Titanium CNC machining looks straightforward until you face heat buildup, work hardening, and tool wear that can destroy your parts and blow your budget. Many manufacturers struggle with inconsistent quality and failed projects when machining this demanding material.

Titanium CNC machining requires specialized techniques, proper cooling systems, and precise tool selection to overcome titanium’s low thermal conductivity and work hardening tendencies while maintaining tight tolerances for high-performance applications.

I’ve worked with titanium parts across aerospace, medical, and marine industries at PTSMAKE. This material demands respect and knowledge. The right approach transforms titanium from a problematic material into precision components that perform flawlessly in critical applications. Below, I’ll share the essential insights that separate successful titanium machining from costly failures.

Why Titanium CNC Machining Matters for High-Performance Industries?

Have you ever specified a material for a critical component, only to see it fail under stress, corrosion, or fatigue? That moment of failure is where high-performance materials become non-negotiable.

Titanium CNC machining is essential for high-performance industries because it combines the metal’s superior strength-to-weight ratio, corrosion resistance, and biocompatibility with the absolute precision of computer-controlled machining. This creates reliable, complex parts that meet the strictest standards of aerospace, medical, and automotive applications.

Titanium isn’t just another metal; it’s a solution to some of engineering’s toughest challenges. Its value comes from a unique combination of properties that other materials simply can’t match. Understanding these characteristics is the first step in appreciating why it’s a go-to choice for parts where failure is not an option.

The Unbeatable Strength-to-Weight Ratio

When engineers talk about strength-to-weight ratio, they’re discussing how strong a material is for its density. This is where titanium, particularly alloys like Ti-6Al-4V (Grade 5), truly shines. It has the strength of many steels but is about 45% lighter. For industries like aerospace and performance automotive, this is a game-changer. Lighter aircraft components mean better fuel efficiency and increased payload capacity. In a race car, reduced weight leads to faster acceleration and better handling. This property allows for the design of robust, durable parts without the weight penalty of traditional metals, opening up new possibilities for innovation.

Superior Corrosion Resistance

Titanium’s resistance to corrosion is legendary. It naturally forms a thin, inert, and highly adherent oxide layer when exposed to oxygen. This process of passivation1 protects the metal from attack by a wide range of acids, chlorides, and saltwater. This makes it indispensable for marine, chemical processing, and desalination applications. While stainless steel might eventually succumb to pitting or crevice corrosion in harsh saltwater environments, titanium components remain unaffected, drastically extending service life and reducing maintenance costs. In past projects at PTSMAKE, we’ve seen clients switch to titanium for subsea components specifically to eliminate costly and frequent replacements.

Essential Biocompatibility

For the medical industry, a material’s interaction with the human body is paramount. Titanium is exceptionally biocompatible, meaning it’s non-toxic, non-allergenic, and isn’t rejected by the body. This allows it to fuse directly with bone in a process called osseointegration. This property makes it the gold standard for medical implants such as joint replacements (hips, knees), dental implants, and bone screws. Its strength ensures the implants can withstand the mechanical stresses of daily life, while its inert nature guarantees long-term safety and performance inside the human body.

| Property | Titanium (Ti-6Al-4V) | Stainless Steel (316L) | Aluminum (6061-T6) |

|---|---|---|---|

| Density (g/cm³) | ~4.43 | ~8.00 | ~2.70 |

| Tensile Strength (MPa) | ~950 | ~570 | ~310 |

| Strength-to-Weight | Very High | Medium | High |

| Corrosion Resistance | Excellent | Good | Fair |

| Biocompatibility | Excellent | Fair | Poor |

While titanium’s properties are impressive on their own, they also make it a notoriously difficult material to work with. It has low thermal conductivity, which causes heat to build up at the cutting tool, and it has a tendency to gall and smear. This is why the manufacturing method is just as important as the material itself. You can’t just throw a block of titanium on any old machine and expect good results. CNC (Computer Numerical Control) machining is the key that unlocks the full potential of this advanced material.

Overcoming Machining Challenges with Precision

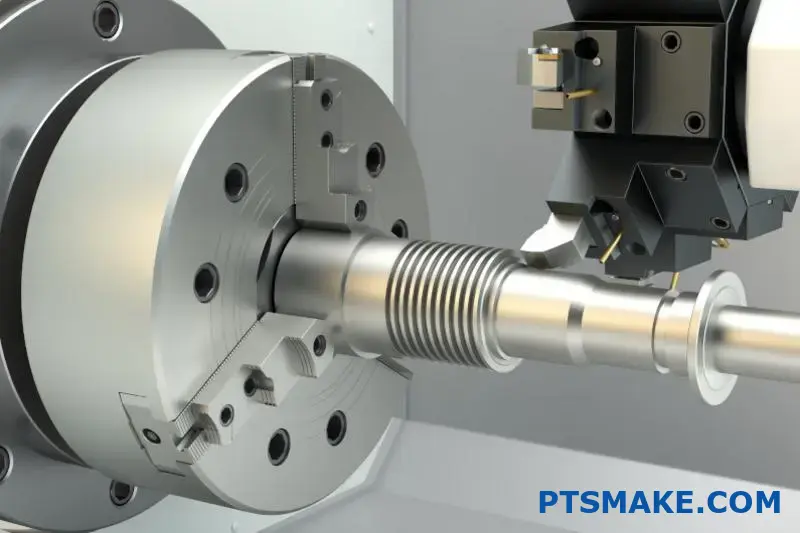

The challenges of working with titanium—namely heat generation and work hardening—require a highly controlled and robust manufacturing process. CNC machining is perfectly suited for this. At PTSMAKE, we use machines with high rigidity, optimized cutting speeds, and high-pressure coolant systems specifically to manage heat and prevent tool wear. Specialized toolpaths programmed into the CNC controller ensure consistent chip load, which prevents the material from work-hardening during the process. This level of control is simply not possible with manual methods. It allows us to cut, drill, and mill titanium efficiently while maintaining the integrity of the material and holding extremely tight tolerances.

Achieving Complex Geometries and Tight Tolerances

High-performance industries demand parts with intricate designs and precise dimensions. Think of the complex internal channels of a fuel injector nozzle or the contoured surfaces of an artificial hip joint. 5-axis CNC machining allows for the creation of these complex geometries in a single setup. This reduces the risk of error from re-fixturing the part and ensures all features are perfectly aligned. Our ability to consistently hold tolerances within a few microns is critical for our clients in the aerospace and medical device sectors. This precision ensures that components fit perfectly, function reliably, and perform optimally under extreme conditions.

Ensuring Repeatability from Prototype to Production

From the first prototype to a full production run of thousands of units, consistency is key. CNC machining is a digital process. Once a program is proven, it can be run over and over, producing identical parts every time. This repeatability is vital for industries where part-to-part consistency is a regulatory or safety requirement. It eliminates the variability often seen in casting or forging, ensuring that every component that comes off our machines meets the exact same specifications as the first one. This reliability streamlines assembly, simplifies quality control, and builds trust in the final product.

Titanium’s value is defined by its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. However, these properties present significant manufacturing challenges. This is where titanium CNC machining becomes indispensable. It provides the necessary control to overcome the material’s difficulty, enabling the creation of complex parts with tight tolerances. By pairing the superior material with a precision manufacturing process, we unlock its full potential for high-performance industries, ensuring reliability and consistency from the first part to the last.

Precision and Tolerances: Meeting Demanding Specifications.

Have you ever worried that a tiny deviation in a titanium part could lead to catastrophic failure? When dealing with high-stakes applications, even a micron-level error can compromise an entire system.

Achieving sub-micron precision in titanium CNC machining is not just possible—it’s essential. Advanced technologies, particularly Swiss-style machining, combined with rigorous process controls, allow us to consistently meet the most stringent specifications, ensuring both optimal performance and uncompromising safety in critical components.

When we talk about precision in titanium machining, we’re discussing more than just hitting a target dimension. It’s about repeatability and consistency across thousands of parts. In demanding industries, the performance of a final assembly often hinges on the quality of its smallest components. This is where the choice of manufacturing technology becomes critical.

The Role of Advanced CNC Technology

At the heart of high-precision titanium cnc machining is the machine itself. While standard CNC mills and lathes are powerful, specialized equipment is needed for parts with extreme tolerance requirements. Swiss-style lathes, for example, are a game-changer. They support the workpiece right next to the cutting tool, which significantly reduces vibration and deflection. This is especially important when machining long, slender titanium parts, where tool pressure can easily cause the material to bend. The result is superior surface finish and the ability to hold much tighter tolerances. In past projects at PTSMAKE, we’ve found that Swiss machining can improve dimensional accuracy by up to 50% for specific geometries compared to conventional turning.

Process Control and Optimization

Technology alone isn’t enough. The machining process must be meticulously controlled. This involves several key factors:

- Toolpath Strategy: We use advanced CAM software to create optimized toolpaths that minimize tool wear and thermal stress on the titanium part. This ensures consistent cutting forces and helps maintain the material’s dimensional stability)2.

- Cutting Tools: Using the right cutting tools—specifically those with sharp edges and specialized coatings designed for titanium—is non-negotiable. Worn or incorrect tools can introduce heat and stress, leading to dimensional inaccuracies.

- Thermal Management: Titanium’s low thermal conductivity means heat builds up at the cutting zone. We use high-pressure coolant systems to efficiently evacuate heat and chips, preventing thermal expansion that could throw tolerances off.

Based on our internal testing, a combination of these factors is what truly unlocks ultra-precision.

| Feature | Standard CNC Turning | Swiss-Style Machining |

|---|---|---|

| Workpiece Support | Supported at ends | Supported near the tool |

| Vibration Dampening | Moderate | Excellent |

| Ideal Part Profile | Shorter, larger diameter | Long, slender parts |

| Typical Tolerance | ±0.015 mm | As low as ±0.002 mm |

The theoretical ability to achieve a certain tolerance is one thing; understanding its practical impact is another. For engineers in sectors like aerospace and medical, precision isn’t just a "nice-to-have" feature on a drawing. It is a fundamental requirement directly linked to performance, reliability, and human safety. A deviation measured in microns can be the difference between a successful mission and a critical failure.

Impact on Aerospace and Defense

In aerospace, the consequences of part failure are severe. Titanium alloys are used in critical applications like landing gear components, engine turbine blades, and structural fasteners because of their high strength-to-weight ratio and corrosion resistance.

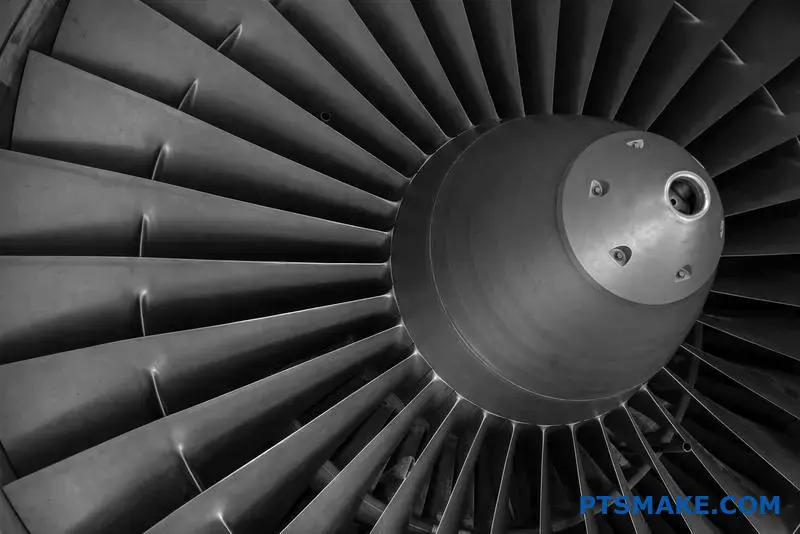

- Engine Components: Turbine blades and discs operate under extreme temperatures and rotational speeds. Precise airfoil contours are essential for aerodynamic efficiency and fuel economy. Any deviation can disrupt airflow, reducing performance and potentially leading to fatigue failure over time.

- Structural Integrity: Fasteners and fittings holding the airframe together must have exact dimensions to ensure a proper interference fit. A loose fit could lead to vibrational fatigue, while a fit that’s too tight could induce stress concentrations, creating a potential point of failure.

Criticality in the Medical Field

The medical device industry demands an even higher level of precision. When a component is implanted in the human body, there is zero margin for error.

- Orthopedic Implants: Components like bone screws, spinal fixation systems, and joint replacements must fit perfectly with both the patient’s anatomy and mating parts. An improperly sized titanium screw could fail to secure a bone plate, leading to surgical failure and requiring a revision surgery.

- Surgical Instruments: The precision of titanium surgical tools, such as forceps and scalpels, directly impacts a surgeon’s ability to perform delicate procedures. The alignment and sharpness achieved through precision machining ensure that the instruments function exactly as intended.

The table below illustrates how tolerances directly correlate with application risk.

| Application | Component Example | Typical Tolerance | Consequence of Deviation |

|---|---|---|---|

| Aerospace | Turbine Blade Root | ±0.005 mm | Reduced engine efficiency, fatigue risk |

| Medical | Bone Screw Thread | ±0.003 mm | Poor fixation, implant loosening |

| Automotive | Turbocharger Shaft | ±0.010 mm | Imbalance, premature bearing failure |

In titanium cnc machining, achieving demanding specifications is non-negotiable. It begins with acknowledging that even micron-level errors can have significant consequences. By leveraging advanced technologies like Swiss-style machining and implementing rigorous process controls, we can consistently meet the stringent tolerances required. This commitment to precision is what ensures the reliability and safety of critical components in high-stakes industries like aerospace and medical, where performance is directly tied to the accuracy of every manufactured part.

Surface Finishing Techniques for Titanium CNC Parts.

Have you ever finalized a titanium part’s design, only to be stumped by the finishing choice? Selecting the wrong finish can undermine the part’s performance, leading to corrosion, excessive wear, or an appearance that fails to impress.

The best finish for titanium CNC parts depends on your specific needs. Key options include anodizing for superior corrosion resistance, bead blasting for a uniform matte texture, and polishing for a smooth, mirror-like surface. For enhanced durability, PVD coating offers exceptional hardness, while powder coating provides robust color options.

After the primary titanium cnc machining is complete, the surface finish you choose is more than just a cosmetic touch-up; it’s a critical engineering decision that dictates the part’s final properties. In my experience at PTSMAKE, aligning the finishing technique with the part’s intended application is the key to success. Let’s look at some of the most common and effective methods.

Anodizing: Enhancing Titanium’s Natural Strengths

Unlike the process for aluminum, titanium anodizing (Type II and Type III) doesn’t just add a coating; it grows the existing protective oxide layer on the surface. This enhancement significantly boosts the material’s inherent resistance to corrosion and wear.

Functional and Aesthetic Gains

The thickened oxide layer created through anodizing is integral to the part, meaning it won’t chip or peel. This is crucial for medical implants, where biocompatibility is non-negotiable and the surface must remain stable. The process of passivation3 is effectively supercharged. Aesthetically, anodizing can produce a range of colors by varying the oxide layer’s thickness, which refracts light differently. However, the color palette is more subtle and limited compared to what you can achieve with aluminum.

Bead Blasting: For a Clean, Uniform Look

Bead blasting is a go-to process for creating a non-reflective, satin finish. It involves propelling fine glass beads at high pressure against the part’s surface. This method is excellent for hiding minor imperfections and tooling marks left over from machining operations. It creates a clean, consistent texture that is both visually appealing and functional, as it can help relieve surface stress induced during machining.

Polishing: Achieving a Flawless Surface

For applications demanding low friction or a high-end cosmetic appearance, nothing beats polishing. The process can range from a basic satin buff to a full mirror polish. A smoother surface isn’t just about looks; it reduces the microscopic peaks and valleys where cracks can initiate, potentially improving the fatigue life of a component. Polishing titanium can be challenging due to its tendency to gall, but the result is a part that is not only beautiful but also easier to clean and sterilize.

| Finishing Method | Primary Benefit | Common Application | Relative Cost |

|---|---|---|---|

| Anodizing (Type II) | Corrosion Resistance, Color | Medical Implants, Aerospace | Moderate |

| Bead Blasting | Uniform Matte Finish | General Components | Low |

| Polishing | Low Friction, Aesthetics | High-Performance Parts | High |

While the previous methods work by treating the titanium’s existing surface, another category of finishes involves applying an entirely new layer of material. These coatings can introduce properties that titanium alone doesn’t possess, opening up new possibilities for performance and durability. This is where advanced techniques come into play, offering solutions for some of the most demanding engineering challenges.

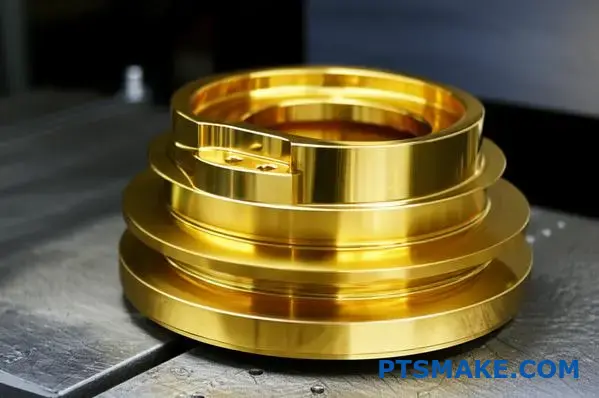

PVD Coating: For Extreme Durability

Physical Vapor Deposition (PVD) is a sophisticated vacuum deposition process that applies a very thin, yet extremely hard, ceramic coating to the part. Coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC) can elevate the surface hardness of a titanium part dramatically, making it exceptionally resistant to scratching and wear. We’ve seen this used effectively in projects requiring parts that endure constant friction, such as in high-performance automotive or industrial machinery. PVD also offers a variety of rich colors—like gold, black, and bronze—that are far more durable than those from anodizing.

Powder Coating: Robust and Colorful Protection

If a specific color or a thick, protective layer is the goal, powder coating is an excellent choice. The process involves electrostatically spraying a dry powder onto the part, which is then cured under heat to form a hard finish. This creates a uniform coating that is much tougher than conventional paint. It’s a great option for components that need to withstand harsh environments. When dealing with titanium cnc machining, it’s important to ensure the part’s geometry allows for even powder application and that the curing temperature won’t affect any critical heat treatments the material may have undergone.

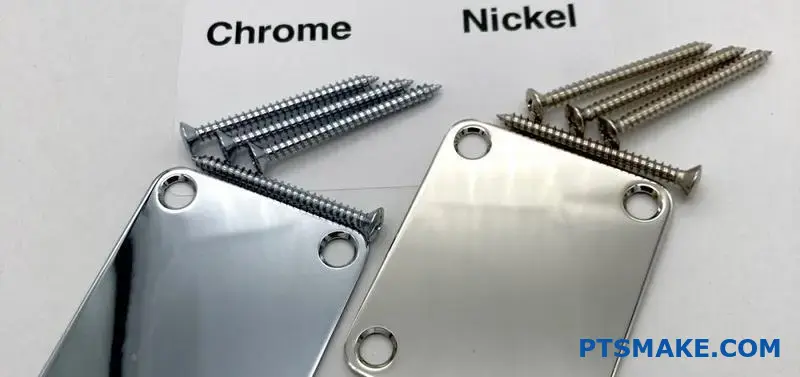

Chroming: A Traditional Finish for Specific Cases

Though less common for titanium than for steel, chromium plating can be applied for specific functional benefits. Hard chroming, for instance, adds a very hard, low-friction surface ideal for certain wear applications. However, applying chrome to titanium is a complex process. Because chrome doesn’t adhere directly to titanium, an intermediate strike layer, typically nickel, must be applied first. This multi-step requirement increases both the complexity and cost, making it a specialized solution rather than a general-purpose finish.

| Coating Method | Added Thickness | Key Advantage | Color Options |

|---|---|---|---|

| PVD Coating | Very Thin (Microns) | Extreme Hardness | Wide Range (Metallics) |

| Powder Coating | Thick (Mils) | Durable Color | Nearly Unlimited |

| Chroming | Varies | Wear Resistance/Lubricity | Silver (Mirror/Satin) |

Choosing the right surface finish for your titanium CNC machined part is a critical decision. Options range from enhancing the material’s natural properties with anodizing or bead blasting to adding entirely new functional layers through PVD or powder coating. The best method always depends on balancing functional requirements like corrosion resistance and hardness with aesthetic goals and budget. Understanding these trade-offs ensures your final component performs exactly as intended in its application.

Industry Applications: From Aerospace to Medical and Beyond.

Have you ever wondered why certain industries bet everything on one material? Why they can’t afford to compromise on performance, even when the cost is high?

Titanium’s incredible strength-to-weight ratio and corrosion resistance, unlocked through CNC machining, make it the non-negotiable choice for critical components in aerospace, medical, marine, and high-performance automotive applications where failure is not an option.

When a material is used to build something that flies at 30,000 feet or is implanted inside the human body, the standards are incredibly high. This is where titanium, shaped by precise CNC machining, truly excels. It’s not just about making a part; it’s about engineering confidence and reliability into every component.

Aerospace: Engineering for Extreme Conditions

In aerospace, every gram counts. Reducing weight directly translates to fuel savings and increased payload capacity, but it can never come at the expense of strength or safety. This is titanium’s home turf.

Structural Components and Airframes

Titanium alloys are extensively used for critical airframe structures like landing gear assemblies, wing spars, and bulkheads. These parts must withstand immense stress during takeoff, flight, and landing. The precision of titanium cnc machining allows us to create complex geometries that optimize strength while minimizing weight, something that is difficult with other materials or manufacturing methods.

Turbine Blades and Engine Parts

Jet engines operate under extreme temperatures and rotational forces. Titanium’s ability to maintain its strength at high temperatures makes it essential for compressor blades, discs, and casings. The parts we machine at PTSMAKE for aerospace clients often have tolerance requirements measured in microns, ensuring perfect balance and aerodynamic efficiency. In our experience, Grade 5 (Ti-6Al-4V) is the workhorse for these applications due to its excellent all-around performance. The process of making these parts requires an understanding of how the material behaves under stress and heat, a knowledge built over years of hands-on work.

Medical: Precision for Human Health

The medical field demands materials that are not only strong and durable but also safe for long-term contact with the human body.

Implants and Prosthetics

Titanium is the leading material for orthopedic implants like hip joints, knee replacements, and dental implants. Its non-toxic nature and resistance to corrosion from bodily fluids ensure it won’t be rejected by the body. This property of biocompatibility4 is crucial. Furthermore, its elasticity is similar to human bone, which helps reduce stress on surrounding bone tissue and promotes better integration.

| Medical Application | Key Titanium Property | Machining Requirement |

|---|---|---|

| Dental Implants | High Biocompatibility | Micro-level precision for fit |

| Joint Replacements | Excellent Strength-to-Weight Ratio | Complex surface finishing |

| Bone Screws/Plates | Corrosion Resistance | High-precision threads |

| Surgical Instruments | Sterilization Resistance | Non-porous surface finish |

Surgical Instruments

Surgeons rely on instruments that are lightweight, strong, and can be repeatedly sterilized without degrading. Titanium surgical tools, from forceps to retractors, meet these needs perfectly. They are non-magnetic, which is a significant advantage in operating rooms with MRI machines and other sensitive electronic equipment.

Beyond the high-profile worlds of aerospace and medicine, titanium’s unique advantages have made it a critical material in several other demanding industries. These sectors might not always grab the headlines, but their performance requirements are just as stringent. The common thread is a need for components that can withstand harsh environments and deliver uncompromising reliability.

Marine: Conquering Corrosive Environments

Saltwater is one of the most corrosive natural environments on Earth, capable of destroying most metals over time. Titanium, however, is virtually immune to it.

Subsea and Naval Components

For naval vessels, submarines, and offshore oil rigs, titanium cnc machining is used to produce parts that are constantly exposed to seawater. This includes propellers, propeller shafts, ballast valves, and housings for underwater sensors. While the initial material cost is higher than stainless steel, titanium’s longevity means lower maintenance and replacement costs over the life of the vessel. In projects we’ve consulted on, switching to titanium for certain subsea components has extended service life by more than double.

Automotive: The Pursuit of Performance

In the world of high-performance and racing vehicles, the engineering goals are similar to aerospace: reduce weight and increase strength.

High-Performance Engine Parts

Titanium is the material of choice for components in racing engines, such as connecting rods, valves, and exhaust systems. Lighter connecting rods allow the engine to rev higher and faster, while titanium valves can withstand extreme combustion temperatures. The result is more power and improved engine response. While you won’t find it in the average family car due to cost, for supercars and competitive racing, it provides a distinct performance edge.

| Industry | Primary Benefit of Titanium | Example CNC Machined Part |

|---|---|---|

| Marine | Exceptional Corrosion Resistance | Propeller Shafts, Subsea Housings |

| Automotive (Racing) | High Strength-to-Weight Ratio | Connecting Rods, Exhaust Valves |

| Chemical Processing | Chemical Inertness | Heat Exchangers, Reactors |

| Consumer Electronics | Premium Feel & Durability | High-end Laptop/Phone Casings |

Industrial and Chemical Processing

In chemical plants, equipment often handles highly corrosive acids and other aggressive chemicals. Titanium’s chemical inertness makes it ideal for manufacturing reactors, heat exchangers, pipes, and valves used in these facilities. Its stability ensures product purity and prevents equipment failure, which could be catastrophic. The ability to machine complex internal pathways into titanium heat exchangers, for example, allows for highly efficient thermal transfer in a compact and durable package.

Titanium’s superior properties make it essential in sectors where performance cannot be compromised. Precision CNC machining is the key that unlocks this potential, shaping it into critical components for aerospace, where weight and heat resistance are paramount, and for medical implants, where biocompatibility is vital. This versatility extends to marine, automotive, and industrial applications, each leveraging titanium’s unique strength and corrosion resistance to operate reliably in the most demanding environments.

Best Practices for Titanium Machining: A Practical Guide!

Have you ever followed the textbook rules for titanium machining, only to end up with a scrapped part and a broken tool? It’s a frustratingly common scenario that drains time and resources.

Mastering titanium CNC machining involves a strategic combination of selecting the right cutting tools, employing advanced coolant strategies, and optimizing machining parameters. These practices are crucial for managing heat, preventing work hardening, and achieving precise, high-quality results consistently.

Moving from theory to practice requires a disciplined approach. In my experience, success in titanium machining isn’t about one single trick; it’s about the systematic application of several core principles. Getting any one of these wrong can quickly lead to failure.

Selecting the Right Cutting Tools

The tool is where the action happens, and for titanium, your choice is critical. You can’t just use the same end mill you’d use for aluminum or steel.

Tool Material and Coatings

Uncoated carbide tools won’t last long against titanium. We almost exclusively use carbide tools with specific coatings like Titanium Aluminum Nitride (TiAlN) or Aluminum Titanium Nitride (AlTiN). These coatings create a thermal barrier, protecting the carbide substrate from the intense heat generated at the cutting zone. The hardness of the coating also provides excellent abrasion resistance against the gummy nature of titanium.

Tool Geometry

Sharpness is non-negotiable. A dull tool will rub rather than cut, instantly causing work hardening and leading to catastrophic failure. We look for tools with a sharp, positive rake angle to shear the material cleanly. A high helix angle (around 35-45 degrees) also helps evacuate chips efficiently, which is crucial for preventing them from being re-cut—a common source of heat and tool breakage. When discussing radial engagement, we must also consider the phenomenon of chip thinning5, which directly affects the feed rate calculations.

Optimizing Feeds and Speeds

This is where many machinists get it wrong. The rules for steel don’t apply here.

| Parameter | Conventional Steel Machining | Recommended Titanium Machining |

|---|---|---|

| Cutting Speed | High | Low (e.g., 150-300 SFM) |

| Feed Rate | Moderate | High and Consistent |

| Depth of Cut | Variable | Consistent and below chip load |

The mantra for titanium is "low speed, high feed." High speeds generate excessive heat that the titanium cannot dissipate, leading to tool wear and part warping. Instead, we reduce the surface feet per minute (SFM) and increase the feed per tooth. This approach maintains a healthy chip load, ensuring the tool is constantly cutting fresh material rather than rubbing against a work-hardened surface. It keeps the heat contained within the chip, which is then carried away from the workpiece and the tool.

Beyond the fundamentals of tooling and speeds, the programming and coolant strategies are where expertise truly makes a difference. These advanced techniques are what separate a struggling shop from one that machines titanium profitably and reliably. At PTSMAKE, we’ve refined these methods through countless projects, turning challenging parts into routine successes.

Intelligent Toolpath Programming

How you move the tool is just as important as the tool itself. Traditional "zig-zag" or offset toolpaths with sharp corners are disastrous for titanium. These create sudden spikes in tool engagement, leading to excessive heat, chatter, and tool breakage.

Constant Tool Engagement

The goal is to maintain a constant, consistent load on the cutting tool. We achieve this using modern CAM strategies.

- Trochoidal Milling: This technique uses a circular "looping" motion to cut slots, ensuring a consistent and low radial depth of cut. It’s perfect for roughing, as it keeps heat stable and allows for much deeper axial cuts than traditional methods.

- Peel Milling: Similar to trochoidal milling, this strategy uses high-speed, light radial cuts to "peel" away material, preventing the tool from ever being fully buried in the cut.

Here’s a simple comparison of the approaches:

| Toolpath Strategy | Key Characteristic | Impact on Titanium Machining |

|---|---|---|

| Traditional Offset | Sharp corners, varying tool load | Causes chatter, heat spikes, work hardening |

| Trochoidal Milling | Constant, low radial engagement | Minimizes heat, allows deep cuts, extends tool life |

| Peel Milling | High-speed, light radial passes | Excellent for chip evacuation and heat control |

Advanced Coolant Application

Coolant isn’t just for cooling; it’s for chip evacuation and lubrication. For titanium, its role is amplified. Flooding the part with a standard coolant nozzle is often insufficient because the high cutting forces create a pressure barrier that prevents fluid from reaching the cutting edge.

That’s why high-pressure coolant (HPC) systems, typically delivering fluid at 1,000 PSI or more, are a game-changer for titanium CNC machining. When delivered through the spindle and out the tip of the tool, HPC blasts chips away from the cutting zone instantly. This prevents chip recutting, drastically reduces heat buildup at the tool tip, and allows for higher feed rates, ultimately improving cycle times and tool life.

Effectively machining titanium hinges on a systematic approach. It starts with selecting sharp, coated carbide tools and maintaining a rigid setup. The key is to use low cutting speeds with high feed rates, supported by high-pressure coolant to manage heat. Furthermore, employing advanced toolpaths like trochoidal milling prevents work hardening and ensures both tool longevity and part quality. This disciplined strategy is fundamental to successful titanium CNC machining projects.

Common Titanium Grades and Their Properties.

Have you ever picked a titanium grade based on a datasheet, only to find it behaves completely differently during machining? This mismatch can derail schedules and inflate costs.

Choosing the correct titanium grade is vital for project success. Commercially Pure Grade 2 offers superior corrosion resistance and formability, while the alloy Grade 5 (Ti-6Al-4V) delivers much higher strength and performance, directly influencing the outcome of any titanium CNC machining project.

Not all titanium is created equal. The grade you select is the single most important factor determining the final part’s strength, corrosion resistance, and, crucially, how it behaves on the CNC machine. In the projects we handle at PTSMAKE, the choice almost always comes down to a few key grades, each with a distinct personality.

Commercially Pure (CP) Grades: The Foundation

Commercially Pure titanium is unalloyed and categorized into four grades. For CNC machining, Grade 2 is by far the most common.

Titanium Grade 2

Think of Grade 2 as the versatile default. It balances good strength with excellent formability and weldability. Its standout feature is its incredible resistance to corrosion, especially in saltwater and chemical processing environments. However, it doesn’t have the high strength of its alloyed cousins. We often use it for parts where corrosion resistance is the primary concern, and high mechanical stress is not a factor. Its machinability is relatively good for titanium, though it still requires careful speed and feed management to avoid work hardening.

The Alpha-Beta Alloy: The Workhorse

When strength is paramount, we turn to the alloys.

Titanium Grade 5 (Ti-6Al-4V)

This is the champion of the titanium world, accounting for over 50% of all titanium usage. The addition of 6% aluminum and 4% vanadium creates an alloy that is significantly stronger than pure titanium and can be heat-treated for even greater strength. This high strength-to-weight ratio makes it the go-to material for aerospace components, high-performance automotive parts, and medical implants. The trade-off is that it’s more challenging to machine than Grade 2. Its properties can exhibit some anisotropic6 behavior depending on how it was processed, which is a key consideration for critical components.

Here’s a quick comparison based on our internal testing and material data:

| Property | Titanium Grade 2 | Titanium Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Tensile Strength (Ultimate) | ~450 MPa (65 ksi) | ~950 MPa (138 ksi) |

| Yield Strength | ~345 MPa (50 ksi) | ~830 MPa (120 ksi) |

| Density | 4.51 g/cm³ | 4.43 g/cm³ |

| Machinability | Fair | Poor to Moderate |

| Corrosion Resistance | Excellent | Very Good |

| Weldability | Excellent | Fair |

This table clearly shows the performance gap. Grade 5 offers more than double the strength of Grade 2 with a slightly lower density, illustrating why it’s a favorite for lightweight, high-stress applications.

Understanding the properties is one thing; knowing how they translate to real-world machining outcomes and application suitability is another. The decision between Grade 2 and Grade 5 impacts everything from cycle time and tooling costs to the final part’s lifespan.

How Grade Selection Affects Machinability

The difference in machining Grade 2 versus Grade 5 is significant.

Cutting Speeds and Feeds

Grade 2 is softer and more ductile, allowing for slightly higher cutting speeds compared to Grade 5. However, its low thermal conductivity means heat builds up at the tool tip quickly. Grade 5 is much harder and more abrasive due to its alloying elements. Machining it requires lower cutting speeds, higher torque, and a very rigid machine setup to prevent chatter and tool deflection. In our experience, attempting to machine Grade 5 with parameters intended for Grade 2 will destroy a cutting tool in seconds.

Tooling and Coolant Strategy

For any titanium CNC machining, sharp tools are non-negotiable. For Grade 5, we exclusively use high-quality carbide tools with specific coatings designed to resist high temperatures and abrasion. A high-pressure coolant system is also essential. It’s not just for lubrication; it’s critical for aggressively flushing chips away from the cutting zone to prevent them from being re-cut, which can cause catastrophic tool failure. Grade 2 is more forgiving, but good coolant practices are still vital for achieving a fine surface finish.

Matching the Grade to the Application

Choosing the right grade is about aligning the material’s strengths with the part’s intended function.

When to Choose Grade 2

- Marine Hardware: Unbeatable resistance to saltwater corrosion.

- Chemical Processing Vessels: Resists a wide range of acidic and alkaline environments.

- Architectural Components: Excellent aesthetics and environmental resistance.

- Medical Casings: Where biocompatibility and corrosion resistance are needed without extreme strength.

When to Choose Grade 5 (Ti-6Al-4V)

- Aerospace Structures: Landing gear, wing spars, and engine components that demand a high strength-to-weight ratio.

- High-Performance Engine Parts: Valves, connecting rods, and retainers that see extreme stress and heat.

- Medical Implants: Joint replacements and bone screws, due to its strength, biocompatibility, and corrosion resistance.

- Robotics and Automation: For structural parts where minimizing weight is critical for performance and speed.

At PTSMAKE, we guide our clients through this selection process. A part destined for a satellite has vastly different requirements than one for a chemical pump. Starting with the end-use application ensures we select a grade that performs reliably without over-engineering and adding unnecessary cost.

Selecting the right titanium grade is a critical first step. Grade 2 is ideal for applications demanding excellent corrosion resistance and formability, while the stronger Grade 5 (Ti-6Al-4V) is the workhorse for high-stress, lightweight components in aerospace and medical fields. This choice directly influences the approach to titanium CNC machining, affecting tooling, speeds, and costs, ultimately determining the final part’s performance and suitability for its intended environment.

Design Considerations for Titanium CNC Parts?

Ever designed the perfect titanium component in CAD, only to see it fail inspection due to warping or dimensional instability? You’re not alone; titanium’s unique properties often challenge conventional design approaches.

Effective design for titanium CNC machining involves simplifying geometry, incorporating generous radii, maintaining uniform wall thickness, and planning for material properties like springback and thermal expansion. These steps ensure manufacturability, improve performance, and control costs from the start.

Optimizing Part Geometry for Manufacturability

When designing for titanium, the geometry of your part directly impacts the machining time, tool wear, and ultimately, the final cost. Overlooking manufacturability at the design stage is a common pitfall that can lead to significant production headaches. The goal is to create a part that is not only functional but also efficient to produce.

Simplify, Simplify, Simplify

Every complex feature, sharp internal corner, and deep pocket adds time and risk to the machining process. At PTSMAKE, we often advise clients to review their designs and eliminate any complexity that isn’t absolutely critical for the part’s function. For instance, replacing complex curved surfaces with simpler, flat ones can drastically reduce machine time. This isn’t about compromising performance; it’s about achieving the same function with a more machine-friendly design. A simpler part means faster cycle times, less specialized tooling, and a more predictable outcome.

The Importance of Radii and Fillets

Sharp internal corners are a major challenge in any CNC machining process, but they are particularly problematic with titanium. They create stress concentrations in the final part and force the use of smaller, less rigid cutting tools that are prone to breakage. This increases the risk of work hardening7 in the material, making subsequent cuts even more difficult. As a best practice, always design with the largest possible internal radii. A good rule of thumb is to make the radius at least 1.5 times the cutter diameter you anticipate will be used.

| Design Feature | Poor Practice | Best Practice | Rationale |

|---|---|---|---|

| Internal Corners | Sharp, 90-degree angles | Generous radii (>1mm) | Reduces tool stress, prevents material work hardening, and improves part strength. |

| Pockets | Deep and narrow | Shallow, wide pockets | Allows for better chip evacuation and the use of more rigid, efficient tools. |

| Holes | Non-standard sizes | Standard drill sizes | Avoids the need for custom tooling, reducing both cost and lead time. |

| Surfaces | Complex, multi-axis curves | Simple, planar surfaces | Minimizes machine time and programming complexity, leading to cost savings. |

Following these geometric guidelines is the first step toward successful and cost-effective titanium CNC machining.

Managing Material Behavior and Tolerances

Beyond basic geometry, a designer must account for how titanium behaves under the stress and heat of machining. Its properties, such as low thermal conductivity and elasticity, present unique challenges that can be mitigated through smart design choices.

The Uniformity Rule

Maintaining a uniform wall thickness throughout your part is critical. Titanium’s low thermal conductivity means heat concentrates at the cutting point instead of dissipating through the workpiece. If you have a design with thick sections adjoining thin walls, the thin sections will heat up and cool down much faster. In our experience, this differential thermal expansion is a primary cause of warping and distortion. A consistent wall thickness helps distribute stress and heat more evenly, leading to a more stable and accurate final part. If varying thickness is unavoidable, try to create gradual transitions between sections.

Realistic Tolerances for Titanium

Engineers naturally want to specify the tightest tolerances possible, but this can unnecessarily inflate the cost of titanium CNC machining. Due to its "springback" or elastic memory, holding extremely tight tolerances (e.g., ±0.005mm) requires slower cutting speeds, multiple finishing passes, and more frequent inspections. Before finalizing your drawing, ask yourself if every feature truly requires such high precision. Loosening non-critical tolerances can result in significant cost savings without affecting the part’s performance. For example, a tolerance of ±0.025mm is often far more achievable and economical.

| Titanium Grade | Key Property | Design Implication |

|---|---|---|

| Grade 2 (Commercially Pure) | High ductility, lower strength | Easier to machine; suitable for parts requiring high formability but less strength. Tolerances can be held more easily. |

| Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio | More challenging to machine due to hardness. Requires robust toolpaths and designs that minimize tool pressure. |

| Grade 9 (Ti-3Al-2.5V) | Weldable, good strength | A middle ground. Good for complex welded assemblies where post-weld machining is needed. |

Choosing the right grade and pairing it with appropriate tolerances is a key part of designing for manufacturability. We work with our clients to find this balance, ensuring the design is optimized for both performance and budget.

To succeed with titanium CNC machining, your design must respect the material’s unique characteristics. By simplifying geometry, using generous internal radii, and maintaining uniform wall thickness, you create a part that is easier and more cost-effective to manufacture. Furthermore, accounting for material properties like thermal expansion and setting realistic tolerances are crucial for preventing defects like warping and ensuring the final component meets specifications without unnecessary expense. A well-considered design is the foundation for a successful outcome.

Quality Assurance and Inspection in Titanium CNC Machining.

Ever wondered if a tiny, unseen defect in a titanium component could cause a major failure? How can you be absolutely sure every single part meets the required specifications without fail?

Quality assurance in titanium CNC machining is a systematic process using advanced inspection, detailed documentation, and complete traceability. It ensures every component meets the stringent standards of industries like aerospace and medical, guaranteeing performance and safety in critical applications.

Quality isn’t just a final check; it’s a core principle built into every step of the titanium CNC machining process. For materials like titanium, where parts are often used in high-stress, zero-failure environments, a robust quality assurance (QA) system is non-negotiable. It’s the only way to deliver parts that you can trust completely. At PTSMAKE, we’ve built our reputation on this foundation.

Core Inspection Techniques

The inspection process starts long before the final part is complete. It involves a combination of methods to verify dimensions, integrity, and surface finish.

Dimensional Verification

This is about confirming the part matches the CAD model and technical drawings down to the micron.

- Coordinate Measuring Machine (CMM): This is the gold standard for complex geometries. A CMM uses a probe to touch multiple points on the part’s surface, creating a 3D map. We use it to verify critical features, hole positions, and complex contours with extreme accuracy. The science of metrology8 is central to our work, and the CMM is its most powerful tool.

- Traditional Tools: Calipers, micrometers, and height gauges are still essential for quick, in-process checks on the shop floor. They allow our machinists to monitor progress and make adjustments in real-time.

Non-Destructive Testing (NDT)

NDT methods allow us to inspect the internal and external integrity of a titanium part without damaging it. This is crucial for detecting flaws that could compromise structural strength.

- Dye Penetrant Inspection (DPI): This technique is excellent for finding surface-breaking cracks. A colored dye is applied to the surface, which seeps into any cracks. After cleaning the surface, a developer is applied, which draws the dye out, making invisible cracks visible.

- Ultrasonic Testing (UT): This method uses high-frequency sound waves to find internal defects. The sound waves travel through the material and reflect off any voids, cracks, or inclusions. It’s like an ultrasound for metal parts.

Here’s a simple breakdown of when we use which dimensional tool:

| Inspection Tool | Best For | Key Advantage |

|---|---|---|

| CMM | Final inspection, complex 3D geometry, tight tolerances | Unmatched accuracy and repeatability |

| Optical Comparator | 2D profiles, threads, and small features | Fast comparison against an overlay |

| Calipers/Micrometers | In-process checks, basic dimensions (length, diameter) | Quick, easy to use on the machine |

Each technique has its place, and a comprehensive quality plan for a critical titanium component will often use a combination of these methods.

Beyond simply measuring and inspecting, a true quality system relies on documentation and traceability. For industries like aerospace and medical, knowing the full history of a part is just as important as knowing its final dimensions. If a problem ever arises, we need to be able to trace it back to its source quickly and efficiently.

The Pillars: Documentation and Traceability

This is where many machine shops fall short. Machining a perfect part is one thing; proving it’s perfect and providing a complete history is another level of service. This is a standard part of our process for every titanium CNC machining project.

Essential Documentation

Every critical part we produce is accompanied by a comprehensive documentation package. This isn’t just paperwork; it’s a verifiable record of quality.

- Material Certifications: This is the starting point. We provide mill certificates for the raw titanium bar or plate, showing its chemical composition and mechanical properties. This proves the material meets specifications (e.g., Ti-6Al-4V Grade 5).

- First Article Inspection Report (FAIR): For any new part or design revision, we perform a FAIR. This is a complete, documented verification of every single dimension on the drawing, ensuring our process is capable of producing the part correctly.

- Final Inspection Report: This report details the measurements of critical features on every part or a statistical sample from the production run, providing objective evidence that the parts are within tolerance.

Building a Chain of Traceability

Traceability connects the finished part back to its origins. It creates an unbroken chain of information that is vital for accountability and quality control.

- Lot Control: We assign a unique lot number to each batch of raw material. This number follows the material through every stage of production, from cutting and machining to finishing and inspection.

- Serialization: For the most critical applications, such as flight-critical aerospace components, each individual part is engraved with a unique serial number. This allows us to track the history of that specific part throughout its entire lifecycle.

This table shows the key documents that create a robust quality record:

| Document | Purpose | Customer Benefit |

|---|---|---|

| Material Certificate | Verifies raw material grade and properties | Confidence in material integrity and performance |

| First Article Inspection Report | Confirms the manufacturing process is correct | Assurance that the design is achievable |

| In-Process Inspection Sheet | Monitors quality during production | Reduces risk of non-conforming parts |

| Final Inspection Report | Provides proof of dimensional compliance | Objective evidence that parts meet specifications |

| Certificate of Conformance (CoC) | A formal declaration of quality | Simplifies receiving inspection and integration |

Together, these practices ensure that every titanium part we ship from PTSMAKE is not only physically perfect but also backed by a transparent and verifiable record of its quality journey.

Quality assurance in titanium CNC machining is a comprehensive system. It begins with confirming the material’s integrity and continues through every production step. We use advanced tools like CMMs for dimensional accuracy and NDT methods to find hidden flaws. Critically, this process is supported by rigorous documentation and complete traceability. This ensures every part we deliver, especially for aerospace and medical clients, is fully certified and meets the highest standards of safety and performance.

Sustainability and Cost Efficiency in Titanium CNC Machining.

Struggling to balance the high cost of titanium with your project budget? Worried about the environmental impact and material waste that comes with every single part you machine?

Achieving sustainability and cost efficiency in titanium CNC machining involves a multi-faceted approach. Key strategies include minimizing material waste through near-net-shape methods, optimizing machining parameters to reduce cycle times and tool wear, diligently recycling scrap, and leveraging digital platforms for streamlined workflow management.

Reducing Material Waste and Embracing Recycling

Titanium is a fantastic material, but it’s not cheap. A significant portion of the cost in any titanium CNC machining project comes directly from the raw material. Therefore, the most direct path to cost efficiency is to use less of it. This sounds simple, but it requires a strategic shift in how we approach the manufacturing process from the very beginning. It’s not just about cutting costs; it’s about responsible manufacturing.

Start Closer to the Finish Line

The traditional method of machining from a solid block of titanium is often incredibly wasteful. It’s not uncommon to see over 80% of an expensive billet turned into chips. A far more sustainable and cost-effective strategy is to use near-net-shape manufacturing methods. This involves starting with a workpiece, like a forging or a casting, that is already very close to the final part’s geometry. By doing this, we drastically reduce the amount of material that needs to be machined away. In some of our past projects at PTSMAKE, switching from bar stock to a custom forging for a complex aerospace component reduced material waste by nearly 60%, which translated into massive cost savings for our client.

The Value of Scraps

Even with the best optimization, there will always be scrap material, or swarf. With titanium, throwing these chips away is like throwing cash in the bin. A robust recycling program is essential. However, it’s not as simple as just collecting the scrap. Proper management is critical. Different titanium alloys (like Grade 2 and Grade 5) must be meticulously segregated. Cross-contamination can render an entire batch of scrap worthless for high-performance applications. The pyrophoricity9 of fine titanium dust also means that safe handling and storage protocols are non-negotiable to prevent fire hazards in the workshop.

Here’s a simplified look at the impact of near-net-shape methods:

| Machining Method | Starting Billet Weight (kg) | Final Part Weight (kg) | Material Waste (%) |

|---|---|---|---|

| Traditional Subtractive | 10.0 | 1.5 | 85% |

| Near-Net-Shape Forging | 2.5 | 1.5 | 40% |

By establishing a closed-loop system where scrap is properly sorted and sent to specialized recyclers, we not only recover a portion of the material cost but also contribute to a more circular economy, reducing the demand for energy-intensive primary titanium production.

Process Optimization and Digital Integration

Beyond material savings, the efficiency of the actual machining process plays a huge role in the overall cost and sustainability. Every minute saved on the machine translates to lower energy consumption, longer tool life, and reduced labor costs. This is where technical expertise and modern technology converge to make titanium CNC machining more accessible and affordable.

Fine-Tuning the Machining Process

Optimizing for titanium is a science. Due to its low thermal conductivity, heat builds up at the cutting edge, leading to rapid tool wear. To combat this, we focus on a few key areas:

- High-Pressure Coolant: Blasting the cutting zone with coolant at over 1,000 PSI is extremely effective. It not only cools the tool and workpiece but also helps break and evacuate chips, preventing them from being re-cut.

- Advanced Tooling: Using carbide tools with specific coatings like AlTiN (Aluminum Titanium Nitride) can significantly improve performance and longevity when machining titanium.

- Optimized Speeds and Feeds: Finding the "sweet spot" for cutting speeds and feed rates is crucial. Going too fast burns up tools, while going too slow can cause work hardening, making the material even more difficult to cut. It’s a delicate balance we’ve honed through years of experience.

The Economics of Batch Production

One of the most effective cost-saving measures is batch production. The initial setup and programming time for a CNC machine is a fixed cost. When we produce a single part, that entire cost is applied to one unit. However, when we produce a batch of 100 parts, that setup cost is distributed across all units, dramatically lowering the price per part. Batching also allows for bulk purchasing of raw materials at a better price and streamlines the entire workflow.

This table illustrates the impact of batching on per-part cost:

| Cost Component | Single Part Cost | Cost Per Part (100-Unit Batch) | Savings Per Part |

|---|---|---|---|

| Material | Illustrative $50 | Illustrative $45 | 10% |

| Setup & Programming | Illustrative $200 | Illustrative $2 | 99% |

| Machining Time | Illustrative $75 | Illustrative $70 | 7% |

| Total (Illustrative) | $325 | $117 | ~64% |

Digital Platforms Streamline Everything

In today’s fast-paced environment, digital tools are indispensable. Digital manufacturing platforms, like the system we use at PTSMAKE, transform the procurement process. Clients can upload a CAD file and receive an instant quote and DFM (Design for Manufacturability) analysis. This feedback loop is invaluable, as it helps identify potential issues that could add cost or time to the project before a single chip is cut. It simplifies communication, provides clear project tracking, and makes managing complex titanium CNC machining projects more efficient than ever.

Achieving both sustainability and cost efficiency in titanium CNC machining isn’t a trade-off; it’s a unified goal. It requires a holistic strategy, starting with smart material use through near-net-shape methods and diligent recycling. This is complemented by deep process optimization, leveraging advanced tooling and the economic power of batch production. Finally, digital platforms tie everything together, creating a streamlined, transparent, and highly efficient workflow from initial design to final delivery, making this advanced manufacturing process more accessible and responsible.

Unlock Titanium CNC Machining Excellence with PTSMAKE Today

Looking for precision, reliability, and innovation in titanium CNC machining? Partner with PTSMAKE—your trusted source from prototype to production. Get a fast quote, expert guidance, and high-quality results for your next project. Contact us now and experience the PTSMAKE advantage!

Learn how this self-healing oxide layer gives titanium its unparalleled resistance to harsh environments. ↩

Explore how a material’s ability to resist dimensional changes is crucial for precision manufacturing. ↩

Understand how this natural protective process works and why it’s critical for titanium’s performance. ↩

Discover the material science behind why titanium is safe for use inside the human body. ↩

Discover how this counter-intuitive effect impacts your tool life and part accuracy. ↩

Learn how a material’s directional properties can impact part strength and design integrity. ↩

Learn how this material behavior impacts tool life and machining strategies for titanium. ↩

Learn more about the science of measurement and its importance in achieving tight tolerances. ↩

Understand the risks associated with titanium dust and how to manage them safely in your workshop. ↩