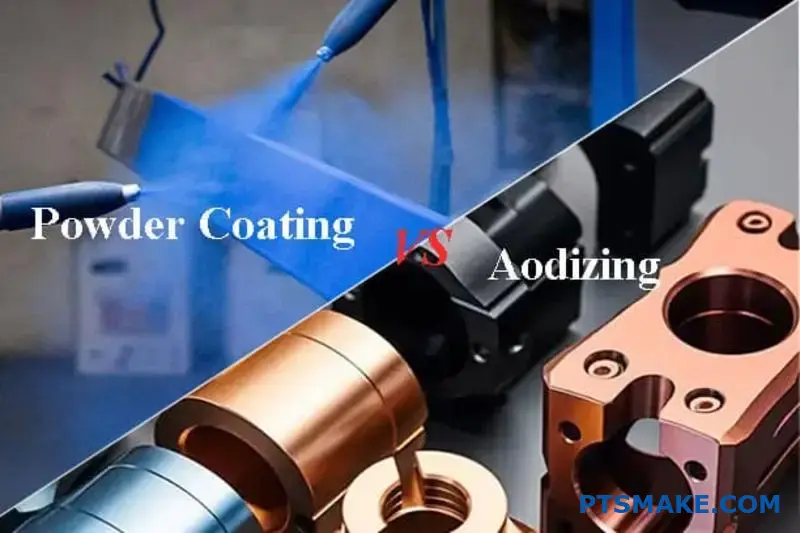

You’re selecting a surface finish for your precision parts, but you’re stuck between anodising and powder coating. Both processes promise durability and protection, yet each comes with different costs, lead times, and performance trade-offs. Making the wrong choice could mean compromised part performance, higher costs, or production delays that impact your entire project timeline.

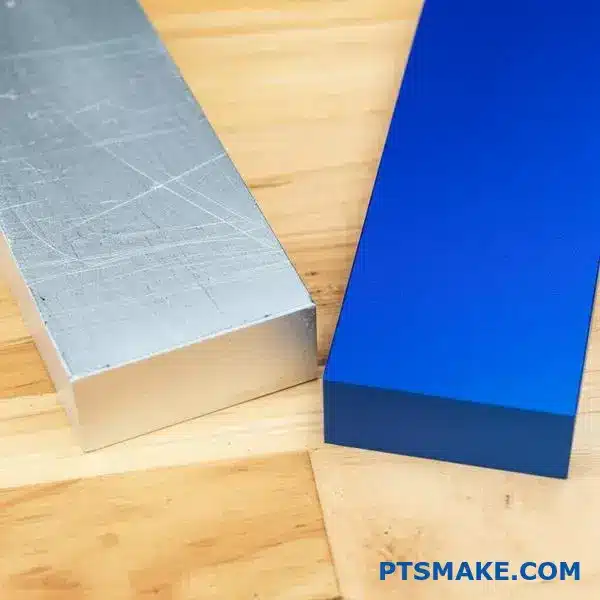

Anodising offers superior precision and corrosion resistance for aluminum parts, while powder coating provides better versatility across materials and color options. The better choice depends on your specific material, performance requirements, and budget constraints.

I’ve worked with both surface treatments extensively at PTSMAKE, and I’ve seen how the wrong choice can create headaches down the line. Some projects demand the precise tolerances that anodising maintains, while others need the impact resistance that powder coating delivers. The key lies in understanding what each process actually does to your parts and how that aligns with your specific application requirements.

What Is The Purpose Of Anodizing?

Have you ever specified a metal finish, only to see it scratch, corrode, or fade disappointingly fast? This can compromise your entire project’s integrity and visual appeal.

The primary purpose of anodizing is to create a durable, corrosion-resistant, and decorative oxide layer on a metal’s surface, typically aluminum. This electrochemical process enhances the material’s natural protection, significantly improving its performance and aesthetic qualities for various demanding applications.

Understanding the Core Enhancement

Anodizing is much more than a simple surface coating; it’s a conversion process. Aluminum naturally forms a thin, passive oxide layer to protect itself. However, this natural layer is often insufficient for industrial or high-performance use. Anodizing enhances this protective mechanism through a controlled electrochemical process1. This method thickens and hardens the oxide layer, integrating it directly into the metal substrate. The result is a surface that is fundamentally more robust. In our tests, we’ve observed a significant difference in durability between a standard part and an anodised one.

| Feature | Natural Oxide Layer | Anodized Layer (Type II) |

|---|---|---|

| Typical Thickness | 2-3 nanometers | 5-25 micrometers |

| Hardness (Mohs) | ~3-5 | ~9 (Sapphire-like) |

| Corrosion Resistance | Limited | Excellent |

Functional and Aesthetic Advantages

The benefits of an anodised finish extend into both function and form. The engineered porous structure of the anodic layer is key. This porosity allows the surface to accept dyes, resulting in vibrant, fade-resistant colors that become part of the metal itself, not just a layer on top. In past projects at PTSMAKE, this has been crucial for clients needing brand-specific colors on consumer electronics. Additionally, this layer can be sealed to create an impermeable barrier against moisture and environmental contaminants, which is vital for parts used in aerospace and medical devices where reliability is non-negotiable.

Key Practical Benefits

- Improved Wear Resistance: The hard, ceramic-like surface resists abrasion and wear, extending the product’s lifespan.

- Enhanced Aesthetics: Provides a consistent, metallic sheen with a wide range of color options.

- Electrical Insulation: The oxide layer is a poor electrical conductor, providing insulation properties.

Anodizing serves a dual purpose: it fundamentally transforms a metal’s surface through an electrochemical process to provide superior durability and corrosion resistance. It also offers significant aesthetic flexibility, allowing for vibrant, integrated colors and finishes essential for modern product design.

What Are The Benefits Of Anodising?

Have you ever designed a perfect aluminum part, only for it to scratch, corrode, or wear out far too soon? This can compromise both the function and appearance of your product.

The primary benefits of anodising are dramatically improved durability, superior corrosion resistance, enhanced aesthetics with a wide range of color options, and creating a non-conductive surface. This process makes aluminum parts stronger and last longer.

When we talk about benefits, durability is usually the first thing that comes to mind. Anodising isn’t just a coating; it’s an electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish. This integrated layer is much harder than raw aluminum. In past projects at PTSMAKE, we’ve found that this process is critical for parts in high-wear applications. The process is a form of electrolytic passivation2 that protects the substrate.

Hardness and Wear Resistance

The anodic oxide layer is exceptionally hard, often ranking just below diamond on the Mohs scale for hardcoat anodising. This makes anodised parts highly resistant to scratches and abrasion.

Performance Comparison

| Property | Raw Aluminum | Anodised Aluminum (Type II) |

|---|---|---|

| Wear Resistance | Low | High |

| Corrosion | Susceptible | Excellent |

| Surface Hardness | Soft | Significantly Harder |

Beyond just being tough, anodising offers significant aesthetic and functional versatility. This is where engineers and designers can get creative without sacrificing performance. The porous nature of the anodic layer before sealing allows it to absorb dyes, offering a spectrum of color choices that are both vibrant and fade-resistant. This is a huge advantage over painting, which can chip or peel.

Aesthetic and Functional Versatility

The ability to add color is a major benefit for branding and product differentiation. Furthermore, the finish can be controlled for different levels of reflectivity, from matte to bright.

Key Functional Gains

- Color Customization: Offers a wide range of stable, UV-resistant colors.

- Improved Adhesion: The surface provides an excellent primer for paint and adhesives if needed later.

- Electrical Insulation: The anodic layer is a non-conductor, which is a critical feature for electronic enclosures and components.

Anodising provides a robust solution to common aluminum vulnerabilities. It fundamentally enhances the material’s surface, offering superior durability and wear resistance. This process also provides extensive aesthetic options and key functional properties like electrical insulation, making parts both tougher and more versatile.

Does Anodizing Make Aluminium Parts Stronger?

Have you ever specified an anodized finish for an aluminum part, assuming it was a simple way to make the entire component stronger? This common assumption can lead to design miscalculations and unexpected failures.

The short answer is no, not in the way most people think. Anodizing does not increase the base tensile or yield strength of the aluminum alloy itself. However, it creates an exceptionally hard, wear-resistant surface layer that significantly improves the part’s durability and longevity.

The Real Strength Anodizing Provides

The process of anodizing transforms the surface of an aluminum part into aluminum oxide, which is a very hard, ceramic-like material. This new layer is integral to the part, not a coating like paint. It dramatically improves the surface’s resistance to scratching and abrasion. The true benefit lies in enhancing its tribological3 properties, which are crucial for parts that slide or rub against other surfaces. In our past projects at PTSMAKE, we’ve seen how a proper anodized finish can extend the life of a component that would otherwise fail from surface wear. The underlying aluminum retains its original strength, but the part as a whole becomes more durable.

| Property | Raw Aluminum (6061-T6) | Anodized Aluminum (Type III) |

|---|---|---|

| Surface Hardness | ~95 HV | 600-700 HV |

| Scratch Resistance | Low | Very High |

| Corrosion Resistance | Moderate | Excellent |

How Different Types of Anodizing Affect Durability

Not all anodizing is the same. The type and thickness of the anodized layer are the most critical factors determining the final surface properties. The two most common types in manufacturing offer very different levels of protection.

Type II Anodizing

This is often called "decorative" or "sulfuric" anodizing. It creates a thinner oxide layer, typically 0.0002" to 0.001" thick. While it offers good corrosion resistance and can be dyed in various colors, its primary benefit is aesthetic. It provides a modest increase in surface hardness and is suitable for parts not exposed to heavy wear.

Type III Hardcoat Anodizing

Hardcoat, or Type III anodizing, is an engineering finish. It produces a much thicker and denser oxide layer (typically >0.001"). Based on our testing, this process can make the surface of the aluminum part harder than tool steel. It’s the go-to choice for components in aerospace, robotics, and industrial machinery where extreme wear resistance is essential.

| Feature | Type II Anodizing | Type III Hardcoat Anodizing |

|---|---|---|

| Typical Thickness | 5-25 µm | 25-150 µm |

| Primary Purpose | Aesthetics, Corrosion Resistance | Wear Resistance, Hardness |

| Common Use | Consumer electronics, architectural trim | Pistons, gears, sliding components |

Anodizing doesn’t strengthen the aluminum core, but it creates a hard, ceramic-like surface. This layer drastically improves wear and scratch resistance. The level of this protection, however, depends heavily on whether you choose a standard Type II or a much more durable Type III hardcoat finish.

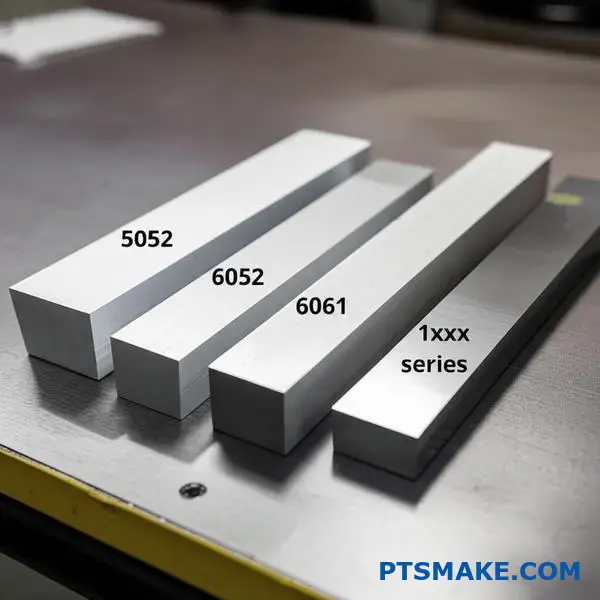

What Is The Best Grade Of Aluminium For Anodising?

Ever chosen a "perfect" aluminium grade only to have the anodised finish come out blotchy or inconsistent? It’s a frustrating problem that can compromise an entire batch of precision parts.

While the 5000 and 6000 series alloys, particularly 5052 and 6061, are top contenders for their excellent response to anodising, the single "best" grade truly depends on your end goal—be it decorative appearance, corrosion resistance, or mechanical performance. High-purity 1xxx series alloys offer superior brightness.

Decoding the Alloy’s Role in Anodising

The "best" grade is not a one-size-fits-all answer. The choice depends entirely on balancing cosmetic requirements with functional demands. Alloying elements like copper, silicon, and zinc, which give alloys their strength, can complicate the anodising process. For example, high copper content in the 2xxx or 7xxx series can lead to less uniform and sometimes less protective anodic films. The presence of these different alloying elements can create microscopic intermetallic particles4 that react differently to the anodising process, affecting the final clarity and color uniformity. In our past projects, we’ve found that understanding this balance is key.

Key Anodising Characteristics of Common Alloys

| Aluminium Grade | Decorative Finish | Protective Quality | Color Consistency |

|---|---|---|---|

| 6061-T6 | Good to Excellent | Excellent | Good |

| 5052-H32 | Excellent | Excellent | Excellent |

| 7075-T6 | Fair to Good | Good | Fair |

| 1100 | Superior (Bright) | Good | Excellent |

Beyond the Alloy: Manufacturing Matters

Even with the ideal alloy, the manufacturing and preparation steps before the part reaches the anodising tank are critical. The surface finish achieved during CNC machining directly impacts the final look. A rougher surface will result in a more matte finish after anodising, while a highly polished surface will yield a brighter, more specular appearance. At PTSMAKE, we manage the entire process from machining to finishing, ensuring the surface preparation aligns perfectly with the desired anodising outcome. This control prevents unexpected results and ensures your parts meet aesthetic and functional specifications every time.

Impact of Surface Finish on Anodised Appearance

| Initial Surface Finish | Anodised Result (Matte vs. Glossy) | Best For |

|---|---|---|

| Bead Blasted | Uniform, Non-Reflective Matte | Hiding machining marks, low-glare parts |

| Standard Machined | Satin to Semi-Gloss | General-purpose functional components |

| Polished | Bright, Reflective Gloss | High-end consumer electronics, cosmetics |

The best aluminium for anodising is a balance between the alloy’s composition and your specific requirements. Grades like 5052 and 6061 offer great all-around performance, but pre-treatment processes like CNC machining surface finish play an equally crucial role in achieving a perfect, consistent result.

Do You Have To Etch Aluminum Before Anodizing?

Struggling with blotchy, uneven anodized finishes? Have you ever had a batch of parts rejected because the color just wasn’t right, costing you time and money?

Yes, etching is a critical and almost always necessary step before anodizing aluminum. It removes the thin, inconsistent native oxide layer and minor surface imperfections, creating a uniform matte surface that is essential for a high-quality, consistent anodized finish.

The "Why" Behind Chemical Etching

Etching is more than just a deep clean; it’s a fundamental surface preparation step. Its primary job is to create a perfectly uniform surface, which is the foundation for a flawless anodized coating. Think of it as priming a wall before painting. Without it, every tiny flaw on the original surface gets magnified after the anodising process. The process removes the natural, non-uniform oxide layer that forms on aluminum instantly when exposed to air. It also smooths out microscopic scratches and removes embedded contaminants or intermetallic5 particles left from machining. At PTSMAKE, we’ve found that a proper etch is the most reliable way to guarantee color consistency and coating adhesion across a production run.

| Feature | Without Etching | With Etching |

|---|---|---|

| Surface Finish | Non-uniform, may show lines | Uniform, matte finish |

| Color Consistency | Often blotchy or uneven | Excellent and consistent |

| Adhesion | Prone to poor bonding | Strong, reliable adhesion |

| Corrosion Resistance | Reduced performance | Optimized performance |

Tailoring the Etch to the Application

Not all etching processes are the same. The type of chemical used, its concentration, temperature, and immersion time are all variables we adjust based on the aluminum alloy and the desired final appearance. For example, a caustic etch (using sodium hydroxide) creates a classic matte finish, which is great for hiding small defects. However, an acid etch might be chosen to achieve a brighter, more specular finish, often called "bright dip anodizing." Based on our test results, different alloys also react differently. A 7075 alloy, for instance, requires a more carefully controlled process than a 6061 alloy to avoid over-etching, which can compromise dimensional tolerances. This is where expertise in both machining and finishing becomes vital for delivering parts that meet precise specifications.

| Etch Type | Primary Use Case | Resulting Finish |

|---|---|---|

| Caustic Etch | General purpose, hiding defects | Diffuse, matte appearance |

| Acid Etch | Decorative, bright finishes | Bright, specular appearance |

| No Etch (Rare) | When preserving machine lines | Retains original texture |

| Custom Blends | Specific cosmetic requirements | Varies from satin to matte |

In short, etching is a vital step before anodizing. It cleans and unifies the aluminum surface, removing the natural oxide layer and minor flaws. This preparation ensures a consistent, high-adhesion anodized coating, though the specific etching method can be tailored to the alloy and desired finish.

How Long Does Anodizing Last?

Have you ever specified an anodized finish, only to see it fade or fail sooner than expected? The surrounding environment is often the overlooked factor that dictates its true durability.

Typically, an anodized coating lasts 10-20 years. High-quality Type III hard coat anodizing can exceed this, while decorative Type II finishes may not. The actual lifespan hinges on environmental exposure, wear, and proper maintenance.

Environmental Impact on Anodizing Longevity

The service environment is the single most critical factor. A part used indoors will outlast one exposed to coastal salt spray or industrial pollutants.

UV Radiation and Weathering

For outdoor applications, UV radiation is a primary enemy, causing colors to fade over time. While the protective oxide layer remains, the aesthetic value can diminish. In our experience with clients’ architectural projects, specifying a UV-resistant dye and a proper sealing process is crucial. Exposure to acid rain or airborne chemicals can also slowly etch away at the surface, reducing its protective qualities and potentially leading to issues like galvanic corrosion6 if other metals are present.

Lifespan Variation by Environment

| Environment Type | Typical Lifespan (Type II) | Typical Lifespan (Type III) |

|---|---|---|

| Indoor, Controlled | 20+ Years | 20+ Years |

| Outdoor, Urban | 10-15 Years | 15-20 Years |

| Coastal/Marine | 5-10 Years | 10-15 Years |

| Industrial/Chemical | 3-8 Years | 7-12 Years |

Maintenance: The Key to a Lasting Finish

How you clean and maintain an anodized part directly impacts its lifespan. Aggressive cleaning can do more harm than good, stripping away the very layer you want to preserve.

The Right Way to Clean

The best approach is gentle and consistent. At PTSMAKE, we advise our partners to implement simple cleaning protocols to protect their investment. Using a mild soap or detergent with water is usually sufficient for removing dirt and grime without damaging the finish. It’s a simple step that preserves both the look and function of the anodising.

Cleaning Best Practices

| Do | Don’t |

|---|---|

| Use mild soap and water | Use harsh alkaline or acidic cleaners |

| Apply with a soft cloth/sponge | Use abrasive pads or steel wool |

| Rinse thoroughly with clean water | Allow cleaning solutions to dry on surface |

| Clean on a regular schedule | Use strong organic solvents |

The lifespan of an anodized finish isn’t fixed; it’s a dynamic variable. While it can last over 20 years, this depends on selecting the right type, considering the environment, and committing to a proper, non-abrasive maintenance schedule.

What Happens If You Don’t Anodize Aluminum?

Have you ever thought about skipping the anodizing step for your aluminum parts to cut costs? It seems like an easy saving, but this decision can lead to significant long-term issues.

If you don’t anodize aluminum, the material remains vulnerable to corrosion, scratching, and general wear. The untreated surface is softer, less durable, and lacks the improved aesthetics and electrical insulation that the anodising process provides, risking premature component failure.

The Inherent Vulnerability of Raw Aluminum

While raw aluminum naturally forms a thin, hard oxide layer that offers some protection, this layer is extremely thin and easily damaged. This process is a form of natural passivation7. However, for most industrial applications, this natural defense is insufficient. In our past projects, we’ve seen untreated parts fail quickly when exposed to moisture, chemicals, or even just frequent handling. The lack of a robust, controlled oxide layer—which anodising provides—leaves the component exposed.

Raw vs. Anodized Aluminum Properties

| Feature | Raw Aluminum | Anodized Aluminum |

|---|---|---|

| Corrosion Resistance | Low to Moderate | High to Very High |

| Hardness | Softer | Significantly Harder |

| Wear Resistance | Poor | Excellent |

| Electrical Insulation | Conductive | Insulating |

This table clearly shows the trade-offs. The decision not to anodize results in a weaker, less reliable part.

Beyond Durability: Aesthetic and Functional Compromises

Skipping anodizing doesn’t just affect durability; it also limits the functional and aesthetic potential of your parts. Untreated aluminum has a plain, often inconsistent finish that can show fingerprints and stains easily. If your component is a visible part of a consumer product, this can significantly detract from its perceived quality. Furthermore, the anodising process creates a porous surface ideal for accepting dyes, allowing for a wide range of color options that are integral to the finish, not just a surface coating.

Adhesion Issues for Secondary Finishes

If you plan to paint or apply other coatings to the aluminum, an untreated surface can be problematic. The natural oxide layer is not an ideal primer. Anodizing creates a surface with excellent molecular bonding properties, ensuring that paint, adhesives, and other finishes adhere much more strongly and last longer without chipping or peeling.

In short, not anodizing aluminum exposes it to rapid corrosion and wear. You also lose out on enhanced durability, aesthetic options like custom colors, and a superior surface for applying paints or adhesives, ultimately compromising the part’s long-term performance and value.

How Much Does Anodising Cost For CNC Machined Parts?

Have you ever received quotes for anodising and wondered why the prices vary so much for seemingly simple parts? This variability can make budgeting for post-processing a real challenge.

Anodising typically adds 5% to 15% to the total cost of a CNC machined part. The final price depends on the anodising type (Type II vs. Type III), coating thickness, part size, batch quantity, and any complex masking requirements.

Breaking Down the Primary Cost Drivers

The cost of anodising isn’t a single flat fee; it’s a sum of several factors directly related to the process itself. Understanding these helps in forecasting your budget more accurately. In past projects at PTSMAKE, we’ve seen how small specification changes can impact the final price. The core of anodising is an electrolytic passivation8 process that builds a protective oxide layer.

Anodising Type and Thickness

The type of anodising is the most significant cost factor. Type III, or hard anodising, requires more energy, longer processing times, and operates at lower temperatures, making it more expensive than the standard Type II.

| Factor | Type II (Sulfuric Acid) | Type III (Hardcoat) |

|---|---|---|

| Primary Use | Decorative, mild corrosion resistance | Wear resistance, high durability |

| Typical Thickness | 0.0002" – 0.001" | 0.001" – 0.004" |

| Relative Cost | Base | 1.5x – 2.5x Base |

Operational Factors That Influence Price

Beyond the technical specifications, logistical and operational details play a crucial role in determining the final anodising cost. These factors are often related to the labor and handling required for your specific parts. It’s not just about the chemistry; it’s about the physical process of handling each component.

Batch Size and Racking

Anodising is a batch process. Larger batches distribute the setup and labor costs over more units, significantly lowering the cost per part.

| Batch Size | Cost Per Part (Relative) | Notes |

|---|---|---|

| 1-10 Parts | High | Dominated by setup fees |

| 50-100 Parts | Medium | Good economy of scale |

| 500+ Parts | Low | Most cost-effective |

Masking and Plugging

If certain areas of your part must remain free of anodising, they require manual masking or plugging. This is a labor-intensive step that adds considerable cost, especially for complex geometries with multiple masked features.

Anodising costs are a small but important part of your budget. The final price is determined by technical choices like anodising type and layer thickness, along with operational factors such as the batch size and the complexity of any required masking.

Choose the Best Anodising Solution with PTSMAKE’s Expertise

Still debating between anodising and powder coating for your next project? Don’t let the wrong surface finish compromise quality or delay your timeline! Partner with PTSMAKE for expert guidance and top-tier precision manufacturing. We help you select the ideal anodising finish tailored to your exact needs—ensuring durability, reliability, and cost-effectiveness every time. Contact PTSMAKE now and elevate your part performance from prototype to production.

Click to understand the science behind this conversion process and how it creates a superior protective layer. ↩

Click to understand the core scientific process behind anodising’s protective layer. ↩

Understand how surface interactions like friction and wear impact component lifespan. ↩

Learn how these microscopic alloy elements can impact your final anodised finish and what to watch for. ↩

Understand these microscopic alloy particles and how they can influence the final surface finish of your machined parts. ↩

Learn how contact with other metals can cause galvanic corrosion and shorten the life of your anodized finish. ↩

Learn how this natural protective process occurs and why it’s often not enough for demanding applications. ↩

Understand the science of how this process creates a durable, corrosion-resistant surface on aluminum parts. ↩