Finding the right casting method can make or break your manufacturing project timeline and budget. Many engineers struggle with this choice, watching costs spiral when they pick the wrong process for their volume requirements or material specifications.

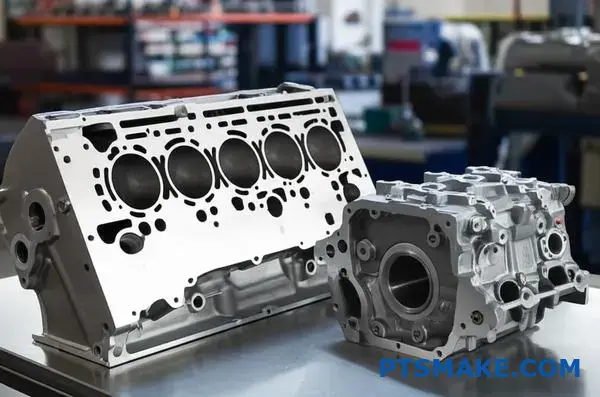

Sand casting uses expendable sand molds for flexible, low-volume production of complex parts in various alloys, while die casting injects molten metal under high pressure into reusable steel dies for high-volume production with superior surface finish and dimensional accuracy.

This decision impacts everything from your prototype timeline to your final production costs. I’ll walk you through the core principles, practical limitations, and economic trade-offs that determine which process fits your specific project requirements.

What is the core principle of sand casting?

Sand casting’s core idea is simple yet powerful. We create a cavity in sand and pour molten metal into it. The sand acts as a mold.

The Role of the Pattern

First, a pattern, a replica of the final part, is pressed into the sand. This creates the mold’s shape.

Key Components

The process relies on a few key elements working together perfectly. Gravity is the driving force that fills the mold.

| Component | Function |

|---|---|

| Sand | Forms the mold cavity |

| Binder | Holds sand grains together |

| Pattern | Creates the shape in the sand |

| Molten Metal | Fills the cavity to form the part |

This method is ancient but still highly effective today.

The Physics at Play

The entire process hinges on fundamental physics. Gravity pulls the molten metal down into every detail of the sand mold cavity. The sand must be strong enough to hold its shape under the metal’s weight and heat. This is where the binder is critical.

At the same time, the mold needs to "breathe." As the hot metal fills the cavity, gases are generated. These gases must escape, or they will cause defects in the final casting. This is a key difference in the sand casting vs die casting debate, where pressure is used instead of gravity.

Why Sand Properties Matter

The sand’s grain size and shape are crucial. They directly influence the final part’s surface finish and the mold’s permeability1. A finer grain gives a smoother surface but can make it harder for gases to escape.

We often work with clients at PTSMAKE to balance these factors. It’s about finding the right sand composition for the specific metal and part geometry.

| Property | Impact on Casting |

|---|---|

| Grain Size | Affects surface finish and permeability |

| Binder Type | Determines mold strength and collapsibility |

| Moisture Content | Influences gas formation and mold stability |

Getting these details right is essential for a successful casting.

The core principle of sand casting involves using a sand-based mold, a pattern to create the cavity, and gravity to fill it with molten metal. The properties of the sand and binder are crucial for controlling the final part’s quality.

What is the core principle of die casting?

The core principle of die casting is simple yet powerful. We inject molten metal into a steel mold, known as a die.

The defining element is the use of extremely high pressure. This force is what truly separates die casting from other methods.

Pressure: The Game Changer

Unlike gravity-fed methods, this intense pressure forces the metal into every tiny detail of the mold. This is a critical distinction in the sand casting vs die casting comparison. It ensures a complete and rapid fill.

| Feature | Die Casting | Gravity Casting |

|---|---|---|

| Driving Force | High Pressure | Gravity |

| Fill Speed | Extremely Fast | Slow |

| Mold Material | Steel Die | Sand, Plaster |

How Pressure Shapes the Final Part

High pressure does more than just fill a mold. It fundamentally dictates the process’s speed, precision, and the final part’s quality. It is the engine behind die casting’s main advantages.

Unlocking Speed and Precision

Pressure injects the molten metal in milliseconds. This rapid fill is crucial. It prevents the metal from solidifying before the mold is completely full. This allows us to create parts with incredibly thin walls.

In our past projects at PTSMAKE, this capability has been essential for complex electronic housings and lightweight automotive components.

Enhancing Material Properties

The combination of intense pressure and rapid cooling creates a very fine and dense material structure. This process leads to superior mechanical properties and a desirable grain refinement2. The result is a part that is stronger and more durable right out of the mold.

This table breaks down how pressure impacts key part characteristics.

| Characteristic | High-Pressure Impact | Low-Pressure/Gravity Impact |

|---|---|---|

| Wall Thickness | Can be very thin (<1mm) | Thicker sections required |

| Surface Finish | Smooth, near net-shape | Rougher, needs more finishing |

| Porosity | Minimized due to force | Higher risk of voids |

| Detail Replication | Excellent, captures fine features | Limited detail fidelity |

The core principle is high pressure. It differentiates die casting from gravity-fed methods and is directly responsible for the process’s speed, precision, and the superior mechanical properties of the final part.

Why is sand casting an ‘expendable mold’ process?

The term ‘expendable’ can sound wasteful. But in sand casting, it’s the key to unlocking unique design possibilities. This process is a one-time affair for each mold.

Once the molten metal cools and solidifies, the mold has served its purpose. To get the part out, we have to break the sand mold apart. There is no other way. This destructive step is fundamental to the process.

The Moment of Retrieval

The only way to retrieve the final metal part is by destroying the sand mold that formed it. This is usually done through shaking or vibration.

| Stage | Mold Condition | Casting Status |

|---|---|---|

| Before Retrieval | Intact, sand packed around the pattern | Solidified inside the mold |

| After Retrieval | Broken into loose sand | Freed, ready for finishing |

This sand can often be reclaimed, treated, and reused to create new molds, making the process sustainable.

The Practical Reality of Expendable Molds

The core implication is straightforward: one mold per part. This directly impacts manufacturing efficiency and cost, especially for high-volume production. It’s a slower, more labor-intensive cycle than permanent mold methods.

When we consider sand casting vs die casting, the difference is stark. Die casting uses durable steel molds that can produce thousands of parts quickly. Sand casting requires a new mold for every single piece.

| Feature | Sand Casting (Expendable) | Die Casting (Permanent) |

|---|---|---|

| Mold Reusability | None | High (thousands of cycles) |

| Production Speed | Slower | Very Fast |

| Tooling Cost | Low | High |

| Part Complexity | High (internal features) | Limited internal features |

The Advantage in the Destruction

So, why choose a destructive process? The answer is design freedom. Because the mold is broken away, we can design complex internal geometries.

We achieve this using sand cores. These are separate, hardened sand shapes placed inside the main mold. Metal flows around them, creating hollow sections or intricate internal features. After casting, the cores are broken up and removed along with the rest of the mold. This level of internal complexity is often impossible with permanent molds. The mold material’s permeability3 also allows gases to escape, preventing defects.

In short, the expendable nature of the sand mold is both its biggest limitation and its greatest strength. It trades speed for incredible design flexibility.

The expendable sand mold is destroyed to retrieve each part. This means slower production rates because a new mold is needed every time. However, this very process enables the use of sand cores for complex internal designs, offering significant geometric freedom.

What makes die casting a ‘permanent mold’ process?

The ‘permanent’ in permanent mold casting comes from the die itself. These molds are not single-use. They are precision tools.

Crafted from robust tool steel, they can withstand immense heat and pressure. This allows for exceptional reusability.

A single die can produce thousands, or even millions, of identical parts before needing replacement or major repair.

This longevity is central to its economics. The initial tooling cost is high, but the per-part cost becomes very low.

| Cost Factor | Die Casting Tooling | Per-Part Cost (High Volume) |

|---|---|---|

| Investment | High | Very Low |

The Core Economic Trade-Off

The high initial tooling cost is often the primary consideration. It’s a significant capital expense that requires careful project evaluation. At PTSMAKE, we help clients analyze this.

The key is calculating the break-even volume. This is the point where the savings from low per-part costs finally outweigh the initial mold investment.

This economic model is fundamentally different from other methods. When considering sand casting vs die casting, the financial structure is a major deciding factor for any project.

Sand casting has very low tooling costs. But a new sand mold is destroyed for every part made. This means labor and material costs per part remain high.

Furthermore, part-to-part consistency can vary more with sand casting. Die casting locks in precision for the entire run, reducing downstream quality issues and costs.

The die’s cost is an investment in efficiency and repeatability. Through the financial process of amortization4, that large initial cost is spread thinly across millions of parts, making the final piece very cost-effective.

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Tooling Cost | Very High | Very Low |

| Tooling Lifespan | 100,000+ Cycles | 1 Cycle (Mold) |

| Per-Part Cost | Decreases with Volume | Stays Relatively Constant |

| Best For | High-Volume Production | Prototypes, Low-Volume |

The permanence of the steel die creates a clear economic trade-off. A high initial investment is justified by extremely low per-part costs at scale, making it the superior choice for high-volume, high-precision manufacturing runs.

How do tooling lead times for each process compare between Sand Casting and Die Casting?

When comparing sand casting vs die casting, time is a critical factor. The difference in tooling lead time is one of the most significant distinctions.

Sand casting tooling, or patterns, can be ready very quickly. Often in just days or a few weeks. This is a huge advantage.

In contrast, die casting requires hardened steel dies. These are complex and take months to produce. This longer timeline is a major consideration for any project.

Tooling Lead Time at a Glance

| Casting Method | Tooling Type | Typical Lead Time |

|---|---|---|

| Sand Casting | Pattern (Wood, Plastic) | 1-3 Weeks |

| Die Casting | Hardened Steel Die | 8-16 Weeks |

This stark difference directly impacts your project schedule and flexibility.

Understanding why these timelines differ is key to making the right choice. The reasons come down to material and manufacturing complexity. This is a topic we frequently discuss with clients at PTSMAKE to align manufacturing with their launch deadlines.

The Simplicity of Sand Casting Patterns

Sand casting patterns are often made from wood, plastic, or aluminum. They can be crafted using simple methods, including CNC machining or even 3D printing. The process is straightforward and fast. This speed makes sand casting perfect for prototyping. You can get a physical part in hand quickly to test your design. It’s also ideal for low-volume production runs where a long wait for tooling isn’t practical.

The Complexity of Die Casting Dies

Die casting dies are entirely different. They are machined from blocks of high-strength, hardened tool steel. This process requires extensive CNC machining, heat treatment, and precise finishing. The dies must withstand immense pressure and high temperatures for thousands of cycles. This engineering and manufacturing effort is substantial, creating a much longer lead time. The initial investment in time and cost means the expense requires amortization5 over a large production volume to be economical.

The lead time is not just about making the tool. It also involves design, simulation, and testing to ensure part quality.

The key takeaway is simple: sand casting’s tooling is fast and ideal for speed and low volumes. Die casting’s tooling is a major, time-intensive investment suited for high-volume, long-term production where you are certain about the design.

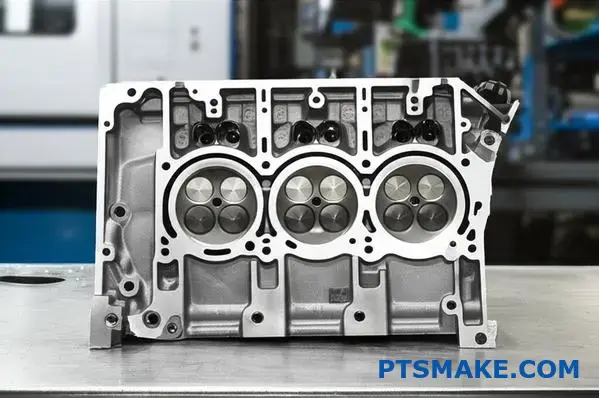

Between Sand Casting and Die Casting: Which process offers superior dimensional accuracy and why?

When comparing sand casting vs die casting, the winner for accuracy is clear. Die casting consistently delivers superior dimensional precision. This is a fundamental difference.

The reason lies in the mold material itself. Die casting uses robust, precision-machined steel molds. Sand casting, however, relies on compacted sand, which can shift.

Typical Tolerance Comparison

The achievable tolerances highlight this difference starkly.

| Casting Process | Typical Tolerance (per inch) |

|---|---|

| Die Casting | ±0.002" to ±0.005" |

| Sand Casting | ±0.020" to ±0.030" |

For components requiring tight fits or complex assembly, this distinction is critical.

The core of die casting’s accuracy is its mold, often called a die or tool. At PTSMAKE, our experience in CNC machining shows us how these steel dies are made. They are machined to extremely tight specifications, creating a rigid and repeatable cavity.

This process ensures that each part produced is nearly identical. The molten metal is injected under high pressure into this stable mold. The result is minimal variation from part to part.

The Instability of Sand Molds

Sand casting molds are inherently less stable. The sand is bound together, but it is still granular. It can be affected by factors like moisture content and compaction consistency.

During the pouring process, the force of the molten metal can cause slight shifts in the sand. This phenomenon, known as Mold Creep6, can lead to dimensional inaccuracies. This variability makes it less suitable for high-precision applications.

Mold Material Impact on Accuracy

| Feature | Die Casting (Steel Mold) | Sand Casting (Sand Mold) |

|---|---|---|

| Rigidity | High | Low to Moderate |

| Repeatability | Excellent | Fair |

| Machining | Precision CNC machined cavity | Formed by packing sand around a pattern |

| Durability | High (thousands of cycles) | Low (single-use) |

This table clearly shows why the steel die in die casting is the foundation of its superior precision.

Die casting’s use of precision-machined steel molds provides exceptional dimensional stability and tight tolerances. In contrast, the deformable nature of sand molds makes sand casting a less accurate process, better suited for parts where precision is not the primary concern.

How does surface finish typically compare between between Sand Casting and Die Casting?

When comparing sand casting vs die casting, surface finish is a major differentiator. We measure this using Roughness Average (Ra).

Die casting produces a much smoother surface. This is because it uses a polished steel mold. Sand casting, using a sand mold, results in a coarser texture.

Ra Value Comparison

The difference in Ra values is significant. Based on our project experience, the typical ranges are quite distinct.

| Casting Method | Typical Ra (micrometers) | Typical Ra (microinches) |

|---|---|---|

| Sand Casting | 6.3 – 25 µm | 250 – 1000 µin |

| Die Casting | 1.0 – 4.0 µm | 40 – 160 µin |

This superior finish on die-cast parts is often a deciding factor.

The reason for this stark difference lies in the mold material. Sand grains create a naturally textured surface with countless microscopic asperities7. A hardened steel die, however, is machined smooth and polished.

This smooth surface is more than just cosmetic. It has a huge impact on your production costs and timeline.

The Cost-Saving Advantage of Die Casting

For many applications, a die-cast part is ready for use right out of the mold. It often requires no further machining to improve the surface.

In contrast, sand-cast parts almost always need secondary operations. This could include milling, grinding, or sanding to achieve the desired smoothness and dimensional accuracy.

Impact on Production Workflow

These extra steps add significant costs. You pay for more machine time, more labor, and a longer lead time.

At PTSMAKE, we help clients analyze these trade-offs. Choosing die casting upfront can eliminate entire stages from the manufacturing process, delivering a finished part faster and more economically.

| Feature | Sand Casting | Die Casting |

|---|---|---|

| Initial Finish | Rough | Smooth |

| Secondary Machining | Often Required | Rarely Required |

| Typical Workflow | Cast → Machine → Finish | Cast → Finish (Optional) |

| Cost Impact | Higher post-processing costs | Lower overall cost for finished part |

This efficiency is a key reason why die casting is preferred for high-volume production where final appearance and minimal processing are critical.

The verdict is clear: die casting delivers a vastly superior surface finish. This often eliminates the need for costly secondary machining, providing a significant practical advantage in both time and budget over sand casting.

What material alloys are suitable for each casting method between Sand Casting and Die Casting?

Choosing between sand casting vs die casting often starts with one question: What is your part made of? The material itself frequently dictates the best method.

Sand Casting: The Universal Recipient

Sand casting is incredibly flexible. It can handle almost any metal alloy you can melt. This includes high-temperature ferrous metals.

Think of various steels, irons, aluminum, and bronze. The single-use nature of the sand mold makes this versatility possible.

Die Casting: The Specialist

Die casting, however, is much more selective. It is primarily used for non-ferrous alloys with lower melting points.

| Casting Method | Common Material Families |

|---|---|

| Sand Casting | Ferrous (Steel, Iron) & Non-Ferrous (Aluminum, Bronze) |

| Die Casting | Non-Ferrous only (Aluminum, Zinc, Magnesium) |

These material constraints are not arbitrary. They are based on the core physics of each process and the interaction between molten metal and the mold material.

The Science Behind Material Selection

The Robustness of Sand Molds

In sand casting, the mold is made from a sand mixture. It’s used only once and then broken away to reveal the part.

This disposable mold is highly refractory, meaning it can withstand extreme temperatures without degrading. This makes it ideal for high-melting-point metals like iron and steel.

The Limitations of Reusable Steel Dies

Die casting relies on a hardened steel tool, or die, which is used for thousands of cycles. Pouring molten steel (melting at ~1500°C) into a steel die would destroy it quickly.

This process, known as thermal shock, would cause the die to crack and wear prematurely. It’s simply not economical. This is why die casting is reserved for lower-temperature alloys. The repeated heating and cooling cycles challenge the metallurgical compatibility8 between the molten metal and the steel die.

This temperature difference is the key constraint.

| Material Alloy | Typical Melting Range (°C) | Viable for Die Casting? |

|---|---|---|

| Zinc | 380 – 390 °C | Yes |

| Aluminum | 580 – 650 °C | Yes |

| Magnesium | 600 – 650 °C | Yes |

| Carbon Steel | 1370 – 1540 °C | No |

This clear divide in melting points is the most significant factor when comparing sand casting vs die casting materials.

In summary, your alloy choice is a primary decision-maker. Sand casting’s disposable molds allow for nearly any metal. Die casting’s reusable steel dies restrict it to non-ferrous alloys with lower melting points to ensure tool longevity and cost-effectiveness.

Why are ferrous metals (like steel) difficult for die casting?

The core issue is a simple conflict of materials. Die casting uses steel molds. Ferrous metals, especially steel, have very high melting points.

Injecting molten steel into a steel die is problematic. The intense heat would quickly damage the mold.

The Melting Point Dilemma

Steel melts at temperatures that are very close to the tolerance limits of the die steel itself. This creates an impossible situation for mass production.

Material Temperature Comparison

Here’s a quick look at the temperatures involved. Based on our tests, the difference is critical.

| Material | Typical Melting Point (°C) |

|---|---|

| Molten Steel | 1370 – 1540 °C |

| Steel Die (H13) | ~1427 °C |

| Aluminum Alloy | ~660 °C |

This closeness in temperature leads to rapid die degradation.

The fundamental problem goes beyond just melting. It’s about thermal dynamics and material science. A steel die, though strong, cannot withstand repeated exposure to molten steel. This is where the sand casting vs die casting debate becomes very clear for steel components.

Why Steel Dies Fail

Each injection cycle subjects the die to extreme temperature changes. The die heats rapidly and then cools.

This repeated cycle causes severe thermal shock9. It leads to cracking, warping, and surface erosion on the expensive die. The molten steel can even weld itself to the die surface, ruining both the part and the tool.

Economic Unfeasibility

Die casting molds are a significant investment. At PTSMAKE, we design them for hundreds of thousands of cycles with metals like aluminum.

With steel, a die might only last for a few hundred shots, if that. The cost of constantly replacing dies makes the process commercially nonviable for almost any application.

Sand Casting: The Practical Alternative

This is why sand casting is the go-to method for steel and iron. A sand mold is used only once and is inexpensive to create.

Its refractory properties handle the high heat of molten steel perfectly. The mold is simply broken away after the part cools. It’s a cost-effective and reliable solution for ferrous metals.

The extreme melting point of steel makes it incompatible with the steel dies used in die casting. This leads to rapid tool destruction and prohibitive costs, making sand casting the superior, practical choice for manufacturing steel and iron parts.

How do part size and weight limitations differ between Sand Casting and Die Casting?

When choosing between casting methods, size is a huge factor. It often makes the decision for you. Sand casting and die casting serve very different ends of the spectrum.

Sand Casting: For Large-Scale Parts

Sand casting excels at producing very large and heavy components. Think of engine blocks or large valve bodies. The process is highly scalable.

Die Casting: For Smaller, Intricate Parts

Die casting is ideal for smaller parts. It’s perfect for components from hand-held sizes up to suitcase-sized items. The machine and die costs limit its scale.

Here’s a practical comparison of sand casting vs die casting size limits.

| Feature | Sand Casting | Die Casting |

|---|---|---|

| Typical Weight | A few pounds to many tons | A few ounces to ~75 lbs (34 kg) |

| Typical Size | Small to extremely large (>20 feet) | Small to medium (e.g., laptop case) |

| Best For | Very large, heavy components | High-volume, smaller, precise parts |

The reasons for these size differences are rooted in the processes themselves. Understanding why helps in making the right choice for your project.

Why Sand Casting Handles Size and Weight

Sand molds are simple to create and scale. You can make the sand mold as large as your foundry floor allows. There’s no massive, expensive steel die to limit you.

This flexibility makes it the go-to for one-off prototypes or huge industrial parts. The tooling cost is also much lower for large components.

Die Casting’s Physical Constraints

Die casting relies on massive machines. These machines use immense pressure to hold the steel die shut. The required clamping force10 increases exponentially with the part’s surface area.

This limits the maximum part size. Larger machines are incredibly expensive. The steel dies needed for big parts are also costly and complex to build. In our past projects at PTSMAKE, we’ve found that these constraints often guide the design from day one.

| Constraint Factor | Die Casting Implication | Sand Casting Advantage |

|---|---|---|

| Tooling (Die) | Very expensive and large dies are difficult to make. | Sand molds are inexpensive and easy to scale up. |

| Machine Size | Limited by the physical size and force of the machine. | Not limited by machine size; depends on foundry space. |

| Material Volume | Limited by shot size and melt furnace capacity. | Can handle very large volumes of molten metal. |

In short, sand casting is your solution for massive parts, offering unmatched scalability. Die casting, constrained by machine and tooling costs, is perfect for producing smaller, high-precision parts in large volumes. It’s a classic trade-off between scale and precision.

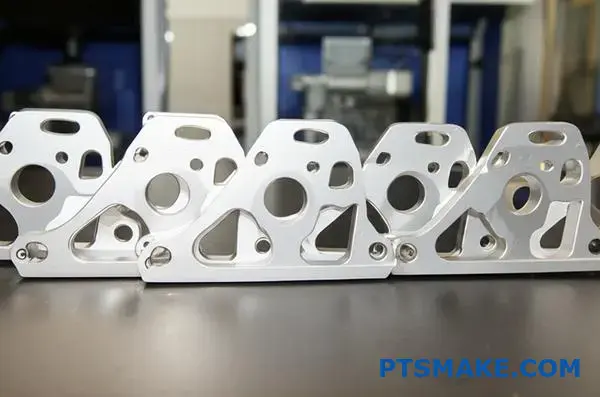

What design features are simple for sand casting?

The true genius of sand casting lies in its mold. Because the sand mold is expendable, it unlocks incredible design freedom.

Features that are difficult or impossible with other methods become simple. This is its core advantage.

Leveraging Expendable Molds

Complex Internal Passageways

Creating complex internal channels is straightforward. We use disposable sand cores, which are placed in the mold. Once the metal solidifies, the cores are simply broken and shaken out.

Undercuts and Thick Sections

Undercuts and thick cross-sections also pose little challenge. The single-use nature of the mold means there are no permanent parts that need to be retracted.

A quick comparison highlights this:

| Feature | Sand Casting Simplicity | Die Casting Simplicity |

|---|---|---|

| Internal Channels | High | Low |

| Undercuts | High | Very Low |

| Thick Sections | High | Moderate |

The key is the disposable sand core. After casting, we just break it apart. This reveals intricate internal geometries that would be impossible to create with a solid, permanent mold.

The Advantage of Disposable Cores

This is a major point of difference in the sand casting vs die casting debate. Die casting uses permanent steel molds. These molds must be pulled away from the finished part.

This mechanical limitation makes complex undercuts and internal cavities extremely difficult. It requires expensive, complex slides and lifters in the tool. With sand casting, we bypass this entirely.

The sand itself is also a factor. The material’s permeability11 allows hot gases to escape during solidification. This is crucial for preventing defects, especially in parts with thick cross-sections that cool slowly.

At PTSMAKE, we often guide clients toward sand casting for prototypes with these complex features. It allows for faster design validation before committing to more expensive tooling.

| Aspect | Sand Casting | Die Casting |

|---|---|---|

| Tooling Cost | Low | High |

| Internal Complexity | Very High | Low |

| Undercut Feasibility | High | Low (Costly) |

| Production Speed | Slower | Faster |

Sand casting excels with complex internal passageways, undercuts, and thick sections. Its use of expendable sand cores removes the limitations of permanent molds, making intricate designs surprisingly simple and cost-effective to produce, especially for prototypes or low-volume runs.

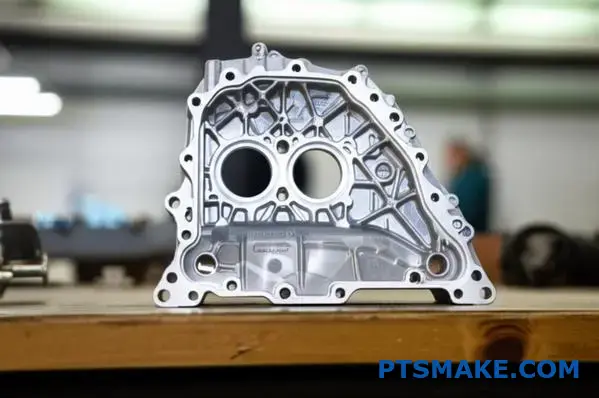

What design features are ideal for die casting?

Die casting excels with features that leverage its core strengths: high pressure and durable steel dies. This combination allows for designs that are difficult or impossible with other methods.

Very Thin Walls

The high-pressure injection forces molten metal into the mold cavity rapidly. This speed is crucial for creating very thin walls, often as thin as 1mm, before the metal solidifies.

Sharp, Intricate Details

Steel dies are rigid and precisely machined. This allows for casting sharp corners, fine textures, and detailed logos directly onto the part. The process replicates these features perfectly.

| Feature | Die Casting | Sand Casting |

|---|---|---|

| Wall Thickness | As thin as 1mm | Typically > 3mm |

| Surface Finish | Smooth, fine detail | Rough, less detailed |

| Production Speed | Very high | Low to medium |

The benefits of high pressure and steel dies extend beyond just aesthetics. They enable functional features that improve part performance and reduce overall production costs.

External Threads

One major advantage is the ability to cast external threads directly onto the part. This eliminates the need for secondary machining operations. It saves both time and money, especially in high-volume production. At PTSMAKE, we often recommend this to clients to streamline their manufacturing process.

High Consistency for Large Runs

The steel die is a permanent mold that does not degrade quickly. This ensures exceptional part-to-part consistency across thousands or even millions of cycles. Every piece is virtually identical. This is a key difference in the sand casting vs die casting debate, where sand molds are single-use. This repeatability is essential for automated assembly lines. The process ensures that the first part and the last part maintain the same tight tolerances, thanks to the controlled laminar flow12 of the molten metal.

| Feature | Benefit | Ideal Application |

|---|---|---|

| Cast-in Threads | Reduces secondary operations | Fasteners, housings |

| Repeatability | Ensures every part meets spec | Automotive, electronics |

| Net-Shape Parts | Minimizes post-processing | Complex geometries |

Die casting’s use of high pressure and robust steel molds makes it perfect for parts with thin walls, sharp details, external threads, and a need for high consistency. It’s an efficient, highly repeatable process.

How do production volume sweet spots compare for both methods between Sand Casting and Die Casting?

Choosing between sand casting and die casting often comes down to one critical factor: production volume. Each method has a distinct "sweet spot" where it is most cost-effective. Understanding these ranges is key to making the right financial decision for your project.

Sand Casting’s Ideal Volume

Sand casting shines for lower quantities. It’s perfect for one-off prototypes. It is also great for small to medium runs, typically up to a few thousand units.

Die Casting’s Production Scale

Die casting is built for mass production. Its economic viability starts where sand casting’s leaves off. Think several thousand parts, scaling up into the millions.

| Casting Method | Typical Production Volume |

|---|---|

| Sand Casting | 1 – 5,000 units |

| Die Casting | 5,000 – 1,000,000+ units |

This stark difference is the most common decision-making axis in the sand casting vs die casting debate.

The Economics Behind the Numbers

The sweet spots are defined by tooling costs versus per-part costs. This is a fundamental concept we explain to clients at PTSMAKE. It helps them align their budget with their production goals.

Tooling Investment Analysis

Sand casting uses inexpensive sand molds. These are temporary and created for each casting. This means your initial investment is very low. It’s ideal for testing designs or for limited production runs where high tooling costs are not justified.

Die casting requires robust, precision-machined steel molds. These are a significant upfront expense. However, this investment becomes cost-effective over large volumes through a process called Amortization13. The high initial cost is spread across thousands or millions of parts.

Per-Unit Cost Comparison

Here’s how the costs break down as volume increases.

| Cost Factor | Sand Casting | Die Casting |

|---|---|---|

| Initial Tooling Cost | Very Low | Very High |

| Per-Unit Cost (Low Vol.) | Lower | Higher |

| Per-Unit Cost (High Vol.) | Higher (due to labor) | Very Low |

| Production Speed | Slow | Very Fast |

In our experience, the high-speed, automated nature of die casting drives the per-unit price down dramatically at scale. Sand casting, being more labor-intensive, has a relatively stable but higher per-part cost.

Production volume is the primary driver. Sand casting is your go-to for low-volume needs, from prototypes to small batches. For high-volume mass production, die casting is the clear economic winner once tooling costs are absorbed.

How do you select the best process for a prototype between Sand Casting and Die Casting?

Choosing the right method for a prototype can feel complex. But for early-stage functional parts, the decision becomes much simpler.

Your main goals are usually speed and low initial cost. You need a part in hand quickly without a huge investment.

This is why we need a clear decision framework. It helps prioritize what truly matters at the prototyping stage.

Let’s look at a simple comparison.

| Factor | Sand Casting | Die Casting |

|---|---|---|

| Initial Cost | Low | Very High |

| Speed (Tooling) | Fast | Slow |

| Best For | Prototypes & Low Volume | Mass Production |

This makes sand casting a strong default choice for initial tests.

A Framework Prioritizing Speed & Cost

When you’re validating a new design, getting a physical part quickly is essential. You need to test form, fit, and function.

Committing to expensive production tooling before this validation is a huge financial risk. This is why our framework for prototypes starts with minimizing upfront costs and lead times.

Why Sand Casting is the Default Choice

Sand casting excels here because its tooling is fast and inexpensive to create. We are not talking about months of waiting.

For simple, one-off prototypes, we can create a basic wood pattern in just a few days. This is perfect for a quick functional test.

The Power of 3D Printing

For more complex geometries, we can skip traditional patterns entirely. In our projects at PTSMAKE, we increasingly use 3D printed sand molds.

The process of binder jetting14 allows us to create the mold directly from a CAD file. This reduces tooling time from days to mere hours.

In the sand casting vs die casting comparison for prototypes, this flexibility is a game-changer. Die casting requires a hardened steel mold, a process that takes weeks or months and represents a major investment. That tooling is simply not practical for a single prototype.

| Tooling Method | Typical Lead Time | Relative Cost | Best Use Case |

|---|---|---|---|

| Wood Pattern | 2-5 Days | Low | Simple Prototypes |

| 3D Printed Sand Mold | 1-3 Days | Low-Medium | Complex Prototypes |

| Steel Die (Die Casting) | 8-16 Weeks | Very High | Production Volumes |

For early-stage prototypes, the decision framework is straightforward. Sand casting is the logical choice when speed and low initial cost are your priorities. Modern techniques like 3D printed molds make it faster and more versatile than ever.

How do you optimize a design for sand casting manufacturability?

To streamline your design for sand casting, a solid DFM checklist is essential. It acts as your guide. This ensures your part is not just functional but also manufacturable.

Following these rules prevents common defects. It also helps control costs from the start.

Key DFM Checklist Items

| Rule | Purpose |

|---|---|

| Draft Angles | Easy pattern removal |

| Fillets/Radii | Prevent stress cracks |

| Machining Stock | For post-casting finishing |

| Simple Cores | Reduce cost and complexity |

This simple checklist covers the most critical aspects. At PTSMAKE, we use it as a starting point for every project review.

Applying these DFM rules requires a deeper understanding of the sand casting process. It’s not just about adding features; it’s about thinking like a foundry engineer. This proactive approach saves time and money.

Draft Angles: The Key to Release

A draft angle is a small taper added to vertical faces. It allows the pattern to be removed from the sand mold without damage. Without it, the mold can break, leading to defects. A typical draft angle is 1-3 degrees.

Avoiding Sharp Corners with Fillets

Sharp internal corners create stress points. This can cause cracks as the metal cools and shrinks. Adding fillets (rounded corners) distributes this stress. This small change greatly improves the part’s structural integrity.

Planning for Machining

Sand casting produces a rough surface finish. If your design requires tight tolerances or smooth surfaces, you must add machining stock. This extra material is removed later. The location of the parting line15 often dictates where stock is needed.

Here’s a quick comparison of design choices:

| Poor Design (High Risk) | Good Design (Low Risk) |

|---|---|

| 90° corners | Rounded corners (fillets) |

| Zero draft | 1-3° draft angles |

| Complex, multi-part cores | Simplified, single-piece cores |

| No extra material for finishing | Added machining stock |

This DFM checklist is your foundation for success in sand casting. Applying draft angles, fillets, and planning for machining stock streamlines production, reduces defects, and ultimately lowers costs for a better final product.

How do you optimize a design for die casting manufacturability?

A solid DFM checklist is your best tool. It guides your design process. This ensures your part is not just functional, but also cost-effective to produce.

Following a checklist helps avoid common pitfalls. You can catch design flaws early. This saves significant time and money later.

Key Checklist Categories

Here are the core areas to focus on. Each one plays a vital role in successful die casting.

| Checklist Area | Primary Goal |

|---|---|

| Wall Thickness | Prevent porosity & sinks |

| Draft Angles | Ensure easy part ejection |

| Metal Flow | Avoid turbulence & defects |

| Feature Complexity | Reduce tool cost & cycle time |

Breaking Down the DFM Checklist

A great die casting design is intentional. Every feature should be reviewed for manufacturability. This checklist is a practical guide we use at PTSMAKE with our clients.

Uniform Wall Thickness

Consistent walls are critical. They ensure the molten metal cools evenly. This minimizes internal defects like porosity and visible sink marks on the part’s surface. While sand casting vs die casting offers different tolerances, die casting demands uniformity.

Sufficient Draft Angles

Draft is a slight taper on vertical surfaces. It allows the part to be easily ejected from the mold. Without it, the part can stick, causing damage to both the part and the tool.

| Feature Type | Recommended Draft Angle |

|---|---|

| Outer Walls | 1° minimum |

| Inner Walls | 2° minimum |

| Ribs/Bosses | 1° per side |

Designing for Smooth Metal Flow

Molten metal should flow like a gentle river, not a turbulent one. Use generous fillets and radii instead of sharp corners. Sharp internal corners can create stress concentrations and cause early tool failure or part cracking due to thermal shock16.

Simplifying Part Geometry

Complex features like undercuts require slides or lifters in the mold. These add significant cost and complexity to the tool. They also increase maintenance needs and cycle times. Always ask if a complex feature can be simplified or eliminated.

This DFM checklist is your blueprint for success. Following guidelines for wall thickness, draft, and metal flow simplifies tooling, boosts part quality, and ensures a smooth production run from the start.

How should post-processing needs influence the initial process choice?

Thinking about the final part cost is crucial. A low initial process cost can be misleading.

If a part requires a lot of extra work later, those savings disappear quickly. This includes machining, heat treatment, or finishing.

The Hidden Costs

Always look at the full picture. The initial quote is just one piece of the puzzle. Post-processing can sometimes double the initial cost.

Process Comparison at a Glance

Consider this simple cost breakdown. It shows how secondary operations can change the financial outcome.

| Process Stage | Process A (Low Initial Cost) | Process B (High Initial Cost) |

|---|---|---|

| Initial Cost | $10 per unit | $15 per unit |

| Machining | $8 per unit | $2 per unit |

| Finishing | $4 per unit | $1 per unit |

| Total Cost | $22 per unit | $18 per unit |

This shows that Process B is more cost-effective in the end.

This is something we constantly discuss with clients at PTSMAKE. A cheaper initial process isn’t always the cheapest overall. The goal is to minimize steps to get to the final, functional part.

Sand Casting vs Die Casting

A classic example is the choice between sand casting vs die casting. Sand casting might seem cheaper at first. However, the parts often have a rough surface finish and looser tolerances. This means they require significant machining to meet specifications.

Die casting, on the other hand, produces parts with excellent surface finish and tight tolerances. It creates a near-net shape17 part that needs very little, if any, post-processing. The initial tooling is more expensive, but the per-part cost drops significantly. Especially for higher volumes.

Factoring in All Operations

Let’s look at the required steps for each. After our tests, we found die casting often eliminates entire stages of production.

| Post-Processing Need | Sand Casting | Die Casting |

|---|---|---|

| Surface Finishing | Almost Always | Rarely |

| Tolerance Machining | Frequently | Occasionally |

| De-burring | Required | Minimal |

| Heat Treatment | Varies | Varies |

Choosing die casting can simplify your supply chain. You avoid coordinating extra machining or finishing services. This saves time and reduces potential quality issues.

Focusing on the total finished-part cost is key. An initially cheaper process can become more expensive after extensive machining, heat treatment, and finishing. Processes like die casting often reduce these secondary steps, offering better overall value.

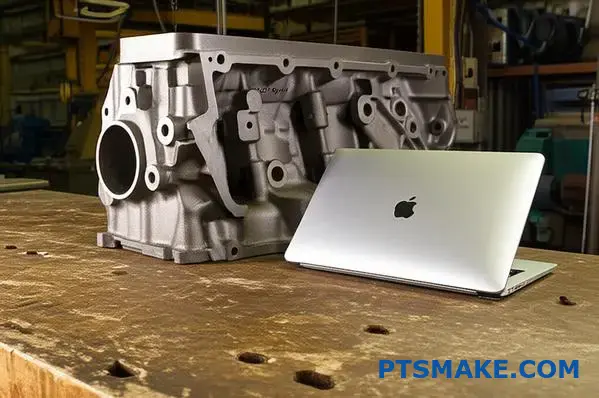

Analyze a complex auto part: choose the casting method.

Let’s put theory into practice with a case study. Consider an automotive engine block. This part presents a classic manufacturing dilemma.

The goal is high-volume production. But it also has incredibly complex internal features.

The Core Decision

You must choose between two very different methods. This decision impacts cost, quality, and production speed. The choice isn’t always obvious when requirements conflict.

Key Factors at Play

| Feature | Implication | Preferred Method |

|---|---|---|

| High Volume | Lower cost per unit | Die Casting |

| Complex Internals | Needs intricate cores | Sand Casting |

| Material (Iron) | High melting point | Sand Casting |

This is where experience becomes critical. An engine block is the heart of a vehicle. Its design has non-negotiable features that directly challenge high-speed manufacturing methods.

The Decisive Analysis

The primary challenge is the intricate network of internal water jackets. These channels are essential for engine cooling. They require complex, single-use sand cores to form their shape accurately. Die casting simply cannot create these hollow passages with such detail.

Sand Casting vs Die Casting

Furthermore, the material choice is often cast iron. Its durability and heat resistance are perfect for an engine.

However, cast iron’s high melting point is unsuitable for typical die casting machines. This material constraint points directly toward sand casting.

| Aspect | Sand Casting | Die Casting | Decision Driver |

|---|---|---|---|

| Complexity | Excellent (uses sacrificial cores18) | Limited | Sand Casting |

| Material | Handles Cast Iron | Poor for Cast Iron | Sand Casting |

| Speed | Slower | Very Fast | Die Casting |

| Tooling Cost | Low | High | Sand Casting |

While high volume favors die casting, the part’s fundamental requirements—its complex internal geometry and material—make sand casting the only practical choice. The design dictates the process.

For an engine block, the complex internal cooling channels and the use of cast iron are non-negotiable. Therefore, sand casting is the clear winner, even though die casting offers higher production speeds for simpler parts.

Your Takeaway on Complex Parts

When analyzing a part, always prioritize the "must-have" features. Production speed is important. But it means nothing if the chosen process cannot create the part to specification.

In our experience, design functionality and material properties must always lead the decision.

Navigating Your Manufacturing Choices

This kind of analysis is something we do daily at PTSMAKE. Choosing the right path from prototype to production requires balancing many factors.

If you’re facing a similar challenge, our team can help you find the most reliable and cost-effective solution.

Your project scales from 100 to 100,000 units. When switch?

Scaling from a prototype to full production is a common journey. Let’s simulate this growth from 100 to 100,000 units. How do you choose your manufacturing process?

Starting with 100 Units

For an initial run of 100 units, sand casting is often the best choice.

The tooling cost is significantly lower. This makes it ideal for testing your design and market without a huge upfront investment. Speed is also a key factor here.

Initial Production Comparison

| Feature | Sand Casting (100 Units) | Die Casting (100 Units) |

|---|---|---|

| Tooling Cost | Low | Very High |

| Per-Unit Cost | Higher | Prohibitively High |

| Lead Time | Fast | Slow |

| Best Use | Prototyping, Low Volume | Not Recommended |

This approach minimizes your initial financial risk.

Planning the Transition to 100,000 Units

As your orders grow, the per-unit cost of sand casting becomes a problem. This is the trigger point to plan your switch to die casting. The high-volume efficiency of die casting now makes sense.

This transition requires a clear strategy and budget. You are not just changing methods; you are investing in scale. The main budget item will be the high-precision steel mold for die casting.

This high initial cost requires careful amortization19 over the entire production run. At PTSMAKE, we help clients map this out. We plan the switch when the total cost of die casting becomes lower than sand casting.

Simplified Transition Strategy

| Phase | Volume Range | Primary Method | Key Action |

|---|---|---|---|

| 1. Validation | 1 – 500 | Sand Casting | Confirm design & market fit. |

| 2. Bridge | 501 – 5,000 | Sand Casting | Begin die cast tool design. |

| 3. Scaling | 5,001+ | Die Casting | Launch mass production. |

This phased approach ensures a smooth ramp-up. It aligns your manufacturing investment with proven market demand. The sand casting vs die casting debate is all about volume and timing.

Starting with sand casting for low volumes minimizes initial risk. As demand grows, a well-planned and budgeted transition to die casting is crucial for achieving cost-efficiency at scale. This strategy ensures a smooth product lifecycle.

Ready to Decide Sand Casting vs Die Casting? Contact PTSMAKE Now!

Still weighing sand casting vs die casting for your next project? Let PTSMAKE’s experts guide your choice and deliver a precise, cost-effective solution—whether prototype or high-volume production. Send us your RFQ today and experience world-class precision manufacturing from a trusted partner!

Learn how this property is measured and why it is critical for preventing casting defects. ↩

Learn how controlling microscopic material structure leads to stronger and more durable final parts for your project. ↩

Understand how this sand property is crucial for preventing casting defects. ↩

Discover how tooling investment is spread across production, directly impacting your final cost-per-part calculation and project budget. ↩

Understand how tooling costs are spread across production runs to calculate the true cost-per-part. ↩

Discover how this subtle mold deformation affects the final dimensional accuracy of cast parts. ↩

Learn how these microscopic peaks and valleys impact your part’s performance and final cost. ↩

Learn more about how different metals interact with tooling materials under extreme thermal stress. ↩

Learn how this rapid temperature cycling compromises material integrity and why it’s a critical factor in manufacturing. ↩

Learn how this critical machine parameter directly impacts your part design and manufacturing costs. ↩

Discover how this sand property is essential for preventing gas-related defects in your castings. ↩

Learn how controlling metal flow impacts part quality and integrity. ↩

Learn how tooling cost is spread over production runs to lower unit prices. ↩

Learn more about this additive manufacturing process for creating complex sand molds without tooling. ↩

Understand how parting line choices can impact tooling complexity and final part quality. ↩

Understand how managing this effect extends the operational life of your expensive die casting mold. ↩

Learn how near-net shape processes can significantly reduce your machining costs and production time. ↩

Learn how these single-use cores enable the creation of complex internal cavities in castings. ↩

Learn how to calculate tooling cost amortization for your project. ↩