Choosing between investment casting and die casting for your parts can make or break your project timeline and budget. Many engineers struggle with this decision because the wrong choice leads to costly redesigns, extended lead times, and parts that don’t meet specifications.

Investment casting uses a sacrificial wax pattern and ceramic shell to create complex, high-precision parts from high-temperature alloys, while die casting injects molten metal under pressure into reusable steel molds for high-volume production of simpler geometries in lower-melting-point materials.

I’ve worked with both processes at PTSMAKE, helping clients navigate this exact decision for automotive components, aerospace parts, and medical devices. The right choice depends on your specific requirements for material, volume, complexity, and budget. Let me walk you through the key differences and decision factors that will help you make the best choice for your project.

What is the core principle of investment casting?

At its heart, investment casting is a process of creation and destruction. We begin by making an exact replica of the final part. This replica is known as the pattern.

The Sacrificial Pattern

This pattern isn’t meant to last. It serves as a temporary tool. We typically make it from wax. Its sole purpose is to create a mold around it.

Then, we melt or burn it away. This leaves a perfect cavity behind.

| Stage | Purpose |

|---|---|

| Creation | Make a precise wax pattern. |

| Destruction | Remove the pattern to form a mold. |

This unique method allows investment casting to produce complex shapes with incredible detail, a key difference when considering investment casting vs die casting.

From Pattern to Mold: The "Investment"

The real magic happens when we "invest" the pattern. This means building a ceramic shell around it. We do this by repeatedly dipping the wax pattern into a ceramic slurry1 and then covering it with sand-like material.

We repeat this process multiple times. Each layer adds strength and thickness to the shell. This creates a robust, one-piece mold. After the shell reaches the right thickness, it must be dried completely. This step is critical for the mold’s integrity.

The Burnout Stage

Once the ceramic shell is dry, we place it in an oven. The high heat melts and burns out all the wax. This is the "lost wax" part of the process. What remains is a hollow, highly detailed ceramic mold. It is now ready for molten metal to be poured in.

This process differs fundamentally from others like die casting, where a permanent metal mold is used. The single-use ceramic mold in investment casting allows for far more intricate designs and undercuts without needing draft angles.

| Process Step | Key Action | Outcome |

|---|---|---|

| 1. Shell Building | Dip pattern in slurry & sand | A ceramic shell forms. |

| 2. Drying | Cure the shell | The mold gains strength. |

| 3. Dewaxing | Heat the shell in an oven | A hollow mold cavity is left. |

In past projects at PTSMAKE, we’ve found that carefully controlling this shell-building process is key. It’s how we ensure every detail from the original pattern is perfectly captured in the final metal part, consistently meeting tight tolerances.

The core of investment casting is straightforward. We create a precise wax pattern, build a ceramic shell around it, and then remove the pattern. This leaves a perfect, one-time-use mold, ideal for producing complex and detailed metal parts.

What is the core principle of die casting?

The core principle is simple yet powerful. We force molten metal into a steel mold under immense pressure. This method ensures speed and precision.

The Heart of the Process

Think of it like a high-tech syringe. A machine injects liquid metal into a pre-shaped cavity. This cavity is called a die.

Metal and Mold

The process relies on two key components. The molten metal, which forms the part, and the steel die, which shapes it.

| Component | Material | Function |

|---|---|---|

| Molten Metal | Aluminum, Zinc, etc. | Forms the final part |

| Die (Mold) | Hardened Steel | Shapes the metal |

This high-pressure injection is what makes die casting so effective for creating complex parts quickly.

The magic of die casting lies in the pressure. This is not a gentle pour. We inject metal at speeds that can fill the entire mold in milliseconds. This is a key difference when considering investment casting vs die casting.

The Power of Pressure

High pressure is crucial. It forces the metal into every tiny detail of the die. This ensures sharp corners, thin walls, and complex geometries are perfectly formed. This rapid fill also helps achieve a fine-grained microstructure.

The process minimizes porosity. Trapped air has little chance to form bubbles. This results in a stronger, more solid component. At PTSMAKE, we precisely control these pressures for optimal part density.

The Reusable Die: A Key Advantage

The die is a permanent, reusable tool made from high-grade steel. This allows us to produce thousands, or even millions, of identical parts from a single mold. The rapid solidification2 allows for fast cycle times.

This reusability is a major benefit over methods that use disposable molds.

| Feature | Die Casting | Investment Casting |

|---|---|---|

| Mold Material | Steel | Wax/Ceramic |

| Reusability | High (100,000+ cycles) | None (Single-use) |

| Initial Cost | High | Low |

While the initial die cost is higher, the per-part cost drops significantly with volume. This makes die casting ideal for production runs.

Die casting’s core principle involves injecting molten metal into a reusable steel mold under high pressure. This process is engineered for speed, precision, and the mass production of complex, strong metal parts, offering excellent repeatability for high-volume manufacturing projects.

How do material choices differ between Investment Casting and Die Casting?

The biggest difference comes down to temperature. Investment casting can handle materials with very high melting points. This is because the ceramic molds are single-use and built to withstand intense heat.

Die casting, however, uses reusable steel molds. These molds can’t handle the high temperatures needed for metals like steel.

Common Investment Casting Alloys

This process excels with high-performance, high-temperature metals. Think of steel, stainless steel, and even superalloys for aerospace parts.

Typical Die Casting Alloys

Here, we focus on non-ferrous metals. These have lower melting points. The most common are aluminum, zinc, and magnesium alloys.

A quick comparison highlights this key point in the investment casting vs die casting debate.

| Casting Method | Metal Type | Common Examples |

|---|---|---|

| Investment Casting | Ferrous (High-Temp) | Steel, Stainless Steel, Cobalt Alloys |

| Die Casting | Non-Ferrous (Low-Temp) | Aluminum, Zinc, Magnesium |

Why Melting Point Dictates the Process

The core reason for the material divide is the mold itself. Investment casting uses an expendable ceramic shell. This shell is created around a wax pattern. Once the wax is melted out, the ceramic can handle molten steel poured at over 1600°C (2900°F). The mold breaks to release the part.

In die casting, the mold is a permanent steel die. Forcing molten steel into a steel die would damage or even weld to the mold. This limits the process to metals that melt at much lower temperatures. This protects the expensive, reusable die. This is a critical factor when choosing between investment casting vs die casting for a project.

Detailed Alloy Comparison

In projects at PTSMAKE, guiding clients on material selection is a crucial first step. The process compatibility directly impacts the final part’s properties and cost. Understanding this helps prevent costly design errors down the line. We often work with various ferrous alloys3 for demanding applications.

The table below breaks down the options further. We’ve seen these materials used in many client projects.

| Feature | Investment Casting Alloys | Die Casting Alloys |

|---|---|---|

| Primary Type | Ferrous Metals | Non-Ferrous Metals |

| Examples | Stainless Steel, Carbon Steel, Tool Steel, Nickel & Cobalt Alloys | Aluminum (A380), Zinc (Zamak 3), Magnesium (AZ91D) |

| Melting Point | High (e.g., Steel ~1510°C) | Low (e.g., Aluminum ~660°C) |

| Key Strengths | High Strength, Hardness, Corrosion Resistance | Lightweight, Excellent Finish, High Conductivity |

| Common Uses | Turbine blades, medical implants, firearm components | Automotive parts, electronics housings, appliance components |

Investment casting’s use of expendable ceramic molds allows it to handle high-temperature ferrous alloys like steel. In contrast, die casting’s reusable steel dies restrict it to lower-melting-point non-ferrous metals like aluminum and zinc to preserve the mold’s integrity.

How does geometric complexity compare between Investment Casting and Die Casting?

When choosing between investment casting vs die casting, design freedom is a critical factor. The process you select directly impacts the complexity you can achieve.

This choice affects features like internal channels and sharp corners. It also determines how thin you can make walls.

Intricate Internal Passages

Investment casting excels at creating complex internal passages. The wax pattern can be molded into almost any shape.

Die casting struggles with these features. Metal dies cannot easily form complex, enclosed pathways. This limits internal geometry significantly.

Handling Undercuts

Undercuts are features that prevent a part from being directly ejected from a mold. Investment casting handles these easily.

The ceramic shell is broken away, so undercuts are not an issue. Die casting requires complex, costly slides or side-cores for undercuts.

Achieving Thin Walls

Both processes can produce thin walls. However, investment casting often has an edge.

It can create thinner and more consistent walls. This is because the molten metal flows into a preheated ceramic mold.

Here is a quick comparison:

| Feature | Investment Casting | Die Casting |

|---|---|---|

| Internal Passages | Excellent | Limited |

| Undercuts | Excellent | Difficult / Costly |

| Thin Walls | Very Good | Good |

| Design Freedom | High | Moderate |

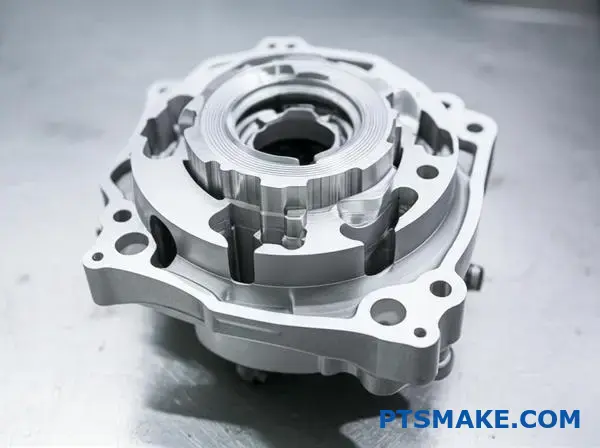

Parts2:

Parts3:

The core reason for investment casting’s superior design freedom lies in its fundamental process. It uses a sacrificial pattern4, typically made of wax, which is an exact replica of the final part.

This wax pattern is coated in a ceramic slurry. After the ceramic hardens, the wax is melted out. This leaves a seamless, one-piece ceramic mold.

This single-use mold allows for almost limitless geometric possibilities. There are no parting lines or draft angles to consider. You can design complex, one-piece structures that would be impossible with other methods.

In contrast, die casting uses a permanent, two-part steel die. The final part must be designed so it can be ejected from this die.

This imposes several constraints. Features must have draft angles. Deep, narrow pockets are challenging. And complex internal cores are often not feasible.

In past projects at PTSMAKE, we have guided clients toward investment casting for parts with integrated, winding cooling channels or complex internal ribbing. These features are simply not practical for die casting.

| Constraint Factor | Investment Casting | Die Casting |

|---|---|---|

| Tooling Type | Expendable Ceramic Mold | Reusable Steel Die |

| Parting Lines | None | Required |

| Draft Angles | Not Required | Required |

| Tooling Cost | Lower | Higher |

Parts4:

Investment casting offers unparalleled design freedom for complex geometries like internal passages and undercuts. Die casting is more restrictive due to its reliance on permanent metal dies, which require features like draft angles for part ejection.

Parts5:

What are the typical surface finishes achievable between Investment Casting and Die Casting?

Let’s get straight to the numbers. When comparing investment casting vs die casting, the "as-cast" surface finish is a critical distinction.

Investment casting generally delivers a significantly smoother surface right from the start. We measure this using Ra (Roughness Average).

A lower Ra value means a smoother finish. This initial quality can drastically cut down on secondary finishing steps, saving you time and money.

Here is a typical comparison we see in our projects.

| Casting Method | Typical As-Cast Ra (μm) | Typical As-Cast Ra (μin) |

|---|---|---|

| Investment Casting | 1.6 – 3.2 | 63 – 125 |

| Die Casting | 3.2 – 6.3 | 125 – 250 |

This difference often dictates the choice of process for parts where aesthetics or fluid dynamics are critical.

The core reason for this difference is the mold material itself. Investment casting uses a ceramic shell built around a wax pattern.

The fine ceramic particles create a mold surface that replicates even the most intricate details with high fidelity. This results in an excellent finish once the wax is removed.

Die casting employs robust, reusable steel dies. While these dies start with a highly polished surface, the process is much more aggressive.

Molten metal is injected under extreme pressure. Over thousands of shots, the repeated heating and cooling, known as thermal cycling5, can cause microscopic wear on the die surface. This wear eventually transfers to the parts.

Other variables matter, too. In die casting, factors like injection speed, pressure, and metal temperature must be perfectly controlled to minimize surface defects like flow lines.

For investment casting, the quality of the wax pattern and the consistency of the ceramic slurry are the most important factors.

| Factor | Investment Casting | Die Casting |

|---|---|---|

| Mold Material | Ceramic Shell (Fine Particles) | Hardened Steel Die |

| Process Pressure | Low (Gravity Pour) | High (Forced Injection) |

| Key Variable | Slurry & Wax Quality | Injection Speed & Pressure |

| Wear Factor | Mold is single-use | Die erosion over time |

At PTSMAKE, we manage these factors closely to ensure your parts meet the specified surface finish from the very first article.

Investment casting’s single-use ceramic molds produce a superior as-cast surface (lower Ra value). In contrast, die casting’s durable steel dies are efficient for high volumes but result in a slightly rougher initial finish due to process stresses.

How do achievable dimensional tolerances differ between Investment Casting and Die Casting?

When comparing investment casting vs die casting, dimensional tolerance is a key differentiator. Die casting generally offers much tighter tolerances right out of the mold.

This precision comes from the process itself.

Based on industry standards and our project data, the typical achievable tolerances vary significantly. Below is a general guide.

| Feature Tolerance | Investment Casting | Die Casting |

|---|---|---|

| Linear Tolerance (Typical) | ±0.005 in/in (0.005 mm/mm) | ±0.0015 in/in (0.0015 mm/mm) |

| Flatness (per inch) | 0.005 inches | 0.002 inches |

| Minimum Wall Thickness | ~0.060" (1.5 mm) | ~0.020" (0.5 mm) |

This table shows die casting’s clear advantage in producing net-shape parts that require less secondary machining.

The primary reason for this difference lies in the mold material and the manufacturing process.

The Stability of Steel Molds

Die casting utilizes robust, precision-machined steel dies. These permanent molds are incredibly stable. They resist wear and thermal distortion over many cycles.

This stability translates directly to part-to-part consistency. Each component produced is a near-perfect replica of the one before it.

Investment casting, however, uses a ceramic shell created around a wax pattern. This shell is single-use and destroyed after each casting.

While effective, the process of creating the shell introduces more variables. This can lead to slight inconsistencies from one shell to another.

Pressure and Process Control

Die casting involves injecting molten metal into the die under extremely high pressure. This ensures the mold cavity is filled quickly and completely.

This controlled process minimizes issues related to uneven volumetric shrinkage6, a common challenge in casting. It reduces porosity and creates fine-grained structures.

Investment casting typically relies on gravity or low pressure. The fill is slower and less forceful, which can result in less-defined details and broader tolerance ranges.

In essence, the die casting process is simply more repeatable.

Die casting offers superior dimensional tolerances due to its durable steel molds and high-pressure injection process. This results in highly consistent and precise parts directly from the tool, often minimizing the need for secondary machining compared to investment casting.

What is the impact of production volume on process selection between Investment Casting and Die Casting?

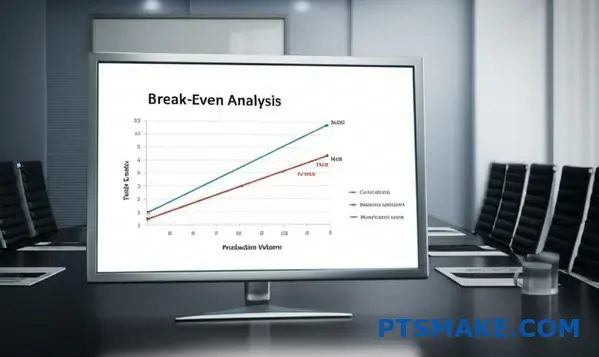

Visualizing the costs is key. A break-even analysis is the perfect tool for this. It helps us pinpoint the exact production volume where one method becomes more economical than the other.

This chart clearly maps total cost against the number of parts produced. It considers both the initial tooling investment and the price per part for each process.

The comparison makes the financial trade-offs in the investment casting vs die casting debate obvious.

| Cost Component | Investment Casting | Die Casting |

|---|---|---|

| Initial Tooling | Low | Very High |

| Price Per Part | Higher | Lower |

Understanding the Cost Curves

A break-even chart plots two lines. One for investment casting and one for die casting. The total cost is on the vertical axis, and production volume is on the horizontal axis.

The investment casting line starts lower. This reflects its low initial tooling cost. However, the line rises more steeply because each individual part costs more to produce.

The die casting line starts much higher. This is due to the significant upfront cost of creating the complex, hardened steel mold. But its slope is much flatter. This shows the low per-part cost.

The Crossover Point is Key

The point where these two lines cross is the break-even volume. If your expected volume is below this point, investment casting is your most cost-effective choice.

If your volume is above this point, die casting is the clear winner. The high tooling cost gets absorbed across many units. This cost distribution is known as Amortization7. At PTSMAKE, this analysis is central to our quoting process.

| Production Volume | Economical Choice | Justification |

|---|---|---|

| Low Volume | Investment Casting | The low initial tooling cost makes small runs affordable. |

| High Volume | Die Casting | The low per-part cost provides significant savings over time. |

The break-even analysis provides a clear financial roadmap. It shows how investment casting is ideal for low volumes due to its low entry cost, while die casting’s efficiency makes it the superior choice for mass production, justifying its high initial investment.

How does the overall cost structure compare between Investment Casting and Die Casting?

When comparing investment casting vs die casting, the cost structure is a primary differentiator. It’s a classic trade-off. You must decide between high upfront costs and low per-part costs, or the reverse.

This choice heavily depends on your expected production volume. Each process has a distinct economic model.

Key Cost Drivers

Understanding these drivers is crucial. They directly impact your project’s bottom line.

| Cost Factor | Investment Casting | Die Casting |

|---|---|---|

| Tooling | Low to Moderate | Very High |

| Material | Higher (More waste) | Lower (Less waste) |

| Labor | High | Low (Automated) |

| Cycle Time | Slow | Very Fast |

Die casting demands a large initial investment. But it pays off with low unit costs in high-volume production.

A Deeper Look at the Cost Breakdown

Let’s break down why these costs differ so significantly. In our work at PTSMAKE, we guide clients through this analysis to find the most cost-effective solution for their specific needs. It’s not just about the initial quote.

Tooling Amortization

Die casting requires robust, hardened steel molds. These are built to withstand immense pressure and heat for thousands of cycles. This makes them very expensive.

Investment casting uses less expensive tooling. Often, it involves creating a master pattern to produce wax replicas. This tooling doesn’t need to endure the same stresses, lowering the upfront cost significantly.

Material, Labor, and Cycle Time

Die casting is a highly automated process. Once the machine is set up, parts can be produced very quickly with minimal labor. This speed drastically reduces the cost per part.

Investment casting is multi-stepped and labor-intensive. It involves shell building, dewaxing, and pouring. Each step adds time and labor cost, making the per-part price higher. This method involves a concept called tooling amortization8.

Volume is the Deciding Factor

The key is production volume. The high tooling cost of die casting is spread across many parts.

| Production Volume | Better Choice | Reason |

|---|---|---|

| Low (e.g., < 5,000) | Investment Casting | Low initial tooling cost justifies higher part price. |

| High (e.g., > 10,000) | Die Casting | High initial cost is offset by very low unit cost. |

Die casting’s high upfront tooling costs are balanced by low per-part prices, ideal for high-volume runs. Conversely, investment casting offers lower initial costs but higher unit prices, making it more suitable for lower volumes and complex designs.

How do mechanical properties of the final parts compare between Investment Casting and Die Casting?

The true strength of a part goes deeper than surface finish. It’s in the microstructure. This is where we see major differences between investment casting vs die casting.

The manufacturing process physics directly shape the final part’s internal quality.

Grain Structure and Density

Investment casting’s slow cooling creates a coarse, uniform grain structure. This generally results in higher density and fewer internal voids.

Die casting’s rapid cooling creates a fine-grained surface. This looks great but can hide subsurface porosity.

Here’s a quick comparison:

| Feature | Investment Casting | Die Casting |

|---|---|---|

| Cooling Rate | Slow & Controlled | Very Fast |

| Grain Structure | Coarse, Uniform | Fine Surface, Variable Core |

| Density | Generally Higher | Can be Lower due to Porosity |

| Porosity Risk | Low | High (Gas Porosity) |

This internal structure is critical for performance.

Let’s dive deeper into the process physics. It’s all about heat and pressure.

The Role of Cooling Rates

In die casting, molten metal is forced into a cool steel die under immense pressure. This "shocks" the metal, causing it to solidify almost instantly.

This rapid cooling creates a very fine grain structure on the part’s surface. This can contribute to excellent surface hardness. However, it can also trap air and gas. This creates tiny bubbles, or porosity, within the part.

Investment casting is the opposite. The ceramic shell is pre-heated before the metal is poured. Cooling happens slowly and uniformly.

This process gives gases time to escape. It also allows for more controlled crystal formation. The slower solidification encourages a more favorable dendritic growth9, leading to a denser, more solid internal structure. In our experience at PTSMAKE, this results in superior integrity for critical applications.

Pressure’s Impact on Defects

| Casting Method | Pressure Level | Primary Defect Risk |

|---|---|---|

| Die Casting | Very High | Gas Porosity |

| Investment Casting | Low (Gravity/Vacuum) | Shrinkage Porosity (can be managed) |

High pressure in die casting is great for detail. But it can force gas into the metal solution, which then gets trapped as the metal cools. Investment casting’s lower pressure environment avoids this specific issue entirely.

Die casting’s rapid process creates a fine-grained surface but risks internal porosity. Investment casting’s slow, controlled cooling results in a denser, more uniform grain structure with minimal voids, impacting the part’s overall integrity and performance.

What secondary operations are typically required between Investment Casting and Die Casting?

Casting is just the beginning. The raw part that comes out of the mold is rarely ready for use. Both investment and die casting require several secondary operations.

These steps are crucial. They ensure the final part meets precise specifications for function and appearance.

Initial Post-Processing

Gate removal is the first step for both. However, the methods often differ. Investment castings require more delicate handling.

| Operation | Investment Casting | Die Casting |

|---|---|---|

| Gate Removal | Manual cutting, grinding | Trimming press, sawing |

| Initial Cleaning | Abrasive blasting | Tumbling, shot blasting |

These initial steps prepare the part for more refined finishing processes.

Deeper Dive into Secondary Operations

The choice between investment casting vs die casting also impacts subsequent steps. Each process has unique requirements to achieve the final desired properties. The initial casting is only a near-net shape.

Heat Treatment

Heat treatment is common for investment castings. It improves strength and durability. This is especially true for steel and aluminum alloys. The process modifies the metal’s microstructure.

Die castings, however, rarely undergo heat treatment. The high-pressure process can create internal porosity. Heat can cause blisters on the surface. We always advise clients on this limitation.

Machining and Finishing

Both methods often need machining. This achieves tight tolerances that casting alone cannot meet. At PTSMAKE, we use CNC machining to create critical features.

Surface finishing is also key. It improves aesthetics and corrosion resistance. The required finish depends entirely on the application.

| Finishing Type | Common for Investment Casting | Common for Die Casting |

|---|---|---|

| Painting | Yes | Yes |

| Plating | Yes | Yes |

| Anodizing | Yes (for aluminum) | Yes (for aluminum) |

| Polishing | Yes, for high-end look | Less common, can reveal pores |

The process of Devesting10 is unique to investment casting. It involves removing the ceramic shell after the metal has solidified. This step must be done carefully to avoid damaging the part’s fine details.

Both casting methods require post-processing, but the steps vary significantly. Investment casting often involves more intensive steps like heat treatment and delicate cleaning, while die casting focuses on high-speed trimming and surface finishing suitable for its as-cast surface.

What are the key limitations for each process between Investment Casting and Die Casting?

Choosing between investment casting and die casting requires understanding their limits. Each method has specific constraints that can impact your project’s success.

This quick guide outlines these key differences. It helps you make a better-informed decision for your components.

Investment Casting Limitations

This process is versatile but has boundaries. Slower production cycles and higher costs per part are notable.

| Constraint | Limitation Details |

|---|---|

| Size & Weight | Typically for smaller parts, from grams to about 75 kg. |

| Production Speed | Slower due to the multi-step wax and shell process. |

| Cost | Higher initial labor and material costs per piece. |

| Geometric | Some internal shapes can be challenging to shell properly. |

Die Casting Limitations

Die casting is fast and cost-effective for high volumes. However, it’s less flexible in other areas.

| Constraint | Limitation Details |

|---|---|

| Material | Mostly limited to non-ferrous alloys like aluminum, zinc, and magnesium. |

| Tooling Cost | Very high initial mold (die) costs. |

| Porosity | Parts can have internal porosity, affecting strength. |

| Geometric | Undercuts and complex internal features increase complexity and cost. |

When we compare investment casting vs die casting, material choice is a major separator. Die casting’s steel molds cannot handle the high melting points of ferrous metals like steel. The tooling would degrade too quickly.

This is why it excels with aluminum and zinc alloys.

Investment casting, on the other hand, uses ceramic shells. These are single-use and can withstand extremely high temperatures. This allows for casting a wide range of metals, including stainless steel and superalloys.

Geometric and Tooling Factors

The size and complexity of your part also guide the choice. Investment casting offers incredible design freedom for intricate parts. The shell’s low permeability11 helps capture fine details.

Die casting is better for parts with simpler designs produced in high volumes. Thin walls are possible, but designers must be mindful of metal flow and potential defects.

Tooling is another critical point. At PTSMAKE, we guide clients through this decision, as it has huge budget implications.

| Factor | Investment Casting | Die Casting |

|---|---|---|

| Tooling Investment | Low to moderate (for the wax pattern mold) | Very High (for the hardened steel die) |

| Lead Time | Shorter for tooling, longer for part production | Longer for tooling, very fast for part production |

| Best Volume | Low to medium volume | High to very high volume |

Understanding these constraints is vital. The limitations in material, size, and geometry directly influence cost, production speed, and final part quality. Making the wrong choice early on can lead to expensive redesigns and delays down the line.

Analyze an aerospace turbine blade: why investment casting?

Aerospace turbine blades are a masterclass in engineering. They face extreme temperatures and stresses. This demanding environment dictates both material and manufacturing choices.

Why is investment casting the go-to method?

The Unbeatable Combination

The answer lies in two key areas. First, the need for high-performance superalloys. Second, the blade’s incredibly complex, hollow design for cooling. No other process handles both requirements so effectively.

| Challenge | Requirement |

|---|---|

| Extreme Heat | High-Temperature Superalloys |

| Efficient Cooling | Complex Internal Passages |

This unique pairing makes investment casting the only viable option.

The Material Imperative: Superalloys

Turbine blades operate in environments exceeding 1,000°C. This requires materials like nickel-based superalloy12. These metals maintain their strength at temperatures that would melt many others.

This high melting point immediately poses a manufacturing challenge. For instance, when considering investment casting vs die casting, the choice is clear. Die casting is unsuitable for such high-temperature materials.

The Geometric Puzzle: Hollow Airfoils

Modern turbine blades are not solid. They have intricate, snake-like internal cooling channels. These passages allow cool air to flow through the blade, preventing it from melting.

Machining these internal features from a solid block is impossible. Investment casting solves this beautifully. It uses pre-formed ceramic cores that are placed inside the wax pattern.

After casting, these ceramic cores are chemically dissolved. This leaves behind the precise, complex internal network needed for cooling. It’s a method that delivers a single, seamless component with features that are otherwise unachievable.

| Method | Suitability for Turbine Blades | Reason |

|---|---|---|

| Investment Casting | Ideal | Handles superalloys and complex hollow shapes. |

| CNC Machining | Unsuitable | Cannot create internal cooling channels. |

| Die Casting | Unsuitable | Cannot handle high-melting-point superalloys. |

This process ensures blades are strong, heat-resistant, and effectively cooled.

The combination of high-temperature superalloys and complex internal cooling channels makes investment casting the only practical solution for modern turbine blades. This method delivers the performance and reliability essential for aerospace applications.

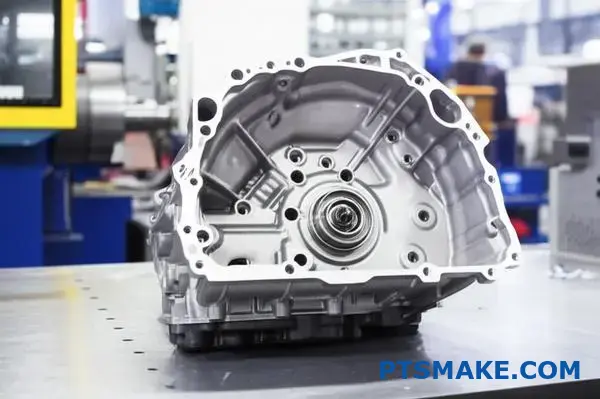

Analyze an automotive gearbox housing: why die casting?

The automotive industry demands massive quantities of identical parts. The gearbox housing is a prime example. Why choose die casting for this?

The upfront tooling cost is very high. This fact often surprises people. But it is the key to an extremely low piece-part cost.

The Logic of High Volume

For applications needing millions of units, the initial investment makes sense. The cost is spread out, making each part cheaper over the entire production run.

Cost Breakdown at Scale

This method shines when production numbers are high. The per-part cost drops dramatically as volume increases.

| Production Volume | Upfront Tooling Cost | Cost Per Part |

|---|---|---|

| Low (e.g., 1,000) | High | Relatively High |

| High (e.g., 1,000,000+) | High | Extremely Low |

This trade-off is central to manufacturing decisions in the automotive sector.

Justifying the Massive Tooling Investment

A die casting mold is a marvel of engineering. It’s made from hardened steel and must withstand immense pressure and heat for millions of cycles. This is why it costs so much.

However, this investment pays for itself through tooling amortization13. The total mold cost is divided across every part produced. For a gearbox housing, this could be millions of units.

The contribution of the tool cost to each part becomes incredibly small.

Dimensional Stability and Consistency

A gearbox housing has complex internal features. It requires tight tolerances for bearings and shafts to fit perfectly. Die casting delivers exceptional dimensional stability, part after part.

When discussing high-volume metal parts, the investment casting vs die casting debate often comes up. While investment casting is excellent for complex shapes, it cannot match the speed and low per-part cost of die casting for this scale.

Based on our test results, die casting provides the required consistency for automated assembly lines. Any deviation could halt production.

| Feature | Die Casting (for Gearbox Housings) | Alternative Methods |

|---|---|---|

| Cycle Time | Seconds per part | Minutes or hours per part |

| Consistency | Extremely High | Variable |

| Cost at Volume | Very Low | High |

At PTSMAKE, we’ve guided clients through this analysis. The math always points to die casting for true mass production.

For gearbox housings, the high upfront die casting investment is a strategic choice. It ensures millions of identical, dimensionally stable parts are produced at the lowest possible piece-part cost, which is essential for the automotive industry’s scale.

Your part needs both complexity and high volume. Investment Casting or Die Casting.

You’re facing a tough choice. Your design is complex, but you need thousands of units. This puts investment casting and die casting head-to-head.

Investment casting excels at complexity. Die casting delivers high volume at a lower cost per part.

The Core Trade-Off

So, what gives? Do you sacrifice design intricacy for speed and cost? Or do you accept a higher price for perfect complexity?

Let’s build a framework to help you decide.

| Decision Path | Best For… | Key Consideration |

|---|---|---|

| Redesign for Die Casting | Cost-sensitive projects | Can functionality be maintained? |

| Split into Multiple Parts | Modular or complex assemblies | Assembly costs and tolerance stack-up |

| Accept Investment Casting | Mission-critical complexity | Is the higher per-part cost viable? |

This table simplifies the initial options. Each path has significant implications for your project’s timeline and budget.

Choosing the right path requires a deeper look. It’s not just about the initial quote. It’s about the total cost of ownership and product lifecycle.

Path 1: Redesign for Manufacturability (DFM)

At PTSMAKE, we often start here. We collaborate with clients to see if a complex design can be simplified for die casting. This process, known as DFM, is crucial.

We analyze features like undercuts, thin walls, and draft angles. Sometimes, a small tweak can make a part die-castable. This often leads to huge cost savings in high-volume production without compromising core function.

Path 2: The Modular Assembly

What if redesign isn’t an option? Consider breaking the part into simpler components. These can be die-cast or machined separately and then assembled.

This modular approach can be very effective. It simplifies tooling and allows for easier repairs. However, you must account for assembly labor and potential tolerance issues.

Path 3: Embracing Investment Casting Costs

Sometimes, complexity is non-negotiable. For critical aerospace or medical parts, the intricate geometry is essential. In these cases, accepting the higher unit economics14 of investment casting is the right call. The performance and reliability justify the expense. A clear understanding of long-term value is key.

| Factor | Redesign (Die Casting) | Split Part (Die Casting) | Accept Cost (Investment Casting) |

|---|---|---|---|

| Tooling Cost | High | Moderate (per part) | Low |

| Part Cost | Low | Low (per piece) | High |

| Assembly | None | Required | None |

| Design Integrity | Potentially altered | Maintained | Fully Maintained |

This helps visualize the financial and engineering trade-offs over the product’s entire life.

The choice between investment and die casting for complex, high-volume parts is a strategic balance. Your decision depends on design flexibility, assembly strategy, and long-term budget considerations. A clear framework guides you to the most effective solution.

Your design requires stainless steel. Investment Casting or Die Casting?

Why can’t you just die cast stainless steel? It’s a common question with a straightforward answer: heat.

Stainless steel has a very high melting point. This heat is too much for the tools used in conventional die casting.

The process would simply destroy the mold. This makes the method impractical and costly for this material.

Investment casting, however, is designed to handle such high temperatures, making it the industry standard.

Melting Point Comparison

| Material | Approximate Melting Point (°C) |

|---|---|

| Stainless Steel (304) | 1400 – 1450 |

| Aluminum Alloys (Die Cast) | ~ 600 |

| Tool Steel (H13 Die) | ~ 1425 |

As the table shows, the melting points are too close for comfort.

The Challenge of High Temperatures in Casting

Die casting relies on reusable steel molds, often made from H13 tool steel. These molds are fantastic for casting lower-temperature metals like aluminum or zinc.

However, stainless steel melts at a temperature that is very close to, or even exceeds, the melting point of the mold material itself.

Pouring molten stainless steel into a steel die would cause catastrophic failure. The intense heat would lead to thermal shock, causing the die to crack and warp almost immediately.

Another major issue is die soldering15, where the molten metal chemically bonds to the mold surface. This ruins the part finish and damages the expensive die, often beyond repair. The investment casting vs die casting choice becomes obvious here.

Why Investment Casting Is the Solution

Investment casting solves this problem by not using a metal mold. Instead, it uses a ceramic shell built around a wax pattern.

This process is ideal for high-temperature alloys.

| Feature | Die Casting Mold | Investment Casting Mold |

|---|---|---|

| Material | Tool Steel | Ceramic |

| Reusability | High | Single-Use |

| Temp. Resistance | Moderate | Very High |

Ceramic can easily withstand the extreme heat of molten stainless steel without degrading.

After the metal solidifies, the ceramic shell is simply broken away. This reveals the finished stainless steel part. This fundamental difference makes it the go-to method.

Stainless steel’s high melting point makes it unsuitable for die casting, as it would destroy the steel molds. Investment casting overcomes this by using disposable, heat-resistant ceramic molds, establishing it as the standard process for stainless steel parts.

How would you justify switching a part between Investment Casting and Die Casting?

Making the switch is a major financial decision. It goes far beyond comparing the per-part price. A true justification requires a Total Cost of Ownership (TCO) analysis.

This means looking at every cost involved. You must account for new tooling, validation, and long-term production. Let’s simulate this critical analysis.

The Cost-Benefit Framework

A comprehensive analysis balances upfront investment against long-term savings. High-volume production is key for die casting to be viable.

| Cost Element | Investment Casting | Die Casting |

|---|---|---|

| Tooling | Low | Very High |

| Per-Part Price | High | Low |

| Validation | Simpler | More Complex |

| Cycle Time | Slower | Very Fast |

Simulating the Total Cost of Ownership

To justify the switch, we must calculate the break-even point. This is where the savings from die casting’s lower per-part cost overtake its high initial tooling investment.

The Upfront Investment

Die casting requires a significant capital outlay for hard tooling. Based on past projects at PTSMAKE, this tool can cost 5 to 10 times more than an investment casting pattern.

You also have validation costs. This includes First Article Inspection (FAI) and potentially a full Production Part Approval Process (PPAP). These ensure the new process meets all specifications.

Calculating the Payback

The core of the analysis is comparing total costs at different volumes. The high initial tooling cost requires a clear amortization16 strategy over the entire production run.

Let’s map out the financial crossover point. This comparison helps clarify the investment casting vs die casting decision at scale.

| Production Volume | Total Cost (Investment Casting) | Total Cost (Die Casting) | Justification |

|---|---|---|---|

| 5,000 Units | Lower | Higher | Not Justified |

| 25,000 Units | Approaching Parity | Approaching Parity | borderline |

| 100,000+ Units | Significantly Higher | Lower | Clearly Justified |

As you can see, the justification hinges entirely on achieving high production volumes where per-part savings accumulate and offset the initial investment.

A full TCO analysis reveals the break-even point. High initial die casting costs are justified by substantial per-part savings at high volumes, making it a strategic long-term investment for scaling production.

Discover Your Best Casting Solution with PTSMAKE Today!

Ready to choose between investment casting and die casting for your next project? Contact the PTSMAKE team now for expert recommendations and a fast, no-obligation quote—precision manufacturing from prototype to production, tailored for your industry’s needs. Your success starts with the right partner!

Discover the material science behind ceramic shells and how it impacts casting quality. ↩

Learn how controlling this phase is crucial for the final part’s strength and finish. ↩

Explore the properties and classifications of iron-based metals used in manufacturing. ↩

Learn how this single-use pattern unlocks the creation of intricate and highly detailed metal components. ↩

Discover how die temperature fluctuations affect part consistency and tool life. ↩

Learn how material shrinkage affects final part accuracy and how to manage it in your design. ↩

Discover how this accounting principle justifies high-cost tooling for mass production. ↩

Understand how to calculate tooling amortization to accurately forecast your project’s total cost. ↩

Learn how crystal structures form during solidification and affect material properties. ↩

Learn more about this crucial shell removal process in investment casting. ↩

Learn how shell properties affect casting quality and design choices. ↩

Learn more about the properties and applications of these advanced high-performance metals. ↩

See how spreading tool costs over high volumes drastically cuts your per-unit manufacturing expenses. ↩

Learn how per-part costs and lifetime value impact your project’s profitability and overall manufacturing strategy. ↩

Learn how this metallurgical bonding can affect tool life and part quality. ↩

Understand how to spread tooling costs across production to accurately calculate your true per-part cost. ↩