You’re planning a critical project that demands precision parts, but choosing the wrong CNC machining partner could mean costly delays, quality issues, and budget overruns that derail your entire timeline.

The right precision CNC machining service partner combines advanced equipment, proven quality systems, material expertise, and reliable communication to deliver consistent results from prototype through production while meeting your specific industry requirements and deadlines.

I’ve worked with hundreds of manufacturing teams at PTSMAKE who faced this exact challenge. The difference between a successful project and a problematic one often comes down to asking the right questions upfront. Smart procurement managers focus on technical capabilities, certifications, and communication processes rather than just price. This guide walks you through the key factors that separate reliable CNC machining partners from those that create headaches, plus practical evaluation criteria you can use immediately.

Material Versatility: Meeting Diverse Industry Needs?

Have you ever found your design compromised by material limitations? Does selecting a less-than-ideal material risk project delays or performance failures, adding unnecessary stress and cost?

The true power of a precision cnc machining service lies in its material versatility. It allows for the processing of a vast array of metals, plastics, and composites, ensuring that the perfect material properties—strength, weight, or biocompatibility—can be selected for any specific application.

Material selection is the cornerstone of any successful engineering project. The choice you make directly impacts everything from performance and durability to cost and manufacturability. This is where the flexibility of CNC machining truly shines. It isn’t just about cutting metal; it’s about shaping the ideal solution from the most suitable material available.

The Core Material Groups

In our projects at PTSMAKE, we typically work with three primary categories of materials, each offering a unique set of properties that can be tailored to specific needs.

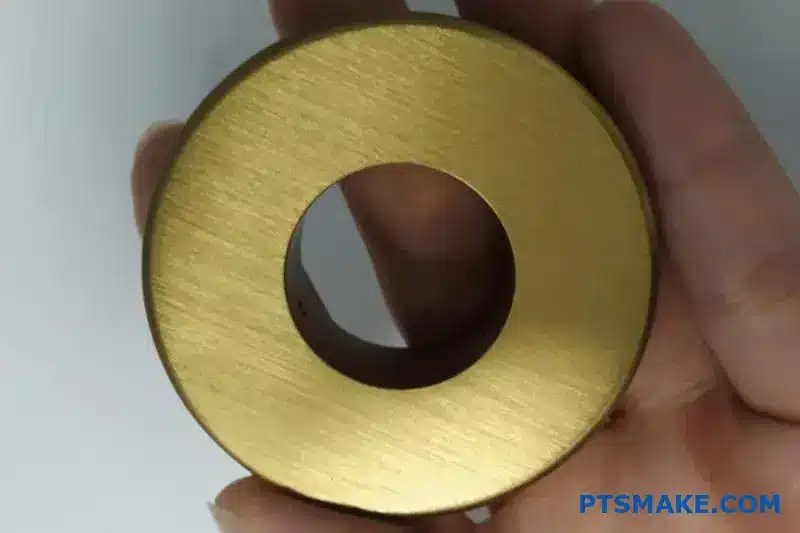

1. Metals: The Workhorses of Industry

Metals are often the default choice for applications requiring high strength, durability, and thermal resistance.

- Aluminum (e.g., 6061, 7075): Valued for its excellent strength-to-weight ratio and natural corrosion resistance. It’s a go-to for aerospace components, automotive parts, and consumer electronics enclosures.

- Steel (e.g., Stainless Steel 304/316, Tool Steels): Known for its toughness, hardness, and versatility. Stainless steel is critical in medical devices and food-grade equipment, while tool steels are essential for creating molds and dies.

- Titanium: This premium material offers the strength of steel at roughly half the weight, along with exceptional corrosion resistance and biocompatibility. It’s indispensable in high-performance aerospace and medical implant applications.

| Metal Type | Key Properties | Common Applications |

|---|---|---|

| Aluminum 6061 | Good strength, machinability, weldability | Structural components, electronics |

| Stainless Steel 304 | Corrosion resistance, formability | Medical instruments, kitchenware |

| Titanium (Ti-6Al-4V) | High strength-to-weight, biocompatible | Aerospace parts, medical implants |

2. Plastics & Polymers: Lightweight and Adaptable

Modern plastics offer a remarkable range of properties, from chemical resistance to electrical insulation. They are often easier and faster to machine, which can provide significant cost benefits. Materials like PEEK, Delrin (POM), and Polycarbonate are perfect for creating complex, lightweight parts that don’t require the brute strength of metal.

3. Composites: Engineered for Performance

Composites like carbon fiber are at the forefront of material innovation. By combining different materials, they achieve properties that are impossible to attain with a single substance. Machining composites requires specialized knowledge due to their abrasive nature and tendency for delamination, but the results are parts with incredible stiffness and minimal weight. Their anisotropic properties1 must be carefully considered during the design and manufacturing phases to ensure strength is oriented correctly.

Beyond simply knowing which materials can be machined, the real skill lies in selecting the optimal one for a specific industry and application. A material that is perfect for a consumer electronic device would likely fail catastrophically in an aerospace context. A reliable precision cnc machining service partner does more than just cut parts; they provide guidance on material selection to ensure your project’s success.

Strategic Material Selection for Key Industries

Over the years, we’ve seen clear patterns in material choices across different sectors. This isn’t about following trends; it’s about aligning material science with real-world operational demands.

Aerospace and Defense

This industry is defined by one primary goal: maximizing strength while minimizing weight. Every gram counts.

- Materials: Titanium alloys, high-strength aluminum (7075), and carbon fiber composites are standard.

- Why: These materials can withstand extreme temperatures, pressures, and mechanical stress without adding unnecessary mass. The focus is on performance and safety above all else.

Medical and Healthcare

Here, the requirements shift to biocompatibility, sterilizability, and precision. Parts must be safe for human contact and withstand repeated sterilization cycles.

- Materials: Medical-grade Stainless Steel (316L), Titanium, and high-performance plastics like PEEK and Radel are common.

- Why: These materials do not react with bodily fluids, are non-toxic, and can endure harsh cleaning methods like autoclaving.

Automotive

The automotive world is a balancing act between performance, durability, and cost-effectiveness for mass production.

- Materials: A mix of aluminum for lightweighting, various steel alloys for structural integrity, and durable plastics like ABS and Nylon for interior components.

- Why: The goal is to create reliable, long-lasting parts that meet performance targets without making the final vehicle prohibitively expensive.

| Industry | Primary Requirement | Common Materials |

|---|---|---|

| Aerospace | Strength-to-Weight Ratio | Titanium, Aluminum 7075, Composites |

| Medical | Biocompatibility | Stainless Steel 316L, PEEK, Titanium |

| Automotive | Durability & Cost | Steel Alloys, Aluminum 6061, ABS |

| Electronics | Thermal & Electrical | Aluminum, Copper, Polycarbonate |

In past explorations with clients, we’ve discovered that switching from a traditional steel component to a precisely machined aluminum 7075 part can reduce weight by over 50% while maintaining the required structural integrity. This highlights how thoughtful material selection, enabled by versatile CNC machining, can unlock significant product innovation.

The versatility of a quality precision cnc machining service is defined by its ability to work with a wide spectrum of materials. This flexibility allows engineers to select the perfect substance for any application, from high-strength metals like titanium for aerospace to biocompatible plastics like PEEK for medical devices. Understanding these material properties and their alignment with industry-specific demands is crucial for turning innovative designs into reliable, high-performance products that meet both budget and performance targets.

Efficiency and Cost-Effectiveness in Production.

Have you ever faced production bottlenecks that inflate costs and delay your timelines? Are manual processes and long setup times eating into your project’s budget and causing unnecessary stress?

Precision CNC machining services boost efficiency through automation and continuous operation, which drastically cuts labor costs, reduces material waste, and shortens production cycles. This makes it a highly cost-effective method for creating initial prototypes and scaling to full production runs.

The Pillars of CNC Machining Efficiency

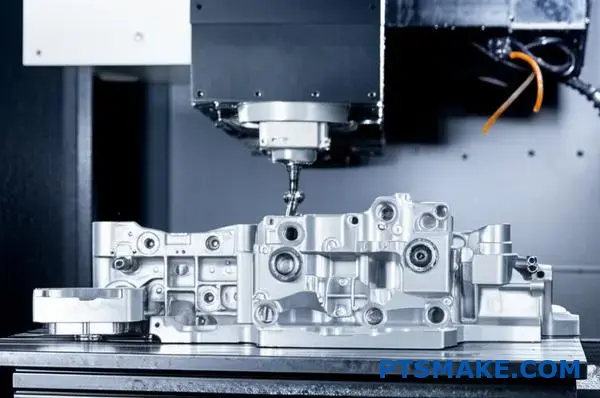

The core advantage of any precision CNC machining service lies in its systematic approach to production. It’s not just about cutting metal; it’s about creating a streamlined, repeatable, and highly efficient manufacturing process. This efficiency is built on three main pillars: automation, continuous operation, and optimized setup procedures. Each element works together to transform a digital design into a physical part with minimal friction.

The Power of Automation

Automation is the engine of CNC machining. Once a machine is programmed with the CAD model and tooling is set, it can execute complex operations with minimal human intervention. This is a world away from manual machining, which demands the constant attention of a skilled operator for every single cut. This automated process nearly eliminates the risk of human error, leading to exceptional consistency from the first part to the ten-thousandth. This repeatability is non-negotiable in industries like aerospace and medical devices, where even the smallest deviation can have significant consequences. Furthermore, automation allows skilled technicians to shift their focus from repetitive manual tasks to higher-value activities like programming, process optimization, and quality assurance.

Achieving 24/7 "Lights-Out" Operation

One of the most powerful capabilities of modern CNC centers is the ability to operate around the clock, often referred to as "lights-out" manufacturing. These machines can continue production overnight and through weekends, long after the last employee has gone home. This drastically increases a facility’s output capacity without the need for a larger physical footprint. In past projects at PTSMAKE, we’ve utilized this 24/7 capability to meet extremely tight deadlines for clients, turning what would have been a multi-week project into one that was completed in days. This ability to maximize machine uptime is a game-changer for accelerating project timelines. Advanced CAM software can accurately translate complex design intent, including intricate specifications from Geometric Dimensioning and Tolerancing (GD&T)2, directly into flawless machine code.

Slashing Setup Times

Setup time—the period spent preparing a machine for a new job—can be a major source of inefficiency. However, modern CNC practices have significantly reduced this downtime. Techniques like quick-change tooling, standardized workholding fixtures, and pallet systems allow operators to prepare the next job while the current one is still running.

| Task | Traditional Setup | Modern CNC Setup |

|---|---|---|

| Tool Changing | Manual, one by one | Automatic Tool Changer (ATC) |

| Workpiece Clamping | Custom jigs, manual alignment | Modular fixtures, pallet systems |

| Program Loading | Manual data entry | Direct network transfer |

| First-Part Inspection | Manual measurement | In-machine probing, CMM |

By minimizing the time a machine sits idle between jobs, we can increase overall throughput and maintain a more agile production schedule.

How Efficiency Translates to Cost-Effectiveness

Efficiency gains are impressive, but for any project, the ultimate question is how they impact the bottom line. Every improvement in the CNC machining process, from automation to faster setups, directly contributes to a more cost-effective manufacturing solution. The financial benefits are realized through reduced operational expenses, optimized material usage, and the strategic advantage of speed.

Driving Down Production Costs

The financial impact of CNC efficiency is clear and direct. By analyzing the primary cost drivers in manufacturing—labor and materials—we can see how CNC machining creates value.

Reduced Labor Expenses

Automation fundamentally changes the labor equation. A single skilled technician can often oversee multiple CNC machines simultaneously, a stark contrast to the one-operator-per-machine requirement of manual processes. With machines running 24/7, the labor cost is spread across a much larger volume of parts, significantly lowering the cost-per-unit. This doesn’t mean eliminating skilled jobs; it means leveraging human expertise for programming and quality control, not for repetitive manual labor.

Optimized Material Usage and Minimized Waste

Precision is the enemy of waste. CNC machines execute cutting paths with micron-level accuracy, ensuring that material is removed exactly as intended. This precision minimizes the amount of raw material that ends up as scrap. In our tests, we’ve found that the consistent accuracy of CNC can reduce material waste by a noticeable percentage compared to less controlled processes. Fewer rejected parts due to manufacturing errors also means less wasted material, less rework, and lower overall project costs.

The Financial Advantage of Faster Turnaround Times

In today’s competitive market, speed is currency. The efficiency of a precision CNC machining service provides a critical time-to-market advantage. Reduced setup and cycle times mean parts are completed and delivered faster. For our clients, this translates into launching products ahead of the competition, fulfilling customer orders sooner, and being more responsive to market demands. Faster turnarounds also enable a more agile supply chain, reducing the need for businesses to hold large, costly inventories. They can order parts as needed, confident in a reliable and speedy delivery schedule. This agility is a powerful financial tool that improves cash flow and reduces risk.

CNC machining boosts production efficiency through automation, 24/7 operation, and minimized setup times. This operational excellence directly translates into significant cost savings by cutting labor expenses, reducing material waste, and accelerating project timelines. This dual advantage of speed and economy makes a professional precision CNC machining service an invaluable partner for both rapid prototyping and scalable, high-volume manufacturing, providing a reliable and cost-effective path from design to a market-ready product.

Quality Assurance and Consistency: Why It Matters?

Have you ever faced project delays because a critical batch of parts failed inspection? That frustrating inconsistency can compromise your entire design and timeline, forcing you back to the drawing board.

Quality assurance is the bedrock of reliable manufacturing. It’s a systematic process that guarantees every single component meets precise specifications, ensuring product performance, safety, and regulatory compliance while preventing costly failures and rework.

The Foundation of Trust: Robust Quality Control Processes

In a high-stakes precision cnc machining service, quality control isn’t just a final step; it’s a philosophy embedded in every stage of production. It begins the moment we receive your CAD file and continues long after the part has been shipped. It’s about creating a documented, repeatable system that minimizes human error and guarantees the process itself is stable. At PTSMAKE, we operate on a principle of proactive prevention rather than reactive detection. This means we focus on controlling the variables—machine calibration, tool wear, material consistency, and operator training—to ensure quality is built into the part from the start, not just inspected at the end. This disciplined approach is fundamental to delivering components you can trust without hesitation.

The Tools of the Trade: Advanced Inspection Equipment

Verifying tolerances that are often thinner than a human hair requires more than just a pair of calipers. It demands sophisticated metrology3 equipment capable of measuring with extreme accuracy and repeatability. Without these tools, claiming high precision is just talk.

Coordinate Measuring Machines (CMMs)

CMMs are the gold standard for 3D inspection. A high-precision probe touches various points on a part to map its geometry, comparing the data directly against the original CAD model. This allows us to verify complex features, contours, and positional tolerances that are impossible to measure with hand tools.

Optical and Vision Systems

For delicate parts or features that require non-contact measurement, we use optical comparators and advanced vision systems. These tools project a magnified silhouette of a part onto a screen or use a camera to capture and analyze its dimensions, perfect for checking profiles, threads, and tiny features.

| Inspection Tool | Primary Use | Key Benefit |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Verifying complex 3D geometry and tight tolerances. | Unmatched accuracy for critical dimensions. |

| Optical Comparator | Measuring 2D profiles and features quickly. | Fast, non-contact inspection for production runs. |

| Digital Calipers/Micrometers | Basic dimensional checks on the shop floor. | Quick verification during the machining process. |

| Surface Roughness Tester | Measuring the texture and finish of a surface. | Ensures compliance with functional and aesthetic needs. |

The Gold Standard: ISO 9001 Certification

An ISO 9001 certification isn’t just a certificate to hang on the wall. It’s an independent verification that a company’s quality management system meets rigorous international standards. For you, the customer, it means we have proven, documented procedures for everything from material sourcing and process control to final inspection and corrective actions. It’s your assurance that we are committed to continuous improvement and that every order is handled with the same systematic attention to detail.

Beyond Inspection: Building Consistency into the Process

Achieving consistency, especially across large production runs or repeat orders, is about controlling the entire manufacturing ecosystem. True reproducibility means the 10,000th part is identical to the first, whether they are made days or months apart. This is achieved through a multi-faceted approach that goes far beyond simple final inspection. It’s about building a predictable and stable production environment where quality is the inevitable outcome.

Material Traceability and Validation

Consistency starts with the raw material. We maintain full traceability for all materials, documenting everything from the supplier’s lot number to its chemical and mechanical properties. Before a single chip is cut, we verify that the material meets your exact specifications. This crucial first step eliminates a major variable and prevents downstream failures that could compromise the integrity of your final product.

Process Control and Documentation

Every successful project at PTSMAKE becomes a detailed roadmap for the future. We document every critical parameter: the specific CNC machine used, the cutting tools, spindle speeds, feed rates, and work-holding setups. This "recipe" is stored and linked to your part number. When you place a reorder, we don’t have to reinvent the wheel. We pull up the exact process, ensuring that the part produced a year from now is an exact replica of the one you approved today. This is the core of reliable and scalable production.

When "Close Enough" Leads to Catastrophe

For many of our clients, precision isn’t a luxury; it’s a non-negotiable requirement dictated by safety, regulation, and performance. In these industries, a single component falling out of tolerance can have severe consequences, making consistent quality a matter of critical importance.

| Industry | Primary Quality Requirement | Why Consistency Matters |

|---|---|---|

| Aerospace | Flawless structural integrity, full traceability. | A single part failure can lead to catastrophic system failure. |

| Medical Devices | Biocompatibility, extreme precision, sterility. | Patient safety is paramount; parts must perform perfectly every time. |

| Automotive | Durability, reliability under stress. | Essential for safety systems like brakes and airbags. |

| Robotics | High repeatability, tight assembly tolerances. | Ensures precise movement and operational accuracy. |

In these fields, providing a precision cnc machining service means understanding that our components are often part of a larger, life-critical system. There is no room for error. That’s why our quality assurance system is designed to provide not just parts, but peace of mind.

In summary, quality assurance is far more than a final check. It is a comprehensive system built on advanced inspection tools, certified processes like ISO 9001, and meticulous process control. This commitment ensures every part is not only correct but also consistently reproducible. For industries where safety and reliability are non-negotiable, this disciplined approach is the only way to transform a design into a trustworthy, high-performance product and avoid the immense costs of failure.

Surface Finish and Post-Processing Capabilities?

Have you ever approved a CNC part’s design, only to find the final surface finish doesn’t meet your functional or aesthetic needs? This can lead to costly and time-consuming secondary operations that delay your entire project.

A high-quality precision CNC machining service delivers parts with exceptional as-machined surface finishes. This often eliminates the need for secondary work. When required, integrated post-processing like grinding, broaching, and assembly creates components that are truly ready for immediate use in your final product.

The final surface finish of a machined part is not an afterthought; it’s a critical design feature determined from the very beginning. A part that comes off the machine already meeting your specifications is the most efficient outcome. At PTSMAKE, we focus on achieving this "as-machined" quality to save our clients time and money. This requires a deep understanding of how every variable in the machining process influences the final surface.

The Science of the As-Machined Finish

Achieving a superior finish directly from the CNC machine is a blend of science and experience. It’s not just about running a program. It involves carefully selecting the right cutting tools, optimizing spindle speeds and feed rates, and using the correct coolant strategy. For example, a higher spindle speed combined with a slower feed rate generally produces a finer finish because the tool’s cutting edge engages with the material more frequently over a smaller distance. In our projects, we’ve found that a final "finishing pass"—a very light cut at the end of the process—can dramatically improve the surface quality, often taking a part from a standard finish to one suitable for cosmetic applications.

Matching Finish to Functionality

Not every part needs a mirror-like surface. Over-specifying a finish is a common way project costs can inflate unnecessarily. The key is to match the finish to the part’s function. In our work with clients in the medical and aerospace industries, we often see requirements for very specific surface characteristics. A smooth surface might be needed for a seal, while a slightly rougher texture could be necessary for paint adhesion. Understanding these nuances is a core part of a reliable precision cnc machining service4. We guide our clients through this selection process to ensure they get the performance they need without paying for a finish they don’t.

The following table provides a general guide we use to help clients understand typical surface roughness (Ra) values.

| Ra Value (μm) | Description | Typical Application |

|---|---|---|

| 12.5 – 6.3 | Rough Machined | Clearance surfaces, non-critical components |

| 3.2 – 1.6 | Standard Machined | Most common, general-purpose parts |

| 0.8 – 0.4 | Fine Machined | Mating surfaces, parts requiring good aesthetics |

| < 0.2 | Ground or Polished | Bearings, high-precision shafts, optical components |

By controlling the machining parameters, we can often achieve an Ra of 1.6 μm or even 0.8 μm directly from the mill or lathe, significantly reducing downstream work.

While an excellent as-machined finish is always the goal, some designs inherently require post-processing to achieve the final specifications. This is where a partner with comprehensive in-house capabilities becomes invaluable. Instead of you having to coordinate with multiple vendors for machining, grinding, and assembly, a single-source supplier simplifies your supply chain, reduces lead times, and ensures accountability. This integrated approach is a cornerstone of how we provide value beyond just making chips.

Value-Added Post-Processing Services

These services are not just extra steps; they are strategic manufacturing processes that add critical features or properties to a component. They transform a near-finished part into a fully functional, ready-to-integrate asset.

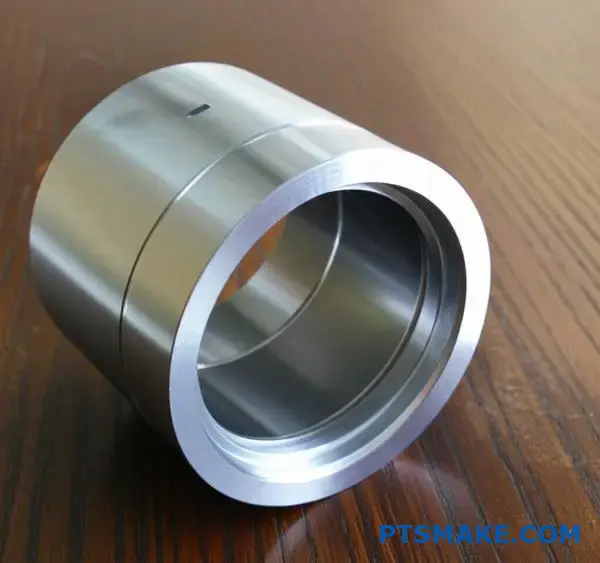

Grinding for Ultimate Precision

When a design requires tolerances or surface finishes that even the best CNC machine can’t achieve alone, grinding is the answer. This abrasive machining process removes tiny amounts of material to achieve extreme flatness, cylindricality, and a mirror-like finish (often below Ra 0.2 μm). We often use grinding for high-performance shafts, precision pins, and critical bearing surfaces where even a microscopic imperfection could lead to failure.

Broaching for Internal Features

What about creating non-round internal shapes, like keyways or splines? While some can be done with advanced CNC techniques, broaching is often faster and more precise. A broach is a tool with a series of progressively taller teeth that is pushed or pulled through a hole to cut a specific shape in a single pass. It’s an incredibly efficient process for producing internal gears or other locking features, and having this capability in-house is a significant advantage.

Assembly for Turnkey Solutions

The ultimate value-add is delivering a component that is ready to be installed right out of the box. Our assembly services can range from simple tasks like pressing in bearings or installing helicoils to more complex sub-assemblies. In a past project for an automotive client, we not only machined a housing but also installed the seals, bearings, and fasteners. This saved their team dozens of hours on the assembly line, allowing them to focus on final product integration. It turns your supplier from a simple parts provider into a true manufacturing partner.

Ultimately, the goal is to get a perfect part efficiently. A top-tier precision CNC machining service achieves this by optimizing the as-machined finish to reduce extra steps. When post-processing is necessary, services like grinding, broaching, and assembly add immense value. By consolidating these capabilities under one roof, a partner like PTSMAKE simplifies your supply chain, shortens lead times, and delivers a complete, ready-to-use component, ensuring your project stays on track and within budget.

Scalability: From Prototyping to High-Volume Production?

Have you ever created a perfect prototype, only to face a manufacturing nightmare when trying to scale up? That critical jump from one unit to thousands can stall your entire project.

CNC machining services offer exceptional scalability by using the same digital design file (CAD) for both single prototypes and large production runs. This digital consistency, combined with rapid machine setup and automation, allows for a seamless transition from prototyping to mass production with minimal friction.

The journey from a concept to a market-ready product is rarely a straight line. The ability to scale efficiently is what separates successful products from those that get stuck in "development hell." A quality precision cnc machining service is built to navigate this journey with you. The core principle lies in the digital nature of the process. Your design exists as a CAD file, which is then translated into machine instructions via CAM software. This single source of truth ensures that the first prototype and the ten-thousandth production part are fundamentally identical.

The Prototyping Advantage

During the initial phases, speed and accuracy are everything. You need to get physical parts in your hands to test form, fit, and function. CNC machining excels here. We can take a design file and produce a high-fidelity prototype in a matter of days, sometimes hours. This allows for rapid iteration. If a design needs a tweak, you simply update the CAD model and we run the program again. There’s no need to invest in expensive tooling or molds just to validate a concept. This phase is about exploring possibilities without committing to a massive upfront cost. The use of standard tooling and simple workholding keeps costs down and turnaround times fast.

The Seamless Transition to Production

Once a design is finalized, the scaling process begins. The beauty of CNC is that the transition doesn’t require starting from scratch. The same CAM program used for the prototype serves as the foundation for production. However, the strategy shifts from speed of iteration to efficiency of production. This involves creating custom fixtures that can hold multiple parts at once, optimizing toolpaths to reduce cycle times, and implementing quality control checks to ensure consistency across the entire batch. In past projects at PTSMAKE, we have seen how careful planning in this transition phase can reduce the cost-per-part significantly. Proper application of Geometric Dimensioning and Tolerancing (GD&T)5 becomes critical here, ensuring every feature on every part meets the exact specification.

| Aspect | Prototyping Phase | High-Volume Production Phase |

|---|---|---|

| Primary Goal | Design validation and iteration | Cost efficiency and consistency |

| Workholding | Standard vises or simple fixtures | Custom, multi-part fixtures |

| Programming | Focused on accuracy and quick setup | Optimized for minimal cycle time |

| Material Usage | Can be less optimized for single parts | Planned for maximum yield from stock |

Beyond the technical setup, the strategic flexibility offered by CNC machining is a massive asset for any business, from a lean startup to an established global manufacturer. This flexibility directly impacts your bottom line, supply chain stability, and ability to react to market changes. It’s about more than just making parts; it’s about building a responsive and resilient manufacturing strategy. The ability to adjust production volumes up or down without severe financial penalties is a game-changer, especially in today’s volatile markets. This agility is a core reason why companies partner with a versatile manufacturing service.

Accommodating Design Evolution

Products are rarely static. Even after a product launch, improvements are identified, or customer feedback necessitates a design change. With manufacturing methods that rely on hard tooling, like injection molding or casting, even a small design tweak can mean weeks of downtime and substantial costs to modify or remake a mold. With CNC machining, the process is far simpler. We update the CAM program, and the next part off the line incorporates the change. This allows for continuous improvement of your product without disrupting the entire supply chain. It empowers an agile development mindset to extend far beyond the software world and into physical hardware production.

Bridge Production and On-Demand Manufacturing

CNC machining provides a perfect solution for "bridge production." This is the process of manufacturing a limited run of parts to meet initial market demand while high-volume tooling, like injection molds, is being prepared. This strategy gets your product to market faster, generating revenue and gathering real-world user data sooner. It also supports an on-demand manufacturing model. Instead of holding a vast, expensive inventory, you can order parts in batches as you need them. In our work with clients at PTSMAKE, this approach has helped them manage cash flow effectively and reduce the risk associated with overproduction, especially for new product introductions. A reliable precision cnc machining service acts as an extension of your own factory floor.

| Business Need | How CNC Machining Provides a Solution |

|---|---|

| Market Uncertainty | Scale production up or down based on actual sales data. |

| Urgent Part Needs | Fast setup allows for quick runs to prevent line-down situations. |

| New Product Launch | Use as bridge production to enter the market while tooling is made. |

| Cash Flow Management | Avoid large capital expenditure on tooling and inventory. |

Scaling from a single prototype to thousands of units is a common hurdle in product development. CNC machining effectively bridges this gap by using a consistent digital file, ensuring fidelity from the first part to the last. This approach offers not just technical consistency but also significant economic flexibility. It easily accommodates design changes and fluctuating demand without the massive re-tooling costs of other methods, providing a reliable and agile path to market for both new and established products.

Selecting the Right Precision CNC Machining Service Provider.

Struggling to sift through countless suppliers for your project? How do you ensure the one you choose won’t cause costly delays or deliver parts that fail inspection?

Choosing the right precision CNC machining service requires evaluating technical capabilities, quality certifications, industry experience, and customer support. Use a structured checklist to objectively compare providers and ensure they can meet your project’s specific demands for complexity, quality, and delivery.

Finding a partner is more than just getting a quote; it’s about securing a reliable link in your supply chain. The right choice can accelerate your time to market, while the wrong one can derail it completely. Let’s break down the essential criteria for making a confident decision.

Technical Capabilities: Look Beyond the Machine List

A long list of 5-axis machines is impressive, but it doesn’t tell the whole story. The real value lies in the expertise behind the equipment. When evaluating a potential provider, you need to dig deeper into their true capabilities.

Equipment and Tolerances

First, confirm their machinery aligns with your project’s needs. Do you need the complex geometries that 5-axis milling provides, or is 3-axis sufficient? More importantly, what are their stated tolerance capabilities? Ask for examples of past work that demonstrate their ability to hold tight tolerances, especially on materials similar to yours. In our work at PTSMAKE, we often show potential clients sample parts that highlight our precision work, which speaks louder than any spec sheet.

Material Expertise

A shop might list dozens of materials, but they will have deeper expertise in a select few. If your project involves a challenging material like Inconel or a specific medical-grade plastic, ask about their experience with it. Inquire about their tooling, cutting speeds, and any challenges they’ve overcome with that specific material. A knowledgeable partner will offer valuable insights that can improve the final part. The science of part measurement, or Metrology6, becomes especially critical with exotic materials that have unique thermal expansion properties.

Validating Quality and Experience

Certifications and industry experience are your proof of a provider’s commitment to quality and their understanding of your market’s demands.

Certifications as a Baseline

Certifications like ISO 9001 are non-negotiable. They indicate that the provider has a robust Quality Management System (QMS) in place. This means they have standardized processes for everything from order entry to final inspection, ensuring consistency and traceability. For specific industries, look for additional certifications like AS9100 for aerospace or ISO 13485 for medical devices. These are not just badges; they are frameworks that dictate a higher level of process control and documentation.

Here’s a quick reference for key quality indicators:

| Quality Indicator | What It Means for You |

|---|---|

| ISO 9001:2015 | Consistent quality and process control. |

| CMM Inspection Reports | Verifiable proof that parts meet dimensional specs. |

| Material Certifications | Full traceability of raw materials used. |

| First Article Inspection (FAI) | Assurance that the production setup is correct. |

These elements build a foundation of trust. Without them, you’re gambling on your supplier’s ability to consistently meet your standards.

Beyond the technical specs and certifications lies the human element of the partnership. How a supplier communicates, supports your design process, and scales with your needs is just as critical as their ability to machine a part.

Communication and Proactive Support

Poor communication is a major red flag. If a potential supplier is slow to respond to your initial RFQ, imagine how they’ll handle a critical issue mid-production. A great partner acts as an extension of your team.

The Value of DFM Feedback

Look for a provider that offers Design for Manufacturability (DFM) feedback. This proactive approach is a sign of a true partner. Instead of blindly machining a flawed design, they will suggest modifications that can reduce cost, improve strength, or shorten machining time. This collaborative process not only saves money but also results in a better final product. It shows they are invested in your success, not just in completing an order.

Responsiveness and Transparency

A dedicated point of contact is essential. You need to know who to call when you have a question or need an update. Their communication should be clear, concise, and transparent, especially if issues arise. A provider who openly discusses a challenge and presents a solution is far more valuable than one who stays silent until the deadline has passed.

Turnaround Time and Scalability

Finally, you need a partner who can meet your timeline and grow with you.

Balancing Speed and Quality

Everyone wants parts quickly, but the cheapest and fastest option is rarely the best. True on-time delivery means receiving quality, in-spec parts by the promised date. Ask potential providers about their typical lead times for projects of similar complexity. Also, inquire about their on-time delivery rate. A reliable precision CNC machining service will have metrics to back up their claims.

From Prototype to Production

Your needs may change. Today you might need a handful of prototypes, but next year you could need thousands of units. Can the provider scale with you? A partner with capabilities for both rapid prototyping and full-scale production, like we have at PTSMAKE, simplifies your supply chain significantly. You avoid the hassle of re-sourcing and re-qualifying a new supplier when your volume increases.

To help you compare potential partners, I’ve created this simple checklist.

| Evaluation Criteria | Provider A | Provider B | Provider C |

|---|---|---|---|

| ISO 9001 Certified? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

| Relevant Industry Experience? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

| 5-Axis Machining Available? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

| Offers DFM Feedback? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

| Dedicated Contact Person? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

| Scalable Production? | ☐ Yes / ☐ No | ☐ Yes / ☐ No | ☐ Yes / ☐ No |

Use this as a starting point to conduct a thorough and objective evaluation.

Choosing the right precision CNC machining service is a strategic decision, not a simple transaction. By systematically evaluating potential partners on their technical capabilities, quality systems, industry expertise, and communication practices, you can find a supplier that truly functions as an extension of your team. Using a checklist to compare providers ensures you make an objective, data-driven choice, mitigating risks and setting your project up for success from the very beginning.

Industry Applications: Real-World Use Cases?

Ever wondered how a single manufacturing process can be critical for both a rocket engine and a life-saving surgical implant? The challenges seem worlds apart, yet the solution is often the same.

Precision CNC machining is the common thread, providing the unparalleled accuracy and material versatility required by demanding industries like aerospace, automotive, medical, and electronics. It transforms complex digital designs into high-performance, real-world components with exceptional reliability.

Theory is one thing, but seeing how a precision cnc machining service performs in the real world is what truly matters. In my experience, the right application of this technology can be the difference between a project’s success and failure, especially in industries where there is no room for error.

The Aerospace and Defense Sector

In aerospace, every gram counts and failure is not an option. Components must withstand extreme temperatures, pressures, and vibrations. This is where the precision of 5-axis CNC machining truly shines. We often work with advanced materials like titanium alloys and Inconel, which are notoriously difficult to machine. The goal is to create complex, lightweight parts without compromising structural integrity.

A great example comes from a project at PTSMAKE involving a structural bracket for a satellite. The original design was bulky. By using topology optimization software and our 5-axis machining capabilities, we were able to remove 40% of the material while maintaining the required strength. This direct weight saving translates into lower launch costs and increased payload capacity for our client. The machine’s ability to maintain tight tolerances across complex curvatures was absolutely critical. This level of precision ensures that every part fits perfectly during assembly, eliminating costly delays. The anisotropic7 nature of some advanced composites also demands specific machining strategies to prevent delamination.

The Automotive Industry

The automotive world is driven by efficiency, reliability, and cost-effectiveness. From engine blocks to transmission components, CNC machining is essential for producing parts that meet strict performance standards. The push towards electric vehicles (EVs) has introduced new challenges, such as manufacturing lightweight battery enclosures and intricate motor components with extremely tight tolerances to maximize efficiency.

Based on our collaborations with automotive clients, a key area is prototyping. Before committing to the high cost of tooling for mass production, companies need to validate their designs. We use CNC machining to produce high-fidelity prototypes of engine pistons or gearbox housings. These parts are so accurate that they can be used for real-world performance testing. This allows engineers to identify design flaws early, iterate quickly, and move to production with confidence.

| Industry | Key Challenge | CNC Machining Solution | Common Materials |

|---|---|---|---|

| Aerospace | Extreme strength-to-weight ratio, complex geometries | 5-axis machining, advanced toolpaths | Titanium, Inconel, Aluminum 7075 |

| Automotive | High-volume reliability, cost efficiency, rapid prototyping | Automated CNC cells, high-speed machining | Steel alloys, Aluminum 6061, Cast Iron |

While aerospace and automotive push the boundaries of performance, the medical and electronics industries demand a different kind of perfection—one focused on safety, miniaturization, and flawless functionality. The principles of precision are the same, but the application and requirements are uniquely tailored.

The Medical Device Field

In the medical field, precision is a matter of health and safety. Surgical instruments, orthopedic implants, and components for diagnostic equipment must be manufactured with absolute accuracy and from biocompatible materials. There is zero tolerance for surface imperfections that could harbor bacteria or cause adverse reactions in the human body.

We frequently machine parts for surgical robotics from materials like PEEK and medical-grade stainless steel. These components often have intricate internal channels and extremely fine features that are impossible to create with other methods. The surface finish is just as important as dimensional accuracy. Our process ensures a smooth, crevice-free finish that is easy to sterilize. For a client developing a new knee implant, we machined prototypes from titanium that perfectly matched the complex geometry of the patient’s anatomy derived from MRI data. This level of customization, enabled by a top-tier precision cnc machining service, is revolutionizing patient care.

The Consumer Electronics Industry

Think about the smartphone in your pocket. Its sleek metal casing, the tiny connectors, and the internal components that dissipate heat—all are products of precision CNC machining. The challenge in electronics is often miniaturization. As devices get smaller and more powerful, the components inside must be more compact and precise than ever.

Heat sinks are a common component we produce for electronics companies. They are typically made from aluminum or copper and feature complex fin designs to maximize surface area for heat dissipation. Machining these thin fins without them warping or breaking requires careful planning and specialized tooling. In our testing and development, we’ve found that the precision of the cut directly impacts thermal performance. A deviation of even a few microns can reduce efficiency. This is why leading electronics brands rely on CNC machining for their premium products, ensuring both aesthetic perfection and functional reliability.

| Industry | Key Challenge | CNC Machining Solution | Regulatory Focus |

|---|---|---|---|

| Medical | Biocompatibility, extreme accuracy, flawless surface finish | Swiss-type machining, micro-machining | FDA, ISO 13485 |

| Electronics | Miniaturization, thermal management, aesthetic quality | High-speed milling, precision turning | RoHS, WEEE |

From satellite brackets to surgical implants, precision CNC machining proves its value across diverse, high-stakes industries. It’s not just about making parts; it’s about solving specific, critical challenges. The technology provides the necessary accuracy for aerospace’s lightweighting needs, the reliability for automotive components, the biocompatibility for medical devices, and the miniaturization required by modern electronics. Each application showcases the tangible impact of precision on performance, safety, and innovation in the real world.

What Are the Emerging Trends and Innovations in Precision CNC Machining?

Struggling to keep up with manufacturing technology that seems to change overnight? Are you worried that traditional machining methods are limiting your design potential and increasing your production costs?

The most significant trends are multi-axis machining, automation, seamless CAD/CAM integration, and the Industrial Internet of Things (IIoT). These innovations are revolutionizing precision CNC machining services by enabling more complex parts, improving efficiency, reducing errors, and ensuring greater reliability through predictive maintenance.

The Shift to Smarter, More Capable Machines

The core of modern manufacturing is evolving. It’s no longer just about cutting metal; it’s about doing it smarter, faster, and with greater precision than ever before. Two major physical trends are leading this charge: multi-axis machining and automation. These are not just buzzwords; they represent a fundamental shift in how we approach part production. In my experience, embracing these technologies is what separates a good machine shop from a great one.

Multi-Axis Machining: Beyond Three Dimensions

Traditionally, CNC machines operated on three axes (X, Y, and Z). While effective, this setup often required multiple fixtures and manual repositioning for complex parts, which introduced opportunities for error and increased setup times. The move to 5-axis machining has been a game-changer. By adding two rotational axes, a 5-axis machine can approach a workpiece from virtually any angle. This allows us to machine intricate geometries in a single setup, which is critical for industries like aerospace and medical devices. This single-setup approach, known as "done-in-one," drastically improves accuracy because the part isn’t moved between operations. This minimizes tolerance stack-up and ensures the final part perfectly matches the design intent. The machine’s kinematics8 become far more complex, but the resulting part quality and efficiency are undeniable.

Automation and Robotics: The Rise of Lights-Out Manufacturing

Automation is another trend that is reshaping the shop floor. This goes beyond just the CNC machine’s automated tool changes. We’re talking about integrating robotic arms for loading and unloading raw materials and finished parts, automated quality inspection systems, and pallet changers that allow machines to run continuously. At PTSMAKE, we’ve seen how integrating robotics allows for "lights-out" manufacturing, where production continues unattended overnight or on weekends. This not only increases our capacity and speeds up delivery times but also improves consistency. A robot performs the same task with the same precision every single time, removing the variability that can come with manual handling. This level of automation is essential for providing a scalable and reliable precision cnc machining service.

| Feature | 3-Axis Machining | 5-Axis Machining | Key Advantage of 5-Axis |

|---|---|---|---|

| Workpiece Access | Limited to 3 linear axes | 5 axes (3 linear, 2 rotational) | Access to complex and deep features |

| Setups Required | Multiple for complex parts | Often a single setup | Reduced setup time and fewer errors |

| Tool Length | Requires longer tools for deep cuts | Can use shorter, more rigid tools | Better surface finish and higher accuracy |

| Ideal For | Simpler, prismatic parts | Complex contours and geometries | Unlocks advanced design possibilities |

The Digital Thread: Connecting Design to Delivery

While advancements in machine hardware are impressive, the software and data integration behind them are equally transformative. The "digital thread" refers to the seamless flow of information from the initial CAD model all the way through to the final inspected part. This connectivity is powered by advanced software and the Industrial Internet of Things (IIoT), and it’s essential for a modern precision CNC machining service.

CAD/CAM Integration: From Design to Toolpath

The link between Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software has become incredibly sophisticated. In the past, translating a 3D model into machine code (G-code) could be a cumbersome and error-prone process. Today, integrated CAD/CAM systems can automatically generate highly efficient toolpaths directly from the native design file. Advanced algorithms can simulate the entire machining process, detecting potential collisions and optimizing cutting strategies for speed and tool life before a single piece of metal is cut. This deep integration means we can move from a customer’s design to actual production much faster. It also allows us to provide valuable Design for Manufacturability (DFM) feedback, suggesting minor design tweaks that could significantly reduce machining time and cost.

IIoT and Predictive Maintenance: Data-Driven Reliability

The Industrial Internet of Things (IIoT) is about connecting machines to a network and using the data they generate to make smarter decisions. Sensors placed on spindles, motors, and other critical machine components collect real-time data on temperature, vibration, and performance. By analyzing this data, we can move from reactive maintenance (fixing things when they break) to predictive maintenance. Algorithms can detect subtle changes in machine behavior that indicate a potential failure is imminent. This allows us to schedule maintenance before a breakdown occurs, preventing costly downtime and ensuring projects stay on schedule. For our clients, this means greater confidence in our ability to deliver high-quality parts on time, every time.

| Innovation | Impact on Manufacturing | Benefit for the Customer |

|---|---|---|

| Integrated CAD/CAM | Reduces programming time and errors | Faster time-to-market and lower costs |

| Machining Simulation | Prevents crashes and optimizes toolpaths | Higher part quality and design confidence |

| IIoT Sensors | Enables real-time machine monitoring | Improved on-time delivery and reliability |

| Predictive Analytics | Prevents unexpected machine downtime | Consistent production and dependable supply chain |

The precision CNC machining industry is rapidly advancing, driven by innovations that enhance both physical and digital capabilities. Key trends like multi-axis machining and automation are enabling the production of more complex parts with greater efficiency and consistency. Simultaneously, the integration of CAD/CAM software and the use of IIoT for predictive maintenance are creating a seamless digital thread from design to delivery. These trends collectively empower a modern precision cnc machining service to offer superior quality, speed, and reliability.

Environmental Impact and Sustainability in CNC Machining?

Have you ever questioned the environmental cost behind your precision components? The manufacturing footprint is a growing concern that can add hidden risks and complexities to any project.

Modern CNC machining significantly reduces environmental impact by optimizing material use, lowering energy consumption, and enabling robust recycling programs. This makes it a far more sustainable choice than many traditional manufacturing methods for creating high-precision parts.

When we discuss manufacturing, efficiency is often measured in time and cost. However, a crucial third metric is emerging: sustainability. Modern precision CNC machining services are not just about creating perfect parts; they are also about doing so responsibly. The environmental advantages over traditional methods are substantial and begin at the most fundamental level.

Minimizing Material Waste: The Core of CNC Sustainability

While CNC machining is a subtractive process, it’s engineered for maximum material efficiency. Sophisticated CAD/CAM software allows us to create highly optimized toolpaths that remove only the absolute minimum material required to achieve the final geometry. This is a stark contrast to older manual methods, which often involved more guesswork and resulted in higher scrap rates. We can simulate the entire process beforehand, ensuring the first part is as efficient as the last. This digital precision drastically reduces waste before a single chip is cut. A full Life Cycle Assessment9 often reveals that optimized machining is superior to processes requiring new molds or dies for each design iteration.

Slashing Energy Consumption

The machines themselves are a huge part of the sustainability equation. Newer CNC centers are designed with energy efficiency in mind, featuring variable-speed drives, smart coolant pumps, and low-power standby modes that activate during downtime. At PTSMAKE, we’ve found that upgrading to modern equipment can cut energy use per part by as much as 30%. Furthermore, the speed and automation of CNC mean machines run for shorter durations compared to the multi-step, labor-intensive processes of traditional fabrication, leading to a smaller overall energy footprint for the entire production run.

| Feature | Traditional Manufacturing | Modern CNC Machining |

|---|---|---|

| Material Utilization | Lower, higher scrap rates | High, optimized with software |

| Energy Consumption | Often high and constant | Lower, with energy-saving modes |

| Coolant/Lubricants | Often oil-based, hazardous | Water-based, biodegradable, or dry |

| Process Control | Operator-dependent | Digitally controlled, repeatable |

Reducing the Overall Environmental Footprint

Sustainability extends to the consumables used in the process. Many older manufacturing techniques relied on harsh, petroleum-based coolants that were difficult and costly to dispose of responsibly. The industry is rapidly shifting towards safer alternatives. Many modern CNC operations, including ours, now use biodegradable, water-based coolants or even employ dry machining or minimum quantity lubrication (MQL) techniques where the material and application allow. This simple change eliminates a significant source of hazardous waste, making the workplace safer and the process greener.

Beyond simply reducing waste during production, a forward-thinking precision cnc machining service builds sustainability into its entire operational philosophy. This involves creating closed-loop systems and adopting technologies that minimize environmental impact at every stage, from material sourcing to facility management. These proactive initiatives are what separate a good supplier from a truly sustainable partner.

Proactive Sustainability Initiatives in Action

A cornerstone of a green machine shop is a comprehensive recycling program. The metal chips and swarf generated during machining are valuable resources, not trash. In our facility, we have a strict process for collecting and segregating this scrap by material type—whether it’s aluminum, stainless steel, or titanium. This sorted material is then sent to certified recyclers to be melted down and repurposed. This creates a circular economy. For example, recycling aluminum uses about 95% less energy than producing it from raw bauxite ore, a massive environmental saving.

The Smart Use of Raw Materials

Efficiency starts before the machine is even turned on. One key strategy is sourcing "near-net shape" materials. Instead of starting with a large, generic block of metal, we procure raw stock that is already close to the final part’s overall dimensions. This simple step drastically reduces the amount of material that needs to be machined away, which in turn saves machining time, tool wear, and energy. It’s a smarter, leaner approach. We also work with clients to select materials that are not only fit for purpose but are also highly recyclable or available with certified recycled content, further closing the sustainability loop.

Embracing Energy-Saving Technologies

A sustainable operation looks beyond the machines to the entire facility. At PTSMAKE, we view the whole shop as a system to be optimized. This includes initiatives like upgrading to high-efficiency LED lighting, which uses a fraction of the power of older systems. We also run a diligent compressed air leak detection program; even a small, inaudible leak in an air line can waste thousands in energy costs over a year. Modern process optimization software also plays a role. It can simulate different machining strategies and predict energy consumption, allowing our programmers to select the most efficient and eco-friendly toolpath that still meets all quality specifications.

Choosing a modern precision CNC machining service is an investment in both quality and sustainability. By leveraging advanced software to minimize waste, utilizing energy-efficient machinery, and implementing robust recycling programs, we actively reduce the environmental footprint of manufacturing. This responsible approach ensures that your high-performance components are not produced at the planet’s expense. Partnering with a supplier committed to these green initiatives helps you achieve your project goals while upholding your own corporate sustainability standards.

Take Your Precision CNC Machining Projects Further with PTSMAKE

Ready to elevate your manufacturing success? Partner with PTSMAKE—your next-generation ally for quality, efficiency, and scalability in precision CNC machining. Visit www.ptsmake.com or contact us now to discuss your project and get a tailored quote from our experienced team!

Understand how material grain or fiber direction affects strength. This is crucial for designing durable, high-performance parts. ↩

Understand the language of engineering drawings to better communicate your design intent for manufacturing. ↩

Dive deeper into the science of measurement and its critical role in precision engineering. ↩

Click to see how our expertise can save you money by optimizing your part’s design for manufacturing. ↩

Learn how GD&T ensures your design intent is perfectly translated into every part, crucial for successful production scaling. ↩

Click to understand how precise measurement science ensures your parts meet exact specifications. ↩

Learn how a material’s directional properties can affect strength and performance during the machining process. ↩

Understand the principles of machine motion that enable the complex, coordinated movements in multi-axis machining. ↩

Understand the full environmental impact of your product, from raw material to disposal, with this comprehensive methodology. ↩