection |

| Outcome | Reduced scrap, lower costs, faster delivery | Higher scrap rates, potential rework, delays |

This proactive strategy is central to how we operate. It’s about engineering success into your project from day one, ensuring the quality of your 2k injection molded parts is never left to chance.

Our commitment to quality is unwavering, built on a foundation of certified processes like ISO 9001:2015 and advanced metrology. We employ tools like CMMs and optical scanners to ensure precision. More importantly, we take a proactive approach, using DFM analysis to mitigate risks before production begins. This system ensures every part, especially for complex 2k injection molding, meets your exact specifications and builds lasting trust in our partnership.

Frequently Asked Questions about 2K Molding.

Getting straight answers is key to moving a project forward. You have questions, and my goal is to provide clear, direct answers. This helps you make informed decisions quickly. Let’s tackle some of the most common inquiries we receive about 2k injection molding.

Understanding the process upfront saves time and prevents surprises. Many factors influence a project’s timeline and cost. We believe in transparency from the start. This ensures a smooth partnership from design to production.

What is the typical cost of a 2K injection mold?

There’s no one-size-fits-all answer. The cost of a 2K mold depends on several key factors. Part complexity is the biggest driver. More intricate designs require more complex tooling.

The material used for the mold itself also plays a role. Hardened steel molds cost more but last for millions of cycles. Aluminum molds are less expensive but have a shorter lifespan. They are great for prototyping.

Here is a breakdown of the main cost influencers:

| Factor | Impact on Cost | Why it Matters |

|---|---|---|

| Part Complexity | High | Intricate details require more machining time. |

| Mold Material | High | Hardened steel vs. aluminum affects longevity. |

| Part Size | Medium | Larger parts require larger, more expensive molds. |

| Production Volume | Medium | High-volume tools need durable, costly materials. |

| Cavitation | Medium | More cavities increase initial cost but lower part price. |

What are your typical lead times for tooling and production?

Lead times vary based on the project’s complexity. A simple 2K injection mold can take 4-6 weeks to build. A highly complex mold might take 8-12 weeks or more.

Once the tool is complete and approved, production can begin. The first production run usually happens within a week after tool validation. We always provide a detailed project timeline. This keeps you informed every step of the way.

What are the minimum order quantities (MOQ)?

Minimum order quantities are necessary for injection molding. The setup process for a 2K machine is complex. It involves loading the mold and calibrating two injection units. This takes time and material.

Our MOQs ensure that the process is efficient and cost-effective. For most projects, our MOQ starts around 1,000 pieces. However, this can be flexible. We evaluate it on a case-by-case basis.

For prototypes or very small runs, other manufacturing methods might be better. We can discuss options to find the best fit for your needs. We are partners in your project’s success. This involves finding the right manufacturing path for your specific stage of development. The goal is to balance cost with your immediate needs.

The concept of rheology11 is crucial here; understanding how materials flow is key.

What design file formats do you accept?

We work with a variety of standard CAD file formats. This ensures seamless communication between your design team and our engineers. Our goal is to make the process as easy as possible for you.

Providing the right file format helps us get started on your quote and DFM analysis quickly.

Here are the most common file formats we accept:

| File Format | Extension | Preferred for |

|---|---|---|

| STEP | .stp / .step | 3D models (Universal) |

| IGES | .igs / .iges | 3D models (Universal) |

| SolidWorks | .sldprt | 3D models (Native) |

| AutoCAD | .dwg / .dxf | 2D drawings |

| 2D drawings |

While we accept many formats, STEP files are often the best choice. They are universal and maintain the integrity of the 3D model without translation issues. Providing a 2D drawing with tolerances is also very helpful.

Can you assist with material selection for my project?

Absolutely. Material selection is one of the most critical steps in 2k injection molding. The right choice ensures your part performs as intended. We actively guide our clients through this process.

Our team helps you consider all the variables. This includes mechanical properties, chemical resistance, and temperature exposure. We also focus on the bond between the two materials. A strong chemical or mechanical bond is essential for a durable part.

In past projects at PTSMAKE, we have seen how critical this is. A poor material combination can lead to delamination and part failure. Our experience helps you avoid these pitfalls.

Here are some common material pairings and their applications:

| Substrate (Hard) | Overmold (Soft) | Common Applications |

|---|---|---|

| PC | TPE | Handheld electronics, grips |

| ABS | TPU | Power tool handles, gaskets |

| Nylon (PA) | TPE | Automotive components, seals |

| PP | TPE | Consumer goods, soft-touch buttons |

We discuss your product’s end-use environment in detail. This conversation allows us to recommend materials that meet your specific performance and budget requirements. We are here to ensure your final product is a success. This collaborative approach is a core part of how we operate at PTSMAKE.

Answering key questions upfront is vital for a successful partnership. We’ve covered the factors that influence 2K mold costs, typical lead times, and why MOQs are necessary. We also discussed preferred design file formats like STEP for smooth collaboration. Our team at PTSMAKE is always ready to assist with crucial decisions, such as material selection, to ensure your project’s success. This transparency helps build a foundation of trust from the very beginning.

Take Your 2K Injection Molding Projects Further with PTSMAKE

Ready to achieve superior part strength, seamless assembly, and design freedom? Contact PTSMAKE’s expert team for a free quote on your next 2K injection molding project. Discover how our state-of-the-art technology and over 20 years’ experience can power your innovation—send your inquiry today!

Discover the critical role of the initial material shot in the 2K molding process. ↩

Learn how material flow behavior impacts the quality of your molded parts. ↩

Explore how material compatibility impacts the molecular bond for maximum part durability. ↩

Click to understand how this base material choice impacts your part’s integrity and performance. ↩

Understand how this material property enhances grip, comfort, and sealing in product design. ↩

Learn how material flow properties influence your design and prevent common molding defects. ↩

Learn more about how this property affects adhesion and bonding performance in our detailed material science guide. ↩

Understand how material flow analysis can prevent defects and save costs in your project. ↩

Discover how different plastics fuse together in 2K molding for maximum durability and performance. ↩

Learn more about how this data-driven method improves part consistency and quality. ↩

Learn how material flow properties can impact your part’s final quality and performance. ↩