Working with titanium grades feels overwhelming when you’re staring at dozens of specifications, each with different strength values, chemical compositions, and application notes. You know choosing the wrong grade could mean costly redesigns, failed parts, or worse—but the technical data sheets don’t make the practical differences clear.

Titanium grades differ primarily in their alloy composition, which directly impacts four key properties: tensile strength, corrosion resistance, formability, and weldability. Understanding these relationships helps you select the right grade for your specific application requirements.

I’ve worked with titanium specifications across aerospace, medical, and industrial projects. The decision framework I’ll share breaks down complex metallurgy into practical selection criteria that actually matter for your parts.

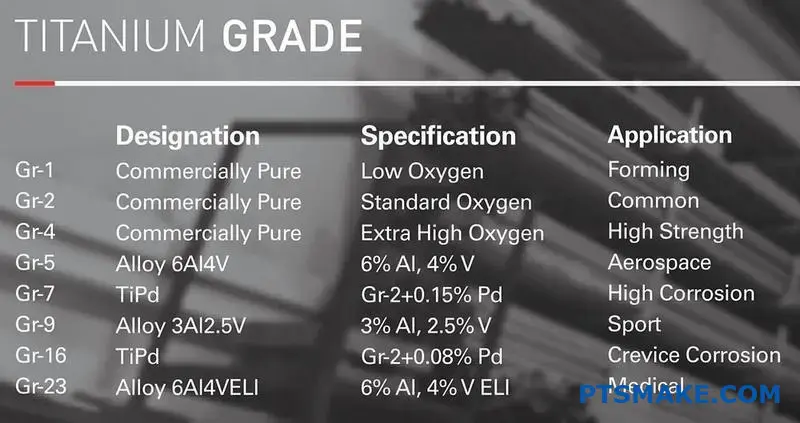

What key properties differentiate common titanium grades?

Choosing the right titanium is not just about picking a name from a list. It hinges on four fundamental properties. These pillars guide every material selection decision.

They are tensile strength, corrosion resistance, ductility, and weldability. Understanding these is the first step in any practical titanium grade comparison.

The Foundation of Selection

These four properties determine how a grade will perform. They dictate its behavior under stress, in harsh environments, and during fabrication. Making the right choice here is critical for your project’s success.

| Key Property | Why It Matters |

|---|---|

| Tensile Strength | Ability to withstand pulling forces without breaking. |

| Corrosion Resistance | Resistance to degradation from chemicals or environment. |

| Ductility/Formability | Ability to be bent or shaped without fracturing. |

| Weldability | Ease of joining the material to itself or others. |

A Deeper Look at Titanium’s Traits

These four properties are often interrelated. You rarely get the best of all worlds. A successful titanium grade comparison involves understanding the necessary trade-offs for your specific application.

Strength vs. Formability

Generally, as tensile strength increases, ductility decreases. Stronger alloys like Grade 5 are fantastic for high-stress aerospace parts.

However, they are harder to form than softer grades like Grade 2. This impacts manufacturing complexity and cost.

The Corrosion Factor

Titanium’s natural oxide layer gives it superb corrosion resistance. This makes it ideal for medical implants and marine hardware.

But, different grades perform differently in specific chemical environments. It’s a key consideration. The presence of interstitial elements1 like oxygen and nitrogen significantly influences these properties.

Weldability’s Practical Impact

Weldability is a crucial factor in fabrication. Pure titanium grades (1-4) are generally easier to weld. Alloys can be more challenging. At PTSMAKE, we help clients navigate these choices. This ensures their designs are both functional and manufacturable.

| Feature Comparison | Grade 2 (Commercially Pure) | Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Tensile Strength | Moderate | Very High |

| Ductility | Excellent | Moderate |

| Corrosion Resistance | Excellent | Excellent |

| Weldability | Good | Fair |

Understanding tensile strength, corrosion resistance, ductility, and weldability is essential. These four pillars form the basis for selecting the right titanium grade, directly influencing your component’s performance, manufacturability, and overall cost.

What is the core difference between CP and alloyed titanium?

The fundamental difference lies in purity versus performance. Commercially Pure (CP) titanium is all about maximizing corrosion resistance. Its grades are defined by their titanium content.

Alloyed titanium, however, is a different story. We intentionally add other elements. This is done to boost specific mechanical properties like strength and hardness.

Commercially Pure (CP) Titanium

CP grades are over 99% titanium. The main differences between Grades 1 to 4 are the amounts of oxygen and iron.

Alloyed Titanium

Grade 5 (Ti-6Al-4V) is a classic example. It contains 6% aluminum and 4% vanadium. These additions make it much stronger than any CP grade.

A simple titanium grade comparison:

| Grade Type | Key Feature | Primary Elements |

|---|---|---|

| CP Grade 2 | High Purity | >99% Titanium (Ti) |

| Alloyed Grade 5 | High Strength | Ti, 6% Aluminum (Al), 4% Vanadium (V) |

This simple choice between purity and added strength is central to material selection.

At its core, the choice is about the end application. Is the part’s environment highly corrosive? Or does it need to withstand extreme mechanical stress? This is the first question we ask at PTSMAKE.

The Purity Principle: CP Grades

Commercially Pure titanium’s strength comes from its simplicity. The different grades (1-4) are classified by their allowable levels of interstitial elements2 like oxygen, nitrogen, and carbon.

More oxygen means higher strength but lower ductility. Grade 1 is the softest and most formable. Grade 4 is the strongest of the CP grades. This makes it a great material for chemical processing equipment where corrosion resistance is key.

The Performance Principle: Alloyed Grades

For applications in aerospace or medical implants, raw strength is critical. This is where alloys shine. Adding elements like aluminum and vanadium creates a material that is significantly stronger and more fatigue-resistant.

How Alloying Works

These added elements change titanium’s internal crystal structure. This makes it harder for the atomic layers to slip past each other. The result is a much stronger material.

Based on our tests, this alloying process can more than double the tensile strength compared to CP grades.

A more detailed titanium grade comparison reveals these trade-offs:

| Property | CP Grade 2 | Alloyed Grade 5 | Rationale |

|---|---|---|---|

| Tensile Strength | Lower | Much Higher | Alloying elements add strength. |

| Corrosion Resistance | Excellent | Very Good | Higher purity boosts resistance. |

| Formability | High | Lower | Purer metals are more ductile. |

| Cost | Lower | Higher | Alloying elements and processing add cost. |

The decision between CP and alloyed titanium is a balance of performance needs and budget.

In short, the main difference is intent. CP titanium prioritizes purity for corrosion resistance, while alloyed titanium is engineered with specific elements to achieve superior mechanical properties. This is a crucial first step in any titanium grade comparison for a project.

Why is Grade 5 (Ti-6Al-4V) the industry workhorse?

The secret to Grade 5’s success lies in its structure. It’s known as an "alpha-beta" alloy. This means it combines two different crystalline phases.

Think of it as the best of both worlds. This unique blend is achieved by adding specific elements.

The Key Ingredients

Aluminum is the primary "alpha stabilizer." Vanadium is the "beta stabilizer." This precise recipe is what makes Grade 5 so versatile and reliable.

| Element | Chemical Symbol | Role |

|---|---|---|

| Titanium | Ti | Base Metal |

| Aluminum | Al | Alpha Stabilizer |

| Vanadium | V | Beta Stabilizer |

This combination is the foundation of its superior performance.

A Perfect Balance of Properties

So, what do these stabilizers actually do? The roles of aluminum and vanadium are distinct yet complementary. They create a material that outperforms many others.

The Role of Aluminum (Al)

Aluminum strengthens the alpha phase. This improves the alloy’s high-temperature strength and creep resistance. It provides the material’s structural backbone.

The Role of Vanadium (V)

Vanadium, on the other hand, stabilizes the beta phase. This phase is crucial for allowing heat treatment. It enhances toughness and high-strength capabilities.

This balancing act creates a refined dual-phase microstructure3 after heat treatment. This is something we’ve confirmed in our work at PTSMAKE. When conducting a titanium grade comparison, Grade 5 consistently hits the sweet spot.

| Alloy Type | Key Characteristic | Common Weakness |

|---|---|---|

| Alpha Alloys | High corrosion resistance | Lower strength |

| Beta Alloys | High strength, formable | More complex processing |

| Alpha-Beta (Grade 5) | Balanced strength & toughness | Excellent all-rounder |

This structure gives it a combination that is hard to beat: strong, light, and corrosion-resistant.

Grade 5’s alpha-beta alloy structure is its defining feature. Aluminum provides high-temperature strength, while vanadium adds toughness and allows for heat treatment. This synergy results in an exceptionally balanced and versatile material, making it the industry standard for demanding applications.

Grade 2 Titanium: The Industry’s Workhorse

Grade 2 titanium hits the perfect sweet spot. It’s often called the "workhorse" of commercially pure titanium grades. And for good reason.

It provides an excellent all-around package. You get moderate strength combined with superior formability and weldability.

This balance makes it incredibly versatile. It’s suitable for a vast range of applications without the higher cost of specialized alloys. This is a key point in any titanium grade comparison.

| Property | Grade 2 Assessment |

|---|---|

| Strength | Moderate |

| Corrosion Resistance | Excellent |

| Formability/Weldability | Excellent |

| Cost | Competitive |

A Deeper Look at the Balance

Grade 2’s popularity isn’t accidental. It’s the result of a carefully engineered set of properties that makes it ideal for manufacturing.

Strength Meets Formability

Unlike stronger grades that can be brittle or hard to work with, Grade 2 is different. It has enough strength for many structural uses.

Yet, it remains highly ductile. This means we can form it into complex shapes without fracturing. This reduces manufacturing complexity and cost.

Unmatched Corrosion Resistance

Its resistance to corrosion is remarkable. It performs exceptionally well in saltwater and various chemical processing environments.

This is due to the stable, protective oxide layer that forms on its surface. This layer self-heals almost instantly if scratched. Its excellent biocompatibility4 also makes it a top choice for medical implants.

Weldability and Cost-Effectiveness

Grade 2 is the most easily welded of all titanium grades. This simplifies the fabrication process significantly.

When you combine this ease of manufacturing with its lower material cost compared to alloys, the value becomes clear. It delivers high performance without a premium price tag.

| Feature Comparison | Grade 2 Titanium | Higher-Grade Alloys |

|---|---|---|

| Machining Complexity | Low | High |

| Welding Ease | Excellent | Moderate to Difficult |

| Material Cost | Lower | Higher |

| Application Range | Wide | Specialized |

Grade 2 titanium offers an optimal blend of strength, corrosion resistance, and formability at a cost-effective price point. This balanced profile makes it the most widely used commercially pure titanium grade across numerous industries.

What is the strength-ductility trade-off in practice?

Let’s look at a real-world example. Consider commercially pure (CP) titanium. This is a classic case of the strength-ductility trade-off.

The choice is clear in practice. When selecting a material, you’re not just picking properties. You are also choosing a manufacturing path.

A Tale of Two Grades

Grade 1 is the softest and most ductile. Grade 4 is the strongest of the CP grades. A simple titanium grade comparison shows this difference. Choosing a stronger grade means sacrificing forming ease.

| Property | Grade 1 Titanium | Grade 4 Titanium |

|---|---|---|

| Tensile Strength | Lowest | Highest (CP) |

| Ductility | Highest | Lowest (CP) |

| Formability | Excellent | Poor |

At PTSMAKE, we guide clients through this choice daily. The decision between Grade 1 and Grade 4 titanium is a perfect illustration of theory meeting reality on the workshop floor.

Manufacturing Implications

Grade 1 is incredibly formable. It’s ideal for parts requiring deep drawing or complex bending. Think of intricate architectural panels or chemical processing vessels. The material flows easily under pressure.

Grade 4, however, resists forming. Its high strength makes it difficult to bend or shape without cracking. This material is better for parts where strength is critical and the geometry is relatively simple.

This difference is clear in processes like bending. Grade 4 exhibits more significant work hardening5 during deformation. This means it gets stronger but less ductile as you work it, requiring more force and careful handling.

Application Suitability

Based on our project experience, the application dictates the grade. You must balance the final part’s needs with manufacturing feasibility.

| Application Example | Recommended Grade | Reason |

|---|---|---|

| Aerospace Fasteners | Grade 4 | High strength is critical for safety. |

| Medical Implants | Grade 4 | Strength and wear resistance are key. |

| Complex Pipe Bends | Grade 1 | High ductility allows for tight radii. |

| Architectural Cladding | Grade 1 | Ease of forming into complex shapes. |

Choosing Grade 4 often means higher tooling costs and potentially slower cycle times. You must be prepared for these manufacturing realities.

The choice between Grade 1 and Grade 4 titanium isn’t just about spec sheets. It’s a practical decision that impacts tooling, cost, and lead time. Higher strength directly translates to more challenging and expensive fabrication processes.

What gives Grade 7 its superior corrosion resistance?

The secret to Grade 7’s strength isn’t a complex formula. It comes down to one critical ingredient: Palladium.

Even a tiny amount, between 0.12% to 0.25%, makes a huge difference. This addition transforms the alloy’s performance in harsh environments.

The Palladium Advantage

Palladium is a noble metal. Its presence fundamentally enhances the titanium’s natural protective oxide layer. This makes it incredibly tough against specific types of chemical attacks. It’s a small change with a massive impact.

Performance in Reducing Acids

Our tests show a stark difference. Grade 7 withstands conditions where other grades would fail quickly. This is crucial for chemical processing equipment.

| Corrosive Agent | Grade 2 Titanium | Grade 7 Titanium |

|---|---|---|

| Hot HCl Acid | High Corrosion Rate | Very Low Corrosion Rate |

| Chloride Solutions | Prone to Crevice Corrosion | Highly Resistant |

The addition of Palladium is what truly sets Grade 7 apart in any titanium grade comparison. It acts as a catalyst on the material’s surface, particularly in reducing acid environments where the passive oxide film can break down.

This catalytic effect helps the titanium to repassivate more easily if the protective layer is damaged. This self-healing ability is vital.

How Palladium Works

Palladium enriches the surface, creating galvanic couples on a micro-scale. This process polarizes the titanium into the passive region. It effectively stops corrosion before it can start. The result is exceptional resistance to localized attacks.

This makes it incredibly effective against crevice corrosion6. This is a common failure mode in equipment with gaskets, seals, or tight joints. These are spots where corrosive solutions can become trapped and concentrated.

Ideal for Chemical Processing

In past projects at PTSMAKE, we’ve seen Grade 7 excel where others could not. Its ability to handle chlorides and reducing acids makes it a go-to choice. It’s perfect for reactors, heat exchangers, and piping systems that handle aggressive chemicals.

| Application Environment | Key Challenge | Grade 7 Solution |

|---|---|---|

| Chemical Reactors | Reducing Acids | Superior resistance prevents failure |

| Heat Exchangers | Chloride-rich fluids | Eliminates crevice corrosion risk |

| Piping Systems | Aggressive Media | Ensures long-term integrity |

The addition of Palladium elevates Grade 7 titanium’s performance. It specifically enhances its ability to resist crevice corrosion in reducing acids and chlorides. This makes it a superior material for demanding chemical processing applications where reliability is critical.

What does a ‘grade’ number actually certify?

A grade number, like ‘Grade 5’ for titanium, is more than a simple name. It is a formal certification. This number guarantees that the material meets strict industry standards.

It’s a promise of consistency for your parts. This certification is crucial for performance.

The Guarantee Behind the Grade

A grade certifies two key areas: chemical composition and mechanical properties. This ensures every batch behaves as expected.

| Certification Area | What It Guarantees |

|---|---|

| Chemical Composition | Specific alloy elements and their percentages. |

| Mechanical Properties | Minimum strength, hardness, and ductility. |

This means you get predictable results every time. It removes guesswork from manufacturing.

A grade number links a material to a specific standard, often from organizations like ASTM International. This standard is the rulebook the material must follow. It dictates the exact recipe and performance benchmarks.

Chemical Recipe and Performance Tests

The chemical composition is specified with precise ranges for each element. For example, Grade 5 Titanium (Ti-6Al-4V) must have a set amount of Aluminum and Vanadium.

Mechanical properties like tensile strength and elongation are also defined. These are not averages; they are guaranteed minimums. The material is physically tested to ensure it meets these values. This process ensures complete material traceability7 from the source.

At PTSMAKE, we always verify these certifications. It’s fundamental to delivering parts that meet our clients’ exact specifications. When conducting a titanium grade comparison, these certified minimums are what we focus on.

Quick Titanium Grade Comparison

Here’s a simplified look at two common titanium grades we work with.

| Property | Grade 2 (Commercially Pure) | Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Tensile Strength (Min) | 345 MPa | 830 MPa |

| Yield Strength (Min) | 275 MPa | 760 MPa |

| Elongation (Min) | 20% | 10% |

This shows how the grade certifies a significant jump in strength.

A grade number is a certification based on a standard. It guarantees the material’s chemical composition and minimum mechanical properties. This ensures the material is reliable and performs exactly as designed for your application.

How are titanium alloys classified into practical families?

Understanding titanium alloys doesn’t have to be complex. We classify them into three main families. This helps predict their behavior.

These families are Alpha, Beta, and Alpha-Beta. Each has unique strengths. This framework simplifies material selection for engineers.

It’s a practical tool we use daily. It helps match the right alloy to the job’s demands, ensuring optimal performance and cost-effectiveness.

A Practical Framework

Thinking in these families builds a strong mental model.

| Alloy Family | Key Characteristic |

|---|---|

| Alpha (α) | High-temperature stability |

| Beta (β) | High strength & formability |

| Alpha-Beta (α-β) | Balanced, all-around performer |

This classification is based on the alloy’s microstructure. It directly influences its mechanical properties. For anyone working in manufacturing, this is essential knowledge for a proper titanium grade comparison.

Alpha (α) Alloys

Alpha alloys are known for excellent weldability. They also have great corrosion resistance. These alloys maintain their strength at high temperatures. This is due to their exceptional Creep resistance8.

However, they are not heat-treatable for strength enhancement. Think of them as the reliable, stable option.

Common Alpha Grades:

- Grade 1-4 (Commercially Pure)

- Ti-5Al-2.5Sn

Beta (β) Alloys

Beta alloys are the strength champions. They can be heat-treated to achieve very high tensile strengths. This makes them ideal for demanding aerospace parts.

They also offer excellent formability in their solution-treated condition. This allows for complex shapes before the final strengthening process.

Alpha-Beta (α-β) Alloys

This family is the versatile workhorse. It offers a balance of the best traits from both Alpha and Beta alloys.

Ti-6Al-4V (Grade 5) is the most famous example. It has good strength, formability, and can be heat-treated. This versatility is why it’s used in over 50% of all titanium applications.

| Family | Weldability | Strength (Heat Treated) | Formability |

|---|---|---|---|

| Alpha (α) | Excellent | Low | Good |

| Beta (β) | Fair | Highest | Excellent |

| Alpha-Beta (α-β) | Good | High | Good |

Understanding Alpha, Beta, and Alpha-Beta families simplifies material selection. Each group offers distinct advantages in weldability, strength, and formability. This framework directly guides your choice for specific applications, a key part of any titanium grade comparison.

What are the primary international standards for titanium?

Navigating titanium standards can seem complex. But it boils down to a few key players. Understanding them is crucial for any project. It ensures you get the right material.

This clarity prevents costly mistakes. Let’s break down the main standards bodies.

Key Standards Organizations

You’ll mainly encounter three organizations. Each has a specific focus area. This helps in making a proper titanium grade comparison.

| Standards Body | Primary Focus |

|---|---|

| ASTM International | Commercial & Industrial |

| SAE-AMS | Aerospace & High-Performance |

| ISO | International |

Understanding these distinctions is the first step. It guides material selection for your application. At PTSMAKE, we always verify these standards.

ASTM International

ASTM standards are the most common. You will see them in commercial and industrial projects. They cover a wide range of products. This includes bars, sheets, and pipes. They define chemical composition and mechanical properties.

Aerospace Material Specifications (AMS)

AMS standards are from SAE International. They are stricter and target aerospace applications. Think of aircraft frames or engine parts. These standards often have tighter tolerance requirements. This ensures maximum safety and performance.

International Organization for Standardization (ISO)

ISO aims to create global standards. This helps unify requirements across different countries. ISO titanium standards are widely accepted. They often overlap with ASTM or AMS specs.

A key point is that one material can meet multiple standards. For instance, a single batch of Grade 5 titanium can be certified for both ASTM and AMS specifications. This concept of dual certification9 is common. It provides flexibility for suppliers and buyers. In past projects, we have helped clients select materials certified to multiple standards. This ensures compliance across different market requirements.

| Titanium Grade | ASTM Standard | AMS Standard |

|---|---|---|

| Grade 5 (Ti-6Al-4V) | ASTM B348 | AMS 4928 |

| Grade 2 (CP Ti) | ASTM B265 | AMS 4902 |

Understanding the primary standards bodies like ASTM, AMS, and ISO is essential. A single titanium grade can often carry multiple certifications, making it suitable for different applications, from commercial products to high-stakes aerospace components.

How do ASTM and AMS specifications practically differ?

Let’s look at a real-world example: Ti-6Al-4V. This is a workhorse titanium alloy. It’s covered by both ASTM B348 and AMS 4928.

On paper, the chemistry is nearly identical. But the practical application and requirements are vastly different.

AMS 4928 is for aerospace components. ASTM B348 serves general industrial needs. This single distinction drives every other difference. This is a core point in any serious titanium grade comparison.

A quick look at their focus areas:

| Feature | ASTM B348 (Grade 5) | AMS 4928 |

|---|---|---|

| Material | Ti-6Al-4V | Ti-6Al-4V |

| Primary Use | General Industrial | Aerospace |

| Focus | Mechanical Properties | Process Control & Quality |

Diving Deeper: Traceability and Testing

AMS specifications demand complete, unbroken traceability. For AMS 4928, we must trace the material back to the specific ingot it came from. Every processing step is documented. This is non-negotiable for mission-critical parts.

ASTM B348 is less strict. Traceability is usually to the batch or lot level, which is fine for most industrial uses.

The Role of Nondestructive Testing (NDT)

Testing is another major difference. AMS 4928 mandates extensive nondestructive testing, like ultrasonic inspection. This checks for internal flaws that could cause failure under stress.

With ASTM B348, such rigorous testing is not a default requirement. The focus is more on ensuring it meets basic mechanical property targets. Material processing around the beta transus10 is also tightly controlled in AMS specifications to achieve desired microstructures.

Quality Management Systems

At PTSMAKE, our quality system adapts to these needs. AMS requires adherence to AS9100, a standard built upon ISO 9001 with additional aerospace requirements. This ensures process consistency.

Here’s a summary of the key differences:

| Requirement | ASTM B348 | AMS 4928 |

|---|---|---|

| Traceability | Batch Level | Individual Ingot/Heat |

| NDT | Not Always Required | Mandatory (e.g., Ultrasonic) |

| Heat Treat Control | General Guidelines | Strict, verified procedures |

| QMS | ISO 9001 (Recommended) | AS9100 (Mandatory) |

The Ti-6Al-4V comparison reveals the core difference: AMS 4928 ensures reliability for critical aerospace parts through strict traceability, testing, and process control. ASTM B348 provides a functional, cost-effective material for general applications where such stringent oversight is unnecessary.

What is the application hierarchy of common titanium grades?

Visualizing titanium grades as a pyramid helps in selection. At the base, you have Commercially Pure (CP) grades. They are perfect for industrial uses needing corrosion resistance.

Moving up, you find the alloys. Grade 5 is the most common. It offers a great mix of strength and low weight. This makes it ideal for aerospace.

This simple hierarchy guides material choice. It ensures you don’t over-engineer your parts. Let’s dive into this titanium grade comparison.

| Grade Category | Primary Application | Key Feature |

|---|---|---|

| Commercially Pure | Industrial, Chemical | Corrosion Resistance |

| Alpha-Beta Alloy | Aerospace, Structural | High Strength |

| Specialty Alloys | Medical, Extreme Environments | Specific Properties |

Let’s break down this hierarchy further. At the foundational level are the CP grades, like Grade 1 and Grade 2. We often use these for chemical processing equipment. Their excellent formability and corrosion resistance are key.

The workhorse of the titanium family is Grade 5 (Ti-6Al-4V). Its high strength-to-weight ratio makes it the top choice for aerospace components, high-performance automotive parts, and structural applications. It’s the go-to for strength.

Then we reach the peak with specialty grades. These are tailored for very specific, demanding roles.

For example, Grade 23 (Ti-6Al-4V ELI) is a higher-purity version of Grade 5. Its superior damage tolerance and biocompatibility11 make it essential for medical implants like bone screws and joint replacements. In past projects at PTSMAKE, we’ve seen its non-reactive nature is critical.

Grade 7 is another specialist. By adding a small amount of palladium, its corrosion resistance is hugely enhanced. This makes it suitable for the most aggressive chemical processing environments where other grades might fail.

Here’s a quick look at their specific strengths.

| Titanium Grade | Common Name | Primary Advantage |

|---|---|---|

| Grade 2 | CP Grade 2 | Best balance of strength & ductility |

| Grade 5 | Ti-6Al-4V | High strength-to-weight ratio |

| Grade 23 | Ti-6Al-4V ELI | Excellent fracture toughness |

| Grade 7 | Ti-0.2Pd | Superior corrosion resistance |

This hierarchy provides a clear selection path. Start with corrosion-resistant CP grades. Move to strong Grade 5 for structural needs. Finally, select highly specialized grades like 23 and 7 for critical medical or chemical applications where performance is non-negotiable.

What are the main application categories driving grade development?

The evolution of titanium grades is not a random process. It’s directly driven by the specific demands of key industries. Each sector faces unique challenges.

These challenges push material science to create stronger, more specialized alloys. This ensures the material perfectly matches the application’s needs.

Key Industry Drivers

A quick look at the main industries reveals a clear pattern. The application’s core requirement directly shapes the development of a specific grade.

| Industry | Primary Requirement |

|---|---|

| Aerospace | High Strength-to-Weight Ratio |

| Medical | Biocompatibility |

| Industrial/Marine | Corrosion Resistance |

| Consumer Goods | Aesthetics & Light Weight |

This direct link is crucial. A simple titanium grade comparison shows how purpose-built each alloy truly is for its intended field.

Let’s explore these applications more deeply. The material requirements are often absolute, especially in high-stakes fields. At PTSMAKE, we guide clients through this selection process, ensuring the chosen grade meets every technical specification.

Aerospace: The Demand for Strength and Lightness

In aerospace, every gram matters. The primary goal is achieving maximum strength with minimum weight. Grade 5 (Ti-6Al-4V) is the undisputed workhorse. Its excellent strength-to-weight ratio makes it ideal for critical airframe structures, engine components, and landing gear.

Medical: Prioritizing Safety and Compatibility

For medical devices, nothing is more important than patient safety. The material must not react negatively with the human body. This crucial property, biocompatibility12, dictates material choice. Grade 2 and Grade 23 (ELI) are widely used for surgical implants, staples, and dental hardware because they are safe and non-toxic.

Industrial and Marine: Battling Corrosion

Industrial and marine environments are incredibly harsh. Constant exposure to chemicals or saltwater demands exceptional corrosion resistance. Grade 2 is a solid choice, but for extreme conditions, Grade 7 (with added palladium) provides superior protection against acidic corrosion.

| Grade | Key Property | Typical Application |

|---|---|---|

| Grade 5 (Ti-6Al-4V) | High Strength-to-Weight | Aerospace Structures, Engine Parts |

| Grade 23 (Ti-6Al-4V ELI) | Superior Biocompatibility | Medical Implants, Surgical Staples |

| Grade 7 (Ti-0.15Pd) | Excellent Corrosion Resistance | Chemical Processing, Marine Hardware |

| Grade 2 (CP Ti) | Good Formability | Consumer Electronics, Watch Cases |

This titanium grade comparison clarifies how specific alloys are tailored. It helps our partners choose the most effective material for performance and longevity.

In summary, industry-specific demands are the engine of titanium grade development. From aerospace strength to medical safety, the application defines the material choice. This targeted approach ensures optimal performance and reliability, no matter the use case.

What are the practical trade-offs between alloy families?

Choosing the right titanium alloy is crucial. The main families—Alpha, Beta, and Alpha-Beta—each offer distinct advantages. Your project’s success often depends on picking the correct one.

This choice isn’t random. It involves balancing key performance factors. We will look at heat treatability, weldability, and stability. A clear titanium grade comparison helps simplify this decision.

Here is a quick breakdown.

The practical differences between these families are significant. Each is tailored for specific environments and stresses. Their distinct behaviors come from their unique microstructures. This is a result of their alloying elements.

Understanding Key Characteristics

The behavior of these families is rooted in titanium’s allotropic transformation13. This property dictates how the material responds to heat and stress. It is why we see such different performance profiles.

Heat and Strength

Alpha alloys are not heat-treatable for strength. Beta alloys, however, respond very well. They can be strengthened significantly. Alpha-Beta alloys offer a good middle ground.

Fabrication Differences

Weldability is a major factor. Alpha alloys are typically the easiest to weld. This makes them ideal for complex fabricated structures. Beta alloys are also weldable, but may require post-weld heat treatment.

Below is a table summarizing these trade-offs. We use it at PTSMAKE to guide clients.

| Alloy Family | Heat Treatability (Strength) | Weldability | High-Temp Stability | Cold Formability |

|---|---|---|---|---|

| Alpha | Poor | Excellent | Excellent | Fair to Good |

| Beta | Excellent | Good | Poor | Excellent |

| Alpha-Beta | Good | Good | Good | Poor to Fair |

Choosing an alloy family is a balancing act. Alpha alloys excel in high-temperature and welding applications. Beta alloys offer top-tier strength and formability. Alpha-Beta alloys provide a versatile, all-around performance, making them the most common choice for many projects.

How do ELI grades differ from standard counterparts?

When comparing titanium grades, the distinction between standard and ELI versions is crucial. The most common titanium grade comparison is between Grade 5 and Grade 23.

‘ELI’ stands for Extra-Low Interstitials. This means Grade 23 is a higher-purity version of Grade 5.

By reducing elements like oxygen and iron, we significantly enhance its properties. This makes it ideal for applications where failure is not an option. It has better ductility and fracture toughness.

| Property | Grade 5 (Standard) | Grade 23 (ELI) |

|---|---|---|

| Purity | Standard | Higher Purity |

| Key Benefit | High Strength | Enhanced Toughness |

| Main Use | General Aerospace | Medical Implants |

The primary difference lies in the chemistry. Grade 23 (Ti-6Al-4V ELI) has stricter limits on certain elements compared to Grade 5 (Ti-6Al-4V).

Specifically, the oxygen and iron content are kept to a minimum. At PTSMAKE, we’ve seen firsthand how these small changes create massive performance shifts. The reduction of these interstitial elements14 is the key.

These tiny atoms, when present, can make the metal more brittle. By removing them, the material becomes more resistant to cracking. This is known as improved fracture toughness.

This property is non-negotiable for medical implants. A crack in a hip replacement could be catastrophic. The same applies to critical airframe components that endure immense stress cycles.

Based on tests we have run with clients, this enhancement in ductility allows the material to deform slightly under stress rather than fracturing.

Here’s a simplified look at the key compositional limits.

| Element | Grade 5 (% Max) | Grade 23 (% Max) |

|---|---|---|

| Oxygen | 0.20 | 0.13 |

| Iron | 0.40 | 0.25 |

This refined chemistry makes Grade 23 the superior choice for high-stakes applications requiring exceptional damage tolerance.

In short, Grade 23 (ELI) is a purer, more damage-tolerant version of Grade 5. The lower interstitial content dramatically improves its ductility and fracture toughness, making it essential for critical medical and aerospace parts.

How do you cross-reference different international grade standards?

Cross-referencing material grades is a daily task in global manufacturing. Using conversion tables is the most direct way to find equivalent materials across different standards. This helps bridge communication gaps between international teams.

For instance, a common request involves a Titanium grade comparison. A designer might specify a material using a familiar standard.

These tables provide a starting point. They map out grades that are considered functionally similar. But this is just the first step in the process.

A Practical Guide to Using Cross-Reference Tables

Cross-reference tables are invaluable, but they are guides, not rulebooks. They show materials with similar properties, but "similar" is not "identical." Let’s look at a popular titanium alloy.

Example: Titanium Grade 5 (Ti-6Al-4V)

This alloy is a workhorse in many industries. A US drawing might call for ASTM Grade 5. Here’s how it typically cross-references:

| Standard | Grade Designation |

|---|---|

| ASTM | Grade 5 |

| UNS | R56400 |

| DIN | 3.7165 |

| AMS | 4911 |

At first glance, these seem interchangeable. However, each standard has its own specific requirements.

Why You Must Check the Details

The allowable ranges for chemical elements can differ slightly. One standard might have a tighter tolerance for iron, for example. Mechanical property requirements, like tensile strength or elongation, can also vary. These small differences can be critical for high-performance applications.

In past projects at PTSMAKE, we’ve seen cases where using a seemingly equivalent material that didn’t match the specific nominal composition15 led to performance issues. We always pull the specific standard documents to verify every detail before starting production.

Cross-referencing is a useful starting point for material selection. However, always verify the specific details of each standard. Assuming direct interchangeability without checking chemical and mechanical properties can lead to production issues and part failure, especially in critical applications.

What is the typical cost structure across titanium grades?

Understanding titanium costs requires a relative view. Not all grades are priced equally. The differences are significant.

We use a simple cost index to help our clients. Commercially Pure (CP) Grade 2 is the baseline. We set its cost at 1x.

A Relative Cost Index

This index shows how costs scale. It highlights the impact of alloying elements and processing. This makes a titanium grade comparison much clearer.

| Titanium Grade | Relative Cost Index | Primary Cost Driver |

|---|---|---|

| Grade 2 (CP) | 1x | Baseline |

| Grade 5 (Ti-6Al-4V) | 2x – 3x | Alloying & Processing |

| Grade 7 (Ti-0.15Pd) | 5x – 10x+ | Noble Metal (Palladium) |

This table simplifies a complex topic.

Deconstructing the Cost Drivers

The cost index provides a quick overview. But what truly drives these price differences? The answer lies in raw materials and manufacturing complexity. Every grade has its own unique production path.

Raw Material Costs

CP Grade 2 is unalloyed. This makes its raw material costs the lowest. It’s primarily refined titanium sponge.

Grade 5 requires adding aluminum and vanadium. These alloying elements add to the base material cost.

Grade 7 is a special case. It contains a small amount of Palladium. Palladium is a precious metal, often more expensive than gold. This makes Grade 7 significantly costlier, even with only 0.12% to 0.25% content.

Processing Complexity

Processing adds another layer of cost. Grade 5, for example, requires carefully controlled heat treatment. This process enhances its strength. It involves heating the material above its Beta-transus temperature16 and then cooling it at a specific rate. This adds energy, time, and equipment costs.

In contrast, CP grades are much simpler to process. They don’t need complex heat treatments. This difference in manufacturing is a major factor in the final price. In our experience at PTSMAKE, optimizing machining parameters for each grade is crucial for managing overall project costs.

| Grade | Key Cost Components |

|---|---|

| Grade 2 | Titanium Sponge, Basic Processing |

| Grade 5 | Titanium Sponge, Aluminum, Vanadium, Heat Treatment |

| Grade 7 | Titanium Sponge, Palladium, Specialized Alloying |

Titanium costs are not uniform. A titanium grade comparison shows that alloying elements like vanadium and palladium, along with complex processing steps like heat treatment, are the main drivers. This creates a wide cost spectrum from basic CP grades to advanced alloys.

How to choose a grade for aggressive chemical environments?

Choosing the right material for harsh chemicals is critical. A wrong choice leads to component failure and costly downtime. Let’s simplify this with a clear decision process.

Step 1: Identify the Chemical Agent

First, you must know what the part will be exposed to. Is it saltwater? A reducing acid? Or another high-chloride solution?

Step 2: Match the Grade to the Threat

The specific chemical dictates the grade. This is a key step in any practical titanium grade comparison. It ensures performance and safety.

Here’s a quick guide based on project experiences at PTSMAKE.

| Chemical Environment | Recommended Titanium Grade(s) |

|---|---|

| General Saltwater | CP Grades (1, 2) |

| Reducing Acids | Grade 7, Grade 12 |

| High-Chloride Solutions | Grade 7, Grade 12 |

This simple approach helps prevent errors from the start.

Why Special Grades for Harsh Chemicals?

Commercially Pure (CP) titanium is excellent for many applications. It performs well in oxidizing and mildly reducing environments. But it has its limits.

Aggressive chemicals, like hydrochloric acid, require more protection. These agents can attack the stable, protective oxide layer on titanium’s surface. This is where specialized alloyed grades become necessary.

The Role of Alloying Elements

We must look beyond CP grades for these specific challenges. The risk of crevice corrosion17 in high-chloride solutions is a major concern. This localized attack can occur in tight gaps where the fluid is stagnant.

To combat this, we use specific alloys. Grade 7 and Grade 12 are prime examples. They contain small amounts of elements that significantly boost resistance.

Key Alloy Additions and Their Benefits

| Grade | Key Alloying Element(s) | Primary Benefit |

|---|---|---|

| Grade 7 | Palladium (Pd) | Enhances resistance to reducing acids and crevice attack. |

| Grade 12 | Molybdenum (Mo) & Nickel (Ni) | Improves strength and boosts corrosion resistance. |

In our work, these grades provide the necessary defense. Choosing between them depends on specific operating temperatures and chemical concentrations. This careful selection ensures long-term component integrity.

Selecting the right titanium is a two-step process. First, identify the specific chemical environment. Then, match the grade. CP grades suit saltwater, but Grade 7 or 12 are essential for reducing acids and high-chloride settings to prevent failure.

What is the practical method for evaluating weldability?

A fundamental rule in material science is that as strength and alloy content increase, weldability often decreases. This is especially true for titanium.

For projects requiring significant welding, we always prioritize Commercially Pure (CP) grades. Grades 1 and 2 are excellent choices. They offer the best formability and weldability.

Alloyed grades, while stronger, introduce complexities. They demand more control and preparation to achieve a reliable weld. A quick comparison highlights this difference.

| Grade Type | Weldability | Common Application |

|---|---|---|

| CP Grades (1, 2) | Excellent | Chemical processing, architecture |

| Alloyed Grades (e.g., Grade 5) | Fair to Poor | Aerospace, high-performance parts |

The Challenge with Alloyed Grades

Alloying elements like aluminum and vanadium, which give Grade 5 its superior strength, also alter its behavior under the heat of a welding torch.

These elements can create a microstructure in the heat-affected zone that is brittle and susceptible to cracking if not handled correctly. This is a critical point in any titanium grade comparison for welded assemblies.

Essential Welding Procedures for Alloys

Successfully welding alloyed titanium isn’t impossible. It just requires a meticulous, controlled process. At PTSMAKE, we follow strict protocols developed over years of experience.

Heat Treatment is Key

Pre-weld and post-weld heat treatment (PWHT) are often mandatory. Pre-heating reduces the thermal gradient, minimizing stress.

PWHT is a stress-relief step. It helps restore ductility to the welded area, preventing future failures under load.

The Critical Role of Shielding Gas

Titanium readily absorbs oxygen and nitrogen at welding temperatures. This contamination causes severe embrittlement18, a primary cause of weld failure.

To prevent this, we use high-purity argon as a shielding gas. This gas must protect the front of the weld, the back of the weld, and the torch itself.

| Factor | CP Titanium | Alloyed Titanium |

|---|---|---|

| Pre-heating | Not usually required | Often necessary |

| PWHT | Rarely needed | Highly recommended |

| Shielding | Essential | Absolutely critical |

| Weld Zone Risk | Low (Ductile) | High (Brittle without control) |

For straightforward weldability, choose CP grades. For high-strength applications involving alloyed grades, rigorous procedures like heat treatment and inert gas shielding are essential to prevent brittleness and ensure a durable, reliable final product.

How do you assess machinability when comparing grades?

When making a Titanium grade comparison, we use a machinability index. This is a simple score to guide our approach. Steel is often the benchmark at 100%.

CP grades are much easier to machine. They have higher machinability ratings. This makes them ideal for less complex components.

| Grade Type | Relative Machinability |

|---|---|

| Commercially Pure | 40-50% |

| Alpha-Beta Alloys | 20-30% |

Stronger alloys are tougher to work with. This is due to factors like intense heat buildup and the material’s tendency to stick to the cutting tool.

Let’s break down these challenges. Understanding them is crucial for successful titanium machining. At PTSMAKE, we’ve refined our methods over many projects to handle these issues.

Low Thermal Conductivity

Titanium does not dissipate heat well. Unlike steel or aluminum, the heat concentrates at the cutting tool’s tip. This can rapidly degrade expensive tooling if not managed.

This intense heat buildup is a primary concern. It forces us to adjust our entire machining strategy to prevent premature tool failure and maintain part integrity.

Tendency for Galling

Titanium alloys can be very sticky. During the cutting process, chips often weld themselves directly onto the tool’s surface. This effect is known as galling19.

When this occurs, it compromises the surface finish. It also dramatically increases cutting forces, which can easily lead to catastrophic tool breakage. We use specialized coolants to help reduce this.

The Right Machining Strategy

Based on our extensive testing, a very specific strategy yields the best results. It often seems counterintuitive to engineers new to titanium.

Tools, Speeds, and Feeds

You must use extremely sharp tools. Additionally, running at low cutting speeds is essential to control the heat generation we discussed earlier.

| Parameter | Recommendation | Reason |

|---|---|---|

| Tool Condition | Extremely Sharp | Ensures clean cuts, less heat |

| Cutting Speed | Low (SFM) | Manages heat buildup |

| Feed Rate | High | Prevents work hardening |

We pair low speeds with a high feed rate. This keeps the tool constantly cutting fresh material, preventing it from rubbing and hardening the surface.

Assessing machinability uses an index where CP grades are easier. Key challenges include poor heat dissipation causing tool wear and galling ruining finishes. Success demands sharp tools, low speeds to manage heat, and high feeds to prevent work hardening.

How to correctly specify a titanium grade on a drawing?

A drawing is a contract between you and your manufacturer. Ambiguity leads to errors. To get the exact titanium part you need, the material callout must be perfect. It leaves no room for guessing.

This clarity ensures we source the correct material from the start. It prevents costly delays and material waste. Think of it as providing a precise recipe.

The Four Pillars of a Material Callout

Your callout must contain four key pieces of information. Leaving any of them out creates risk.

| Component | Example | Purpose |

|---|---|---|

| Material Standard | ASTM B348 | Defines quality and properties |

| Specific Grade | Grade 5 | Specifies the exact alloy |

| Form | Bar | Indicates the raw material shape |

| Condition | Annealed | States the required heat treatment |

Why Each Detail Matters in Your Callout

Omitting any part of the specification can lead to a component that fails in its application. It is not about being difficult; it’s about ensuring function and safety. In our experience at PTSMAKE, precision begins with the drawing.

The Material Standard: Your Foundation

Think of the standard (e.g., ASTM, AMS) as the rulebook. It defines the chemical composition, mechanical property limits, and testing requirements. Specifying ASTM B348 tells the supplier to provide a titanium alloy bar that meets globally recognized criteria for quality. It’s a universal language.

The Specific Grade: The Heart of the Spec

This is the most critical detail. A titanium grade comparison shows that Grade 2 is commercially pure and ductile. Grade 5 is an alloy with high strength. Using the wrong one means the part will not perform as designed. There is no substitute for being specific here.

The Material Form: Shape Matters

Does your part need to be machined from a bar, plate, or sheet? The raw material’s form impacts its internal metallurgical properties20 and grain flow. This can affect the final part’s strength and machining characteristics. Specifying "Bar" ensures the correct stock is used.

The Material Condition: The Final Polish

The "condition" refers to the heat treatment state of the material. This directly influences its strength, hardness, and internal stresses.

| Condition | Primary Effect | Best For… |

|---|---|---|

| Annealed | Softened, stress-relieved | General machining, forming |

| STA | Solution Treated and Aged | High-strength applications |

Specifying "Annealed" often provides the best balance of strength and machinability for many applications we handle.

A complete callout on your drawing is essential. It includes the standard, grade, form, and condition. This precision removes supplier guesswork, prevents errors, and ensures you receive parts that meet your exact engineering requirements from day one.

How to perform a cost-benefit analysis between two grades?

Let’s use a practical example. We will compare Titanium Grade 2 and Grade 5. This is a common decision point for many projects.

The first step is always the material cost. Grade 5 is more expensive. It’s crucial to know exactly how much more.

Initial Material Cost

The price difference can be significant. Grade 5 contains additional elements. This makes it a more complex alloy to produce.

| Grade | Relative Material Cost |

|---|---|

| Titanium Grade 2 | Baseline |

| Titanium Grade 5 | 50-100% Higher |

Potential Long-Term Benefits

But cost is only one part. We must also look at performance. Grade 5 is much stronger. This strength is the key to finding its true value.

Now, let’s quantify the benefit. How does Grade 5’s superior strength translate into real-world value? The answer often lies in weight reduction.

Because Grade 5 is significantly stronger, you can design parts that are thinner and lighter. They will still have the same structural integrity as a thicker Grade 2 part. This is a critical factor in aerospace and automotive applications.

Calculating Lifetime Value

Consider a component for a drone. Weight directly impacts flight time and payload capacity. Here, the higher initial cost of Grade 5 starts to make sense.

In past projects at PTSMAKE, we’ve explored this exact scenario. A lighter part might extend battery life. This creates a more efficient and valuable final product. This kind of tensile strength21 analysis is key.

This Titanium grade comparison shows the bigger picture.

| Feature | Grade 2 Part | Grade 5 Part |

|---|---|---|

| Required Thickness | 3mm | 1.8mm |

| Final Part Weight | 150g | 90g |

| Lifetime Benefit | Standard Performance | Increased Efficiency |

Over the product’s lifetime, the savings from improved performance can easily outweigh the higher material cost.

This analysis shows that the "cheaper" option isn’t always the most cost-effective. A holistic view, considering lifetime performance and efficiency gains, often justifies a higher upfront investment in superior materials like Grade 5.

Choose between Grade 5 and Grade 23 for a fracture-critical airframe component.

When selecting a material for a fracture-critical airframe component, the stakes are incredibly high. A wrong choice can lead to catastrophic failure.

The decision often comes down to a titanium grade comparison between two powerhouses: Grade 5 (Ti 6Al-4V) and Grade 23 (Ti 6Al-4V ELI).

The Primary Decision Driver

For these parts, strength is important, but fracture toughness is the non-negotiable trait. It dictates how a material resists the growth of a crack.

Initial Property Overview

| Property | Grade 5 | Grade 23 |

|---|---|---|

| Tensile Strength | Very High | High |

| Fracture Toughness | Good | Superior |

| Purity | Standard | High (ELI) |

This initial comparison already points toward Grade 23 for safety.

Let’s analyze this real-world scenario more deeply. While Grade 5 is the workhorse of the aerospace industry, its use in fracture-critical applications requires careful consideration. The primary driver here is damage tolerance. We need a material that can withstand flaws without failing unexpectedly.

This is where Grade 23 shines. Its "ELI" designation, meaning Extra Low Interstitials, is the key. It has significantly lower amounts of oxygen, nitrogen, and carbon. This specific chemistry, especially the reduced oxygen interstitial content22, dramatically improves the alloy’s ductility and fracture toughness.

The Impact of ELI Chemistry

In practice, this means Grade 23 has a superior ability to slow down crack propagation. A small flaw or crack in a Grade 23 component will grow much more slowly under stress than it would in Grade 5.

Our testing confirms this difference.

Interstitial Limits Comparison

| Element | Grade 5 (max %) | Grade 23 (max %) |

|---|---|---|

| Oxygen | 0.20 | 0.13 |

| Iron | 0.40 | 0.25 |

| Carbon | 0.08 | 0.08 |

| Nitrogen | 0.05 | 0.03 |

This "forgiveness" provides a critical safety margin, allowing for inspection and detection before a crack reaches a critical length. For any part where failure is not an option, Grade 23 is the only responsible choice.

While Grade 5 offers slightly higher strength, Grade 23’s superior fracture toughness and damage tolerance make it the definitive choice for fracture-critical airframe parts. Its ELI chemistry provides an essential, non-negotiable safety margin.

A welded marine component is required. Defend your grade selection.

When selecting titanium for a welded marine part, it’s a balancing act. You need strength, corrosion resistance, and excellent weldability. Many engineers default to stronger grades.

But for welded applications, this can be a mistake.

The Clear Winner: Grade 2 Titanium

My choice is almost always Grade 2. It offers the best combination of properties for this specific need. It is easily welded and provides fantastic corrosion resistance in saltwater.

Weldability vs. Strength

In our projects at PTSMAKE, we prioritize manufacturability. Grade 2’s weldability ensures a strong, reliable final component without complex procedures.

| Feature | Grade 2 | Grade 5 |

|---|---|---|

| Weldability | Excellent | Poor/Fair |

| Corrosion Resistance | Excellent | Excellent |

| Post-Weld Needs | Minimal | Heat Treatment |

This titanium grade comparison makes the choice clear.

Why Not Stronger Alloys?

Stronger alloys like Grade 5 (Ti-6Al-4V) are tempting. Their mechanical properties are superior on paper. But paper specs don’t tell the whole story, especially when welding is involved.

The Welding Challenge with Grade 5

Grade 5 is an alpha-beta alloy. Welding it without proper post-weld heat treatment (PWHT) is a significant risk. The process can create a brittle weld zone.

This zone is highly susceptible to cracking under stress. Without an oven for proper stress relief, you risk component failure. This potential for embrittlement23 is a critical factor.

Practical and Cost Considerations

Most fabrication shops do not have the specialized furnaces required for titanium PWHT. Outsourcing this step adds significant cost and lead time.

In our collaboration with clients, we have noted that choosing Grade 5 for complex weldments can increase project costs by 20-40% due to these secondary processes. This detailed titanium grade comparison highlights the practical advantages of Grade 2.

| Consideration | Grade 2 | Grade 5 |

|---|---|---|

| Welding Complexity | Low | High |

| PWHT Required | No | Yes |

| Risk of Weld Failure | Very Low | High (without PWHT) |

| Overall Cost | Lower | Higher |

Grade 2 provides sufficient strength and corrosion resistance for most marine applications while avoiding these significant manufacturing hurdles.

For welded marine components, Grade 2 Titanium is the superior choice. It ensures reliability and manufacturability by avoiding the complex heat treatments required by stronger alloys like Grade 5, making it a more practical and cost-effective solution for long-term performance.

Select a grade for a complex part made by deep drawing.

Choosing the right material for a complex deep-drawn part is a critical decision. You face a classic trade-off: formability versus final strength. Get it wrong, and you risk production failure.

Prioritizing Formability

For intricate shapes, we must prioritize formability. This is why CP Grade 1 Titanium is often the best starting point. Its excellent ductility allows it to be drawn into complex geometries without cracking.

Titanium Grade Comparison

| Grade | Formability | Final Strength |

|---|---|---|

| CP Grade 1 | Excellent | Lower |

| CP Grade 2 | Good | Medium |

Opting for Grade 1 ensures the part can be manufactured successfully. This avoids costly tool modifications and material waste down the line.

The central challenge pits manufacturing feasibility against in-service performance. A complex geometry requires a material that can stretch and flow into a die. Pushing a stronger, less formable grade often leads to fractures.

Why Grade 1 is a Safe Bet

CP Grade 1 has superior elongation properties. Its lower yield strength allows the metal to deform significantly before tearing. This is essential for parts with deep pockets or sharp features. In our experience at PTSMAKE, switching to Grade 1 has solved persistent cracking issues for clients.

The material’s low strain hardening24 is also a factor. It deforms more uniformly during the deep drawing process.

Addressing the Strength Concern

So, the part is formed perfectly. But can it handle the job? This is where design engineering meets material science. A part’s final geometry contributes significantly to its stiffness and strength. We must ask: is the weaker material still strong enough?

Compensating with Design

| Strategy | Description |

|---|---|

| Add Ribs | Incorporate features to increase stiffness. |

| Adjust Thickness | Use a slightly thicker gauge material. |

| Leverage Work Hardening | The forming process itself adds strength. |

We need to analyze if the final part meets performance specs. A thoughtful design adjustment can often compensate for the material’s lower initial strength, creating a successful outcome.

Choosing CP Grade 1 prioritizes successful manufacturing for complex parts. The key challenge then shifts to verifying if the final design, using this more formable material, still meets all performance and strength requirements after the deep drawing process is complete.

Unlock Titanium Solutions with PTSMAKE Expertise Today

Have questions about titanium grade selection for your manufacturing project? Partner with PTSMAKE for precision CNC machining and injection molding solutions—get a fast, reliable quote now. Our experts help you navigate material choices, ensuring part performance and cost-effectiveness from prototype to production. Send your RFQ today!

Learn how these tiny elements dramatically alter titanium’s mechanical behavior and performance in your parts. ↩

Learn how these tiny, trapped atoms dramatically impact metal properties and performance. ↩

Understand how an alloy’s internal structure dictates its mechanical properties. ↩

Understand why this property makes titanium safe for use inside the human body. ↩

Click to understand how plastic deformation increases a metal’s hardness and strength. ↩

Learn more about this localized corrosion and how to mitigate it in component design. ↩

Learn how tracking materials from source to part ensures quality and compliance in precision manufacturing. ↩

Learn how this property affects material performance under high temperatures and constant stress. ↩

Learn how dual certification can streamline your supply chain and material selection process. ↩

Learn about this critical temperature in titanium heat treatment and its impact on material properties for aerospace uses. ↩

Learn how material purity and surface properties are critical for success in biomedical applications. ↩

Learn why this property is essential for medical device safety and patient-implant interaction. ↩

Learn how titanium’s crystal structure changes with heat, defining alloy properties. ↩

Discover how these atomic-level impurities affect the overall performance and reliability of advanced engineering materials. ↩

Discover how slight changes in chemical makeup affect material behavior and project outcomes. ↩

Discover how this critical temperature affects titanium’s final strength and structure. ↩

Click to understand how this localized corrosion can cause unexpected component failure in tight, shielded areas. ↩

Learn how embrittlement weakens welds and discover methods to ensure the structural integrity of your parts. ↩

Discover the science behind this material adhesion and learn techniques to effectively prevent it in your machining. ↩

Learn how a material’s internal structure dictates its performance, strength, and machinability. ↩

Learn how this key material property impacts your part’s performance and design possibilities. ↩

Discover how these atomic-level elements impact titanium’s toughness and safety in demanding aerospace applications. ↩

Discover how welding can alter material integrity and what you need to know to prevent critical failures. ↩

Learn how this property affects how a material behaves under stress during forming. ↩