Finding a reliable machining partner for complex, tight-tolerance parts often feels like an impossible task. You need precision that meets aerospace or medical standards, but most suppliers either lack the capability or deliver inconsistent results that force costly rework and project delays.

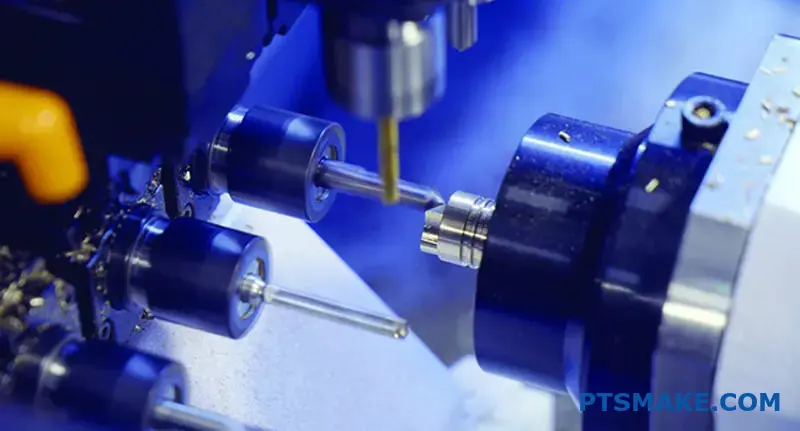

Swiss CNC machining delivers unmatched precision through its unique sliding headstock design and guide bushing system, which minimizes part deflection to achieve tolerances as tight as ±0.0001" while handling multiple operations in a single setup.

I’ve worked with procurement teams who struggled with the same challenge you’re facing right now. They needed a manufacturing solution that could handle everything from rapid prototyping to full production runs without sacrificing quality or extending lead times. The difference between standard CNC machining and Swiss CNC machining becomes clear when you’re working with small, intricate components that demand both speed and precision. This guide walks you through exactly how Swiss CNC technology solves these manufacturing challenges and what to look for in the right partner.

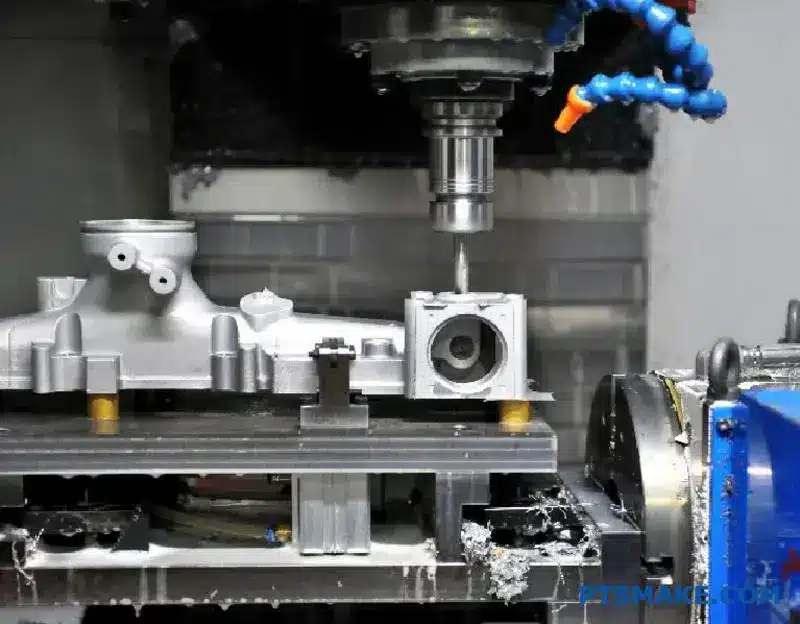

How Swiss CNC Machining Delivers Unmatched Precision.

Struggling to hold tight tolerances on long, slender parts? Are you finding that vibration and material deflection constantly compromise the finish and accuracy of your most intricate components?

Swiss CNC machining achieves unmatched precision by using a unique sliding headstock and guide bushing system. This design supports the workpiece directly adjacent to the cutting tool, virtually eliminating deflection and vibration to produce parts with extremely tight tolerances and superior surface finishes.

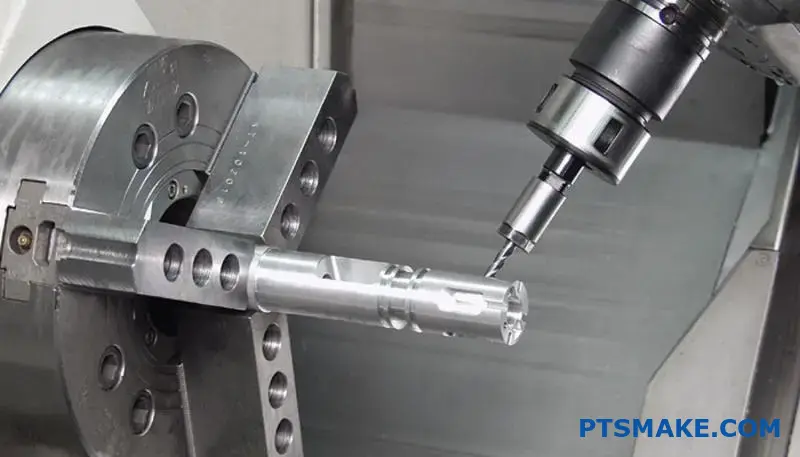

The magic of Swiss CNC machining lies in its fundamental design, which completely rethinks how a workpiece is supported during the cutting process. Unlike conventional lathes where the workpiece is held at one or both ends and can deflect in the middle, a Swiss-type machine feeds the material through a guide bushing. The cutting tools are placed right at the exit point of this bushing. This means the workpiece is always rigidly supported, regardless of its length. The machine achieves this by moving the entire headstock (which holds and rotates the bar stock) along the Z-axis, pushing the material into the tooling area. This approach is the key to minimizing deflection and vibration, the two biggest enemies of precision machining.

The Sliding Headstock and Guide Bushing Synergy

The sliding headstock and guide bushing work in perfect harmony. The headstock provides the axial movement (Z-axis), while the guide bushing acts as a rock-solid support point for the workpiece. Think of it like a pencil sharpener; the blade cuts right where the pencil emerges from the support structure, preventing the tip from wobbling. This synergy is what allows for the machining of very long parts with small diameters, a task that is nearly impossible on conventional lathes without significant issues. The machine’s kinematics1 are optimized for this continuous support, ensuring that the cutting forces are absorbed by the bushing, not by the workpiece itself.

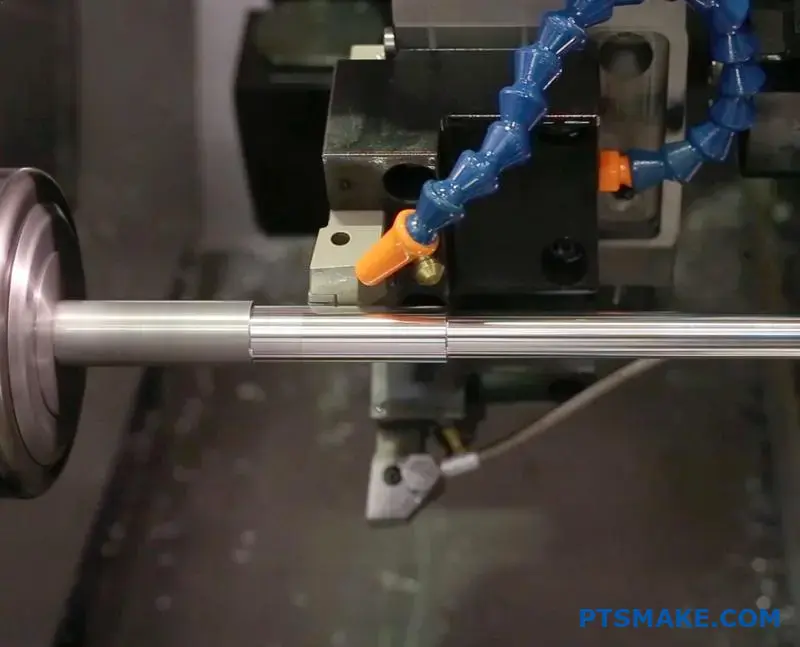

Eliminating Deflection and Vibration at the Source

Deflection happens when a cutting tool applies force to a workpiece, causing it to bend slightly. Vibration is the rapid oscillation that can result from this deflection or from the cutting action itself. Both are detrimental to achieving tight tolerances and a smooth surface finish. In past projects at PTSMAKE, we’ve found that Swiss machining can reduce deflection by over 75% compared to conventional turning on high length-to-diameter ratio parts. This stability is critical.

| Feature | Conventional CNC Lathe | Swiss CNC Machining |

|---|---|---|

| Workpiece Support | Held in a chuck, support is far from the tool | Supported by a guide bushing, right at the tool |

| Deflection Risk | High, especially on long/slender parts | Minimal, due to constant support |

| Ideal L/D Ratio | Generally below 4:1 for high precision | Can exceed 20:1 with high precision |

| Vibration Level | Can be significant, affecting finish | Very low, enabling superior finishes |

This fundamental difference is why Swiss CNC machining is not just an alternative but a necessity for components where precision is non-negotiable.

The exceptional precision delivered by the sliding headstock and guide bushing system makes Swiss CNC machining indispensable for the world’s most demanding industries. When a component’s failure could have critical consequences, engineers simply cannot afford the variability that comes with other manufacturing methods. This process is the gold standard for producing intricate, high-precision components that form the backbone of advanced technologies in fields like aerospace, medical devices, and electronics. The reliability of this method ensures that every part, from the first to the ten-thousandth, meets the exact same stringent specifications.

Why Demanding Industries Rely on Swiss Machining

In my experience, clients from critical sectors choose Swiss machining for three main reasons: consistency, complexity, and miniaturization.

- Consistency: Industries like aerospace require parts with documented, repeatable precision. A mission-critical fastener or valve component must be identical every time.

- Complexity: Medical devices often feature complex geometries, such as the intricate threads on a bone screw or the multi-faceted features of a surgical tool.

- Miniaturization: In electronics, components like connectors and pins are constantly shrinking. Swiss machines excel at producing these tiny, delicate parts with flawless accuracy.

At PTSMAKE, we frequently partner with clients in these fields, turning their most challenging designs into reality. The process allows us to create features like micro-holes, thin walls, and complex external profiles that would be impossible to produce reliably otherwise.

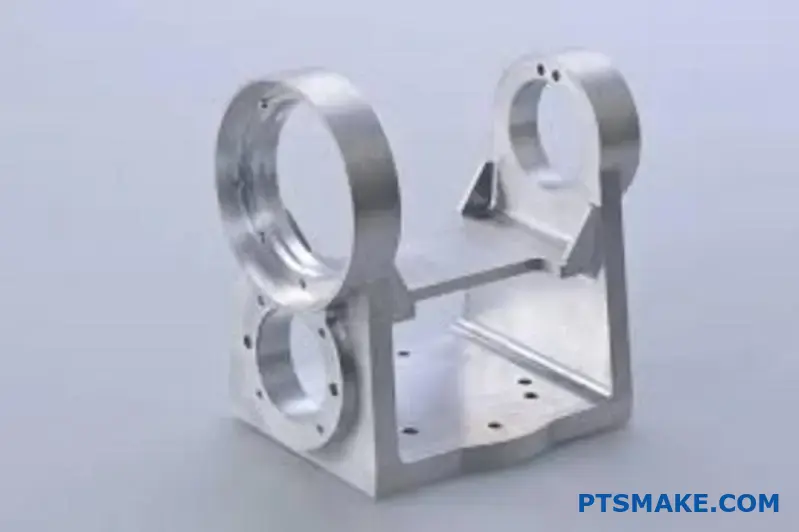

A Closer Look at Ideal Components

What kinds of parts are perfectly suited for this process? It’s all about the geometry. If a part is longer than it is wide, especially with a length-to-diameter ratio greater than 4:1, it’s a prime candidate.

| Industry | Example Components | Key Requirement |

|---|---|---|

| Medical Devices | Bone screws, dental implants, surgical instruments | Biocompatibility, extreme precision, perfect surface finish |

| Aerospace & Defense | High-pressure fittings, sensor housings, guidance system pins | High strength-to-weight ratio, tight tolerances, reliability |

| Electronics | Fiber optic connectors, probe tips, small shafts | Miniaturization, complex features, excellent conductivity |

| Automotive | Fuel injector nozzles, ABS sensor components | Durability, high-volume consistency, tight tolerances |

The ability to perform multiple operations—turning, milling, drilling, and threading—in a single setup also means parts come off the machine complete. This reduces handling, eliminates the risk of errors from multiple setups, and ultimately improves the overall quality and cost-effectiveness for our clients.

Swiss CNC machining provides unparalleled precision by using a sliding headstock and guide bushing to eliminate workpiece deflection. This makes it the essential manufacturing process for intricate, high-tolerance components in critical industries like medical and aerospace, where absolute consistency and reliability are paramount.

Reducing Lead Times with Multi-Operation Efficiency.

Ever found your project timeline stretching out because parts need to be moved from machine to machine? The constant re-fixturing and handling add delays and introduce risks of error.

Swiss CNC machining drastically cuts lead times by performing turning, milling, drilling, and threading in one continuous process. This single-setup approach eliminates secondary operations, reducing handling time and accelerating turnaround from prototype to full production runs.

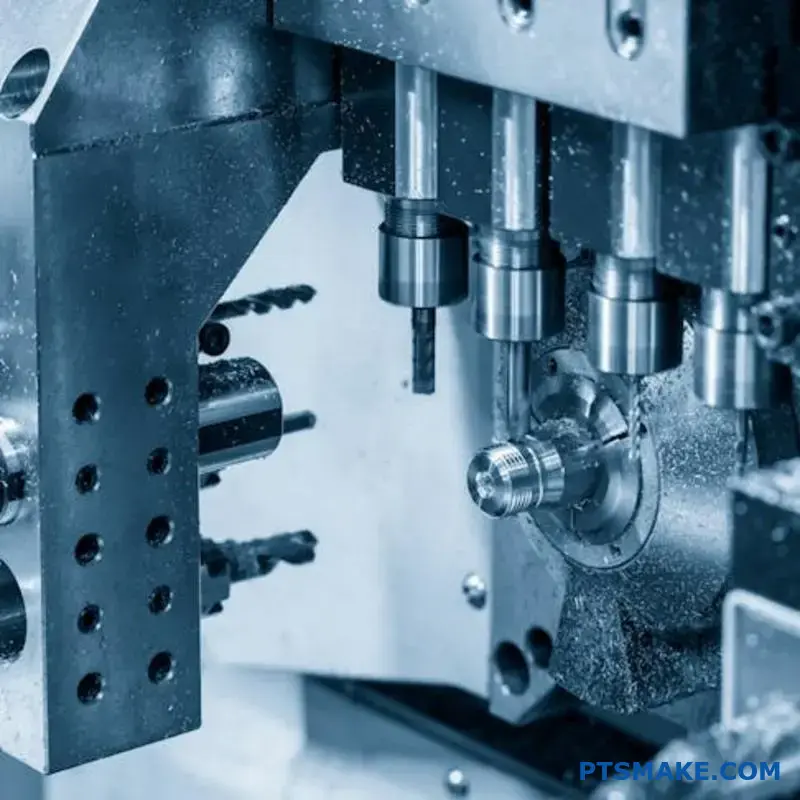

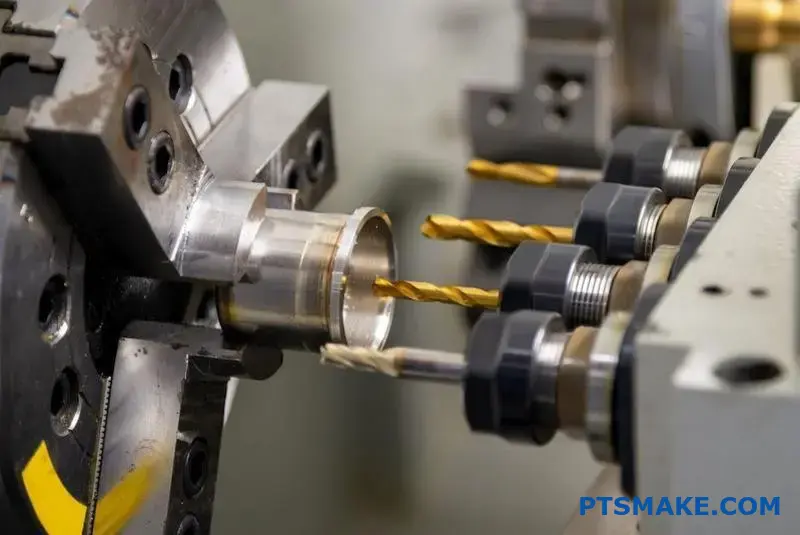

The "Done-in-One" Philosophy

The core magic of Swiss CNC machining isn’t just speed; it’s the consolidation of processes. In traditional manufacturing, a complex part might first go to a lathe for turning, then to a milling machine for flat features, and finally to a drill press. Each step requires a new setup, new programming, and manual handling, all of which add time and potential for error. Swiss machining turns this entire workflow on its head. By using a sliding headstock and a guide bushing, the machine feeds the raw material through the tooling area, allowing multiple tools to work on the part at once or in rapid succession without ever releasing it.

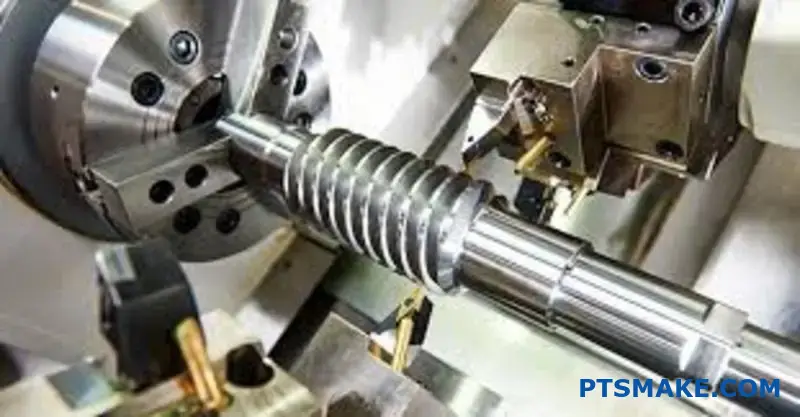

Combining Operations Seamlessly

Imagine a machine with multiple axes and live tooling stations working in perfect harmony. While the main spindle is turning a precise diameter on a long, slender shaft, a cross-drilling tool can be creating a hole, and a milling cutter can be machining a flat or a slot. This capability for simultaneous machining2 is what sets it apart. It means complex geometries that would normally require several distinct operations are completed before the part is even cut off the bar stock. In many of the projects we handle at PTSMAKE, this ability is the deciding factor for clients needing intricate medical or electronic components on a tight schedule.

Eliminating Secondary Processes: The Real Time-Saver

The most significant impact on lead time comes from eliminating secondary operations. These are any steps that have to be performed on a part after the primary machining is complete. This includes things like deburring, slotting, or cross-drilling on a separate machine. Each secondary step adds queuing time, setup time, and handling risk. A Swiss CNC machine often produces a part that is 100% complete, including complex features on the front and back of the part thanks to a sub-spindle.

The table below illustrates the dramatic difference in workflow.

| Traditional Workflow | Swiss CNC Machining Workflow |

|---|---|

| 1. Load stock into Lathe | 1. Load bar stock into Swiss machine |

| 2. Turn primary features | 2. Perform all operations (turn, mill, drill) |

| 3. Unload parts | 3. Part is cut off, complete |

| 4. Queue for Milling Machine | |

| 5. Set up and fixture part | |

| 6. Mill features | |

| 7. Unload parts | |

| 8. Queue for Drilling | |

| 9. Set up and drill holes | |

| 10. Final inspection and deburr |

This condensed process doesn’t just shorten the timeline; it simplifies the entire production chain.

From Faster Prototypes to Consistent Production

The multi-operation efficiency of Swiss CNC machining delivers tangible benefits beyond just a shorter schedule. It fundamentally changes how quickly you can move from design to a physical part and how consistently you can produce that part at scale. This dual advantage impacts both the initial development phase and long-term production runs, making it a powerful tool for modern manufacturing.

Accelerating the Prototyping Cycle

For engineers and product designers, speed during the prototyping phase is critical. When a part needs to be moved between three different machines, the lead time for a single prototype can stretch into weeks. With Swiss machining, a design can go from a CAD file to a finished physical part in a matter of days, sometimes even hours. Because there’s only one machine to program and set up, the entire process is streamlined. This allows for faster design iterations, quicker validation, and a shorter overall time-to-market. In our work with clients in fast-moving sectors like consumer electronics, this rapid turnaround is non-negotiable.

The Impact on Consistency and Quality

Every time a part is removed from a machine and re-fixtured in another, a small amount of error is introduced. This is known as tolerance stack-up. While each individual setup might be within tolerance, the combined variations can lead to a final part that is out of spec. Swiss CNC machining avoids this problem entirely.

| Feature | Multi-Setup Process | Single-Setup Swiss Process |

|---|---|---|

| Datum Reference | Changes with each machine | Constant from a single reference |

| Positional Accuracy | ±0.05 mm (cumulative) | ±0.01 mm (single setup) |

| Concentricity | Can vary between features | Extremely high and consistent |

| Risk of Handling Damage | High (scratches, dings) | Minimal (no manual transfer) |

By performing all operations in a single clamping, the machine maintains a single, consistent point of reference for all features. The turning, milling, and drilling operations are all perfectly aligned with one another, resulting in exceptional concentricity and positional accuracy. This is why Swiss CNC machining is the go-to method for parts where precision is paramount, such as in aerospace guidance systems or medical implants. The process inherently delivers higher quality and consistency, reducing scrap rates and ensuring that the first part is identical to the thousandth.

Swiss CNC machining eliminates the delays of multi-machine workflows by combining turning, milling, and drilling into one setup. This single-process efficiency drastically reduces handling, accelerates turnaround for both prototypes and production, and improves overall part consistency by removing the risk of tolerance stack-up.

Material Versatility: Metals and Plastics for Every Application.

Have you ever finalized a complex design, only to discover your manufacturing process can’t handle the specific material you need for peak performance?

Swiss CNC machining excels with its material versatility. It precisely shapes everything from tough metals like stainless steel and titanium to advanced engineering plastics like PEEK. This makes it the go-to solution for industries with strict material standards, including aerospace, medical, and electronics.

The World of Metals in Swiss Turning

The core strength of Swiss CNC machining lies in its unique design. A guide bushing provides exceptional support to the workpiece right at the point of cutting. This stability minimizes deflection and vibration, which is a game-changer when working with tough or exotic metals. It allows us to machine materials that would be difficult or impossible on conventional lathes, all while holding incredibly tight tolerances. At PTSMAKE, we’ve found this capability is often the deciding factor for clients with demanding applications.

Stainless Steel (300 & 400 Series)

Stainless steel is a cornerstone material for its blend of strength, corrosion resistance, and hygienic properties. In the medical field, we frequently machine 316L stainless steel for surgical instruments and implants due to its excellent biocompatibility. For food and beverage applications, the 304 grade is a popular choice. The challenge with stainless steel is its tendency for work hardening3 during machining, but the constant support from the guide bushing in a Swiss machine helps maintain a consistent cut, preventing the material from hardening mid-process.

Titanium (Grade 2, Grade 5)

When high strength and low weight are critical, titanium is often the answer. It’s a favorite in the aerospace industry for fasteners and structural components, as well as in the medical sector for long-term implants like bone screws. Titanium is notoriously difficult to machine due to its poor thermal conductivity and chemical reactivity at high temperatures. However, Swiss CNC machining, often using high-pressure coolant, effectively manages heat at the cutting zone, producing the pristine surface finishes required for these critical parts.

Aluminum Alloys (6061, 7075)

Aluminum is prized for its excellent strength-to-weight ratio, thermal conductivity, and machinability. We use 6061 for many general-purpose applications, from electronic enclosures to automotive components. For high-stress aerospace parts, the stronger 7075 alloy is preferred. Swiss machines can produce complex aluminum parts with fine threads and thin walls at very high speeds, making it a cost-effective choice for both prototypes and large production runs.

| Metal Type | Key Properties | Common Swiss-Machined Applications |

|---|---|---|

| Stainless Steel | Corrosion Resistance, Strength | Medical Instruments, Watch Components, Food-Grade Fittings |

| Titanium | High Strength-to-Weight, Biocompatible | Aerospace Fasteners, Medical Implants, Dental Screws |

| Aluminum | Lightweight, High Thermal Conductivity | Electronic Housings, Drone Parts, Automotive Sensors |

| Brass & Copper | Electrical Conductivity, Corrosion Resistance | Electrical Connectors, Pins, Plumbing Valves |

Engineering Plastics and Industry-Specific Solutions

The precision of Swiss CNC machining isn’t limited to metals. The same principles of stability and tight control apply beautifully to high-performance engineering plastics. While plastics can present unique challenges like thermal expansion and lower rigidity, the Swiss-type lathe’s design ensures that even soft or flexible materials can be machined to exact specifications without melting or deforming. This capability unlocks new possibilities for designers in specialized fields.

High-Performance Plastics

In past projects, we’ve seen a growing demand for metal replacement using advanced polymers. These materials offer unique benefits like chemical inertness, electrical insulation, and self-lubricating properties.

PEEK (Polyether Ether Ketone)

PEEK is one of the most robust thermoplastics available. It retains its mechanical properties at high temperatures and is resistant to harsh chemicals and sterilization processes. This makes it a prime candidate for medical implants, such as spinal fusion cages, and for insulating components in demanding aerospace and semiconductor environments.

Delrin® (Acetal / POM)

Delrin is known for its high stiffness, low friction, and excellent dimensional stability. It’s an ideal material for precision mechanical parts like small gears, bearings, and rollers that require a long wear life without lubrication. Swiss machining allows us to create intricate gear profiles and smooth bearing surfaces on tiny Delrin components.

Teflon™ (PTFE)

With its legendary non-stick surface and chemical inertness, PTFE is the material of choice for seals, gaskets, and insulators. It is notoriously difficult to machine because it is so soft. However, the guide bushing on a Swiss machine provides the necessary support to machine very fine features and thin walls in PTFE parts for medical devices and electronic connectors.

Matching the Right Material to the Industry

The success of a part often comes down to selecting the perfect material.

- Aerospace & Defense: This industry demands certified, traceable materials. Lightweighting is key, so aluminum and titanium are common, but high-performance plastics like PEEK are also used for insulators and interior components.

- Medical & Dental: Biocompatibility is non-negotiable. Titanium, 316L stainless steel, and PEEK are the primary choices for parts that come into contact with the human body. The burr-free finish from Swiss machining is a critical safety requirement.

- Electronics: Miniaturization drives material choices here. We often machine brass and copper for conductive pins and connectors, aluminum for heat sinks, and insulating plastics like PTFE and Delrin for tiny standoffs and housings in complex electronic assemblies.

Swiss CNC machining’s remarkable versatility allows for the precise fabrication of parts from a wide spectrum of materials. From robust metals like titanium for aerospace to biocompatible plastics like PEEK for medical implants, this technology delivers the performance and reliability required by today’s most demanding industries.

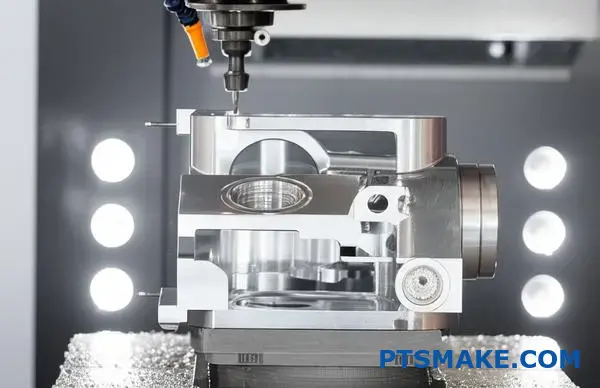

Quality Assurance: Meeting Stringent International Standards?

Ever faced project delays because a critical component failed inspection? That frustrating scramble to find a solution costs more than just money; it costs time and trust.

At PTSMAKE, quality assurance in Swiss CNC machining is built on a robust system of ISO 9001 certification, multi-stage inspections, and comprehensive documentation. This ensures every part meets strict international standards and provides full traceability from raw material to final product.

Beyond the Certificate: How ISO 9001 Shapes Our Operations

Many see an ISO 9001 certificate as just a badge to display on a website. For us, it’s the blueprint for our entire quality management system. It’s not a static document; it’s a dynamic framework that dictates our daily processes, from quoting to shipping. It forces a discipline of process control, risk management, and continuous improvement. This means we aren’t just checking for quality at the end; we are building it into every step. For an engineer, this translates to reliability and predictability. You know that the parts you receive on your hundredth order will be identical to the ones from your first.

The Foundation: Material Verification and Process Control

Quality begins long before a machine starts cutting metal. It starts with the raw material. Every batch of material that enters our facility is accompanied by a Material Test Report (MTR). We don’t just file these away; we verify them to ensure the material’s chemical and mechanical properties match your specifications perfectly. Once approved, the material is assigned a unique lot number that follows it throughout the entire production cycle. This rigorous traceability is non-negotiable, especially for our clients in the medical and aerospace sectors. We continuously monitor our processes using statistical methods to maintain a high Process Capability Index (Cpk)4, ensuring consistency across thousands of parts.

This table outlines our fundamental quality checks:

| Quality Stage | Key Activities | Why It Matters for You |

|---|---|---|

| Material Receiving | Verify Material Test Reports (MTRs) and conduct inspections. | Guarantees your part is made from the exact alloy or polymer specified, preventing material-related failures. |

| Process Planning | Define critical dimensions, inspection points, and toolpaths. | Proactively identifies potential manufacturing challenges, reducing the risk of errors during production. |

| Machine Setup | Calibrate machines and verify tooling. | Ensures the manufacturing process starts on a stable, accurate foundation, critical for tight tolerances. |

This systematic approach ensures that by the time we start machining, we have already eliminated major sources of potential error.

A Multi-Layered Inspection Strategy

A single final inspection is never enough, especially for the complex parts produced by Swiss CNC machining. Problems caught at the end of the line are expensive for everyone. That’s why we employ a multi-layered inspection strategy that embeds quality checks throughout the entire manufacturing flow.

1. First Article Inspection (FAI)

Before we begin a full production run, we produce a single part—the "first article." This part undergoes an exhaustive inspection where every single dimension, feature, and note on your drawing is measured and verified against the CAD model. The results are documented in a First Article Inspection Report (FAIR). This step provides definitive proof that our setup and process are correct, giving you the confidence to approve full-scale production. It’s the ultimate risk-reduction measure.

2. In-Process Inspection (IPI)

During the production run, our machinists and quality technicians perform regular checks on critical dimensions. This isn’t random; it’s a scheduled, systematic process. Using calibrated gauges and automated probes on the CNC machines themselves, we monitor the process for any signs of drift, such as tool wear. Catching a dimension moving even slightly out of the median tolerance allows us to make adjustments in real-time, preventing the production of any non-conforming parts.

3. Final Inspection

This is the final gatekeeper. Before packaging, every part undergoes a final inspection. Depending on your requirements and the part’s criticality, this can range from a statistically significant sample (using AQL standards) to a 100% inspection of every part. We use advanced metrology equipment like CMMs and optical comparators to ensure objective, accurate measurements.

This table highlights the documentation you can expect:

| Document Type | Purpose | How It Helps You |

|---|---|---|

| First Article Inspection Report (FAIR) | Confirms the setup and process are capable of meeting all specifications. | Gives you hard data and approval power before a large investment in production. |

| Certificate of Conformance (CoC) | A formal declaration that the entire shipped lot meets your requirements. | Simplifies your receiving process and provides a formal record for your quality system. |

| Full Dimensional Report | Provides detailed measurements for specific parts from the batch. | Offers objective proof of quality and traceability for critical components in your assembly. |

True quality assurance is an active, multi-stage process. It relies on the ISO 9001 framework, from initial material verification to in-process checks and final inspection. This comprehensive system, supported by transparent documentation, ensures every Swiss CNC machined part we deliver is a component you can trust.

Solving Procurement Challenges: From Prototype to Production.

Have you ever finalized a prototype only to find that scaling to production feels like starting from scratch? That transition can introduce a whole new set of unexpected challenges and delays, right?

A unified Swiss CNC machining partner solves procurement challenges by acting as a single point of contact from prototype to production. This streamlines communication, ensures design intent is maintained, mitigates risk, and provides the flexibility to scale order volumes without changing suppliers.

The Seamless Transition: From One to One Thousand

One of the biggest hurdles in manufacturing is the "prototyping gap"—the disconnect that happens when you move from a prototyping specialist to a mass production facility. Critical knowledge gained during prototyping is often lost in this handoff. The new supplier has to start from zero, re-learning the part’s nuances, its critical features, and its potential manufacturing challenges. This not only wastes time but also introduces significant risk. A single-source partner completely eliminates this gap. At PTSMAKE, the same team of engineers and machinists who dialed in your prototype are the ones who will oversee its production run.

Knowledge Retention is Your Competitive Advantage

When one team handles the entire lifecycle, the learning curve is flattened. We document every adjustment made during prototyping—from toolpath optimizations to specific workholding strategies. This data becomes the foundation for production planning. It allows us to apply Design for Manufacturability (DFM) insights gained from the prototype to optimize the process for larger volumes. This could mean minor design tweaks that reduce cycle time, material waste, or the need for secondary operations. This iterative feedback loop is only possible when prototyping and production happen under one roof. The process respects the material’s physical properties, such as Anisotropy5, ensuring that the part’s performance is consistent from the first unit to the ten-thousandth.

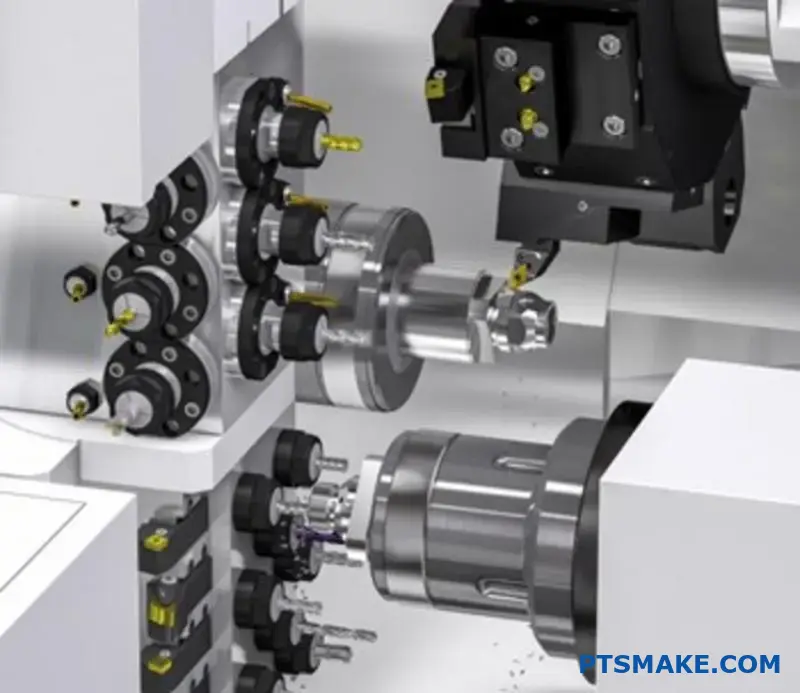

Scaling with Swiss CNC Machining

Swiss CNC machining is uniquely suited for this seamless scaling. Its efficiency in producing complex, high-precision parts makes it ideal for both rapid prototyping and full-scale production. The same machine that can produce a single, perfect prototype can be programmed to run lights-out, producing thousands of identical components with unwavering quality.

Here’s a practical look at how the sourcing model impacts this transition:

| Feature | Single-Source Partner (e.g., PTSMAKE) | Multi-Supplier Approach |

|---|---|---|

| Knowledge Transfer | Seamless; knowledge is retained internally | High risk of loss; requires extensive documentation |

| DFM Feedback | Continuous loop from prototype to production | Disjointed; feedback is often lost in handoff |

| Ramp-Up Time | Fast; leverages existing setups and data | Slow; requires new supplier onboarding and qualification |

| Quality Consistency | High; same processes and quality standards | Variable; depends on aligning multiple suppliers |

This integrated approach means you aren’t just buying parts; you are partnering with a team that understands your project’s history and is invested in its future success.

De-Risking and Streamlining Your Supply Chain

Coordinating with multiple suppliers introduces multiple points of potential failure. One delay from your prototyping shop, a quality issue with your production machinist, and a problem with your finishing service can create a domino effect that derails your entire project timeline. Every handoff is a risk—a risk of miscommunication, of parts being damaged in transit, or of accountability being blurred when something goes wrong. Who is responsible if a part fails? The machinist or the anodizer? A single-source partner takes full ownership of the final part, simplifying your role to managing one relationship.

The True Cost of Coordination

The sticker price of a part is only one component of its total cost. The "soft costs" of managing a fragmented supply chain can be substantial. Think about the hours your engineers and procurement managers spend:

- Vetting multiple vendors.

- Managing separate POs, invoices, and payment terms.

- Coordinating logistics between facilities.

- Acting as the middleman to resolve technical queries or quality disputes.

These activities don’t add value to your final product, but they drain valuable resources. In our experience with clients at PTSMAKE, consolidating manufacturing with a single partner can reduce these administrative overheads by as much as 30-40%, freeing up your team to focus on innovation and core business activities.

Flexibility for Modern Product Cycles

Today’s market demands agility. You may need a small batch of 50 units for a pilot run, followed by 5,000 units three months later. A traditional mass-production facility may not be interested in your low-volume orders, while a small prototype shop may lack the capacity to scale. A versatile partner equipped with advanced systems like Swiss CNC machining can easily accommodate this. We can run a small batch efficiently and then seamlessly transition to higher volumes using the same qualified process.

Here’s how a single partner simplifies risk management:

| Risk Factor | Single-Source Partner | Multi-Supplier Approach |

|---|---|---|

| Accountability | Clear; one partner is fully responsible | Blurred; suppliers may blame each other |

| Logistical Complexity | Minimal; parts are made and finished in one place | High; requires coordination of shipping and handling |

| Design Change Mgmt. | Agile; one conversation to update the process | Cumbersome; requires updating multiple suppliers |

| Points of Failure | One relationship to manage | Multiple relationships, multiplying risk |

This streamlined model isn’t just about convenience; it’s a strategic approach to building a more resilient, responsive, and cost-effective supply chain.

Struggling with the jump from prototype to production? A single-source Swiss CNC machining partner simplifies this by retaining project knowledge, de-risking the supply chain, and offering flexible volumes. This unified approach ensures consistency, streamlines communication, and accelerates your time to market effectively.

Cost-Effectiveness Without Compromising Quality?

Have you ever been torn between a strict budget and the absolute need for high-quality parts? It often feels like a trade-off where you can’t have both.

Swiss CNC machining achieves remarkable cost-effectiveness by minimizing material waste, reducing labor through automation, and slashing setup times with its single-setup process. This enables high-volume production of complex parts at a lower cost per unit without sacrificing the precision or quality your project demands.

The Built-In Economic Advantages

Swiss CNC machining isn’t just about precision; it’s about smart, efficient manufacturing. The cost benefits are engineered directly into the process itself, stemming from three core pillars: automation, material efficiency, and reduced setup complexity. In my experience, understanding these fundamentals is key to unlocking the full economic potential of this technology.

The Power of Automation

Modern Swiss lathes are designed for high-volume, continuous operation with minimal human intervention. This capability for "lights-out" manufacturing, where machines run overnight or on weekends without an operator present, drastically reduces labor costs. At PTSMAKE, we leverage this automation for our clients’ larger production runs. The machine handles the part loading, machining, and unloading, which means the cost of labor is spread across thousands of parts, making the per-unit cost significantly lower than with more manual processes. This efficiency also accelerates production timelines, getting parts into your hands faster.

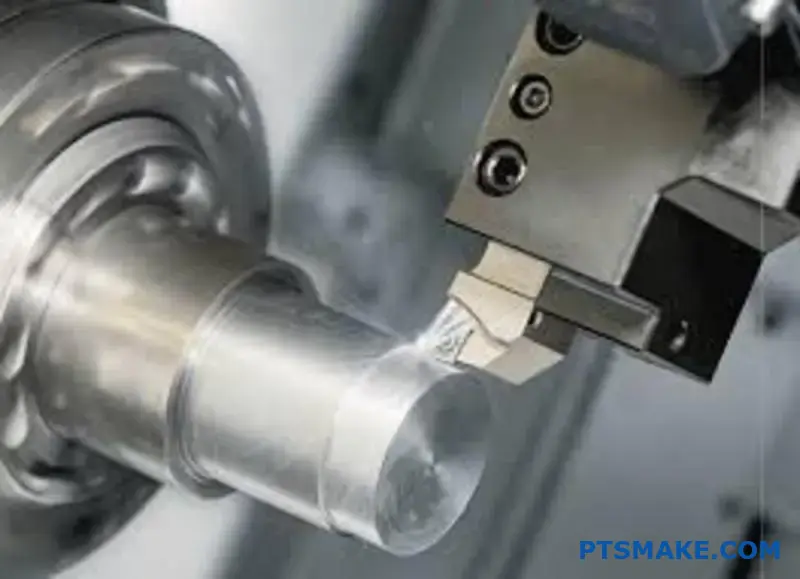

Minimizing Material Waste

Material cost is a significant driver in any machining project. Swiss machines excel at conserving material. They use bar stock that is fed through a guide bushing, providing rigid support extremely close to the cutting tool. This stability allows for the machining of very slender, complex parts without deflection, and it results in less scrap. Unlike some conventional CNC methods that may require larger stock for clamping, the Swiss method uses material far more efficiently. The savings become especially noticeable when working with expensive materials like titanium or medical-grade stainless steel.

| Feature | Swiss CNC Machining | Conventional CNC Turning |

|---|---|---|

| Material Support | Guide bushing supports stock near the tool | Supported by chuck, further from tool |

| Typical Scrap Rate | Lower, due to efficient bar stock use | Can be higher, especially with remnants |

| Thin Part Capability | Excellent, minimal deflection | Limited, prone to vibration |

Slashing Setup Times

In manufacturing, time is money, and setup time is a major cost factor. A key advantage of the Swiss CNC process is its ability to perform multiple operations—turning, milling, drilling, threading—in a single cycle. The part is completed before it’s cut off the bar stock. This "done-in-one" approach eliminates the need for multiple machines and the labor-intensive process of moving a part from a lathe to a mill. Each avoided setup not only saves time and money but also removes a potential source of error, contributing to higher overall quality and consistency. Effective Cycle Time Optimization6 is central to this efficiency.

Strategic Levers for Optimizing Cost

While Swiss CNC machining has inherent cost advantages, you can further enhance its cost-effectiveness through smart planning in design and production volume. It’s a collaborative effort. In past projects with clients, we’ve found that a few strategic adjustments before production begins can lead to substantial savings without impacting the part’s function or quality.

Designing for Manufacturability (DFM)

The most impactful cost-saving measures often happen at the design stage. Applying Design for Manufacturability (DFM) principles is crucial. For instance, questioning whether a tolerance needs to be +/- 0.005mm when +/- 0.02mm would suffice can make a part much easier and faster to produce.

Here are a few key DFM considerations for Swiss machining:

- Tolerances: Specify only the tightest tolerances where they are functionally critical. Over-tolerancing is one of the most common drivers of unnecessary cost.

- Standardization: Using standard drill sizes or thread forms reduces the need for custom tooling, which saves both time and money.

- Feature Design: Avoid deep, narrow pockets or overly complex internal geometries if simpler alternatives exist. Small simplifications can significantly speed up machining time.

The Impact of Batch Size

The relationship between production volume and per-unit cost is straightforward but powerful. Every job has fixed initial setup costs. These costs are the same whether you’re making 100 parts or 10,000 parts. By increasing the batch size, you spread that fixed setup cost over more units, dramatically lowering the price of each individual part.

| Batch Size | Setup Cost (Fixed) | Per-Unit Cost (Relative) |

|---|---|---|

| Low Volume (e.g., 500 pcs) | $X | High |

| Medium Volume (e.g., 5,000 pcs) | $X | Medium |

| High Volume (e.g., 50,000 pcs) | $X | Low |

Finding the Balance

The ultimate goal is to find the perfect equilibrium between cost, speed, and quality. This often involves a conversation about batch sizes and production scheduling. For a new product, a smaller initial run might make sense for validation. But for established parts, planning for larger, consolidated orders can unlock significant savings. At PTSMAKE, we often work with clients to analyze their annual demand and suggest an ordering schedule that maximizes cost-effectiveness while ensuring a steady supply of high-quality components.

Swiss CNC machining offers cost-effectiveness through automation and minimal waste. By optimizing part designs for manufacturability and strategically selecting batch sizes, you can achieve the ideal balance of price, speed, and uncompromising quality for your precision components.

Design for Manufacturability: Tips for Engineers and Buyers?

Have you ever finalized a design only to find it’s surprisingly expensive or slow to produce? This disconnect between design intent and manufacturing reality can derail project timelines and budgets.

Effective Design for Manufacturability (DFM) for Swiss CNC machining involves specifying realistic tolerances, understanding machine limitations for features, and selecting materials that balance performance with machinability. This strategic approach prevents costly redesigns and streamlines production from prototype to production.

Mastering Tolerances for Swiss CNC Machining

One of the most common areas where design intent clashes with manufacturing cost is tolerances. Engineers naturally want parts to be as precise as possible, but over-tolerancing is a frequent source of unnecessary expense. While Swiss-type lathes are renowned for their precision, every additional decimal point on a tolerance callout can increase cycle time, require more frequent tool changes, and drive up inspection costs.

In past projects at PTSMAKE, we’ve worked with clients to optimize their drawings. For example, a non-critical surface doesn’t need the same tight tolerance as a bearing bore. A good rule of thumb is to specify a standard tolerance of ±0.001" (0.025 mm) for most features and reserve tighter tolerances, like ±0.0002" (0.005 mm), only for functionally critical dimensions. This small change can have a significant impact on the final piece price, especially in high-volume production.

Navigating Feature Limitations

Understanding the physical capabilities of the machine is crucial. Swiss CNC machining is ideal for long, slender parts, but even it has its limits.

Aspect Ratios for Holes and Pins

A part’s length-to-diameter ratio is a key consideration. The guide bushing provides excellent support, allowing for high concentricity7 over long lengths. However, drilling very deep, small-diameter holes remains a challenge. A hole depth-to-diameter ratio of 10:1 is generally straightforward. Pushing beyond that, towards 20:1 or even 30:1, is possible but requires special tooling, peck drilling cycles, and slower speeds, all of which increase cost.

Wall Thickness and Corner Radii

Thin walls are susceptible to vibration and deformation during machining, which can compromise dimensional accuracy and surface finish. While material-dependent, a wall thickness greater than 0.020" (0.5 mm) is a safe starting point. Similarly, sharp internal corners (90 degrees) are difficult and often impossible to machine. Adding a small internal corner radius, even just 0.010" (0.25 mm), allows the tool to move smoothly and creates a stronger part.

A quick reference can help guide these decisions during the design phase.

| Feature | Standard Recommendation | Challenging (Higher Cost) |

|---|---|---|

| General Tolerances | ±0.001" (0.025 mm) | < ±0.0005" (0.013 mm) |

| Hole Depth (L:D Ratio) | < 10:1 | 10:1 to 30:1 |

| Min. Wall Thickness | > 0.020" (0.5 mm) | 0.010" – 0.020" (0.25-0.5 mm) |

| Internal Corner Radii | > 0.010" (0.25 mm) | Sharp corners (requires EDM) |

Strategic Material Selection for Optimal Results

Your material choice is a cornerstone of DFM. It affects not only the part’s final performance but also its machinability, which directly influences production speed and cost. A material that is difficult to machine wears out tools faster, requires slower cutting speeds, and can lead to lower-quality surface finishes if not handled correctly. Partnering with a manufacturer like PTSMAKE, who has extensive experience across various materials, can help you make the most cost-effective choice without compromising your design requirements.

Balancing Performance and Machinability

It’s a classic engineering trade-off. For instance, 303 stainless steel is formulated for machinability and is a great choice for many applications. However, if your part requires superior corrosion resistance, you might need 316 stainless steel, which is tougher to machine. Understanding this difference allows for an informed decision. Is the added corrosion resistance of 316 worth the potential increase in machining cost? Sometimes it is, but often, 303 is more than sufficient.

We can analyze this using a simple machinability index, where a higher rating means easier and faster machining.

| Material | Key Characteristics | Best For | Machinability Index (Approx.) |

|---|---|---|---|

| Brass C360 | Excellent machinability, corrosion resistant | Electrical connectors, fittings | 100% (Baseline) |

| Aluminum 6061 | Good strength-to-weight, versatile | Structural parts, housings | 90% |

| Stainless Steel 303 | Free-machining, good corrosion resistance | Shafts, fasteners, valves | 78% |

| Delrin® (Acetal) | High stiffness, low friction, stable | Bearings, gears, insulators | 75% |

| Stainless Steel 316 | Superior corrosion resistance, tough | Marine, medical, food-grade parts | 45% |

| Titanium (Ti-6Al-4V) | High strength-to-weight, biocompatible | Aerospace components, medical implants | 22% |

A Realistic Approach to Surface Finish

Like tolerances, surface finish is another area where over-specifying leads to higher costs. A standard machined finish for Swiss CNC parts is typically around 63-125 Ra (µin). This is suitable for most applications. Requesting a smoother finish, such as 32 Ra or 16 Ra, requires slower feed rates, finer cutting tools, and sometimes secondary processes like grinding or polishing. Each step adds time and expense.

The key is to apply fine surface finish callouts only where they are functionally necessary. These critical areas often include sealing surfaces, bearing journals, or dynamic components where friction is a concern. For all other non-critical surfaces, a standard machine finish is usually perfectly acceptable and far more economical.

Effective DFM for Swiss CNC machining hinges on balancing ideal design with practical realities. Prioritize realistic tolerances, respect machine feature limitations, and choose materials wisely. This proactive approach saves time, reduces costs, and ensures your complex parts are made right the first time.

Choosing the Right Swiss CNC Machining Partner.

Have you ever selected a supplier that seemed perfect on paper, only to be met with communication gaps and quality issues down the line? It’s a frustrating and costly experience.

Choosing the right partner means looking beyond price. Evaluate their technical capabilities, communication responsiveness, and track record. Prioritize partners who offer transparency, solid after-sales support, and are committed to a long-term relationship for sourcing success.

Beyond the Spec Sheet: Assessing True Technical Capability

Selecting a partner for Swiss CNC machining is much more than a simple price comparison. The true value lies in their technical depth and manufacturing philosophy. In my experience, the best suppliers are those who act as an extension of your engineering team, not just a service on a purchase order.

Equipment and Technology

The first checkpoint is their machinery. A modern, well-maintained fleet of Swiss-type lathes from reputable brands like Citizen, Tsugami, or Star is non-negotiable for high-precision work. But don’t stop there. Ask about their maintenance schedules and technology upgrade cycles. At PTSMAKE, we’ve found that investing in the latest machine technology directly translates to better surface finishes, tighter tolerances, and improved cycle times, which ultimately benefits our clients’ projects. A partner who invests in their own tools is a partner who invests in your success.

Material and Machining Expertise

A machine is only as good as the machinist running it. A potential partner must demonstrate deep expertise with a wide range of materials, from common stainless steels and aluminum alloys to more challenging materials like titanium and high-performance plastics. Their ability to advise on material selection for a specific application is a strong indicator of their expertise. They should understand how different materials react under the high speeds of Swiss CNC machining and how to manage chip control and heat dissipation. This knowledge is critical for achieving consistent quality and respecting complex specifications like Geometric Dimensioning and Tolerancing8.

A supplier’s true value becomes clear when you compare their approach.

| Feature | Transactional Supplier | Partnership Supplier |

|---|---|---|

| Quality Focus | Meets the minimum spec on the drawing. | Understands the design intent and part function. |

| Communication | Provides updates only when asked. | Proactively communicates progress and potential issues. |

| Problem Solving | Reports a problem and waits for instructions. | Identifies a problem and proposes solutions. |

| Long-Term Value | Focuses on the cost of a single order. | Focuses on optimizing the part for manufacturability. |

Choosing a partner is about finding a team whose expertise complements and enhances your own. It’s the difference between buying parts and building a resilient supply chain.

The Partnership Factor: Communication and Trust

While technical specifications are the foundation, the strength of a partnership is built on communication and trust. Over the past 15+ years, I’ve seen projects succeed or fail based on these "softer" metrics. A great Swiss CNC machining partner doesn’t just make parts; they make the entire process smoother and more predictable.

Responsiveness and Clarity

How quickly and clearly does a potential partner respond to your inquiries? When working across different time zones, as we often do with our clients in the US and Europe, responsiveness is key. A 24-hour delay in answering a simple question can halt progress for an entire day. Look for a supplier with a dedicated point of contact who understands your project and can provide clear, concise answers. Vague responses or constant hand-offs between departments are red flags. This is why at PTSMAKE, we assign a dedicated project engineer to each client to ensure seamless communication from quote to delivery.

Transparency in Process

Trust is built on transparency. A good partner is open about their processes, capabilities, and even their limitations. They should be willing to share their quality control procedures, provide production updates without being prompted, and be honest if a challenge arises. A supplier who tries to hide a problem is a liability. In contrast, a partner who alerts you to a potential issue and comes to the table with a proposed solution is invaluable. This collaborative approach prevents surprises and strengthens the relationship, turning a potential crisis into an opportunity for improvement.

Evaluating Long-Term Viability

After-Sales Support

The job isn’t finished when the parts are shipped. What happens if there’s a non-conformance issue or if you need slight modifications for the next production run? A reliable partner stands by their work. Before committing, ask about their policy on defective parts, their corrective action process (like an 8D report), and how they incorporate feedback into future production. Strong after-sales support shows that a supplier is invested in your long-term success, not just a one-time transaction.

Track Record with Western Clients

Finally, consider their experience working with companies in your region. A supplier with a strong track record serving clients in North America and Europe will already understand the expectations for quality, documentation, and business ethics. They will be familiar with common standards and have processes in place to manage international logistics and communication, making them a more reliable and lower-risk choice for your Swiss CNC machining needs.

Choosing a Swiss CNC machining supplier requires a balanced evaluation. Look beyond the quote to assess their technical depth, equipment, and material expertise. Equally important are their communication practices, transparency, and the after-sales support they provide, as these factors build the trust essential for a successful partnership.

Explore the principles of motion that enable Swiss-type machines to deliver such consistent, high-precision results on complex parts. ↩

Learn more about the advanced tool coordination that makes this level of efficiency possible in modern CNC systems. ↩

Learn more about how work hardening affects material selection and machining strategies for stronger parts. ↩

Learn how this statistical measure predicts process performance and ensures consistent quality in manufacturing. ↩

Understand how directional material properties can impact component performance and machining precision by clicking here. ↩

Learn how optimizing every second of the manufacturing process can lead to significant cost reductions in your production runs. ↩

Click to understand how concentricity affects the performance and cost of your precision machined parts. ↩

Click to understand this engineering language for defining and communicating tolerances, ensuring your part’s function and fit. ↩