Manufacturing teams often struggle with finding materials that combine the castability of traditional iron with the strength properties of steel. You need parts that can handle complex geometries while delivering reliable performance, but standard materials force you to compromise on either manufacturing feasibility or mechanical properties.

Nodular cast iron serves as an effective ‘cast steel’ alternative by combining the excellent castability of gray iron with mechanical properties that closely approach those of steel, offering superior strength and ductility compared to conventional cast irons.

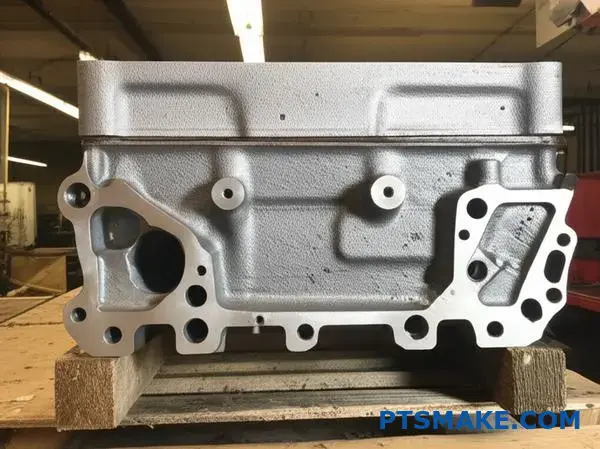

From my experience working with various casting projects at PTSMAKE, I’ve seen how proper material selection directly impacts both manufacturing success and final product performance. This guide covers the essential aspects of nodular cast iron that will help you make informed decisions for your next project.

What makes nodular cast iron a ‘cast steel’ alternative?

Engineers often face a choice: the easy casting of iron or the strength of steel. But what if you could get the best of both worlds?

A Unique Blend

Nodular cast iron offers this unique combination. It flows well into complex molds, much like traditional gray iron.

Strength and Ductility

Yet, its mechanical properties are much closer to steel. This gives it surprising strength and the ability to bend without breaking. Let’s see a quick comparison.

| Property | Gray Iron | Nodular Iron | Cast Steel |

|---|---|---|---|

| Castability | Excellent | Very Good | Fair |

| Strength | Low | High | Very High |

| Ductility | Very Low | Good | Excellent |

The key difference lies in the material’s microstructure. Gray cast iron has graphite in flake form. These flakes create internal stress points, which is why it’s brittle.

The Secret is in the Graphite

Nodular cast iron, however, contains spheroidal graphite1. Achieved by adding specific elements during production, these round nodules allow the metal matrix to flow around them. This structure eliminates the internal stress points found in gray iron.

The result is a material with impressive ductility and impact resistance. It can handle shock and heavy loads far better than its gray iron counterpart, performing almost like steel.

Performance in Detail

From our internal testing at PTSMAKE, we see clear performance advantages that make it a compelling choice.

| Mechanical Property | Nodular Iron (60-40-18) | Low-Carbon Steel (1020) |

|---|---|---|

| Tensile Strength (MPa) | 414 | 420 |

| Yield Strength (MPa) | 276 | 350 |

| Elongation (%) | 18 | 25 |

A Smart Alternative

This unique combination makes it a cost-effective alternative to cast steel. It allows us to produce durable, complex parts without the higher costs and casting difficulties associated with steel. It’s a strategic choice for balancing performance and budget.

In short, nodular cast iron’s special graphite structure gives it superior strength and ductility. It effectively bridges the gap between the easy castability of iron and the robust performance of steel, making it a highly versatile engineering material.

How are different grades of nodular iron classified?

Understanding nodular iron grades is simpler than it looks. The key is the naming convention. Most grades follow a standard system, like ASTM A536.

This system uses three numbers to define the material’s properties. It’s a straightforward code that tells engineers exactly what to expect from the material’s performance.

The Three-Number Code

Let’s break down a common grade: 65-45-12. Each number represents a key mechanical property, measured in specific units. This code makes material selection clear and precise.

| Number | Property | Unit | Minimum Value |

|---|---|---|---|

| 65 | Tensile Strength | ksi | 65 |

| 45 | Yield Strength | ksi | 45 |

| 12 | Percent Elongation | % | 12 |

This naming standard removes guesswork. It provides the essential data needed for designing strong and reliable parts.

The ASTM A536 standard is widely used because it focuses on the most critical mechanical properties for design engineers. When selecting a Nodular Cast Iron, these numbers are your guide. At PTSMAKE, we always start here with our clients.

Understanding the Properties

Tensile and Yield Strength

The first two numbers are about strength. The tensile strength2 is the maximum stress the material can take before breaking. Yield strength is the point where it starts to deform permanently.

For engineers, yield strength is often more critical. Designing a part to operate below its yield strength ensures it won’t bend or warp under normal operating loads.

The Importance of Elongation

The third number, elongation, measures ductility. It tells you how much the material can stretch or deform before it fractures.

A higher elongation percentage means the material is more forgiving. It can handle unexpected overloads or impacts without catastrophic failure. This is crucial for safety-critical components in automotive or industrial machinery.

Here’s a quick comparison of two common grades we work with.

| Grade | Minimum Tensile Strength (ksi) | Minimum Yield Strength (ksi) | Minimum Elongation (%) |

|---|---|---|---|

| 65-45-12 | 65 | 45 | 12 |

| 80-55-06 | 80 | 55 | 6 |

As you can see, the stronger 80-55-06 grade is less ductile than the 65-45-12 grade. This trade-off is a fundamental consideration in material selection.

The ASTM A536 standard classifies nodular iron using three key metrics: minimum tensile strength, yield strength, and percent elongation. This system provides engineers with the essential data needed to select the appropriate material for their specific application, balancing strength with ductility.

What are the main categories of nodular cast iron?

The true value of nodular cast iron lies in its versatility. This adaptability comes from its internal matrix structure. By controlling this structure, we can tailor its mechanical properties.

This allows for a wide range of applications. Let’s break down the main classifications based on the metal’s matrix.

| Grade Category | Primary Characteristic | Best For |

|---|---|---|

| Ferritic | Maximum Ductility & Toughness | Parts needing impact resistance |

| Pearlitic | High Strength & Wear Resistance | High-stress components like gears |

| Ferritic-Pearlitic | Balanced Properties | General-purpose engineering parts |

Choosing the right grade is critical for performance. A balanced Ferritic-Pearlitic structure is often a go-to choice. It provides a reliable mix of strength and ductility for many components.

However, some applications demand more. This is where specialty grades come into play.

Specialty Grade: Austempered Ductile Iron (ADI)

ADI represents a significant leap in performance. It is produced through a specialized isothermal heat treatment3 process. This results in a material with an outstanding combination of properties.

This material bridges the gap between cast iron and cast steel. In our experience at PTSMAKE, ADI can often replace steel forgings. It offers comparable strength with lower weight and potentially reduced manufacturing costs.

Here’s a simplified comparison based on our test data.

| Material Type | Typical Tensile Strength | Key Advantage |

|---|---|---|

| Pearlitic Nodular Iron | 600-800 MPa | Good wear resistance |

| ADI (High Grade) | >1200 MPa | Superior strength & fatigue life |

| Forged Steel (e.g., 1045) | ~625 MPa (Annealed) | High toughness |

Selecting ADI requires careful consideration of the application’s stress and wear conditions.

The matrix structure fundamentally dictates the performance of Nodular Cast Iron. From the ductile Ferritic grades to high-strength ADI, each category serves specific engineering needs. Making the right choice is crucial for the final part’s success and longevity.

What are the typical applications for a ferritic grade?

Ferritic grades excel where toughness and ductility are more important than pure strength. Think about safety-critical components.

Their ability to deform without fracturing is a key advantage. This makes them ideal for systems that handle pressure.

Pressure-Containing Parts

Components like valves, pumps, and fittings must withstand internal pressure. Ferritic ductile iron ensures they don’t fail catastrophically. Instead, they might deform slightly, providing a warning.

Components Requiring High Toughness

These materials also absorb energy well. They are used for parts that face impacts or sudden loads.

| Application Area | Example Component | Critical Property |

|---|---|---|

| Fluid Systems | Valve Bodies | Ductility |

| Heavy Machinery | Gearbox Housings | Impact Resistance |

| Infrastructure | Pipe Fittings | Toughness |

At PTSMAKE, we frequently recommend ferritic grades for applications where failure is not an option. The choice isn’t just about handling a specified load; it’s about how the material behaves when pushed beyond its limits.

Ductility as a Safety Mechanism

For pressure-containing parts, high ductility prevents brittle fracture. A crack in a high-strength, low-ductility material can propagate instantly. A ferritic Nodular Cast Iron component, however, will yield and deform first. This visible change often allows for intervention before a complete failure occurs.

Real-World Impact Resistance

Consider automotive components like suspension arms or steering knuckles. These parts need to absorb significant impact energy during a collision. A material that shatters on impact is dangerous. A ferritic grade will bend and deform, absorbing energy and enhancing vehicle safety. Verifying this performance often involves a process like Charpy impact testing4 to quantify the material’s toughness.

Based on our project data, this characteristic makes ferritic grades a reliable choice.

| Industry | Typical Application | Key Engineering Need |

|---|---|---|

| Automotive | Suspension Components | Energy Absorption |

| Oil & Gas | Flanges and Fittings | Pressure Integrity |

| Agriculture | Tractor Axle Housings | Shock & Load Resistance |

| Municipal | Manhole Covers | Durability & Toughness |

Ferritic grades are specified for applications where reliability and safety are paramount. Their ductility and toughness ensure parts deform predictably under extreme stress or impact, preventing sudden, catastrophic failures in critical systems like pressure vessels and automotive components.

Where are pearlitic grades commonly used in practice?

Pearlitic grades excel where strength is paramount. We often see them in high-stress environments. In these cases, ductility is less critical.

Automotive and Heavy Machinery

Think of components that work hard every day. Crankshafts, gears, and connecting rods are prime examples. They must resist constant wear and high loads.

The material choice is crucial for these parts.

| Component | Primary Requirement | Why Pearlitic Grade? |

|---|---|---|

| Gears | Wear Resistance | Prevents tooth wear under load |

| Crankshafts | High Strength | Endures combustion forces |

| Axle Shafts | Fatigue Strength | Resists repeated stress cycles |

These applications demand robust performance. Pearlitic grades deliver it consistently.

Let’s dive deeper into why this trade-off makes sense. Why sacrifice ductility for superior strength? It is a necessary engineering decision for certain parts.

In demanding applications, failure often begins with wear or deformation, not from bending.

The Strength vs. Ductility Trade-Off

A crankshaft does not need to be flexible. It must remain rigid under the immense, repetitive forces from the engine’s pistons. Any deformation could lead to catastrophic failure.

Pearlitic Nodular Cast Iron provides this required rigidity. Its internal microstructure5 is the source of this high performance. The lamellar pearlite creates a tough and highly wear-resistant material.

This internal structure is fundamentally different from more ductile grades.

High-Strength Structural Components

We also specify these grades for structural components. This includes machine frames or parts for hydraulic presses. These components are under constant and significant loads.

They must maintain their precise shape to ensure operational accuracy. From our past projects, we know pearlitic grades show minimal creep under sustained stress.

Here is a quick comparison for a gear application:

| Property | Pearlitic Grade | Ferritic Grade |

|---|---|---|

| Tensile Strength | High | Moderate |

| Wear Resistance | Excellent | Fair |

| Ductility | Lower | High |

| Machinability | Good | Excellent |

For a long-lasting gear, the choice is clear. At PTSMAKE, we help clients navigate this selection. This ensures the final part perfectly meets its operational demands.

Pearlitic grades are the top choice for high-strength parts like crankshafts and gears. Their robust microstructure offers excellent wear resistance. This makes them ideal for applications where strength and durability are more important than flexibility.

Which international standards govern nodular cast iron specification?

When your project goes global, relying only on ASTM standards is not enough. Other regions have their own robust specifications for Nodular Cast Iron.

Understanding these global standards is critical. It ensures your material specifications are met consistently, no matter where your parts are made. Key standards include ISO 1083 and Japan’s JIS G5502.

Knowing their equivalents avoids confusion in procurement. It helps maintain design integrity across international supply chains.

| Standard Body | Common Region | Key Standard for Nodular Iron |

|---|---|---|

| ISO | International | ISO 1083 |

| EN (CEN) | Europe | EN 1563 |

| JIS | Japan | JIS G5502 |

Let’s dive into the specifics. These standards are more straightforward than they appear, each with a logical naming system that reveals the material’s properties.

European Standard (EN 1563 / ISO 1083)

The European standard uses a clear designation. For example, in EN-GJS-500-7, the numbers tell you everything. ‘500’ is the minimum tensile strength in MPa, and ‘7’ is the minimum elongation percentage. It’s a simple and effective system.

Japanese Industrial Standards (JIS G5502)

The JIS system is equally direct. A common grade is FCD450. The ‘FCD’ identifies it as ductile cast iron. The ‘450’ indicates its minimum tensile strength in MPa.

The unique properties of nodular iron come from the even distribution of spheroidal graphite6 in the iron matrix. At PTSMAKE, we use this knowledge to guarantee material consistency for every client’s project. This allows for precise material cross-referencing.

Here is a quick comparison of some common equivalent grades we frequently work with.

| Standard | Grade Designation | Min. Tensile Strength (MPa) | Min. Elongation (%) |

|---|---|---|---|

| ASTM (USA) | A536 65-45-12 | 448 | 12 |

| ISO / EN | EN-GJS-450-10 | 450 | 10 |

| JIS (Japan) | FCD450-10 | 450 | 10 |

While ASTM is prevalent in the US, ISO and JIS standards are vital for global manufacturing. Understanding their equivalents ensures consistent quality and accurate specifications for your Nodular Cast Iron parts, regardless of the manufacturing location.

A Multi-faceted Action Plan for Prevention

A solid action plan is your best defense against shrinkage porosity. It’s not about a single magic fix. Instead, it involves several adjustments working together.

We will focus on four key areas. These include riser design, sleeve use, pouring temperature, and material chemistry.

Each plays a critical role. By optimizing them all, you can effectively feed the casting. This ensures a solid, defect-free final part.

| Strategy | Primary Goal | Impact Level |

|---|---|---|

| Riser Sizing | Provide a larger reservoir of molten metal | High |

| Exothermic Sleeves | Keep the riser molten for a longer period | High |

| Pouring Temperature | Control the solidification rate and pattern | Medium |

| Chemical Composition | Reduce the overall liquid-to-solid shrinkage | High |

This combined approach provides the most reliable results.

Increasing Riser Size and Efficiency

The riser must be the last part of the casting to solidify. To achieve this, its size is critical. A larger riser holds more molten metal, acting as a reservoir. It feeds the casting as it cools and shrinks.

Using Exothermic Sleeves

Exothermic sleeves are a game-changer. These sleeves are placed around the riser. When molten metal fills the mold, the sleeve ignites an exothermic reaction. This generates heat, keeping the riser metal liquid for much longer. This extended time allows it to feed the thick sections more effectively.

Optimizing Pouring Temperature

Pouring temperature is a delicate balance. A higher temperature can improve fluidity. However, it also increases the total volume of shrinkage.

Conversely, a lower temperature reduces shrinkage. But it risks premature solidification, causing other defects. We found that a carefully controlled, slightly lower pouring temperature often works best. It requires precise control.

Adjusting Chemical Composition

Finally, we can adjust the alloy’s chemistry. For materials like Nodular Cast Iron, we focus on the Carbon Equivalent (CE). A higher CE promotes graphite expansion during eutectic solidification7. This expansion counteracts some of the shrinkage.

| Adjustment | Effect on Shrinkage | Typical Material |

|---|---|---|

| Increase Carbon Equivalent | Decreases tendency | Cast Irons |

| Add Inoculants | Promotes uniform solidification | Various Alloys |

| Control Phosphorus | Narrows solidification range | Steels |

This metallurgical approach tackles the problem at its source.

A successful strategy combines optimized riser design with exothermic sleeves, precise temperature control, and smart chemical adjustments. This holistic method provides the most robust solution to prevent shrinkage porosity in thick sections.

How do you balance cost versus performance when selecting materials?

Choosing materials often feels like a balancing act. You have cost on one side and performance on the other. This trade-off is perfectly illustrated when we look at Nodular Cast Iron.

A Tale of Two Irons: Pearlitic vs. ADI

Let’s compare two popular grades. First, there’s the standard ‘as-cast’ pearlitic grade. It’s a solid, cost-effective choice for many applications.

Then, there’s Austempered Ductile Iron (ADI). It offers superior strength and wear resistance, but this comes at a higher initial price point.

The Initial Decision Point

Your choice depends entirely on the application’s demands. Is upfront cost the main driver, or is long-term durability non-negotiable?

| Material Grade | Initial Cost | Performance |

|---|---|---|

| Pearlitic Ductile Iron | Lower | Standard |

| Austempered Ductile Iron (ADI) | Higher | Superior |

The higher price of ADI is not arbitrary. It results directly from a specialized heat treatment process known as austempering8. This carefully controlled thermal cycle transforms the material’s microstructure. It creates a unique matrix that provides exceptional mechanical properties.

The True Cost of Performance

While an ‘as-cast’ pearlitic grade is cheaper to produce, ADI’s treatment adds manufacturing steps. This increases the cost per part. However, this investment directly translates into superior performance characteristics.

In past projects at PTSMAKE, we’ve seen this pay off for demanding applications. For components like gears or high-stress brackets, the enhanced durability of ADI is critical.

When is the Extra Expense Justified?

The decision becomes clear when part failure is not an option. The improved toughness and wear resistance of ADI lead to longer service life. This reduces maintenance and replacement costs over the product’s lifetime.

Our test results show significant gains with ADI.

| Property | Pearlitic Ductile Iron | Austempered Ductile Iron (ADI) |

|---|---|---|

| Tensile Strength | Good | Excellent |

| Wear Resistance | Good | Excellent |

| Ductility | Moderate | High |

This makes ADI the smarter long-term investment for critical components.

The choice between pearlitic ductile iron and ADI is a classic cost-versus-performance analysis. One offers immediate savings, while the other delivers superior durability and long-term value for demanding applications, justifying the higher upfront investment.

Unlock Your Next Nodular Cast Iron Advantage with PTSMAKE

Elevate your projects with superior nodular cast iron solutions from PTSMAKE! Our team specializes in custom, high-precision castings tailored to your exact requirements. Send us your RFQ today and experience the reliability, expertise, and efficiency that sets PTSMAKE apart in global precision manufacturing.

Explore how this unique microscopic structure gives nodular iron its impressive strength and ductility. ↩

Click to understand how this critical property impacts material selection and part performance. ↩

Discover how this unique heat treatment creates superior strength and toughness in ductile iron components. ↩

Learn about this key test method for measuring a material’s toughness and impact strength. ↩

Explore how a material’s internal structure dictates its mechanical properties for better design choices. ↩

Learn how this unique microstructure gives nodular iron its superior strength and ductility compared to other cast irons. ↩

Understand how this specific solidification process directly impacts casting integrity and final part quality. ↩

Discover how this specialized heat treatment process enhances material strength and toughness. ↩