Vad är liten CNC-bearbetning?

Kämpar du med höga kostnader och långa ledtider för små, komplicerade detaljer? Håller traditionella tillverkningsmetoder tillbaka din produktutvecklingscykel och belastar din budget för projekt som inte kräver storskaliga maskiner?

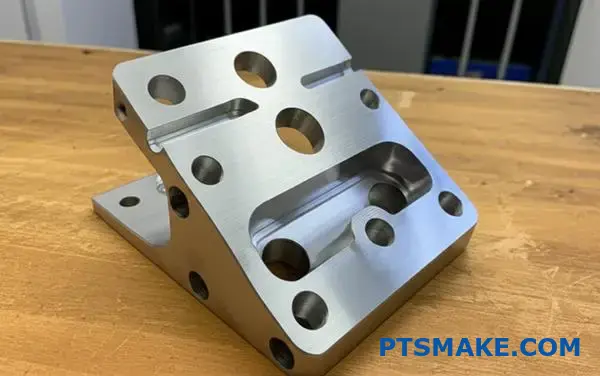

CNC-bearbetning av små detaljer erbjuder en kraftfull lösning. Den ger betydande kostnadsbesparingar, snabbare prototyptillverkning och kortare ställtider med lägre initial investering, samtidigt som den levererar den höga precisionskvalitet som ditt företag kräver för komplexa komponenter.

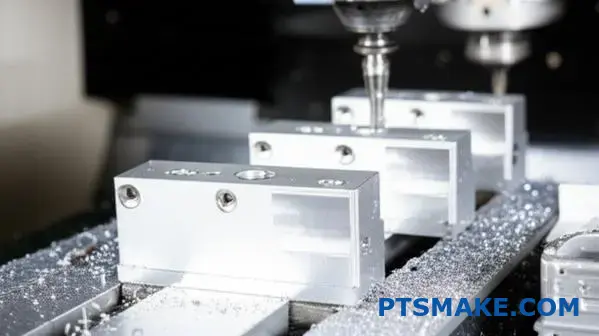

CNC-bearbetning av små detaljer är ett mycket effektivt alternativ för många tillverkningsbehov. I tidigare projekt har vi sett kunder uppnå betydande besparingar, inte bara på det slutliga priset på detaljen, utan genom hela produktionsprocessen. Den främsta fördelen ligger i minskade driftskostnader. Mindre maskiner förbrukar mindre kraft och använder ofta mer prisvärda verktyg. Dessutom är inställningsprocessen snabbare och enklare. Denna smidighet möjliggör snabbare övergångar mellan olika jobb, vilket är en avgörande faktor för produktionskörningar med hög mix och låga volymer. Effektivt optimering av verktygsbanor1 förbättrar dessa fördelar ytterligare genom att minimera maskintid och materialspill, vilket direkt påverkar ditt resultat.

Sänkta driftskostnader

En av de mest direkta fördelarna är att de dagliga driftskostnaderna minskar.

Jämförelse av installationstid och kostnad

| Funktion | Liten CNC-bearbetning | CNC-bearbetning i stor skala |

|---|---|---|

| Avg. Installationstid | 1-2 timmar | 4-8+ timmar |

| Energiförbrukning | Låg-Medium | Hög |

| Kostnad för verktyg | Lägre | Högre |

De strategiska fördelarna med CNC-bearbetning i små serier sträcker sig inte bara till operativ effektivitet, utan även direkt till produktutvecklingens livscykel. Möjligheten att snabbt kunna tillverka prototyper och små serier är ovärderlig på dagens snabba marknad.

Snabbare innovation med snabb prototyptillverkning

Enligt vår erfarenhet på PTSMAKE är en snabbare iterationscykel en viktig drivkraft för innovation. Med liten CNC-bearbetning kan ingenjörer få fysiska delar i sina händer på dagar, inte veckor. Denna hastighet möjliggör snabb testning, validering och förfining av konstruktioner, vilket hjälper dig att komma ut på marknaden snabbare och med en mer robust produkt.

Sänka trösklarna för inträde

Det lägre investeringskravet gör högprecisionstillverkning mer tillgänglig. Det gör det möjligt för nystartade företag och småföretag att konkurrera med större företag utan att binda sig för de enorma investeringar och den infrastruktur som storskaliga maskiner kräver.

Kort sagt är liten CNC-bearbetning en strategisk fördel. Det minskar tillverkningskostnaderna och påskyndar prototypfasen, vilket ger högkvalitativa delar utan den ekonomiska bördan eller förseningarna av storskaliga operationer. Detta gör den idealisk för moderna, agila affärsbehov.

Budgetöverväganden: Kostnadsanalys för små CNC-utrustningar?

Har du någonsin märkt att priset på en ny utrustning bara är början? De oväntade utgifterna för verktyg, programvara och underhåll kan snabbt förvandla en bra investering till en budgetmardröm.

En noggrann kostnadsanalys för liten CNC-utrustning måste sträcka sig längre än till det första inköpet. Att ta hänsyn till verktyg, programvara, underhåll och driftskostnader är avgörande för att korrekt beräkna den totala investeringen och säkerställa en positiv avkastning.

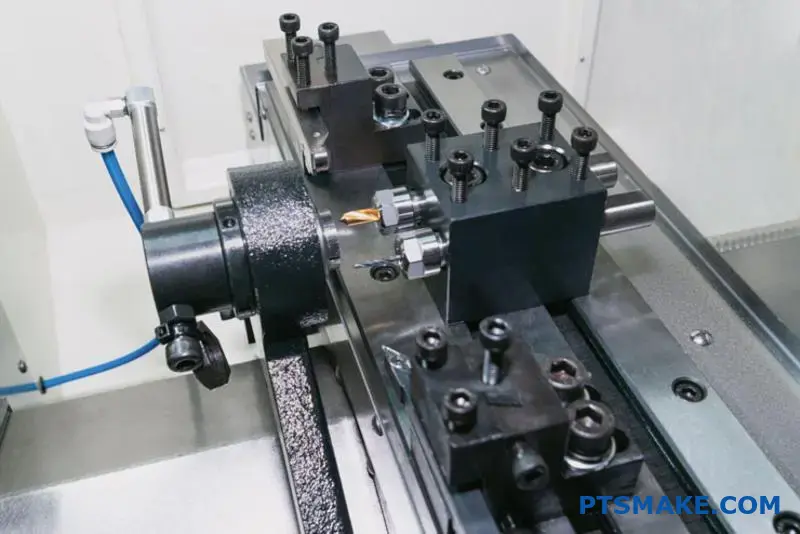

Den initiala investeringen: Mer än bara maskinen

Det ursprungliga inköpspriset är den mest synliga kostnaden, men det är bara en del av ekvationen. För att få en effektiv budget måste du ta hänsyn till alla delar som krävs för att få maskinen i drift. När vi på PTSMAKE ger råd till kunder som överväger att lägga produktionen internt betonar vi alltid att man måste se till helheten. Den första installationen omfattar själva maskinen, viktiga verktyg och programvaran för att köra den. Om någon av dessa komponenter försummas kan det leda till förseningar och oförutsedda kostnader. Effektivt arbetshållare2 lösningar är till exempel avgörande för att uppnå precision i alla små CNC-bearbetningsprojekt.

Fördelning av initiala kostnader

| Kostnadskomponent | Beskrivning | Relativ betydelse |

|---|---|---|

| Köp av maskin | Baspriset för den 3-axliga eller 5-axliga enheten. | Hög |

| Initial verktygsuppsättning | Fräsar, pinnfräsar, borrar och hållare. | Medium |

| Programvara (CAD/CAM) | För konstruktion av detaljer och generering av verktygsbanor. | Medium |

| Frakt & installation | Frakt, riggning och professionell installation. | Låg |

Bortom köpet: Löpande driftskostnader

När din maskin är igång måste du ta hänsyn till återkommande kostnader. Dessa löpande kostnader är avgörande för att upprätthålla prestanda, säkerställa kvalitet och maximera livslängden på din utrustning. Om du glömmer att budgetera för dessa kostnader kan det påverka din långsiktiga lönsamhet och kvaliteten på dina detaljer negativt. Baserat på vår erfarenhet av otaliga små CNC-bearbetningsföretag är konsekvent underhåll och operatörens skicklighet de största faktorerna för långsiktig framgång. Det handlar inte om engångskostnader, utan om kontinuerliga investeringar i produktionskapaciteten.

Översikt över återkommande utgifter

| Löpande kostnader | Frekvens | Påverkan på ROI |

|---|---|---|

| Förebyggande underhåll | Kvartalsvis/Årligen | Hög (förhindrar stilleståndstid) |

| Byte av verktyg | Per projekt/varjebaserad | Medium |

| Förbrukningsvaror | Dagligen/Veckovis | Låg |

| Utbildning för operatörer | Efter behov | Hög (Säkerställer kvalitet) |

För att göra en smart investering i liten CNC-utrustning måste du analysera hela det ekonomiska utrymmet. En riktig budget tar hänsyn till det första inköpet, viktiga verktyg och programvara samt långsiktiga driftskostnader som underhåll och utbildning. Den här helhetsbilden säkerställer ett hållbart och lönsamt beslut.

Kapacitet för material: Vad kan små CNC-maskiner hantera?

Har du någonsin valt ett material för din prototyp, bara för att upptäcka att det är olämpligt för liten CNC-bearbetning? Denna missmatchning kan orsaka projektförseningar och höja din budget oväntat.

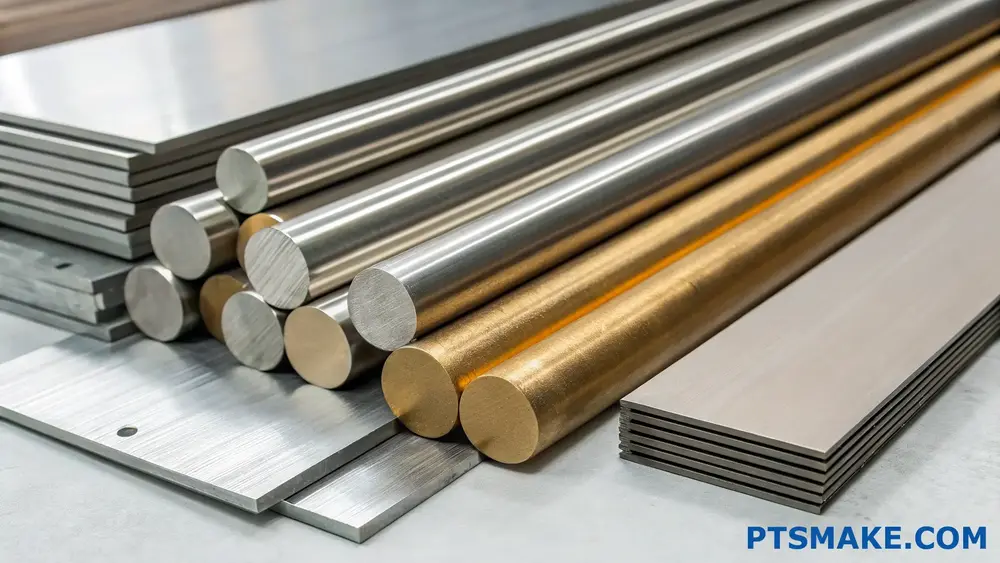

Små CNC-maskiner är förvånansvärt mångsidiga. De utmärker sig med material som aluminium, olika plaster och trä. De hanterar även mjuka metaller som mässing och koppar, men framgången beror i hög grad på materialets hårdhet och tjocklek, vilket är viktiga begränsningar att ta hänsyn till för alla projekt.

Kapaciteten hos små CNC-maskiner underskattas ofta. Även om de inte kan hantera härdat stål som sina större industriella motsvarigheter, utmärker de sig i precisionsarbete med ett specifikt utbud av material. I tidigare projekt på PTSMAKE har vi märkt att det är viktigt att förstå denna "sweet spot" för att lyckas med prototypframtagning och produktion.

Mjukare metaller: Det självklara valet

Aluminium, särskilt kvaliteter som 6061, är en favorit för små CNC-bearbetningar på grund av dess utmärkta styrka/vikt-förhållande och bearbetbarhet. Det möjliggör snabba cykeltider och en fantastisk ytfinish.

Tekniska plaster: Kraftpaket för prototyptillverkning

Plaster är otroligt användbara. Material som Delrin (POM) ger låg friktion för rörliga delar, medan ABS är utmärkt för prototyper för allmänt bruk. För anisotropi3 i vissa fyllda plaster kräver dock noggrann orientering av bearbetningen.

| Material | Bearbetbarhet | Gemensam användning | Viktig funktion |

|---|---|---|---|

| Aluminium 6061 | Utmärkt | Elektroniska höljen, ramar | Lätt och stark |

| Delrin (POM) | Utmärkt | Kugghjul, lager | Låg friktion, hög styvhet |

| ABS | Bra | Funktionella prototyper | Slagtålig, lätt att bearbeta |

| Polykarbonat | Rättvist | Linser, ljusrör | Transparent, tålig |

Utöver de vanligaste valen sträcker sig materialspektrumet för små CNC-bearbetningar längre, men det är här begränsningarna blir mer uppenbara. Det handlar inte bara om vad material, men också hur mycket av det som maskinen kan hantera.

Trä och andra mjuka metaller

Hårda träslag som lönn och ek är mycket lättbearbetade och ger detaljerade resultat för dekorativa eller funktionella delar. Mjukare metaller som mässing och koppar är också användbara. Men deras gummiaktiga textur kan leda till verktygsuppbyggnad, så det är viktigt att justera bearbetningsparametrarna. Genom omfattande tester har vi lärt oss att specifika kombinationer av kylvätska och verktygsbeläggning kan minska detta problem på ett effektivt sätt.

De verkliga gränserna: Tjocklek och hårdhet

De främsta begränsningarna är maskinens styvhet och spindeleffekten. En liten maskin kan få problem med ett tjockt aluminiumblock, vilket kräver flera grunda passeringar i stället för en djup skärning. Detta ökar bearbetningstiden. När det gäller metaller rekommenderar vi ofta att man håller sig under en viss tjocklek för att bibehålla både precision och kostnadseffektivitet.

Små CNC-maskiner hanterar effektivt material från aluminium och teknisk plast till trä och mjuka metaller. För att ditt projekt ska bli framgångsrikt måste du matcha materialets egenskaper - särskilt dess hårdhet och tjocklek - med maskinens kapacitet för att säkerställa precision och effektivitet.

Precisionsstandarder och kvalitetskontroll i små CNC-verksamheter?

Har du någonsin godkänt en konstruktion, bara för att upptäcka att de tillverkade delarna inte klarar inspektionen på grund av små toleransavvikelser? Det är en vanlig frustration som kan stoppa ett helt projekt.

För att uppnå konsekvent precision vid små CNC-bearbetningar krävs ett strukturerat kvalitetskontrollsystem. Detta innebär att man kombinerar maskinens kapacitet med rigorösa processer som FAI (First Article Inspection), processkontroller och slutlig verifiering med hjälp av avancerade metrologiverktyg, allt styrt av ett certifierat kvalitetsstyrningssystem (QMS).

Precisionsnivån vid liten CNC-bearbetning beror i hög grad på maskinen, materialet och processtyrningen. Det handlar inte bara om maskinens angivna specifikationer. Enligt vår erfarenhet på PTSMAKE är det en balansgång att upprätthålla snäva och konsekventa toleranser.

Faktorer som påverkar noggrannheten

Den slutliga noggrannheten är ett resultat av flera faktorer som samverkar. En styv maskinram minimerar vibrationerna, medan en högkvalitativ spindel och vassa verktyg säkerställer rena snitt. Materialvalet är också avgörande; stabila material som aluminium 6061 är mer förutsägbara än vissa plastmaterial som kan bli skeva. Vi använder en dokumenterad process som kallas Mätdonets repeterbarhet och reproducerbarhet4 för att validera att våra mätsystem är tillförlitliga innan vi ens startar en produktionskörning.

Typiska uppnåeliga toleranser

Nedan finns en allmän guide till standardtoleranser som vi ofta arbetar med för små CNC-bearbetningsprojekt.

| Material | Standard Tolerans | Tätare tolerans (med processkontroller) |

|---|---|---|

| Aluminium (t.ex. 6061) | ±0,005" (±0,127 mm) | ±0,001" (±0,025 mm) |

| Rostfritt stål (t.ex. 304) | ±0,005" (±0,127 mm) | ±0,002" (±0,051 mm) |

| Plast (t.ex. ABS, PEEK) | ±0,010" (±0,254 mm) | ±0,003" (±0,076 mm) |

Det är möjligt att uppnå toleranser som är snävare än dessa standarder, men det kräver vanligtvis särskild hantering och ytterligare kvalitetskontroller, vilket kan påverka projektets tidsramar och kostnader.

En maskins kapacitet är bara halva sanningen. Sann konsekvens kommer från en robust kvalitetssäkringsprocess (QA) som övervakar detaljen från första skärningen till den slutliga leveransen. Det är här som ett dokumenterat system gör hela skillnaden och förhindrar avvikelser innan de blir till stora problem.

Vårt arbetsflöde för kvalitetssäkring

På PTSMAKE utgör vårt ISO 9001-certifierade system ramen för varje projekt.

1. Första artikelinspektion (FAI)

Innan vi startar en full produktionskörning producerar vi en enda detalj och inspekterar varje dimension mot utskriften. Denna FAI-rapport dokumenteras och godkänns internt, vilket säkerställer att vår installation och programmering är perfekt.

2. Kvalitetskontroll under processens gång (IPQC)

Vi väntar inte bara till slutet. Våra operatörer utför regelbundna kontroller med bestämda intervall under hela bearbetningsprocessen. Detta hjälper oss att upptäcka verktygsslitage eller maskindrift tidigt och bibehålla enhetligheten i hela partiet.

3. Slutlig kvalitetskontroll (FQC)

Varje del genomgår en slutkontroll med hjälp av kalibrerade verktyg, inklusive digitala skjutmått, mikrometrar och koordinatmätmaskiner (CMM) för komplexa geometrier. Detta sista steg garanterar att det vi skickar är exakt vad du beställde.

Sammanfattningsvis är det ingen tillfällighet att upprätthålla hög precision för små CNC-bearbetade detaljer. Det bygger på en djup förståelse för maskinens kapacitet i kombination med en rigorös kvalitetssäkringsprocess i flera steg som omfattar FAI, processkontroller och slutkontroll som styrs av ett certifierat QMS.

Ledtider och produktionshastighet för beställningar av små volymer?

Har du någonsin oroat dig för att en snäv deadline för en kritisk prototyp ska missas? Stressar du över produktionsförseningar när du behöver små partier av delar snabbt?

För mindre CNC-bearbetningar är standardledtiderna normalt 7-15 arbetsdagar. Faktorer som komplexitet, materialtillgänglighet och efterbehandling kan dock påverka detta. Många verkstäder, inklusive vi på PTSMAKE, erbjuder snabba tjänster och levererar delar på så lite som 3-5 dagar för brådskande behov.

Det utlovade leveransdatumet är inte bara ett slumpmässigt tal, utan en beräkning som baseras på flera viktiga variabler. Den enskilt största faktorn är ofta materialtillgängligheten. Det går snabbt att få tag på standardaluminium 6061, men en specialkvalitet av rostfritt stål eller en exotisk polymer kan lägga till en vecka på tidslinjen innan ett chip ens har skurits. Delens komplexitet följer tätt efter. En enkel svarvad axel kräver minimal programmering och inställning, medan ett fleraxligt fräst hus med snäva toleranser kräver betydande CAM-arbete och noggrann maskininställning. Optimering av hela arbetsflödet för att hantera cykeltid5 för varje steg är grundläggande. Detta fokus på effektivitet i små CNC-bearbetningar är hur vi levererar tillförlitliga tidslinjer för våra kunder.

| Faktor | Påverkan på standardledtiden |

|---|---|

| Materialanskaffning | Lägger till 1-10+ arbetsdagar |

| Delens komplexitet | Lägger till 1-5+ arbetsdagar |

| Ytfinish | Lägger till 1-3+ arbetsdagar |

| Krav på inspektion | Lägger till 1-2+ arbetsdagar |

Så hur kan en CNC-maskinverkstad ge snabbare leveranser för brådskande tillverkningsbehov? Nyckeln är operativ smidighet, särskilt när det gäller att hantera snabba beställningar. Till skillnad från massiva produktionsanläggningar som är låsta till högvolymkörningar kan butiker som fokuserar på tillverkning av små partier svänga snabbt. I tidigare projekt på PTSMAKE har vi lyckats hålla snäva deadlines genom att använda särskilda maskinceller som är reserverade för snabb prototyptillverkning och brådskande jobb. Detta säkerställer att en liten men kritisk order inte går förlorad i en lång produktionskö. Genom att införa automatiserad offerthantering och strömlinjeformad CAM-programmering kan man dessutom spara mycket tid redan i inledningsskedet. Denna flexibilitet är en viktig fördel med specialiserade tjänster för CNC-bearbetning av små enheter, vilket gör det möjligt att snabbt svara på brådskande kundkrav utan att kompromissa med delarnas slutliga kvalitet.

För små beställningar av CNC-bearbetning kan du förvänta dig ledtider på 7-15 dagar, med möjlighet till skyndsam leverans. Tidslinjerna beror i hög grad på detaljens komplexitet och materialtillgång, men flexibla verksamheter kan ge snabbare leveranser genom att utnyttja dedikerade maskinceller och strömlinjeformade front-end-processer för brådskande projekt.

Hur väljer man rätt partner för små CNC-bearbetningsföretag?

Har du någonsin valt en leverantör baserat på en låg offert, bara för att möta oändliga förseningar och delar som inte passar? En sådan chansning kan få hela projektets tidsplan och budget att spåra ur.

Att välja rätt partner för små CNC-bearbetningsföretag innebär att se bortom priset. Du måste noggrant utvärdera deras tekniska kapacitet, kvalitetskontrollsystem, kommunikationsstandarder och deras potential som en långsiktig partner för att säkerställa tillförlitlighet och framgång.

När du väljer en partner bör du börja med deras tekniska grund. Har de rätt utrustning för ditt projekts komplexitet? En verkstad med enbart 3-axliga maskiner kan få problem med delar som kräver 5-axlig simultanbearbetning. På PTSMAKE har vi kommit fram till att ett varierat maskinutbud är nyckeln till flexibla lösningar. Kontrollera också kvalitetscertifieringar som ISO 9001. Det här är inte bara ett papper, utan ett bevis på att man arbetar med konsekventa, dokumenterade processer som minskar antalet fel. Leverantörens förmåga att förstå och tolka komplexa konstruktionsspecifikationer, inklusive aspekter som Geometrisk dimensionering och toleransberäkning6är en viktig indikator på deras expertis.

Viktiga tekniska och kvalitetsmässiga indikatorer

| Kriterium | Vad ska man leta efter? | Varför det är viktigt |

|---|---|---|

| Maskiner | 3-axliga, 4-axliga, 5-axliga CNC-maskiner; svarvar | Säkerställer kapacitet för varierande komplexitet hos detaljerna. |

| Certifieringar | ISO 9001, AS9100 (för flyg- och rymdindustrin) | Uppvisar ett standardiserat kvalitetsledningssystem. |

| Inspektion | CMM, skjutmått, mikrometrar, optiska komparatorer | Garanterar att delar mäts mot dina specifikationer. |

Utöver hårdvara och certifieringar är det den mänskliga faktorn som gör en leverantör till en verklig partner. Hur ett företag kommunicerar och hanterar ditt projekt är lika viktigt som hur de skär metall. En pålitlig partner för CNC-bearbetning av små maskiner ger proaktiva uppdateringar, diskuterar utmaningar på ett öppet sätt och arbetar tillsammans med dig för att hitta lösningar. Deras projekthanteringsprocess bör vara tydlig, med definierade milstolpar från offert till slutleverans. I tidigare projekt har vi lärt oss att en dedikerad projektledare som förstår dina mål kan göra hela skillnaden. Detta tillvägagångssätt lägger grunden för en långsiktig relation där leverantören känns som en förlängning av ditt eget team, som investerar i din framgång.

Utvärdering av partnerskapspotential

| Aspekt | Röd flagga | Grön Flagg |

|---|---|---|

| Kommunikation | Långsamma reaktioner, vaga svar | Proaktiva uppdateringar, tydlig och direkt kontakt |

| Projektledning | Ingen tydlig tidslinje eller process | Särskild kontaktperson, regelbundna rapporter |

| Problemlösning | Skyller problemen på kunden | Tar ansvar och erbjuder lösningar |

Att välja rätt partner för små CNC-bearbetningsföretag kräver en helhetssyn. Balansera deras tekniska färdigheter och kvalitetssystem med deras kommunikationsstil och projektledning. Detta dubbla fokus säkerställer att du får högkvalitativa delar och bygger en pålitlig, långsiktig tillverkningsrelation.

Installationskrav och tekniska specifikationer?

Har du någonsin ställt in din lilla CNC-maskin, kontrollerat alla rutor för kraft och programvara, men ändå inte lyckats få den precision du behöver? Det är frustrerande när enskilda komponenter verkar perfekta, men hela systemet underpresterar.

Nyckeln till optimal prestanda vid CNC-bearbetning av små maskiner ligger i att integrera alla tekniska specifikationer. Verklig precision får du genom att se till att arbetsyta, strömförsörjning, verktyg och programvara fungerar sömlöst tillsammans, vilket eliminerar flaskhalsar och skapar ett verkligt effektivt system.

Verklig precision vid CNC-bearbetning av små detaljer uppstår genom synergin mellan komponenterna, inte bara deras individuella kvalitet. Ett vanligt förbiseende är förhållandet mellan din kraftkälla och dina verktygsval. Detta samspel är avgörande för att uppnå de fina detaljer och ytfinishar som krävs vid högprecisionsarbete. En instabil strömförsörjning kan orsaka mindre fluktuationer i spindelhastigheten, vilket direkt påverkar kvaliteten på skäret, särskilt med känsliga verktyg. Hela det mekaniska systemet, eller Kinematisk kedja7förlitar sig på denna stabilitet. I tidigare projekt på PTSMAKE har vi spårat brister tillbaka till till synes mindre strömavbrott som äventyrat verktygets prestanda.

Anslutningen för elverktyg

Stabil kraft för konsekventa snitt

Även en kortvarig spänningsdipp kan ändra spindelns varvtal, vilket leder till verktygsknatter och synliga defekter på detaljens yta.

Matchning av verktyg och maskinstyrka

Att använda aggressiva verktyg på en spindel med för låg effekt leder till dålig noggrannhet och verktygsbrott.

| Stabilitet i kraftförsörjningen | Spindelvarvtal | Verktygets prestanda | Bearbetning Resultat |

|---|---|---|---|

| Stabilt och rent | Konsekvent | Optimal | Hög precision |

| Fluktuerande | Inkonsekvent | Dålig | Chatter & defekter |

En annan kritisk integrationspunkt är mellan din digitala designmiljö och den fysiska arbetsytan. Din CAM-programvara kan generera felfria verktygsbanor, men de är meningslösa om den fysiska installationen inte kan utföra dem på ett korrekt sätt. Arbetsytan är inte bara en plats där du kan ställa din maskin; den är grunden för hela din verksamhet. På PTSMAKE behandlar vi den fysiska uppställningen med samma omsorg om detaljerna som vår digitala programmering. Detta omfattande tillvägagångssätt är avgörande för att förvandla komplexa konstruktioner till konkreta delar av hög kvalitet.

Överbryggar digitala och fysiska världar

Arbetsytan som fysisk grund

Vibrationer från ett ojämnt golv eller utrustning i närheten kan överföras direkt till arbetsstycket och undergräva precisionen i G-koden. En styv, jämn och isolerad bas är inte förhandlingsbar för liten CNC-bearbetning.

Kalibrera programvaran till din maskin

Programvaran måste kalibreras efter maskinens unika förutsättningar, inklusive kompensation för glapp och verktygsoffset, för att säkerställa att den färdiga detaljen stämmer perfekt överens med den digitala modellen.

Framgångsrik CNC-bearbetning av små maskiner är beroende av en holistisk strategi. Det handlar om att förstå hur tekniska specifikationer för kraft, verktyg, programvara och arbetsyta hänger ihop. Denna synergi är grunden för att uppnå de högprecisionsresultat som förvandlar ett bra projekt till ett exceptionellt.

Vanliga tillämpningar och branschspecifika användningsområden?

Har du någonsin undrat var precisionen i små CNC-bearbetningar verkligen gör skillnad? Det är lätt att förbise hur denna teknik driver de komplexa enheter och system som vi förlitar oss på varje dag.

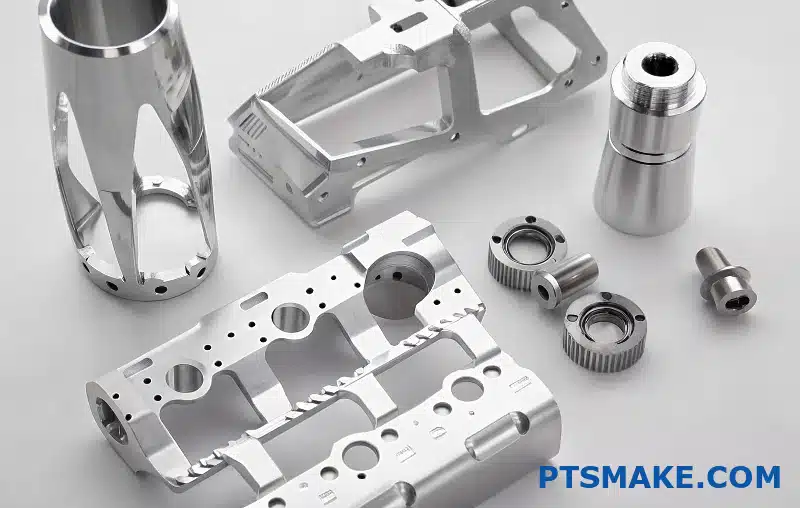

CNC-bearbetning av små detaljer är avgörande för att skapa komponenter med hög precision inom olika sektorer. Viktiga tillämpningar är snabb prototyptillverkning, tillverkning av kundanpassade delar och produktion av små serier för branscher som medicinteknik, flyg, fordon och konsumentelektronik, där snäva toleranser är avgörande.

CNC-bearbetningens mångsidighet gör att den kan bli en hörnstensteknik inom produktutveckling och specialiserad tillverkning. Dess inverkan märks långt innan en produkt når massproduktion. Inom robotteknik, till exempel, kräver skapandet av anpassade leder och kopplingar med exakt rörelse en djup förståelse för komponent kinematik8. På PTSMAKE har vi med egna ögon sett hur ingenjörer utnyttjar denna teknik för att förverkliga komplexa idéer.

Från koncept till verklighet: Snabb prototypframtagning

Ingenjörer behöver validera konstruktioner snabbt. CNC-bearbetning i små serier ger prototyper med slutliga materialegenskaper, vilket är en betydande fördel jämfört med andra metoder för funktionstestning.

Specialiserade komponenter för nischade behov

Denna process är utmärkt för att skapa anpassade jiggar, fixturer eller reservdelar till äldre utrustning, vilket visar på dess flexibilitet.

| Tillämpning | Nyckelfördel med liten CNC-bearbetning | Gemensam industri |

|---|---|---|

| Snabb prototyptillverkning | Funktionstester som är materialnära | Elektronik, medicinteknik |

| Specialtillverkade delar | Hög precision för unika krav | Fordon, Robotteknik |

| Produktion av små partier | Kostnadseffektivt för små volymer | Flyg- och rymdindustrin, specialiserade maskiner |

Utöver utveckling är CNC-bearbetning av små detaljer en viktig del av produktionen av kritiska slutanvändningsdetaljer, särskilt där fel inte är ett alternativ. Möjligheten att arbeta med ett stort antal olika tekniska material gör den oumbärlig för krävande applikationer. I tidigare projekt har vi konstaterat att valet av material är lika avgörande som själva bearbetningsprocessen för att säkerställa komponentens prestanda och livslängd.

Kraftförsörjning för kritiska industrier

Medicintekniksektorn

Precision är av yttersta vikt för kirurgiska verktyg, anpassade implantat och komponenter till diagnostisk utrustning, ofta med biokompatibla material som titan och PEEK.

Fordons- och flygindustrin

Tekniken används för prestandakritiska komponenter i motorer och sensorer samt för specialanpassade inredningsdetaljer där både styrka och låg vikt är viktiga egenskaper.

Konsumentelektronik

Invecklade aluminiumhöljen, små kontakter och interna monteringsfästen för enheter som smartphones, drönare och kameror tillverkas ofta med hjälp av små CNC-bearbetningar.

Från de första prototyperna och anpassade fixturer till kritiska slutanvändningsdelar i krävande sektorer som medicin, flyg och elektronik är CNC-bearbetning av små detaljer oumbärlig. Dess precision och materialflexibilitet gör den till en kärnteknik för modern innovation och tillverkning över hela linjen.

Lär dig hur effektiva verktygsbanor dramatiskt kan minska dina bearbetningstider och -kostnader. ↩

Upptäck hur korrekta lösningar för arbetsuppspänning dramatiskt kan förbättra precisionen och effektiviteten i dina bearbetningsoperationer. ↩

Förstå hur denna riktningsegenskap kan påverka styrkan och integriteten hos dina CNC-bearbetade delar. ↩

Lär dig hur denna metod validerar mätsystemets tillförlitlighet för att säkerställa att dina kvalitetsdata är tillförlitliga. ↩

Upptäck hur en djup förståelse för detta mått kan hjälpa dig att bättre uppskatta projektets tidsramar och identifiera möjligheter till kostnadsbesparingar. ↩

Lär dig hur detta symboliska språk säkerställer att din designintention översätts perfekt till en fysisk del. ↩

Lär dig hur maskinens mekaniska struktur direkt påverkar den slutliga noggrannheten i dina små CNC-bearbetningsprojekt. ↩

Lär dig mer om principerna för rörelse i mekaniska system för att förbättra din komponentdesign. ↩