Are you struggling to understand what Swiss machining actually is and how it differs from conventional CNC machining? Many engineers and procurement managers get confused about this specialized technique, often leading to ordering the wrong type of machining for precision parts. The consequences can be costly – with wasted materials, missed deadlines, and parts that simply don’t meet your specifications.

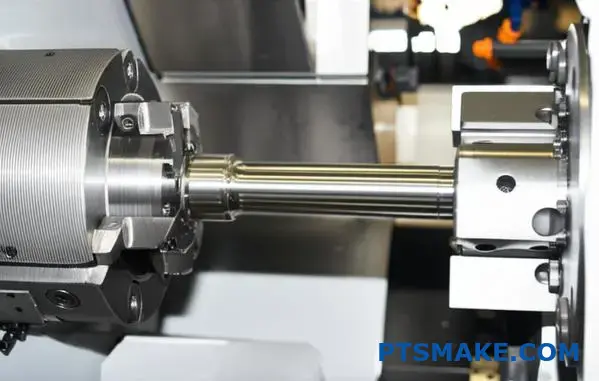

Swiss machining is a specialized turning process that uses a sliding headstock to feed material through a guide bushing, allowing for exceptional precision on small, complex parts. This technique excels at producing long, slender components with tight tolerances as small as 0.0001 inches.

Having worked with many clients who initially confused Swiss turning with conventional machining, I can tell you that understanding the difference is crucial for your project success. Whether you’re designing medical devices, aerospace components, or precision electronics, the right machining choice can significantly impact your product quality, timeline, and budget. Let me explain the key aspects of Swiss machining so you can make informed manufacturing decisions.

Why Is It Called A Swiss Machine?

Ever wondered if the "Swiss Machine" actually comes from Switzerland, or if it’s just a name? This question often pops up, leaving engineers and procurement managers curious about its true origins and unique capabilities.

The term "Swiss Machine" directly honors its country of origin. It was invented in Switzerland in the late 19th century, specifically to produce the incredibly small and precise screws and parts needed for the nation’s legendary watchmaking industry.

The Watchmaker’s Dilemma: A Necessity for Innovation

To truly grasp the name, we must look back at the problem it solved. Late 19th-century watchmakers faced a significant challenge: producing long, slender components with incredible accuracy. Traditional lathes struggled with this, as the workpiece would vibrate or deflect under the pressure of the cutting tool, ruining the precision. The Swiss-type lathe was born out of this necessity. Its revolutionary design supported the workpiece with a guide bushing1 extremely close to the cutting tool. This eliminated deflection and enabled the mass production of tiny, perfect parts that were foundational to the Swiss watch industry’s global dominance. This core principle remains central to modern swiss cnc machining.

| Challenge | Traditional Lathe Issue | Swiss Machine Solution |

|---|---|---|

| Part Deflection | Long, thin parts bend away from the tool. | Workpiece is supported right at the point of cut. |

| Tolerance Control | Difficult to maintain consistency over length. | High precision is maintained along the entire part. |

| Vibration | Causes poor surface finish and inaccuracy. | Minimized due to robust workpiece support. |

From Cams to Code: The Evolution of "Swiss"

While the name is historical, its meaning has evolved. The original machines were mechanically controlled by intricate cam systems, marvels of their time. Today, the term "Swiss Machine" or "Swiss CNC" refers to a machine that employs the same sliding headstock principle but is driven by advanced computer numerical control (CNC). At PTSMAKE, when we discuss a project requiring swiss cnc machining, we’re leveraging a legacy of precision that has been enhanced by modern technology. The name has become a classification—a synonym for a specific, high-precision manufacturing process rather than just a geographical marker.

| Feature | Original Cam-Operated Machine | Modern Swiss CNC Machine |

|---|---|---|

| Control System | Mechanical Cams | Computer Numerical Control (CNC) |

| Setup Time | Very long and complex | Faster, software-driven programming |

| Application Scope | Primarily watch parts | Aerospace, Medical, Electronics |

The Swiss machine earned its name from its Swiss watchmaking origins, where it solved the critical problem of machining small, slender parts with high precision. This legacy continues today, with "Swiss" signifying a specific, highly accurate manufacturing process used across many advanced industries.

What Is Standard CNC Machining?

Ever feel like the term "CNC machining" is used so broadly it loses its meaning? This can lead to confusion when specifying a project, potentially resulting in misaligned expectations on cost and capability.

Standard CNC machining is a subtractive manufacturing process where computer-controlled tools cut material from a stationary workpiece. The cutting tool moves along multiple axes to precisely shape the part, making it highly versatile for a vast range of components.

To truly grasp its capabilities, it’s best to break down its core mechanics. Unlike Swiss-style machines, the defining feature of standard CNC machining is that the workpiece is held firmly in place while the cutting tools do all the moving. This fundamental approach is what makes it a go-to process for so many applications. In past projects at PTSMAKE, we’ve found this method is incredibly effective for creating robust parts from solid blocks of material. The process relies on secure workholding2 to prevent any movement or vibration, which is critical for maintaining accuracy. Think of it as a sculptor carefully carving a stationary block of marble, but with incredible robotic precision.

Key Operational Differences

| Aspect | CNC Milling | CNC Turning (Lathe) |

|---|---|---|

| Workpiece Motion | Stationary | Rotating |

| Tool Motion | Rotating and moves on X,Y,Z axes | Stationary and moves into the piece |

| Best For | Blocks, flat surfaces, complex shapes | Cylindrical or conical parts |

The versatility of standard CNC machining is its greatest strength. It excels at producing everything from one-off prototypes to large production runs. Because the workpiece is fixed, it’s ideal for larger, bulkier parts that require significant material removal, such as engine components, enclosures, or structural brackets. However, this method has its limitations. When machining very long and slender parts, the distance from the chuck to the cutting point can cause the material to deflect or vibrate. This makes it challenging to hold tight tolerances along the entire length of the part, which is a problem that Swiss CNC machining was specifically designed to solve. This distinction is crucial for any engineer or procurement manager to understand before starting a project.

Typical Use-Cases

| Application | Common Materials | Key Advantage |

|---|---|---|

| Prototyping | Aluminum, ABS, Nylon | Speed and cost-effectiveness |

| Housings & Enclosures | Aluminum, Stainless Steel | Ability to machine large parts |

| Jigs & Fixtures | Tool Steel, Delrin (POM) | High accuracy and durability |

Standard CNC machining uses computer-controlled tools on a stationary workpiece, making it ideal for a wide range of parts, especially larger ones. While highly versatile, its main limitation is maintaining precision on long, slender components due to potential material deflection.

How Does Swiss CNC Machining Achieve Higher Precision?

Have you ever specified a part with tight tolerances, only to have it fail inspection? The subtle mechanical difference between standard and Swiss CNC machining might be the critical factor you overlooked.

Swiss CNC machining achieves superior precision by using a guide bushing that supports the workpiece right at the cutting point. This design eliminates material deflection and vibration, common issues in standard turning, ensuring consistent, tight tolerances, especially on long, slender components.

The Guide Bushing and Sliding Headstock Advantage

The secret to Swiss precision lies in its unique architecture. Unlike standard lathes where the workpiece extends far from the chuck, a Swiss machine feeds the material through a guide bushing. This bushing acts as a solid support point, with tools cutting the stock the instant it emerges. This design provides incredible rigidity3 and virtually eliminates deflection, the primary cause of inaccuracies on long, slender parts.

The sliding headstock works in tandem with the bushing. Instead of the tools moving along the workpiece for the Z-axis cut, the headstock itself pushes the entire bar stock forward.

| Feature | Swiss CNC Machining | Standard CNC Turning |

|---|---|---|

| Workpiece Support | At the cutting point | Far from the chuck/collet |

| Deflection Risk | Minimal | High on long/thin parts |

| Z-Axis Motion | Headstock moves the material | Tool turret moves along the bed |

This combination is why Swiss CNC machining can consistently hold micron-level tolerances.

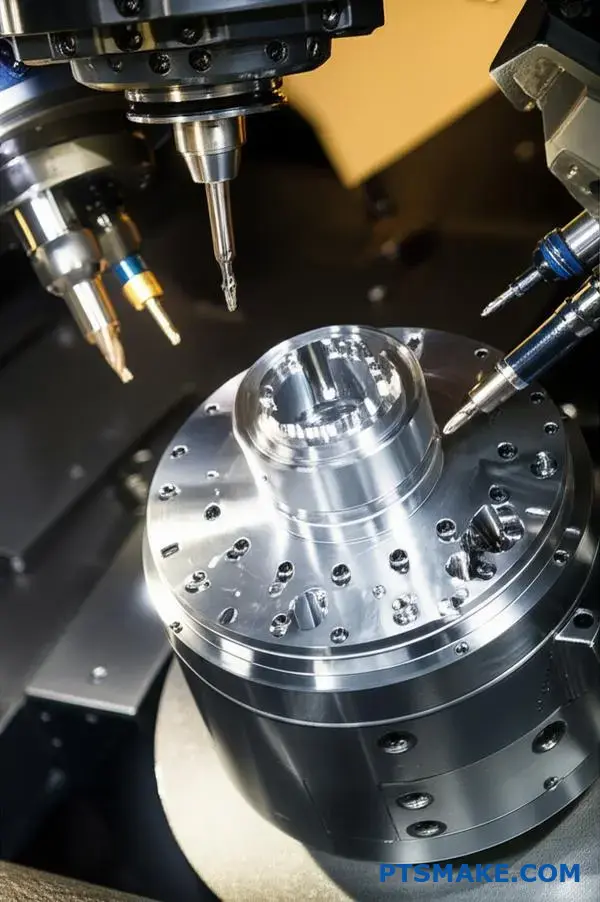

More Than Turning: The Power of Live Tooling

Modern Swiss machines are not just simple lathes; they are multi-axis machining centers. They are equipped with live tooling, which allows for milling, drilling, and tapping operations to be performed on the part without removing it from the machine. This "done-in-one" capability is another cornerstone of their precision.

Reducing Setup Errors

In standard machining, a complex part might move from a lathe to a mill for secondary operations. Each time the part is re-clamped, small inaccuracies are introduced. By completing all operations in a single setup, Swiss CNC machining eliminates these cumulative errors.

| Aspect | Multi-Setup Process | Swiss "Done-in-One" |

|---|---|---|

| Part Handling | Requires re-fixturing | No manual intervention |

| Tolerance Stacking | Errors accumulate with each setup | Minimized to a single datum |

| Production Efficiency | Lower; includes setup time | Higher; continuous machining |

This integrated approach, which we utilize at PTSMAKE for complex components, ensures that all features on a part are perfectly aligned with one another.

Swiss CNC machining’s precision stems from its guide bushing design, which prevents material deflection. Combined with "done-in-one" capabilities from live tooling, it completes complex parts in one setup, eliminating the cumulative errors found in multi-step processes and ensuring exceptional accuracy.

How Does Swiss CNC Machining Achieve Long Parts?

Ever designed a long, slender pin, only to find that manufacturing it with a consistent diameter is a huge challenge? This common issue often leads to scrap parts and project delays.

Its exceptional precision comes from a unique sliding headstock and guide bushing system. This provides constant support to the material right where it’s being cut, effectively preventing the bending and vibration that ruin accuracy on long components.

Stability at the Point of Cut

The core principle behind Swiss CNC machining is eliminating instability. In a standard lathe, a long part held only at one end will inevitably deflect or vibrate when a tool applies pressure in the middle. The Swiss method solves this by feeding the bar stock through a guide bushing. The cutting tools engage the material just millimeters from this support point. This setup creates an incredibly stable cutting zone, preventing the tool from pushing the material away. This stability is the primary reason Swiss turning can produce parts with exceptional straightness and a uniform diameter along their entire length. This process nearly eliminates the risk of chatter4, which is critical for achieving a fine surface finish.

| Factor | Standard Lathe | Swiss CNC Machine |

|---|---|---|

| Workpiece Support | At the chuck, far from the cut | At the guide bushing, next to the cut |

| Deflection Risk | High on slender parts | Virtually eliminated |

| Tool Pressure Effect | Can cause tapering or bending | Minimal impact on part geometry |

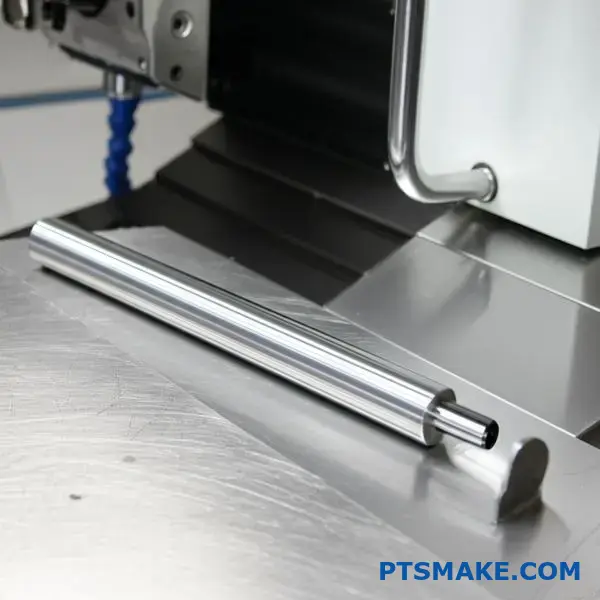

Flawless Handoffs with a Sub-Spindle

Modern Swiss machines take precision a step further with the use of a sub-spindle. After the primary machining operations are complete on the front side of the part, the sub-spindle moves in to grip the finished section. The main spindle then cuts the part off the bar stock. The sub-spindle then retracts, holding the part securely to present its back side to another set of tools for secondary operations. This automated handoff is perfectly concentric and happens within the same machine cycle. In my experience at PTSMAKE, this eliminates the risk of human error and tolerance stacking that occurs when a part is manually moved and re-clamped in a different machine or fixture for back-working.

The Accuracy of a Single Clamping

| Process Step | Manual Second Operation | Swiss Sub-Spindle Operation |

|---|---|---|

| Part Transfer | Operator moves part to another fixture | Sub-spindle grips and transfers part |

| Alignment | Relies on manual setup and fixture | Perfectly concentric with main spindle |

| Error Potential | High risk of misalignment | Minimal; controlled by the machine |

Swiss CNC machining achieves its superior precision through a guide bushing that provides robust support at the cutting point, preventing deflection. This is enhanced by a sub-spindle that enables seamless back-working operations within a single setup, eliminating re-clamping errors and ensuring perfect concentricity.

What Materials Can Be Used In Swiss CNC Machining?

Struggling to balance material properties with the unique demands of Swiss machining? Choosing the wrong one can lead to poor surface finishes, increased tool wear, and unexpected costs on your project.

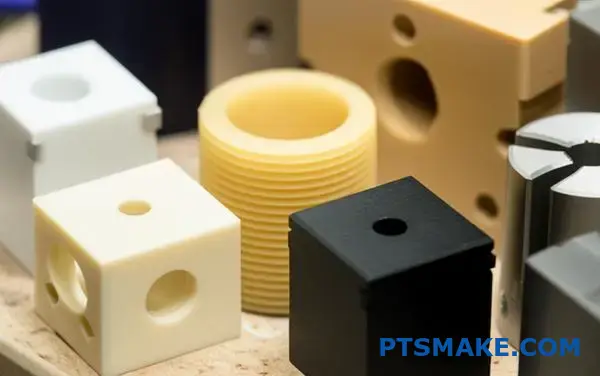

Swiss CNC machining is compatible with a wide range of materials, including metals like aluminum, stainless steel, titanium, and brass, as well as engineering plastics like PEEK and Delrin (POM). The best choice depends on your application’s specific mechanical and cost requirements.

When selecting a material for swiss cnc machining, machinability is the most critical factor. Metals are the most common choice, and for good reason. They offer a great balance of strength, durability, and performance. In our experience at PTSMAKE, we guide clients toward materials that will cut cleanly and efficiently in a Swiss-style lathe.

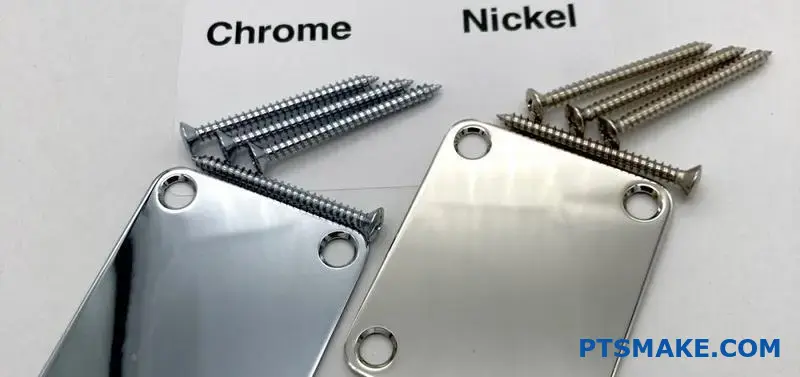

Common Metals for Swiss Machining

Aluminum alloys, particularly 6061 and 7075, are popular for their excellent strength-to-weight ratio and ease of machining. Stainless steel grades like 303 and 304 are also favorites due to their corrosion resistance, though they are tougher to machine. Brass is another excellent option, often chosen for its outstanding machinability, which leads to faster cycle times and lower costs for high-volume runs. The material’s yield strength5 is a key consideration, as it influences cutting forces and the final integrity of the part.

| Metal | Key Advantage | Common Application |

|---|---|---|

| Aluminum (6061) | Lightweight, cost-effective | Aerospace fittings, electronic housings |

| Stainless Steel (303) | Corrosion resistance, machinable | Medical device components, shafts |

| Brass (C360) | Excellent machinability, conductive | Connectors, fasteners, valves |

| Titanium | High strength, biocompatible | Medical implants, aerospace parts |

Beyond metals, engineering plastics are gaining significant traction in swiss cnc machining, especially for applications where metal is not suitable. These advanced polymers offer unique properties like chemical resistance, electrical insulation, and being lightweight, which are essential for medical, electronic, and automotive industries. However, machining plastics requires a different approach. Heat management is crucial, as excessive friction can cause the material to melt rather than cut cleanly.

High-Performance Plastics

Delrin (POM) is a fantastic all-arounder, known for its low friction, high stiffness, and dimensional stability. PEEK is a high-performance thermoplastic that can withstand extreme temperatures and harsh chemicals, making it a go-to for demanding medical and aerospace components. While more expensive, its properties often justify the cost.

| Plastic | Key Advantage | Common Application |

|---|---|---|

| Delrin (POM) | Low friction, high stiffness | Bearings, gears, insulators |

| PEEK | High temperature & chemical resistance | Medical implants, electronic connectors |

| Nylon | Toughness, wear resistance | Bushings, seals, wear pads |

Choosing the right plastic requires understanding the interplay between its properties and the machining process.

Swiss CNC machining supports a diverse material palette, from common metals like aluminum and stainless steel to advanced plastics such as PEEK and Delrin. Successful material selection hinges on balancing application requirements—like strength and corrosion resistance—with the material’s machinability to ensure precision and cost-effectiveness.

When Is Swiss CNC Machining the Most Cost-Effective Choice?

Ever quoted a complex, slender part and been puzzled by the cost? Deciding between Swiss CNC and standard turning can feel like a gamble for your budget.

Swiss CNC machining becomes most cost-effective for high-volume production of small, complex parts. While its setup can be more involved, the incredible speed, ‘done-in-one’ processing, and reduced material waste deliver a significantly lower per-part cost on larger production runs.

The key to understanding its cost-effectiveness lies in balancing setup costs against production volume. A Swiss machine setup is often more complex than a standard lathe’s, involving intricate programming for multiple axes and synchronized operations. This initial investment in time and expertise means that for very small batches or one-off prototypes, it might not be the cheapest option.

The Volume Break-Even Point

However, once the machine is running, its efficiency is unmatched for the right kind of part. The fast cycle times and unmanned operation ("lights-out" manufacturing) quickly offset the initial setup cost. The cost Amortization6 over a large run is where Swiss CNC machining truly shines. At PTSMAKE, we often see the break-even point emerge on runs of several thousand pieces.

| Cost Factor | Low Volume (e.g., 100 pcs) | High Volume (e.g., 10,000 pcs) |

|---|---|---|

| Setup Cost per Part | High | Very Low |

| Cycle Time Cost per Part | Moderate | Very Low |

| Overall Part Cost | Relatively High | Low |

Beyond cycle times, Swiss CNC machining drives down costs in two other critical areas: material waste and quality control. Because Swiss machines use bar stock that is typically very close to the finished part’s outer diameter, there is significantly less material turned into chips compared to machining a part from a larger billet on a standard CNC mill. Over a run of thousands of parts, this material saving adds up substantially.

The Hidden Cost Savings

Furthermore, the "done-in-one" capability drastically reduces downstream costs. By completing a complex part in a single setup, you eliminate the labor and potential for error associated with moving a part between different machines for secondary operations. This means fewer rejected parts, less time spent on inspection, and higher overall quality consistency.

| Cost Savings Area | Standard Multi-Op Process | Swiss CNC "Done-in-One" |

|---|---|---|

| Material Waste | Higher (from larger blanks) | Minimal (from bar stock) |

| Secondary Labor | Required for re-fixturing | Eliminated |

| Rejection Rate | Higher due to tolerance stack-up | Lower due to single setup |

Swiss CNC machining proves most cost-effective for high-volume, complex parts. Its higher initial setup cost is offset by rapid cycle times, minimal material waste, and reduced labor for secondary operations, leading to a lower per-part cost and superior quality on long production runs.

What Are The Limitations Of Swiss CNC Machining?

Thinking Swiss CNC is the ultimate solution for every small, precise part? This mindset can lead to blown budgets and production headaches when a simpler, more direct method would have worked better.

The primary limitations of Swiss CNC machining are its higher initial setup costs, making it less economical for low-volume runs, and its physical constraint on material diameter, typically under 1.5 inches. It is also inefficient for producing simple parts that don’t require its multi-axis complexity.

While Swiss CNC machining is a champion of precision for complex, slender parts, it’s not a universal solution. Its greatest strengths can become its weaknesses when misapplied. The most significant limitation is the initial setup cost and complexity. Programming a multi-axis Swiss machine with synchronized movements for the main spindle, sub-spindle, and live tooling is far more intensive than setting up a standard lathe. This investment in time and expertise only pays off over high-volume production. For prototypes or small batches, the cost per part can be prohibitively high compared to other methods. The process relies on intricate toolpath choreography7 which, while powerful, is not quickly configured for a run of just ten pieces.

Cost-Effectiveness vs. Production Volume

| Production Volume | Swiss CNC Machining | Standard CNC Turning |

|---|---|---|

| 1-100 Pieces | High Per-Part Cost | More Economical |

| 1,000+ Pieces | Setup Cost Amortized | Less Competitive |

| 10,000+ Pieces | Highly Cost-Effective | Significantly Higher Cost |

Another hard limit is physical size. The entire architecture of a Swiss machine, from the sliding headstock to the guide bushing, is designed around bar stock. This inherently limits the maximum diameter of the raw material that can be used. Most Swiss machines handle stock up to about 1.25 or 1.5 inches (around 38mm). If your part’s largest diameter exceeds this, Swiss machining is simply not an option. Furthermore, the process is inherently inefficient for parts that are not long and slender. For producing short, stout parts or components with a low length-to-diameter ratio, the unique advantage of the guide bushing offers no real benefit. In these cases, a standard CNC lathe or mill is often faster and more cost-effective.

Geometric and Dimensional Constraints

| Part Characteristic | Suitability for Swiss CNC | Alternative Process |

|---|---|---|

| Diameter > 1.5 inches | Not Feasible | Standard CNC Lathe |

| Low Length-to-Diameter Ratio | Inefficient | Standard CNC Lathe |

| Simple Geometry (No cross-work) | Overkill / Costly | Basic 2-Axis Lathe |

Swiss CNC machining has key limitations: it’s not cost-effective for low-volume runs due to high setup costs, is constrained to raw material diameters typically under 1.5 inches, and is inefficient for simple parts that don’t leverage its complex, multi-axis capabilities.

How To Choose A Reliable Swiss CNC Machining Partner?

Ever select a supplier who seemed perfect on paper, only to face communication breakdowns and critical delivery delays? Choosing the wrong partner can quickly derail your project and compromise quality.

To choose a reliable Swiss CNC machining partner, you must evaluate their technical capabilities, quality control systems, communication responsiveness, and proven industry experience. A true partner provides engineering support and demonstrates a clear understanding of your project’s specific requirements.

When you’re vetting a potential partner, move beyond the basic machine list. While having modern Swiss CNC machines is essential, it’s the expertise behind them that truly matters. I always advise looking for a partner who offers robust engineering support. Do they provide Design for Manufacturability (DFM) feedback to optimize your parts for production, potentially lowering costs and improving quality? A great partner will proactively suggest material alternatives or minor design tweaks that can make a huge difference. Their proficiency in Metrology8 is also non-negotiable; they must have the tools and skills to verify the tight tolerances your parts demand. In past projects at PTSMAKE, this collaborative engineering approach has been the key to turning a challenging design into a successful, repeatable component.

Supplier vs. True Partner

| Aspect | Basic Supplier | True Partner |

|---|---|---|

| Feedback | Makes the part as drawn | Offers DFM suggestions |

| Problem-Solving | Reports issues as they arise | Proposes solutions proactively |

| Material Expertise | Uses specified material | Recommends optimal materials |

Beyond technical skill, the partner’s operational processes are just as crucial for a smooth experience. Clear and consistent communication is the foundation of a reliable partnership. How do they handle project management? You should expect a single point of contact who is both technically knowledgeable and responsive. Nothing is more frustrating than having your questions bounce between departments. Evaluate their quality management system (QMS). Are they certified with standards like ISO 9001? Ask to see examples of their quality documentation, such as inspection reports and material certifications. A transparent partner will gladly share this information, demonstrating their commitment to quality and traceability. This operational excellence ensures that from quote to delivery, your project is in capable hands, minimizing surprises and keeping you informed every step of the way.

Evaluating Communication and Quality

| Factor | Red Flag | Green Flag |

|---|---|---|

| Response Time | > 48 hours, vague answers | < 24 hours, clear answers |

| Project Updates | Only when prompted | Proactive, regular updates |

| Quality Proof | Hesitant to share docs | Provides ISO certs, reports |

Choosing a reliable Swiss CNC machining partner means looking beyond the machinery. It requires a thorough evaluation of their engineering support, communication protocols, and documented quality systems. A true partner acts as an extension of your team, ensuring a successful outcome for your project.

Discover how this key component works with a technical ↩

Explore how different workholding techniques can impact the final accuracy and finish of your machined parts. ↩

Understand how material and structural rigidity directly impacts machining precision and part quality in this technical deep dive. ↩

Learn how machining chatter creates poor surface finishes and how Swiss technology effectively prevents it. ↩

Understanding this property helps predict how a material will behave under cutting forces, preventing part failure. ↩

Learn how to calculate cost amortization to justify your choice between different manufacturing processes for your next project. ↩

See how intricate tool movements are planned and executed to understand what drives setup complexity and cost. ↩

Discover the advanced measurement tools and techniques that verify your parts meet the strictest tolerance requirements. ↩