You’re trying to manufacture complex parts with tight tolerances, but traditional 3-axis CNC machining keeps falling short. Multiple setups mean longer lead times, higher costs, and quality inconsistencies that put your projects at risk.

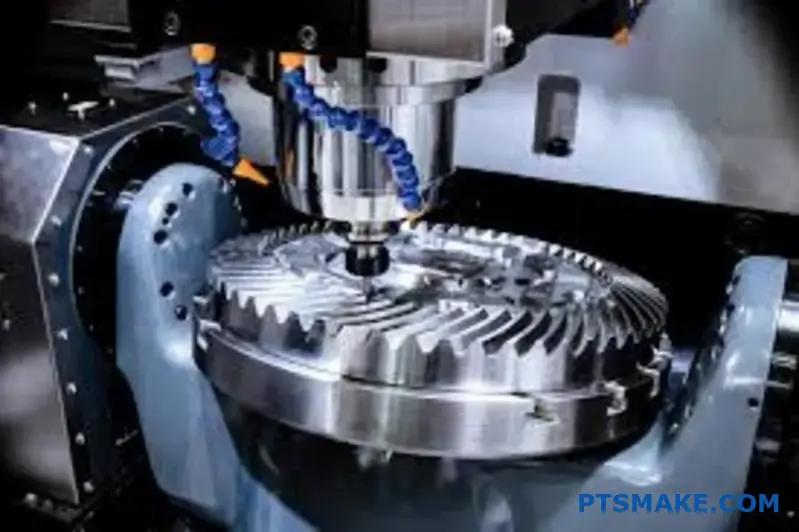

5-axis CNC machining enables simultaneous movement across five different axes, allowing manufacturers to produce complex geometries with superior precision, shorter lead times, and reduced costs compared to traditional 3-axis methods.

I’ve worked with countless procurement managers and engineers who struggle with the same challenge: finding a manufacturing solution that delivers both precision and efficiency for complex parts. The difference between success and costly delays often comes down to choosing the right machining approach. Let me walk you through exactly how 5-axis CNC machining solves these challenges and why it might be the game-changer your next project needs.

What Sets 5 Axis CNC Machining Apart?

Have you ever designed a part with complex curves and undercuts, only to find that traditional manufacturing methods require multiple, costly setups that compromise accuracy?

5 axis CNC machining sets itself apart by moving a part or cutting tool along five different axes simultaneously. This capability allows for the creation of incredibly complex geometries in a single setup, drastically improving precision, efficiency, and design freedom compared to traditional 3-axis methods.

Beyond the X, Y, and Z: Introducing Rotation

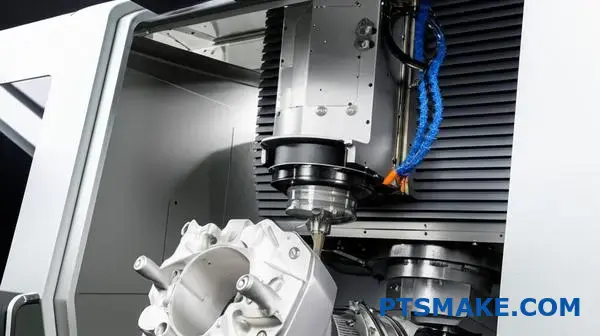

Traditional 3-axis CNC machines operate on a simple principle, moving the cutting tool along the X, Y, and Z linear axes. While effective for simpler, more prismatic parts, this approach falls short when dealing with components that have deep cavities or complex curves. This is where 5-axis machining fundamentally changes the game. It adds two rotational axes, typically the A and B axes, which rotate around the X and Y axes, respectively. This allows the cutting tool to approach the workpiece from virtually any angle.

The Single-Setup Advantage

The most significant operational difference is the ability to machine a complex part in a single setup. With a 3-axis machine, a part with features on multiple faces would require the operator to stop the machine, unclamp the workpiece, manually re-fixture it in a new orientation, and then recalibrate the machine. Each new setup introduces the potential for human error, leading to slight misalignments that can stack up and compromise the final part’s tolerance. In our past projects at PTSMAKE, we’ve seen how eliminating these extra steps not only speeds up production but also significantly increases part-to-part consistency. The machine maintains a constant reference point, ensuring every feature is perfectly aligned relative to the others. A shorter, more efficient toolpath1 means less wear on the tools and a better surface finish.

| Feature | 3-Axis CNC Machining | 5-Axis CNC Machining |

|---|---|---|

| Movement | X, Y, Z linear axes | X, Y, Z linear axes + 2 rotational axes |

| Setups | Multiple setups for complex parts | Single setup for most complex parts |

| Geometry | Best for prismatic, simpler parts | Ideal for complex curves and contours |

| Accuracy | Good, but risks error with re-fixturing | Superior, due to single setup |

Why This Matters for Advanced Engineering

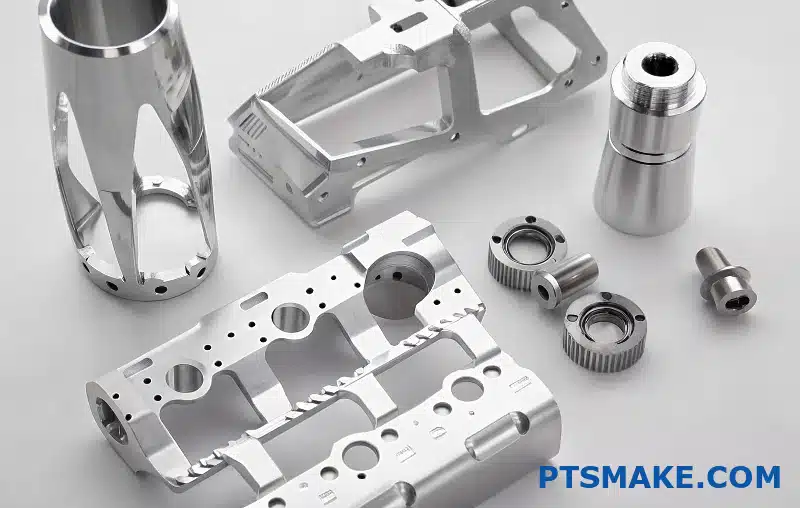

The benefits of 5 axis CNC machining extend far beyond just operational efficiency; they directly empower engineers and designers to innovate. When you’re not constrained by the manufacturing limitations of 3-axis machines, you can design parts that are stronger, lighter, and more organically shaped. This is particularly crucial in industries where performance is non-negotiable.

The Impact on Demanding Industries

In the aerospace sector, for example, every gram matters. 5-axis machining allows for the creation of monolithic parts—machining a single block of material into a complex component that might have previously required assembling multiple smaller pieces. This eliminates weak points like welds or fasteners and results in a stronger, lighter final part, such as an impeller or a turbine blade with optimized aerodynamic surfaces. Similarly, in the medical field, custom orthopedic implants must perfectly match a patient’s anatomy. The ability to machine complex, organic shapes with high precision makes 5 axis CNC machining an indispensable technology for creating these life-changing devices.

From Prototype to Production

This technology accelerates the entire product development cycle. When we work with clients on prototypes, 5-axis capabilities mean we can produce a functional, high-fidelity model in a fraction of the time it would take with multiple setups. The design you create is the part you get, without compromises. This allows for faster design iterations and a quicker path to market. This capability ensures that the final production parts, whether for robotics, automotive, or consumer electronics, meet the exact design intent without costly delays or quality issues.

5 axis CNC machining transforms manufacturing by enabling multi-axis movement in a single setup. This produces complex parts with unmatched accuracy and finish, empowering engineers in advanced industries and streamlining the entire journey from innovative design to market-ready product.

How Single-Setup Machining Reduces Production Cycles?

Are you constantly battling project delays caused by multiple, time-consuming machine setups? The endless cycle of repositioning and re-fixturing parts can quickly derail even the best-laid production schedules.

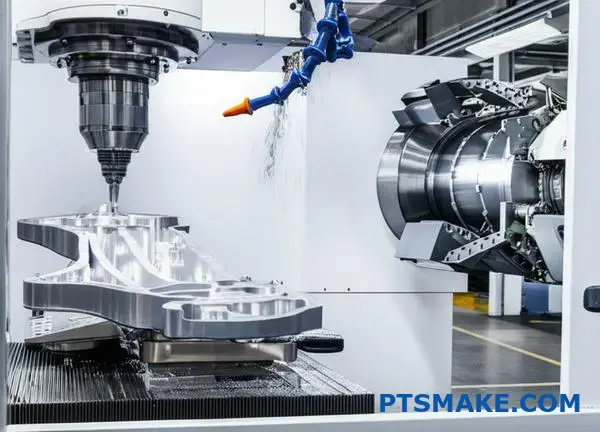

5-axis CNC machining revolutionizes this process through single-setup, or "Done-in-One," manufacturing. By machining complex shapes in a single clamping, it eliminates the downtime associated with manual repositioning, drastically reducing the overall production cycle and ensuring faster, more reliable delivery.

The core advantage of 5-axis technology in speeding up production lies in its ability to minimize non-value-added time. In traditional 3-axis machining, a complex part might require six or more separate setups to machine each face. Each setup involves stopping the machine, manually un-clamping the part, creating a new fixture, re-clamping the part, and re-calibrating the machine’s starting point. This process is not only slow but also introduces a high risk of human error with every single touch.

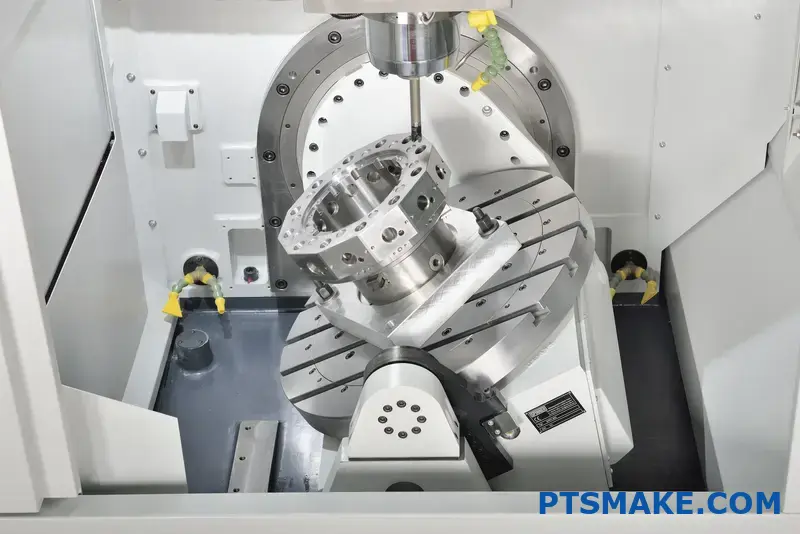

The "Done-in-One" Principle

5-axis machining changes the game entirely. The machine’s two additional rotational axes (the A and B axes) tilt the workpiece or the cutting tool, allowing access to five sides of the part in a single clamping. This means the entire machining process for a complex part can often be completed without any manual intervention once the cycle starts. The machine’s Kinematic Chain2 is what allows for this coordinated, multi-axis movement, turning what was once a series of disjointed steps into one fluid operation.

Comparing Setup Time: 3-Axis vs. 5-Axis

In our work at PTSMAKE, we’ve seen the difference firsthand. Let’s compare the process for a moderately complex component.

| Process Step | Traditional 3-Axis | 5-Axis CNC Machining |

|---|---|---|

| Initial Setup | 45 minutes | 60 minutes |

| Subsequent Setups | 4 x 30 minutes = 120 minutes | 0 minutes |

| Total Setup Time | 165 minutes | 60 minutes |

| Risk of Error | High (multiple re-calibrations) | Low (single calibration) |

As the table shows, while the initial 5-axis setup might be slightly more involved, it completely eliminates the time spent on all subsequent setups. This saved time compounds significantly, slashing hours or even days off the total lead time.

Beyond simply reducing setups, 5-axis machining shortens lead times by optimizing other critical areas of the production workflow. It streamlines the entire process from programming to final inspection, creating a more efficient and predictable manufacturing environment.

Reduced Tooling and Fixturing Complexity

With 3-axis machining, each new orientation of the part often requires a unique, custom-made fixture to hold it securely. Designing and manufacturing these fixtures adds significant time and cost to a project before a single chip is even cut. 5-axis machining, however, often allows for much simpler workholding solutions. Since the machine can orient the part itself, a single, versatile vise or a straightforward fixture plate is often sufficient. This eliminates the "pre-production" lead time associated with fixture development.

Enhanced Accuracy Leads to Less Rework

Every time a part is unclamped and repositioned, the potential for error increases. Even the slightest misalignment can lead to features being out of tolerance, resulting in costly and time-consuming rework or, in the worst case, scrapped parts. These unexpected delays are a primary cause of missed deadlines.

The Cumulative Effect of Errors

| Number of Setups | Potential for Positional Error | Impact on Lead Time |

|---|---|---|

| 1 (5-Axis) | Minimal | Negligible |

| 3 (3-Axis) | Moderate | Potential for minor rework |

| 6+ (3-Axis) | High | High probability of rework/scrap |

By completing the part in a single setup, 5-axis CNC machining maintains a single point of reference for all features. This inherent accuracy significantly reduces the likelihood of errors, ensuring parts are made correctly the first time. For procurement managers like Matthew, this translates directly to greater reliability and confidence in meeting project timelines. At PTSMAKE, this is how we help our clients move from prototype to production with maximum speed and minimum friction.

In short, 5-axis CNC machining accelerates production by enabling "Done-in-One" manufacturing. This single-setup approach eliminates manual repositioning, simplifies fixturing needs, and improves accuracy to minimize rework, resulting in significantly shorter and more dependable lead times for complex parts.

Ensuring Consistent Quality and Tight Tolerances.

Have you ever had a critical component fail inspection due to a minor tolerance deviation? That single setback can delay your entire production schedule and strain your budget.

5-axis CNC machining ensures consistent quality by minimizing setups, which drastically reduces the potential for cumulative error. Its ability to use shorter, more rigid tools and approach the workpiece from optimal angles delivers superior accuracy, repeatability, and surface finish for demanding parts.

The Pillars of Precision: Accuracy and Repeatability

The primary reason 5-axis CNC machining delivers such high quality is its ability to machine complex shapes in a single setup. In traditional 3-axis machining, a part with features on multiple faces requires the operator to stop the machine, unclamp the part, rotate it, and then meticulously re-align it for the next operation. Each one of these steps introduces a small but significant risk of error. When you have three, four, or even five setups, these tiny errors stack up, potentially pushing a part out of its specified tolerance.

At PTSMAKE, we leverage the "one-and-done" approach of 5-axis machining to eliminate this cumulative error. By maintaining a single point of reference, we ensure that every feature is machined in precise relation to the others. This is fundamental for achieving the tight tolerances required in industries like aerospace and medical devices. This single-setup principle is also the key to unwavering repeatability across an entire production run. Because the process is automated and removes manual re-fixturing, the first part is virtually identical to the hundredth. Machine calibration, not operator intervention, becomes the dominant factor in consistency. Our investment in machines with advanced Volumetric Compensation3 allows us to maintain this high level of precision over time.

| Feature | 3-Axis Machining | 5-Axis CNC Machining |

|---|---|---|

| Setups for Complex Parts | Multiple (3-5+) | Single (or Two) |

| Primary Source of Error | Cumulative error from re-fixturing | Minimized; primarily machine calibration |

| Part-to-Part Consistency | Lower; operator dependent | Higher; machine controlled |

| Ideal for… | Simpler geometries | Complex, high-tolerance parts |

This table clearly shows why for critical components, 5-axis technology is not just an option, but a necessity for guaranteeing quality.

Achieving Flawless Surfaces and Complex Geometries

Beyond accuracy, the surface finish of a part is often a critical engineering requirement, not just an aesthetic one. A smooth, flawless surface can be essential for sealing, reducing friction, or improving fatigue life. This is another area where 5-axis CNC machining excels.

The Advantage of Optimal Tool Engagement

A 5-axis machine can tilt the tool or rotate the workpiece to maintain a perfect angle between the cutter and the part’s surface. This allows us to use the side of the tool for milling, rather than just the tip. This technique, sometimes called flank milling, results in a significantly better surface finish because it eliminates the cusp marks often left by ball-end mills in 3-axis operations. In our experience at PTSMAKE, this capability can reduce or even eliminate the need for secondary finishing operations like polishing, saving both time and cost.

Shorter Tools Mean Higher Rigidity

To reach deep pockets or angled features on a 3-axis machine, you often need to use very long, slender tools. These tools are prone to vibration and deflection, which negatively impacts both accuracy and surface finish. With 5-axis movement, we can tilt the head or the part itself, allowing us to use much shorter, more rigid tools to reach the same areas. A shorter tool is inherently more stable. This stability translates directly into cleaner cuts, sharper corners, and the ability to hold tighter tolerances on complex part features, which is a non-negotiable for many of our clients.

5-axis CNC machining provides superior quality by reducing setups, which boosts accuracy and repeatability. By enabling optimal tool angles and the use of shorter, more rigid tools, it also achieves a finer surface finish, consistently meeting the tight tolerances required in critical manufacturing industries.

Cost-Effectiveness: Reducing Total Manufacturing Expenses.

Have you ever scrutinized a final bill and been baffled by the high labor and tooling costs, even for what seemed like a straightforward component?

The core financial benefit of 5-axis CNC machining is its ability to lower total manufacturing expenses. It achieves this by drastically reducing the number of setups, simplifying fixturing needs, and optimizing material removal, delivering significant savings in both labor and tooling costs for a clear ROI.

The most immediate cost saving with 5-axis machining comes from consolidating operations. Traditional manufacturing, often relying on 3-axis machines, requires multiple setups to access different faces of a complex part. Each time a part is repositioned, costs accumulate. You pay for the operator’s time to stop the machine, unclamp the part, set up a new fixture, and recalibrate the machine’s zero point. This process is not just time-consuming; it also introduces a higher risk of error with each new setup.

With 5-axis CNC machining, we can often machine five of a part’s six sides in a single clamping. This "done-in-one" approach is a game-changer for cost efficiency.

Fewer Setups, Lower Labor Costs

Think of it this way: a complex part that might require four separate setups on a 3-axis machine could be completed in just one on a 5-axis machine. The machine’s ability to tilt the workpiece or the cutting tool eliminates the need to manually reorient the part. This directly translates into fewer labor hours billed to your project. Furthermore, fewer setups improve the overall volumetric accuracy4 of the final component, as the part remains in a single, stable position for most of the machining process.

Simplified Fixturing

Fewer setups also mean less investment in complex, custom fixturing. For a 3-axis process involving multiple operations, you might need several different jigs and fixtures, each designed to hold the part in a specific orientation. These custom fixtures add to the upfront tooling costs. In contrast, a 5-axis setup often requires only one, often simpler, fixture, reducing both the cost and the lead time associated with tooling production.

| Aspect | 3-Axis Machining | 5-Axis Machining | Impact on Total Cost |

|---|---|---|---|

| Setups for Complex Part | 3-5 setups | 1-2 setups | Significantly Reduced Labor |

| Fixturing Required | Multiple custom jigs | One simple fixture | Lower Tooling Expenditure |

| Operator Intervention | High (for each setup) | Low (primarily monitoring) | Lower Risk & Labor Costs |

| Lead Time | Longer | Shorter | Faster Time-to-Market |

Beyond setups, 5-axis technology fundamentally changes how we remove material, leading to further savings in tooling and time. The ability to control the tool’s angle relative to the part surface offers significant advantages that are not possible with a fixed, 3-axis approach. This optimization directly impacts cycle time and the longevity of your cutting tools, both of which are critical components of the total manufacturing cost.

Optimized Tool Paths and Tool Life

In 5-axis machining, we can continuously adjust the tool’s angle to maintain an optimal cutting position. This allows us to use shorter, more rigid cutting tools. A shorter tool is less susceptible to vibration and deflection, which are common issues in deep-pocket milling on 3-axis machines where long, fragile tools are necessary. Less vibration means we can increase cutting speeds and feeds, drastically reducing the time it takes to machine a feature. In our experience at PTSMAKE, this can shorten cycle times by 20-30% on suitable components.

This enhanced stability also extends the life of the cutting tools. By maintaining a constant, optimal engagement with the material, we prevent excessive wear and tear. This means tools last longer and require fewer replacements over the course of a production run, lowering the overall tooling cost.

Superior Surface Finish

The optimized tool angle also results in a better surface finish. By using the side of the cutting tool instead of just the tip (a technique known as swarf milling), we can create smooth, finished surfaces in a single pass. This can often eliminate the need for secondary finishing operations like grinding or hand polishing, which are labor-intensive and add significant cost. This capability is especially valuable for parts with complex curved surfaces, such as turbine blades or medical implants, where achieving a high-quality finish is paramount.

In essence, 5-axis CNC machining drives cost-effectiveness by minimizing setups, which directly cuts down on labor and fixturing expenses. It further reduces costs by enabling optimized tool paths for faster material removal, longer tool life, and superior surface finishes that reduce secondary operations.

Complex Part Geometries: Unlocking Design Freedom.

Have your most innovative designs ever been shelved because they were deemed "unmanufacturable"? Are you tired of compromising your vision to fit within the constraints of traditional machining methods?

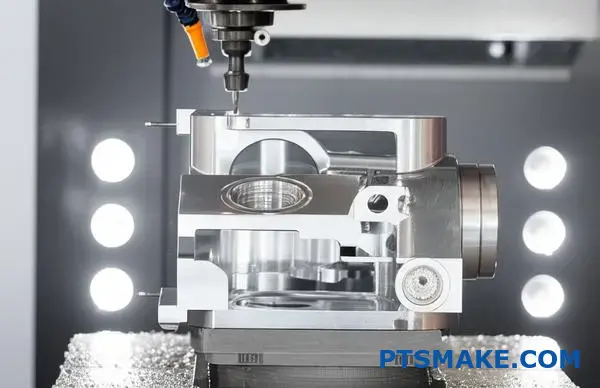

Five-axis CNC machining shatters these limitations. By allowing the cutting tool to approach a workpiece from multiple angles in a single setup, it makes complex features like undercuts, angled holes, and intricate curved surfaces not just possible, but practical to produce with exceptional precision.

Traditional 3-axis machining operates on a simple XYZ plane, which is effective for basic parts but falls short when faced with genuine complexity. This is where the advanced capabilities of 5-axis CNC machining truly shine, turning design challenges into manufacturing triumphs. In past projects at PTSMAKE, we’ve guided many clients through this transition, enabling them to realize designs they once thought were impossible.

Mastering Undercuts and Deep Cavities

Undercuts are features that cannot be machined from a single top-down approach. With a 3-axis machine, creating them often requires flipping the part and running multiple operations, which introduces the risk of misalignment and increases production time. A 5-axis machine solves this elegantly by tilting the workpiece or the tool head, allowing the cutter to reach underneath ledges and into deep, angled cavities without a new setup. This single-setup approach, a core benefit of 5-axis CNC machining, is crucial for maintaining tight tolerances on features that are relative to one another.

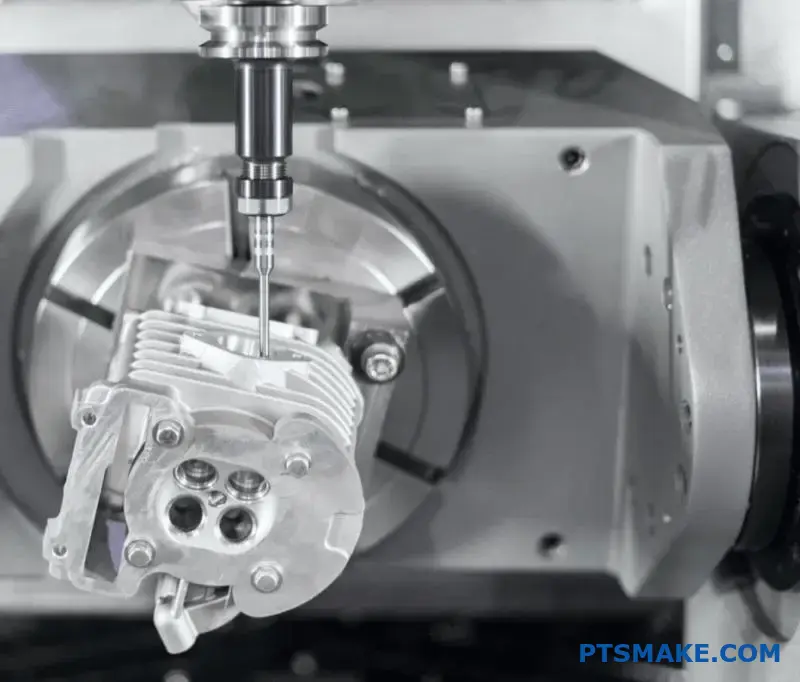

Precision in Angled Holes and Passages

Drilling holes that are not perpendicular to the part’s main faces is another common hurdle. Traditional methods might involve creating custom fixtures to hold the part at the correct angle—a costly and time-consuming process.

Here’s a comparison based on our project experience:

| Feature | 3-Axis Machining | 5-Axis CNC Machining |

|---|---|---|

| Setup | Requires custom fixtures or multiple setups | Single setup |

| Accuracy | Prone to cumulative errors | High precision and repeatability |

| Cycle Time | Longer due to manual intervention | Significantly faster |

| Cost | Higher tooling and labor costs | Lower overall cost for complex parts |

With 5-axis technology, the machine simply orients the part or tool to the precise angle needed and drills the hole. This is not just about efficiency; it’s about achieving a level of accuracy that is difficult to replicate with constant re-fixturing. This process, known as Simultaneous 5-axis Machining5, is fundamental for components with complex internal fluid or gas passages, like those found in aerospace and medical devices.

The freedom granted by 5-axis technology extends beyond just reaching difficult spots; it fundamentally changes how designers can think about form and function. It encourages a shift from designing for manufacturability to manufacturing for optimal design performance. This capability has been a game-changer for clients we work with at PTSMAKE, particularly in the robotics and automotive sectors where performance and weight are critical.

Achieving Organic Curves and Flawless Surfaces

Creating smooth, continuously curving surfaces—often called organic or biomimetic shapes—is a significant challenge for 3-axis machines. They approximate curves by making a series of tiny, straight-line cuts, which can leave a stepped or "scalloped" finish that requires extensive manual polishing. In contrast, 5-axis machining allows the tool to maintain a constant, tangential contact point with the surface.

The Tangential Advantage

This continuous tool engagement results in a superior surface finish directly off the machine. It allows for the creation of components that are not only aesthetically pleasing but also functionally superior, such as:

- Aerodynamic surfaces: Turbine blades, impellers, and automotive body panels.

- Ergonomic shapes: Medical implants, custom prosthetics, and high-performance consumer products.

The Power of Part Consolidation

Perhaps one of the most transformative benefits is the ability to consolidate multiple, simpler components into a single, complex part. Instead of designing, manufacturing, and assembling several individual pieces, an engineer can design one integrated component.

| Aspect | Multi-Part Assembly | Consolidated 5-Axis Part |

|---|---|---|

| Part Count | High | Single part |

| Assembly | Required, adding time and labor | None |

| Strength | Weaker due to joints and fasteners | Inherently stronger, monolithic structure |

| Weight | Heavier | Lighter |

| Failure Points | Multiple (welds, bolts, seams) | Minimal |

This strategy reduces assembly time, eliminates potential points of failure at joints or welds, and often results in a lighter, stronger, and more reliable final product. It’s a powerful approach we’ve used to help clients streamline their supply chains and improve product integrity.

In essence, 5-axis CNC machining liberates designers from the constraints of right angles and simple planes. It empowers the creation of intricate parts with undercuts, angled features, and flowing organic surfaces, enabling true innovation by manufacturing complex geometries directly from your design file.

Supplier Selection: What to Look for in a 5 Axis CNC Partner?

Have you ever been burned by a supplier who promised the world but delivered headaches? Choosing a partner based solely on a low price can quickly lead to project delays, communication nightmares, and parts that don’t meet spec.

When selecting a 5 axis CNC partner, you must evaluate four key areas: their machine capability and technology, their quality management systems, their communication efficiency, and their experience with international standards. A strong partner excels in all four, ensuring reliability from prototype to production.

Choosing a 5 axis CNC machining partner goes far beyond simply confirming they own a 5-axis machine. The real value lies in their technical depth, the condition of their equipment, and the skill of the people operating it. A cheap machine in the wrong hands produces expensive scrap.

Assessing Core Technical Capabilities

The first step is to look at the hardware itself. Are their machines from reputable brands like DMG Mori, Haas, or Mazak? In our experience at PTSMAKE, we’ve found that high-quality machines provide better accuracy and reliability. Ask about their maintenance schedule; a well-maintained machine is less likely to experience unexpected downtime that could delay your project. A supplier who can proudly show you their maintenance logs is one who takes precision seriously.

Evaluating Programming and Staff Expertise

A powerful machine is useless without a skilled programmer. The complexity of 5-axis machining requires sophisticated CAM software and operators who can optimize toolpaths to reduce cycle times and improve surface finishes. You should inquire about their team’s experience with parts similar to yours in complexity and material. We often find that verifying complex geometries requires advanced inspection skills, including CMM programming6, to ensure every feature matches the CAD model perfectly.

Material and Tooling Knowledge

A supplier’s expertise with different materials is crucial. Each metal or plastic behaves differently during machining, and the right tooling and cutting strategy can make all the difference.

| Material | Key Machining Challenge | Recommended Approach |

|---|---|---|

| Aluminum 6061 | Gummy texture can lead to tool buildup. | Use high-speed machining (HSM) with sharp, coated carbide tools. |

| Stainless Steel 316 | Work hardens quickly, causing tool wear. | Employ lower cutting speeds, high feed rates, and constant coolant flow. |

| Titanium (Ti-6Al-4V) | Poor thermal conductivity leads to high heat at the tool tip. | Use high-pressure coolant and specific tool geometries to manage heat. |

Beyond the machines and programmers, a supplier’s operational processes are what separate the great partners from the merely adequate. Robust quality systems and clear, efficient communication are the foundation of a successful manufacturing relationship, especially when dealing with complex 5 axis CNC machining projects. If a supplier can’t get these right, even the best technology won’t prevent problems.

Deconstructing the Quality Management System

Don’t just ask if they have an ISO 9001 certification; ask how they implement it on the shop floor. What does their inspection process look like? A reliable partner should have a multi-stage inspection protocol, including first article inspection (FAI) for new parts, in-process checks to catch deviations early, and a final inspection report that ships with your parts. At PTSMAKE, we provide detailed reports with key dimensional data, giving our clients full confidence that their specifications have been met.

Communication and Project Management

Effective communication can make or break a project. Is there a dedicated project manager or single point of contact for your account? How quickly do they respond to technical questions or requests for updates? Clear, proactive communication prevents misunderstandings and keeps the project on track. Vague answers or slow responses are often early warning signs of internal disorganization. A good partner should also provide Design for Manufacturability (DFM) feedback, offering suggestions to improve your part’s design for better efficiency and lower cost.

Red Flags in Supplier Communication

| Communication Red Flag | Potential Impact on Your Project |

|---|---|

| Vague or Inconsistent Answers | The supplier may not fully understand your requirements. |

| Slow Response Times (>24h) | Delays in decision-making and problem-solving. |

| No Dedicated Point of Contact | Confusion, missed details, and lack of accountability. |

| Resistance to DFM Feedback | Lost opportunities for cost savings and improved part quality. |

Selecting the right 5 axis CNC partner requires looking past the quote. A thorough evaluation of their machine technology, quality systems, communication practices, and experience with global standards is essential. This diligence ensures you find a reliable partner committed to delivering precision and value.

Overcoming Common Challenges in 5 Axis CNC Machining?

Have you ever felt that complex 5-axis toolpaths are a constant battle against errors? Or that you’re just one wrong move away from a costly machine collision or scrapped part?

The key to overcoming common 5-axis CNC machining challenges lies in a combined strategy: utilizing advanced CAM software with rigorous simulation, establishing robust process controls, and empowering highly skilled operators who understand the machine’s intricacies.

Mastering 5-axis machining is less about avoiding challenges and more about having the right systems to conquer them. The increased complexity compared to 3-axis work introduces more variables, but these can be managed effectively with a modern approach that blends technology and human expertise.

Taming Programming Complexity

The initial hurdle for many is programming. Unlike simpler setups, 5-axis toolpaths involve simultaneous rotational and linear movements, dramatically increasing the risk of collisions between the tool, holder, workpiece, fixture, and machine components. This is where advanced CAM (Computer-Aided Manufacturing) software becomes indispensable. Modern systems offer sophisticated toolpath strategies designed specifically for 5-axis operations, such as swarf milling and multi-axis contouring. More importantly, they provide integrated simulation environments. Before any code reaches the machine, we can run a complete digital simulation. This isn’t just a simple line drawing; it’s a virtual representation of the entire machining process, checking for gouges, collisions, and inefficient movements. It models the machine’s unique kinematics7, ensuring the simulation accurately reflects reality.

The Power of G-Code Verification

A common point of failure can occur during post-processing, where the CAM toolpath is translated into the specific G-code your machine understands. A poorly configured post-processor can introduce subtle errors that the CAM simulation might not catch. To mitigate this, we rely on a final step: G-code verification. This process simulates the actual G-code, not just the CAM data, providing the ultimate pre-flight check before pressing "cycle start."

| Verification Method | Primary Focus | Key Benefit |

|---|---|---|

| CAM Toolpath Simulation | Cutter path against the part model | Catches gouging and basic programming mistakes. |

| Machine Simulation | Full machine movement (tool, holder, fixtures) | Prevents costly collisions with machine components. |

| G-Code Verification | The final, machine-readable code | Confirms post-processor accuracy and catches hidden errors. |

This multi-layered verification process is a cornerstone of reliable 5-axis CNC machining, transforming potential disasters into predictable successes.

While technology provides a powerful safety net, it cannot replace the experience and intuition of a skilled machinist. The most sophisticated software in the world can’t account for every real-world variable. At PTSMAKE, we view our operators as the final and most crucial element of process control.

The Irreplaceable Human Element

A skilled operator does more than just load parts and press buttons. They are attuned to the machine’s feedback. They can hear the subtle change in sound that indicates tool wear or excessive chatter. They monitor chip evacuation to prevent re-cutting, which can lead to poor surface finish or tool breakage. They have the authority and knowledge to make real-time adjustments, such as using feed rate overrides to optimize cutting conditions on the fly. This active engagement is critical, especially when machining exotic materials or complex geometries for the first time. In our experience with past projects, investing in continuous operator training yields a higher return in quality and efficiency than any single piece of equipment.

Building Robust and Repeatable Processes

Achieving a perfect part once is good; achieving it every time is the goal. This requires robust process controls that standardize the entire workflow.

Standardized Setups

Every job begins with a documented setup sheet. This specifies the exact workholding strategy, tool data (including length and diameter offsets), and probing cycles to establish precise work coordinate systems. By minimizing variables from one setup to the next, we ensure that the program runs the same way every time.

In-Process Verification

For parts with critical tolerances, we often program in-process probing cycles. The machine will pause cutting, use a probe to measure a feature it just machined, and compare that measurement to the nominal value. If any deviation is detected, the system can automatically apply offsets to correct it on subsequent features, ensuring the final part is well within specification without manual intervention. This proactive approach to quality control is fundamental to successful 5-axis CNC machining.

Successfully navigating 5-axis machining relies on uniting advanced CAM software and simulation with the irreplaceable expertise of skilled operators. This synergy, supported by robust process controls for consistency, is the foundation for producing complex, high-quality parts reliably and efficiently.

Discover how optimizing this crucial element can significantly reduce machining time and improve the quality of your final part. ↩

Explore the mechanics of machine motion to better grasp how 5-axis technology delivers superior speed and precision. ↩

Learn how this advanced calibration maps and corrects a CNC machine’s entire 3D working volume for ultimate precision. ↩

Learn how this key machine attribute guarantees your part’s precision from every angle. ↩

Click to explore how all five axes coordinate to machine complex contours with unparalleled precision and finish. ↩

Learn how advanced CMM programming is used to verify complex geometries and ensure your parts meet tight tolerance requirements. ↩

Click to understand how a machine’s kinematic model is essential for accurate simulation and collision avoidance in 5-axis programming. ↩