Rozważasz obróbkę CNC w Chinach, ale martwisz się o spójność jakości i niezawodność dostawcy? Wielu zachodnich producentów staje przed tym samym dylematem - równoważąc oszczędności z ryzykiem opóźnień w produkcji i wyzwaniami komunikacyjnymi.

Chińska obróbka CNC oferuje oszczędność kosztów 30-50% w porównaniu z zachodnimi dostawcami, zapewniając jednocześnie konkurencyjną jakość dzięki zaawansowanemu sprzętowi, wykwalifikowanej sile roboczej i ugruntowanej infrastrukturze produkcyjnej, która obsługuje zarówno prototypy, jak i potrzeby produkcji masowej.

Współpracowałem z dziesiątkami zachodnich firm, które początkowo wahały się przed pozyskiwaniem dostawców z Chin ze względu na obawy dotyczące precyzji, komunikacji i zarządzania projektami. Sytuacja uległa jednak znaczącej zmianie. Obecnie wiodące chińskie warsztaty CNC korzystają z tego samego zaawansowanego sprzętu, co ich zachodnie odpowiedniki i obsługują wymagające branże, takie jak lotnictwo i kosmonautyka oraz urządzenia medyczne. Kluczem jest wiedza, jak oceniać dostawców, skutecznie zarządzać komunikacją i ustanawiać odpowiednie kontrole jakości. Niniejszy przewodnik zawiera wszystko, czego potrzebujesz, aby podejmować świadome decyzje dotyczące współpracy z chińskimi firmami zajmującymi się obróbką CNC.

Dlaczego globalni producenci wybierają obróbkę CNC w Chinach?

Starasz się znaleźć usługi obróbki CNC, które równoważą koszty, szybkość i bezkompromisową jakość? Czy poruszanie się po globalnych łańcuchach dostaw niestandardowych części wydaje się przytłaczająco złożone i ryzykowne?

Globalni producenci wybierają obróbkę CNC w Chinach ze względu na potężne połączenie opłacalności, zaawansowanych możliwości technologicznych i ogromnej skalowalności produkcji. Dojrzały ekosystem produkcyjny Chin, wykwalifikowana siła robocza i szybka industrializacja zapewniają niezawodne rozwiązanie dla wszystkiego, od szybkich prototypów po duże serie produkcyjne.

Fundacja: Światowej klasy ekosystem produkcyjny

Kiedy ludzie myślą o produkcji w Chinach, często zwracają uwagę na oszczędność kosztów. Chociaż jest to część historii, prawdziwa przewaga leży w głębi i dojrzałości ekosystemu przemysłowego. Nie powstał on z dnia na dzień. Dziesięciolecia ukierunkowanego rozwoju stworzyły wysoce zintegrowaną sieć, w której wszystko, czego potrzebuje projekt, jest łatwo dostępne. Od dostawców surowców do specjalistycznych stopów po obiekty do obróbki końcowej, takie jak anodowanie lub obróbka cieplna, cały łańcuch dostaw jest skoncentrowany geograficznie. Taka integracja znacznie skraca czas realizacji zamówień. Zamiast współpracować z wieloma dostawcami w różnych regionach, często można znaleźć jednego partnera, który zarządza całym procesem. W naszych poprzednich projektach w PTSMAKE zaobserwowaliśmy, że konsolidacja ta skróciła czas realizacji projektu o tygodnie, po prostu eliminując przeszkody logistyczne między etapami produkcji. Ta kompleksowa infrastruktura zapewnia stabilność i szybkość, które są trudne do odtworzenia gdzie indziej.

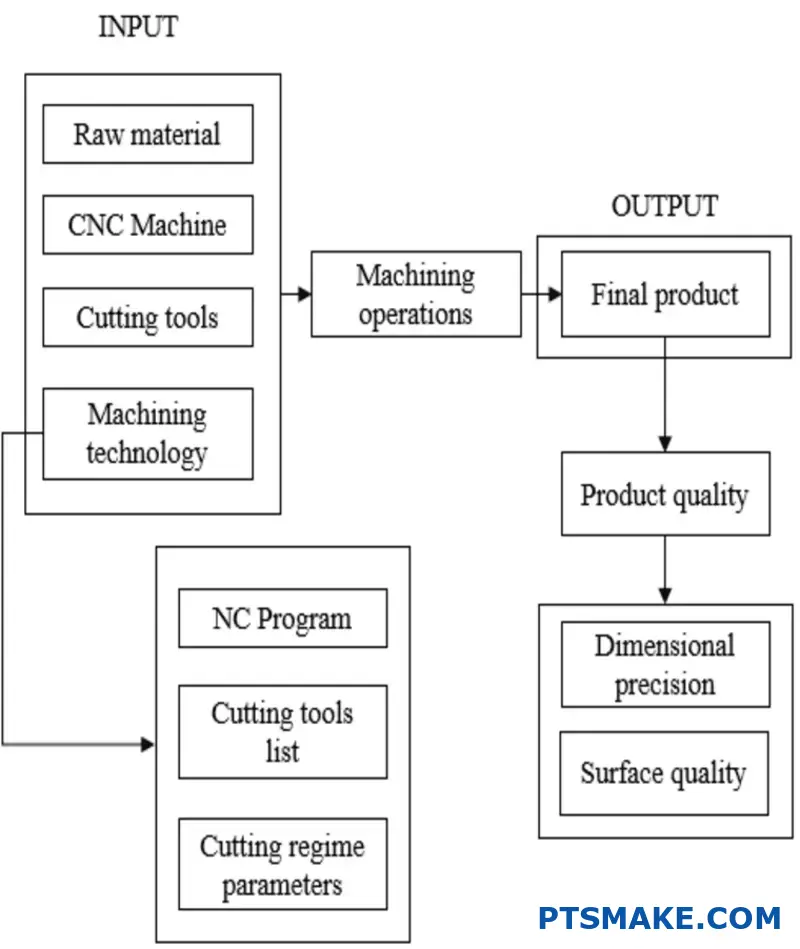

Wykorzystanie zaawansowanych technologii na dużą skalę

Etykieta "Made in China" znacząco ewoluowała. Obecnie najlepsi chińscy producenci są wczesnymi użytkownikami i inwestują w najnowocześniejsze technologie. Często można zobaczyć warsztaty wypełnione zaawansowanymi 5-osiowymi centrami obróbczymi CNC, które mogą wytwarzać bardzo złożone geometrie w jednym ustawieniu, poprawiając precyzję i wydajność. To zaangażowanie w technologię rozciąga się na oprogramowanie, z powszechnym wykorzystaniem zaawansowanych platform CAD/CAM zapewniających płynne przejście od projektu cyfrowego do części fizycznej. Ma to kluczowe znaczenie dla zachowania intencji projektowych i przestrzegania precyzyjnych specyfikacji, takich jak te określone przez Wymiarowanie geometryczne i tolerowanie1. Inwestycja nie polega tylko na posiadaniu najnowszych maszyn; chodzi o rozwijanie wiedzy specjalistycznej, aby wykorzystać je do granic możliwości, produkując części, które spełniają rygorystyczne wymagania jakościowe w branżach takich jak lotnictwo i kosmonautyka oraz urządzenia medyczne. Ta biegłość technologiczna jest głównym powodem, dla którego firmy zwracają się do Chin po więcej niż tylko proste komponenty.

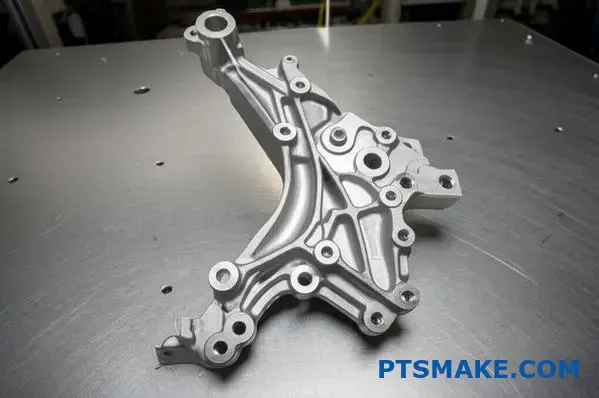

Od pojedynczego prototypu do masowej produkcji

Jedną z największych zalet jest skalowalność. Wielu inżynierów staje przed wspólnym wyzwaniem: partner, który stworzył świetny prototyp, nie poradzi sobie z produkcją 10 000 sztuk. I odwrotnie, fabryka masowej produkcji nie będzie zawracać sobie głowy jednorazowym prototypem. Chiński krajobraz produkcyjny w elegancki sposób rozwiązuje ten problem. Ekosystem wspiera cały cykl życia produktu, od wstępnej weryfikacji koncepcji po produkcję na pełną skalę. Prototypy można opracowywać i iterować szybko i ekonomicznie, a po sfinalizowaniu projektu można zwiększyć produkcję u tego samego lub pobliskiego partnera, zapewniając spójność. To płynne przejście stanowi strategiczną zaletę, oszczędzając czas i zmniejszając ryzyko związane ze zmianą dostawcy w trakcie realizacji projektu.

| Cecha | Faza prototypowania | Faza produkcji masowej |

|---|---|---|

| Typowa objętość | 1 - 100 jednostek | 1,000 - 1,000,000+ jednostek |

| Główny cel | Walidacja projektu, testowanie dopasowania/funkcji | Efektywność kosztowa, spójność, szybkość |

| Przewaga Chin | Szybka realizacja, niskie koszty konfiguracji | Ekonomia skali, ogromne możliwości |

| Nasza rola w PTSMAKE | Informacje zwrotne od DfM, sugestie dotyczące materiałów | Optymalizacja procesów, kontrola jakości |

Element ludzki: Doświadczenie i kunszt

Podczas gdy maszyny wykonują cięcie, to ludzie stojący za nimi gwarantują jakość. Chiny posiadają ogromną i głęboko wykwalifikowaną siłę roboczą inżynierów, programistów i mechaników. Nie chodzi tylko o dużą pulę siły roboczej; chodzi o pokolenie, które dorastało w gospodarce skoncentrowanej na produkcji. Mają oni praktyczne doświadczenie i zrozumienie tego, co jest potrzebne do przekształcenia złożonego pliku CAD w bezbłędnie wykończoną część. Z mojego doświadczenia wynika, że najlepsi chińscy partnerzy łączą wiedzę techniczną z silną etyką pracy i zaangażowaniem w rozwiązywanie problemów. Gdy projekt stanowi wyzwanie produkcyjne, nie poddają się; współpracują, aby znaleźć rozwiązanie. W PTSMAKE, nasz zespół kontroli jakości jest doskonałym przykładem. To nie tylko inspektorzy; to doświadczeni profesjonaliści w dziedzinie produkcji, którzy rozumieją niuanse procesu obróbki CNC, co pozwala im wychwycić potencjalne problemy na długo przed ich wystąpieniem. Ta ludzka wiedza jest niematerialnym, ale nieocenionym zasobem, który bezpośrednio przyczynia się do sukcesu projektu.

Dlaczego opłacalność wykracza poza pracę

Dyskusja na temat kosztów jest często zbyt uproszczona. Podczas gdy koszty pracy są czynnikiem, prawdziwa opłacalność obróbki CNC w Chinach wynika z wydajności systemowej. Zintegrowany łańcuch dostaw, o którym wspomniałem wcześniej, zmniejsza koszty logistyczne i koszty pozyskiwania materiałów. Wysoki poziom automatyzacji i zaawansowane maszyny prowadzą do krótszych czasów cykli i niższych wskaźników błędów, co przekłada się na mniejszą ilość odpadów i przeróbek. Co więcej, sama skala produkcji tworzy ogromne korzyści skali. Konkurencja jest zaciekła, co zmusza dostawców do ciągłej optymalizacji procesów w celu oferowania lepszej wartości. Nie chodzi o znalezienie "najtańszej" opcji, ale o osiągnięcie optymalnej równowagi między ceną, jakością i szybkością. Celem jest uzyskanie najlepszej całkowitej wartości lub całkowitego kosztu posiadania (TCO), a nie tylko najniższej ceny za część. Nieco tańsza część, która zawodzi w terenie lub powoduje opóźnienia w produkcji, w dłuższej perspektywie okazuje się znacznie droższa.

| Współczynnik kosztów | Wyzwanie związane z tradycyjnym zaopatrzeniem | Zalety obróbki CNC w Chinach |

|---|---|---|

| Surowce | Wysoki koszt, ograniczona dostępność lokalna | Scentralizowane zaopatrzenie, masowa siła nabywcza |

| Oprzyrządowanie i konfiguracja | Drogie w przypadku małych serii | Wydajne procesy konfiguracji, niższe koszty ogólne |

| Wydajność procesu | Dłuższy czas cyklu, możliwość wystąpienia błędu | Wysoka automatyzacja, zoptymalizowane przepływy pracy |

| Logistyka | Złożona koordynacja, wiele punktów wysyłki | Zintegrowany łańcuch dostaw, usprawniony eksport |

Budowanie odpornego łańcucha dostaw

Wiele firm, co zrozumiałe, obawia się koncentracji produkcji w jednym kraju. Jednak baza produkcyjna Chin jest tak rozległa i zróżnicowana, że funkcjonuje bardziej jak kontynent dostawców niż pojedyncze źródło. Począwszy od technologicznego centrum Shenzhen, a skończywszy na przemysłowych zagłębiach Jiangsu i Zhejiang, różne regiony specjalizują się w różnych zdolnościach. Ta wewnętrzna różnorodność pozwala na wbudowaną redundancję. Jeśli w jednym obszarze wystąpią zakłócenia, produkcję często można przenieść do innego. Doświadczony partner na miejscu może pomóc w poruszaniu się po tym krajobrazie, budując łańcuch dostaw, który jest nie tylko wydajny, ale także odporny. Współpracując z uznanymi dostawcami, którzy mają sieć zaufanych dostawców wtórnych, można ograniczyć ryzyko i zapewnić ciągłość działalności.

Wybór obróbki CNC w Chinach oferuje strategiczną przewagę zbudowaną na ekosystemie zaawansowanej technologii, skalowalności i wykwalifikowanej siły roboczej. To połączenie zapewnia nie tylko oszczędność kosztów, ale także wydajność, jakość i odporność łańcucha dostaw, spełniając złożone wymagania nowoczesnej globalnej produkcji od prototypu do produkcji.

Równoważenie kosztów i jakości: Czego się spodziewać?

Czy kiedykolwiek zdarzyło Ci się patrzeć na wycenę obróbki CNC z Chin, która wydaje się zbyt dobra, aby mogła być prawdziwa? Zastanawiasz się, czy niska cena nie oznacza poświęcenia jakości, której wymaga Twój projekt?

Oczekuj znacznie niższych kosztów, często 30-50% niższych niż w przypadku zachodnich odpowiedników, ze względu na wydajność pracy i wydajność operacyjną. Jednak dostawcy z najwyższej półki osiągają to bez uszczerbku dla międzynarodowych standardów jakości, oferując ogromną wartość, która wykracza daleko poza początkową cenę.

Dekonstrukcja korzyści związanych z kosztami

Różnica w cenie nie jest magiczna; jest ona zakorzeniona w fundamentalnych czynnikach ekonomicznych i strukturalnych. Kiedy pozyskujesz Obróbka CNC w ChinachW ten sposób korzystasz z dojrzałego ekosystemu produkcyjnego. Zaczyna się od niższych kosztów pracy, ale błędem jest utożsamianie tego z niższymi umiejętnościami. Chiny mają ogromną pulę wysoko wykwalifikowanych i doświadczonych mechaników i inżynierów, których wynagrodzenie jest po prostu skalowane do innych kosztów utrzymania. Przewaga ta jest wzmacniana przez znaczną wydajność operacyjną. Łańcuchy dostaw surowców są niezwykle usprawnione i zlokalizowane, co zmniejsza koszty zaopatrzenia i czas realizacji.

Co więcej, wiodący chińscy producenci agresywnie inwestują w technologię. W naszych zakładach w PTSMAKE korzystamy z zaawansowanych 5-osiowych centrów CNC i zautomatyzowanych systemów, które działają 24 godziny na dobę, 7 dni w tygodniu. Ten poziom inwestycji zwiększa produktywność i, co ważniejsze, zwiększa precyzję i spójność, co bezpośrednio przekłada się na niższy koszt części bez poświęcania jakości. Ten parytet technologiczny jest kluczowym powodem, dla którego stare stereotypy na temat chińskiej produkcji są nieaktualne. Najlepsi dostawcy koncentrują się na wydajności i jakości, a nie tylko na taniej sile roboczej. Prawdziwe oszczędności wynikają z połączenia wykwalifikowanej siły roboczej, zoptymalizowanego łańcucha dostaw i zaawansowanej technologicznie automatyzacji.

Jak wiodący dostawcy gwarantują międzynarodową jakość

Niska cena jest bezwartościowa, jeśli części nie spełniają specyfikacji. W tym miejscu zaangażowanie dostawcy w jakość staje się najbardziej krytycznym czynnikiem. Renomowani chińscy dostawcy nie tylko mówią o jakości; wbudowują ją w swoje procesy. Punktem wyjścia jest zawsze solidny system zarządzania jakością (QMS), zazwyczaj certyfikowany zgodnie z normami ISO 9001. To nie jest tylko kawałek papieru; to ramy, które regulują każdy krok od wyceny do ostatecznej wysyłki.

Na poziomie praktycznym wiąże się to ze skrupulatną inspekcją i kontrolą procesu. Polegamy na zaawansowanym sprzęcie metrologicznym, takim jak współrzędnościowe maszyny pomiarowe (CMM) i projektory optyczne, aby sprawdzić, czy każdy wymiar jest zgodny z dokładnymi specyfikacjami określonymi w plikach CAD. Przestrzeganie standardów takich jak Geometryczne wymiarowanie i tolerowanie (GD&T)2 nie podlega negocjacjom, ponieważ zapewnia uniwersalny język do definiowania i kontrolowania cech części. Weryfikacja materiałów to kolejny kamień węgielny. Zapewniamy certyfikaty materiałowe dla każdej partii, zapewniając, że użyty metal lub tworzywo sztuczne jest dokładnie tym, co określił klient.

Oto uproszczone zestawienie podstawowych czynników kosztowych:

| Współczynnik kosztów | Obróbka CNC w Chinach | Zachodnia obróbka CNC (USA/UE) |

|---|---|---|

| Wykwalifikowana siła robocza | Niższy | Wyższy |

| Surowce | Często niższe ze względu na skalę i lokalną produkcję | Ogólnie wyższy |

| Koszty operacyjne | Niższy | Wyższe (czynsz, media, przepisy) |

| Łańcuch dostaw | Wysoce zintegrowany i wydajny | Może być bardziej rozdrobniony |

Integrując te kontrole jakości w całym procesie produkcyjnym, możemy z pewnością dostarczać części, które spełniają lub przewyższają standardy każdego producenta na świecie.

Realistyczne spojrzenie na ceny: Chiny kontra Zachód

Chociaż oszczędności są realne, warto zrozumieć, gdzie są one najbardziej znaczące. Zasada "30-50% taniej" jest dobrą ogólną wytyczną, ale rzeczywiste oszczędności zależą w dużej mierze od złożoności i ilości części. W naszym doświadczeniu w PTSMAKE widzieliśmy to w tysiącach projektów. W przypadku prostych, wysokonakładowych komponentów, których konstrukcja jest prosta, korzyści kosztowe chińskiego ekosystemu produkcyjnego są maksymalne. Oszczędności mogą czasami przekraczać 50% w porównaniu z wyceną z Ameryki Północnej lub Europy.

Jednak wraz ze wzrostem złożoności części, różnica w cenie ma tendencję do zmniejszania się. W przypadku skomplikowanych części 5-osiowych o wyjątkowo wąskich tolerancjach lub wymagających egzotycznych materiałów i specjalistycznej obróbki końcowej, oszczędności mogą być bliższe zakresowi 20-30%. Wynika to z faktu, że koszt staje się bardziej zależny od wyspecjalizowanych maszyn, specjalistycznego programowania i intensywnej kontroli jakości - czynników, w przypadku których różnica w kosztach jest mniej wyraźna. Kluczowe znaczenie ma analiza ofert w oparciu o konkretne wymagania projektu.

Oto tabela, która pomoże ustalić realistyczne oczekiwania:

| Złożoność części | Typowe oszczędności kosztów w Chinach | Kluczowe kwestie |

|---|---|---|

| Prosty, wysokowydajny | 40-60% | Dostępność materiałów, koszty logistyczne |

| Umiarkowanie złożony | 30-50% | Możliwości techniczne dostawcy, tolerancje |

| Wysoce złożone (np. 5-osiowe) | 20-40% | Wiedza inżynierska, kontrola jakości, komunikacja |

Ocena prawdziwej wartości: Dlaczego najniższa wycena nie zawsze jest najlepsza

Menedżer ds. zaopatrzenia skupiający się wyłącznie na najniższym koszcie jednostkowym traci z oczu szerszy obraz. Prawdziwa wartość to połączenie ceny, jakości, niezawodności i obsługi. Ukryte koszty złego dostawcy mogą szybko zniwelować wszelkie początkowe oszczędności. Pomyśl o skutkach finansowych opóźnionej dostawy, która zatrzymuje linię montażową, lub kosztach przeróbek i ponownej wysyłki części, które nie przeszły kontroli jakości. Ryzyko to jest realne, a jego ograniczenie jest warte niewielkiej dopłaty do ceny części.

W tym miejscu należy ocenić dostawcę jako partnera, a nie tylko sprzedawcę. Jedną z najważniejszych wartości dodanych jest komunikacja. Czy dostawca ma dedykowanego, anglojęzycznego kierownika projektu, który rozumie wymagania techniczne i szybko reaguje? Dla nas to nie podlega negocjacjom. Jasna komunikacja zapobiega kosztownym nieporozumieniom. Kolejnym krytycznym elementem jest wsparcie inżynieryjne. Prawdziwy partner zaoferuje informacje zwrotne dotyczące projektowania pod kątem możliwości produkcyjnych (DFM), sugerując drobne poprawki projektowe, które mogą skrócić czas obróbki, poprawić wytrzymałość części lub obniżyć koszty bez wpływu na funkcjonalność. Takie podejście oparte na współpracy jest cechą charakterystyczną najlepszych dostawców i zapewnia wartość, która znacznie przekracza liczbę na wycenie. Wybór odpowiedniego partnera dla Obróbka CNC w Chinach polega na znalezieniu najlepszej łącznej wartości, a nie tylko najniższej ceny.

Pozyskiwanie obróbki CNC z Chin zapewnia znaczne korzyści kosztowe bez poświęcania jakości. Kluczem jest spojrzenie poza wstępną wycenę i ocena systemów jakości dostawcy, praktyk komunikacyjnych i wsparcia inżynieryjnego, aby znaleźć prawdziwego partnera produkcyjnego, który zapewnia długoterminową wartość.

Zapewnienie precyzji i tolerancji dla krytycznych części?

Czy kiedykolwiek otrzymałeś partię "precyzyjnych" części, ale okazało się, że nie pasują? Frustracja związana z komponentami, które nie przeszły kontroli, może zniweczyć cały projekt, kosztując cenny czas i pieniądze.

Zapewnienie precyzji i tolerancji krytycznych części opiera się na triadzie doskonałości: inwestowaniu w najnowocześniejsze maszyny CNC, zatrudnianiu wysoko wykwalifikowanych techników i wdrażaniu rygorystycznych, wieloetapowych procesów zapewniania jakości. Dzięki takiemu połączeniu najlepsi dostawcy konsekwentnie dostarczają części spełniające najbardziej rygorystyczne specyfikacje.

Kiedy projektujesz części dla takich branż jak lotnictwo, urządzenia medyczne lub robotyka, "wystarczająco blisko" po prostu nie istnieje. Tolerancje mierzone są w mikronach, a awaria nie wchodzi w grę. Jak więc wiodące zakłady obróbki CNC w Chinach konsekwentnie spełniają te ekstremalne wymagania? To nie magia; to zdyscyplinowane, systematyczne połączenie technologii, wiedzy i kontroli procesu.

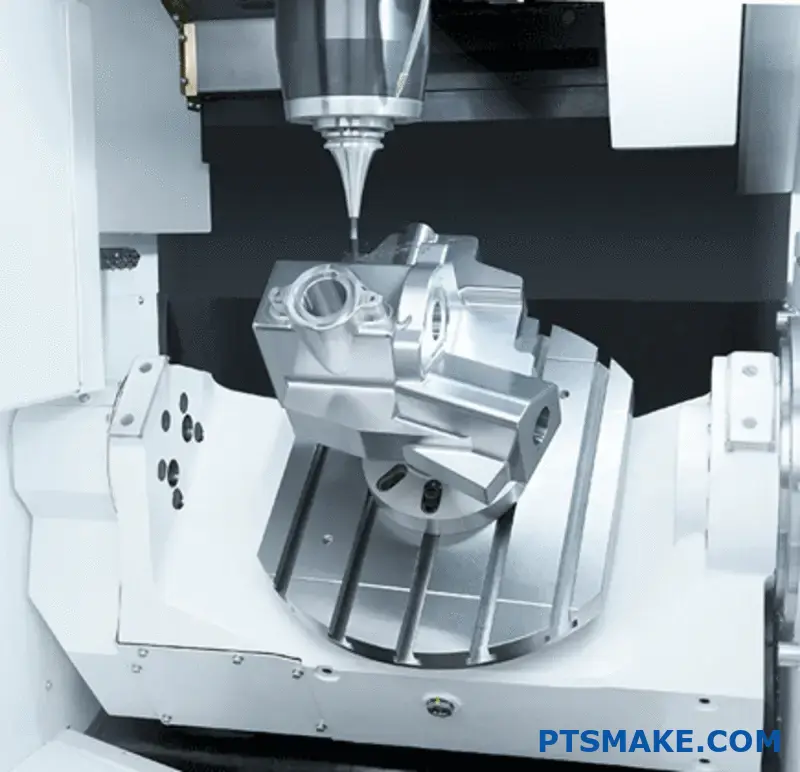

Fundacja: Zaawansowane maszyny CNC

Podstawą każdej precyzyjnej pracy jest sprzęt. Nie da się osiągnąć wąskich tolerancji przy użyciu przestarzałych lub źle utrzymanych maszyn. Wiodące zakłady intensywnie inwestują w najnowocześniejszy sprzęt, w szczególności 5-osiowe centra frezarskie CNC i tokarki typu szwajcarskiego. Maszyny 5-osiowe mają kluczowe znaczenie, ponieważ mogą obrabiać złożone geometrie w jednym ustawieniu. Za każdym razem, gdy trzeba usunąć zacisk i ponownie zamocować część, pojawia się ryzyko błędu. Minimalizując te ustawienia, znacznie zwiększamy dokładność. Tokarki typu szwajcarskiego są równie ważne w przypadku małych, skomplikowanych części powszechnych w medycynie i elektronice, zapewniając niesamowitą precyzję i stabilność przy dużych seriach. W PTSMAKE odkryliśmy, że regularna kalibracja i ścisły harmonogram konserwacji naszego sprzętu są tak samo ważne, jak początkowa inwestycja.

Czynnik ludzki: Wykwalifikowani technicy i programiści

Światowej klasy maszyna jest tak dobra, jak osoba, która ją obsługuje. Najbardziej pomijanym czynnikiem w precyzji jest często czynnik ludzki. Nasi technicy to nie tylko naciskacze przycisków; to rzemieślnicy, którzy rozumieją niuanse materiałów i narzędzi. Przekładają cyfrowy plik CAD na fizyczną rzeczywistość, podejmując krytyczne decyzje dotyczące ścieżek narzędzi, prędkości cięcia i posuwów w celu zarządzania ciepłem, wibracjami i zużyciem narzędzi. Ta wiedza ma kluczowe znaczenie podczas pracy z wymagającymi materiałami. Kluczową częścią tego procesu jest solidna Metrologia3co pozwala naszemu zespołowi weryfikować swoją pracę na każdym etapie. To połączenie umiejętności programowania i praktycznego doświadczenia jest niezbędne do rozwiązywania problemów na bieżąco i zapewnienia, że pierwsza część jest tak samo doskonała jak ostatnia.

Ramy: Rygorystyczne zapewnienie jakości

Ustrukturyzowany proces zapewniania jakości (QA) spaja wszystko razem. Jest to siatka bezpieczeństwa, która zapewnia, że żaden defekt się nie prześlizgnie. Nie jest to tylko końcowa kontrola; to wieloetapowy proces.

| Etap inspekcji | Cel | Najważniejsze kontrole i używany sprzęt |

|---|---|---|

| Kontrola surowców | Weryfikacja integralności materiału przed obróbką. | Skład materiału (analizator XRF), badanie twardości, kontrola wymiarów. |

| Kontrola w trakcie procesu | Wychwytywanie odchyleń podczas procesu obróbki. | Kontrola pierwszego elementu (FAI), regularne kontrole przeprowadzane przez operatorów przy użyciu suwmiarek, mikrometrów, sond CMM. |

| Kontrola końcowa | Aby potwierdzić, że wszystkie specyfikacje są spełnione przed wysyłką. | Kontrola wymiarów 100% za pomocą CMM, testowanie chropowatości powierzchni, kontrola wizualna pod kątem zadziorów/wad. |

To systematyczne podejście odróżnia niezawodnych dostawców od reszty. Buduje zaufanie i gwarantuje, że otrzymane części są naprawdę gotowe do użycia w krytycznych zastosowaniach.

Osiągnięcie wąskiej tolerancji dla jednej części to dobry początek, ale wymagające branże wymagają, aby ta sama precyzja była stosowana konsekwentnie w tysiącach komponentów, często z unikalnymi i trudnymi wymaganiami. Strategie zapewniające precyzję muszą być dostosowane do konkretnego zastosowania, niezależnie od tego, czy chodzi o skrzydło samolotu, narzędzie chirurgiczne czy ramię robota. To właśnie w tym obszarze doświadczenie dostawcy naprawdę się sprawdza.

Dostosowywanie procesów dla przemysłu lotniczego i obronnego

W sektorze lotniczym precyzja wykracza poza same wymiary. Chodzi o absolutną niezawodność i identyfikowalność. Klienci muszą znać całą historię komponentu, od kęsa surowca do gotowej części. Wymaga to skrupulatnej dokumentacji i przestrzegania rygorystycznych norm, takich jak AS9100. Podczas pracy z materiałami takimi jak tytan czy Inconel, które są bardzo trudne w obróbce, proces musi być dokładnie kontrolowany. Parametry cięcia są precyzyjnie dostrajane, aby zarządzać intensywnym ciepłem i ciśnieniem, zapobiegając naprężeniom materiału, które mogłyby zagrozić integralności części w terenie. Każda cecha jest definiowana przez Geometric Dimensioning and Tolerancing (GD&T), uniwersalny język, który nie pozostawia miejsca na błędną interpretację.

Spełnianie wymagań branży urządzeń medycznych

W przypadku urządzeń medycznych nacisk kładzie się na biokompatybilność, wykończenie powierzchni i absolutną czystość. Mikroskopijny zadzior na instrumencie chirurgicznym to nie tylko defekt kosmetyczny; to potencjalne miejsce rozwoju bakterii. Oznacza to, że nasze etapy obróbki końcowej, takie jak usuwanie zadziorów, elektropolerowanie i pasywacja, są równie ważne jak obróbka początkowa. Dzięki naszemu doświadczeniu z klientami z branży medycznej opracowaliśmy specjalistyczne protokoły czyszczenia i obsługi, aby zapewnić, że części są dostarczane w nieskazitelnym stanie, gotowe do sterylizacji i montażu. Proces walidacji jest również niezwykle rygorystyczny, często obejmując IQ/OQ/PQ (kwalifikacje instalacyjne, operacyjne i wydajnościowe), aby zagwarantować stabilność i powtarzalność procesu produkcyjnego.

Zapewnienie powtarzalności dla robotyki i automatyki

Podczas gdy pojedynczy element zrobotyzowany może mieć nieco luźniejsze tolerancje niż krytyczna część lotnicza, wyzwaniem w robotyce jest utrzymanie tej tolerancji idealnie w bardzo dużych ilościach. Zrobotyzowana linia montażowa opiera się na tysiącach wymiennych części. Jeśli wymiary różnią się nawet nieznacznie między poszczególnymi partiami, może to spowodować zatrzymanie całej produkcji. Aby temu zaradzić, stosujemy statystyczną kontrolę procesu (SPC). Wykonując pomiary podczas całego cyklu produkcyjnego i wykreślając je na wykresach kontrolnych, nasi technicy mogą zidentyfikować i skorygować wszelkie odchylenia procesu, zanim doprowadzą one do powstania części niezgodnych ze specyfikacją. Takie podejście oparte na danych ma fundamentalne znaczenie dla każdej poważnej firmy. obróbka cnc chiny dostawca obsługujący branżę automatyki, ponieważ dowodzi, że proces jest stabilny i zdolny do zapewnienia stałej jakości na dużą skalę.

Osiągnięcie wąskich tolerancji dla krytycznych części wymaga systematycznego podejścia. Łączy ono zaawansowane maszyny, doświadczonych techników i rygorystyczne, specyficzne dla branży procesy kontroli jakości. Gwarantuje to, że każdy komponent, od lotnictwa po urządzenia medyczne, bezbłędnie spełnia najbardziej wymagające specyfikacje.

Praktyczne strategie zarządzania terminami we współpracy z chińskimi partnerami w zakresie obróbki CNC.

Czy kiedykolwiek czułeś ten przeszywający niepokój, gdy zbliżał się termin realizacji projektu, ale informacje od dostawcy były niejasne i rzadkie? Czy jesteś zmęczony terminami ciągnącymi się w nieskończoność, wykolejającymi twój harmonogram produkcji?

Skuteczne zarządzanie harmonogramami obejmuje tworzenie szczegółowego, wspólnego harmonogramu projektu z jasnymi kamieniami milowymi, wdrażanie regularnych kontroli i budowanie czasu buforowego w planie. Takie proaktywne podejście zapobiega eskalacji drobnych opóźnień w poważne komplikacje projektowe podczas pozyskiwania obróbki CNC z Chin.

Zarządzanie harmonogramami z dostawcą oddalonym o tysiące kilometrów wymaga czegoś więcej niż tylko ustalenia ostatecznej daty dostawy. Wymaga ustrukturyzowanego, przejrzystego i opartego na współpracy podejścia. Z mojego doświadczenia wynika, że najbardziej udane projekty to te, w których oś czasu nie jest tylko terminem, ale wspólną mapą drogową. Bez tego zasadniczo lecisz na ślepo.

Fundacja: Szczegółowy i wspólny harmonogram

Najskuteczniejszym narzędziem do zarządzania osią czasu jest kompleksowy, wspólny harmonogram projektu. Proste "dostarczenie do daty X" jest zaproszeniem do kłopotów. Cały proces należy podzielić na konkretne etapy. W PTSMAKE budujemy ten harmonogram wspólnie z naszymi klientami od pierwszego dnia.

Definiowanie kluczowych kamieni milowych

Zamiast jednego dużego terminu, ustal kilka mniejszych. Pozwala to na stopniowe śledzenie postępów i wczesne wykrywanie potencjalnych opóźnień. Pomyśl o tym jak o serii punktów kontrolnych, które muszą zostać osiągnięte przed przejściem do następnego etapu. Typowy projekt obróbki CNC może mieć takie kamienie milowe:

| Kamień milowy | Typowy czas trwania | Kluczowy rezultat |

|---|---|---|

| Analiza i zatwierdzenie DFM | 2-3 dni | Sfinalizowane i zatwierdzone modele 3D |

| Zaopatrzenie w surowce | 3-7 dni | Potwierdzenie przybycia materiałów i certyfikaty |

| Kontrola pierwszego artykułu (FAI) | 5-10 dni | Raport FAI i przykładowe części do przeglądu |

| Production Run | Różne | Aktualizacje postępów w 25%, 50%, 75% |

| Obróbka końcowa i wykończenie | Różne | Kompletne wykończenie części (np. anodowanie) |

| Końcowa kontrola jakości i pakowanie | 1-2 dni | Raport z kontroli końcowej |

Taka struktura tworzy odpowiedzialność. Przekroczenie daty zatwierdzenia DFM ma bezpośredni wpływ na datę zakupu materiałów, dzięki czemu konsekwencje każdego opóźnienia są natychmiast widoczne dla obu stron.

Korzystanie z narzędzi wizualnych dla jasności

Nie lekceważ potęgi prostego wykresu Gantta. Przedstawia on wizualnie oś czasu projektu, zależności między zadaniami oraz Metoda ścieżki krytycznej4. Gdy istnieją bariery językowe, wykres wizualny jest językiem uniwersalnym. Wyraźnie pokazuje, w jaki sposób opóźnienie w jednym zadaniu - np. opóźnienie w pozyskiwaniu materiałów - będzie miało bezpośredni wpływ na każde kolejne zadanie. Ta wizualna pomoc eliminuje niejasności i pomaga dostosować oczekiwania, zapewniając, że wszyscy rozumieją przepływ projektu i pilność każdego kroku. Przekształca oś czasu z listy dat w dynamiczny, wzajemnie powiązany plan.

Podczas gdy solidny plan początkowy jest niezbędny, zarządzanie projektem polega również na radzeniu sobie z nieoczekiwanymi sytuacjami. Produkcja w świecie rzeczywistym wiąże się ze zmiennymi, od konserwacji maszyn po czkawkę łańcucha dostaw. Wbudowanie odporności w oś czasu jest tak samo ważne, jak tworzenie wstępnego harmonogramu. Oznacza to planowanie potencjalnych problemów jeszcze przed ich wystąpieniem.

Budowanie odporności i radzenie sobie z opóźnieniami

Plan bez możliwości awaryjnych jest kruchy. Kluczem do poruszania się po zawiłościach produkcji zagranicznej, w tym zaopatrzenia obróbka cnc chiny usług, jest przewidywanie wyzwań i budowanie mechanizmów absorbujących drobne wstrząsy bez wykolejania całego projektu.

Sztuka buforowania

Dodanie "czasu buforowego" do harmonogramu nie jest oznaką pesymizmu; to znak doświadczonego kierownika projektu. Bufor nie powinien być jednak przypadkowy. Powinien być strategiczny.

- Identyfikacja kroków wysokiego ryzyka: Które części procesu są najbardziej narażone na opóźnienia? Pozyskiwanie specjalistycznych materiałów, złożone konfiguracje obróbki wieloosiowej lub skomplikowana obróbka końcowa, taka jak galwanizacja lub malowanie, często wiążą się z wyższym ryzykiem.

- Odpowiednio przydziel bufory: Na podstawie danych z naszych projektów stwierdziliśmy, że rozsądne jest dodanie bufora czasowego 10-15% do standardowych procesów. W przypadku etapów wysokiego ryzyka bufor 20-25% zapewnia bardziej realistyczną siatkę bezpieczeństwa. Zapobiega to wywołaniu efektu domina przez niewielki problem w jednym obszarze.

- Czynnik w logistyce: Nie zapomnij o wysyłce i odprawie celnej. Zwłaszcza w przypadku transportu morskiego czas tranzytu może być różny. Dodanie dodatkowego tygodnia do planu logistycznego może zaoszczędzić wiele stresu.

Ustanowienie jasnej ścieżki eskalacji

Gdy wystąpi opóźnienie, potrzebny jest wstępnie zdefiniowany plan działania. Panika i frustracja nie rozwiązują problemów; jasny protokół komunikacyjny tak.

| Istotność problemu | Pierwszy punkt kontaktowy | Kontakt eskalacyjny (jeśli nierozwiązany w ciągu 24h) | Działanie |

|---|---|---|---|

| Niewielkie opóźnienie (< 2 dni) | Kierownik projektu / inżynier sprzedaży | NIE DOTYCZY | Udokumentuj problem, dostosuj lokalny harmonogram |

| Umiarkowane opóźnienie (3-5 dni) | Kierownik projektu / inżynier sprzedaży | Kierownik ds. inżynierii | Analiza przyczyn źródłowych, plan naprawczy |

| Poważne opóźnienie (> 5 dni) | Kierownik ds. inżynierii | Dyrektor ds. klientów / kierownictwo wyższego szczebla | Zmiana priorytetów produkcji, zbadanie możliwości przyspieszonej wysyłki |

Uzgodnienie tej ścieżki eskalacji na początku projektu gwarantuje, że problemy będą rozwiązywane przez właściwe osoby we właściwym czasie. Usuwa to domysły i emocje z rozwiązywania problemów, zastępując je ustrukturyzowanym, wydajnym procesem. Takie proaktywne zarządzanie jest tym, co oddziela stresujący projekt od udanego partnerstwa.

Aby skutecznie zarządzać harmonogramami z chińskimi dostawcami, stwórz wspólny harmonogram z wyraźnymi kamieniami milowymi i korzystaj z narzędzi wizualnych, takich jak wykresy Gantta. Buduj odporność, dodając strategiczne bufory do etapów wysokiego ryzyka i ustanawiając jasną ścieżkę eskalacji, gdy nieuchronnie wystąpią opóźnienia.

Czy kiedykolwiek wahałeś się przed wysłaniem plików CAD za granicę, obawiając się, że Twój unikalny projekt może zostać naruszony? Obawa ta jest główną przeszkodą dla wielu inżynierów rozważających globalną produkcję.

Ochrona własności intelektualnej podczas outsourcingu obróbki CNC do Chin wymaga solidnej, wielowarstwowej strategii. Wiąże się to z dokładną weryfikacją partnerów pod kątem ich protokołów bezpieczeństwa, stosowaniem egzekwowalnych w Chinach umów NNN zamiast standardowych umów NDA oraz utrzymywaniem ścisłej kontroli danych w całym procesie produkcyjnym.

Podstawowe filary ochrony własności intelektualnej

Ochrona własności intelektualnej nie jest pojedynczym działaniem, ale ciągłym procesem, który rozpoczyna się na długo przed zaprogramowaniem maszyny. Pierwszym i najważniejszym krokiem jest wybór odpowiedniego partnera produkcyjnego. Chociaż certyfikaty takie jak ISO 9001 są dobrym punktem wyjścia, nie mówią wszystkiego o bezpieczeństwie danych. Trzeba sięgnąć głębiej.

Ocena kultury bezpieczeństwa partnera

Prawdziwie bezpieczny partner integruje ochronę IP ze swoimi codziennymi operacjami. Kiedy wdrażamy nowego klienta w PTSMAKE, jedną z pierwszych rzeczy, które omawiamy, jest nasz protokół bezpieczeństwa. Oto pytania, które powinieneś zadać każdemu potencjalnemu dostawcy:

- Kontrola dostępu: Kto będzie miał dostęp do moich plików projektowych? W jaki sposób dostęp ten jest rejestrowany i monitorowany?

- Bezpieczeństwo sieci: Czy twoje sieci są chronione przez zapory sieciowe? Czy przeprowadzasz regularne audyty bezpieczeństwa?

- Bezpieczeństwo fizyczne: Czy obszary produkcyjne z wrażliwymi projektami są ograniczone?

Gotowość partnera do otwartego i szczegółowego odpowiadania na te pytania jest silnym wskaźnikiem jego zaangażowania. Niejasna lub lekceważąca odpowiedź powinna być główną czerwoną flagą. Z naszego doświadczenia w pracy z klientami z branży zaawansowanych technologii wynika, że zademonstrowanie bezpiecznego, oddzielnego środowiska cyfrowego dla każdego projektu to nie tylko punkt sprzedaży; to podstawowy wymóg.

Więcej niż standardowa umowa o zachowaniu poufności

Wiele zachodnich firm zakłada, że ich standardowa umowa o zachowaniu poufności (NDA) zapewnia ochronę w Chinach. Niestety, dokumenty te są często trudne lub wręcz niemożliwe do wyegzekwowania w chińskich sądach. Są one zazwyczaj regulowane przez prawo USA lub UE i mogą nie obejmować krytycznych aspektów istotnych dla produkcji. To właśnie w tym przypadku wyspecjalizowana umowa, często nazywana Umowa o nieujawnianiu, nieużywaniu i nieobchodzeniu (NNN)5staje się niezbędny.

Umowa NNN została zaprojektowana specjalnie z myślą o chińskim środowisku prawnym i biznesowym. Obejmuje ona trzy kluczowe obszary:

| Typ umowy | Główny cel | Kluczowe zabezpieczenia | Egzekwowalność w Chinach |

|---|---|---|---|

| Standardowa umowa o zachowaniu poufności | Poufność | Zapobiega udostępnianiu informacji. | Niski do umiarkowanego |

| Umowa NNN | Poufność, wykorzystanie, obejście | Zapobiega udostępnianiu, wykorzystywaniu adresu IP dla własnych korzyści i pomijaniu użytkownika w celu pracy z jego kontaktami. | Wysoki (jeśli został prawidłowo opracowany) |

Ta prosta zmiana w dokumentacji prawnej może stanowić różnicę między bezpiecznym partnerstwem a kosztowną lekcją. Dla każdego poważnego Obróbka CNC Chiny projekt, NNN nie podlega negocjacjom.

Praktyczne środki bezpieczeństwa i zabezpieczenia prawne

Mając sprawdzonego partnera i solidną umowę NNN, kolejna warstwa ochrony obejmuje praktyczne, codzienne środki bezpieczeństwa i wykorzystanie dostępnych ram prawnych. Potraktuj NNN jako fundament prawny, a poniższe kroki jako bezpieczne mury, które na nim zbudujesz.

Kontrolowanie przepływu informacji

Można znacznie zmniejszyć ryzyko, zarządzając sposobem i zakresem udostępnianych informacji. Nie każda osoba w łańcuchu dostaw musi widzieć pełny obraz produktu.

1. Segmentacja informacji

Czy dostawca potrzebuje kompletnego pliku CAD zespołu do obróbki pojedynczego komponentu? Rzadko. Wysyłając tylko rysunek i model konkretnej produkowanej części, ograniczasz ich wiedzę na temat ogólnego projektu produktu. Ta prosta praktyka udostępniania informacji "niezbędnych" minimalizuje potencjalny wpływ każdego naruszenia.

2. Bezpieczna transmisja danych

Poczta elektroniczna nie jest bezpieczną metodą przesyłania wrażliwych adresów IP. Renomowani partnerzy powinni oferować bezpieczny protokół transferu plików (SFTP) lub dedykowany portal klienta dla wszystkich wymian plików. W PTSMAKE stworzyliśmy bezpieczny system portalowy wiele lat temu, aby zapewnić, że każdy plik od naszych klientów jest szyfrowany podczas przesyłania i przechowywany na odizolowanych serwerach. Możesz również dodać znaki wodne z nazwą dostawcy i datą na swoich rysunkach jako środek odstraszający.

Proaktywne korzystanie z chińskiego systemu prawnego

Narracja, że Chiny nie oferują ochrony własności intelektualnej jest przestarzała. Chociaż wyzwania pozostają, kraj ten poczynił znaczne postępy we wzmacnianiu swoich przepisów dotyczących własności intelektualnej. Kluczem jest proaktywne, a nie reaktywne korzystanie z systemu.

Rejestracja własności intelektualnej w Chinach

Jest to najpotężniejszy krok, jaki można podjąć. Chiny działają w oparciu o system "first-to-file" dla patentów i znaków towarowych. Oznacza to, że ten, kto pierwszy złoży wniosek, posiada prawa w Chinach, niezależnie od tego, kto pierwszy go wynalazł. Rejestracja patentów i znaków towarowych w Chinach daje legitymację prawną do walki z naruszeniami w ich systemie sądowym. Przekształca to potencjalną kwestię własności intelektualnej ze sporu handlowego w spór prawny, który chińskie władze traktują znacznie poważniej.

Poniższa tabela przedstawia możliwe do podjęcia kroki, które można wdrożyć natychmiast:

| Strategia | Punkt działania | Korzyści |

|---|---|---|

| Kontrola danych | Używaj bezpiecznego FTP/portalu do wszystkich transferów plików. | Zapobiega przechwytywaniu danych. |

| Silos informacyjny | Wysyłaj tylko niezbędne pliki komponentów, a nie pełne zespoły. | Ogranicza zakres wiedzy dostawcy. |

| Proaktywność prawna | Zgłaszanie patentów i znaków towarowych w Chinach przed angażowanie dostawców. | Zapewnia legalną własność i pozycję w Chinach. |

| Dokumentacja | Wszystkie rysunki należy opatrzyć znakiem wodnym z nazwą dostawcy i napisem "Poufne". | Zapobiega dzieleniu się i pomaga w śledzeniu wycieków. |

Te praktyczne środki, w połączeniu z solidnymi podstawami prawnymi, tworzą kompleksową strategię bezpieczeństwa dla projektów obróbki CNC w Chinach.

Aby chronić swoją własność intelektualną podczas outsourcingu obróbki CNC do Chin, należy zweryfikować partnerów pod kątem ich kultury bezpieczeństwa, a nie tylko certyfikatów. Skorzystaj z umowy NNN specyficznej dla Chin, a nie standardowej umowy NDA, i proaktywnie zarejestruj swoje patenty i znaki towarowe w Chinach, aby uzyskać kluczową przewagę prawną.

Twoja ostateczna lista kontrolna do weryfikacji partnerów obróbki CNC w Chinach?

Masz trudności ze stworzeniem wiarygodnej krótkiej listy spośród ogromnej puli chińskich dostawców CNC? Martwisz się, że przeoczysz krytyczny szczegół, który może zagrozić Twojemu projektowi?

Kluczem do wyboru wiarygodnego partnera jest użycie ustrukturyzowanej listy kontrolnej oceny. Proces ten powinien obejmować certyfikaty, możliwości produkcyjne, walidację próbek, referencje klientów i przejrzystość komunikacji, aby zbudować podstawę dla długoterminowej, udanej relacji.

Podstawa: Certyfikaty i możliwości produkcyjne

Zanim jeszcze poprosisz o wycenę, pierwszym krokiem jest zweryfikowanie podstawowych kwalifikacji potencjalnego partnera. Potraktuj to jako sprawdzenie planów przed położeniem fundamentów. Bez odpowiednich certyfikatów i sprzętu, nawet najlepsze obietnice mogą okazać się bez pokrycia.

Niezbędne certyfikaty zarządzania jakością

Certyfikaty nie są tylko kawałkami papieru; są dowodem zaangażowania dostawcy w kontrolę jakości i procesów. Pokazują, że niezależny organ przeprowadził audyt systemów i uznał je za zgodne z międzynarodowymi standardami.

- ISO 9001: Jest to absolutne minimum. Potwierdza on, że dostawca posiada system zarządzania jakością (QMS) zapewniający spójność i zadowolenie klienta. Jeśli sklep nie posiada certyfikatu ISO 9001, byłbym bardzo ostrożny.

- AS9100: Jeśli pracujesz w przemyśle lotniczym lub obronnym, nie podlega to negocjacjom. Obejmuje wszystkie wymagania ISO 9001 oraz bardziej rygorystyczne normy bezpieczeństwa, niezawodności i jakości specyficzne dla sektora lotniczego.

- ISO 13485: Jest to standard dla urządzeń medycznych. Gwarantuje on, że dostawca spełnia rygorystyczne wymogi regulacyjne dotyczące identyfikowalności, zarządzania ryzykiem i walidacji procesów wymaganych dla komponentów medycznych.

W PTSMAKE utrzymujemy te certyfikaty nie tylko ze względu na zgodność, ale także dlatego, że wymuszają one dyscyplinę potrzebną do produkcji o wysokiej precyzji.

Ocena prawdziwej siły produkcyjnej

Strona internetowa dostawcy może zawierać listę imponujących maszyn, ale trzeba sięgnąć głębiej. Odpowiedni sprzęt ma kluczowe znaczenie dla osiągnięcia wymaganych tolerancji i geometrii. Zrozumienie przez partnera geometrii wymiarowania i tolerowania (GD&T) jest równie ważne, ponieważ jest to uniwersalny język do przekazywania precyzyjnych założeń projektowych.

Oto zestawienie tego, czego należy szukać na liście wyposażenia:

| Typ maszyny | Kluczowe zastosowanie | Co to oznacza dla użytkownika |

|---|---|---|

| 3-osiowe frezarki CNC | Standardowe części pryzmatyczne, otwory, szczeliny | Ekonomiczne rozwiązanie dla prostszych geometrii. Podstawowy element każdego poważnego sklepu. |

| 4/5-osiowe frezarki CNC | Złożone krzywe, wyprofilowane powierzchnie | Zdolność do produkcji bardzo złożonych części w jednym ustawieniu, co poprawia dokładność i wydajność. |

| Tokarki CNC/centra tokarskie | Części cylindryczne, wały, pierścienie | Niezbędne dla wszystkich okrągłych komponentów. Oprzyrządowanie pod napięciem zwiększa możliwości frezowania/wiercenia. |

| CMM (współrzędnościowa maszyna pomiarowa) | Kontrola jakości i inspekcja | Kluczowe znaczenie dla weryfikacji, czy części spełniają rygorystyczne specyfikacje tolerancji. Brak współrzędnościowej maszyny pomiarowej jest poważnym sygnałem ostrzegawczym. |

Nie wierz im na słowo. Poproś o pełną listę sprzętu, w tym markę maszyny, wiek i harmonogram konserwacji. Przejrzysty partner chętnie to zapewni. Ten poziom szczegółowości pokazuje, że poważnie podchodzą do swojego rzemiosła i są wiarygodnym wyborem dla obróbka cnc chiny6.

Dowód: Walidacja próbki i wskaźniki relacji

Gdy dostawca przejdzie wstępną weryfikację techniczną, nadchodzi czas na ocenę jego rzeczywistych wyników i stylu komunikacji. Ta faza oddziela zdolne sklepy od prawdziwych partnerów. Wspaniałe partnerstwo opiera się na zaufaniu i przejrzystości, a nie tylko na zamówieniach transakcyjnych.

Zatwierdzanie pierwszego artykułu

Fizyczna próbka to ostateczny test. To tutaj cyfrowy plik CAD staje się namacalną rzeczywistością. Ale przegląd próbki to coś więcej niż tylko szybka kontrola wizualna.

- Raport z inspekcji pierwszego artykułu (FAI): Profesjonalny dostawca dostarczy kompleksowy raport FAI wraz z próbką. Dokument ten powinien odwzorowywać każdy wymiar, tolerancję i uwagę na rysunku z rzeczywistymi wynikami pomiarów z maszyny CMM lub innych narzędzi metrologicznych.

- Certyfikat materiałowy: Zawsze żądaj certyfikatów materiałowych. Gwarantuje to, że użyty materiał jest dokładnie taki, jak określono (np. Al 6061-T6, SUS 304). W naszych poprzednich projektach w PTSMAKE widzieliśmy, jak nieprawidłowe gatunki materiałów mogą prowadzić do awarii w terenie, dlatego traktujemy ten krok z najwyższą powagą.

- Wykończenie powierzchni i estetyka: Czy wykończenie części spełnia Twoje wymagania? Czy krawędzie są odpowiednio gratowane? Czy są jakieś ślady narzędzi tam, gdzie nie powinno ich być? Te szczegóły odzwierciedlają dbałość sklepu o szczegóły i ogólną dumę z jego pracy.

Dostawca, który spieszy się na tym etapie lub dostarcza niekompletny raport, może pójść na skróty w innym miejscu.

Ocena komunikacji i przejrzystości

W trakcie procesu wyceny i pobierania próbek należy zwracać szczególną uwagę na komunikację z dostawcą. Jest to silny predyktor przyszłych relacji roboczych. To, jak radzą sobie z drobnymi rzeczami teraz, mówi ci, jak będą radzić sobie z dużymi rzeczami później.

Oto prosta lista kontrolna do oceny ich stylu komunikacji:

| Wskaźnik dobrego partnera | Wskaźnik czerwonej flagi |

|---|---|

| Proaktywne aktualizacje | Zawsze musisz prosić o aktualizacje statusu. |

| Zadaje pytania wyjaśniające | Przyjmuje założenia dotyczące projektu. |

| Przejrzystość w kwestii wyzwań | Ukrywa potencjalne problemy, dopóki nie jest za późno. |

| Zapewnia informacje zwrotne DFM | Po prostu cytuje część "taką, jaka jest", nawet z wadami. |

| Odpowiedź w ciągu 24 godzin | Odpowiedź na zwykłą wiadomość e-mail zajmuje kilka dni. |

Ostatecznie szukasz partnera, a nie tylko dostawcy części. Znalezienie niezawodnego obróbka cnc chiny Dostawca oznacza znalezienie zespołu, który zainwestuje w Twój sukces. Powinien on funkcjonować jako rozszerzenie własnego działu inżynieryjnego. To zaangażowanie w budowanie długoterminowych relacji, zakorzenione w przejrzystości, jest najważniejszą cechą, której należy szukać.

Aby zweryfikować chińskiego partnera CNC, należy połączyć ocenę techniczną i relacyjną. Najpierw zweryfikuj podstawowe kwalifikacje, takie jak certyfikaty ISO i możliwości produkcyjne. Następnie przeanalizuj ich rzeczywiste wyniki poprzez szczegółową walidację próbek i oceń ich styl komunikacji pod kątem przejrzystości i proaktywności.

Trendy przyszłości: Automatyzacja, zrównoważony rozwój i inteligentna produkcja?

Zastanawiasz się, czy Twój obecny partner w zakresie obróbki CNC jest przygotowany na przyszłość? Skąd możesz mieć pewność, że jego procesy nie staną się przestarzałe, wpływając na jakość i wydajność Twojego projektu?

Przyszłość obróbki CNC w Chinach jest definiowana przez trzy główne filary: powszechną automatyzację, silne zaangażowanie w ekologiczną produkcję oraz integrację sztucznej inteligencji i IoT z inteligentnymi systemami fabrycznymi. Trendy te rewolucjonizują jakość, wydajność i globalną konkurencyjność.

Automatyzacja i rozwój inteligentnej produkcji

Rozmowa na temat produkcji w Chinach nie dotyczy już tylko skali; chodzi o inteligencję. Integracja automatyzacji i inteligentnych technologii to najbardziej znacząca zmiana, jaką widziałem. To nie jest science fiction - to dzieje się teraz na halach produkcyjnych.

Rola automatyzacji w zwiększaniu wydajności

Automatyzacja w obróbce CNC wykracza poza zwykłe zastąpienie pracy ręcznej. Chodzi o stworzenie płynnego, powtarzalnego i wysoce precyzyjnego przepływu pracy. W poprzednich projektach PTSMAKE widzieliśmy na własne oczy, jak zautomatyzowane systemy zmieniają produkcję.

- Robotic Tending: Ramiona robotów ładują surowce i rozładowują gotowe części 24/7 bez zmęczenia. Nie tylko przyspiesza to produkcję, ale także eliminuje ryzyko błędu ludzkiego podczas obsługi, co ma kluczowe znaczenie w przypadku części o delikatnym wykończeniu powierzchni.

- Zautomatyzowana kontrola jakości: Kamery i czujniki o wysokiej rozdzielczości są obecnie zintegrowane bezpośrednio z liniami produkcyjnymi. Mogą one sprawdzać części pod kątem dokładności wymiarowej i wad powierzchniowych w czasie rzeczywistym, wychwytując potencjalne problemy znacznie wcześniej niż tradycyjne ręczne kontrole wyrywkowe. To przejście od reaktywnej do proaktywnej kontroli jakości zmienia zasady gry.

AI i IoT: Mózgi operacji

Jeśli automatyzacja jest mięśniem, to Internet rzeczy (IoT) i sztuczna inteligencja (AI) są mózgami. To właśnie stąd bierze się "smart" w inteligentnej produkcji. Czujniki IoT są wbudowane w maszyny CNC w celu gromadzenia ogromnych ilości danych dotyczących wibracji, temperatury, prędkości wrzeciona i zużycia narzędzi. Dane te są następnie wprowadzane do algorytmów sztucznej inteligencji, które mogą przewidzieć, kiedy maszyna wymaga konserwacji, zanim się zepsuje. Koncepcja ta, znana jako systemy cyberfizyczne7umożliwia stworzenie prawdziwie połączonego i inteligentnego środowiska produkcyjnego. Dla naszych klientów oznacza to większą niezawodność i mniej nieoczekiwanych opóźnień.

| Aspekt | Obróbka tradycyjna | Inteligentna obróbka (AI/IoT) |

|---|---|---|

| Gromadzenie danych | Ręczne dzienniki, okresowe kontrole | Dane z czujników w czasie rzeczywistym |

| Konserwacja | Reaktywny (naprawia, gdy jest uszkodzony) | Predykcyjne (naprawa przed awarią) |

| Kontrola jakości | Kontrola ręczna (postprodukcja) | Zautomatyzowana kontrola na linii produkcyjnej |

| Rola operatora | Operator maszyn i operator ręczny | Nadzorca i analityk systemu |

Ta ewolucja zasadniczo zmienia propozycję wartości obróbki CNC w Chinach. Zmienia się ona z przewagi w zakresie kosztów pracy na przewagę w zakresie technologii i wydajności.

Dążenie do zrównoważonego rozwoju i cyfryzacji

Wraz z rewolucją technologiczną, potężny ruch w kierunku zrównoważonego rozwoju i kompleksowej cyfryzacji przekształca branżę. Globalni klienci, zwłaszcza z USA i Europy, coraz częściej wymagają odpowiedzialnych środowiskowo łańcuchów dostaw, a chińscy producenci aktywnie na to reagują.

Zielone inicjatywy produkcyjne

Zrównoważony rozwój nie jest już tylko modnym hasłem, ale podstawową zasadą biznesową. Kierując się zarówno bardziej rygorystycznymi przepisami dotyczącymi ochrony środowiska, jak i oczekiwaniami rynku, myślące przyszłościowo zakłady CNC wdrażają ekologiczne praktyki.

- Energooszczędny sprzęt: Nowoczesne maszyny CNC zużywają znacznie mniej energii. Po porównaniu wyników testów stwierdziliśmy, że niektóre nowe modele mogą zmniejszyć zużycie energii nawet o 30%, obniżając koszty operacyjne i ślad węglowy.

- Redukcja odpadów i recykling: Wiąże się to z czymś więcej niż tylko recyklingiem złomu. Zaawansowane oprogramowanie CAM jest wykorzystywane do optymalizacji ścieżek narzędzi, maksymalizacji wykorzystania materiału z każdego bloku metalu i minimalizacji odpadów. Chłodziwa i płyny chłodząco-smarujące są również poddawane recyklingowi dzięki zaawansowanym systemom filtracji.

- Zrównoważone pozyskiwanie materiałów: Coraz większy nacisk kładzie się na współpracę z dostawcami materiałów, którzy mogą dostarczyć dokumentację swoich praktyk w zakresie pozyskiwania i ochrony środowiska, zapewniając, że cały łańcuch dostaw jest czysty.

Cyfryzacja dla lepszej współpracy

Cyfryzacja łączy wszystko razem. Tworzy przejrzyste, oparte na danych połączenie między klientem a producentem. W przeciwieństwie do automatyzacji, która koncentruje się na fizycznej hali produkcyjnej, cyfryzacja przekształca cały proces biznesowy.

- Systemy realizacji produkcji (MES): Platformy te zapewniają jedno źródło prawdy dla każdego projektu. Z naszej strony w PTSMAKE możemy śledzić każdy etap produkcji. Dla naszych klientów oznacza to bezprecedensową przejrzystość - mogą zalogować się do portalu i zobaczyć status swojego zamówienia w czasie rzeczywistym.

- Cyfrowe bliźniaki: W przypadku złożonych projektów możemy stworzyć wirtualną replikę części i procesu produkcyjnego. Pozwala nam to symulować cały proces obróbki, identyfikować potencjalne wyzwania i optymalizować proces przed wycięciem pojedynczego kawałka metalu.

| Inicjatywa | Wpływ na działalność operacyjną | Korzyści dla klientów |

|---|---|---|

| Energooszczędne maszyny | Niższe zużycie energii w fabryce | Niższe koszty operacyjne, bardziej stabilne ceny |

| Zoptymalizowane ścieżki narzędzia | Mniej generowanych odpadów materiałowych | Niższe koszty materiałów i bardziej ekologiczny ślad |

| Platformy cyfrowe (MES) | Scentralizowane śledzenie produkcji | Widoczność i przejrzystość projektu w czasie rzeczywistym |

Trendy te pokazują, że przyszłość obróbka cnc chiny nie chodzi tylko o to, aby części były tańsze lub szybsze, ale o to, aby były inteligentniejsze, czystsze i bardziej odpowiedzialne.

Przyszłość obróbki CNC w Chinach to synergia automatyzacji zapewniającej wydajność, inteligentnej technologii zapewniającej inteligencję predykcyjną oraz zrównoważonych praktyk zapewniających długoterminową rentowność. Ta ewolucja poprawia jakość, zwiększa niezawodność i wzmacnia pozycję konkurencyjną na arenie światowej.

Studia przypadków: Historie sukcesu zachodnich producentów OEM!

Słyszałeś historie o zaopatrzeniu z Chin i zastanawiałeś się, czy są one zbyt piękne, aby mogły być prawdziwe? Wahasz się, obawiając się, że ryzyko może przeważyć nad korzyściami?

Udane partnerstwa z chińskimi dostawcami obróbki CNC są nie tylko możliwe, ale stanowią strategiczną przewagę. Zachodni producenci OEM osiągają znaczne oszczędności kosztów, uzyskują dostęp do zaawansowanych możliwości produkcyjnych i przyspieszają czas wprowadzania produktów na rynek, pokonując wyzwania dzięki współpracy w zakresie komunikacji i rygorystycznej kontroli jakości z odpowiednim partnerem.

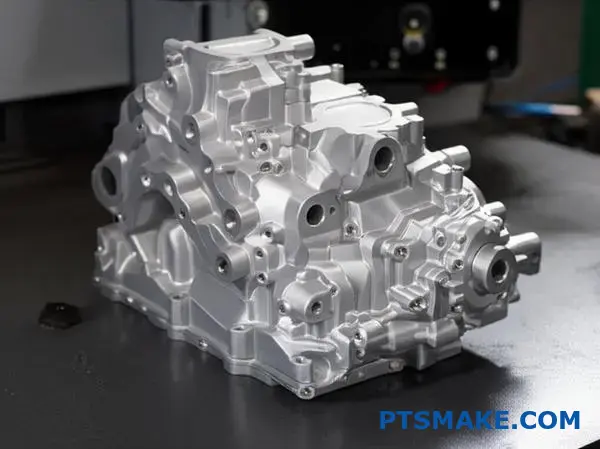

Studium przypadku 1: Niemiecki dostawca motoryzacyjny Tier 1

Znany niemiecki dostawca z branży motoryzacyjnej zwrócił się do nas z poważnym wyzwaniem. Musieli oni wyprodukować złożony aluminiowy element przekładni o niezwykle wąskich tolerancjach, ale stanęli w obliczu ogromnej presji, aby obniżyć koszty produkcji o co najmniej 20%, aby pozostać konkurencyjnym na nowej platformie samochodowej. Dotychczasowi europejscy dostawcy nie byli w stanie osiągnąć tego celu kosztowego bez uszczerbku dla jakości, która w sektorze motoryzacyjnym nie podlegała negocjacjom.

Wyzwanie: Równoważenie redukcji kosztów i ekstremalnej precyzji

Głównym problemem były wysokie koszty surowców i czasu obróbki w Europie. Projekt części zawierał skomplikowane geometrie, które wymagały wieloosiowej obróbki CNC i szeroko zakrojonych kontroli jakości. Klient był sceptyczny co do tego, czy dostawca oferujący usługi "obróbki cnc w Chinach" może konsekwentnie spełniać jego rygorystyczne standardy jakości, które obejmowały precyzyjne wykończenie powierzchni i wymagania dotyczące braku defektów. Martwili się o bariery komunikacyjne, ochronę własności intelektualnej i potencjalne opóźnienia w dostawach, które mogłyby zakłócić harmonogram produkcji just-in-time.

Nasze rozwiązanie: Współpraca DFM i optymalizacja procesów

Zamiast po prostu przedstawić wycenę, rozpoczęliśmy dogłębną analizę ich projektu. Nasz zespół inżynierów w PTSMAKE współpracował z projektantami w serii warsztatów Design for Manufacturability (DFM). Dzięki tej współpracy zidentyfikowaliśmy drobne, niekrytyczne modyfikacje projektu, które znacznie skróciły czas obróbki bez wpływu na funkcję lub integralność części. Wykorzystaliśmy również nasz ugruntowany łańcuch dostaw, aby pozyskać wysokiej jakości aluminium po korzystniejszych kosztach. Wdrożyliśmy dedykowaną linię produkcyjną dla tego komponentu, wykorzystując statystyczna kontrola procesu8 do monitorowania jakości w czasie rzeczywistym.

Poniższa tabela przedstawia usprawnienia, które wspólnie osiągnęliśmy.

| Metryczny | Poprzedni europejski dostawca | Rozwiązanie PTSMAKE | Ulepszenie |

|---|---|---|---|

| Koszt jednostkowy | Linia bazowa | -22% | 22% Redukcja |

| Czas realizacji (prototypy) | 6 tygodni | 3 tygodnie | 50% Szybciej |

| Współczynnik akceptacji jakości | 99.5% | 99.9% | +0.4% |

| Opóźnienie w komunikacji | Do 24 godzin | < 4 godziny | Szybsza reakcja |

Rezultat okazał się spektakularnym sukcesem. Klient nie tylko osiągnął swój cel redukcji kosztów, ale także zauważył poprawę spójności części.

Studium przypadku 2: Innowator urządzeń medycznych z siedzibą w USA

Kolejna historia sukcesu pochodzi od szybko rozwijającego się startupu z branży urządzeń medycznych w Stanach Zjednoczonych. Opracowali oni innowacyjne ręczne narzędzie diagnostyczne i potrzebowali partnera produkcyjnego, który mógłby skalować się wraz z nimi od prototypów na końcowym etapie do produkcji na pełną skalę. Ich wyzwanie było wieloaspektowe: potrzebowali partnera, który rozumiałby rygorystyczną dokumentację i wymagania dotyczące identyfikowalności materiałów w branży medycznej, mógłby szybko dostarczać precyzyjne części i skalować produkcję bez spadku jakości.

Wyzwanie: Szybkość wprowadzania produktów na rynek przy bezkompromisowej kontroli jakości

Startup był w wyścigu, aby wprowadzić swój produkt na rynek. Jakiekolwiek opóźnienie w otrzymaniu wysokiej jakości części do testów i przedłożenia do organów regulacyjnych mogło kosztować ich przewagę na rynku. Firma potrzebowała obrabianych CNC obudów wykonanych ze specjalnego biokompatybilnego polimeru (PEEK). Ich poprzedni lokalny warsztat maszynowy był doskonały do jednorazowych prototypów, ale brakowało mu mocy produkcyjnych i formalnego systemu zarządzania jakością (QMS) wymaganego do produkcji urządzeń medycznych. Obawiali się, że outsourcing do Chin zwiększy złożoność ich ścieżki audytu i spowolni komunikację, zagrażając napiętym terminom.

Rozwiązanie: Zwinne prototypowanie i skalowalna produkcja

Pokazaliśmy, w jaki sposób nasze procesy w PTSMAKE zostały zaprojektowane dokładnie dla tego scenariusza. Przydzieliliśmy dedykowanego kierownika projektu, który działał jako pojedynczy punkt kontaktowy, zapewniając jasną i szybką komunikację. Zaczęliśmy od wyprodukowania początkowej partii 10 prototypów w mniej niż dwa tygodnie, dostarczając pełną certyfikację materiałów i raporty z inspekcji. Po udanych testach byliśmy w stanie płynnie przejść do produkcji małoseryjnej. Nasz system jakości zapewnił identyfikowalność potrzebną do złożenia wniosku do FDA.

Poniżej przedstawiamy postęp na osi czasu projektu:

| Faza projektu | Wstępna prognoza lokalnych dostawców | Rzeczywista oś czasu z PTSMAKE | Zaoszczędzony czas |

|---|---|---|---|

| Prototyp Iteracja 1 | 3 tygodnie | 1,5 tygodnia | 50% |

| Prototyp Iteracja 2 | 3 tygodnie | 1,5 tygodnia | 50% |

| Pierwsza partia produkcyjna (500 sztuk) | 8 tygodni | 5 tygodni | 37.5% |

| Pakiet dokumentacji regulacyjnej | 2 tygodnie | 1 tydzień (równolegle) | 50% |

Dzięki współpracy z nami startup był w stanie sfinalizować swój projekt i przejść do produkcji kilka miesięcy przed terminem. Z powodzeniem wprowadzili swój produkt na rynek, a my nadal jesteśmy ich partnerem produkcyjnym w miarę skalowania ich działalności. To pokazuje, jak pozyskiwanie usług obróbki CNC z Chin może być potężnym akceleratorem innowacji.

Te przykłady ze świata rzeczywistego pokazują, że z odpowiednim partnerem, zaopatrywanie się w części obrabiane CNC z Chin jest zwycięską strategią. Sukces opiera się na współpracy inżynieryjnej, przejrzystej komunikacji i silnym zaangażowaniu w jakość, przekształcając potencjalne wyzwania w przewagę konkurencyjną dla zachodnich producentów OEM.

Zrozumienie tego niezbędnego języka inżynieryjnego zapewnia doskonałe przełożenie intencji projektowych na fizyczną część. ↩

Dowiedz się, w jaki sposób GD&T zapewnia idealne dopasowanie i działanie części, niezależnie od miejsca ich produkcji. ↩

Dowiedz się więcej o podstawowych zasadach nauki o pomiarach, aby lepiej zdefiniować wymagania dotyczące kontroli części. ↩

Dowiedz się, w jaki sposób ta technika pomaga zidentyfikować kluczowe zadania, aby utrzymać projekt zgodnie z harmonogramem i skutecznie zarządzać zależnościami. ↩

Zrozum kluczowe różnice między standardową umową NDA a umową NNN, aby naprawdę chronić swoją własność intelektualną w Chinach. ↩

Dowiedz się, w jaki sposób GD&T zapewnia uniwersalny język inżynieryjny, gwarantując, że zamierzenia projektowe są doskonale rozumiane i produkowane. ↩

Dowiedz się, w jaki sposób te zintegrowane systemy obliczeniowe i fizyczne tworzą szkielet nowoczesnych inteligentnych fabryk. ↩

Dowiedz się, w jaki sposób ta metoda oparta na danych zapewnia stałą jakość i zmniejsza liczbę wad w procesie produkcyjnym. ↩