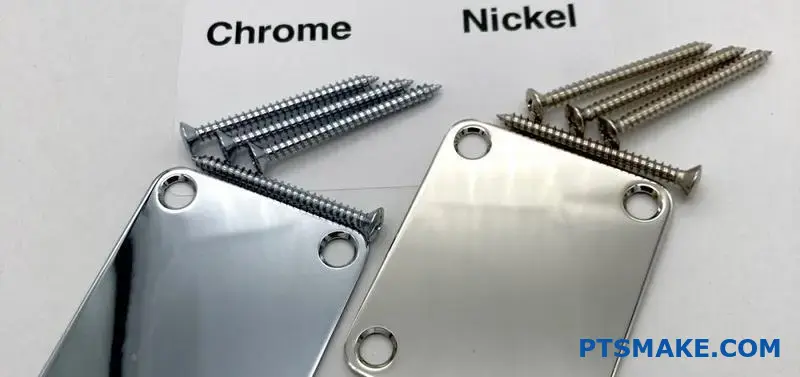

Finding the right surface coating for precision parts can be a nightmare. You specify a coating, receive the parts, and discover uneven thickness, poor adhesion, or coating buildup that throws off your tolerances. Traditional electroplating often fails when you need uniform coverage on complex geometries.

Electroless nickel plating (ENP) is an autocatalytic chemical process that deposits a uniform nickel-phosphorus alloy coating without electrical current, providing consistent thickness and superior corrosion resistance on complex part geometries.

I’ve worked with engineers who switched to ENP after dealing with coating failures that cost thousands in rework. This guide covers everything from cost analysis to material compatibility, helping you avoid the mistakes that lead to rejected parts and delayed projects.

Why Electroless Nickel Plating Beats Traditional Plating In Mission-Critical Applications

In mission-critical applications, coating failure isn’t an option. Traditional methods like electroplating often fall short. They struggle with complex geometries.

This can result in uneven coating thickness. You often see build-up at edges and poor adhesion in recesses.

The Uniformity Challenge

Electroless Nickel Plating (ENP) solves these problems. It provides a completely uniform layer. This boosts nickel coating performance on intricate parts.

Let’s compare the core differences.

| Feature | Traditional Electroplating | Electroless Nickel Plating |

|---|---|---|

| Uniformity | Inconsistent | Highly Uniform |

| Complex Parts | Poor Coverage | Excellent Coverage |

| Build-up on Edges | Common Issue | Not an Issue |

ENP is the clear choice for reliability.

Deeper Dive: Process vs. Performance

The core difference lies in the deposition method. Electrolytic plating relies on an external electrical current. This current naturally concentrates on high points and sharp edges, a phenomenon known as the "dog-bone effect."

This leaves recessed areas and internal diameters with a dangerously thin coating. For precision components, such inconsistencies can lead to premature failure from corrosion or wear. It’s a risk we can’t afford in industries like aerospace or medical devices.

Electroless Nickel Plating, however, is an entirely different process. It deposits the coating through an autocatalytic reaction1 within a chemical solution. Because there’s no electric current dictating where the metal deposits, the coating builds up perfectly evenly across the entire surface of the part, including inside holes and complex internal features.

Key Performance Advantages

This uniform thickness plating directly translates to superior protection. At PTSMAKE, we have seen how ENP provides exceptional hardness and corrosion resistance consistently across every millimeter of a part.

| Metric | Electroplating | Electroless Nickel Plating |

|---|---|---|

| Corrosion Resistance | Good | Excellent |

| Hardness (As-Plated) | ~400 HV | ~550 HV |

| Wear Resistance | Good | Excellent |

| Internal Coverage | Poor | Complete |

This reliability is why engineers specify ENP for their most demanding components.

Electroless Nickel Plating delivers uniform coverage that traditional electroplating cannot match. Its chemical deposition process eliminates inconsistencies, providing superior protection, hardness, and reliability for complex, mission-critical parts where performance is paramount.

The Hidden Cost Savings Of Electroless Nickel On Complex CNC Parts

When evaluating finishing options, many focus only on the initial price per part. This is a narrow view. The real savings are found by looking at the total cost of ownership. Electroless Nickel Plating might have a higher upfront cost. But it saves you much more money over time.

Longer Part Life and Less Maintenance

A key benefit is durability. The uniform coating protects parts from wear and corrosion. This means they last longer. Longer-lasting parts reduce the need for frequent replacements and maintenance downtime.

| Feature | Impact on Cost |

|---|---|

| Enhanced Durability | Fewer replacement part purchases |

| Corrosion Resistance | Less downtime for maintenance |

| Reduced Wear | Extended operational life |

This proactive approach leads to significant long-term savings. It’s a classic case of investing a little more now to save a lot later.

The true financial benefit of Electroless Nickel Plating becomes clear when you conduct a proper ENP cost analysis. It’s not just about preventing failures; it’s about optimizing production efficiency from the start. This is a conversation I often have with clients at PTSMAKE.

Rework Reduction: A Major Saving

For complex CNC parts with tight tolerances, rework is a huge cost driver. Non-uniform coatings can cause parts to be out of spec. Electroless Nickel Plating deposits a perfectly even layer, even on intricate geometries. The uniform deposit improves the part’s tribological properties2, reducing wear over time.

This consistency virtually eliminates rework caused by plating issues.

Lowering Rejection Rates

Lowering your rejection rate directly improves your ROI on nickel coating. In our experience, inconsistent plating is a top reason for final inspection failure. By choosing cost-effective plating services that guarantee uniformity, you increase your yield of good parts.

| Cost Factor | Standard Plating | Electroless Nickel Plating |

|---|---|---|

| Rejection Rate | Potentially Higher | Consistently Lower |

| Rework Needs | Common | Rare |

| Per-Piece Cost | Lower (Initial) | Higher (Initial) |

| Effective Cost | Increases with failures | Remains stable |

Each rejected part adds to your total cost. Electroless Nickel Plating minimizes this risk, making your production more predictable and profitable.

Electroless Nickel Plating’s initial cost is offset by its long-term value. It extends part life, cuts maintenance, and drastically reduces costly rework and rejections. This makes it a superior investment for high-precision components.

How Electroless Nickel Plating Enhances Corrosion Resistance In Harsh Environments

Electroless Nickel Plating (ENP) excels in the toughest conditions. Its uniform, non-porous layer offers a powerful shield. This is vital where parts constantly face corrosive elements.

ENP in Marine Environments

Saltwater is relentless. It attacks metals aggressively. I’ve seen how ENP for marine parts significantly extends component life. The coating completely seals the substrate from moisture.

Surviving Chemical Exposure

In industrial settings, exposure to harsh chemicals is common. ENP provides a robust defense. This makes it a leading nickel coating for harsh applications.

| Environment | Key Challenge | ENP’s Advantage |

|---|---|---|

| Marine | Salt Spray | Non-porous barrier |

| Chemical | Acid/Alkali | High chemical inertness |

| Humidity | Condensation | Uniform coverage |

The plating’s consistency is its greatest strength, ensuring no weak points exist.

The superior performance of Electroless Nickel Plating comes from its unique deposition method. Unlike electroplating, ENP doesn’t need an external electric current. Instead, it relies on a specific chemical process.

The Science Behind the Shield

The coating is applied through a controlled autocatalytic reaction3. This deposits a nickel-phosphorus alloy directly onto the substrate. The process is self-sustaining, creating a remarkably consistent and dense layer across the entire part.

Uniformity: The Critical Advantage

This method ensures the plating covers every surface evenly. It coats internal cavities, threads, and sharp corners with the same thickness. This eliminates thin spots where corrosion often begins. This uniform barrier is what makes it a superior corrosion-resistant plating.

How Phosphorus Content Affects Protection

The level of phosphorus in the alloy can be adjusted. This changes the coating’s properties. After many projects at PTSMAKE, we guide clients to high-phosphorus ENP for the most extreme corrosion resistance.

| Phosphorus Content | Corrosion Resistance | Structure |

|---|---|---|

| Low (1-4%) | Good | Crystalline |

| Medium (5-9%) | Very Good | Mixed |

| High (10-13%) | Excellent | Amorphous |

This adaptability allows us to tailor the finish for specific harsh applications, ensuring optimal performance.

In short, Electroless Nickel Plating provides a uniform, non-porous barrier due to its unique chemical process. This offers unmatched protection against corrosion in marine, chemical, and high-humidity settings, making it an ideal choice for demanding applications.

The Critical Role Of Electroless Nickel In Dimensional Stability And Tolerances

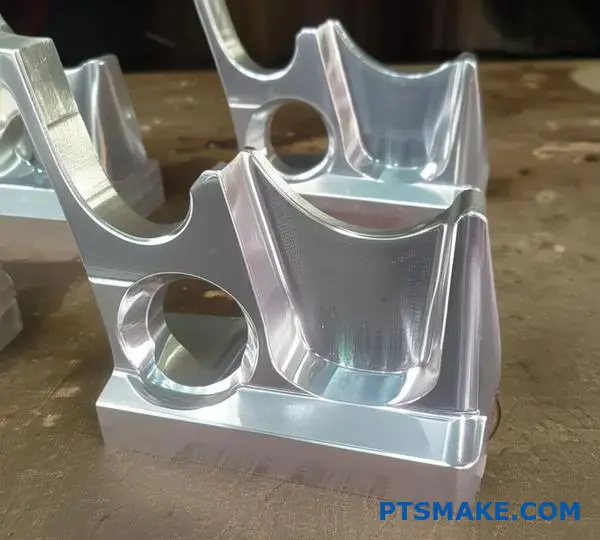

In precision manufacturing, maintaining dimensional integrity is non-negotiable. Traditional plating methods often add uneven layers. This can ruin carefully machined tolerances.

Electroless Nickel Plating (ENP) solves this problem. It deposits a perfectly uniform coating. This applies even on complex shapes or internal surfaces. This makes it a superior choice for dimensional tolerance plating, protecting parts without compromising their fit or function.

A Predictable and Controllable Process

The thickness of an ENP coating is highly predictable. It depends on time and bath chemistry. This control is crucial for engineers.

| Plating Method | Uniformity | Control Over Thickness |

|---|---|---|

| Electroless Nickel | High (±5-10%) | Excellent |

| Electroplating | Low (varies) | Poor on complex shapes |

This level of control ensures parts meet exact specifications every time.

For parts in aerospace or robotics, failure is not an option. These components often have intricate geometries and require extremely tight fits. This is where we see the true value of Electroless Nickel Plating.

Precision Plating for Tight Fits

The process is not reliant on electric current. This eliminates the "dog-boning" effect common in electroplating. High-current areas on a part won’t build up thicker layers. This ensures that every surface, from sharp corners to deep recesses, receives an even coating.

This consistent deposition is what makes ENP ideal for tolerance-critical parts. When you have two components that must fit together with micron-level precision, you cannot afford any variability in the protective coating. The autocatalytic deposition4 of ENP provides that reliability.

Eliminating Distortion and Stress

Furthermore, some plating processes introduce thermal stress. This can cause microscopic distortion in the substrate. For high-precision components, even minor warping is unacceptable.

At PTSMAKE, we recommend ENP for parts made from sensitive alloys. The low-temperature application bath minimizes the risk of thermal stress. This preserves the part’s original dimensions and mechanical properties.

| Feature | Impact on Tolerances |

|---|---|

| Uniform Coating | No uneven buildup, maintains design dimensions. |

| No Edge Buildup | Corners and edges are not oversized. |

| Low-Stress Process | Prevents warping or material distortion. |

This makes it the go-to solution for precision plating for tight fits.

Electroless Nickel Plating provides a uniform coating that respects tight design tolerances. It eliminates distortion and the need for post-plating machining, making it perfect for complex, high-precision parts in critical industries like aerospace and robotics.

Secrets To Selecting The Right ENP Thickness For Your Application

Selecting the right Electroless Nickel Plating thickness isn’t guesswork. It’s a calculated decision based on your application’s specific demands. The goal is to find the perfect balance.

You need enough thickness for protection. But too much can alter dimensions and increase costs unnecessarily. This guide helps you navigate the key factors.

Primary Thickness Factors

Consider four main areas: wear, load, material, and environment. Each plays a critical role in determining the ideal plating depth for optimal performance.

Basic Thickness Recommendations

Here is a general starting point we often discuss with clients.

| Environment/Use | Recommended Thickness (microns) |

|---|---|

| Mild Corrosion | 5-10 µm |

| Moderate Wear | 15-25 µm |

| Severe Corrosion/Wear | 25-50 µm |

| Salvage/Build-up | > 50 µm |

This table provides a basic framework. Your specific needs will refine these numbers.

Deciding on the optimal ENP microns requires a deeper look into the part’s function. It’s more than just looking at a chart. It’s about understanding the forces at play.

Wear and Load Considerations

Higher loads and abrasive contact demand greater thickness. This is crucial for achieving superior thickness for wear resistance. A thin coating will simply wear away too quickly under stress.

For example, a part with sliding contact needs more protection. It requires a thicker layer than a static component exposed only to mild corrosion.

The As-plated hardness5 of the deposit offers excellent initial wear resistance. However, for extreme applications, a thicker coating provides a longer service life before the substrate is exposed.

Material and End-Use Analysis

The substrate material also influences the choice. Softer materials like aluminum might need a thicker ENP layer. This helps to enhance surface hardness and prevent damage.

At PTSMAKE, we always analyze the end-use environment. A medical device in a sterile field has different needs than an automotive part exposed to road salt. This detailed analysis ensures the plating performs as expected.

| Application Detail | Key Consideration | Optimal ENP Microns (µm) |

|---|---|---|

| High-Load Bearing | Maximize wear resistance | 25-50 |

| Complex Geometry | Ensure uniform coverage | 10-20 |

| Electrical Contact | Maintain conductivity | 5-10 |

| Food-Grade Surface | Prevent contamination | 15-25 |

This electroless nickel plating thickness guide helps match the coating to the job perfectly.

Choosing the optimal ENP thickness involves analyzing wear, load, material, and the part’s final use case. This systematic approach ensures durability and cost-effectiveness without compromising the part’s critical dimensions or function.

Avoid These Common Mistakes When Specifying Nickel Plating On Engineering Drawings

Engineering drawings are the single source of truth. When specifying nickel plating, mistakes on this document can be costly. They often lead to delays and parts that don’t fit.

Clear communication through the drawing is essential. It ensures the final product meets all functional requirements perfectly. Let’s cover some common pitfalls.

Forgetting Plating Thickness

A frequent issue is ignoring how plating adds to dimensions. This oversight causes major tolerance stacking problems. The part might not assemble correctly.

Following ENP drawing best practices from the start saves headaches later.

Critical Drawing Errors to Avoid

| Common Mistake | Consequence |

|---|---|

| Ignoring Plating Buildup | Parts are oversized, fail inspection. |

| Over-specifying Tolerances | Unnecessary cost increase, longer lead times. |

| Vague Plating Notes | Inconsistent coating, potential part failure. |

These are simple yet critical specification tips for nickel plating.

The most critical details involve dimensions. You must clearly define whether dimensions are for the part before or after plating. Ambiguity here is a recipe for failure. The machinist and the plater need different information.

GD&T and Plating Layers

Geometric Dimensioning and Tolerancing (GD&T) calls are significantly impacted by coatings. A uniform layer of Electroless Nickel Plating will alter the size of features. This change can affect how parts interact within an assembly.

For instance, a hole’s diameter will shrink, and a shaft’s diameter will grow. This directly impacts clearance and fits. Your drawing must account for this shift.

Post-Plate Dimensions are Key

At PTSMAKE, we always advise clients to specify final dimensions after plating. This removes any guesswork for quality control. It becomes the standard for final part acceptance. This practice is vital when dealing with features controlled by maximum material condition6.

Properly considering GD&T and nickel coatings ensures functional success.

| Dimension Type | Who Uses It | Purpose |

|---|---|---|

| Pre-Plate | Machinist | To machine the part to the correct size before coating. |

| Post-Plate | Inspector / End-User | To verify the final part meets all specifications. |

This clear separation of information is a cornerstone of good design for manufacturing.

Accurate engineering drawings are non-negotiable. Clearly defining pre-plate and post-plate dimensions, especially with GD&T callouts, prevents tolerance issues. This ensures your Electroless Nickel Plating project is successful, avoiding costly rework and delays.

Why Engineers Choose ENP Over Hard Chrome For Wear Resistance

When comparing Electroless Nickel Plating to hard chrome, the differences are critical. It’s not just about hardness.

Engineers often choose ENP for its unique process benefits. These advantages directly impact part performance and manufacturing cost.

Key Differences at a Glance

Hard chrome is an electrolytic process. This can cause uneven buildup on edges. ENP, however, is a chemical process. It deposits a perfectly uniform layer. This makes it a great chrome alternative for wear.

| Feature | Electroless Nickel Plating (ENP) | Hard Chrome |

|---|---|---|

| Uniformity | Excellent, even on complex shapes | Prone to buildup on edges |

| Masking | Often not required | Extensive masking needed |

| Embrittlement | No hydrogen embrittlement | Risk of hydrogen embrittlement |

This uniform coverage is vital for parts with tight tolerances. It ensures consistent wear resistance across the entire surface.

Deciding between ENP vs hard chrome often comes down to the part’s geometry and material. Each coating has its place, but ENP solves problems that hard chrome cannot.

The Uniformity Advantage of ENP

The primary benefit of Electroless Nickel Plating is its uniform deposit. It coats threads, holes, and internal surfaces evenly. Hard chrome struggles with this.

It builds up on corners, a "dog-boning" effect. This forces post-plating grinding, adding steps and costs. ENP eliminates this, saving time and money. For complex parts, ENP is the superior choice.

Eliminating Hydrogen Embrittlement

Hard chrome plating can weaken high-strength steels. The process introduces hydrogen, which makes the metal brittle. This is a major failure risk.

ENP is deposited through an autocatalytic reaction7. This process does not introduce hydrogen into the substrate. This makes the nickel vs chrome coating debate simple for critical, high-strength components. Our tests confirm ENP maintains substrate integrity.

Masking-Free Application

Hard chrome requires extensive masking for areas that shouldn’t be coated. This is a labor-intensive and costly step.

With ENP, you often don’t need masking. The coating only deposits on the surfaces it’s intended for. This simplifies the entire process, leading to faster turnaround times and lower overall project costs at PTSMAKE.

Electroless Nickel Plating provides unmatched uniform coverage, preventing the need for post-machining. It also eliminates the risk of hydrogen embrittlement in high-strength steels and simplifies manufacturing by reducing or removing the need for complex masking. This makes it a smart choice.

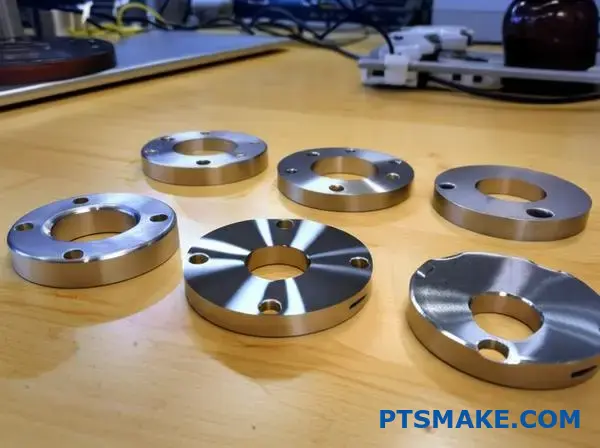

Ultimate Material Compatibility Guide For Electroless Nickel Plating

The success of Electroless Nickel Plating starts with the substrate. Not all materials are created equal. Choosing the right one is the foundation for a flawless finish.

This process is incredibly versatile. It works well on many common metals used in manufacturing.

ENP Compatible Metals

We primarily work with aluminum, steel, and copper alloys. Each has unique properties that demand a specific approach to surface preparation for optimal adhesion and performance.

| Material | Key Pre-Treatment Factor |

|---|---|

| Aluminum | Oxide Layer Removal |

| Steel | Surface Activation |

| Copper | Degreasing & Deoxidation |

Understanding these nuances is key. It ensures the plating bonds perfectly. This prevents defects down the line.

Material pre-treatment is not a one-size-fits-all process. The steps we take at PTSMAKE are tailored to the specific metal. This ensures the best possible bond between the substrate and the nickel-phosphorus layer. This attention to detail is critical for performance.

Surface Preparation: The Critical First Step

A pristine surface is non-negotiable. Any contaminants like oils, oxides, or greases will cause adhesion failure. The preparation sequence is as important as the plating bath itself.

Nickel Plating on Aluminum

Aluminum is popular but tricky. It instantly forms a passive oxide layer in air. We must remove this layer and prevent it from re-forming before plating. This is often done using a special zincate process8 which deposits a thin zinc layer.

Steel and Copper Alloys

These materials are more straightforward. The main goal is removing machining oils and surface oxides. A thorough alkaline cleaning followed by an acid dip is usually sufficient to create an active surface ready for plating.

Challenging Substrates like Titanium

Materials like titanium require highly specialized multi-stage activation processes. These often involve aggressive etchants or specific strike layers to ensure the ENP deposit will adhere properly.

| Material | Cleaning | Etching | Activation |

|---|---|---|---|

| Aluminum | Alkaline Soak | Acid/Alkaline Etch | Zincate Bath |

| Carbon Steel | Alkaline Soak | Acid Pickling | Nickel Strike |

| Copper/Brass | Alkaline Soak | Acid Dip | Direct Plating |

Successful Electroless Nickel Plating depends on two things. First, selecting a compatible substrate. Second, applying a meticulous, material-specific pre-treatment process. These initial steps are crucial for achieving a durable and high-quality finish that meets specifications.

Busting Myths: Electroless Nickel Is Not Just For Corrosion Resistance

Many engineers see Electroless Nickel Plating purely as a shield against rust. This is a common electroplating myth. The reality is far more interesting.

ENP offers significant mechanical advantages. Its hardness is a key feature. With heat treatment, it can reach impressive levels.

This makes it ideal for wear resistance. We also consider its magnetic properties. These change based on phosphorus content.

Its electrical conductivity is another useful trait. It’s a versatile coating for many applications beyond just corrosion control.

Let’s break down these ENP advantages beyond corrosion. The benefits depend heavily on the phosphorus content in the plating bath. This is a crucial detail for any project.

Hardness and Wear Resistance

As-plated ENP is already hard. After heat treatment, its hardness increases significantly. This process transforms its internal structure, enhancing wear resistance for demanding components.

The following table, based on our internal testing, shows the difference:

| Phosphorus Content | As-Plated Hardness (HV) | Heat-Treated Hardness (HV) |

|---|---|---|

| Low (1-4%) | 550 – 650 | Up to 1100 |

| Medium (5-9%) | 450 – 550 | Up to 1000 |

| High (10-13%) | 400 – 500 | Up to 900 |

We measure this using the Vickers hardness9 test. For parts needing extreme durability, low-phosphorus, heat-treated ENP is an excellent choice. We’ve used it at PTSMAKE for high-wear industrial machinery parts.

Magnetic and Electrical Properties

The magnetic properties of ENP are directly tied to its phosphorus level. Low-phosphorus coatings are magnetic. This is useful for applications requiring a magnetic response.

Conversely, high-phosphorus coatings are non-magnetic. This is critical for electronics, where magnetic interference must be avoided. It’s a key reason clients choose ENP for sensitive devices.

Electrically, ENP is conductive, though less so than pure nickel. Its resistivity varies with phosphorus content. This makes it suitable for EMI shielding applications.

In short, Electroless Nickel Plating offers far more than corrosion protection. Its tunable hardness, specific magnetic properties, and useful conductivity make it a powerful engineering tool for high-performance applications.

Real-World Case Study: How ENP Prevented Premature Failure In Critical Aerospace Parts

A client approached us with a recurring issue. Their critical flight hardware components were failing prematurely. The original coating choice just wasn’t holding up.

This wasn’t a minor problem. It caused costly delays and raised serious safety concerns. They needed a robust solution fast.

Initial Coating Options

Their team had considered several standard options before turning to us. Each had significant drawbacks for their specific application, as our joint analysis revealed.

| Coating | Primary Benefit | Disadvantage for Application |

|---|---|---|

| Hard Chrome | Extreme Hardness | Non-uniform coating, risk of cracking |

| Anodizing | Good Corrosion Resistance | Poor wear resistance on moving parts |

| Zinc Plating | Cost-Effective | Insufficient protection in harsh environments |

This is a classic aerospace coating case study. The initial choices seemed logical, but they failed to address the complex operational stresses. We proposed Electroless Nickel Plating (ENP).

This situation highlighted a common challenge in aerospace engineering. The interaction between different materials and extreme operational demands can be unforgiving. The client’s part, made from a high-strength aluminum alloy, was failing due to a combination of wear and corrosion.

Why Alternative Coatings Failed

The hard chrome plating they tested created micro-cracks under stress, which became failure points. The anodized coating, while protective against corrosion, quickly wore away on contact surfaces. This exposed the base metal, leading to rapid degradation.

This degradation was accelerated by contact with stainless steel fasteners. This created a perfect environment for galvanic corrosion10, a problem the original design overlooked. A simple coating wasn’t enough; they needed a multifunctional barrier.

ENP as the Solution

Electroless Nickel Plating offered the perfect answer. Its key advantage is uniformity. The coating perfectly followed the part’s complex geometry, leaving no thin spots or buildups. This is crucial for nickel for flight hardware.

After our testing phase with the client, the results were clear. ENP provided superior protection and prevented the component failures.

| Performance Metric | Previous Coating (Anodizing) | Electroless Nickel Plating (ENP) |

|---|---|---|

| Wear Resistance (Taber) | Moderate | Excellent |

| Corrosion Resistance (Salt Spray) | 250 hours | >1000 hours |

| Coating Uniformity | Fair | Excellent |

This case demonstrates effective ENP failure prevention. It solved the wear, corrosion, and uniformity issues in a single, reliable process.

This real-world aerospace case study shows that the right surface treatment is not just a final step but a critical design element. ENP provided the comprehensive protection needed, preventing premature failure and ensuring the reliability of critical flight hardware.

Choosing Between ENP And Anodizing For Aluminum Parts

Choosing the right finish for aluminum parts is a critical decision. It directly impacts performance, durability, and cost.

Two of the most common options are Electroless Nickel Plating (ENP) and Anodizing.

They both protect aluminum, but in fundamentally different ways. Understanding these differences is key. This is especially true for parts in sensitive electronics or defense assemblies. Let’s compare them.

Key Functional Differences

| Property | Electroless Nickel Plating (ENP) | Anodizing (Type II & III) |

|---|---|---|

| Process | Additive (Coating Deposition) | Conversive (Surface Conversion) |

| Conductivity | Conductive | Non-Conductive (Insulator) |

| Uniformity | Excellent, even on complex shapes | Fair, can vary with geometry |

| Hardness | Very High (45-70 HRC) | High (60-70 HRC for Hardcoat) |

When clients ask for guidance, I first clarify the part’s primary function. The choice between ENP and anodizing hinges on this. It’s not about which is better, but which is right for the job.

Process and Properties

Anodizing is an electrochemical process. It converts the aluminum surface into a durable aluminum oxide layer. This layer is porous and an excellent electrical insulator. It’s integral to the part itself.

Electroless Nickel Plating is different. It is a chemical deposition process. It coats the part with a uniform layer of nickel-phosphorus alloy. This happens through an autocatalytic reaction11.

The main advantage of ENP is its uniformity. The coating perfectly follows the contours of the part. This is true even for complex internal cavities. This makes it ideal for components requiring tight tolerances and consistent coverage.

Wear Life and Cost Analysis

Anodizing, especially Type III (hardcoat), offers great abrasion resistance. It is often a more cost-effective solution for general protection.

However, for parts under high stress or friction, ENP often provides superior wear life. Based on our client collaborations, the lubricity and hardness of a high-phosphorus ENP can significantly extend a component’s service life, justifying the initial investment.

Your final decision will balance performance needs with budget constraints.

The choice between ENP and anodizing depends on your application’s specific needs. Consider factors like required electrical conductivity, wear resistance, and thickness uniformity. Both finishes offer excellent protection for aluminum when applied correctly.

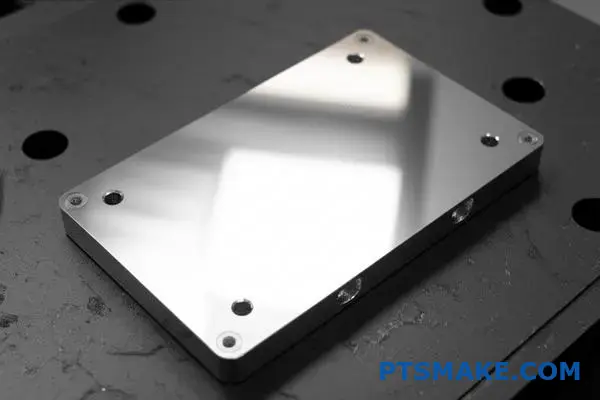

Why Surface Finish Matters: ENP And Ra Requirements Explained

Electroless Nickel Plating (ENP) does more than protect parts. It actively improves the surface finish. This process is key for achieving a consistent, smooth surface for demanding applications.

Improving Ra with ENP

The uniform nature of ENP deposition helps level the microscopic peaks and valleys of a substrate. This directly lowers the final Ra value. The result is a smoother, more functional surface.

The impact on Ra after plating is significant.

| Property | Before ENP | After ENP |

|---|---|---|

| Ra (μm) | 1.6 | 0.8 |

This table shows a typical improvement. The final surface roughness plating ENP provides is often much better than the original part.

How ENP Creates a Flawless Finish

The magic of ENP lies in its chemical process. Unlike electroplating, which can build up on edges, ENP deposits a perfectly uniform layer. This covers every corner and internal feature equally.

This uniformity is crucial for complex parts. It ensures consistent thickness without manual adjustments. This process helps us at PTSMAKE deliver predictable results for our clients.

The Science of Smoothness

ENP works by filling in the tiny imperfections on a part’s surface. This leveling effect is what gives you a smooth finish nickel plating. The initial roughness of the part is a starting point, which ENP then refines.

The coating’s amorphous structure12 also contributes to its smoothness and lack of grain boundaries. This is especially true for high-phosphorus ENP coatings, which are known for their excellent performance.

Below is a comparison of coating uniformity:

| Plating Method | Coating Uniformity | Best For |

|---|---|---|

| Electroless Nickel | Excellent, highly uniform | Complex geometries, tight tolerances |

| Electroplating | Varies with part geometry | Simple shapes, decorative finishes |

The data above highlights why ENP is superior for precision applications. The consistency of Ra after plating is a major benefit for parts requiring reliable performance.

Electroless Nickel Plating is an effective method for enhancing surface quality. It creates a highly uniform coating that fills microscopic imperfections, significantly improving the surface roughness (Ra) and ensuring a consistent, smooth finish nickel plating for precision components.

Understanding Accelerated Salt Spray Testing For ENP Coatings

How do we prove the corrosion resistance of an ENP coating? We rely on standardized tests. These methods simulate harsh conditions effectively.

The most common is the salt spray test. It is a key part of nickel plating corrosion resistance tests. It helps us predict performance quickly.

Different tests serve specific needs. Understanding them is vital for choosing the right coating.

Here is a quick overview of common methods:

| Test Method | Primary Goal | Typical Application |

|---|---|---|

| Salt Spray (ASTM B117) | General Corrosion Resistance | Most ENP applications |

| CASS (ASTM B368) | Accelerated Acidic Corrosion | Decorative chrome finishes |

| Porosity Testing | Detect Coating Pores | High-reliability parts |

This table helps set a baseline for evaluating ENP quality.

The Neutral Salt Spray (NSS) test, under ASTM B117, is the industry benchmark. It’s the standard for evaluating the corrosion protection of Electroless Nickel Plating. We expose coated parts to a controlled, corrosive salt fog.

Test duration is the primary metric. We measure the hours until the first sign of corrosion appears. This is typically red rust from the base metal. The required hours depend directly on the ENP coating’s thickness and phosphorus content.

High-phosphorus ENP coatings consistently show superior performance in salt spray test ENP evaluations. A mid-phosphorus coating might be specified for 96-200 hours. A high-phosphorus coating can easily exceed 1000 hours. We use these benchmarks at PTSMAKE to align with client requirements.

Other specialized nickel plating corrosion resistance tests are also important. Porosity tests13, for instance, identify microscopic defects in the coating. These tiny openings can become initiation sites for corrosion, compromising the entire part.

Here’s how different ENP types typically perform:

| ENP Type | Phosphorus Content | Expected ASTM B117 Hours (per 25µm) |

|---|---|---|

| Low-Phosphorus | 1-4% | 24 – 48 hours |

| Mid-Phosphorus | 5-9% | 96 – 200 hours |

| High-Phosphorus | 10-13% | > 1000 hours |

Remember, these are guidelines. The quality of the substrate preparation and the plating process itself are critical. A well-applied coating on a clean surface will always outperform a poorly executed one, no matter the type.

Choosing the right corrosion test is essential. The salt spray test offers a reliable benchmark. However, considering coating type, thickness, and potential defects provides a more complete assessment of the ENP coating’s real-world durability and performance.

The Future Of Electroless Nickel: Trends Every Engineering Leader Should Watch

The future of Electroless Nickel Plating is evolving rapidly. We are seeing a move towards smarter and cleaner solutions. For any engineering leader, understanding these plating technology trends is crucial for innovation.

Automation is bringing new levels of precision. Eco-friendly baths are becoming standard, not an exception. Advanced nickel coating options with nanoparticles are pushing performance boundaries. This is where the industry is headed.

| Trend | Key Benefit for Engineers |

|---|---|

| Automation & AI | Unmatched consistency and quality control |

| Eco-Friendly Baths | Compliance with global regulations |

| Nano-Enhanced Coatings | Superior hardness and wear resistance |

These shifts are changing how we design and manufacture parts.

The future of ENP is more than just theory; it’s about practical applications that solve complex engineering challenges. These advanced nickel coating developments directly impact component reliability and performance. I see these changes creating new opportunities.

Automation for Flawless Consistency

Automated plating lines are a game-changer. They use sensors to monitor and adjust solution parameters in real-time. This includes precise control over the bath stoichiometry14, ensuring every part receives a uniform coating. This level of control is essential for the tight-tolerance components we often work with. It removes variables and boosts repeatability.

The Shift to Greener Chemistry

There is a strong push to eliminate harmful substances from plating baths. New formulations are replacing traditional stabilizers containing lead or cadmium. This focus on eco-friendly solutions helps meet sustainability goals. It also ensures compliance with regulations like RoHS and REACH without compromising coating quality.

Advanced Nano-Composite Coatings

This is a truly exciting frontier. We can now embed nano-sized particles into the nickel-phosphorus matrix. This creates a composite coating with enhanced properties.

| Particle Type | Primary Advantage |

|---|---|

| PTFE | Low coefficient of friction |

| Diamond | Extreme hardness and abrasion resistance |

| Boron Nitride | High-temperature lubricity |

These coatings offer performance far beyond standard Electroless Nickel Plating. They are ideal for parts in demanding environments.

The future of ENP is driven by automation for precision, greener chemistries for sustainability, and nano-composites for enhanced performance. These plating technology trends are creating stronger, more reliable, and environmentally responsible components, which is a significant step forward for the industry.

Unlock Precision Engineering with PTSMAKE—Electroless Nickel Experts

Ready to boost your parts’ reliability, corrosion resistance, and cost-effectiveness? Contact PTSMAKE’s expert team now. Get a fast, tailored quote on Electroless Nickel Plating for your next project—ensure performance, precision, and peace of mind, from prototype to production!

Discover the chemical process that ensures a perfectly uniform coating, regardless of part geometry. ↩

Learn how surface friction, wear, and lubrication impact your component’s performance and lifespan. ↩

Understand the chemical process that enables this perfectly uniform and protective coating. ↩

Learn about the unique chemical reaction that ensures ENP’s exceptional uniformity and precision. ↩

Understand how this property is measured and why it impacts your part’s final performance. ↩

Learn how this GD&T principle impacts your coated parts to ensure perfect assembly and function. ↩

Learn the chemical process that gives ENP its perfectly uniform coating advantage. ↩

Learn more about this immersion plating process essential for preparing aluminum for ENP. ↩

Learn how this microhardness test precisely measures the durability of materials and coatings. ↩

Understand this electrochemical process and how to prevent it when designing multi-metal assemblies. ↩

Discover how this unique chemical process provides a perfectly uniform protective coating on complex parts. ↩

Discover how this unique non-crystalline structure provides superior smoothness and protection in ENP coatings. ↩

Learn how these tests find invisible flaws that can compromise component integrity and cause premature failure. ↩

Understand how chemical balance in plating baths impacts coating quality and performance. ↩