You’re designing a heat sink for your next project, but the overwhelming array of aluminum options, manufacturing methods, and design considerations makes choosing the right solution feel like navigating a technical minefield. One wrong decision on material selection or manufacturing process can lead to thermal failures, cost overruns, or production delays that derail your entire project timeline.

Aluminum heat sinks dominate thermal management because they offer the optimal balance of thermal conductivity (around 205 W/m·K), lightweight properties, cost-effectiveness, and excellent machinability compared to alternatives like copper, making them the go-to choice for most air cooling applications.

This guide breaks down everything from material science fundamentals to advanced manufacturing techniques. You’ll discover how to match the right aluminum alloy to your thermal requirements, when CNC machining beats extrusion, and how to optimize designs for both performance and manufacturability without breaking your budget.

Why is aluminum the dominant material for heat sinks?

When we select a material for heat sinks, it’s about finding a perfect balance. You need effective heat dissipation, but practicality in manufacturing is just as crucial. Aluminum perfectly hits this sweet spot for most projects.

The Winning Combination

It provides an excellent blend of thermal performance, low weight, and cost-effectiveness. This combination makes it the default material for a huge range of applications.

At a Glance Comparison

This quick table highlights the core trade-offs.

| Feature | Aluminum | Copper |

|---|---|---|

| Performance | Good | Excellent |

| Cost | Low | High |

| Weight | Light | Heavy |

A Deeper Material Analysis

It’s true that copper has superior thermal conductivity. It can transfer heat about 60% more effectively than the most common aluminum alloys used for heat sinks. But performance is only one piece of the puzzle.

The Cost-to-Performance Ratio

Copper is significantly more expensive than aluminum. It is also more than three times denser. This extra cost and weight often make it impractical for many designs, despite its thermal advantages. For an aluminum heat sink, the cost savings are substantial.

From project experience, the choice often comes down to budget and weight constraints. Unless an application absolutely requires maximum thermal dissipation in a very small space, aluminum provides the best overall value. This is a common discussion we have with clients at PTSMAKE.

Machinability and Design Freedom

Aluminum is much easier to machine and extrude. This allows for the creation of complex fin geometries that maximize the cooling surface area. Creating these intricate designs in copper is possible but drives manufacturing costs up sharply. It also readily accepts treatments like anodization1, improving its durability.

| Property | Aluminum (6061) | Copper (C110) |

|---|---|---|

| Thermal Conductivity (W/mK) | ~167 | ~385 |

| Density (g/cm³) | 2.70 | 8.96 |

| Relative Cost | 1x | ~3-4x |

| Machinability | Excellent | Fair |

Aluminum’s dominance stems from its unbeatable balance. It offers good thermal performance, low density, and excellent machinability at a much lower cost than materials like copper. This makes it the most practical and efficient choice for a vast majority of heat sink applications.

What are the key aluminum alloys used for heat sinks?

When selecting an aluminum heat sink, the specific alloy is crucial. The most common choices are 6061 and 6063.

This decision is a careful balance. It impacts thermal conductivity, ease of manufacturing, and the final surface finish.

Key Alloy Comparison

Your project’s needs will determine the best fit. Will the heat sink be visible? Does it need to be strong?

Let’s compare the two primary options.

| Feature | 6061 Alloy | 6063 Alloy |

|---|---|---|

| Primary Use | Structural applications | Architectural, complex shapes |

| Strength | Higher | Medium |

| Extrusion | Good | Excellent |

Choosing correctly from the start prevents costly redesigns and performance issues later on.

Thermal Conductivity vs. Manufacturability

The perfect aluminum heat sink alloy is a trade-off. Pure aluminum offers the best thermal conductivity. But it’s soft and difficult to machine.

Adding alloys like magnesium and silicon creates the 6000 series. These additions increase strength and improve manufacturability. However, they slightly reduce thermal conductivity.

The Role of 6063 and 6061

6063 alloy is often the preferred choice. Its excellent extrudability2 allows us to create intricate fin designs. More complex fins mean more surface area and better heat dissipation.

We at PTSMAKE typically recommend 6061 when the heat sink also serves a structural purpose. It is stronger, but creating complex shapes with it is more challenging.

Finishing Options and Alloy Impact

Anodizing is common for corrosion resistance and aesthetics. The alloy choice significantly affects the final look. 6063 is renowned for its superior surface finish after anodizing.

This makes it perfect for visible components in high-end electronics. Based on our tests with clients, 6063 consistently delivers a better cosmetic result.

| Property | 6061 Aluminum | 6063 Aluminum | 1050A Aluminum |

|---|---|---|---|

| Thermal Conductivity (W/mK) | ~167 | ~201 | ~229 |

| Extrudability | Good | Excellent | Poor (as is) |

| Anodizing Finish Quality | Fair | Excellent | Good |

| Best For | Structural needs | Complex profiles | Maximum conductivity |

Choosing the right alloy for your aluminum heat sink is a critical engineering decision. It balances thermal needs against manufacturing capabilities and cosmetic requirements. Alloys 6063 and 6061 are common, each offering distinct advantages for specific applications.

How does surface area affect heat sink performance?

The connection is direct and simple. More surface area means better heat dissipation. This process works primarily through convection. Air moves across the surface and carries heat away from the component.

The Core Principle: Convection

Think of each fin on a heat sink as a pathway. It provides an escape route for heat. The goal is to expose more of the material to the cooler, surrounding air.

This is why an aluminum heat sink with many fins cools better than a flat block.

| Feature | Impact on Performance |

|---|---|

| Low Surface Area | Slower, less effective cooling |

| High Surface Area | Faster, more effective cooling |

Essentially, a larger surface provides more real estate for heat to transfer into the air.

The Law of Diminishing Returns

While more surface is generally better, there is a limit. Simply packing fins closer and closer together is not always the answer. At a certain point, it becomes counterproductive.

This is because airflow is just as important as surface area. If fins are too dense, they restrict the air’s ability to move between them. The trapped air gets hot and stops absorbing more heat.

Fin Density and Practical Design

The space between fins, or fin pitch, is a critical design factor. In past projects at PTSMAKE, we have seen how poor optimization here leads to failure. The air forms an insulating thermal boundary layer3 that hurts performance.

The right design always depends on the application, especially the type of airflow involved. We always consider this when engineering a solution.

| Airflow Type | Optimal Fin Spacing | Design Rationale |

|---|---|---|

| Natural Convection | Wider | Allows air to move freely without a fan. |

| Forced Convection | Tighter | A fan can push air through the tighter gaps. |

Finding this balance is key. Through simulation and testing, we determine the ideal fin geometry. This ensures the final product delivers the best possible thermal performance for its specific operating environment.

Increasing surface area boosts cooling, but this strategy has its limits. Fins that are too dense restrict airflow, trapping heat. Effective heat sink design requires a careful balance between maximizing surface area and ensuring unobstructed airflow.

What is the purpose of fins on a heat sink?

The primary purpose of fins is simple. They dramatically increase the surface area of a heat sink. This allows more heat to transfer into the surrounding air.

Think of it like this. A larger surface gives heat more escape routes. This process is essential for cooling electronics effectively.

How Fin Geometry Affects Cooling

The design of the fins is critical. Their shape and arrangement directly impact how well the heat sink performs. Key factors include thickness, height, and the spacing between them.

A Balancing Act

We must balance these elements for optimal results. For example, taller fins add surface area. But, they can be less efficient at their tips.

| Fin Geometry | Impact on Heat Dissipation | Key Consideration |

|---|---|---|

| Thickness | Thicker fins conduct heat better along their length. | Increases material cost and overall weight. |

| Height | Taller fins provide more surface area for cooling. | Can reduce efficiency at the fin tip. |

| Spacing | Wider spacing improves natural airflow. | Reduces the total number of fins and area. |

The real engineering challenge is in the details. It’s not just about adding more metal. It’s about designing that metal to work as efficiently as possible with the air around it. This is where experience in thermal design becomes invaluable.

Fin Efficiency: Not All Surface Area is Equal

A fin’s temperature is not uniform. The base of the fin, closest to the heat source, is always hotter than its tip. This temperature gradient affects performance. Fin efficiency measures how effectively a fin transfers heat compared to an ideal, perfectly conductive fin.

An ideal fin would have the same temperature all over. In our experience at PTSMAKE, achieving high efficiency means finding the right balance between material conductivity and fin geometry. An aluminum heat sink, for instance, offers a great balance of performance and weight.

Optimizing for Airflow

The spacing between fins is crucial. It dictates how air interacts with the heat sink. The right spacing depends entirely on the type of airflow available.

Natural vs. Forced Convection

With natural convection, air moves due to buoyancy. Hot air rises, drawing cooler air in. This process requires wider fin spacing to reduce air resistance.

Forced convection uses a fan to push air across the fins. This allows for much tighter spacing. More fins can be packed into the same volume, increasing surface area.

However, if fins are too close, the thermal boundary layer4 from each fin can overlap. This chokes the airflow, trapping hot air and drastically reducing performance.

| Convection Type | Optimal Fin Spacing | Rationale |

|---|---|---|

| Natural | Wider | Allows for unimpeded, buoyancy-driven airflow. |

| Forced (Fan) | Tighter | Active airflow overcomes resistance from close spacing. |

Fins increase a heat sink’s surface area to improve heat dissipation. The design of these fins—specifically their thickness, height, and spacing—is critical. This geometry must be optimized for the available airflow to achieve maximum cooling performance.

How does surface finish affect heat sink performance?

Surface treatments are more than just aesthetics. They play a critical role. Anodization, for example, is a popular choice for an aluminum heat sink.

This process transforms the surface. It enhances its ability to radiate heat. It also adds a protective layer. Let’s look at how this works.

The Anodization Advantage

Anodizing creates a durable, oxide layer. This finish dramatically improves thermal performance and longevity. It’s a key consideration in many designs.

| Feature | Bare Aluminum | Anodized Aluminum |

|---|---|---|

| Heat Radiation | Poor | Excellent |

| Corrosion Shield | Low | High |

| Surface Hardness | Soft | Hard |

This simple treatment offers significant functional upgrades. It goes beyond a simple color change.

Boosting Radiation with Anodization

Anodization significantly enhances a heat sink’s ability to radiate heat. A bare aluminum surface is shiny and reflective. It has a very low thermal emissivity5, typically around 0.05. This means it’s poor at releasing heat through radiation.

After anodizing, especially black anodizing, the emissivity value skyrockets. Our tests show it can jump to over 0.85. This makes the surface an extremely efficient radiator. It’s perfect for passive cooling systems where air movement is minimal.

Protection Against the Elements

Another key benefit is corrosion resistance. An aluminum heat sink can corrode in humid or harsh environments. The anodized layer acts as a tough, non-conductive barrier. This protects the metal underneath. It ensures long-term performance and reliability.

The Convection Trade-Off

However, there is a small trade-off. The anodized layer is an oxide. It is less thermally conductive than the aluminum itself. This can slightly impede heat transfer to the surrounding air via convection.

The impact is usually minor. In our experience at PTSMAKE, the massive gain in radiation performance often outweighs the slight reduction in convection efficiency. This is especially true for passive cooling scenarios.

| Surface Finish | Emissivity | Corrosion Resistance | Convection Impact |

|---|---|---|---|

| Bare Aluminum | Very Low | Poor | None (Baseline) |

| Clear Anodizing | High | Excellent | Minor Negative |

| Black Anodizing | Very High | Excellent | Minor Negative |

Anodization is a powerful tool. It boosts radiative cooling and corrosion resistance. While it can slightly reduce convection, the overall thermal performance gain is usually significant, especially in passive cooling applications.

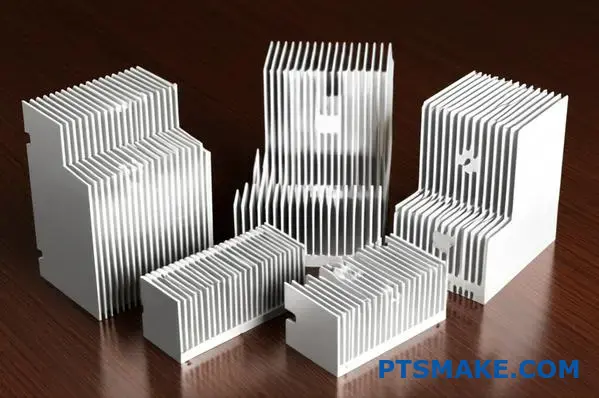

What fundamental trade-offs exist in heat sink design?

In every heat sink design project, we face a set of core trade-offs. You can’t maximize everything.

Better cooling performance often means a larger, heavier, and more expensive part.

The goal is to find the right balance for your specific application. This is where experience really matters.

Understanding these competing factors is the first step. It helps set realistic expectations and guides the entire design process.

The Four Pillars of Heat Sink Trade-offs

We always start by balancing four key factors:

- Performance: How well does it dissipate heat?

- Size/Volume: How much physical space can it occupy?

- Weight: How much can the component weigh?

- Cost: What is the budget for manufacturing?

These pillars are interconnected. Changing one almost always affects the others. A high-performance aluminum heat sink with many fins will cost more than a simple block.

Balancing Competing Demands

Every project has unique priorities. A heat sink for a dense server rack has strict size limits. One for a portable medical device must be lightweight.

In past projects at PTSMAKE, we’ve helped clients navigate this. For example, a customer needed a solution for a compact LED lighting system. High performance was crucial, but space was extremely limited.

We couldn’t just add more fins or make the base thicker. Instead, we explored different aluminum alloys and manufacturing methods. We also looked at optimizing airflow around the unit. The final design was a compromise. It met the thermal requirements without exceeding the size constraints. This involved carefully considering the Thermal Resistance6 of different designs.

This balancing act is central to effective thermal management.

Here’s a simple breakdown of how these factors typically relate:

| Priority Factor | Impact on Performance | Impact on Size/Weight | Impact on Cost |

|---|---|---|---|

| Performance | Increases | Increases | Increases |

| Size/Volume | Decreases | Decreases | May Increase |

| Weight | Decreases | Decreases | May Increase |

| Cost | Decreases | Decreases | Decreases |

Ultimately, the perfect heat sink doesn’t exist. The best heat sink is the one that perfectly balances the specific needs of your product.

Heat sink design is a constant balancing act. Performance, size, weight, and cost are always in tension. The optimal solution is application-specific, requiring a clear understanding of your project’s primary constraints and goals before manufacturing begins.

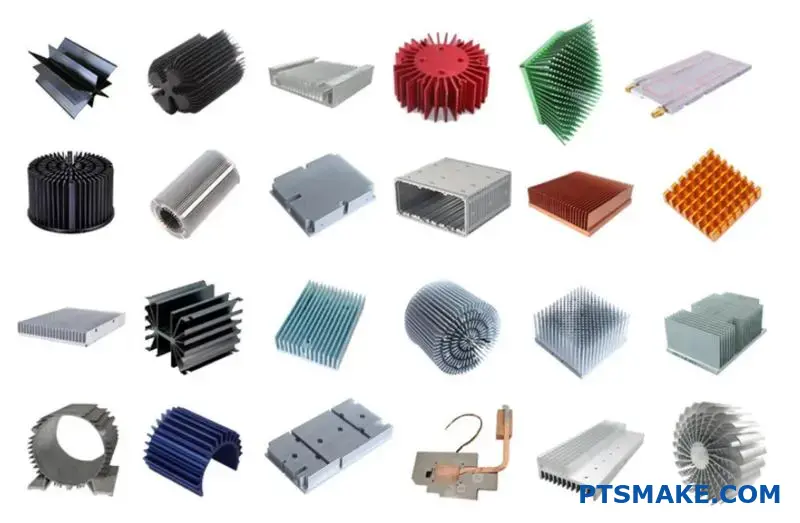

How do manufacturing processes dictate heat sink types?

The way an aluminum heat sink is made directly shapes its performance and cost. It’s the first thing we consider. Different methods create distinct features.

This determines which one is right for your project. Let’s classify the main types.

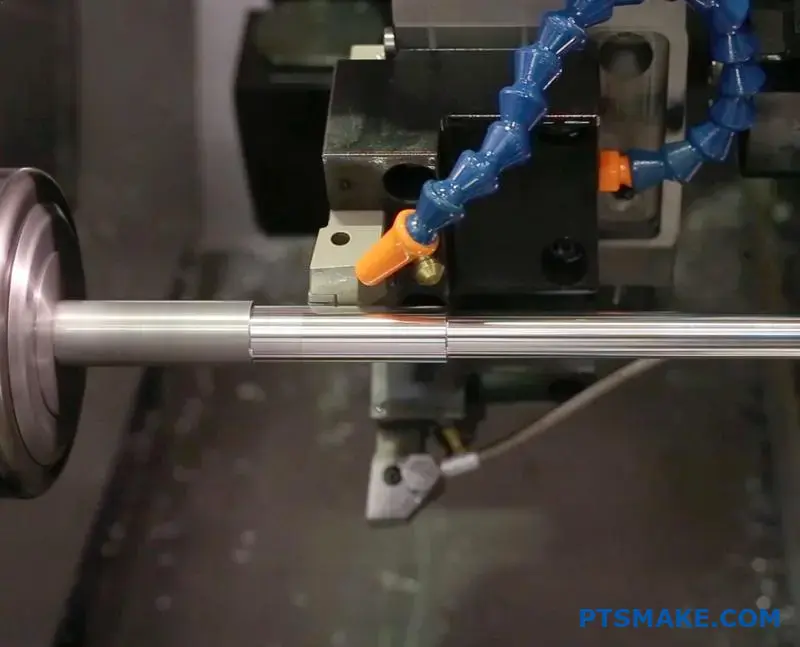

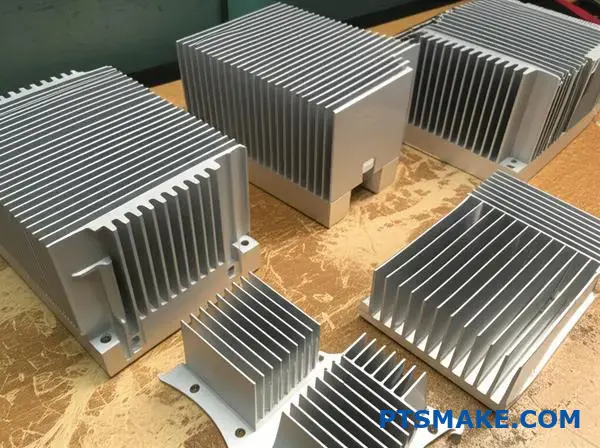

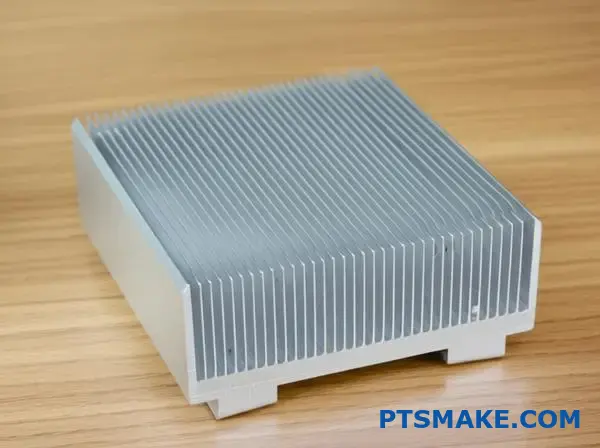

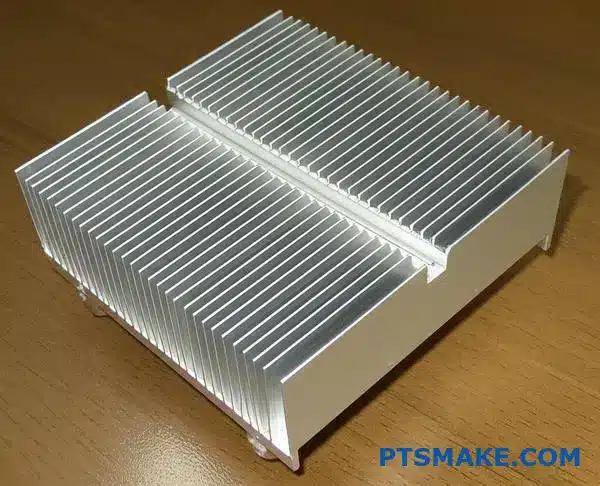

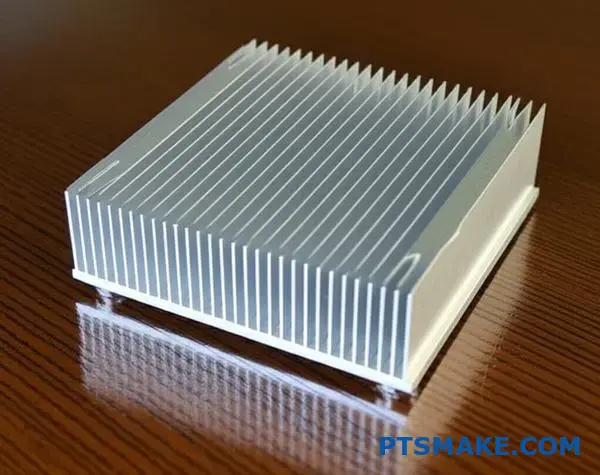

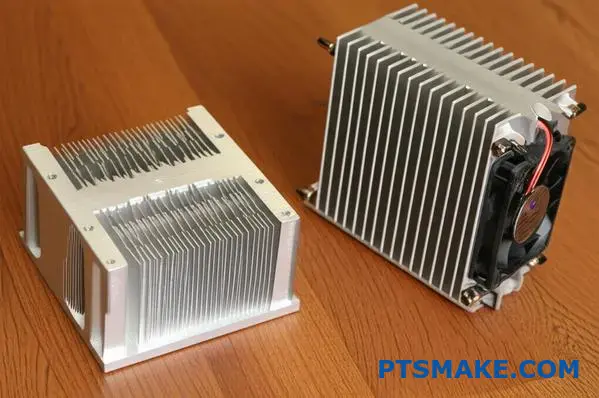

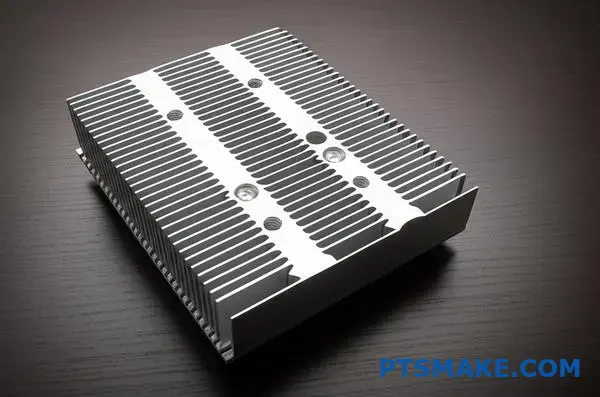

Extruded Heat Sinks

This is the most common and cost-effective method. Aluminum is pushed through a die to create a long, finned profile. It’s great for many standard applications.

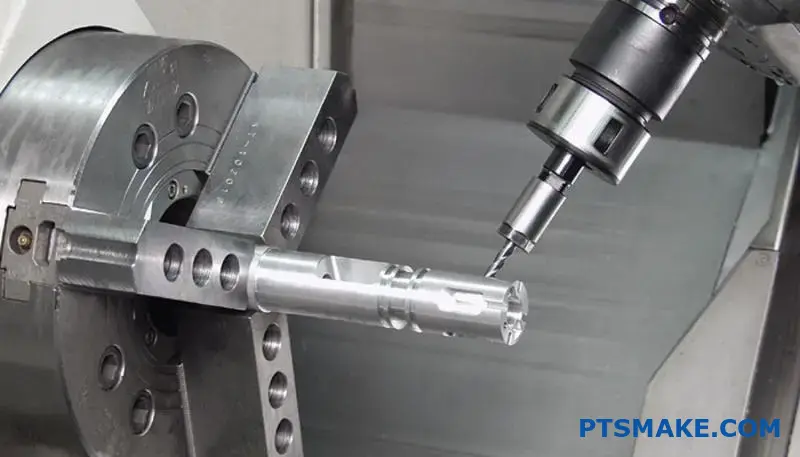

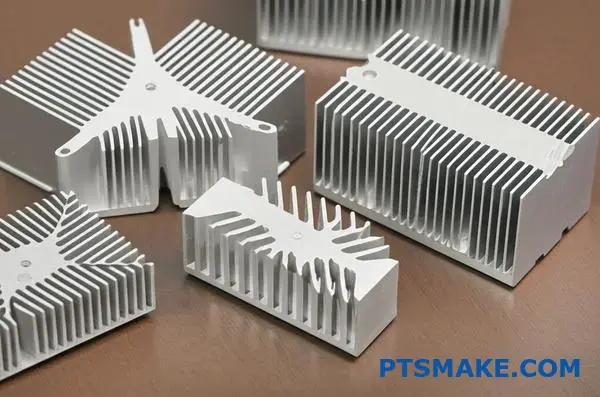

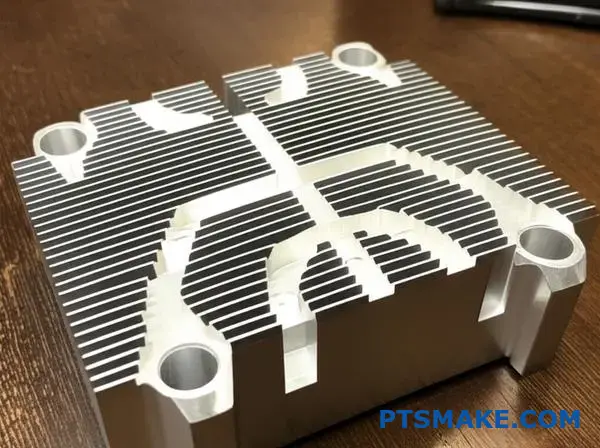

CNC Machined Heat Sinks

For complex geometries or prototypes, we use CNC machining. At PTSMAKE, this is our specialty. It offers total design freedom but at a higher unit cost.

Here’s a quick comparison:

| Feature | Extrusion | CNC Machining |

|---|---|---|

| Tooling Cost | High | Low / None |

| Unit Cost | Low | High |

| Complexity | Low | High |

| Lead Time | Medium | Fast |

Beyond the basics, other methods serve specific needs. The choice always involves balancing performance, volume, and budget. Each process has clear trade-offs.

Die-Cast & Forged Heat Sinks

Die casting creates complex 3D shapes by injecting molten metal into a mold. It’s excellent for high-volume orders where intricate forms are needed. Think of housings that also act as heat sinks.

Forging, on the other hand, stamps aluminum under immense pressure. This process enhances the material’s grain structure. It results in superior thermal conductivity compared to die casting.

Key Differences

Forging is often preferred for high-power LEDs. The material integrity is simply better. Die casting may have slight internal porosity, which can hinder heat transfer.

Skived & Bonded Fin Heat Sinks

Skiving shaves thin fins from a solid block of aluminum. This method produces a high fin density without an interface material between the fin and base. This improves thermal transfer.

Bonded fins are for large-scale applications. Individual fins are attached to a base using epoxy or brazing. This allows for very large heat sinks and even mixing materials, like using copper fins on an aluminum base for optimized performance. The process of bonding introduces a thermal resistance that needs to be considered in the design. We found that the Aspect Ratio7 of the fins can be much higher in bonded designs.

A look at these advanced methods:

| Method | Key Advantage | Best Application |

|---|---|---|

| Die Casting | Complex 3D shapes | High-volume electronics |

| Forging | High thermal conductivity | High-power lighting |

| Skiving | High fin density | Compact, high-performance systems |

| Bonded Fin | Very large sizes | High-power industrial equipment |

Choosing the right manufacturing process is crucial. It’s a balance of thermal needs, design complexity, production volume, and cost. Each method, from extrusion to forging, provides a unique solution for thermal management challenges.

What are the design limitations of extruded aluminum heat sinks?

The extrusion process itself imposes clear design rules. We cannot just create any shape we imagine.

These limits come from the physics of forcing aluminum through a steel die. The die’s strength is a major factor. So is the way the aluminum alloy flows under pressure.

Understanding these boundaries is key for effective thermal management. It helps avoid costly redesigns later.

Key Process Constraints

Here are some common constraints we work with at PTSMAKE:

| Constraint | Typical Guideline |

|---|---|

| Maximum Width | ~500 mm (20 inches) |

| Minimum Fin Thickness | ~0.5 mm (0.02 inches) |

| Fin Aspect Ratio (H:G) | Up to 15:1 |

These numbers are general guidelines. They can vary based on the specific alloy and the extrusion equipment used.

Let’s explore how these constraints affect your design. Thin fins increase surface area, but they are fragile. If fins are too thin, they can bend or break during the extrusion process. This is a common issue we help clients navigate.

The Challenge of Aspect Ratio

The height-to-gap aspect ratio is crucial. A higher ratio means more surface area in a smaller footprint. But pushing aluminum into tall, narrow channels is difficult. The material can cool too quickly, leading to incomplete fills or defects.

Impact on Thermal Performance

This limitation directly impacts an aluminum heat sink’s ability to cool. It restricts how effectively heat moves away through air convection8. Poor airflow between tall, dense fins can create pockets of hot, stagnant air. This reduces overall performance.

These factors force a compromise between the ideal thermal design and what is manufacturable.

| Limitation | Design Impact | Thermal Consequence |

|---|---|---|

| Min Fin Thickness | Limits fin density and count | Less total surface area for dissipation |

| Max Aspect Ratio | Restricts fin height and spacing | Can hinder natural airflow and cooling |

| Max Width | Constrains overall heat sink size | May require multiple parts for large devices |

At PTSMAKE, we analyze these trade-offs early. We help you optimize your design within real-world limits. This ensures both performance and manufacturability.

Extrusion has physical limits like width, fin thickness, and aspect ratio. These constraints directly influence thermal design and manufacturability, requiring a careful balance between ideal performance and the practical capabilities of the process.

In what applications are CNC machined heat sinks superior?

CNC machining is not always the default choice. However, it becomes the superior method in specific scenarios.

It excels where other methods fall short. This is especially true for custom designs.

When Precision is Paramount

For complex geometries, machining is unbeatable. Think of heat sinks with unique fin patterns or integrated features.

Speed and Flexibility

Rapid prototyping is a key area. CNC allows us to create functional prototypes quickly for testing and validation. This is vital for new product development.

Low-volume production runs are also ideal. They avoid the high initial costs associated with other methods like casting or extrusion.

| Scenario | CNC Machining Advantage | Other Methods’ Limitation |

|---|---|---|

| Complex Geometry | High precision, design freedom | Tooling constraints |

| Rapid Prototyping | Fast turnaround, no tooling | Slow, high setup cost |

| Low-Volume Runs | Cost-effective, no mold cost | Expensive for small batches |

CNC machining provides unmatched design freedom. This allows engineers to create heat sinks perfectly tailored to their thermal management needs.

At PTSMAKE, we often work on projects where off-the-shelf solutions just don’t work. This is where machining truly shines.

Intricate and Integrated Designs

Consider an aluminum heat sink for a dense electronics board. It might need fins of varying heights, curved profiles, or specific cutouts to avoid other components.

CNC can create these intricate shapes with tight tolerances. This ensures optimal contact and heat transfer where it matters most.

Another huge benefit is feature integration. We can machine mounting holes, threaded standoffs, and connector cutouts directly into the heat sink. This creates a single, robust part. It simplifies assembly and reduces the total component count. This process often relies on advanced toolpath optimization9 to be efficient.

Prototyping and Small Batches

When you’re testing a new design, speed is critical. CNC machining lets us produce a single prototype or a small batch in days, not weeks.

This rapid turnaround is invaluable for iterative design and testing. You can quickly validate thermal performance and make adjustments. For low-volume production, machining remains cost-effective because it bypasses expensive tooling.

The table below shows where machining typically wins.

| Application | CNC Machining | Extrusion | Casting |

|---|---|---|---|

| Prototypes | Excellent | Not suitable | Not suitable |

| Low-Volume | Excellent | Poor | Poor |

| Complex Fins | Excellent | Limited | Good |

| Integrated Features | Excellent | Poor | Limited |

In essence, CNC machining is the ideal solution for custom, complex, and low-volume heat sinks. It provides the precision for intricate geometries and the flexibility for rapid prototyping and integrated features. This method ensures optimal thermal performance without costly tooling.

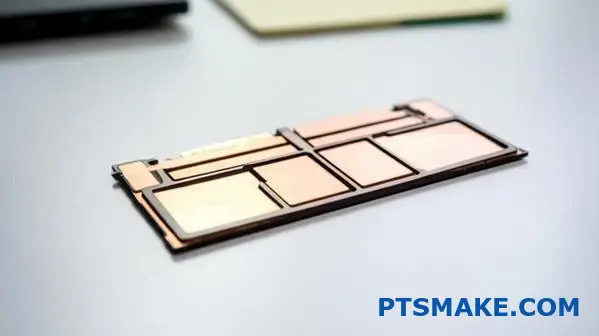

What characterizes a skived fin heat sink?

The skiving process is truly unique. It literally shaves thin fins from a solid block of metal, usually copper or aluminum. This method allows us to create very high-density fins.

These fins remain part of the original base. This creates a seamless thermal path.

The Skiving Method Explained

Creating High-Density Fins

A special cutting tool peels each fin. It lifts it and bends it vertically. The result is a highly efficient fin structure without any joints.

| Feature | Skived Fin | Extruded Fin |

|---|---|---|

| Fin Density | Very High | Moderate |

| Base Joint | None | None |

| Material | Copper/Aluminum | Aluminum |

This process makes an exceptional aluminum heat sink for tight spaces.

Performance and Cost Analysis

When choosing a heat sink, performance and cost are key. Skived fins offer top-tier thermal performance. This is because they have a high aspect ratio and no interface between the fin and the base.

Bonded fin heat sinks, another high-performance option, involve attaching individual fins to a base. This creates a potential thermal interface resistance10 at the joint, which skiving avoids. This is a small detail that can make a big difference in demanding applications.

Thermal Efficiency Comparison

Based on our tests, skived fins can outperform extruded fins significantly. This is especially true where airflow is limited. They provide more surface area in the same volume.

Cost Considerations

Extrusion is generally the most cost-effective method for high-volume production. It has lower tooling costs. Skiving involves a more precise, slower process, which can increase the unit cost. Bonded fins often fall somewhere in between.

At PTSMAKE, we guide clients through these trade-offs. We help them select the best solution for their budget and performance needs, whether it’s a custom aluminum heat sink or another design.

| Heat Sink Type | Thermal Performance | Relative Cost | Best For |

|---|---|---|---|

| Skived Fin | Excellent | High | High-power, compact devices |

| Extruded Fin | Good | Low | General purpose, high volume |

| Bonded Fin | Very Good | Medium-High | Large heat sinks, custom shapes |

Skived fin heat sinks offer superior thermal performance due to their single-piece, high-density fin design. This comes at a higher cost compared to extruded heat sinks but avoids the joint resistance found in bonded alternatives, making them ideal for demanding applications.

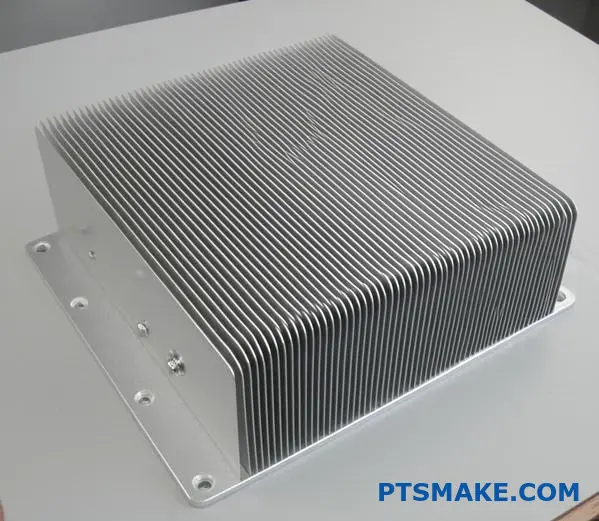

How do bonded fin heat sinks overcome extrusion limits?

Bonded fin heat sinks offer a clever solution. They overcome the design limits of single-piece extrusions. Instead of pushing metal through a die, we assemble them.

Individual fins are attached to a base plate. This construction method opens up new design possibilities. It allows for taller and more densely packed fins.

Bonded vs. Extruded Fins

| Feature | Bonded Fin | Extruded Fin |

|---|---|---|

| Fin Height | Very high | Limited |

| Fin Density | High | Limited |

| Material Mix | Yes | No |

| Cost | Higher | Lower |

This approach gives us greater design freedom for complex thermal challenges.

The Art of Construction

The magic of bonded fin heat sinks lies in their assembly. We manufacture the base and fins separately. This allows for optimization of each component before they are joined. The fins are typically stamped or skived.

Then, they are attached to the base using methods like thermal epoxy or brazing. This ensures a strong mechanical and thermal bond between the parts.

Unlocking Higher Aspect Ratios

This method allows for much higher aspect ratios. Extrusion is limited by how thin and tall fins can be. Bonded fins don’t have this constraint.

We can make fins much taller and place them closer together. This dramatically increases the surface area available for heat dissipation. It’s a key advantage for high-power applications where space is tight. The superior thermal conductivity11 of some materials can be fully leveraged this way.

Combining Dissimilar Metals

Another huge benefit is using different metals. At PTSMAKE, we often design solutions with a copper base and aluminum fins. Copper quickly pulls heat from the source.

The lightweight aluminum fins then efficiently dissipate that heat into the air. This combination optimizes both performance and weight. A standard extruded aluminum heat sink cannot offer this hybrid advantage.

| Component | Optimal Material | Reason |

|---|---|---|

| Base | Copper | High thermal conductivity |

| Fins | Aluminum | Lightweight, good dissipation |

Bonded fin heat sinks break through traditional extrusion limitations. They allow for taller, denser fins and the strategic use of dissimilar metals. This combination results in superior thermal performance for demanding applications.

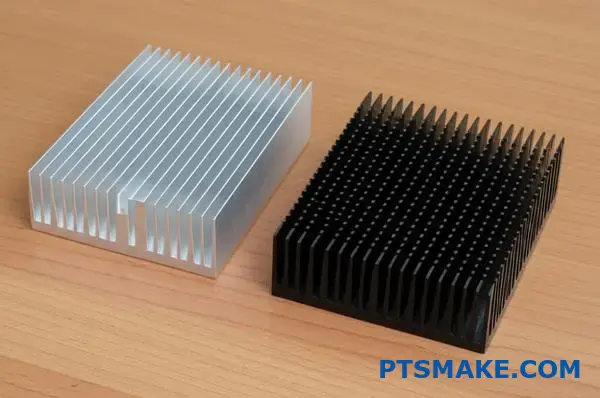

What are the different types of surface anodization for heat sinks?

When choosing an anodized finish, the debate often comes down to clear versus black. It’s more than just aesthetics. Your choice directly impacts thermal performance.

Clear anodizing protects the aluminum. It keeps the original metallic look. Black anodizing, however, does more. It enhances the heat sink’s ability to radiate heat.

Key Differences at a Glance

This choice depends on your product’s specific needs. Is it purely for protection or also for thermal management?

| Feature | Clear (Natural) Anodizing | Black Anodizing |

|---|---|---|

| Primary Goal | Corrosion & wear resistance | Enhanced heat radiation |

| Appearance | Natural metallic finish | Matte or glossy black |

| Heat Transfer | Good | Excellent (for radiation) |

The real performance difference lies in heat radiation. All objects radiate thermal energy. But some surfaces do it much better than others. This is where black anodizing shines.

The Role of Surface Emissivity

A bare aluminum heat sink is a poor radiator. Its shiny surface reflects heat instead of emitting it. Anodizing changes this dramatically.

The process creates a porous oxide layer. For black anodizing, a dye fills these pores. This results in a surface with very high emissivity12.

A higher emissivity value means the surface is more effective at radiating heat away. In our tests, black anodized surfaces consistently outperform clear or bare ones in passive cooling scenarios. This is critical in systems with limited airflow. Here, radiation becomes a major mode of heat transfer.

Emissivity Comparison

Our findings show how significant the change is. This makes black anodizing a functional, not just cosmetic, upgrade.

| Surface Finish | Typical Emissivity Value |

|---|---|

| Bare Polished Aluminum | ~0.05 |

| Clear Anodized Aluminum | ~0.80 |

| Black Anodized Aluminum | ~0.95 |

So, for high-performance applications, especially in natural convection, black anodizing is the superior choice we recommend at PTSMAKE.

In summary, clear anodizing offers protection while keeping a metallic look. Black anodizing provides the same protection but adds a crucial thermal advantage by maximizing heat radiation. This makes it ideal for demanding passive cooling applications.

How do you optimize a design for cost versus performance?

Let’s explore a practical case study. We need to cool a 50W processor. This is a common challenge.

We have two distinct options. The first is a complex, high-performance machined aluminum heat sink. The second is a simpler, larger extruded heat sink paired with a fan.

This choice highlights the core engineering dilemma. You must balance cost, size, and performance. Let’s compare them directly.

| Feature | Solution A: Machined | Solution B: Extruded + Fan |

|---|---|---|

| Performance | High (Passive) | Moderate (Active) |

| Complexity | High | Low |

| Size | Compact | Larger |

| BOM Cost | Higher | Lower |

A Deeper Dive into the Trade-Offs

Choosing the right cooling solution requires a detailed look at several factors. Each path has unique implications for the final product.

BOM Cost and Manufacturing Complexity

The custom machined heat sink is a single, intricate part. Its cost is driven by CNC machining time and material scrap. At PTSMAKE, we optimize toolpaths to manage this, but upfront costs are higher.

The extruded solution seems cheaper initially. The extrusion process is very cost-effective for simple profiles. However, you must add the costs of the fan, fasteners, and assembly labor to the Bill of Materials (BOM).

Size, Performance, and Reliability

The machined part offers superior passive cooling in a smaller package. It’s ideal for compact devices where space is a premium. Its design can be highly optimized for airflow and surface area.

The extruded sink plus fan is bulkier. It needs more volume. Its cooling performance depends on the fan, which requires power and creates noise. This active cooling helps lower the overall thermal resistance13 but introduces a critical point of failure.

A solid, machined part has no moving components. It is incredibly reliable. The fan in the second option, however, has a finite lifespan and can fail, potentially compromising the entire system.

| Factor | Machined Heat Sink | Extruded Heat Sink + Fan |

|---|---|---|

| Manufacturing | Complex CNC milling | Simple extrusion, plus assembly |

| Reliability | Extremely high (passive) | Lower (fan is a failure point) |

| Maintenance | None required | Fan may need replacement |

| Footprint | Smaller, more compact | Larger, requires more volume |

The machined sink provides top-tier reliability and performance in a compact form. The extruded sink with a fan lowers upfront costs but introduces risks in reliability and requires more space. The best choice depends on your project’s specific priorities.

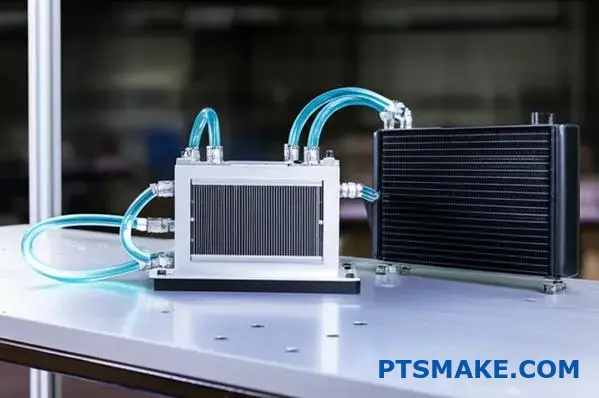

When should you consider liquid cooling over air cooling?

So, when is it time to switch? The decision to move from air to liquid cooling isn’t always simple.

There is a practical crossover point. This is where even the most advanced custom aluminum heat sink starts to fall short.

At PTSMAKE, we analyze several key factors. We look at heat density, total power load, available space, and noise requirements. This helps us guide clients to the most effective solution.

Deciding on the crossover point requires a look at the specific application’s demands. It’s not just about which is "better," but which is right for the job.

Analyzing Key Performance Metrics

The crossover point is often defined by a few critical metrics. When one or more of these metrics are pushed to their limits, liquid cooling becomes the more viable choice. The thermal power density14 is a critical factor in this evaluation process.

Heat Load and Density

High-performance components now generate immense heat in a small area. We often see that when power density exceeds 100 W/cm², air coolers struggle to dissipate heat effectively. Liquid cooling excels here, directly transferring heat away.

Space and Noise Constraints

A powerful air cooler needs a large aluminum heat sink and fan, which can be bulky. Liquid cooling systems move heat to a radiator. This allows for more design flexibility in compact systems. Also, for high heat loads, air cooler fans get very loud. Liquid systems can often cool more efficiently with slower, quieter fans.

| Factor | Air Cooling (Advanced Aluminum) | Liquid Cooling | When to Crossover |

|---|---|---|---|

| Heat Density | Effective up to ~100 W/cm² | Excels above 100 W/cm² | Components with high power density |

| Total Heat Load | Becomes bulky for >250W TDP | Manages >400W TDP effectively | Systems with high-TDP processors |

| Space Constraints | Requires large space at source | Flexible radiator placement | Compact or dense product designs |

| Acoustic Noise | Can be loud under high load | Generally quieter at high load | Applications requiring low noise |

The crossover point is reached when factors like high heat density, tight space, or low noise requirements become critical. At this stage, the superior thermal performance and design flexibility of liquid cooling outweigh its higher complexity and cost.

How does altitude impact heat sink performance?

At higher altitudes, atmospheric pressure drops. This causes air molecules to spread out, resulting in lower air density.

This "thinner" air is less effective at removing heat from a surface.

For an aluminum heat sink, this means its ability to cool components is significantly reduced. Performance must be adjusted for high-altitude applications.

Air Density and Altitude

As you go higher, the air gets thinner. This directly impacts cooling performance.

| Altitude | Air Density (Approx. % of Sea Level) |

|---|---|

| Sea Level | 100% |

| 1,500 m (5,000 ft) | 86% |

| 3,000 m (10,000 ft) | 74% |

This reduction is a critical factor in thermal design for electronics used in aviation or mountainous regions.

The Physics of Convective Cooling at Altitude

Heat sinks rely on convection. Air flows over the fins, absorbs heat, and carries it away. The efficiency of this process depends on air density.

Fewer air molecules at high altitudes mean less mass to absorb and transport thermal energy.

This directly reduces the convective heat transfer coefficient15, a key metric for cooling performance. Based on our tests, this reduction is not linear and becomes more severe at extreme altitudes.

Why Derating is Necessary

Because cooling is less effective, a heat sink rated for sea-level operation will fail to meet performance targets at high altitude. This leads to component overheating.

To compensate, engineers must "derate" the heat sink. This involves selecting a larger heat sink or increasing airflow with more powerful fans to achieve the required cooling.

| Altitude | Typical Performance Derating Factor |

|---|---|

| Sea Level | 1.0 (Baseline) |

| 1,500 m (5,000 ft) | ~0.9 |

| 3,000 m (10,000 ft) | ~0.8 |

In past projects at PTSMAKE, we’ve guided clients in aerospace and telecom to account for these factors, ensuring product reliability regardless of deployment altitude.

At higher altitudes, lower air density reduces convective cooling efficiency. This directly degrades heat sink performance, making it essential to derate thermal solutions to prevent components from overheating and ensure long-term reliability in the final product.

How do you design for manufacturability (DFM) for a custom heat sink?

A DFM checklist is essential for any custom extrusion project. It prevents costly errors and production delays. Think of it as your roadmap to a successful part.

Your main goal is to simplify the design for manufacturing. At PTSMAKE, we guide our clients through this process. We focus on key areas to ensure the final product is both effective and economical.

Uniform Wall Thicknesses

Keeping wall thicknesses consistent is critical. This ensures even material flow and cooling during extrusion. It prevents warping and weak spots in the final aluminum heat sink.

Avoiding Sharp Corners

Always use generous radii on internal and external corners. Sharp corners create stress points in the extrusion die. This can lead to die failure and higher tooling costs.

Aspect Ratio Limits

The ratio of fin height to gap width is important. Pushing this ratio too far makes the die weak and prone to breaking. We work with clients to find the optimal balance.

A simple checklist can make a big difference.

| DFM Checkpoint | Recommendation | Reason |

|---|---|---|

| Wall Thickness | Maintain uniformity | Prevents warping & stress |

| Corners | Add radii (>0.5mm) | Increases die life |

| Aspect Ratio | Adhere to limits (e.g., <10:1) | Ensures die strength |

| Tolerances | Specify only where needed | Reduces machining costs |

Beyond the basics, we dive deeper into the extrusion process itself. A well-designed profile considers not just the final shape, but how the aluminum will flow through the die. This is where experience really pays off.

Aligning Features with Extrusion Flow

Features should align with the direction of extrusion. This creates a stronger part and a smoother surface finish. Avoid complex, transverse features that require extensive post-machining. This adds unnecessary cost and time.

Designing for Post-Machining

Think about how the part will be held for secondary operations. Add features that simplify workholding if needed. For example, a flat surface can make CNC milling much easier. In past projects at PTSMAKE, we found this simple step can reduce machining time significantly.

Hollows and Enclosed Voids

Creating hollow sections adds complexity and cost. It requires a more intricate and expensive die. If a hollow is not essential for function, a solid or open profile is always a better choice for an aluminum heat sink16. The integrity of the die’s tongue, which forms the void, is a major concern.

Here is a quick comparison of design choices.

| Design Feature | Poor DFM Practice | Good DFM Practice |

|---|---|---|

| Internal Corners | Sharp, 90-degree angles | Rounded with generous radii |

| Wall Junctions | Abrupt thickness changes | Gradual, blended transitions |

| Fin Design | Extremely high aspect ratio | Moderate, balanced ratio |

| Symmetry | Asymmetrical, unbalanced shape | Symmetrical profile where possible |

This attention to detail ensures your design is optimized not just for performance, but for efficient and reliable manufacturing.

A DFM checklist for extruded heat sinks is crucial. It ensures uniform walls, rounded corners, and proper aspect ratios. Aligning your design with both extrusion and machining capabilities from the start prevents costly rework and production delays, leading to a superior final product.

How would you design a heat sink for a ruggedized, high-vibration environment?

A standard heat sink simply won’t last in a high-vibration environment. The constant shaking can lead to mechanical failure.

To create a rugged design, we must modify a standard heat sink. The focus is on improving its mechanical reliability. This involves three critical upgrades.

Key Modification Areas

We need to look at mounting hardware first. Then, we analyze for resonant frequencies. Finally, we select a stronger manufacturing process.

| Modification Area | Goal |

|---|---|

| Mounting Hardware | Prevent loosening and failure |

| Resonance Analysis | Avoid vibration amplification |

| Manufacturing Method | Enhance structural integrity |

These changes ensure the heat sink survives the harshest conditions.

Standard heat sinks often fail because they are not designed for dynamic loads. Their mounting hardware, like simple screws or clips, can easily loosen over time. This leads to poor thermal contact and eventual detachment.

Upgrading Mounting Systems

We must use more robust hardware. This includes larger diameter bolts and captive screws. Using thread-locking compounds or lock washers is also essential. In past projects at PTSMAKE, we’ve designed custom steel brackets. These brackets secure the heat sink directly to the chassis, distributing stress.

Preventing Resonant Failure

Every component has a natural frequency. If the external vibration matches this frequency, mechanical resonance17 occurs. This phenomenon dramatically amplifies motion, causing fins to fatigue and break off. We use software to simulate and predict these frequencies. This allows us to adjust the heat sink’s mass and stiffness.

Choosing a Better Manufacturing Method

The way a heat sink is made matters greatly. Bonded or brazed fins create weak points at the joints. A much better choice is a single-piece construction.

| Method | Vibration Resistance | Key Feature |

|---|---|---|

| Bonded Fin | Poor | Joints are failure points |

| Extrusion | Good | Single-piece structure |

| Forging | Excellent | Densest grain structure |

Forging an aluminum heat sink creates a monolithic part with superior strength. It eliminates the risk of joint failure completely, making it ideal for rugged applications.

To ruggedize a heat sink, we enhance its physical structure. This involves using stronger mounting hardware, analyzing for and designing against mechanical resonance, and selecting a robust, single-piece manufacturing method like forging to ensure ultimate durability and reliability.

Deconstruct the passive cooling solution in a compact electronic device.

Modern smartphones pack immense power. But they have no space for traditional fans. How do they stay cool? The answer is a clever passive system.

A Finless Cooling System

Instead of fins, devices use internal heat spreaders. These components work with the phone’s frame. They pull heat from the processor quickly.

This turns the entire device’s body into a large surface area. It helps dissipate heat into the air around you.

| Spreader Type | Key Characteristic | Common Use |

|---|---|---|

| Vapor Chamber | High-efficiency heat transfer | High-performance gaming phones |

| Graphite Sheet | Flexible and lightweight | Mainstream smartphones |

This integrated approach is key to managing thermals in a slim design.

The Heat Spreader’s Critical Role

The first job is moving heat away from the chip. This must happen instantly to prevent overheating. That’s where advanced materials come in.

Vapor Chambers in Action

Vapor chambers are thin, sealed copper envelopes. Inside, a liquid vaporizes over the hot spot. This gas then spreads out. It condenses on cooler surfaces, releasing its heat. This process, known as phase-change cooling18, is incredibly efficient at spreading thermal energy.

The Frame as a Functional Component

Once the heat is spread, it needs to escape. This is where the device’s metal frame takes over. In past projects at PTSMAKE, we’ve machined aluminum frames that serve a dual purpose. They provide structural integrity and act as the final stage of the cooling system.

The heat spreader transfers its thermal load to the frame. The frame then acts as a large, passive aluminum heat sink. It radiates heat away from the device into your hand and the surrounding air.

| Component | Thermal Function | Manufacturing Note |

|---|---|---|

| Heat Spreader | Conducts heat away from the CPU | Requires precise, flat surface |

| Aluminum Frame | Radiates heat into the environment | CNC machining ensures a perfect fit |

| Thermal Paste | Fills microscopic air gaps | Ensures efficient transfer |

This elegant system manages thermals without a single moving part. It relies entirely on smart material science and precision engineering.

Passive cooling in compact devices is a system. Heat spreaders quickly move thermal energy from the chip to the aluminum frame. This frame then acts as a large heat sink to dissipate the heat, all without needing fans.

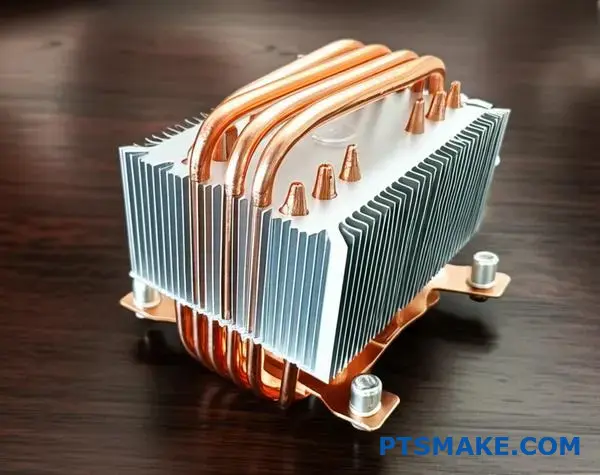

When is a copper-aluminum hybrid heat sink the optimal solution?

Let’s consider a common scenario: cooling a high-power density CPU. These components generate intense heat in a tiny area. This creates a significant thermal challenge.

The Modern CPU Dilemma

A standard aluminum heat sink struggles here. The heat is too concentrated. A copper-aluminum hybrid design excels by combining the best of both materials.

| Material | Primary Function in Hybrid Sink |

|---|---|

| Copper | Rapidly spreads concentrated heat |

| Aluminum | Dissipates the spread-out heat |

This dual-material approach directly tackles the core problem of high-power density cooling. It’s an engineered solution for a specific, demanding task.

A Tale of Two Metals

A high-performance CPU doesn’t heat evenly. It creates an intense "hot spot" directly on the die. The primary challenge is moving this heat away from that spot as quickly as possible. If you don’t, the CPU’s performance will suffer.

The Copper Base Advantage

This is where the hybrid design shines. We embed a copper base or vapor chamber directly under the heat source. Copper’s high thermal conductivity acts like a superhighway for heat. It rapidly pulls the intense thermal energy from the small CPU die. This effectively spreads it over a much larger surface area. This process drastically reduces the thermal spreading resistance19, preventing a bottleneck.

Aluminum Fins Take Over

Once the heat is spread out, the aluminum fins can do their job. Aluminum is lighter and more cost-effective than copper. Its thermal properties are more than sufficient for dissipating this less-concentrated heat into the surrounding air. The fins provide a large surface area for this convection to occur.

| Stage | Action | Dominant Material |

|---|---|---|

| 1. Heat Generation | Concentrated heat at the CPU die | – |

| 2. Heat Spreading | Heat is pulled away and spread out | Copper |

| 3. Heat Dissipation | Spread-out heat is released into the air | Aluminum |

At PTSMAKE, we have seen this design provide superior performance over a pure aluminum heat sink in demanding electronics applications.

In high-power density situations like CPU cooling, the hybrid heat sink is optimal. Copper quickly spreads the concentrated heat, and the lighter, cheaper aluminum fins efficiently dissipate it. This synergy provides a balanced, high-performance thermal solution.

What are the next-generation trends in air cooling technology?

For years, the standard aluminum heat sink has been the go-to for thermal management. It’s a reliable and cost-effective choice for many applications.

However, modern electronics are generating more heat in smaller spaces. This pushes traditional cooling methods to their limits.

New solutions are now emerging. They move beyond simple passive fins. These innovations promise significantly better cooling. Let’s look at what’s next.

Key Technology Shifts

| Old Technology | Next-Generation Trend | Benefit |

|---|---|---|

| Passive Fins | Active Air Movement | Enhanced Heat Transfer |

| Standard Materials | Advanced Composites | Higher Conductivity |

| Human Design | AI-Optimized Topology | Maximum Efficiency |

Beyond Traditional Heat Sinks

While the aluminum heat sink remains a staple, the future requires more advanced approaches. The goal is to dissipate more heat from smaller, more powerful components. This challenge is driving major innovation.

Oscillating Fins and Jets

We are seeing exciting developments with technologies like Synthetic jets20. These devices use vibrating diaphragms to create high-velocity air pulses.

This targeted airflow is very effective. It disrupts the stagnant air layer insulating the hot surface. This greatly improves heat transfer without traditional fans.

Advanced Materials

Material science is also playing a huge role. We’re moving beyond just aluminum and copper.

Materials like Annealed Pyrolytic Graphite (APG) offer thermal conductivity far superior to traditional metals. Based on our research, APG can spread heat much faster, eliminating hot spots. At PTSMAKE, we are exploring the manufacturability of these novel materials.

AI-Optimized Topologies

Artificial intelligence is changing how we design components. AI and machine learning can create heat sink designs that are impossible for a human to conceive. This process is called topology optimization.

AI algorithms generate complex, organic shapes. These designs maximize surface area and optimize airflow for unparalleled cooling performance.

| Feature | Traditional Design | AI-Optimized Design |

|---|---|---|

| Geometry | Simple, linear fins | Complex, organic |

| Performance | Good | Superior |

| Design Process | Human-led, iterative | AI-led, generative |

The future of air cooling lies beyond passive fins. Technologies like synthetic jets, advanced materials, and AI-driven design are setting new performance standards. They are essential for next-generation electronics.

Get an Instant Quote for Your Aluminum Heat Sink Project | PTSMAKE

Ready to optimize your thermal solutions with expert help? Contact PTSMAKE today to get a fast, no-obligation quote for your custom aluminum heat sink needs. Let’s bring your design to life with precision, reliability, and proven expertise—start your inquiry now!

Learn how this electrochemical process enhances corrosion resistance and surface emissivity. ↩

Discover how a material’s ability to be extruded shapes the final design and performance of your parts. ↩

Click to understand how this invisible air layer impacts your heat sink’s efficiency and overall thermal management. ↩

Understand how this invisible air layer impacts your heat sink’s cooling performance. ↩

Learn more about how this surface property impacts radiative heat transfer. ↩

Learn how this key metric directly impacts your heat sink’s cooling efficiency and overall system performance. ↩

Learn how fin height and spacing impact thermal efficiency in heat sink design. ↩

Learn more about how different modes of heat transfer impact heat sink efficiency. ↩

Learn how this process enhances machining precision and reduces production time for complex parts. ↩

Understand how this material gap impacts overall thermal efficiency. ↩

Discover how a material’s ability to conduct heat can impact your thermal management strategy. ↩

Learn more about this crucial property for understanding heat transfer in materials. ↩

Understand this key metric to better evaluate and compare the efficiency of different cooling solutions. ↩

Understand how this key metric directly impacts your cooling solution’s efficiency and design. ↩

Understand the core principle of how heat moves through fluids like air, a critical factor in thermal management. ↩

Learn how material choice and design influence the structural integrity and performance of your parts. ↩

Learn how vibrations can amplify forces and cause catastrophic failure in your designs. ↩

Learn more about the physics behind this highly efficient thermal management technology. ↩

Learn how this critical property impacts thermal management and heat sink design effectiveness. ↩

Learn how these jet systems cool effectively without the mechanical wear of traditional moving parts. ↩