Finding reliable CNC machining services in Milwaukee can feel overwhelming when your project timeline is tight and quality requirements are non-negotiable. Many manufacturers struggle with inconsistent part quality, missed deadlines, and poor communication from local shops.

Milwaukee offers several established CNC machining providers with advanced equipment and proven track records in precision manufacturing. The key is knowing how to evaluate their capabilities, lead times, and quality systems to match your specific project requirements.

This guide walks you through everything you need to know about CNC machining in Milwaukee. You’ll discover how to identify trustworthy suppliers, reduce lead times, ensure tight tolerances, and scale your production effectively while keeping costs under control.

Ultimate Guide to Finding Reliable CNC Machining in Milwaukee

Finding a dependable partner for CNC machining in Milwaukee can be challenging. Your project’s success depends on their precision and reliability. It’s more than just finding a shop with the right machines.

You need to evaluate several key factors.

Wichtige Bewertungskriterien

Experience matters, but look for relevant experience. Do they handle projects similar to yours? Check their equipment list. Modern machines often mean tighter tolerances and better finishes.

Finally, review customer feedback. Look for detailed testimonials, not just star ratings. This provides insight into their process and communication.

| Kriterien | Bedeutung | Was zu beachten ist |

|---|---|---|

| Erleben Sie | Hoch | Portfolio of similar projects |

| Ausrüstung | Hoch | Modern, well-maintained machines |

| Customer Feedback | Mittel | Detailed, specific reviews |

A Deeper Dive into Supplier Evaluation

To find the best CNC machining shops in Milwaukee, you must look beyond their website claims. A deeper evaluation of their technical capabilities and partnership potential is essential for long-term success.

Bewertung der technischen Fähigkeiten

Ask for a detailed equipment list. Do they have 5-axis machines for complex geometries? What about their quality control process? A shop that is serious about quality will have robust inspection procedures.

They should be proficient in creating parts that meet strict specifications. This often involves a deep understanding of Geometrische Bemaßung und Tolerierung1 to ensure every feature is correctly defined and inspected. This is crucial for reliable CNC machining in Milwaukee.

Evaluating Communication and Partnership

The best suppliers act as partners, not just vendors. Evaluate their communication style. Are they responsive? Do they offer design feedback to improve manufacturability?

At PTSMAKE, we believe transparent communication is key. Finding a team that works with you to solve problems is a sign of trusted CNC services in Milwaukee.

| Quality Control Method | Beschreibung | Hauptnutzen |

|---|---|---|

| CMM-Prüfung | Coordinate Measuring Machine checks dimensions. | High accuracy and repeatability. |

| Erste Artikelüberprüfung | Full inspection of the first part produced. | Ensures setup and process are correct. |

| In-Process Checks | Regular checks during the production run. | Catches deviations early to reduce scrap. |

Vetting a CNC machining supplier requires a thorough look at their experience, equipment, and client feedback. A deeper analysis of their technical skills, quality control, and communication style is crucial to finding a true manufacturing partner in Milwaukee.

Secrets to Reducing Lead Times with Local Milwaukee CNC Shops

Reducing production delays is a common goal. It often comes down to simple, proactive steps. Working with local providers offers a huge advantage for this.

Clear planning and open communication are key. These two elements form the foundation for achieving reduced lead times Milwaukee shops can offer.

The Planning Phase

Before production begins, ensure all your designs are finalized. Constant changes are a primary source of delay. Lock in your specs early.

| Planning Step | Erforderliche Maßnahmen | Auswirkungen auf die Vorlaufzeit |

|---|---|---|

| Design Freeze | Finalize CAD models and drawings. | Prevents mid-project rework. |

| Material Spezifikation | Specify materials and alternatives. | Allows for faster sourcing. |

| Toleranz | Clearly define critical tolerances. | Avoids clarification delays. |

This upfront effort streamlines the entire process. It allows for fast CNC machining Milwaukee services to start without hesitation.

Advanced Strategies for Speed

Beyond basic planning, we can implement more advanced tactics. These strategies are about creating a partnership with your CNC shop, not just a transaction. It fosters a smoother workflow.

Good communication prevents misunderstandings that cause delays. I always recommend a single point of contact on both sides. This simplifies information flow and accountability.

Establishing Communication Protocols

Set up a regular check-in schedule. This could be a brief daily email or a weekly call. It keeps everyone aligned and addresses issues before they grow. This is essential for quick turnaround CNC services.

A shared project management tool can also be very effective. It provides real-time visibility into the project’s progress. We’ve found that this transparency helps manage expectations and identify potential bottlenecks early on. Techniques like the Methode des kritischen Pfades2 can be applied to map out dependencies and optimize the schedule for the fastest possible completion.

Material and Tooling Pre-Planning

Another effective strategy is discussing material sourcing in advance. If you’re using a common material, ask if the shop can stock it for you. For specialized materials, ordering them ahead of time can shave weeks off your timeline.

| Communication Tactic | Am besten für | Nutzen Sie |

|---|---|---|

| Single Point of Contact | Complex Projects | Reduces confusion |

| Regelmäßige Check-ins | Long-term Production | Proactive problem-solving |

| Shared PM Tool | All Projects | Vollständige Transparenz |

Proactive communication and smart material management are your best tools for accelerating production.

Effective planning and clear communication are essential for reducing lead times. By finalizing designs early and establishing strong communication protocols, you can leverage local Milwaukee CNC shops for significantly faster turnaround times on your projects.

How to Ensure Precision and Tolerance in Milwaukee CNC Services

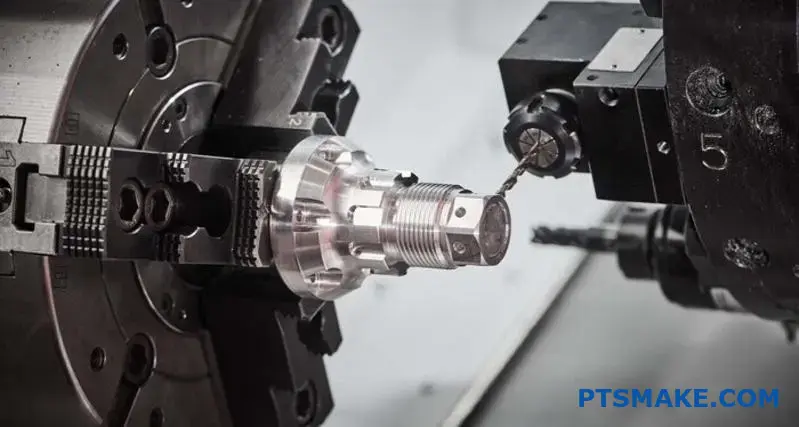

Achieving tight tolerances is about method, not luck. It combines advanced equipment with strict process controls. This discipline is the foundation of precision CNC machining Milwaukee.

We focus on the machine’s capabilities and constant monitoring. Every step is managed carefully.

Key Control Points

This approach ensures every component meets exact specifications. It is essential for high-stakes industries.

| Kontrollmethode | Primärer Schwerpunkt | Auswirkungen auf die Verträglichkeit |

|---|---|---|

| Advanced CNC Machines | Machine rigidity and accuracy | Reduces vibration and errors |

| In-Prozess-Sondierung | Real-time measurement | Corrects tool wear immediately |

| Klimatisierung | Stable temperature | Verhindert Materialausdehnung |

Superior equipment is just the starting point. The real challenge is maintaining precision consistently. This is how we produce accurate CNC parts Milwaukee. It requires a deep focus on process control.

Advanced Equipment and Process Controls

Thermal Compensation

CNC machines generate heat during operation. This heat can cause the machine and workpiece to expand. Our machines use sensors to monitor temperature. They automatically adjust to compensate for these changes, maintaining accuracy.

High-Performance Tooling

The quality of the cutting tool is critical. We use premium tooling that resists wear and deflection. This directly improves the surface finish and dimensional accuracy of the final part. It is a key factor in tight tolerance machining.

The process isn’t over when the cutting stops. We use advanced Metrologie3 tools, like Coordinate Measuring Machines (CMMs), to verify every dimension against the design.

| Process Control Factor | Beschreibung | Warum es wichtig ist |

|---|---|---|

| CAM-Programmierung | Optimized toolpaths and cutting strategies. | Reduces tool stress and improves surface finish. |

| Bedienerschulung | Skilled machinists who understand the process. | They can spot potential issues before they become defects. |

| Zertifizierung von Materialien | Verifying raw material properties. | Ensures material behaves as expected during machining. |

Achieving precision demands a holistic approach. It combines high-end equipment with rigorous process controls, including thermal compensation, premium tooling, and advanced measurement. These systems ensure consistent quality and tight tolerances for every machined component.

Cost-Effective Strategies for CNC Machining Projects in Milwaukee

To achieve cost-effective manufacturing, you don’t need to sacrifice quality. The key lies in smart, upfront decisions. These choices are made before a machine even turns on. This approach ensures your project stays on budget.

Material Selection Matters

Choosing the right material is critical. Softer metals machine faster, reducing labor and tool costs. This is a simple path toward affordable CNC machining Milwaukee.

| Material | Relative Kosten | Bearbeitbarkeit |

|---|---|---|

| Aluminium 6061 | Niedrig | Ausgezeichnet |

| Rostfreier Stahl 304 | Mittel | Messe |

Optimize Your Design

Simple designs are cheaper to produce. Complex features require more setup and machining time. Every detail, from corner radii to pocket depth, impacts the final cost.

Embracing Design for Manufacturability (DFM)

DFM is a core principle we apply at PTSMAKE. It involves designing parts for ease of manufacturing. This proactive approach is essential for providing budget-friendly CNC services. It minimizes potential production issues and unnecessary expenses.

Overlooking DFM can lead to multiple revisions. It also increases setup times and tooling costs significantly. A simple consultation can often prevent these costly mistakes down the line.

Wichtige DFM-Erwägungen

Focusing on a few key areas can yield big savings. For instance, specifying tolerances only where functionally necessary avoids over-engineering. Each tight tolerance adds machine time and inspection steps. Understanding concepts like Geometrische Dimensionierung und Tolerierung (GD&T)4 directly impacts your budget.

| DFM-Prinzip | Auswirkungen auf die Kosten | Empfehlung |

|---|---|---|

| Simplify Geometries | Hoch | Avoid undercuts and deep, narrow pockets. |

| Merkmale standardisieren | Mittel | Use standard hole sizes and thread types. |

| Loosen Tolerances | Hoch | Specify tight tolerances only when critical. |

| Optimize Finishes | Mittel | Request specific surface finishes only on key areas. |

At PTSMAKE, we often collaborate with clients on their designs. This partnership ensures parts are optimized for our CNC machining processes in Milwaukee. We help you achieve the best balance of performance and cost for every project.

Strategic material selection and embracing DFM principles are fundamental for cost control. These early-stage decisions directly influence machining complexity and time, ensuring you receive high-quality, budget-friendly parts for your Milwaukee-based projects without compromise.

Secrets to Scaling Production with Milwaukee CNC Machining Partners

Scaling from prototype to high-volume production is a critical step. It’s where many promising projects falter. A smooth transition is not guaranteed.

Success hinges on your partner’s scalability. This requires robust manufacturing scaling strategies. It’s about more than just having machines.

True scalability involves careful planning and process control. Finding a partner for scalable CNC machining in the Milwaukee area, or anywhere else, means looking for this deep expertise.

Let’s explore what this transition truly involves.

Key Transition Stages

| Bühne | Schwerpunkt | Zentrale Herausforderung |

|---|---|---|

| Geringes Volumen | Prototyping, Validation | Geschwindigkeit und Flexibilität |

| Mid-Volume | Prozess-Optimierung | Konsistenz |

| Großes Volumen | Automation, Cost Control | Efficiency and Quality |

Planning for High-Volume Success

A truly scalable CNC machining partner prepares for high volume from the start. This involves deep capacity planning and process validation, long before the first large order is placed. At PTSMAKE, we begin these conversations during the prototyping phase.

From Manual to Automated

For low-volume runs, a skilled machinist can manually adjust settings. This approach is not feasible for high-volume production. The process must be repeatable and stable without constant intervention. This is where automation and robust quality systems become vital.

When scaling, ensuring every part meets the original design intent is paramount. This is where mastering concepts like Geometrische Bemaßung und Tolerierung5 becomes non-negotiable. It provides a clear, mathematical language that removes ambiguity from engineering drawings, ensuring consistency across thousands of parts.

Capacity and Capability

Your partner must prove their capacity. Ask them to outline their plan for your project. This plan should detail machine allocation, cycle times, and quality checks. It’s a core part of effective manufacturing scaling strategies.

Below is a comparison of what to look for at each stage.

| Faktor | Low-Volume Focus | High-Volume Focus |

|---|---|---|

| Werkzeugbau | Soft tooling, general fixtures | Hard tooling, custom fixtures |

| Programmierung | Manual G-code edits | Optimized, locked-down programs |

| Inspektion | Manual checks, CMM for FAI | In-process probing, automated inspection |

| Materialhandhabung | Manual loading/unloading | Bar feeders, robotic arms |

Scaling from small batches to high-volume production requires more than adding machines. It demands strategic capacity planning, process validation, and a partner who understands scalable CNC machining. Clear communication and detailed planning are essential for a smooth transition from prototype to production.

Complete Overview of Materials Available for CNC Machining in Milwaukee

Choosing the right material is a critical first step. It impacts performance, cost, and manufacturing time. The selection available for CNC machining in Milwaukee is vast.

We can machine both metals and plastics. Each has unique properties making them suitable for different applications. This decision directly influences the final part’s functionality.

Common Metal Options

Metals offer strength and durability. They are ideal for structural components and high-stress applications. We often work with aluminum, steel, and titanium.

| Metall | Wichtigste Eigenschaft | Gemeinsame Bewerbung |

|---|---|---|

| Aluminium 6061 | Ausgezeichnetes Verhältnis von Festigkeit zu Gewicht | Aerospace parts, consumer electronics |

| Rostfreier Stahl 304 | Hohe Korrosionsbeständigkeit | Medizinische Geräte, lebensmitteltaugliche Geräte |

| Titan | Very high strength, low density | Hochleistungsteile für die Automobilindustrie |

Popular Plastic Choices

Plastics provide versatility and are often lighter. They are great for prototypes and specific end-use parts. Options like ABS, PEEK, and Nylon are common choices.

Making the right choice involves more than just datasheets. It’s a balance of properties, cost, and how the material behaves during machining. This is a key part of our process at PTSMAKE. We help clients navigate these options.

A Deeper Material Selection Guide

Your project’s success depends on this choice. Consider the operating environment. Will the part face high temperatures, chemicals, or physical stress? Answering these questions narrows down the metal and plastic options.

For example, PEEK is expensive. But its high-temperature resistance is essential for certain aerospace uses. In contrast, ABS is affordable and great for prototyping enclosures. The right material depends entirely on the application. Some materials also exhibit Anisotropie6, which affects their strength in different directions.

This is a crucial detail for load-bearing parts. Below is a quick guide to some popular CNC machining materials in Milwaukee.

| Material | Am besten für | Avoid If |

|---|---|---|

| ABS | Prototyping, low-stress parts | High temperatures or UV exposure |

| Nylon | Gears, bearings, wear parts | High moisture environments |

| PEEK | Demanding aerospace/medical uses | Budget-sensitive projects |

| Delrin (POM) | High-precision, low-friction parts | Applications requiring strong adhesives |

Our team guides you through these trade-offs. We ensure your final product meets every specification, from performance to budget. This collaborative approach removes guesswork.

Choosing the right material is foundational for successful CNC machining. Balancing physical properties, machinability, and budget is key. Our guide offers a starting point for Milwaukee businesses to select the best metal and plastic options for their specific projects.

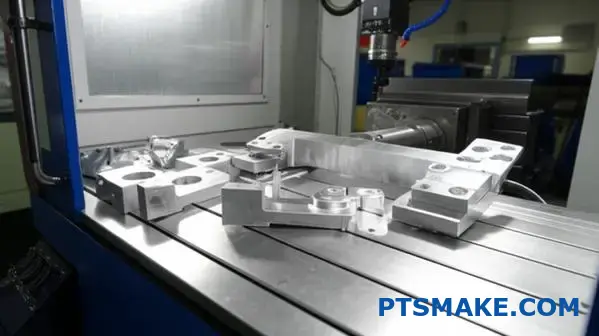

How to Handle Complex Geometries with Local CNC Machining Experts

Manufacturing intricate parts requires more than just standard equipment. It demands advanced techniques and deep expertise. This is where specialized shops excel.

They use specific methods for creating complex shapes and features. This capability is crucial for modern engineering.

Advanced Machining Approaches

Success in intricate parts manufacturing depends on the right technology. Not all machines are created equal.

Key Techniques Overview

| Technik | Primäre Verwendung | Grad der Komplexität |

|---|---|---|

| 5-Achsen-CNC-Bearbeitung | Undercuts, complex curves | Hoch |

| Drahterodieren | Scharfe Innenecken | Sehr hoch |

| Schweizer Zerspanung | Small, long, slender parts | Hoch |

These methods allow for designs that were once impossible. They push the boundaries of manufacturing.

True mastery of advanced geometry CNC lies in combining techniques. A single complex part might require multiple machining processes. For instance, we often start with 5-axis milling for the overall shape.

Then, we might use Wire EDM for sharp internal corners. Or we could use a lathe for cylindrical features. This integrated approach is key. Partners providing complex CNC machining in Milwaukee understand this workflow.

Material and Software Synergy

The material choice heavily influences the machining strategy. Harder materials require different tools and cutting speeds. Software plays a vital role in this process.

| Material | Zentrale Herausforderung | Recommended Technique |

|---|---|---|

| Titan | Heat generation | High-pressure coolant, 5-axis |

| Inconel | Arbeitsverhärtung | Slow speeds, rigid setups |

| Gehärteter Stahl | Zerbrechlichkeit | Grinding, Wire EDM |

Advanced CAM software is essential for success. It allows us to simulate the entire process before cutting any metal. This prevents costly errors and optimizes the manufacturing path. Effective Optimierung der Werkzeugwege7 is a non-negotiable part of our process at PTSMAKE. It ensures both precision and efficiency for every component we produce.

Advanced techniques like 5-axis machining and EDM, combined with smart software and material expertise, are essential. They make the manufacturing of complex, intricate parts possible and efficient, meeting the highest standards of precision and quality for any project.

The Ultimate Checklist for On-Time Delivery from Milwaukee CNC Shops

A checklist is your best tool for ensuring on-time delivery. It transforms hope into a structured plan. It’s about defining clear steps and tracking progress.

This approach prevents delays before they happen. For any on-time delivery CNC Milwaukee project, a solid checklist is non-negotiable.

Wichtige Meilensteine des Projekts

Here’s a simple breakdown of milestones. Every stage must be confirmed before moving to the next. This ensures accountability and clear communication.

| Meilenstein | Schlüsselaktion | Status |

|---|---|---|

| Design Lock | Final CAD models approved | |

| Material Order | Materials procured & verified | |

| Production Start | First part machining begins | |

| Endgültige QA | All parts pass inspection |

A simple milestone checklist is a good start. But what happens when issues arise? True reliable scheduling comes from anticipating problems. This is where contingency planning becomes vital.

You need to ask "what if?" for each stage. What if the material is delayed? What if a machine needs maintenance?

Building a Resilient Schedule

At PTSMAKE, we build buffer time into our schedules. We also identify potential risks early on. We learned that having a backup plan isn’t a sign of pessimism; it’s a mark of professionalism. It’s a core part of providing timely manufacturing services.

A great CNC partner doesn’t just follow the plan. They have a plan for when things go off-plan. This requires a deep understanding of the entire process, from material sourcing to final logistics. Using tools like the Methode des kritischen Pfades8 helps identify which tasks have the least slack, allowing us to focus our risk management efforts where they matter most.

Contingency Plan Example

A practical contingency plan might look like this:

| Potenzielles Risiko | Trigger for Action | Contingency Plan |

|---|---|---|

| Material Delay | Supplier confirms a 2+ day delay | Activate pre-vetted backup supplier. |

| Tooling Failure | Critical tool breaks unexpectedly | Use redundant tooling kept in stock. |

| QA Bottleneck | Inspection queue exceeds 8 hours | Re-assign a machinist to assist QA. |

This proactive approach separates reliable shops from the rest when it comes to cnc machining milwaukee services.

A detailed checklist with clear milestones and robust contingency plans is essential. This proactive strategy ensures reliable scheduling and is the foundation for achieving consistent on-time delivery from any Milwaukee CNC shop.

Secrets to Integrating CNC Machining with Injection Molding in Milwaukee

Combining CNC machining and injection molding isn’t just a trend. It’s a powerful strategy for streamlining production. This integration creates a seamless workflow.

It moves from initial mold creation to final part finishing under one roof. This approach offers huge benefits for projects in Milwaukee.

Why Integration Matters

Full-service manufacturing reduces complexity. It also cuts down lead times and improves overall part quality. You work with a single, accountable partner.

| Aspekt | Standalone Services | Integrated Solution |

|---|---|---|

| Kommunikation | Multiple contacts | Zentrale Anlaufstelle |

| Vorlaufzeit | Longer, sequential | Shorter, parallel tasks |

| Kosten | Higher coordination costs | Kostengünstiger |

| Qualitätskontrolle | Varies by supplier | Durchgängig konsistent |

This integrated model is the future of efficient production.

True integration goes beyond simply offering two services. It’s about how they interact to create a superior result. At PTSMAKE, we leverage this synergy daily for our clients.

Streamlining the Production Flow

The process starts with CNC machining. We use it to create high-precision injection molds. This is where accuracy is critical. A precise mold means precise parts.

Next, we move to injection molding. After the parts are molded, they might need secondary operations. This is where CNC machining re-enters the process for tasks like drilling, tapping, or creating fine details that are difficult to mold directly. This is a core advantage of full-service manufacturing.

Case Study: Milwaukee Medical Device

A client needed a complex housing with threaded features. We used CNC for the initial mold. After molding, the parts returned to our CNC machines. We precisely drilled and tapped the holes. This ensured perfect alignment and function. Using our integrated production solutions saved the client significant time and budget. Our tests show this method reduces post-processing defects by over 30%.

This workflow also allows for quick modifications. If a design needs a change, we can rapidly adjust the mold using CNC. This flexibility is invaluable for prototyping and iterative design. It’s a key part of the value we provide in tooling inserts9 and mold modifications.

| Bühne | Aktion | Nutzen Sie |

|---|---|---|

| 1. Mold Creation | CNC machine the mold | High precision, complex geometry |

| 2. Molding | Injection mold parts | High-volume, repeatable |

| 3. Post-Processing | CNC machine features | Add details, ensure tight tolerance |

| 4. QC & Finish | Endkontrolle | Guaranteed quality, single source |

This approach to CNC and injection molding in Milwaukee ensures a streamlined, reliable, and efficient manufacturing journey.

Integrating CNC machining and injection molding offers a powerful, streamlined solution. This full-service approach reduces lead times, improves quality control, and simplifies supplier management, providing a significant competitive advantage for complex projects from a single trusted partner.

The Ultimate Guide to Post-Processing and Finishing in Milwaukee CNC

CNC machining creates the part’s shape. But the finish determines its final performance. This step is crucial for function and appearance.

The right finish protects your part. It can prevent corrosion and wear.

Common Finishing Techniques

Anodizing is excellent for aluminum parts. It adds a hard, protective, and non-conductive layer.

Painting offers endless color options. It also provides a good barrier against moisture and environmental factors.

| Finishing-Methode | Am besten für | Hauptvorteil |

|---|---|---|

| Eloxieren | Aluminium | Korrosionsbeständigkeit |

| Malerei | Verschiedene Metalle | Aesthetic Flexibility |

Richtig CNC finishing Milwaukee ensures your components meet all specifications, from tolerance to final look.

How Finishes Affect Part Performance

Choosing the right finish is not just about aesthetics. It directly impacts the durability, lifespan, and overall function of your CNC machined parts. These Oberflächenbehandlungen are an engineering decision.

Enhancing Corrosion Resistance

Anodizing creates a controlled oxide layer on aluminum. This layer is much thicker than the natural one. It effectively seals the base metal from moisture and other corrosive elements.

Improving Wear and Hardness

Einige post-processing options focus on mechanical properties. Hardcoat anodizing, for example, makes aluminum surfaces almost as hard as steel. This is perfect for parts that face friction and wear.

Proper surface preparation is vital for good Untergrundhaftung10. Without it, even the best coating can flake or peel off, compromising the part’s integrity. We always emphasize this with our clients.

Comparing Key Post-Processing Options

Here is a quick comparison of common treatments we handle at PTSMAKE. This helps illustrate how the choice impacts the final product.

| Behandlung | Material | Auswirkungen auf die Leistung | Typischer Anwendungsfall |

|---|---|---|---|

| Hartbeschichtung durch Eloxieren | Aluminium | Hohe Verschleißfestigkeit | High-contact mechanical parts |

| Pulverbeschichtung | Die meisten Metalle | Durable, thick coating | Automotive, outdoor equipment |

| Elektropolieren | Rostfreier Stahl | Smooth, clean surface | Medical, food-grade parts |

The best choice depends entirely on your application’s demands. Considering options for cnc machining milwaukee early in the design phase saves time and prevents future failures.

Post-processing is a critical final step. The right surface treatment enhances durability, corrosion resistance, and aesthetics. Choosing wisely ensures your CNC machined parts perform as intended and last longer, delivering true value for your project.

Unlock Milwaukee CNC Success—Partner with PTSMAKE Today

Ready to take your next CNC machining project in Milwaukee to new heights? Choose PTSMAKE for unrivaled precision, fast lead times, and expert support from prototype to production. Send us your inquiry now—let’s deliver exceptional, reliable results together!

Click to understand this engineering language for precise design communication. ↩

Explore how this technique identifies the most crucial steps to shorten your production timeline effectively. ↩

Learn about the science of measurement and its critical role in quality control for manufacturing. ↩

Learn how proper GD&T application can reduce manufacturing costs and improve part functionality. ↩

Learn how precise GD&T ensures part consistency and reduces costs in high-volume manufacturing. ↩

Learn how a material’s directional properties can impact the strength and performance of your final part. ↩

Learn how optimized toolpaths reduce cycle times and improve surface finish. ↩

Learn more about this project management technique to optimize your production timelines. ↩

Discover how custom inserts can boost mold versatility and part complexity. ↩

Learn more about how surface preparation affects coating performance and part longevity. ↩