Oil and gas operations demand parts that can withstand extreme pressures, corrosive environments, and critical safety requirements. A single component failure in drilling or refining can result in costly downtime, environmental disasters, and safety hazards that put lives at risk.

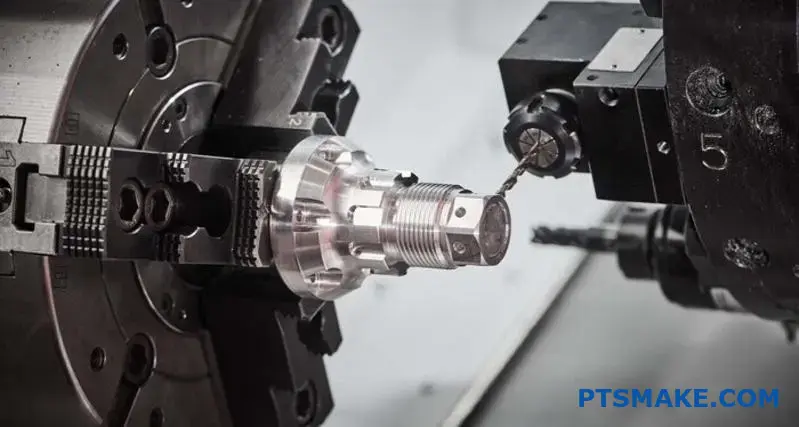

High-precision CNC machining delivers the exact tolerances, material integrity, and reliability that oil and gas applications require, producing custom components from corrosion-resistant alloys that meet strict industry standards and safety certifications.

Whether you’re sourcing valve bodies for offshore platforms or pump housings for refineries, this guide covers everything you need to know about CNC machined components in the energy sector. I’ll share practical insights on material selection, quality validation, and supplier evaluation based on real oilfield projects.

The Ultimate Guide To CNC Machined Components In The Oil & Gas Industry

The oil and gas industry operates in extreme conditions. High pressure, intense heat, and corrosive materials are daily challenges. Precision isn’t just a goal; it’s essential for safety and efficiency.

This is where CNC machining for oil and gas becomes critical. It delivers the tight tolerances and robust components needed. These parts must perform flawlessly miles underground or on remote platforms.

Key Application Stages

From exploration to refining, reliable oilfield CNC components are indispensable. Each stage has unique demands for precision and material strength.

| Industry Stage | Key CNC Components |

|---|---|

| Exploration | Sensor Housings, Seismic Equipment Parts |

| Boring | Drill Bits, MWD/LWD Tools, Collars |

| Produktion | Valves, Flanges, Pump Components |

| Raffinering | Fittings, Heat Exchanger Parts |

Energy sector precision machining provides the backbone for these operations.

CNC machining’s role extends across the entire oil and gas value chain. It’s not just about making parts; it’s about engineering solutions for some of the world’s toughest environments. Each component we produce at PTSMAKE is designed for a specific, high-stakes function.

From Seabed to Refinery

In exploration, seismic tools require intricate housings. These protect sensitive electronics from immense pressure. Precision is key to ensuring accurate data collection. In drilling, components face extreme abrasion and stress.

Drill collars and Measurement While Drilling (MWD) tools demand materials like non-magnetic steel alloys. The machining must be perfect to prevent catastrophic failure deep within a wellbore. This is where oil and gas cnc machining truly proves its value.

Material and Performance Challenges

During production and refining, parts handle corrosive fluids and high temperatures. Components like valves and flanges are often made from materials such as austenitic stainless steel1. The choice of material and the quality of the machining directly impact operational lifespan and safety.

| Materialeegenskab | Importance in Oil & Gas |

|---|---|

| Modstandsdygtighed over for korrosion | Prevents failure from chemical exposure |

| Høj styrke | Withstands extreme pressures and temperatures |

| Modstandsdygtighed over for slid | Extends component life in abrasive conditions |

| Snævre tolerancer | Ensures perfect fit and sealing in assemblies |

At PTSMAKE, we focus heavily on material expertise. We work with clients to select and machine the optimal material for each specific application, guaranteeing performance.

CNC machining is fundamental to the oil and gas sector. It ensures the precision, reliability, and durability of critical components used in exploration, drilling, production, and refining. This technology enables safer and more efficient operations in demanding environments.

Top CNC Machined Parts Critical To Oilfield Operations

In the oil and gas industry, certain components are absolutely non-negotiable. Their failure can lead to severe safety issues and costly operational shutdowns. This is where precision is paramount.

CNC machining is the key technology that delivers this necessary precision. It produces the critical oil and gas components that must perform under extreme conditions. Let’s look at some key CNC machined oilfield parts.

| Komponent | Primær funktion |

|---|---|

| Ventilhuse | Control fluid flow and pressure |

| Drill Heads | Cut through rock and earth |

| Pump Housings | Enclose and protect pump internals |

| Casing Parts | Support and line the wellbore |

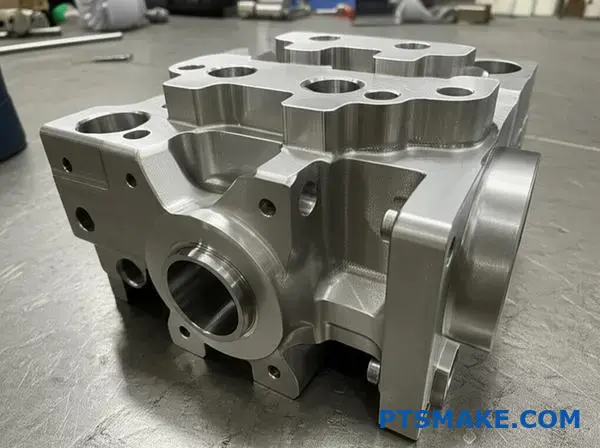

The demands placed on these parts are immense. Consider a valve body. It must withstand enormous pressure and corrosive fluids without failing. We often use robust materials like stainless steel or Inconel for them. The internal passages require flawless surface finishes to ensure a perfect seal.

Drill heads are another great example. They face incredible abrasion and impact forces deep underground. The complexity of their cutting surfaces and fluid channels can only be achieved through advanced 5-axis oil and gas cnc machining. Precision here directly translates to drilling efficiency and speed.

For these custom metal parts for the energy industry, complete Sporbarhed af materialer2 is not just a preference. It is a mandatory requirement for safety and compliance, linking a part back to its raw material batch.

Below is a quick comparison of manufacturing priorities for these components.

| Del | Key Machining Focus | Almindeligt materiale |

|---|---|---|

| Valve Body | Internal sealing surfaces, pressure integrity | Stainless Steel 316, Inconel |

| Drill Head | Complex geometries, hardness, wear resistance | Tungsten Carbide, Hardened Steel |

| Pump Housing | Tight tolerances for internal fits, durability | Cast Iron, Duplex Stainless Steel |

These critical components form the backbone of any oilfield operation. The precision achieved through CNC machining is not just a quality feature; it’s a fundamental requirement for safety, reliability, and performance in one of the world’s most demanding industries.

The Buyer’s Checklist For CNC Machined Oil And Gas Parts

Choosing the right partner for oil and gas parts is critical. A mistake can lead to costly downtime. A structured checklist simplifies vendor qualification.

This tool helps you objectively assess potential suppliers. It ensures they meet your demanding requirements for precision and reliability.

Key Assessment Areas

- Technical Capability: Do they have the right equipment?

- Quality Systems: How do they ensure precision?

- Certifications: Do they meet industry standards?

This CNC machining checklist helps you find a reliable oil and gas precision parts supplier. It prevents surprises down the line.

The Vendor Qualification CNC Checklist

Finding the right partner for oil and gas CNC machining requires a deep dive. This checklist helps you ask the right questions during vendor qualification. It moves beyond simple cost comparisons to evaluate true capability and long-term reliability.

Technical & Capacity Assessment

A supplier must have the right tools and capacity. Ask about their 5-axis CNC capabilities. This is crucial for complex geometries found in oil and gas components. Also, inquire about their production scheduling and current workload to avoid bottlenecks.

| Punkt på tjeklisten | Spørgsmål at stille | Hvorfor det er vigtigt |

|---|---|---|

| Maskinens kapacitet | What is your range of CNC machines (3, 4, 5-axis)? | Determines geometric complexity they can handle. |

| Production Capacity | What is your typical lead time for our part volume? | Ensures they can meet your production schedule. |

| Materialehåndtering | What corrosion-resistant alloys can you machine? | Confirms expertise with materials like Inconel or Duplex. |

Quality and Tolerance Control

Precision is non-negotiable. Discuss their quality control process in detail. Ask for documentation on their inspection equipment, like CMMs. Understanding their approach to Geometrisk dimensionering og tolerance (GD&T)3 is essential for parts with complex functional relationships. A good supplier provides detailed inspection reports with every shipment. This proactive approach shows a commitment to quality.

This systematic approach ensures your chosen supplier has the technical expertise, capacity, and quality systems required for oil and gas applications. It transforms vendor selection from a guess into a strategic decision, securing your supply chain for critical components.

Material Matters: Selecting The Right Alloys For Oilfield Components

Choosing the right alloy is a critical decision. It’s a balance of field performance and manufacturability. This is especially true for demanding materials for oil and gas environments.

De vigtigste materialekonkurrenter

We often work with several high-performance alloys. Each has unique properties. These are some of the best corrosion-resistant materials available today.

Hurtig sammenligning

Here is a brief look at their primary benefits.

| Materiale | Vigtig fordel | Almindelig brug |

|---|---|---|

| Rustfrit stål | Cost-effective corrosion resistance | Valves, fittings |

| Duplex-stål | High strength & chloride resistance | Pipelines, heat exchangers |

| Titanium | Fremragende styrke-til-vægt-forhold | Risers, stress joints |

| Inconel | Superior high-temp performance | Downhole equipment |

This selection directly impacts the component’s final cost and lead time.

The Machinability Factor

Performance in the field is just one side of the coin. We must also consider how these materials behave during manufacturing. This is a major cost driver in oil and gas cnc machining.

Stainless & Duplex Steels

Stainless steels are relatively straightforward to machine. Duplex steels, with their dual-phase structure, are tougher. They require slower speeds and specialized tooling to manage heat and prevent excessive tool wear.

Titanium and Inconel: The Real Challenge

Titanium has low thermal conductivity. This traps heat at the tool tip, which requires precise coolant management to avoid tool failure.

Inconel is notoriously difficult. Its tendency for arbejdshærdning4 means the material becomes harder as you cut it. This demands rigid machine setups and a deep understanding of the process. Effective CNC machining Inconel is a specialized skill.

At PTSMAKE, we have optimized our processes for these challenging alloys. We ensure part precision without sacrificing efficiency.

Here is a simplified machinability comparison based on our internal testing.

| Materiale | Vurdering af bearbejdelighed (i forhold til 1212 stål) | Den vigtigste udfordring |

|---|---|---|

| 316 Rustfrit stål | ~45% | Gummy, tool wear |

| Duplex 2205 | ~20% | High strength, abrasive |

| Titanium (Ti-6Al-4V) | ~22% | Poor thermal conductivity |

| Inconel 718 | ~12% | Extreme work hardening |

This data shows why expertise is so crucial for predictable results.

Selecting the best alloy requires balancing field performance with manufacturing realities. High-performance materials like Inconel offer superior properties but present significant machining challenges, impacting project timelines and costs. Expertise in handling these materials is non-negotiable for reliable outcomes.

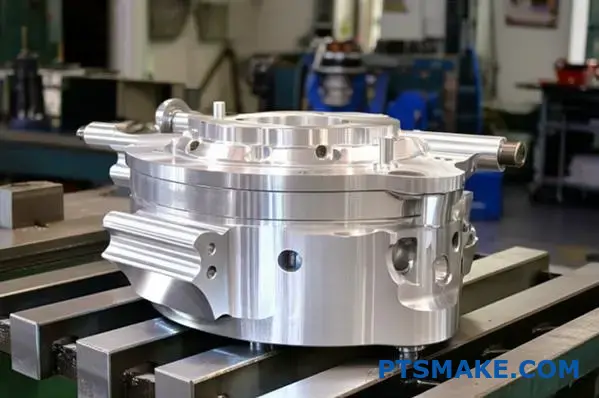

Secrets To Achieving Tight Tolerances In Large CNC Parts

Achieving tight tolerances on large parts isn’t just about the machine. It starts with the right strategy. Tooling choice and setup design are absolutely fundamental.

Smart Tooling and Setup Choices

For large-scale jobs, especially in large machining oil and gas applications, tool rigidity is key. It directly impacts surface finish and accuracy. A stable, well-designed setup prevents micro-vibrations that ruin precision.

The Value of Design Feedback

Providing precision engineering support early is crucial. A simple design review can identify features that are difficult or impossible to machine accurately. This collaborative feedback saves time and money.

| Aspekt | Standardtilgang | High-Precision Approach |

|---|---|---|

| Værktøj | General-purpose cutters | Application-specific, high-rigidity tools |

| Opsætning | Basic clamps | Custom fixturing, vibration damping |

| Feedback | After production issues | Proactive DFM analysis |

Mastering tight tolerance CNC machining on large parts requires a deeper look into the setup and design process. It goes beyond just clamping a workpiece and pressing ‘start’. At PTSMAKE, we focus on a holistic approach.

Advanced Fixturing and Engineering

Fixturing is more than just holding the part. It’s about creating a stable, repeatable, and accessible foundation for machining. This is critical for complex geometries often found in oil and gas cnc machining.

Custom Fixture Design

For multi-operation parts, custom fixtures are essential. They ensure that each feature is machined in perfect relation to the others. For ultimate repeatability, we often use principles of Kinematic Coupling5 in our fixture designs. This eliminates positioning errors between setups.

The Iterative Feedback Loop

Vores precision engineering support involves a constant dialogue. We don’t just point out problems. We suggest alternative solutions that maintain design intent while improving manufacturability. This partnership is key to success.

| Feedback Area | Potentielt problem | Anbefalet løsning |

|---|---|---|

| Indvendige radier | Tool access limitations | Increase radius or add corner reliefs |

| Væggens tykkelse | Prone to vibration/deflection | Gør væggene tykkere eller tilføj midlertidige støtter |

| Datum Strategy | Inconsistent locating | Define clear, accessible datums |

Proper tooling, robust setups, and a collaborative design feedback loop are essential for precision on large parts. This integrated strategy prevents errors and ensures that final components meet strict specifications for tight tolerance CNC projects.

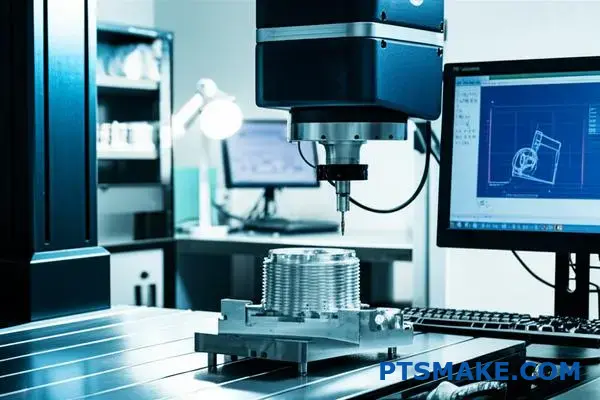

How To Validate CNC Quality For Safety-Critical Energy Components

Verifying component quality is non-negotiable. Especially for safety-critical parts in the energy sector. We rely on a structured process. This ensures every part meets exact specifications.

The Role of CMM Inspection

Coordinate Measuring Machines (CMMs) are key. They use probes to measure the geometry of physical objects. This method provides highly accurate data. It confirms complex features are within tolerance.

Første artikelinspektion (FAI)

FAI is a critical checkpoint. It’s a formal process. We verify that the first production run part meets all engineering requirements. This step catches issues before mass production.

Rigorous inspection is more than a final check. It’s a philosophy embedded in the entire manufacturing process. At PTSMAKE, we see it as the foundation of trust, particularly for demanding sectors. The quality systems we adhere to are not just certificates on a wall; they are active frameworks.

The Bedrock of Trust: ISO and AS Standards

Standards provide a clear roadmap for quality. For oil and gas cnc machining, specific certifications are essential. They demonstrate a commitment to process control and risk management. This is where oil and gas part validation becomes a documented, repeatable practice. The science of Metrologi6 is fundamental to these standards. It ensures that measurements are consistent and reliable across all operations.

Compliance with these standards is not a one-time event. It involves continuous audits and improvements. This dedication is what separates a reliable supplier from the rest.

Key Quality Standards in CNC Machining

| Standard | Primært fokus | Relevance to Energy Sector |

|---|---|---|

| ISO 9001 | Kvalitetsstyringssystemer | Establishes a baseline for process control, consistency, and customer satisfaction. |

| AS9100 | Aerospace Quality Standard | Adds stringent requirements for risk management, crucial for high-consequence parts. |

This structured approach, combining advanced inspection for CNC machined parts with certified AS9100, ISO 9001 CNC systems, ensures every component we deliver is ready for its critical mission.

Rigorous validation relies on CMM and FAI for precise physical verification. Underpinning this is a commitment to quality standards like ISO 9001 and AS9100, which provide a framework for consistent, reliable manufacturing, especially for critical energy components.

Why Global OEMs Trust Asian CNC Shops For Oil & Gas Projects

Choosing the right manufacturing partner is crucial. Many global OEMs look to Asia for their oil and gas CNC machining needs. This isn’t just a trend.

It’s a strategic decision based on tangible benefits. Experienced suppliers offer a powerful combination of advantages.

Scalability for Dynamic Demand

The oil and gas industry has fluctuating demands. A reliable partner must scale production up or down quickly. Asian manufacturers excel here.

Cost-Effectiveness and Quality

Outsourcing CNC to Asia offers competitive pricing. This is achieved through efficiency, not by sacrificing quality. Firms like PTSMAKE uphold international standards.

| Fordel | Sourcing in Asia | Local Sourcing |

|---|---|---|

| Skalerbarhed | Høj | Moderat |

| Omkostninger | Konkurrencedygtig | Højere |

| Kvalitet | Meets Global Standards | Meets Global Standards |

We provide a balance that is hard to find elsewhere.

The Trifecta: Scalability, Cost, and Quality

Global OEMs in the oil and gas sector require more than just parts. They need a reliable supply chain partner. When considering global CNC suppliers for oil and gas, Asia, particularly China, stands out for several key reasons.

Unmatched Production Scalability

The manufacturing infrastructure in Asia is immense. At PTSMAKE, we can access a vast network of resources. This allows us to handle both low-volume prototypes and large-scale production runs without compromising lead times. This flexibility is vital. It ensures your project timelines are met, even when demand suddenly increases. This capacity directly contributes to your project’s Forsyningskædens modstandsdygtighed7.

Strategic Cost Structure

The cost benefits of outsourcing CNC to Asia go beyond labor. It’s about operational efficiency, advanced automation, and streamlined processes. These factors reduce overhead and production costs. The savings are passed on to you.

| Omkostningsfaktor | Impact of Asian Sourcing |

|---|---|

| Arbejde | Efficient and skilled workforce |

| Materialer | Proximity to raw material suppliers |

| Overhead | Lower operational expenses |

| Teknologi | Investment in high-efficiency machinery |

Commitment to International Quality

A common misconception is that lower cost means lower quality. This is not true for established suppliers. At PTSMAKE CNC China, we are ISO 9001 certified. We use advanced metrology and CMM inspections. This ensures every part meets the stringent tolerances required for oil and gas cnc machining.

Partnering with an experienced Asian supplier like PTSMAKE offers a strategic advantage. It combines scalability, cost-effectiveness, and internationally certified quality, ensuring your demanding oil and gas projects are supported by a robust and efficient manufacturing backbone.

Real-World Case Studies Of CNC Excellence In The Oil Sector

Theory is one thing, but results are what matter. I want to share some real-world examples. These success stories show how custom CNC manufacturing solves specific oilfield challenges.

We’ll look at projects across the entire sector. From upstream exploration to downstream refining. Each stage has unique demands.

Upstream: Downhole Tool Components

A client needed a critical component for a downhole sensor. The environment involved extreme pressure and corrosion. Our solution delivered on all fronts.

| Udfordring | CNC-bearbejdningsløsning |

|---|---|

| High Pressure & Temp | Machining from Inconel 718 |

| Kompleks geometri | 5-axis CNC milling |

| Snævre tolerancer | +/- 0.005 mm precision |

This oil and gas case study CNC is a great example. It shows how precision directly impacts operational safety and data accuracy deep underground.

Seeing these projects succeed is what drives my work. The oil and gas industry leaves no room for error. Every component must perform flawlessly. This is where the true value of precision machining becomes clear.

Midstream: Pipeline Inspection Gauge (PIG) Parts

In midstream operations, pipeline integrity is everything. We once provided custom CNC manufacturing for components of a smart PIG. These devices travel through pipelines to detect flaws.

The parts required a perfect surface finish. This was to avoid damaging the pipeline’s interior. After collaborating with our client, we optimized the toolpaths. This achieved the necessary finish without extra polishing steps. We used various quality checks, including Ikke-destruktiv testning8, to validate every part.

| Project Parameter | Specification Met |

|---|---|

| Materiale | Rustfrit stål 316L |

| Overfladefinish | Ra 0,4 μm |

| Turnaround Time | 25% faster than previous supplier |

Downstream: Custom Valve Bodies

For a downstream refinery, we produced custom valve bodies. These were for a system handling corrosive chemicals at high temperatures. The design was complex. It had internal channels that were difficult to machine.

Using advanced CAM software and 5-axis machining, we delivered parts that exceeded performance specs. These success stories in machining show that challenges can be overcome with the right technology and expertise.

These case studies show how custom CNC solutions directly address critical challenges in the oil and gas sector. From upstream durability to downstream chemical resistance, precision machining delivers reliable performance where it matters most, ensuring safety and operational efficiency across the board.

The Complete Quality Control Process Behind CNC Oilfield Components

In the oil and gas industry, there’s no room for error. A single faulty component can lead to catastrophic failure. That’s why a complete CNC QC process isn’t just a goal; it’s a requirement.

At PTSMAKE, our process is built on verification at every stage. It begins before a single chip is cut and ends long after the part is finished. This ensures every component meets demanding specifications.

Here is a simplified overview of the core stages.

| QC-fase | Primært fokus | Vigtige resultater |

|---|---|---|

| Råmateriale | Verifikation af materiale | Certified & Correct Grade |

| I proces | Dimensionel nøjagtighed | Conformance to CAD model |

| Pre-Shipment | Final Verification & Docs | Full Traceability |

A comprehensive quality system for oilfield parts is non-negotiable. Our approach follows strict ISO CNC machining standards. We break it down into distinct, rigorous phases to ensure total control.

Phase 1: Raw Material Inspection

It all starts with the material. We require a Material Test Certificate (MTC) with every single batch. This document verifies the material’s chemical composition and mechanical properties. We don’t just take it on faith; we perform our own checks.

Phase 2: In-Process Quality Control (IPQC)

During production, constant monitoring is key. We conduct a First Article Inspection (FAI) to confirm the machine setup is perfect. Then, our operators perform regular checks on critical dimensions throughout the machining run. This prevents deviations before they become major problems.

This proactive approach is crucial for complex oil and gas CNC machining projects. We also use various gauges and advanced Ikke-destruktiv testning9 methods to check for hidden flaws without damaging the part itself.

Phase 3: Final Quality Control (FQC) & Reporting

Before anything ships, a final comprehensive inspection occurs. We use Coordinate Measuring Machines (CMM) for high-precision verification against the 3D CAD model. A full report, including material certificates and inspection data, is compiled. This creates a complete quality record for every single part.

Our multi-stage quality control process ensures every CNC oilfield component meets stringent industry standards, from raw material verification to final inspection reports. This systematic approach guarantees reliability and performance in critical applications.

How To Communicate Engineering Specs Effectively With CNC Suppliers

Clear technical specifications are the bedrock of successful CNC machining. Your engineering drawing is the single most important document you provide.

It must be comprehensive and unambiguous.

The Blueprint: Your Engineering Drawing

A well-made engineering drawing CNC file leaves no room for interpretation. It’s our primary guide for programming and inspection.

Think of it as our contract for precision.

Key Specifications to Define

Critical details like tolerances and surface finish must be clearly noted. This is especially true for demanding applications like oil and gas cnc machining.

These specs directly impact part performance and cost.

| Specifikation | Importance for CNC |

|---|---|

| Tolerancer | Defines acceptable dimensional deviation |

| Overfladefinish | Impacts friction, sealing, and wear |

| Materialekvalitet | Determines tool selection and speeds |

Beyond the Basics: Mastering Technical Communication

A complete technical RFQ CNC machining package goes beyond a 3D model. It includes a 2D drawing with all necessary manufacturing information.

Ambiguity is the enemy of precision. Any unclear instruction can lead to delays or non-conforming parts. It forces us to stop and ask questions, breaking the production flow.

Tolerance Communication

Effektiv tolerance communication is crucial. Specify if tolerances are bilateral or unilateral. Understand that tighter tolerances require more machine time and specialized inspection, which increases costs. We can often help find a balance between function and manufacturability.

The Language of Precision

For complex parts, simple plus/minus tolerances are not enough. This is where Geometrisk dimensionering og tolerance (GD&T)10 becomes essential. It is a symbolic language that defines the form, orientation, and location of features more precisely.

Overvejelser om overfladefinish

Specifying surface finish is vital. A low Ra value (a smoother finish) might be needed for sealing surfaces or bearings. This detail affects the manufacturing process directly, often requiring secondary operations like grinding or polishing. This is a common requirement in oil and gas cnc machining.

| GD&T Symbol | Repræsenterer |

|---|---|

| ⌖ | Position |

| ⏥ | Fladhed |

| ○ | Circularity |

| профиль | Profile of a Surface |

Your engineering drawing, complete with clear tolerances, surface finish callouts, and proper GD&T, is your best tool. It ensures you get the exact parts you designed, preventing costly rework and delays in your project timeline.

When Not To 3D Print: Why Machining Still Wins For Oilfield Parts

3D printing is impressive for prototypes. But it’s not ready for critical oilfield jobs. Why? It comes down to three non-negotiables: strength, accuracy, and heat resistance.

For these factors, CNC machining is still the clear winner. This is crucial for parts where failure is not an option.

Strength Under Pressure

Oil and gas components face extreme forces. CNC parts are machined from solid metal blocks. This process ensures maximum material integrity. Additive manufacturing builds parts in layers, which can create weak points.

The Precision Mandate

Accuracy is everything in downhole tools. CNC machining consistently achieves tighter tolerances. Our clients require this level of precision for safety and performance.

Handling Extreme Heat

Heat resistance is another major factor. Many 3D printing materials cannot withstand the high temperatures of oilfield operations.

| Funktion | CNC-bearbejdning | 3D-udskrivning |

|---|---|---|

| Materialets styrke | Superior (Solid Block) | Variable (Layered) |

| Dimensionel nøjagtighed | High (±0.001") | Moderat |

| Varmebestandighed | Excellent (Metals) | Limited (Polymers) |

While additive manufacturing has its place, its limitations in the oilfield are clear. The discussion of CNC vs 3D printing in oil and gas often overlooks the fundamental material science behind each process.

The Strength of Solid Metal

CNC machining carves parts from a solid billet of metal or high-performance plastic. This subtractive method preserves the material’s inherent strength and structural integrity. There are no layers to delaminate or separate under extreme pressure or vibration. This is vital for machining for critical applications.

In contrast, 3D printed parts are built layer by layer. This process can result in anisotropiske egenskaber11, meaning the part is weaker in one direction than another. Our tests show this can be a significant risk in high-stress environments. The bond between layers is often the point of failure.

Unmatched Precision and Surface Finish

The oil and gas industry demands parts with extremely tight tolerances. CNC machines can reliably produce features with an accuracy that many 3D printers cannot match.

A smooth surface finish is also essential for sealing surfaces and reducing friction. CNC machining excels here, often requiring minimal post-processing. Additive manufacturing frequently needs extensive finishing to achieve similar results.

| Fremstillingsmetode | Typiske materialer | Key Advantage in Oil & Gas |

|---|---|---|

| CNC-bearbejdning | Stainless Steel, Inconel, Titanium | Isotropic strength, heat resistance |

| 3D Printing (Additive) | PEEK, Ultem, some metal powders | Complex internal geometries, rapid prototyping |

This comparison highlights the additive limitations oilfield teams must consider. The reliability of oil and gas cnc machining from solid stock is simply unmatched for critical components.

For oilfield parts where strength, precision, and heat resistance are paramount, CNC machining is the proven and reliable choice. It delivers the performance and safety required for the industry’s most demanding and critical applications.

Unlock Oil & Gas Precision—Partner With PTSMAKE Today

Ready to elevate your oil and gas CNC machining project? Get in touch with PTSMAKE for expert solutions, rapid quotes, and trusted quality. Send your RFQ now and discover why leading energy companies rely on us for mission-critical components—precision and reliability from prototype to production.

Learn more about selecting the right high-performance materials for corrosive oil and gas applications. ↩

Learn why a material’s documented history is vital for ensuring part safety and meeting regulations. ↩

Learn how GD&T ensures your parts meet exact design specifications for critical applications. ↩

Learn how work hardening affects tool selection and machining strategies for high-strength alloys. ↩

Learn how this principle ensures perfect part positioning every time. ↩

Learn more about the science of measurement and its role in precision manufacturing. ↩

Understand how a resilient supply chain prevents disruptions and ensures on-time delivery for your critical components. ↩

Learn about methods used to inspect parts for flaws without causing any damage. ↩

Discover the various NDT methods used to ensure the internal integrity of mission-critical components. ↩

Explore our guide to understand the fundamental symbols and principles of GD&T for better part design. ↩

Discover how a material’s internal structure impacts its strength and reliability in different directions. ↩