Finding the right CNC machining partner in Boston can make or break your product development timeline. You need precision parts delivered on schedule, but the local market is flooded with suppliers making bold promises they can’t keep.

Boston offers numerous CNC machining services, but the best partners combine advanced equipment, proven quality systems, and clear communication to deliver precision parts from prototype through production.

I’ve worked with procurement teams across New England, and the companies that succeed are those who look beyond location and price. This guide walks you through the real factors that separate reliable Boston CNC partners from the rest, giving you a clear roadmap to make the right choice for your next project.

The Complete Guide to Finding a Reliable CNC Machining Partner in Boston

Finding a provider for CNC machining Boston can seem easy. A quick search reveals many local options. But identifying a trustworthy, long-term manufacturing partner is a completely different challenge.

This isn’t just about proximity. You need a team that deeply understands your project’s technical demands.

Critical factors like communication and quality systems are what separate a simple supplier from a valuable Boston CNC machining partner.

| Czynnik krytyczny | Dlaczego to ma znaczenie |

|---|---|

| Umiejętności techniczne | Ensures parts meet exact specifications. |

| Komunikacja | Prevents costly mistakes and delays. |

| Systemy jakości | Guarantees consistent, reliable results. |

This guide helps you look beyond the map to find a truly reliable partner.

Choosing a local shop for convenience is tempting. But a true partnership is built on capability, not just a zip code. The search for reliable CNC machining services Boston must go deeper into what a shop can truly deliver.

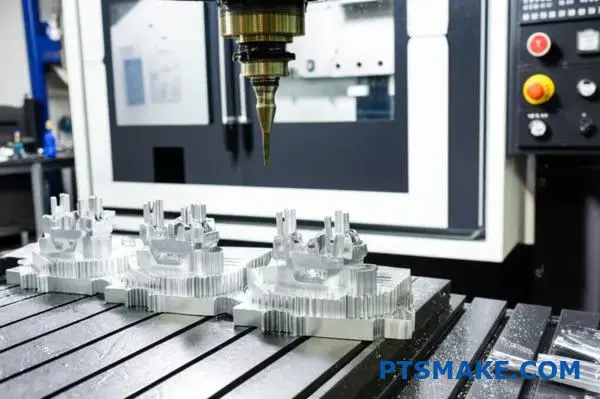

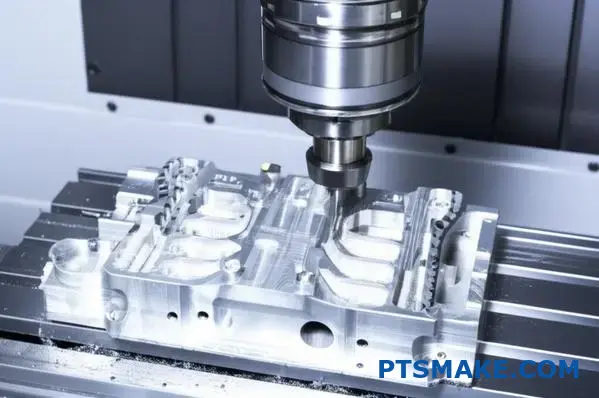

What does technical capability mean in practice? It’s a shop’s proven ability to handle your specified materials. It’s their capacity to meet tight tolerances and use advanced machinery, like 5-axis mills, for complex geometries.

This technical expertise must be paired with excellent communication. A real partner proactively clarifies design questions before machining begins. They provide regular updates, ensuring you are never left in the dark. This prevents misunderstandings that derail project timelines.

Equally important are their quality systems. Do they hold an ISO 9001 certification? How do they manage inspections and document compliance? A strong quality framework ensures the first part is identical to the last. Understanding their fluency with Geometryczne wymiarowanie i tolerowanie (GD&T)1 is a key indicator of their commitment to precision.

| Simple Vendor | Prawdziwy partner |

|---|---|

| Focuses on one-off jobs. | Invests in your long-term success. |

| Reactive communication. | Proactive problem-solving. |

| Basic quality checks. | Certified, documented quality systems. |

| Delivers a part. | Delivers a solution. |

This deeper evaluation is essential for your entire product lifecycle.

Finding the right Boston CNC partner requires more than a local search. You must evaluate their technical skills, communication practices, and quality systems. This deeper analysis builds a reliable, long-term manufacturing relationship that ensures project success.

Secrets to Evaluating a Boston CNC Machine Shop’s True Capabilities

A glossy brochure doesn’t make a precision part. To truly vet a supplier, you must look deeper. The real story is told on the shop floor, through their equipment and processes.

It’s about asking specific, targeted questions. This is how you perform a proper Boston CNC machine shop evaluation.

Machine Types and Their Impact

Don’t settle for a simple "yes" when asking about capabilities. The type of machine dictates the complexity and efficiency of a project. Each machine serves a different purpose for your needs.

| Typ maszyny | Najlepsze dla | Kluczowe pytanie do zadania |

|---|---|---|

| 3-osiowe CNC | Simple geometries, flat parts | "What is the work envelope of your 3-axis machines?" |

| 5-osiowe CNC | Complex curves, single-setup parts | "Can you show examples of parts made on your 5-axis?" |

| Tokarka szwajcarska | Small, intricate, high-volume parts | "What is your experience with Swiss machining for parts like mine?" |

Understanding their equipment is the first step in assessing true CNC machining capabilities Boston.

Material and Quality Control Expertise

A shop’s technical depth extends beyond its machines. It includes their knowledge of materials and their commitment to quality. These are non-negotiable aspects of precision manufacturing.

A shop might claim to work with many materials. But you need to confirm their actual experience. Ask for case studies or part examples in the specific material you require. This is especially true for tricky plastics or exotic metal alloys.

The Quality Process Litmus Test

Quality control is more than a final inspection. It should be embedded in every step. An ISO 9001 certification is a good sign. However, it’s just the starting point.

The real test is their process. Ask how they ensure specifications are met from start to finish. A deep understanding of Wymiarowanie geometryczne i tolerowanie2 is often a sign of a highly capable shop. This level of detail is crucial for complex projects requiring precision machining Boston.

We found that shops with documented in-process checks catch deviations early. This prevents scrap and delays. It’s a core part of a successful Boston CNC machine shop evaluation.

| Obszar badania | Kluczowe pytanie do zadania | Dlaczego to ma znaczenie |

|---|---|---|

| Certyfikaty | "Can I see your current ISO 9001 certificate?" | Verifies a baseline commitment to quality standards. |

| Narzędzia inspekcyjne | "What inspection equipment do you have? (CMM, etc.)" | Confirms they can measure and validate tight tolerances. |

| Kontrola procesu | "How do you document and control quality during production?" | Reveals their proactiveness in preventing defects. |

These questions help you gauge if they just talk about quality or if they truly live it. This diligence is key for successful cnc machining boston projects.

To properly assess a supplier, you must probe their technical capabilities. This means asking detailed questions about their machinery, material expertise, and, most importantly, their quality control systems. This uncovers their true potential as a long-term partner.

The Ultimate Checklist for Your Next CNC Machining Project in Boston

A successful project begins long before the first chip is cut. It starts with a clear, comprehensive Request for Quotation (RFQ). This is the foundation for everything that follows.

This practical CNC machining project checklist Boston ensures nothing is missed. It helps you get accurate quotes and avoids costly delays down the line.

Your Essential RFQ Checklist

To get a precise quote, your manufacturing partner needs specific details. Providing incomplete information often leads to follow-up questions and slows down the process.

Here is a simple breakdown of what to include:

| Kategoria | Essential Information |

|---|---|

| Drawings | 2D (PDF) and 3D (STEP/IGS) files are ideal. |

| Materiały | Specify the exact material grade (e.g., Aluminum 6061-T6). |

| Quantities | Provide quantities for prototypes, and potential production runs. |

| Tolerancje | Clearly mark critical dimensions and required tolerances. |

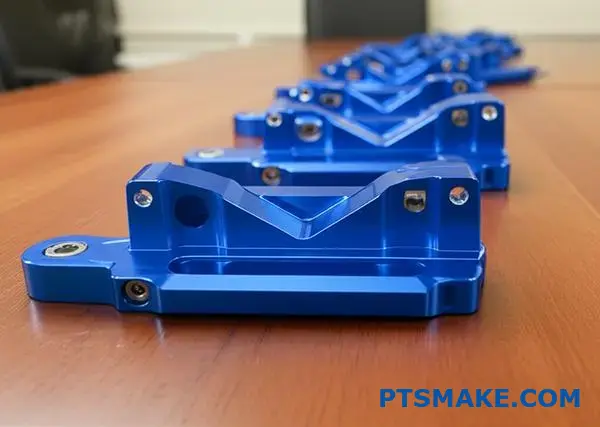

| Wykończenie | Specify any surface finishes like anodizing or painting. |

Providing these details upfront streamlines the entire quoting process for your cnc machining boston projekt.

A detailed RFQ is your first step. However, a truly successful partnership goes beyond the initial documents. This is where clear communication and aligned expectations become crucial for project success.

Think of your RFQ as the start of a conversation. I always recommend a follow-up call to discuss the project’s nuances. This is a great time to clarify any complex features or tight tolerances.

Beyond the RFQ: Communication and Delivery

This phase is about building a reliable process. It ensures the final parts match your design intent and arrive when you need them. It’s a key part of any effective Boston CNC machining RFQ guide.

We often discuss specifics that aren’t on the drawing, like how certain features might be inspected. It’s also where we align on the application of standards like Geometryczne wymiarowanie i tolerowanie (GD&T)3 to ensure everyone interprets the requirements the same way. This proactive communication prevents misunderstandings.

| Communication & Logistics | Key Points |

|---|---|

| Key Contacts | Who is the main point of contact on both sides? |

| Częstotliwość aktualizacji | How often do you need progress updates? Weekly? At key milestones? |

| Wysyłka | What are the shipping requirements and delivery address? |

| Opakowanie | Are there specific packaging needs to protect sensitive parts? |

This structured approach transforms a simple transaction into a smooth, predictable manufacturing partnership.

This detailed checklist moves beyond just getting a price. It establishes clear expectations, prevents errors, and ensures your Boston project is delivered on time and to your exact specifications. It is your roadmap to a successful partnership.

Critical Questions to Ask Before Hiring a Boston CNC Machining Service

Finding the right CNC partner goes beyond the price quote. You need to ask specific, hard-hitting questions. These questions reveal a shop’s true capabilities. They show you their process and communication style. This is how you avoid production headaches down the line.

Key Areas of Inquiry

These are the essential questions I always ask. They cover technical capabilities, process efficiency, and quality control. This is the first step in a proper vetting process.

Technical and Process Questions

I always start with their equipment and workflow. It tells me if they can actually make my parts to spec.

| Kategoria pytań | Przykładowe pytanie |

|---|---|

| Design Feedback | What is your process for DFM feedback? |

| Studia przypadków | Can you share examples of similar parts? |

| Lead Times | What are your typical prototype vs. production lead times? |

This initial list of questions for CNC machining Boston helps filter out shops that are not a good fit.

Let’s go deeper than just asking questions. You need to understand the "why" behind their answers. This is a crucial part of the Boston CNC service vetting process. It separates a simple vendor from a true manufacturing partner who adds value.

Evaluating the Production Workflow

When you ask about their process for handling Projektowanie pod kątem możliwości produkcyjnych4 (DFM) feedback, don’t accept a simple "yes, we do that." A vague answer is a red flag.

Ask for specifics. How is the feedback documented and delivered? Who on their team is involved? Can they show you a sample DFM report? At PTSMAKE, we provide a detailed, actionable report before any machining begins. This prevents costly errors.

Analyzing Lead Time Commitments

Another critical area is lead time. The urgency for a prototype is very different from a full production run. A reliable shop must have clear processes for both.

Here’s how to evaluate their responses:

| Lead Time Aspect | Vague Answer | Strong Answer |

|---|---|---|

| Prototyp | "A few weeks, maybe." | "5-7 business days for standard parts. We provide a firm ship date upon order confirmation." |

| Produkcja | "Depends on the quantity." | "Our standard is 3-4 weeks after first article approval. We will provide a detailed GANTT chart." |

Specific, confident answers demonstrate a robust scheduling system. It shows they understand the demands of modern manufacturing.

Asking detailed questions about process, technology, and lead times is vital. These questions help you assess a supplier’s true capability and reliability, moving beyond simple quotes to find a real manufacturing partner for your Boston-based needs.

How to Ensure Consistent Quality with Your Boston CNC Supplier

Inconsistent quality is a project killer. One batch of parts is perfect, but the next is unusable. This stops your assembly line and inflates costs.

True consistency isn’t about luck. It’s the result of a rigorous, documented system.

The Foundation: Documented QC Procedures

Your supplier must have clear, written quality control (QC) procedures. This is the foundation for achieving consistent part quality Boston.

Na co zwrócić uwagę

Ask to see their quality manual. It should detail their processes for inspection and control.

| Typ dokumentu | Cel |

|---|---|

| Quality Manual | Outlines the entire quality system |

| Work Instructions | Step-by-step guides for operators |

| Calibration Records | Proof that measuring tools are accurate |

| Certyfikaty materiałowe | Traceability for raw materials |

A solid quality system goes beyond a manual. It involves active, documented verification at critical stages. This is key to effective CNC machining quality control Boston.

Verifying the First Piece: FAI Reports

Before a full production run, always request a First Article Inspection (FAI) report. This document proves that the first part produced meets every dimension and specification on your drawing.

At PTSMAKE, we see the FAI as a critical partnership step. It confirms our setup is perfect before we machine hundreds or thousands of parts.

Maintaining Consistency: SPC

For larger production runs, Statistical Process Control (SPC) is essential. It uses statistical methods to monitor and control the manufacturing process in real time. This ensures quality remains stable throughout the entire run.

SPC helps catch potential issues before they result in out-of-spec parts. It relies on metrics like process capability indices5 to predict performance. This commitment aligns with top Boston precision machining standards.

Oto szybkie porównanie:

| Metoda | When It’s Used | Główny cel |

|---|---|---|

| FAI | At the start of a production run | To validate the setup and first part |

| SPC | During the entire production run | To monitor and maintain process stability |

Inconsistent parts are a failure of process, not a random event. To ensure reliability, partner with a Boston supplier that proves their commitment through documented QC, First Article Inspections, and Statistical Process Control. This is non-negotiable for consistent quality.

The Real Cost of CNC Machining in Boston: A Complete Breakdown

Looking at a quote for CNC machining in Boston can be tricky. The final number is more than just labor and material. It’s a mix of several key factors. Understanding these drivers is crucial for managing your budget effectively.

Unpacking the Core Cost Factors

Several elements directly influence your final price.

Material Selection and Part Complexity

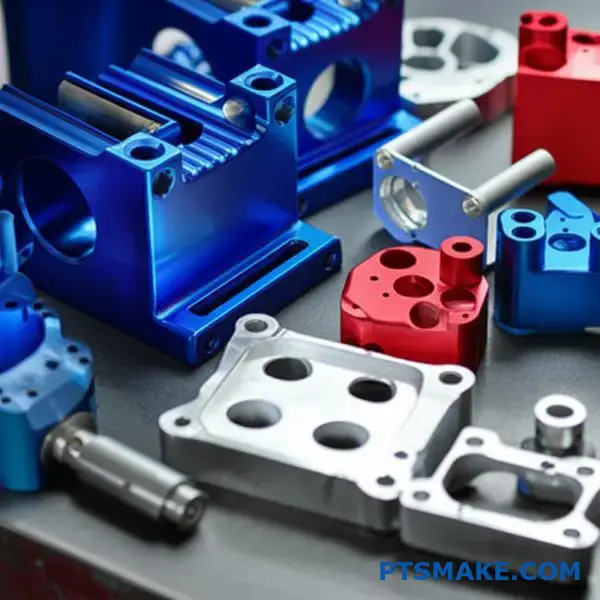

The material you choose is a primary cost driver. Standard aluminum is much cheaper than aerospace-grade titanium. Similarly, a simple block part costs less than one with complex curves and deep pockets.

Tolerances and Surface Finishes

Tighter tolerances require more precise machine setups and longer cycle times. Special surface finishes like anodizing or electropolishing also add extra steps and costs to the process.

Here is a quick breakdown of major pricing factors:

| Czynnik kosztowy | Poziom wpływu | Uwaga |

|---|---|---|

| Wybór materiału | Wysoki | Exotic alloys increase cost significantly. |

| Złożoność części | Wysoki | Intricate designs require more machine time. |

| Tolerancje | Średni | Tighter specs demand more precision. |

| Wielkość zamówienia | Wysoki | Higher volumes lower the per-unit price. |

The Power of Smart Design Choices

The quote you receive is not set in stone. The most significant way to achieve cost-effective CNC Boston services is through smart design, specifically by applying Design for Manufacturability (DFM). This isn’t just a technical term; it’s a practical approach to cost reduction.

At PTSMAKE, DFM is a core part of our process. We analyze a design before any metal is cut. We look for opportunities to make manufacturing simpler, faster, and therefore, more affordable for our clients.

DFM in Action: Reducing Costs

Simple changes can have a big impact. For example, using a standard corner radius that matches a common tool can eliminate the need for tool changes. This saves significant time and money.

Defining tolerances clearly using systems like Geometryczne wymiarowanie i tolerowanie (GD&T)6 is also vital. It prevents over-engineering parts that don’t require extreme precision, which directly cuts down on machining costs.

Working with clients on DFM, we have seen part costs reduced by optimizing design features.

| Element projektu | Before DFM | After DFM | Wynik |

|---|---|---|---|

| Pocket Corners | Sharp, custom radii | Standardized radii | Faster machining |

| Hole Depths | Rozmiary niestandardowe | Standard drill depths | Less custom tooling |

| Tolerancje | Uniformly tight | Optimized by function | Lower inspection cost |

Understanding the key drivers of CNC machining costs—materials, complexity, tolerances, and volume—is the first step. Applying rigorous Design for Manufacturability (DFM) principles is how you truly optimize your budget and ensure a successful project outcome in the Boston area.

On-time delivery is non-negotiable. Delays can derail your entire project schedule. It’s important to understand realistic timelines from the start.

Prototyping needs speed. Production demands consistency and scale. These two phases have very different lead times.

Typical Turnaround Times

Navigating ‘CNC machining lead times Boston’ requires clear expectations. Here’s a general guide for planning purposes.

| Part Stage | Estimated Lead Time |

|---|---|

| Proste prototypy | 3-7 Business Days |

| Złożone prototypy | 7-15 Business Days |

| Serie produkcyjne | 3-6+ Weeks |

These are estimates. Your project’s specifics will determine the final schedule.

Understanding what drives these timelines is key to managing them. Delays often stem from a few predictable sources. Effective management can mitigate nearly all of them.

Factors That Cause Delays

Several variables can impact your delivery schedule.

Pozyskiwanie materiałów

Specialty alloys or plastics can have long procurement times. We always verify material availability at the quoting stage to prevent surprises.

Złożoność projektu

Parts with intricate geometries or extremely tight tolerances require more programming and machine time. A Design for Manufacturability (DFM) review helps streamline this.

Potrzeby przetwarzania końcowego

Finishing steps like anodizing, plating, or heat treatment add time. Coordinating with third-party vendors requires careful scheduling. A reliable partner manages this logistics flow seamlessly.

Proactive Scheduling and Management

Achieving fast turnaround CNC in Boston isn’t about rushing. It’s about smart planning. We use methods like the Metoda ścieżki krytycznej7 to map out every step. This identifies potential bottlenecks before they become problems, ensuring reliable, on-time delivery for Boston machining projects.

| Common Bottleneck | Our Mitigation Strategy |

|---|---|

| Vague requirements | Detailed kickoff and DFM review |

| Unforeseen machine issues | Preventative maintenance schedule |

| Third-party finishing delays | Strong vendor relationships and buffer time |

This structured approach transforms scheduling from a guess into a science.

Understanding realistic lead times, common delay factors, and a partner’s scheduling strategy is crucial. Proactive management and clear communication are the foundations of on-time delivery, ensuring your project stays on track from prototype to production.

Advanced Materials Guide for Boston CNC Machining Projects

Choosing the right material is critical for any CNC machining project in Boston. The selection directly impacts performance, cost, and lead time. It’s a balance of mechanical properties and budget.

For engineers and designers, this choice defines the final part’s success. Let’s explore common options.

Aluminum Alloys: The Workhorses

Aluminum is popular for its strength-to-weight ratio. Two alloys dominate our work at PTSMAKE.

6061 vs. 7075 Aluminum

| Własność | Aluminium 6061 | Aluminium 7075 |

|---|---|---|

| Siła | Dobry | Doskonały |

| Obrabialność | Doskonały | Dobry |

| Odporność na korozję | Doskonały | Uczciwy |

| Koszt | Niższy | Higher (~40-50%) |

| Wspólne użytkowanie | General-purpose parts, fixtures | High-stress, aerospace parts |

6061 is a versatile and cost-effective choice. 7075 offers superior strength for demanding applications.

Opcje ze stali nierdzewnej

When corrosion resistance is key, stainless steel is the answer. The two most common grades we see in Boston machining projects are 304 and 316.

304 is the standard for general applications. It offers good corrosion resistance and is widely available. However, for projects exposed to chlorides, like marine environments, 316 is superior due to its molybdenum content. This addition significantly enhances its resistance to pitting and crevice corrosion. This upgrade in performance comes with a moderate increase in material cost and slightly tougher machining.

Engineering Plastics CNC Boston

Beyond metals, engineering plastics offer unique advantages. Materials like PEEK and Delrin provide excellent chemical resistance, low weight, and self-lubricating features. These are ideal for specific applications where metal might fail. Their trybologiczny8 properties are a key consideration.

PEEK vs. Delrin (Acetal)

Here is a quick comparison based on projects we’ve handled.

| Własność | PEEK | Delrin (Acetal) |

|---|---|---|

| Wydajność | High-temp, chemical resistant | Niskie tarcie, wysoka sztywność |

| Obrabialność | Dobry | Doskonały |

| Koszt | Bardzo wysoka | Umiarkowany |

| Zastosowanie | Implanty medyczne, lotnictwo i kosmonautyka | Bearings, gears, fixtures |

Choosing between them depends heavily on the operating environment and budget. Delrin is a go-to for mechanical components, while PEEK excels in extreme conditions. This is a common discussion for CNC machining materials Boston projects.

Material selection is a crucial tradeoff. Balancing performance requirements like strength and corrosion resistance against machinability and budget is key. This decision sets the foundation for a successful CNC machining project, from prototypes to full production runs in the Boston area.

5-Axis CNC Machining in Boston: When and Why You Need It

Deciding if your project needs 5-axis CNC machining in Boston can be tricky. It’s not always necessary. However, for certain parts, it’s the only practical solution.

This advanced technology shines when dealing with highly complex geometries. It reduces production time and improves the final part’s accuracy. It is a game-changer for specific applications. Let’s explore when to make that call.

Key Differences: 3-Axis vs. 5-Axis

| Cecha | Obróbka 3-osiowa | Obróbka 5-osiowa |

|---|---|---|

| Ruch narzędzia | X, Y, Z axes | X, Y, Z + 2 rotational axes |

| Najlepsze dla | Prostsze, pryzmatyczne części | Complex curves, undercuts |

| Konfiguracje | Multiple setups often needed | Często pojedyncza konfiguracja |

| Dokładność | Dobry | Excellent, less error |

Odblokowywanie złożonych geometrii

The main advantage of 5-axis machining is its ability to create intricate shapes. Think of parts with deep cavities or curved surfaces. A 3-axis machine simply cannot reach these areas without multiple, time-consuming setups.

Reduced Setups, Faster Turnaround

For complex part machining in Boston, fewer setups mean faster delivery. Each time a part is removed and re-fixtured, time is lost. With 5-axis, we can often machine five sides of a part in a single operation. This efficiency directly translates to shorter lead times for you.

Improved Accuracy and Finish

Fewer setups also lead to higher accuracy. Every time a part is moved, there’s a risk of minor misalignment. This can lead to stos tolerancji9, where small errors accumulate. Boston multi-axis machining avoids this by completing most, if not all, work in one go. The tool can also approach the workpiece at an optimal angle, resulting in a superior surface finish.

Does Your Project Need 5-Axis Capability?

Use this table as a quick guide. If your project ticks multiple boxes in the "5-Axis" column, it’s a strong candidate.

| Project Characteristic | Better for 3-Axis | Ideal for 5-Axis |

|---|---|---|

| Geometria części | Proste, płaskie powierzchnie | Complex curves, organic shapes |

| Cechy | Holes on a single plane | Angled holes, undercuts |

| Accuracy Needs | Standardowe tolerancje | Very tight tolerances (<0.025mm) |

| Wielkość produkcji | High volume, simple parts | Prototypy, niski i średni wolumen |

5-axis CNC machining is a powerful tool for complex parts. It streamlines production by reducing setups, which boosts accuracy and shortens lead times. It is the best choice for intricate designs where precision cannot be compromised.

Prototype to Production: Streamlining Your Boston Manufacturing Process

The leap from a validated prototype to full-scale production is where many great ideas falter. This transition is not just about making more units; it’s a completely different challenge.

The Prototyping Mindset vs. Production Reality

In Boston, the focus on prototypowa obróbka CNC is often on proving a concept. Speed and functional accuracy are key. But production demands a shift in thinking.

| Etap | Główny cel | Kluczowe wskaźniki |

|---|---|---|

| Prototyp | Concept Validation | Speed, Functionality |

| Produkcja | Scalability & Cost | Repeatability, Efficiency, Cpk |

This shift can introduce risks if not managed by a single, knowledgeable partner.

The Power of a Single Partner

Choosing one partner for both prototyping and production is the most effective strategy for streamlining your process. Why? It eliminates the knowledge gap. The lessons we learn during prototyping directly inform our approach to Boston production machining.

This continuity is crucial. When a new supplier takes over for production, they have to re-learn your design’s nuances. This costs time and money. It also introduces the risk of misinterpretation.

Eliminating Re-Engineering Delays

With a unified partner like PTSMAKE, the design for manufacturability (DFM) insights gained during prototyping are already baked into the production plan. There is no hand-off, only a transition. This ensures that scaling your manufacturing in Boston is seamless and efficient.

| Podejście | Design Consistency | Transfer wiedzy | Poziom ryzyka |

|---|---|---|---|

| Two Suppliers | Niski | Inefficient / Lost | Wysoki |

| Single Partner | Wysoki | Seamless | Niski |

This seamless transfer of knowledge is essential for maintaining quality. When we understand a part’s history, we anticipate production challenges. We’ve already refined toolpaths and material choices. True scalability requires this deep, continuous understanding of the project. This is how we ensure that a part’s Projektowanie pod kątem możliwości produkcyjnych (DFM)10 is not just a one-time check, but an evolving process.

Using a single, experienced partner for your journey from prototype to production mitigates risk. It ensures design intent is preserved, accelerates timelines, and creates a smoother path for scaling your manufacturing operations in Boston and beyond.

The Hidden Risks of Choosing the Cheapest Boston CNC Machining Quote

Everyone wants a good deal. But when it comes to CNC machining in Boston, the lowest price can be a trap. It often signals sacrifices in critical areas.

The initial savings can quickly disappear. You might face costs from delays, rework, or part failures down the line. It’s a classic case of paying less now, but much more later.

The Lure of the Low Quote

A cheap quote looks great on a spreadsheet. However, it rarely reflects the total cost of a project. True value is a balance of price, quality, and reliability.

Boston Machining: Value vs. Cost

Consider the real trade-offs. A focus on value protects your project’s integrity and timeline. Prioritizing only cost introduces significant risks.

Oto proste porównanie:

| Cecha | Cheapest Quote Shop | Value-Oriented Partner |

|---|---|---|

| Cena początkowa | Najniższy | Konkurencyjność |

| Material Quality | Questionable | Certified |

| Komunikacja | Slow / Unclear | Proactive / Clear |

| Final Cost | Often Higher | As Quoted |

Choosing reliable CNC services in Boston from the start is the smarter financial decision.

When evaluating the risks of cheap CNC machining in Boston, you must look beyond the initial number. Low-cost providers often have to cut corners somewhere to make a profit. This can manifest in several dangerous ways for your project.

Corner-Cutting on Quality

The most common issue is compromised quality. This could mean using a lower-grade alloy than specified. It could also involve skipping essential deburring or surface finishing steps. These small cuts save the shop money but can lead to catastrophic part failure in the field.

Another risk is rushed production. This leads to poor dimensional accuracy and parts that don’t meet tolerance specifications. When parts don’t fit together correctly, the entire assembly is compromised. This can lead to issues like układanie tolerancji11, where minor errors accumulate into a major problem.

Communication and Hidden Fees

Poor communication is another red flag. Slow responses and vague answers can derail your project timeline. What seems like a bargain is no longer cheap when you miss a critical launch date.

Be aware of the following hidden risks:

| Risk Category | Konkretny przykład | Potencjalne konsekwencje |

|---|---|---|

| Materiały | Uncertified metal substitution | Part failure, safety hazards |

| Processes | Skipped quality checks | Out-of-spec parts |

| Komunikacja | Delayed email responses | Production schedule delays |

| Billing | Surprise tooling or shipping fees | Budget overruns |

At PTSMAKE, we focus on transparent pricing and clear communication. We believe Boston machining value vs cost is not just about the price. It’s about a reliable partnership that protects your project.

Choosing the cheapest CNC machining quote in Boston often means accepting hidden risks. These can include poor quality, communication breakdowns, and unexpected fees. True value comes from a reliable partner who delivers quality parts on time and within the quoted budget.

Solving Complex Geometry Challenges with Boston CNC Experts

Complex designs often look great on screen. But they can be a nightmare to machine. This is where experience really matters.

True experts turn your difficult designs into reality. They handle challenges with ease.

The Thin Wall Dilemma

Thin walls can easily warp or break. This requires careful toolpath planning. It also needs precise speed and feed adjustments.

Navigating Deep Pockets

Deep pockets pose another issue. Chip evacuation becomes critical. So does tool rigidity to avoid vibration. This is a common hurdle in difficult part machining Boston.

| Wyzwanie | Podejście tradycyjne | Expert Solution |

|---|---|---|

| Cienkie ściany | Slow speeds, risk of failure | Optimized toolpaths, stress relief |

| Głębokie kieszenie | Multiple setups, long tools | High-pressure coolant, special tooling |

A capable partner foresees these problems. They provide solutions before production begins.

Turning a complex digital file into a physical part requires more than just pushing "start" on a machine. It’s about a deep understanding of physics, materials, and tooling. Many Boston machining design challenges stem from a disconnect between design intent and manufacturing reality. This is where a partnership truly shines.

DFM: The Collaborative Advantage

We use a Design for Manufacturability (DFM) process. This isn’t just a report; it’s a conversation. We work with your engineers to identify potential issues early. This collaborative approach saves time and money. It prevents costly redesigns down the line.

We analyze features that can cause problems. This includes sharp internal corners or features that create excessive ugięcie narzędzia12. Our goal is to maintain your design’s integrity while making it manufacturable.

Solving Intricate Features

Small, intricate features require specialized tooling and techniques. For a medical device component we produced, we used micro-milling to achieve features smaller than a millimeter. This level of detail is a core part of handling complex CNC machining Boston.

| DFM Step | Nasza akcja | Korzyści dla klienta |

|---|---|---|

| 1. Przegląd projektu | Analyze CAD for risks | Identify cost drivers early |

| 2. Suggestion | Propose minor tweaks | Improve part strength |

| 3. Validation | Simulate toolpaths | Guarantee manufacturability |

| 4. Finalization | Agree on final design | Faster, reliable production |

This DFM process transforms potential failures into manufacturing successes.

Overcoming complex geometries like thin walls and deep pockets requires more than advanced machines. It demands a proactive partnership built on collaborative DFM to bridge the gap between design and reality, ensuring high-quality, manufacturable parts.

Surface Finishes and Post-Processing for Boston-Machined Parts

The journey of a part doesn’t end when it comes off the CNC machine. The final steps, surface finishing and post-processing, are critical. They determine the part’s final look, feel, and performance.

These processes add durability, corrosion resistance, and specific aesthetic qualities. They transform a raw component into a finished product. Choosing the right finish is essential for meeting project specifications.

Common Surface Finishes

A good finish protects the part and improves its function. We often recommend these options for machined aluminum and steel parts.

| Typ wykończenia | Główny cel | Wspólne materiały |

|---|---|---|

| Anodowanie | Odporność na korozję i zużycie | Aluminium |

| Malowanie proszkowe | Durable Color Finish | Metale |

| Poszycie | Conductivity, Hardness | Różne metale |

| Pasywacja | Odporność na korozję | Stal nierdzewna |

Operacje dodatkowe

These steps add final features to the machined part. They are crucial for assembly and identification purposes.

Selecting the right finish goes beyond aesthetics. It’s about meeting functional requirements for durability, conductivity, or chemical resistance. For projects requiring robust CNC machining finishes in Boston, understanding the specifications is key.

Finishes: A Deeper Look

Anodizing Specifications

When customers ask for anodizing services in Boston, they often need specifics. Type II anodizing offers a decorative, corrosion-resistant finish. Type III, or hardcoat, provides a much thicker, wear-resistant layer for demanding applications. Both can be dyed in various colors.

Coating and Plating

Powder coating provides a durable, uniform finish that is more resilient than traditional paint. It’s great for parts exposed to harsh environments. Plating, on the other hand, adds a thin metallic layer. Nickel plating adds wear resistance, while gold plating ensures excellent conductivity for electronics.

Essential Post-Processing

Secondary operations are just as important. Tapping creates internal threads for screws. Engraving adds part numbers, logos, or instructions. These Boston part post-processing steps ensure parts are ready for final assembly without delay. At PTSMAKE, we integrate these into the production plan. This removes coordination headaches for our clients. Many parts require a cleaning process to remove contaminants before finishing. This process, known as pasywacja13, enhances corrosion resistance without adding a coating.

Surface finishes and secondary operations are integral to the manufacturing process. They ensure the machined part meets all functional, aesthetic, and assembly requirements, turning a precisely cut component into a ready-to-use product.

Streamline Your Boston CNC Projects with PTSMAKE Precision

Ready to take your CNC machining Boston projects to the next level? Send your RFQ or inquiry to PTSMAKE today. Experience unmatched quality, reliability, and responsive communication from prototype to production—trusted by top brands worldwide. Partner with PTSMAKE for peace of mind and consistent results!

Learn how GD&T ensures your designs are interpreted and manufactured with absolute precision every single time. ↩

Click to understand how this system ensures your part’s design intent is met with precision. ↩

Understand how this symbolic language communicates precise engineering tolerances on your technical drawings. ↩

Learn how DFM feedback can significantly reduce your production costs and improve part quality. ↩

Learn how these metrics predict if a process can consistently meet your tolerance requirements. ↩

Learn how precise GD&T callouts can impact your final machining costs and part functionality. ↩

Learn how this project management technique keeps your CNC project on schedule by identifying critical tasks. ↩

Understand how these properties impact wear and friction in your moving components. ↩

Understand how small errors accumulate and impact your part’s final precision. ↩

Learn how optimizing your design for the manufacturing process can reduce costs and improve quality. ↩

Discover how small, acceptable variances can compound to cause major assembly issues. ↩

Understand how this phenomenon affects precision and how our experts prevent it. ↩

Learn the chemistry behind how this treatment enhances the natural corrosion resistance of stainless steel. ↩