Are you tired of dealing with CNC lathe suppliers who promise precision but deliver parts that don’t meet your specs? You’re not alone—poor quality control and miscommunication plague many procurement processes, leading to costly delays and rework.

CNC lathe machining is a precision manufacturing process that uses computer-controlled lathes to create cylindrical and complex rotational parts with tight tolerances, offering consistent quality and repeatability for demanding industrial applications.

As someone who has worked with CNC lathe projects at PTSMAKE for over 15 years, I’ve seen how the right knowledge can transform your procurement experience. This guide breaks down everything you need to know—from evaluating suppliers and managing quality factors to optimizing designs for cost-effectiveness. You’ll discover practical strategies to avoid common pitfalls, reduce lead times, and build reliable partnerships that deliver results consistently. Whether you’re sourcing for aerospace, automotive, or medical applications, these insights will help you make smarter decisions and achieve better outcomes.

Understanding CNC Lathe Machining Capabilities?

Struggling to source cylindrical parts that meet exact specifications every single time? Are slight inconsistencies in production runs causing downstream assembly issues and project delays?

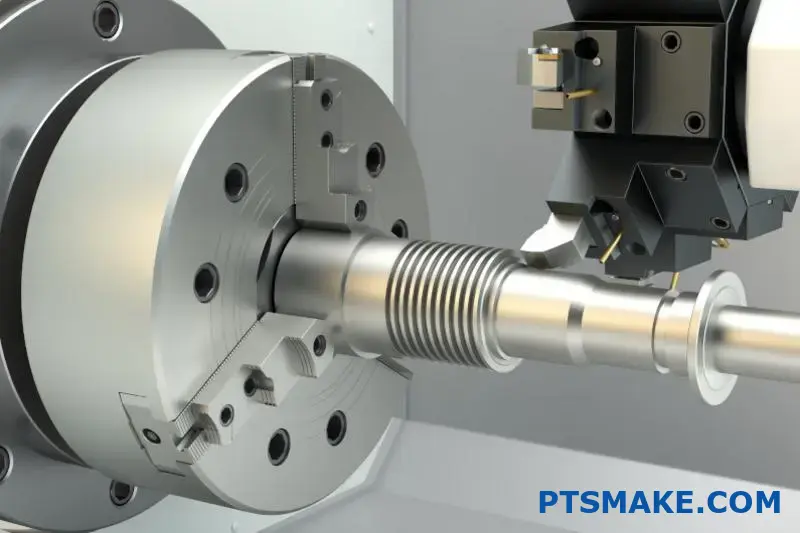

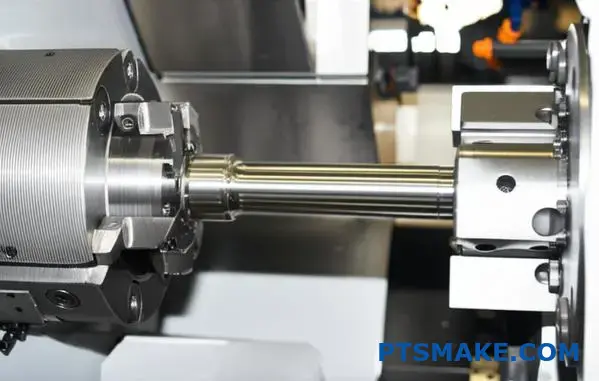

CNC lathe machining is a computer-controlled subtractive process where a workpiece rotates against a cutting tool. It excels at producing cylindrical or complex rotational parts with exceptionally high precision and repeatability, making it the preferred method for industries that demand consistent quality and tight tolerances.

The Core Functions of CNC Lathe Machining

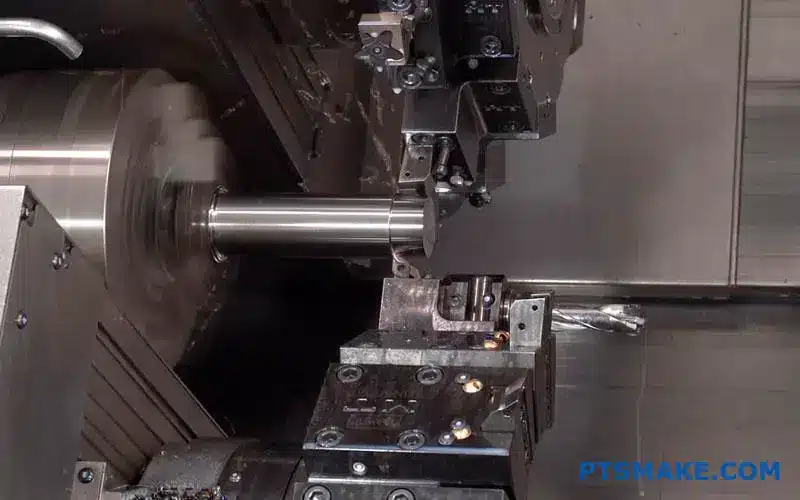

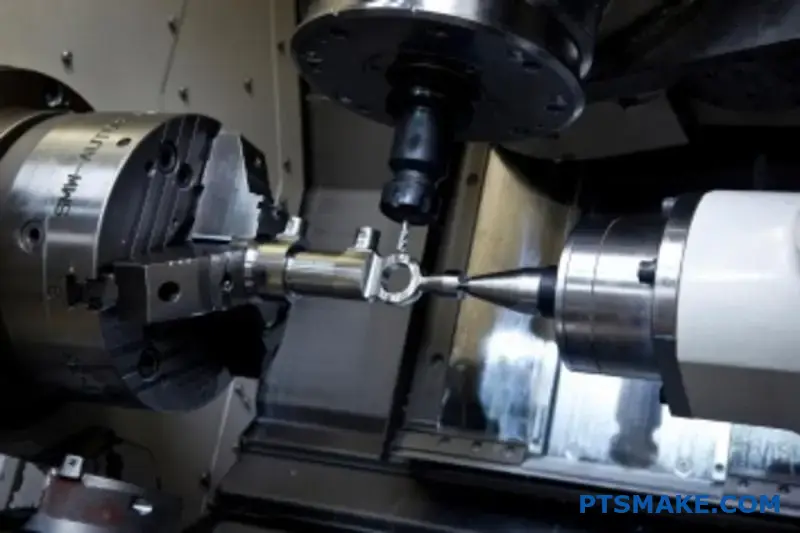

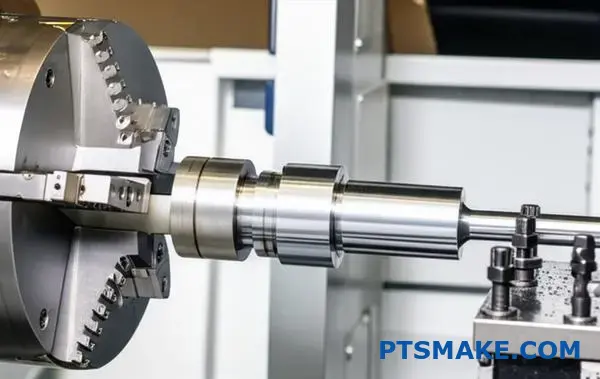

At its heart, CNC lathe machining is about precision through rotation. Unlike a milling machine where the tool spins, a lathe spins the material itself. A computer guides a stationary cutting tool along the rotating workpiece, precisely removing material to create the desired shape. This fundamental difference makes it incredibly efficient for creating any part with a central axis of rotation. In past projects at PTSMAKE, we’ve relied on this process for everything from simple shafts and pins to complex components for aerospace and medical devices. The level of control is what sets it apart. The G-code instructions sent to the machine dictate every movement, speed, and feed rate, eliminating the variability that comes with manual operation. This ensures that the first part produced is identical to the thousandth.

Fundamental Operations

Understanding the basic operations is key to grasping the full capabilities of CNC turning. Each one serves a specific purpose in shaping the final component.

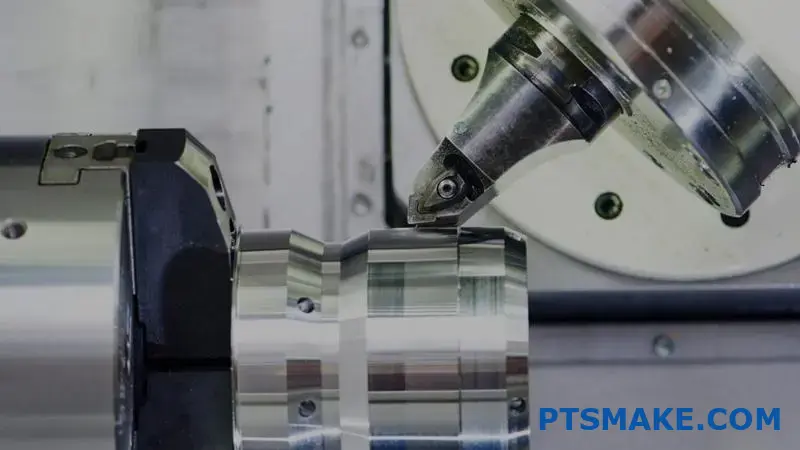

- Turning: This is the primary operation, where a single-point tool moves parallel to the axis of rotation, reducing the diameter of the workpiece. This can be used to create straight, tapered, or contoured profiles.

- Facing: The tool moves perpendicularly across the end of the workpiece to create a flat, smooth surface. This is often the first step to ensure the part is at the correct length.

- Drilling and Boring: A drill bit can be used to create a hole along the central axis. Boring then enlarges and refines that hole to a precise internal diameter.

- Threading: This operation cuts external or internal threads onto the part, essential for creating screws, bolts, and other fasteners.

The precision of these operations is directly affected by factors like machine rigidity, tool sharpness, and controlling thermal expansion. One critical factor we always monitor is runout1, as excessive deviation can lead to parts failing quality control.

Why CNC Lathes are Essential for Quality

The main reason engineers and procurement managers specify CNC lathe machining is for its unmatched repeatability. Once a program is perfected, the machine can execute it endlessly with minimal deviation. This is crucial in industries where part failure is not an option.

| Operation | Primary Goal | Common Application |

|---|---|---|

| Turning | Reduce workpiece diameter | Shafts, pins, contoured surfaces |

| Facing | Create a flat end surface | Squaring up stock, setting length |

| Drilling | Create a central hole | Pilot holes, clearance holes |

| Threading | Cut helical grooves | Screws, nuts, threaded fittings |

This automated precision not only guarantees quality but also optimizes production time and reduces waste, making it a cost-effective solution for both prototyping and large-scale production runs.

Achieving Consistency and Precision in Demanding Industries

The true value of CNC lathe machining becomes clear when you consider its application in high-stakes industries. For sectors like aerospace, automotive, and medical, part-to-part consistency isn’t just a preference; it’s a non-negotiable requirement for safety and performance. A small deviation in a single component could have significant consequences. CNC turning directly addresses this need by removing the element of human error from the production process. The digital precision of the controller ensures that every feature, from diameter and length to thread pitch and surface finish, adheres strictly to the design specifications. This level of reliability is simply unattainable with manual lathing, especially across high-volume production.

Repeatability: The Cornerstone of Modern Manufacturing

Repeatability means that whether we are producing a batch of 100 or 10,000 parts, the last one off the line will be functionally identical to the first. This is achieved through a combination of factors inherent to the CNC process.

- Programmed Control: The G-code program is a fixed set of instructions. It doesn’t get tired or distracted.

- Rigid Machine Construction: CNC lathes are built to be incredibly stiff to absorb cutting forces and minimize vibration, which is a primary cause of inaccuracy.

- Automated Tool Changing: On more advanced lathes, an automatic tool turret can switch between turning, drilling, and threading tools in seconds, maintaining process continuity and precision without manual intervention.

In our work with clients in the robotics industry, for example, the precise fit of shafts and bearings is critical for smooth operation. Based on our tests, the tight tolerances achieved with CNC turning are essential for ensuring the longevity and reliability of their complex assemblies.

The Impact on Quality and Cost

Consistency has a direct impact on both quality and overall project cost. When parts are consistently within spec, it significantly reduces the rate of rejection and rework. This not only saves material and machine time but also prevents costly delays in the final assembly and testing phases.

| Industry | Critical Requirement | Example CNC Lathed Part |

|---|---|---|

| Aerospace | High strength-to-weight ratio, extreme tolerances | Turbine engine shafts, hydraulic fittings |

| Medical | Biocompatibility, flawless surface finish | Surgical instruments, bone screws, dental implants |

| Automotive | Durability, high-volume consistency | Transmission shafts, valve components, piston rods |

| Electronics | Miniaturization, electrical conductivity | Connector pins, custom fasteners, housing components |

Ultimately, investing in a manufacturing process that guarantees repeatability is a strategic decision. It provides peace of mind, streamlines the supply chain, and ensures the final product performs exactly as designed. This is why at PTSMAKE, CNC lathe machining is a core pillar of our precision manufacturing services.

CNC lathe machining provides unparalleled precision by rotating a workpiece against a cutting tool. Its core operations—turning, facing, and threading—are automated to deliver exceptional consistency and repeatability, making it essential for industries where part quality and reliability are critical for performance and safety.

Critical Quality Factors in CNC Lathe Parts?

Have you ever received a batch of turned parts that meet the drawing specs but still fail in application? It’s a frustrating experience that can derail an entire project.

The most critical quality factors for CNC lathe parts are dimensional accuracy, surface finish, and material integrity. These three pillars directly determine a part’s performance, longevity, and reliability in its final assembly. Getting them right is essential for any successful project.

When we talk about quality in CNC lathe machining, we go far beyond just looking at a finished part and saying, "it looks good." True quality is measurable, and it starts with dimensional accuracy. This isn’t just about the length or diameter; it’s about ensuring every feature is within the specified tolerance range, every single time.

The Foundation: Dimensional Tolerance

Tolerance is the acceptable range of variation for a given dimension. A part that is out of tolerance, even by a fraction of a millimeter, can cause assembly failures, premature wear, or a complete breakdown of the final product. In our projects at PTSMAKE, we’ve seen how an incorrectly toleranced fit can be the difference between a smooth-operating bearing and a seized one.

Beyond Basic Dimensions

It’s crucial to look beyond simple plus/minus tolerances. We also focus on geometric dimensioning and tolerancing (GD&T), which controls the form, orientation, and location of features. This ensures not just the size, but the relationships between features are correct. For example, concentricity is vital for rotating shafts to prevent vibration and wear, while perpendicularity is key for mounting surfaces to ensure proper alignment. A failure in these geometric controls can lead to subtle performance issues that are difficult to diagnose later.

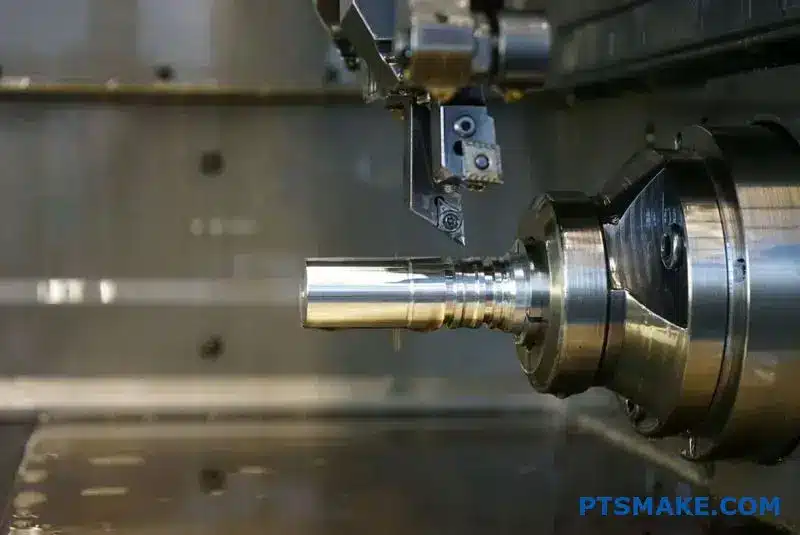

The Feel of Quality: Surface Finish

A part can be dimensionally perfect but still fail if the surface finish is wrong. Surface finish, or surface roughness, refers to the fine-scale texture of a surface. It is composed of tiny peaks and valleys, often called micro-asperities2, left by the cutting tool. This texture is typically measured in micrometers (µm) or microinches (µin) as a Roughness Average (Ra). A lower Ra value indicates a smoother surface. Why does this matter?

- Friction and Wear: Smoother surfaces have less friction and are more resistant to wear, which is critical for moving parts.

- Sealing: For parts that require seals, like O-rings, a specific surface finish is needed to allow the seal to function correctly without leaking or being damaged.

- Corrosion Resistance: Rougher surfaces have more surface area and can trap contaminants, making them more susceptible to corrosion.

Here’s a quick guide we often share with clients to help them specify the right finish for their application.

| Ra Value (µm) | Ra Value (µin) | Texture | Typical CNC Lathe Machining Application |

|---|---|---|---|

| >6.3 | >250 | Rough Machined | Clearance surfaces, non-functional areas |

| 3.2 | 125 | Standard Machined | General purpose parts, non-mating surfaces |

| 1.6 | 63 | Smooth Machined | Mating surfaces, parts with moderate loads |

| 0.8 | 32 | Fine Machined/Ground | Low-friction bearings, precise fits |

| 0.4 | 16 | Ground/Lapped | High-stress bearings, critical sealing surfaces |

While dimensions and finish are specified on the drawing, they cannot be achieved without the right material. Material selection is the third critical factor, directly influencing both the machining process and the final part’s performance. The properties of the raw material dictate everything from cutting speeds and tool life to the component’s final strength and stability.

The Core: Material Selection and Integrity

Choosing the right material is a balancing act between performance requirements, cost, and machinability. A material that is perfect for the end-use application might be incredibly difficult, and therefore expensive, to machine.

Key Material Properties for Machining

When planning a cnc lathe machining project, we analyze several material characteristics:

- Machinability: This is a rating of how easily a material can be cut. Materials like Brass C360 are considered "free-machining" and can be turned very quickly, reducing cycle times and cost. In contrast, materials like Inconel or Titanium are tough and require slower speeds, specialized tooling, and more robust processes.

- Hardness: Harder materials are more resistant to wear but are also more challenging to machine. They cause cutting tools to wear out faster, which can impact both cost and the ability to maintain a consistent surface finish over a production run.

- Thermal Stability: During machining, both the part and the tool generate heat. Materials that expand significantly with heat can be challenging to hold to tight tolerances, as they will measure differently when hot versus when they have cooled to room temperature. This requires careful management of coolants and cutting parameters.

Communicating Your Material Needs

To ensure you get the performance you expect, it’s not enough to just specify "aluminum" or "steel." You must be specific. In the past, we’ve had projects delayed because a generic material callout led to the use of a grade that couldn’t meet the performance requirements. Always specify the exact grade and temper. For example:

| Material Specified | Key Characteristics & Common Use |

|---|---|

| Aluminum 6061-T6 | Excellent machinability, good strength. Used for structural parts, prototypes. |

| Stainless Steel 304 | Great corrosion resistance, good for food-grade and medical applications. Tougher to machine. |

| PEEK | High temperature and chemical resistance. Used for aerospace, medical implants. Expensive. |

| Brass C360 | The standard for machinability. Ideal for fittings, valves, and electrical components. |

By clearly defining the material, tolerances, and surface finish on your drawings and RFQs, you empower your manufacturing partner to deliver parts that work not just on paper, but in the real world.

Achieving top-tier CNC lathe parts hinges on mastering the interplay between dimensional tolerances, surface finish, and material selection. These factors are not independent; they are deeply connected, and a clear specification of all three is essential for ensuring reliable component performance in its final application.

What Are the Key Criteria for Selecting a Reliable CNC Machining Partner?

Have you ever faced production delays because a supplier couldn’t handle your volume, or received parts that failed inspection? These issues often stem from an incomplete evaluation process before the first order is even placed.

To properly evaluate a CNC lathe machining supplier, you must assess four core areas: their quality certifications, in-depth inspection processes, actual production capacity, and their standards for communication. These pillars determine reliability, quality consistency, and on-time delivery.

To avoid partnerships that lead to costly errors and delays, you need a systematic approach to vetting potential suppliers. It’s not just about what they promise on their website; it’s about verifying their capabilities through tangible evidence. The right partner becomes an extension of your team, while the wrong one becomes a constant source of problems.

Verify Quality System Certifications

Certifications are more than just badges on a website; they are proof of a commitment to standardized, repeatable processes. A supplier without them might still produce a good part, but there’s no guarantee of consistency.

- ISO 9001: This is the foundational certification for quality management. It ensures the supplier has documented processes for everything from quoting to shipping. It’s the minimum requirement for any serious manufacturing partner. At PTSMAKE, our ISO 9001 system is the backbone of every project, ensuring every step is traceable and controlled.

- Industry-Specific Certifications: If you are in a highly regulated industry, look for specialized certifications. For example, AS9100 is critical for aerospace, while IATF 16949 is the standard for automotive. These indicate the supplier understands the stringent requirements and traceability demands of your sector.

Scrutinize the Quality Inspection Process

A supplier’s inspection capabilities are a direct indicator of the quality you will receive. You need to understand not just if they inspect parts, but how and when. Ask potential suppliers for a copy of their quality manual.

In-Process vs. Final Inspection

A reliable supplier performs both. In-process quality control (IPQC) catches deviations during the cnc lathe machining process, preventing an entire batch from being scrapped. Final inspection is the last gate, but it shouldn’t be the only one. Relying solely on final inspection is risky and inefficient. We also perform a First Article Inspection (FAI)3 to confirm that our production setup meets all specifications before mass production begins.

Inspection Equipment and Reporting

The right tools are essential for verifying tight tolerances. A supplier’s equipment list should align with your part complexity.

| Inspection Tool | Best For | What It Tells You |

|---|---|---|

| Calipers/Micrometers | Basic dimensions | Measures length, width, diameter. Good for general tolerances. |

| CMM | Complex geometries | Provides highly accurate 3D measurements for complex surfaces and features. |

| Optical Comparator | 2D profiles | Projects a magnified silhouette of a part to check profiles and contours. |

| Gauges (Go/No-Go) | Repetitive features | Quickly verifies if a feature like a hole or thread is within tolerance. |

Always ask for sample inspection reports. A detailed report demonstrates their meticulous approach to quality.

Beyond the paperwork and machinery, the human element is crucial. How a supplier manages its resources, communicates with clients, and plans for contingencies reveals its true strength as a partner. These factors are often overlooked during initial evaluations but are vital for a successful long-term relationship.

Gauge Realistic Production Capacity

A supplier’s capacity is not just the number of CNC lathes they own. True capacity is a combination of machinery, skilled labor, and efficient workflow management.

Machinery and Technology

Ask for a detailed equipment list. Are their machines new or old? Do they have multi-axis lathes that can complete complex parts in a single setup? Modern equipment, like the multi-axis CNC machines we use at PTSMAKE, reduces cycle times and improves accuracy. Also, inquire about their maintenance schedule. A well-maintained machine is a reliable machine.

Workforce and Scheduling

A shop full of advanced machines is useless without skilled operators and programmers to run them. Ask about the experience level of their team and if they run multiple shifts. A supplier running two or three shifts has significantly more effective capacity and flexibility than one running a single shift. In our past projects, we found that a robust production scheduling system is key to providing customers with accurate lead times and accommodating urgent requests without disrupting existing orders.

Evaluate Communication Standards and Responsiveness

Poor communication can derail a project faster than a machine breakdown. Your supplier should be proactive, transparent, and easy to reach.

| Communication Aspect | Green Flag (Good Supplier) | Red Flag (Poor Supplier) |

|---|---|---|

| Response Time | Responds to emails/calls within 24 hours. | Takes days to reply; responses are vague. |

| Technical Feedback | Proactively suggests design for manufacturability (DFM) improvements. | Accepts any design without feedback, leading to production issues later. |

| Problem Solving | Informs you immediately of any issues and presents solutions. | Hides problems until the deadline is missed. |

| Project Updates | Provides regular, unsolicited updates on project status. | You constantly have to chase them for information. |

Establish a single point of contact. Having a dedicated project manager who understands your requirements ensures nothing gets lost in translation. This is a standard practice at PTSMAKE to ensure clarity and accountability for all our clients.

Evaluating a CNC lathe machining supplier requires a methodical review of their certifications, inspection processes, true production capacity, and communication protocols. These four pillars are essential for ensuring you partner with a reliable manufacturer who can deliver high-quality parts on time, every time.

Design Tips for Cost-Effective CNC Lathe Manufacturing.

Ever submitted a part for a quote and been shocked by the cost, even though the design seemed straightforward? The geometry and features you define are often the hidden drivers behind high manufacturing expenses.

To achieve cost-effective CNC lathe manufacturing, designers must optimize part geometry based on Design for Manufacturability (DFM) principles. This involves simplifying features, avoiding thin walls, standardizing elements like radii, and specifying tolerances only as tight as functionally necessary to reduce machine time and tooling costs.

Applying DFM to Lathe Parts

Design for Manufacturability (DFM) isn’t just a buzzword; it’s a practical approach to designing parts that are easier and therefore cheaper to produce. In CNC lathe machining, where the workpiece rotates against a cutting tool, every design choice impacts cycle time and tooling requirements. The goal is to remove material efficiently. Overly complex designs work against this fundamental principle. From my experience collaborating with clients at PTSMAKE, the simplest designs are often the most elegant and cost-effective solutions.

Simplify Part Geometry

The more complex a part’s profile, the more machine time it requires. Multiple diameters, tapers, and contours necessitate more tool movements and potentially more tool changes. Each tool change adds non-cutting time to the process, increasing the overall cost. Before finalizing a design, ask yourself if every feature is essential for the part’s function. Can two different diameters be consolidated into one? Is that complex curve truly necessary, or would a simple chamfer or radius suffice? Simplifying the overall profile is the most direct way to reduce the time your part spends on the machine.

Design for Standard Tooling

CNC lathes use a variety of standard cutting tools. Designing features that can be created with these off-the-shelf tools is a major cost-saver. A common issue we see is non-standard internal corner radii. If you specify a 0.2 mm internal radius, but the standard tool produces a 0.5 mm radius, a special, smaller tool will be needed. This not only adds the cost of the tool itself but also increases the risk of tool breakage and requires slower cutting speeds.

| Feature Type | Cost-Effective Approach | High-Cost Approach |

|---|---|---|

| Internal Corner Radii | Use standard tool nose radii (e.g., 0.4mm, 0.8mm). | Specify a non-standard or sharp internal corner. |

| Grooves | Design grooves to match standard grooving tool widths. | Require custom-width grooves or complex profiles. |

| Threads | Specify standard threads (e.g., UNC, UNF, Metric). | Design custom or non-standard thread profiles. |

Optimize for Workholding

How a part is held in the lathe’s chuck or collet is a critical consideration. The design must provide a stable, secure surface for clamping that won’t deform the part. If the only available clamping surfaces are thin-walled or on a finished, critical diameter, it complicates the process immensely. This can lead to the need for custom fixtures or a second operation, both of which add significant cost. Poor workholding can also introduce vibration and concentricity problems, leading to issues with factors like runout4 that can cause an entire batch of parts to be scrapped.

The Critical Role of Tolerances and Features

While geometry lays the foundation, the specifics of your tolerances and features are where costs can quickly escalate. Many engineers, especially those new to manufacturing, tend to over-tolerance parts out of caution. However, every tightened tolerance adds a layer of complexity and cost to the cnc lathe machining process, often without providing any real functional benefit. It’s a balance between ensuring performance and maintaining a reasonable budget.

Specify Tolerances Strategically

A blanket tolerance block on a drawing is one of the most common mistakes that inflates manufacturing costs. Not all features on a part require the same level of precision. Mating surfaces, bearing bores, and alignment pins need tight tolerances, but non-critical surfaces do not. Applying a tight tolerance of ±0.01 mm to a surface that has no functional interface can double or triple the cost of that feature. It forces the machinist to use slower cutting speeds, take more finishing passes, and perform more frequent in-process inspections.

| Tolerance Level | Relative Cost Impact | Typical Application |

|---|---|---|

| Standard (e.g., ±0.1mm) | 1x (Baseline) | Non-critical surfaces, general dimensions. |

| Tight (e.g., ±0.025mm) | 2x – 4x | Mating parts, press-fit interfaces. |

| Very Tight (e.g., <±0.01mm) | 5x – 10x+ | High-precision bearings, critical alignments. |

Avoid Unnecessarily Deep and Small Holes

Deep holes, especially those with a small diameter (a high depth-to-diameter ratio), are challenging for any machining process. On a lathe, this requires special peck drilling cycles to clear chips and prevent tool breakage. The deeper the hole, the slower the process and the higher the risk. Before specifying a deep, small-diameter hole, consider if the depth is truly necessary or if the hole diameter could be increased.

Re-evaluate Complex Features like Undercuts

Undercuts and internal relief grooves require special tooling, such as grooving or boring bars with specific geometries. These tools are often more fragile and require slower, more careful operation than standard turning tools. While sometimes unavoidable, it’s always worth asking if the undercut is essential. Could the mating part be modified with a chamfer to provide the necessary clearance instead? In past projects at PTSMAKE, we’ve helped clients redesign mating components to eliminate the need for costly undercuts, saving them a significant percentage on production costs. This collaborative approach early in the design phase is key to unlocking savings.

For cost-effective cnc lathe machining, focus on DFM principles. Simplify part geometry, use standard tools, and design for secure workholding. Be strategic with tolerances, applying them only where functionally necessary, and critically evaluate complex features like deep holes and undercuts to minimize machine time and cost.

Managing Lead Times and Delivery Risks?

Ever had a critical project derailed by an unexpected delay? A simple material shortage or a communication gap can throw your entire production schedule into chaos, costing you time and money.

To effectively manage lead times in CNC lathe machining, you must adopt a proactive strategy. This involves establishing crystal-clear project timelines, maintaining constant communication with your supplier, and developing robust contingency plans for potential disruptions. This approach is your best defense against costly delays.

Deconstructing Common Production Delays

Understanding why delays happen is the first step to preventing them. In CNC lathe machining, disruptions rarely come out of nowhere. They are often the result of underlying issues that can be anticipated and managed. Overlooking these factors can turn a straightforward project into a logistical nightmare. It’s about looking beyond the final delivery date and examining the entire production chain for potential weak spots.

The Material Procurement Puzzle

One of the most frequent causes of delay is material availability. This isn’t just about whether a material is in stock; it’s about its quality, certification

Ensuring Consistent Communication and Project Transparency.

Have you ever seen a project get derailed by a simple miscommunication? An unclear specification or a missed email can quickly spiral into costly delays and frustrating rework, jeopardizing your entire timeline.

Consistent communication is achieved by establishing clear protocols, using centralized platforms for updates, holding regular check-ins, and providing real-time project access. This proactive approach minimizes misunderstandings and keeps all stakeholders aligned from procurement through production, especially for complex CNC lathe machining projects.

Effective communication is more than just sending emails; it’s about creating a system that prevents problems before they start. In my experience, the most successful projects are built on a foundation of clear, documented, and consistent dialogue. Without it, you’re navigating the manufacturing process with a blindfold on.

Proactive Strategies to Preempt Communication Breakdowns

The best way to solve a problem is to prevent it from ever happening. Instead of waiting for a misunderstanding to cause a delay, we implement systems designed to ensure clarity from day one. This is especially crucial when dealing with the precise requirements of CNC lathe machining. A proactive approach turns potential crises into simple clarifications.

Establishing a Communication Escalation Matrix

One of the most effective tools we use at PTSMAKE is a communication escalation matrix. This is a simple but powerful document agreed upon at the project kickoff. It clearly outlines who to contact for specific issues and what the expected response time is. It removes ambiguity and prevents messages from getting lost. For instance, a minor question about material finish might go to the project manager, while a critical design flaw alert is immediately escalated to the lead engineer. This structure prevents small issues from festering.

The Role of the Single Point of Contact (SPOC)

To streamline communication further, assigning a Single Point of Contact (SPOC) on both the client and supplier side is essential. This person acts as the central hub for all project-related information. For our clients, having one dedicated project manager at PTSMAKE to talk to means they always know who to call. They don’t have to chase down different people in engineering, quality, or logistics. This model dramatically reduces the risk of Information Asymmetry5, ensuring both sides are working with the same data and expectations.

A well-defined communication plan should look something like this:

| Issue Severity | First Point of Contact | Response Timeframe | Escalation Contact |

|---|---|---|---|

| Low | Project Manager (SPOC) | Within 24 hours | N/A |

| Medium | Project Manager (SPOC) | Within 8 hours | Engineering Lead |

| High | Project Manager (SPOC) | Within 1 hour | Department Head |

| Critical | Direct Call to SPOC | Immediate | VP of Operations |

This structured approach ensures that nothing falls through the cracks, from a simple query to a production-halting emergency.

Beyond proactive plans, the tools you use for day-to-day communication and tracking play a massive role in maintaining project transparency. Relying on outdated methods in a fast-paced manufacturing environment is a recipe for failure. Modern projects demand modern solutions that provide instant clarity and a single source of truth.

Leveraging Technology for Real-Time Project Transparency

Technology has transformed how we manage projects. Gone are the days of endless email chains and uncertainty about project status. Today, we can provide clients with a clear, real-time window into their project’s lifecycle, from raw material procurement to final inspection of their CNC machined parts.

From Email Chains to Centralized Project Dashboards

Email is a terrible tool for project management. Important files get buried, feedback becomes fragmented, and it’s nearly impossible to track the latest version of a document. In our past projects with clients, we’ve found that moving all communication and documentation to a centralized project dashboard is a game-changer. These platforms allow everyone to see the latest CAD files, view the production schedule, check quality reports, and ask questions in one organized place. This transparency builds immense trust.

Document Control and Revision Management

For any cnc lathe machining project, precise specifications are everything. A project can be completely derailed if the shop floor works from an outdated drawing. Proper document control is non-negotiable. A good supplier will have a robust system for revision management. At PTSMAKE, our system ensures that only the latest, approved version of any document is accessible for production. When a client submits a revision, the old version is automatically archived and the new one is flagged for review, ensuring that our machinists are always working with the correct specifications. This simple control prevents costly mistakes and material waste.

Here’s a quick comparison of old versus new methods:

| Feature | Traditional Method (Email/Phone) | Modern Method (Project Dashboard) |

|---|---|---|

| Status Updates | Reactive; requires a call/email | Proactive; real-time, 24/7 access |

| Document Sharing | Attachment version confusion | Centralized; single source of truth |

| Issue Tracking | Lost in email threads | Organized tickets with clear ownership |

| Approval Process | Slow, hard to track | Streamlined with digital signatures |

Adopting modern tools isn’t about adding complexity; it’s about creating simplicity and clarity for everyone involved.

Successful CNC lathe machining projects depend on clear, consistent communication. By using proactive strategies like escalation matrices and leveraging modern project dashboards for real-time transparency, you can eliminate misunderstandings, ensure technical accuracy, and build a strong, trusting partnership with your manufacturer.

Integrating CNC Lathe Machining into Global Supply Chains?

Feeling overwhelmed by the logistics, customs, and quality control challenges of sourcing CNC parts globally? Worried about how these complexities will impact your production timeline and budget?

Successfully integrating CNC lathe machining into global supply chains requires a strategic partnership. This involves selecting a supplier with proven logistics expertise, transparent customs procedures, and a rigorous quality assurance system to ensure seamless delivery and part consistency.

Integrating an overseas supplier into your existing supply chain can seem daunting, but it doesn’t have to be a source of constant stress. The key is to break the process down into manageable components: logistics, customs, and quality. When you partner with a manufacturer who has a deep understanding of these areas, integration becomes a strategic advantage rather than a logistical nightmare.

Navigating the Logistics Maze

The physical movement of parts from the factory floor to your assembly line is the first major hurdle. The choice between air and sea freight is a fundamental decision that impacts both cost and speed. In our experience at PTSMAKE, we guide clients through this choice based on their specific project needs—urgency versus budget.

| Shipping Method | Typical Transit Time | Cost Factor | Best For |

|---|---|---|---|

| Air Freight | 3-7 days | High | Urgent prototypes, time-sensitive production runs |

| Sea Freight | 25-40 days | Low | High-volume production, non-urgent stock replenishment |

Beyond the shipping method, understanding trade terms is crucial. These terms define who is responsible for the shipment at every stage of its journey. Clear agreements on Incoterms6 like FOB (Free On Board) or DDP (Delivered Duty Paid) prevent misunderstandings and unexpected costs down the line. A reliable partner will be transparent about these terms and help you select the one that best suits your procurement strategy, taking the guesswork out of international shipping.

Demystifying Customs and Tariffs

Customs clearance can be a significant bottleneck if not handled correctly. Delays here can disrupt even the most carefully planned production schedules. The foundation of a smooth customs process is accurate and complete documentation. This includes the Commercial Invoice, a detailed Packing List, and sometimes a Certificate of Origin.

A common point of failure is the incorrect classification of goods using Harmonized System (HS) codes. An incorrect code can lead to customs holds, inspections, and even financial penalties. An experienced overseas supplier specializing in cnc lathe machining will have a dedicated team that understands the specific HS codes for machined parts, ensuring all paperwork is filed correctly the first time. This proactive approach minimizes complexity for you, the procurement manager, allowing you to focus on your core responsibilities instead of chasing customs brokers.

Once logistics and customs are mapped out, the focus shifts to the most critical element: ensuring the parts you receive are exactly what you ordered. Quality assurance and communication are the pillars that support a successful long-distance manufacturing relationship.

Maintaining Quality Across Continents

Trust in quality cannot be left to chance. When sourcing from an overseas partner, you need a verifiable system that guarantees consistency. Look for suppliers with a robust Quality Management System (QMS), often validated by certifications like ISO 9001. This isn’t just a piece of paper; it’s proof of a commitment to standardized processes that deliver repeatable results.

At PTSMAKE, we provide comprehensive inspection reports at every key stage.

- First Article Inspection (FAI): Confirms the first part off the line meets all specifications before mass production begins.

- In-Process Quality Control (IPQC): Regular checks during the cnc lathe machining process to catch any deviations early.

- Final Quality Control (FQC): A final, thorough inspection of the entire batch before it’s packed for shipment.

This multi-layered inspection process, combined with full material traceability, provides the transparency needed to build trust. You receive documented proof that your parts meet spec, giving you the confidence to integrate them directly into your assembly line without costly incoming inspections on your end.

The Pillar of Integration: Proactive Communication

Poor communication is one of the biggest pain points in global sourcing. Waiting days for a response to a simple question is not acceptable when production deadlines are on the line. Effective integration hinges on clear, consistent, and proactive communication.

An ideal manufacturing partner assigns a dedicated project manager or engineer as your single point of contact. This individual should be fluent in your language and available during your business hours. In past projects with our clients, we’ve found that a simple system of weekly progress reports, complete with photos and production updates, can eliminate almost all communication friction. Modern tools like secure client portals and video conferencing make it easy to stay connected, review progress, and make decisions in real-time. This level of transparency makes working with a supplier thousands of miles away feel as seamless as working with one next door.

Integrating global CNC lathe machining services is achievable with the right strategy. By focusing on a partner who excels in logistics, customs clearance, robust quality assurance, and proactive communication, you can simplify complexity and turn global sourcing into a powerful competitive advantage for your supply chain.

Future Trends in CNC Lathe Machining for Industrial Buyers.

Are you struggling to anticipate how the latest manufacturing technologies will affect your supply chain and product quality? Are you concerned about falling behind the curve?

The future of CNC lathe machining is being shaped by automation, real-time quality monitoring, and digital twin integration. For industrial buyers, these trends mean higher efficiency, better traceability, and greater potential for innovation in part production.

The landscape of manufacturing is in constant motion, and CNC lathe machining is at the forefront of this evolution. As an industrial buyer, understanding these shifts is crucial for maintaining a competitive edge. It’s not just about getting parts made; it’s about getting them made smarter, faster, and with more transparency than ever before. Two of the most impactful trends right now are automation and real-time quality monitoring.

The Push Towards Full Automation

Automation in CNC turning is moving beyond simple bar feeders. We’re seeing a surge in the adoption of sophisticated robotic systems.

Robotic Tending and Material Handling

Robotic arms that load raw billets and unload finished parts are becoming a common sight. In the projects we handle at PTSMAKE, integrating robotics can increase machine uptime by over 30%, as the machine can run continuously, even through breaks or overnight. This leads to more predictable lead times and stable costs for our clients. It also eliminates the variability that can come from manual loading, ensuring each part is seated in the chuck with perfect consistency.

In-Process Measurement and Adjustment

Modern CNC lathes can be equipped with probing systems that measure a part while it’s still in the machine. If a dimension is drifting from the specification, the machine’s controller can automatically adjust the tool offsets to correct it on the next part. This proactive approach to quality control is a game-changer. It dramatically reduces scrap rates and the need for extensive post-production inspection, which directly translates to cost savings and faster delivery for you. This integration of machinery and data networks forms the backbone of modern smart factories, often referred to as cyber-physical systems7.

| Feature | Traditional Machining | Automated Machining |

|---|---|---|

| Machine Uptime | Dependent on operator availability | Up to 24/7 operation possible |

| Part Loading | Manual, potential for inconsistency | Robotic, highly consistent |

| Quality Control | Post-process inspection | In-process, real-time adjustments |

| Ideal Batch Size | Medium to high volume | Efficient for both low and high volume |

This level of automation ensures that the cnc lathe machining process is not only efficient but also incredibly reliable, providing a stable foundation for your supply chain.

Beyond automation and immediate quality checks, the next frontier is about creating a complete digital narrative for every component produced. This is where technologies like digital twins and advanced data analytics come into play, offering unprecedented levels of traceability and process optimization.

Digital Twin Integration for Full Traceability

The concept of a digital twin is one of the most exciting developments for industrial manufacturing. It’s more than just a 3D model; it’s a dynamic, virtual replica of the entire machining process.

What is a Digital Twin?

Imagine a virtual dashboard that mirrors a specific CNC lathe on our shop floor in real-time. This digital twin shows not only the machine’s current status but also simulates the entire tool path, tracks tool wear, and monitors temperatures and vibrations. For a buyer, this means we can run a virtual simulation of your part’s production run before a single piece of metal is cut. This allows us to identify potential challenges, optimize cycle times, and guarantee the process is stable from the very first part.

Benefits for Industrial Buyers

The advantages are clear. First, it offers complete traceability. Every parameter from the production of your part is recorded and linked to that specific component or batch. If a quality issue arises years later, we can pull up the complete digital history. Second, it enables predictive maintenance. The digital twin can predict when a tool will fail or a machine needs service, preventing unexpected downtime that could delay your order.

| Aspect | Conventional Process | Digital Twin Enabled Process |

|---|---|---|

| Process Planning | Based on experience and trial runs | Optimized via virtual simulation |

| Maintenance | Reactive or scheduled | Predictive and condition-based |

| Traceability | Paper-based or fragmented data | Complete, integrated digital record |

| Problem Solving | Post-mortem analysis | Real-time diagnostics & historical data |

In one of our past explorations with a client in the aerospace sector, we used a process simulation to refine the toolpaths for a complex component made from a tough alloy. This digital workshopping saved an estimated 40 hours of on-machine trial and error, getting their critical parts into production faster. The integration of these digital tools into cnc lathe machining is fundamentally changing the supplier-client relationship, moving it towards a more transparent and collaborative partnership.

The future of CNC lathe machining is defined by smarter, more connected processes. Automation and real-time monitoring deliver immediate efficiency and quality gains, while digital twins offer a new level of traceability and predictive power, ensuring a more reliable and innovative manufacturing partnership for industrial buyers.

Achieve Flawless CNC Lathe Machining with PTSMAKE

Ready for zero-defect CNC lathe parts and seamless procurement? Partner with PTSMAKE to solve your toughest precision manufacturing challenges. Send us your inquiry now—experience responsive service, on-time delivery, and consistent quality from prototype to production, start your project today!

Learn how minimizing runout is crucial for the performance and lifespan of your precision components. ↩

Understand how these microscopic peaks and valleys on a surface affect part function, friction, and wear in our guide. ↩

Learn what a First Article Inspection report includes to guarantee your first production run meets every single specification. ↩

Understand how this critical geometric tolerance affects rotational accuracy and learn design strategies to control it effectively. ↩

Learn how bridging this knowledge gap with your supplier leads to better outcomes and fewer production errors. ↩

Understand these trade terms to clarify responsibilities and avoid unexpected costs in your international shipments. ↩

Learn how these integrated computational and physical components are redefining efficiency and control in modern smart factories. ↩