Many engineers struggle with selecting the right CNC machining service provider, often facing unexpected costs, quality issues, and delivery delays that can derail entire projects. Without clear guidance on material selection, design optimization, and cost factors, these challenges become even more frustrating and expensive.

CNC machining services in 2025 require strategic provider selection, design optimization, quality control integration, and understanding cost drivers including materials, complexity, tolerances, and batch sizes for successful project outcomes.

The CNC machining landscape has evolved significantly, and understanding these changes can save you thousands of dollars and weeks of production time. I’ve worked with hundreds of projects at PTSMAKE, and I’ve seen how the right approach to service selection, material choices, and design considerations can make or break a manufacturing project. This guide covers the essential trends, practical tips, and cost factors that will help you navigate CNC machining services more effectively in 2025.

Choosing the Right CNC Machining Service Provider.

Have you ever faced project delays or failures because your machined parts didn’t meet specifications? The issue often isn’t the design, but the partner you chose.

Choosing the right CNC machining service requires a deep evaluation of technical capabilities, material expertise, quality assurance, scalability, and communication. A true partner integrates these elements to transform your design into a successful product, ensuring reliability from the first prototype to full-scale production.

When you’re searching for a partner for your next project, the technical details matter most. It’s not just about finding a shop with machines; it’s about finding a provider whose capabilities align perfectly with your project’s demands. This ensures you get the quality and precision your application requires without overpaying for unnecessary capacity.

Assessing Technical Capabilities

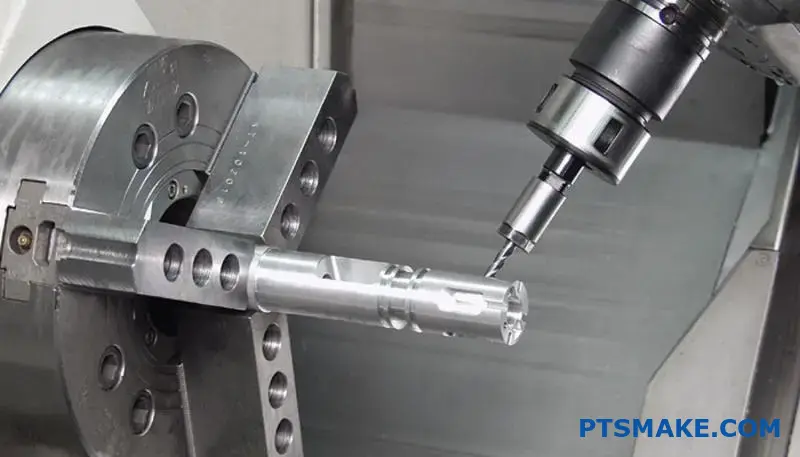

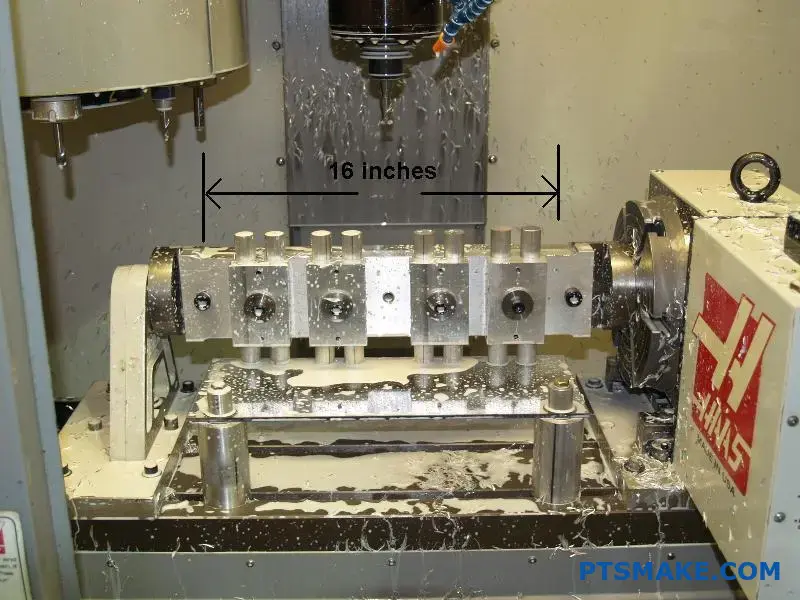

The first step is to look at their machinery. Do they have modern 3-axis, 4-axis, and 5-axis CNC machines? 5-axis machining is crucial for complex geometries, as it can produce intricate parts in a single setup, reducing cycle times and improving accuracy. At PTSMAKE, we’ve found that investing in advanced machinery directly translates to better outcomes for our clients, especially in aerospace and medical device projects. Ask about the tightest tolerances they can consistently hold. For most applications, a tolerance of ±0.005 inches (0.127 mm) is standard, but high-precision jobs may require much tighter controls.

Material Expertise is Crucial

A provider’s experience with various materials is just as important as their equipment. Working with standard aluminum 6061 is very different from machining titanium or PEEK. Each material has unique properties that affect tool selection, cutting speeds, and feeds. A lack of experience can lead to poor surface finishes, internal stresses, or even part failure. In our experience with automotive clients, the ability to effectively machine hardened steels for molds and fixtures has been a key differentiator. A good provider should be able to offer advice on material selection to optimize for performance, cost, and manufacturability. True expertise in metrology1 is also essential to verify that parts made from these advanced materials meet every dimensional requirement.

Quality, Lead Time, and Scalability

Finally, consider the operational aspects that ensure a smooth project flow. A robust quality assurance system, clear lead times, and the ability to scale are non-negotiable. Quality isn’t just a final inspection; it should be integrated throughout the entire manufacturing process.

| Factor | What to Look For | Red Flag |

|---|---|---|

| Quality Assurance | In-process inspection, CMM reports, material traceability. | Final inspection only, no documentation. |

| Lead Time | Clear, realistic timelines with updates. | Vague promises, history of delays. |

| Scalability | Ability to handle prototype (1-100) and production runs (1000+). | Only specializes in one-off parts or massive runs. |

A partner should be able to grow with you. They must have the capacity to handle a small batch of prototypes and then seamlessly transition to low-volume or high-volume production without compromising on quality or delivery schedules. This flexibility is vital for bringing a product to market effectively.

Beyond the machines and materials, the foundational elements of a great partnership are trust and reliability. These qualities are built on verifiable standards, deep industry knowledge, and clear communication. Choosing a CNC machining service provider without considering these factors is like building a house on an unstable foundation—it’s only a matter of time before problems appear. These elements are what separate a simple supplier from a long-term manufacturing partner.

Why Certifications and Industry Specialization Matter

Certifications like ISO 9001 are more than just a logo on a website. They represent a commitment to a documented, repeatable process designed to ensure consistent quality. An ISO 9001 certified company has proven that its quality management system meets rigorous international standards. This means you can expect better process control, clear documentation, and a focus on continuous improvement.

Industry specialization is another critical factor. The requirements for an aerospace component are vastly different from those for a consumer electronics part.

Key Industry Requirements:

- Aerospace: Extreme precision, traceability of materials, and extensive documentation are mandatory. Providers must be comfortable with exotic alloys and complex five-axis machining.

- Medical: Biocompatible materials, pristine surface finishes, and strict process validation are key. There is zero room for error.

- Automotive: Focus is on high-volume production, cost-effectiveness, and durability. Jigs, fixtures, and rapid prototyping are common needs.

A provider that specializes in your industry will understand its unique challenges, standards, and terminology. They can provide valuable DFM (Design for Manufacturability) feedback that a generalist shop might miss.

Transparent Communication: The Project’s Lifeline

Poor communication is one of the most common points of failure in manufacturing partnerships. A reliable partner establishes clear and consistent communication from the very beginning. You should have a dedicated point of contact who understands your project and can provide regular updates.

| Communication Style | Good Partner | Poor Partner |

|---|---|---|

| Initial Quote | Detailed, itemized, and includes DFM feedback. | A single price with no explanation. |

| During Production | Proactive updates on progress and potential issues. | Silence until the due date (or after). |

| Problem Solving | Collaborative approach to find solutions. | Blames the design or other external factors. |

Transparent communication builds trust and allows for agile problem-solving. When a potential issue is flagged early, we can work together to find a solution without impacting the project timeline. In past projects at PTSMAKE, this open dialogue has been the key to navigating complex challenges and delivering successful outcomes, reinforcing the idea that we are an extension of our client’s team.

Choosing the right CNC machining service provider goes beyond just finding the lowest price. It involves a thorough assessment of their technical capabilities, material experience, and operational structure. You need a partner whose equipment and expertise match your project’s complexity. Equally important are the foundational elements: verifiable certifications like ISO 9001, proven specialization in your industry, and a commitment to transparent communication. These factors ensure reliability, build trust, and ultimately determine the success of your project.

Modern Quality Assurance Methods in CNC Machining?

Have you ever had a batch of CNC parts rejected during final inspection? It’s a frustrating setback that wastes time and money, especially when the error could have been caught hours earlier.

Modern quality assurance uses methods like in-process inspection, laser scanning, and AI systems to monitor production in real-time. This data-driven approach catches deviations as they happen, ensuring every part meets precise specifications and reducing defects before they become costly problems.

Traditional quality control often happens after a part is finished. This is like proofreading a book only after it’s been printed. If you find a mistake, it’s too late. Modern CNC machining services have moved beyond this reactive model. We now focus on proactive quality assurance, embedding inspection directly into the manufacturing process.

In-Process Inspection: Your First Line of Defense

In-process inspection uses automated probes and sensors inside the CNC machine. These tools measure the part at critical stages without removing it from the machine. If a tool is wearing down or a dimension is drifting from the specification, the system can flag it immediately. The machine can even make real-time adjustments or stop the process to prevent creating more out-of-spec parts. This is a game-changer for maintaining tight tolerances throughout a long production run. It turns quality control from a final gate into a continuous feedback loop.

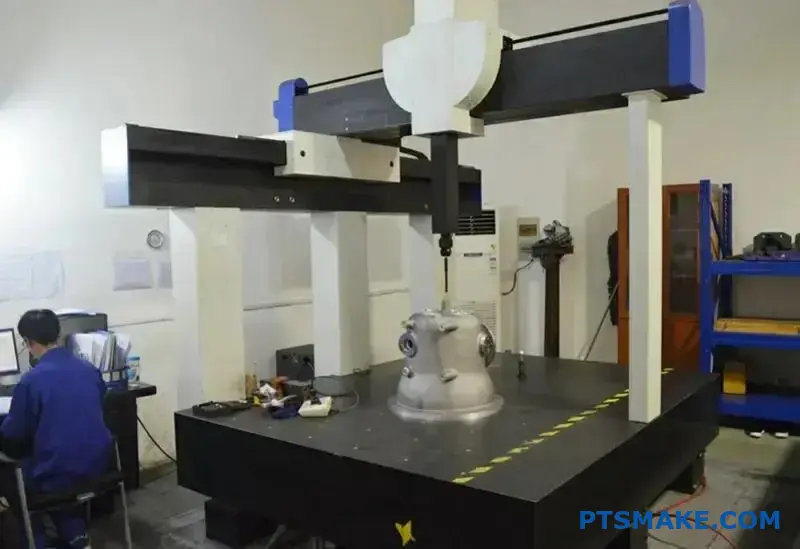

Advanced Inspection with CMM and Laser Scanning

For complex geometries, we move to more advanced tools after the initial machining.

Coordinate Measuring Machines (CMM)

A CMM uses a highly sensitive probe to touch points on a part’s surface, collecting precise X, Y, and Z coordinates. It is incredibly accurate for verifying critical dimensions, hole locations, and geometric features. In our experience, CMMs are the gold standard for final validation where absolute precision is non-negotiable.

3D Laser Scanning

3D laser scanning captures millions of data points from a part’s surface, creating a detailed digital "point cloud." This method is much faster than a CMM and excels at inspecting complex curves, freeform surfaces, and overall part shape. We use it to compare the finished part against its original CAD model, generating a color-coded map that instantly highlights any deviations. The field of metrology2 underpins both of these technologies, providing the framework for reliable and repeatable measurements.

Here’s a simple breakdown of when to use each:

| Inspection Method | Best For | Key Advantage |

|---|---|---|

| In-Process Probing | High-volume production, tight tolerances | Catches errors instantly, reduces scrap |

| CMM Inspection | Critical dimensions, geometric validation | Extremely high accuracy and repeatability |

| 3D Laser Scanning | Complex surfaces, reverse engineering | Speed and comprehensive surface data |

Integrating these modern methods is about more than just finding defects; it’s about building a system that prevents them. The data collected from these inspections drives continuous improvement and ensures unmatched reliability, especially in high-stakes industries like aerospace and medical devices.

The Power of Data Analytics and Traceability

Collecting data is only half the battle. The real value comes from analyzing it to ensure consistency and provide complete transparency. This is where data analytics and traceability become essential pillars of modern quality assurance.

Real-Time Monitoring and Data Analytics

Every measurement from in-process probes, CMMs, and scanners feeds into a centralized system. We use Statistical Process Control (SPC) to monitor this data in real-time. SPC helps us identify trends and variations in the manufacturing process. For instance, if we see a gradual change in a specific dimension over a hundred parts, it might indicate tool wear. We can then schedule a tool change before any parts go out of tolerance. This predictive approach is far more efficient than reacting to failures. It’s a core principle we apply at PTSMAKE to deliver consistent quality across thousands of components.

AI-Driven Inspection and Full Traceability

The future of quality control is autonomous and fully transparent.

Autonomous AI-Driven Inspection

Artificial intelligence is taking inspection to the next level. AI-powered vision systems can inspect parts for surface defects, such as scratches or burrs, with incredible speed and accuracy. The AI algorithm learns from a vast dataset of "good" and "bad" parts, becoming more effective over time. It can spot subtle imperfections that a human inspector might miss after hours of repetitive work. This technology ensures that not only are the dimensions correct, but the cosmetic finish is perfect as well.

The Importance of Traceability

Traceability means having a complete digital record of a part’s entire journey—from the raw material batch number to the specific machine it was on, the operator who oversaw it, and all its inspection data. For industries like aerospace or medical devices, this is not just a benefit; it’s a requirement. If a single component fails, manufacturers need to trace its origin immediately. We provide our clients with comprehensive traceability reports that offer complete confidence in the parts we deliver.

Here is a comparison of these advanced approaches:

| Feature | Data Analytics (SPC) | AI-Driven Inspection | Traceability System |

|---|---|---|---|

| Primary Goal | Process stability, defect prevention | Automated defect detection | Part history documentation |

| Key Technology | Statistical algorithms | Machine learning, computer vision | Database logging, serialization |

| Main Benefit | Reduces process variability | Higher speed and consistency | Compliance and risk management |

Relying on outdated final inspection methods introduces unnecessary risks and costs. Modern quality assurance in CNC machining is a proactive, data-driven system. By integrating in-process monitoring, advanced scanning technologies, and AI-powered analytics, we shift from finding defects to preventing them entirely. This approach, combined with full traceability, provides the verifiable proof of quality that high-precision industries demand. It ensures every single part is not just made, but made right from the start.

Design for Manufacturability: Essential Guidelines.

Ever finalized a design that looked perfect in CAD, only to face shocking manufacturing quotes and long lead times? It’s a common and frustrating roadblock for many engineers.

Design for Manufacturability (DFM) is the practice of designing parts for ease of manufacturing. By simplifying geometry, setting realistic tolerances, and considering machine access, you can dramatically reduce costs, shorten production time, and improve the quality of your finished components.

Great design isn’t just about function and aesthetics; it’s also about how efficiently it can be made. In our CNC machining services, the simplest changes can lead to the biggest cost savings. The core principles of DFM are not restrictive rules but practical guidelines that bridge the gap between your design intent and the realities of the machine shop floor.

Simplify Your Geometry: Less is More

The complexity of your part’s geometry is a primary driver of cost. Every complex curve, tight pocket, and non-standard feature adds to the machining time and may require specialized tooling.

Embrace Radii and Fillets

Sharp internal corners are a classic DFM pitfall. CNC cutting tools are round, so they naturally create an internal radius. Designing a sharp 90-degree internal corner requires a secondary operation like EDM (Electrical Discharge Machining), which significantly increases cost. By designing internal corners with a radius that is slightly larger than the cutting tool’s radius, you enable continuous, faster machining. A good rule of thumb is to make the corner radius at least 1/3 of the cavity depth.

Maintain Uniform Wall Thickness

Drastic changes in wall thickness can lead to part warping during machining, especially with plastics and some metals. Thin walls are also prone to vibration, which affects surface finish and accuracy. Aiming for a consistent wall thickness throughout your part improves stability and makes it easier to machine predictably. When working with materials that exhibit Anisotropy3, uniform thickness becomes even more critical for predictable results.

Specify Achievable Tolerances: The Balancing Act

Tolerances define the acceptable deviation for a specific dimension. While tight tolerances are necessary for critical features, over-tolerancing a part is one of the quickest ways to inflate costs without adding functional value. Tighter tolerances require more precise machine setups, slower cutting speeds, and more frequent inspections.

Before specifying a tolerance, always ask: "Is this level of precision essential for my part’s function?" Often, standard machine tolerances are perfectly adequate for non-critical features.

| Tolerance Range (inches) | Relative Cost Increase | Typical Application |

|---|---|---|

| +/- 0.010" | Base Cost (1x) | General, non-critical features |

| +/- 0.005" | 1.5x – 2x | Mating parts, good fit |

| +/- 0.002" | 3x – 5x | Press fits, precise alignment |

| +/- 0.0005" | 6x – 10x+ | High-precision bearings, aerospace |

As the table shows, moving from a standard tolerance to a very tight one can increase the cost of a feature exponentially. Reserve the tightest tolerances for only the most critical interfaces.

Beyond the part’s internal geometry, we must also consider how the machine interacts with it. How will the part be held securely, and can the cutting tools reach every surface they need to? Answering these questions early in the design phase prevents costly redesigns and production delays down the line. It’s a perspective we’ve developed through countless projects at PTSMAKE.

Design for Easy Fixturing

Fixturing is the process of securing the raw material or workpiece to the CNC machine. A part that is difficult to hold is difficult to machine accurately. Custom fixtures add significant time and cost to a project.

Provide Flat, Stable Surfaces

Whenever possible, design your parts with at least one or two flat, parallel surfaces. These features make it easy to clamp the part in a standard vise, which is the fastest and most cost-effective fixturing method. Parts that are purely organic or have complex curved surfaces often require custom-milled soft jaws or complex multi-axis fixtures to hold them securely, which adds upfront cost and setup time for your cnc machining services provider.

Think About Tool Access

A machinist’s simple mantra is: "If the tool can’t reach it, we can’t cut it." Your design must allow physical space for the cutting tool and its holder to access every feature without colliding with another part of the workpiece.

Mind the Depth of Pockets and Holes

Deep, narrow pockets are challenging to machine. They require long, slender tools that are prone to deflection and vibration, leading to poor surface finishes and potential tool breakage. A good guideline is to keep the depth of any pocket to no more than 4-6 times its width. Similarly, for drilled holes, exceeding a depth-to-diameter ratio of 10:1 often requires specialized "peck drilling" cycles, which slows down the process.

The Power of Early Collaboration

The single most effective DFM strategy is to communicate with your manufacturer early and often. A brief conversation with an experienced machinist during the conceptual design phase can provide invaluable feedback. They can spot potential manufacturing issues, suggest minor design tweaks that lead to major cost savings, and offer advice on material selection. At PTSMAKE, we view ourselves as partners, not just suppliers. We encourage our clients to share their designs with us early so we can provide DFM feedback and ensure the most efficient path from prototype to production. This collaborative approach is the foundation of a successful manufacturing relationship.

Effective Design for Manufacturability boils down to a few core ideas. Simplify your part’s geometry, use tolerances only as tight as necessary, and design with fixturing and tool access in mind. Most importantly, collaborating early with your manufacturing partner transforms the process into a true partnership, ensuring better results. This proactive approach is key to optimizing any cnc machining services project for cost and speed, turning a good design into a great, manufacturable product.

Material Selection Strategies for CNC Machining.

Ever picked a material that seemed perfect, only to see it double your machining time and shred your tools? That misstep can derail an entire project timeline and budget.

Effective material selection for CNC machining hinges on a strategic balance of machinability, overall project cost, and the specific performance requirements of the final part. This choice directly influences production efficiency, durability, and the success of your entire project.

Choosing the right material is more than just looking at a spec sheet. It’s a foundational decision that impacts every subsequent step of the manufacturing process. The three pillars of this decision are machinability, cost, and application requirements. Let’s break them down.

Understanding Machinability

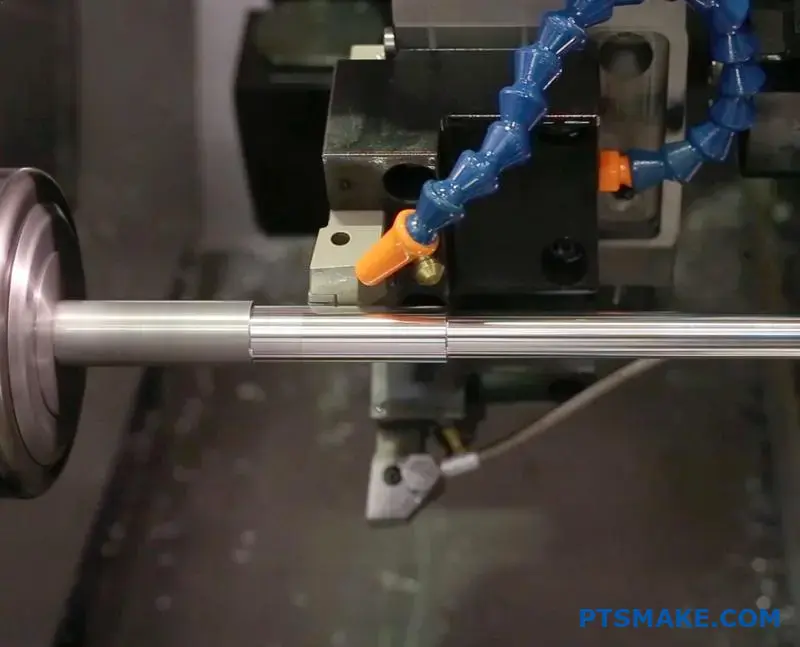

Machinability refers to how easily a material can be cut, drilled, or shaped by a machine tool. A material with high machinability, like Aluminum 6061, allows for faster cutting speeds, results in a better surface finish, and causes less wear on cutting tools. In contrast, materials like Stainless Steel 316 have lower machinability. They are tougher, generate more heat during cutting, and wear down tools much faster. This directly increases the time and cost required for any cnc machining services. Considering this factor early on prevents unexpected delays and tool replacement costs.

Analyzing the True Cost

The cost of a material isn’t just its price per kilogram. The total cost includes several hidden factors:

- Raw Material Price: The initial purchase price, which can fluctuate.

- Machining Time: A less machinable material requires slower speeds and more passes, increasing machine and operator time.

- Tooling Costs: Tougher materials lead to more frequent tool changes, adding to the overall expense.

- Scrap Rate: Some materials are more difficult to machine precisely, potentially leading to a higher rate of failed parts.

In our experience at PTSMAKE, a cheaper raw material can sometimes result in a more expensive final part if its machinability is poor.

Aligning with Application Requirements

The material must meet the functional needs of the final part. Will it be exposed to chemicals? Does it need to be lightweight but strong? Key properties like tensile strength, corrosion resistance, and thermal conductivity are critical. For example, a part for a medical device might require biocompatible titanium, while a component for an aerospace application might need the high strength-to-weight ratio of an aluminum alloy. The unique properties of some materials, like Anisotropy4, must also be considered as they can affect performance under stress.

A simple comparison can help guide this decision:

| Material | Key Strengths | Common Applications |

|---|---|---|

| Aluminum 6061 | Excellent machinability, good strength-to-weight ratio | Aerospace components, consumer electronics, frames |

| Stainless Steel 304 | High corrosion resistance, strong, durable | Medical instruments, food processing equipment |

| PEEK | High-temp resistance, chemical inertness, strong | Bearings, pump parts, electrical insulators |

| Titanium Ti-6Al-4V | Highest strength-to-weight ratio, biocompatible | Medical implants, aerospace structural parts |

Beyond standard metals and plastics, the demand for advanced materials is growing. Composites and high-performance alloys like titanium offer incredible performance benefits, but they also introduce new challenges for design and production. Navigating this landscape requires a deep understanding of both the materials and the machining processes.

The Rise of Advanced Materials

Materials like carbon fiber reinforced polymers (CFRP) and titanium alloys are no longer exclusive to top-tier aerospace and F1 racing. They are now found in robotics, high-end consumer goods, and medical devices. Their appeal is clear: unparalleled strength-to-weight ratios, exceptional durability, and resistance to extreme environments. However, machining these materials is a completely different challenge.

Machining Challenges

- Titanium Alloys: These have low thermal conductivity, meaning heat generated during cutting doesn’t dissipate through the chip. Instead, it concentrates on the cutting tool, leading to rapid tool wear and potential part deformation. It requires specialized coatings, rigid machine setups, and carefully controlled speeds.

- Composites (CFRP): These materials are abrasive and don’t form chips like metals. Instead, they create a fine, sharp dust that is hazardous to inhale and can damage machine components. Machining composites often causes delamination (layer separation) if not done with extremely sharp, specialized diamond-coated tools and proper support.

Balancing Performance, Cost, and Lead Time

Every project operates within a triangle of constraints: performance, cost, and time. You can rarely maximize all three. Choosing an advanced material often means prioritizing performance at the expense of higher costs and longer lead times. A key part of our role in providing cnc machining services is helping clients find the sweet spot. We’ve found it’s helpful to visualize the trade-offs.

| Material Category | Performance | Cost | Lead Time |

|---|---|---|---|

| Standard Aluminum | Good | Low | Short |

| Engineering Plastics | Very Good (Specific Properties) | Medium | Short-Medium |

| Stainless Steel | Excellent (Durability) | Medium-High | Medium |

| Titanium / Composites | Superior (Strength/Weight) | High | Long |

For a prototype where speed is critical, a standard aluminum might be perfect. For a final production part that needs to last for years in a corrosive environment, the higher cost and longer lead time of stainless steel or even titanium could be a necessary investment. The key is to make a conscious, informed decision that aligns with your project’s most important goals.

In summary, choosing the right material for CNC machining is a critical strategic decision. It requires a thorough analysis of machinability to control production efficiency, a clear understanding of the true costs involved beyond the raw material price, and a precise alignment with the application’s performance needs. As advanced materials become more common, balancing their superior properties against the practical constraints of budget and lead time becomes essential for project success.

Optimizing Technical Drawings and RFQs for CNC Projects?

Ever submitted an RFQ only to get confusing quotes or complete silence? Vague drawings and incomplete requests often lead to delays and costly errors, putting your entire project timeline at risk.

Optimizing your technical drawings and RFQs involves providing crystal-clear dimensions, tolerances, material specifications, and surface finishes. This precision eliminates guesswork for your manufacturing partner, ensuring you receive accurate quotes and high-quality parts on time, forming the foundation for successful CNC machining services.

The Blueprint for Success: Perfecting Your Technical Drawing

A detailed technical drawing is the single most important document you can provide to a CNC machining shop. It’s our primary source of truth. While a 3D CAD model is essential for programming the machines, the 2D drawing contains the nuances that a model alone cannot convey—specifically, tolerances, finishes, and critical-to-function features. In past projects at PTSMAKE, we’ve seen how a well-prepared drawing can cut down quoting time by half and prevent costly production errors down the line.

Specifying Critical Tolerances

Not all dimensions are created equal. Some features require high precision for assembly or function, while others can have looser tolerances. Clearly defining these is crucial. Over-tolerancing every feature is a common mistake that significantly drives up cost and manufacturing time without adding value. Instead, identify which features are critical and apply tight tolerances only where necessary. This shows your manufacturing partner that you understand the design intent and helps them focus their quality control efforts. The use of a symbolic language like Geometric Dimensioning and Tolerancing5 is the industry standard for communicating this complex information concisely and without ambiguity.

Material and Surface Finish Callouts

Be explicit with your material choice. Specifying "Aluminum" is not enough. Is it 6061-T6, 7075-T6, or 5052? Each has different properties, costs, and machining characteristics. The same level of detail is required for surface finishes. A callout like "smooth finish" is subjective. Instead, use quantitative measures like "Ra 1.6 μm" or specify a particular post-processing step like "Anodize Type II, Black, MIL-A-8625F."

This table illustrates how specific callouts impact the final part:

| Specification | Vague Callout | Clear Callout | Result |

|---|---|---|---|

| Material | Steel | 4140 Alloy Steel, Pre-hardened | Correct strength and hardness |

| Finish | Smooth | Ra 0.8 μm max | Meets functional friction requirements |

| Coating | Black coating | Black Oxide, MIL-DTL-13924D | Ensures correct corrosion resistance |

| Edge | Break edges | Break all sharp edges 0.2mm max | Safe handling and proper assembly |

Providing this level of detail removes all guesswork and ensures the parts you receive match your exact requirements.

Assembling an RFQ That Gets a Fast, Accurate Response

Once your technical drawing is complete, the next step is to assemble a comprehensive Request for Quote (RFQ) package. This package provides the commercial and logistical context that your drawing lacks. A well-organized RFQ allows us to quickly understand the full scope of your project and provide a competitive quote for our cnc machining services. It signals that you are a serious and professional partner, which always gets prioritized attention. Think of the RFQ as the cover letter and the drawing as the resume for your part.

Essential Components of a Strong RFQ

A complete RFQ package minimizes back-and-forth communication and accelerates the quoting process. Every detail you provide helps us to more accurately forecast machining time, material costs, and potential challenges. At PTSMAKE, a complete package helps our quoting team turn around a detailed estimate much faster.

Your RFQ should always include:

- 3D CAD Files: Native files are good, but neutral formats like STEP or IGES are universally accepted.

- 2D Technical Drawings: A PDF version corresponding to each 3D model.

- Quantities: Specify the volumes you need quoting (e.g., 10, 50, 200 pcs). This allows us to optimize for production scale.

- Desired Lead Time: Let us know your target delivery date so we can check feasibility against our production schedule.

- Shipping Destination: Essential for calculating logistics costs and timelines.

Avoiding Common RFQ Mistakes

We often see RFQs that contain simple, avoidable errors that cause significant delays. By double-checking your package before sending it, you can ensure a smoother process. Here are some common pitfalls and how to avoid them.

| Common Pitfall | The Problem It Creates | How to Avoid It |

|---|---|---|

| Conflicting Information | The 2D drawing shows a Ø10mm hole, but the 3D model has Ø10.5mm. | Always designate one document (usually the 2D drawing) as the ultimate source of truth. |

| Missing Quantities | We cannot calculate per-unit cost without knowing the production volume. | Provide quantity breaks (e.g., 50, 100, 500) to see price scaling. |

| No Delivery Date | It’s impossible to know if we can meet your timeline if it isn’t stated. | Provide a target delivery date, even if it’s flexible. |

| Vague Contact Info | If we have a question, we don’t know who to contact, slowing everything down. | Include the name, email, and phone number of the primary technical contact. |

A little diligence here goes a long way. It helps build a foundation of clear communication with your manufacturing partner from the very beginning.

A meticulously prepared technical drawing and a comprehensive RFQ are not bureaucratic hurdles; they are your most powerful communication tools. They bridge the gap between your design intent and the final machined part. By clearly defining every detail—from dimensions and tolerances to materials and quantities—you eliminate ambiguity, reduce risks, and empower your manufacturing partner. This clarity is the cornerstone of receiving accurate quotes, on-time delivery, and parts that perform exactly as you envisioned from professional cnc machining services.

Cost Factors and Budgeting for CNC Machining Services.

Ever received a CNC machining quote that was wildly different from what you expected? It can be frustrating when the numbers don’t align with your budget, leaving you wondering what went wrong.

The primary cost drivers for CNC machining services include material choice, design complexity, tolerance requirements, production volume, and any necessary post-processing. Understanding these elements is crucial for accurate budgeting and finding opportunities for significant cost savings without compromising quality.

When a quote for CNC machining services lands on your desk, several key factors are at play behind the final number. Gaining a clear understanding of these drivers can transform how you approach your project budget.

Material Selection: The Foundation of Cost

The raw material is often the most straightforward cost component. It’s not just about the price per kilogram; it’s also about machinability. For instance, Aluminum 6061 is relatively inexpensive and machines quickly, which keeps costs down. On the other hand, materials like Titanium or PEEK are costly to purchase and much harder to machine. They require slower cutting speeds and cause more tool wear, which directly increases machine time and overall expense. The material’s properties, such as its thermal stability or potential for anisotropy6, can also introduce challenges that require specialized handling, adding to the cost.

Part Complexity and Geometry

The more complex your part’s geometry, the more it will cost to produce. Features like deep pockets, thin walls, and intricate curves require more sophisticated programming and longer machining cycles. A critical factor is the number of setups required. Every time a part must be unclamped, rotated, and re-fixtured to access a different face, it adds manual labor and machine downtime. A part that can be machined in a single setup will always be more cost-effective than one requiring three or four.

Tolerances and Surface Finish

Precision comes at a price. Standard tolerances (e.g., ±0.1mm) are relatively easy to achieve. However, if your design calls for extremely tight tolerances (e.g., ±0.01mm), the cost will rise significantly. Achieving such precision demands more advanced machinery, specialized cutting tools, and a slower, more deliberate machining process. It also necessitates more rigorous quality control and inspection, often involving CMM (Coordinate Measuring Machine) verification. The same principle applies to surface finish requirements. A standard machined finish is inexpensive, but achieving a mirror-like or highly specific Ra value requires additional grinding, polishing, or lapping operations.

| Cost Driver | Low Impact | Medium Impact | High Impact |

|---|---|---|---|

| Material | Aluminum 6061, Acetal | Stainless Steel 304, Mild Steel | Titanium, PEEK, Inconel |

| Complexity | Simple block with thru-holes | Multiple faces, pockets, threads | Thin walls, complex 3D contours |

| Tolerances | Standard (e.g., ±0.1mm) | Tight (e.g., ±0.025mm) | Extremely Tight (e.g., < ±0.01mm) |

| Volume | 1000+ Units | 100-500 Units | 1-10 Units (Prototypes) |

Understanding the cost drivers is only half the battle. The next step is actively implementing strategies to reduce those costs without sacrificing the part’s essential function. This is where a Design for Manufacturability (DFM) mindset becomes invaluable.

Strategic Cost Reduction Through DFM

Applying DFM principles during the design phase is the most effective way to manage your budget for CNC machining services. Small adjustments can lead to substantial savings down the line.

Consolidate Parts and Standardize Features

Where possible, consider if multiple components in an assembly can be redesigned into a single, consolidated part. While this might slightly increase the complexity of the one piece, it often eliminates the need for assembly labor, fasteners, and potential tolerance stack-up issues, resulting in a lower total cost. Additionally, standardizing features across your design minimizes production time. For example, using the same hole size throughout a part means the machine doesn’t have to stop for a tool change. Similarly, designing with a consistent corner radius allows a single tool to complete more of the work efficiently.

Loosen Tolerances Where Possible

Critically review every tolerance on your drawing. Ask yourself: "Is this level of precision absolutely necessary for the part’s function?" Often, engineers apply a blanket tight tolerance to an entire part when only one or two features truly require it. By relaxing tolerances on non-critical features, you allow for faster machining speeds and reduce the chance of parts being rejected during inspection, saving both time and money.

Leveraging Production Volume

The economics of CNC machining are heavily influenced by quantity. It’s a classic case of economies of scale.

Understanding Batch Size

A significant portion of the cost for any CNC job is in the initial setup. This includes programming the CAM software, preparing the machine, and fabricating any custom fixtures. For a single prototype, this entire setup cost is applied to one part. However, for a run of 100 parts, that same setup cost is divided across all 100 units, drastically lowering the per-part price. In our projects at PTSMAKE, we’ve seen per-unit costs drop by over 50% when moving from a 10-piece run to a 100-piece run. When planning your project, consider future needs. Ordering a slightly larger batch might offer a much better value. This makes on-demand manufacturing a powerful tool for both prototyping and managing low-volume production runs effectively.

Effectively budgeting for CNC machining services hinges on understanding a few core cost drivers: material, complexity, tolerances, and volume. Simple but powerful design choices, such as standardizing features and relaxing non-critical tolerances, can yield significant savings. By applying a Design for Manufacturability mindset and strategically planning your batch sizes, you can strike the perfect balance between achieving high-quality results and meeting your project budget, ensuring your design intent is realized without unnecessary expense.

Lead Time Management and Production Scalability?

Have your projects ever been derailed by unexpected delays in part delivery? Does the leap from a single prototype to full-scale production feel like a huge, risky jump?

Effective lead time management is achieved through digital quoting, rapid prototyping, and optimized supplier networks. True production scalability comes from choosing a CNC machining services provider with a flexible manufacturing platform and proven capacity for both low and high-volume runs, ensuring a smooth transition from concept to market.

In CNC machining, time is a critical resource. Every day saved in the manufacturing cycle is a day gained in market advantage. Minimizing lead time is not just about getting parts faster; it’s about accelerating your entire product development lifecycle. Based on our work with clients at PTSMAKE, we’ve identified key strategies that consistently shorten the time from design to delivery.

Embracing Digital Quoting and Automation

The traditional quoting process, filled with back-and-forth emails and manual reviews, is a major bottleneck. Modern CNC machining services leverage digital quoting platforms. You can upload your CAD file, specify materials and finishes, and receive a quote, often with DFM (Design for Manufacturability) feedback, within hours or even minutes. This immediate feedback loop allows your engineering team to make necessary design adjustments quickly, avoiding costly delays down the line. It transforms procurement from a week-long waiting game into a swift, data-driven decision.

The Power of Rapid Prototyping

Getting a physical part in hand quickly is invaluable. Rapid prototyping allows you to test form, fit, and function early in the design process. A supplier who can deliver a high-fidelity prototype in a matter of days gives you a significant edge. This speed enables iterative design, where you can refine your product based on real-world testing rather than just simulations. This approach reduces the risk of discovering a critical design flaw after you’ve already invested in expensive tooling for mass production. A philosophy similar to Heijunka7 can be applied here, smoothing the workflow by tackling potential issues in small, manageable batches.

Optimizing Your Supplier Network

Relying on a single supplier for everything can be risky. A more resilient strategy is to partner with a provider who has a well-managed and optimized network. This doesn’t mean you have to juggle multiple contacts. Instead, your primary partner acts as a single point of contact, leveraging their network to manage capacity, access specialized capabilities, and mitigate risks. If one facility is at capacity, work can be seamlessly shifted to another without impacting your delivery schedule.

| Strategy | Traditional Approach | Optimized Approach |

|---|---|---|

| Quoting | Manual review, 2-5 day turnaround | Automated platform, instant or same-day quote |

| Prototyping | Long setup times, slow delivery | Dedicated rapid prototyping lines, 1-5 day delivery |

| Capacity | Single facility, fixed capacity | Vetted supplier network, flexible capacity |

| Risk | High risk of single-point failure | Low risk due to distributed manufacturing |

This networked approach provides the flexibility and reliability needed to keep projects on track, even when faced with unexpected challenges.

While speed is crucial for prototyping, scalability is what determines your long-term success. A partner who can produce one perfect prototype might not have the infrastructure, processes, or capacity to manufacture ten thousand units with the same quality and consistency. Assessing a provider’s scalability is a critical step in supplier selection, ensuring they can grow with you from the first part to full-scale production.

Evaluating a Provider’s Scalability

How can you tell if a supplier is truly scalable? It’s about asking the right questions and looking for specific evidence. Move beyond their marketing materials and dig into their operational capabilities. In past projects, we’ve guided clients through this evaluation process by focusing on a few key areas.

Key Questions for Assessing Scalability:

- Machine Capacity and Redundancy: How many machines do you have? What is your current utilization rate? Do you have redundant equipment to prevent downtime from halting production? A scalable partner has invested in a robust fleet of well-maintained equipment.

- Quality Control at Scale: How does your quality assurance process change from a 10-piece run to a 10,000-piece run? Look for documented processes, statistical process control (SPC), and automated inspection capabilities. Quality can’t be an afterthought; it must be built into the production workflow.

- Material Sourcing and Supply Chain: How do you manage your raw material inventory for large orders? Do you have established relationships with multiple material suppliers to avoid shortages? A strong supply chain is the backbone of scalable manufacturing.

The Benefits of Flexible Manufacturing Platforms

A flexible manufacturing platform is designed to adapt to changing demands efficiently. This is where modern CNC machining services truly shine. These systems use standardized tooling, automated workflows, and data-driven scheduling to switch between different jobs with minimal setup time. This agility offers tremendous benefits.

| Feature | Prototyping Phase | Production Phase |

|---|---|---|

| Volume | 1 – 100+ units | 1,000 – 100,000+ units |

| Lead Time | Days | Weeks |

| Cost Per Unit | Higher | Lower (due to economies of scale) |

| Process Focus | Speed and design iteration | Consistency, efficiency, and cost control |

A provider with this flexibility, like us at PTSMAKE, can use the same quality standards and core processes for your prototypes as they do for your production runs. This creates a seamless transition. The lessons learned during prototyping are directly applied to mass production, eliminating the need to re-qualify a new supplier and start from scratch. This continuity saves time, reduces risk, and ensures the parts you specified are the parts you receive, every single time.

To succeed, you must master both speed and scale. Efficient lead time management, driven by digital tools and smart supplier strategies, accelerates your development cycle. At the same time, true scalability requires a manufacturing partner with the proven capacity, robust quality systems, and flexible platforms to seamlessly transition your project from a single prototype to full-scale production. Choosing the right partner for CNC machining services is crucial for navigating this entire lifecycle effectively and bringing your product to market successfully.

Integrating CNC Machining with Other Manufacturing Technologies?

Have you ever designed a part that was too complex for traditional machining, but 3D printing alone couldn’t deliver the required precision or surface finish? This common challenge can stall innovation.

Integrating CNC machining with technologies like additive manufacturing creates a powerful hybrid approach. This method combines the design freedom of 3D printing with the precision of CNC to produce highly complex, accurate parts that were once impossible to make.

CNC machining and additive manufacturing (3D printing) are often seen as competing technologies. One is subtractive, carving material away, while the other is additive, building material up layer by layer. The real breakthrough, however, comes when we stop seeing them as rivals and start using them as partners. This combination, often called hybrid manufacturing, leverages the best of both worlds.

The Core Synergy: Additive Freedom Meets Subtractive Precision

Additive manufacturing excels at creating incredibly complex internal geometries, lightweight lattice structures, and consolidated parts that would be impossible to machine from a single block. Think of internal cooling channels in a mold insert or a custom medical implant with a porous surface. However, 3D-printed parts often lack the tight tolerances and smooth surface finishes required for high-performance applications.

This is where our expertise in cnc machining services becomes essential. After a part is 3D printed, we use CNC machining to finish critical features.

- Mating Surfaces: We machine flat and precise surfaces where the part needs to connect with other components.

- Holes and Threads: We drill, tap, and ream holes to exact specifications.

- Bearing Mounts: We finish critical diameters to ensure a perfect fit for bearings and other moving parts.

This two-step process allows for unparalleled design freedom without sacrificing mechanical precision.

Why Combine Technologies?

Combining these methods isn’t just about making difficult parts; it’s about making better parts. At PTSMAKE, we’ve guided clients through this process to achieve results that a single technology couldn’t deliver. The benefits are clear and measurable. The process of Directed Energy Deposition8 is a great example where material is added and can then be machined in a single setup.

| Feature | Additive Only | CNC Only | Hybrid Approach |

|---|---|---|---|

| Geometric Complexity | Very High | Limited | Very High |

| Internal Features | Excellent | Very Limited | Excellent |

| Tolerance Control | Moderate | Excellent | Excellent |

| Surface Finish | Fair to Good | Excellent | Excellent |

| Material Waste | Low | High | Low |

This approach allows us to produce components that are lighter, stronger, and more efficient than their traditionally manufactured counterparts.

The practical applications of hybrid manufacturing are already transforming some of the world’s most demanding industries. By strategically combining additive processes with precision cnc machining services, we can unlock new levels of performance and functionality. This isn’t just a theoretical concept; it’s a practical solution we implement for our clients to solve real-world engineering challenges.

Real-World Applications in Critical Industries

The benefits of a hybrid approach are most evident in sectors where performance and customization are non-negotiable.

Aerospace and Defense

In aerospace, every gram of weight matters. Hybrid manufacturing allows engineers to design components like turbine blades and structural brackets with optimized, organic shapes and internal lattice structures. These parts are 3D printed to near-net shape using high-performance metals like titanium or Inconel. Afterward, we use 5-axis CNC machining to finish the critical airfoil surfaces and mounting points to ensure they meet stringent aerospace tolerances. This results in lighter, stronger, and more fuel-efficient aircraft.

Medical Devices

The medical field benefits immensely from part customization. A surgeon might need a specific orthopedic implant that perfectly matches a patient’s anatomy. Using a hybrid process, a custom titanium implant can be 3D printed with a porous surface structure that encourages bone integration (osseointegration). We then step in at PTSMAKE to CNC machine the joint surfaces and connection points for a flawless fit and smooth articulation, improving patient outcomes.

Essential Post-Processing for Hybrid Parts

Creating the part is only half the battle. Post-processing is a critical stage that ensures the final component meets all functional and quality requirements.

is a key part of this, but other steps are often necessary.

| Post-Processing Step | Purpose | Impact on Final Part |

|---|---|---|

| Heat Treatment | Relieve internal stresses from printing, improve material properties. | Increases strength and durability. |

| CNC Machining | Achieve tight tolerances and fine surface finishes on critical features. | Ensures proper fit and function. |

| Surface Polishing | Improve surface smoothness beyond machining capabilities. | Reduces friction, improves aesthetics. |

| Coating (e.g., PVD) | Add wear resistance, biocompatibility, or other surface properties. | Enhances performance and lifespan. |

Each step is carefully planned based on the part’s final application. In our past projects, this integrated workflow has been the key to turning an innovative design into a reliable, high-performance product.

In summary, integrating CNC machining with other technologies, particularly additive manufacturing, is not a compromise but a powerful synergy. This hybrid approach overcomes the limitations of any single method. It allows for the creation of parts with immense geometric freedom and complex internal features, while our precision cnc machining services ensure that all critical surfaces and dimensions meet the tightest tolerances. This unlocks new possibilities for innovation, especially in demanding fields like aerospace and medical devices.

Key Considerations for Design Engineers Using CNC Machining Services.

Ever wonder why a part that looks perfect in CAD becomes a manufacturing headache? Have you faced unexpected costs or delays because of a small design oversight that ballooned into a major production issue?

The key is balancing design intent with manufacturability. This involves clear communication with your CNC machining services provider, specifying only necessary critical features, and anticipating production constraints early in the design phase for optimal cost, quality, and speed.

How to Collaborate with Your CNC Service Provider

Effective collaboration is not just about sending a CAD file and waiting for a quote. It’s a two-way street that starts long before a machine is powered on. In our experience at PTSMAKE, the most successful projects begin with a conversation.

Pre-Design Consultation

Before you finalize your design, talk to your manufacturing partner. A quick discussion can save you weeks of redesigns later. Share your project goals, including the part’s function, mating components, and expected loads. This context helps the machinists understand which features are truly critical and where they might suggest DFM (Design for Manufacturability) improvements. For example, they might recommend a different material that offers similar performance at a lower cost or is easier to machine.

Providing Clear and Complete Technical Drawings

Your CAD model shows the geometry, but the technical drawing tells the full story. It’s the primary communication tool for our machinists. A well-documented drawing is essential for any professional cnc machining services.

Here are the essentials to include:

- Critical Dimensions and Tolerances: Only apply tight tolerances where absolutely necessary. Over-tolerancing is one of the biggest drivers of unnecessary cost.

- Material and Finish Specifications: Clearly state the material type (e.g., Aluminum 6061-T6), any required heat treatments, and the desired surface finish (e.g., Ra 1.6 μm).

- GD&T Callouts: Use Geometric Dimensioning and Tolerancing to define functional requirements like flatness, perpendicularity, and position. This is more precise than simple linear tolerances. Establishing a clear datum9 reference frame is the foundation for all GD&T.

A common pitfall is ambiguity. For instance, simply stating "deburr all edges" is vague. Specifying "break all sharp edges 0.2mm max" is a clear, actionable instruction.

| Annotation Type | Example | Purpose |

|---|---|---|

| Tolerance | 10.00 ±0.05 mm | Defines the acceptable range for a dimension. |

| Surface Finish | Ra 1.6 μm | Specifies the average roughness of a surface. |

| GD&T | ⌖|ø0.1(M)|A|B(M) | Controls the position of a feature relative to datums. |

| Material Spec | AL 6061-T6 | Calls out the exact raw material to be used. |

Good communication transforms a simple supplier into a valuable manufacturing partner.

Balancing Design Intent with Practical Manufacturability

As a design engineer, your primary goal is to create a part that fulfills its function perfectly. However, the most elegant design is useless if it cannot be manufactured efficiently and affordably. This is where the art of balancing ideals with reality comes into play.

Understanding Manufacturing Constraints

Every manufacturing process has limitations. For CNC machining, these constraints are dictated by tool access, tool size, material properties, and machine capabilities.

- Tool Access: Can a cutting tool physically reach all the surfaces that need to be machined? Deep pockets with small openings are a classic challenge.

- Internal Corners: All internal corners will have a radius left by the cutting tool. Designing for a specific, standard-sized radius (e.g., 3mm) is much cheaper than demanding a sharp corner, which requires a secondary process like EDM.

- Wall Thickness: Very thin walls can be difficult to machine without warping or vibrating, especially in metals. A good rule of thumb is to keep wall thicknesses above 0.8mm for metals and 1.5mm for plastics where possible.

In a past project with a client in the robotics industry, the initial design had several deep, narrow channels with sharp internal corners. While perfect in theory, it would have required specialized tooling and extremely long cycle times. By collaborating with them, we suggested slightly widening the channels and adding a small corner radius. This minor change, which had no impact on the part’s function, reduced the machining cost by nearly 40%.

Leveraging Provider Expertise

Your CNC machining services provider is a deep well of practical knowledge. They understand how design features translate into machine time, tool wear, and ultimately, cost. Don’t be afraid to ask for their input during the design phase.

| Design Choice | Lower-Cost Alternative | Reason for Savings |

|---|---|---|

| Sharp Internal Corner | Add a Radius | Eliminates need for secondary operations (EDM). |

| Very Tight Tolerance | Loosen to Standard | Reduces machine time, inspection, and scrap rate. |

| Complex, Single Part | Design as a Multi-part Assembly | Can simplify machining and reduce material waste. |

| Non-Standard Hole Size | Use Standard Drill Size | Avoids custom tooling costs. |

Think of DFM feedback not as a critique of your design, but as a collaborative effort to achieve the same functional goal in a more efficient way. This partnership approach ensures you get the best possible part at the best possible price.

To get the best results from CNC machining services, design engineers must focus on early and clear collaboration. This involves discussing design intent with your provider before finalizing plans, providing unambiguous technical drawings, and specifying only the most critical features. Balancing your design vision with practical manufacturing constraints, like tool access and wall thickness, is crucial. Leveraging your provider’s DFM expertise doesn’t compromise your design; it optimizes it for cost-effective and efficient production.

Take Your CNC Machining Projects Further with PTSMAKE

Discover why top engineers and procurement managers trust PTSMAKE for precision cnc machining services—from prototypes to high-volume production. Ready to elevate your parts’ quality, optimize lead time, and ensure reliability? Submit your RFQ now and experience our expert support firsthand!

Learn more about how the science of measurement ensures your parts meet exact specifications. ↩

Learn more about the core principles of measurement that ensure precision in all manufacturing processes. ↩

Discover how a material’s directional properties can influence its machinability and final part integrity in our expert guide. ↩

Learn how this directional property affects material behavior and your design choices. ↩

Click to understand this symbolic language used on drawings to define part geometry and its allowable variation. ↩

Discover how this material property can unexpectedly impact machining outcomes and how to design around it effectively. ↩

Learn how this production leveling technique can help you reduce waste and improve manufacturing predictability. ↩

Learn more about this advanced hybrid manufacturing process for building and repairing metal parts. ↩

Learn how defining datums correctly can improve part consistency and reduce ambiguity in your technical drawings. ↩