Designing a gearbox system that delivers precise torque multiplication while maintaining efficiency can make or break your entire mechanical system. One wrong calculation or poor component selection leads to premature failures, excessive energy consumption, and costly downtime that disrupts your production schedule.

Reduction gears are mechanical devices that decrease rotational speed while proportionally increasing torque output through gear ratio multiplication. They operate on the fundamental principle of trading speed for torque, following the conservation of energy with efficiency losses from friction and mechanical interactions.

I’ve worked with engineers who struggle with gearbox selection daily at PTSMAKE. This guide covers 16 essential insights that will help you master reduction gear fundamentals, from basic principles to real-world application challenges you face in your projects.

What is the first principle of reduction gears?

Have you ever wondered how a small motor moves a heavy robotic arm? The secret lies in a fundamental trade-off. The core principle of reduction gears is simple.

They swap high speed for high torque. You can think of a gear as a continuously rotating lever.

This action multiplies force but at the cost of rotational speed. This balance is crucial. It allows us to control and apply power effectively in mechanical systems.

| Wejście | Wyjście |

|---|---|

| Wysoka prędkość | Niska prędkość |

| Niski moment obrotowy | Wysoki moment obrotowy |

At PTSMAKE, this principle guides every gearbox we design and manufacture.

The Physics Behind the Trade-Off

This speed-for-torque exchange isn’t magic. It is governed by the law of conservation of energy. In an ideal system, the power you put in is the power you get out.

Power is a product of rotational speed and torque. So, if you decrease speed, torque must increase to maintain the same power level.

Of course, no mechanical system is perfectly ideal. Energy is always lost to friction and heat. This is where factors like meshing efficiency1 become critical. It quantifies how much power is actually transferred.

How Gears Make it Happen

The gear ratio is what makes this trade-off possible. It’s determined by the number of teeth on the input gear compared to the output gear.

A larger output gear with more teeth rotates much slower than the smaller input gear. In return, it delivers a proportionally higher amount of torque. This mechanical advantage is the source of its power.

In our work at PTSMAKE, we often machine custom gears. We precisely calculate the gear ratio to meet the exact torque and speed requirements for everything from medical devices to robotics.

| Input Gear Teeth | Output Gear Teeth | Redukcja prędkości | Torque Multiplication |

|---|---|---|---|

| 10 | 50 | 5x | ~5x |

| 15 | 90 | 6x | ~6x |

This simple rule is the foundation for all complex reduction gears.

The fundamental principle of reduction gears is trading rotational speed for increased torque. This exchange, governed by energy conservation and gear ratios, allows high-speed motors to produce powerful, controlled force for precision applications.

How is the gear ratio fundamentally calculated and what does it represent?

Calculating the gear ratio is simpler than it sounds. At its core, it’s a comparison between the driven gear and the driving gear. This ratio dictates the machine’s final performance.

The Easiest Method: Teeth Count

The most common way is counting teeth. If the driving gear has 10 teeth and the driven gear has 40, the ratio is 4:1.

Alternative Calculation Methods

You can also use gear diameters or speeds. The principle remains the same—comparing the output to the input. The results are always consistent.

| Metoda obliczania | Formula (Driven Gear / Driving Gear) | Example (40-tooth driven, 10-tooth driver) |

|---|---|---|

| Liczba zębów | Teeth_Driven / Teeth_Driver | 40 / 10 = 4 |

| Średnica | Diameter_Driven / Diameter_Driver | 80mm / 20mm = 4 |

| Angular Speed | Speed_Driver / Speed_Driven | 100 RPM / 25 RPM = 4 |

This number is crucial. It tells you exactly how speed and torque are modified.

The gear ratio is not just an abstract number. It represents a fundamental trade-off in mechanical systems: speed versus torque. Understanding this is key to effective design.

The Core Function: Speed and Torque Trade-off

A gear ratio directly multiplies torque. Simultaneously, it divides speed by the same factor. This is a law of physics; you can’t get something for nothing. You trade speed for power.

For instance, a 4:1 ratio means the output torque is four times greater than the input. However, the output speed will be only one-quarter of the input speed. This principle is the foundation of all reduction gears systems.

What This Means in Practice

In our projects at PTSMAKE, we apply this constantly. If a motor is fast but weak, we use a high gear ratio. This setup increases torque to perform heavy work. The Przewaga mechaniczna2 gained is what allows a small motor to move a large robotic arm.

The relationship is inverse and predictable. Knowing this allows engineers to select the perfect motor and gear combination for any task, ensuring efficiency and reliability.

| Przełożenie | Effect on Output Speed | Effect on Output Torque | Typowy przypadek użycia |

|---|---|---|---|

| 1:1 | Bez zmian | Bez zmian | Napęd bezpośredni |

| 2:1 | Halved (÷2) | Doubled (x2) | Moderate Torque Increase |

| 4:1 | Quartered (÷4) | Quadrupled (x4) | High-Torque, Low-Speed |

| 1:2 | Doubled (x2) | Halved (÷2) | Speed Increase (e.g., fans) |

The gear ratio is a simple comparison between the output and input gears. This single number fundamentally defines the trade-off between output speed and output torque, which is the core of its practical function in any mechanical system.

What defines the efficiency of a reduction gear system?

Efficiency is fundamentally a ratio. It compares the power you get out to the power you put in. No system is 100% efficient. Energy is always lost, often as unwanted heat.

Understanding these losses is crucial for any mechanical design, especially with reduction gears. Let’s break down where this power typically escapes.

Key Areas of Energy Loss

| Źródło strat | Opis |

|---|---|

| Gear Mesh | Friction between engaging gear teeth. |

| Smarowanie | Energy used to churn the oil or grease. |

| Łożyska | Friction within the supporting bearings. |

Let’s dive deeper into these energy losses. Friction is the main culprit, appearing in multiple forms. Each one chips away at your system’s overall efficiency, affecting performance in subtle yet significant ways.

Frictional Losses in Detail

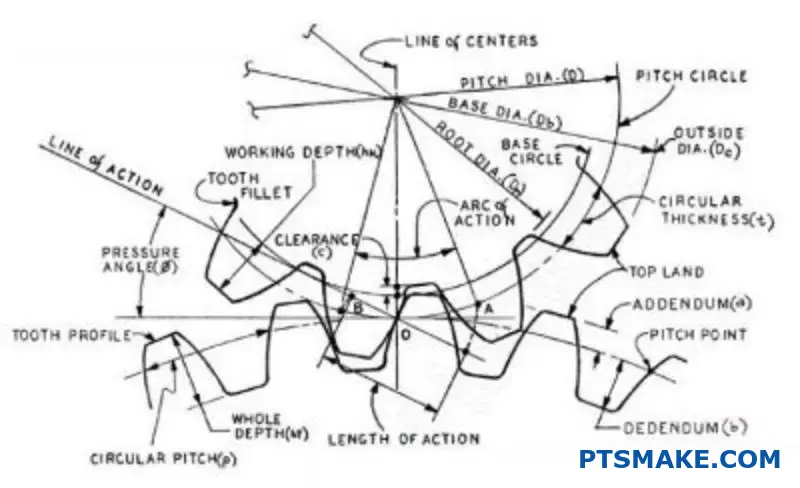

Gear Tooth Interaction

When gear teeth mesh, they slide and roll against each other. This creates friction. The surface finish, material, and pressure angle of the teeth all play significant roles here. Poor manufacturing leads to rougher surfaces and higher losses.

Lubricant Dynamics

The lubricant is essential, but it also causes drag. As gears spin, they churn the oil, creating internal friction. This process, involving viscous shear3, is especially noticeable at high speeds or with high-viscosity lubricants.

Real-World Consequences

These seemingly small losses have big implications. They directly increase energy consumption, leading to higher operating costs. The lost energy also generates heat. This heat must be managed to prevent overheating, which can damage components and reduce lubricant life.

In past projects at PTSMAKE, we’ve helped clients by focusing on tight tolerances and superior surface finishes, which directly minimize these frictional losses.

| Loss Factor | Główny wpływ | Wpływ wtórny |

|---|---|---|

| Tooth Friction | Wytwarzanie ciepła | Component Wear |

| Strata na ubijaniu | Increased Torque Demand | Lubricant Degradation |

| Tarcie łożyska | Zużycie energii | Reduced Bearing Life |

To summarize, a reduction gear system’s efficiency is the ratio of its power output to input. Primary losses stem from friction at the gear teeth, within bearings, and from lubricant churning. These factors directly influence energy use and thermal management.

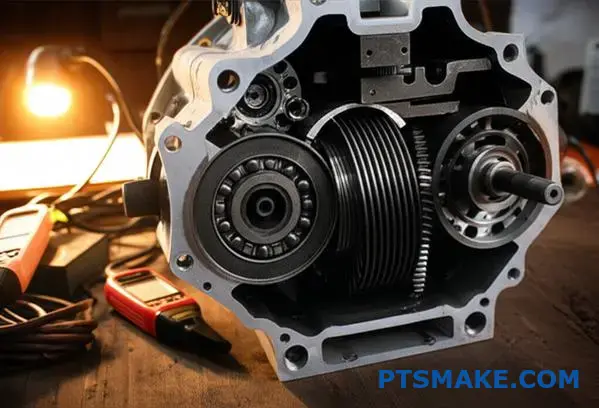

How does a gearbox transmit and multiply torque?

Gears transmit force through their meshing teeth. You can think of each gear as a rotating lever. The contact point is where the force gets applied.

The Lever Arm Principle

The distance from the gear’s center to this contact point is the lever arm. We also call this the pitch radius.

A larger gear naturally has a longer lever arm. When a small input gear turns a large output gear, the force is multiplied. This is the secret behind torque multiplication in reduction gears.

| Gear Attribute | Input Gear (Small) | Output Gear (Large) |

|---|---|---|

| Radius (Lever Arm) | Krótszy | Dłuższy |

| Resulting Torque | Niższy | Wyższy |

This simple principle is fundamental to how gearboxes work. It’s all about leverage.

The Physics of Torque Multiplication

At the point where the teeth meet, the force from the input gear is equal and opposite to the force on the output gear. This is a basic rule of physics.

The key difference is the distance from the center of rotation. We call this the pitch radius4. It functions as the lever arm in the system.

Calculating the Advantage

Torque is simply Force multiplied by Radius (T = F × r). Since the force (F) is the same for both meshing gears, the torque is directly tied to the radius. A gear with twice the radius will output twice the torque.

This mechanical advantage is the core of how reduction gears function.

In our projects at PTSMAKE, precision is everything. The tooth profile and material choice are critical. They ensure this force is transmitted smoothly. Any imperfection can lead to energy loss or component failure, undermining the entire mechanical advantage.

Here is a simple ratio example.

| Komponent | Radius | Siła | Moment obrotowy |

|---|---|---|---|

| Input Gear | 1 unit | 1 unit | 1 unit |

| Output Gear | 3 units | 1 unit | 3 units |

This shows how a 3:1 gear ratio triples the output torque. The trade-off is that the output speed is reduced by the same factor.

In essence, gear teeth transmit a constant force. The output gear’s larger radius acts as a longer lever arm. This mechanism directly multiplies the input force, resulting in a higher output torque, albeit at a reduced speed.

What are the key performance metrics for a reduction gear?

When you’re looking at a datasheet for reduction gears, it’s easy to get lost in the numbers. But a few key metrics truly define performance. These specifications tell you exactly what the gear can do.

Understanding the Core Numbers

We focus on these specs to match the right component to the application. It ensures reliability and precision.

Torque and Speed

Rated torque is your continuous-duty limit. Peak torque is for short bursts, like startup. The input speed sets the maximum operational RPM for the gearbox.

| Metryczny | Practitioner’s Viewpoint |

|---|---|

| Rated Torque | The safe, everyday working load. |

| Szczytowy moment obrotowy | The "push it" limit for brief moments. |

| Input Speed | The redline you should not cross. |

| Przełożenie | The fundamental speed vs. torque trade-off. |

These numbers are the foundation of your selection process.

The Nuances: Backlash and Efficiency

Beyond the primary specs, backlash and efficiency are crucial for precision systems. They often separate a good design from a great one. These factors dictate the accuracy and energy consumption of your machine.

Backlash is the small gap or "play" between gear teeth. In robotics or CNC machining, high backlash can cause inaccuracies. It directly contributes to positional error5 in the final output. Minimizing this is a key goal in high-precision manufacturing, a challenge we often tackle at PTSMAKE.

Efficiency measures how much power makes it from the input to the output. The rest is lost, mostly as heat. Higher efficiency means less wasted energy and simpler thermal management for the system.

Szybkie porównanie

Different gear types offer different trade-offs. The choice depends entirely on your application’s needs for precision versus cost.

| Typ przekładni | Typical Backlash (arc-min) | Typical Efficiency (%) |

|---|---|---|

| Ostroga | 5 – 20 | 94 – 98 |

| Planetarny | 1 - 8 | 95 – 98 |

| Harmoniczny | < 1 | 70 – 85 |

As you can see, a harmonic drive offers incredible precision. However, this comes at the cost of lower efficiency compared to a planetary gearbox.

A datasheet provides the essential metrics for choosing reduction gears. While torque and ratio are fundamental, backlash and efficiency are critical for precision and energy use, dictating the system’s true performance and long-term operating costs.

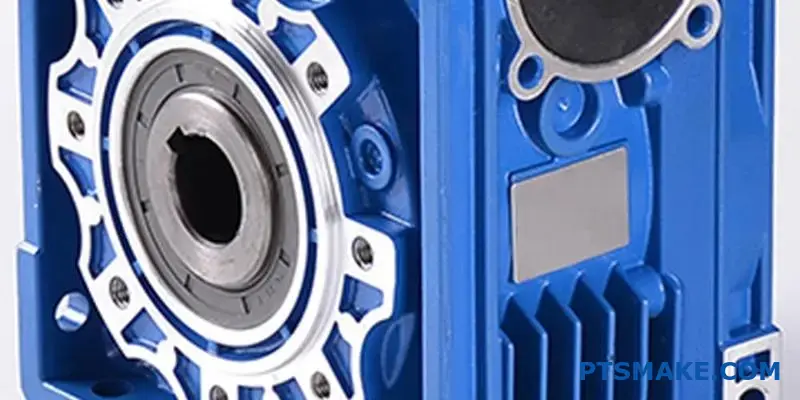

What are the core components of any reduction gearbox?

Every reduction gearbox, from simple to complex, is built from the same fundamental parts. Understanding these components is key to grasping how they function. Think of it as a team where each member has a specific job.

The Essential Team Members

The core components work together seamlessly. They transfer power, reduce speed, and multiply torque. It’s a precise mechanical dance.

Here is a quick breakdown of the main players:

| Komponent | Podstawowa funkcja |

|---|---|

| Shafts (Input/Output) | Transmit power into and out of the gearbox |

| Przekładnie | The heart of speed reduction and torque multiplication |

| Łożyska | Support rotating shafts and handle loads |

| Obudowa | Provides protection and structural alignment |

Each part is critical for the reliable operation of reduction gears.

How Components Work Together

A gearbox is more than a sum of its parts. It’s a balanced system. The housing, for example, isn’t just a protective case. Its rigidity and precision are vital for maintaining perfect gear and bearing alignment.

The Power Flow Path

Power enters through the input shaft. It drives the first gear in the train. As gears mesh, speed is reduced, and torque increases. This modified power then exits through the output shaft. It’s a direct and efficient energy transfer.

Supporting the System

This process generates significant forces. Bearings are crucial for supporting the shafts against these radial and axial loads. Without proper bearings, friction would quickly lead to catastrophic failure. Seals are the unsung heroes, keeping vital lubricant in and harmful contaminants out. The right lubricant minimizes wear between moving parts, managing heat and preventing premature failure due to factors like Naprężenie kontaktowe Hertza6.

In our work at PTSMAKE, we often see failures originating from one underrated component.

| Komponent | Critical Role in System Integrity |

|---|---|

| Obudowa | Maintains precise alignment of all internal parts |

| Smar | Reduces friction, dissipates heat, and cleans components |

| Seals | Protect the system from external contamination and lubricant loss |

A failure in any of these components can compromise the entire gearbox.

Each component is a critical link. The housing ensures alignment, gears transmit power, bearings manage loads, and seals protect the internals. A failure in one part will inevitably cascade, affecting the entire system’s performance and longevity.

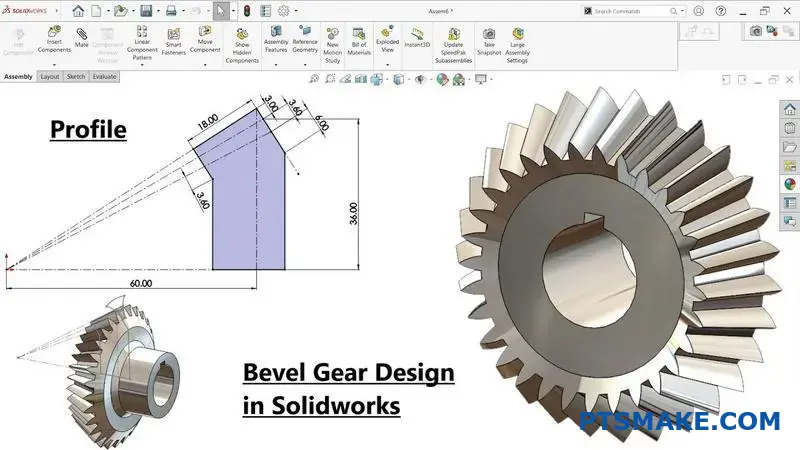

What are the main classifications of reduction gears?

One of the clearest ways to classify reduction gears is by the orientation of their gear shafts. This fundamental difference dictates how motion and torque are transferred. It is the first thing we consider.

Understanding this helps you choose the right design. It impacts efficiency, space, and cost.

Przekładnie z osią równoległą

Here, the input and output shafts are parallel. This is the most common arrangement.

- Spur Gears: Simple, straight teeth.

- Helical Gears: Angled teeth for smoother operation.

Przekładnie z przecinającymi się osiami

These gears have shafts that intersect, usually at a 90-degree angle.

- Bevel Gears: Cone-shaped gears for changing rotational direction.

Non-Intersecting, Non-Parallel Axis

The shafts in this group cross in different planes and do not intersect.

| Orientacja wału | Typowe rodzaje przekładni |

|---|---|

| Równoległy | Ostroga, spirala |

| Przecinające się | Skos |

| Nieingerujący | Ślimak, hipoidalny |

Let’s look deeper into these classifications. The choice of gear type is critical for performance. It’s a key discussion point in our projects at PTSMAKE. We help clients balance efficiency with design constraints.

Parallel Axis: The Workhorses

Spur gears are cost-effective and easy to manufacture. They are great for many applications but can be noisy at high speeds.

Helical gears operate more smoothly and quietly. Their angled teeth engage gradually. However, this design creates nacisk osiowy7, which requires specific bearing support. This is a crucial detail often overlooked in early design stages.

Angled Power Transmission

Bevel gears are essential for right-angle power transmission. They are common in everything from hand drills to automotive differentials. Their conical shape allows shafts to intersect and change the direction of rotation.

High Reduction Ratios

Worm gears are excellent for achieving high reduction gears ratios in a compact space. The worm (screw) drives a worm wheel. This setup is naturally self-locking. It prevents back-driving, which is useful for safety.

Finally, we also consider if the gearing is open or enclosed. Enclosed systems protect gears from debris and contain lubrication, extending their life. Open gearing is simpler but requires more maintenance.

| Typ przekładni | Kluczowa zaleta | Wspólna aplikacja |

|---|---|---|

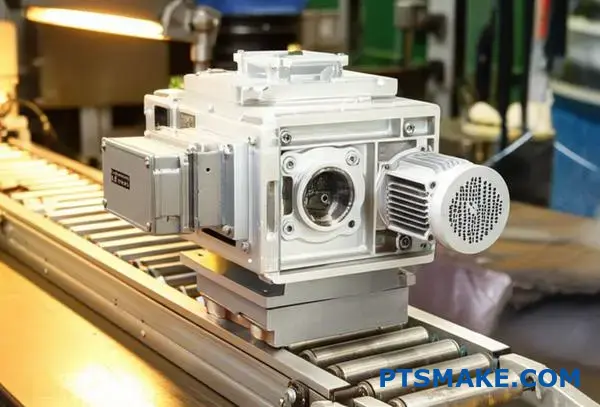

| Ostroga | Opłacalność | Systemy przenośników |

| Spirala | Płynna i cicha praca | Samochodowe skrzynie biegów |

| Skos | Changes rotation angle | Hand drills |

| Robak | High reduction ratio | Lifts, elevators |

Classifying reduction gears by shaft orientation—parallel, intersecting, or non-intersecting—provides a clear framework. Each type offers specific advantages for different applications. The choice between an open or enclosed system further defines the gear’s durability and maintenance needs.

How do you systematically select a reduction gear for an application?

Selecting the right reduction gear isn’t about guesswork. It requires a clear, step-by-step process. This method ensures you get the performance and reliability you need.

It all starts with understanding your application’s core demands. Without this foundation, your selection will be flawed from the start.

Step 1: Define Application Requirements

First, we must define the operational parameters. These numbers are the bedrock of our entire selection process.

Here are the key metrics to establish:

| Parametr | Jednostka | Opis |

|---|---|---|

| Input/Output Speed | RPM | The required rotational speed for the load. |

| Required Torque | Nm | The rotational force needed to drive the load. |

| Duty Cycle | % or Hours/Day | How often and for how long the gear will operate. |

Step 2: Calculate Load and Apply Service Factor

Once you have your base requirements, you need to calculate the actual operational load. This involves a critical component: the service factor.

The service factor is a multiplier. It accounts for real-world conditions like shock loads, and temperature variations. It provides a necessary safety margin.

A mismatch in system inertia can lead to poor performance. Proper calculation prevents this. The inertia mismatch8 between the motor and the load is a key consideration. At PTSMAKE, we help clients navigate these complex calculations.

Step 3: Choose Your Gear Type

Your choice depends heavily on project constraints. Space, required precision, and budget will guide you to the right type of reduction gears.

Consider these common tradeoffs:

| Typ przekładni | Kluczowa zaleta | Common Constraint |

|---|---|---|

| Ostroga | Cost-effective, simple | Noisy, lower torque |

| Spirala | Quiet, smooth operation | Higher cost, axial thrust |

| Planetarny | High torque, compact | Complex, higher cost |

| Robak | High reduction, self-locking | Lower efficiency |

Step 4: Consult the Catalog

With all specifications defined, you can now consult a manufacturer’s catalog. Match your calculated torque, speed, and service factor to a specific model. This final step confirms your choice.

This systematic four-step process—defining needs, calculating load, selecting a gear type, and consulting a catalog—removes uncertainty. It ensures your chosen reduction gear perfectly matches the application’s demands for optimal performance and longevity.

What are the essential steps for sizing a gearbox?

A practical calculation workflow is key. It turns complex requirements into a clear specification. This process ensures the gearbox isn’t just a fit, but a lasting solution.

Start with Core Requirements

First, define the required output torque and speed. These are the non-negotiable performance targets for your machine. They form the basis of all subsequent calculations.

Factor in Application Stress

Next, consider the real-world operating conditions. This includes shock loads and the overall duty cycle. These factors significantly impact wear and tear.

A simple way to classify loads:

| Typ obciążenia | Opis | Przykład |

|---|---|---|

| Mundur | Smooth, constant operation | Conveyor belt |

| Moderate Shock | Routine starts and stops | Indexing table |

| Heavy Shock | Abrupt, high-impact forces | Rock crusher |

The Critical Role of the Service Factor (SF)

The Service Factor (SF) is a multiplier. It adjusts your base torque requirement to account for the harshness of the application. It considers factors like the Duty Cycle9 and load type.

Ignoring the SF is a common shortcut that often leads to premature failure. It’s the safety margin that ensures reliability over the long term.

A higher SF is needed for more demanding jobs. Working with our clients, we’ve found that a well-chosen SF is crucial for the longevity of custom reduction gears.

Calculating Nominal Torque

Formuła jest prosta:

Required Nominal Torque = Application Output Torque × Service Factor

This calculation gives you the minimum continuous torque rating you should look for in a manufacturer’s catalog.

Here’s a simplified example of how SF is determined:

| Operating Hours / Day | Uniform Load | Moderate Shock | Heavy Shock |

|---|---|---|---|

| Up to 2 | 1.00 | 1.25 | 1.75 |

| 3-10 | 1.25 | 1.50 | 2.00 |

| Over 10 | 1.50 | 1.75 | 2.25 |

Verify Against Specifications

Finally, take your calculated nominal torque. Compare it against the specifications provided by the gearbox manufacturer. The catalog’s nominal torque rating must be equal to or greater than your calculated value. At PTSMAKE, we always double-check these details to prevent costly errors.

This systematic workflow transforms application needs into a concrete gearbox specification. By starting with torque and speed, applying a service factor, and verifying against datasheets, you ensure a reliable and durable selection. This prevents under-sizing and extends component life.

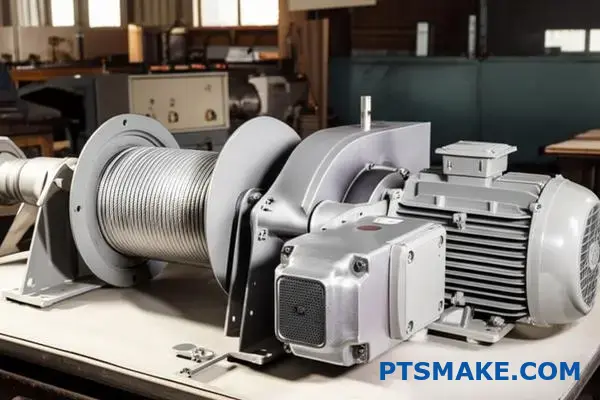

How do you calculate the required torque for a lifting application?

Let’s walk through a practical example. Theory is great, but seeing the numbers makes it clear. We’ll calculate the torque needed for a simple winch system.

This calculation is straightforward. It involves the load’s weight, the drum’s radius, and system friction. We’ll break it down step-by-step.

Here are the variables we’ll use:

| Zmienna | Opis |

|---|---|

| Load Mass | The weight we need to lift. |

| Drum Radius | The radius of the winch drum. |

| Wydajność systemu | Accounts for friction and losses. |

This process helps select the right motor and gearbox.

A Step-by-Step Calculation Example

Let’s imagine a common scenario. We need to design a winch to lift a load of 100 kg. This is a typical weight for many industrial applications we handle at PTSMAKE.

Step 1: Determine the Force

First, convert the mass into a linear force. We use the acceleration due to gravity (approximately 9.8 m/s²).

- Force (F) = Mass (m) × Gravity (g)

- Force (F) = 100 kg × 9.8 m/s² = 980 Newtons (N)

This is the force pulling down on the cable.

Step 2: Calculate the Ideal Torque

Now, let’s assume our winch drum has a radius of 0.1 meters (100 mm). The ideal torque is this force multiplied by the radius.

- Torque (T) = Force (F) × Radius (r)

- Torque (T) = 980 N × 0.1 m = 98 Newton-meters (Nm)

This is the torque needed without considering any inefficiencies.

Step 3: Account for Real-World Losses

No mechanical system is perfect. We must account for Straty tarcia10 in the bearings, gears, and other components. A conservative efficiency estimate is 80% (or 0.8).

To find the actual required torque, we divide the ideal torque by the efficiency factor.

- Required Torque = Ideal Torque / Efficiency

- Required Torque = 98 Nm / 0.8 = 122.5 Nm

This 122.5 Nm value is what you need to select the right motor and reduction gears. The reduction gears multiply the motor’s torque to meet this requirement.

In this example, the ideal torque was 98 Nm. However, after accounting for system friction, the required torque increased to 122.5 Nm. This safety margin is crucial for reliable performance and preventing component failure.

Select a gearbox for a constant-speed conveyor belt system.

Let’s walk through a practical case study. A client needed a gearbox for a system moving packaged goods. The primary goal was reliability, not pinpoint accuracy.

The conveyor system had specific operational demands. Here are the basic parameters we started with:

| Parametr | Wartość |

|---|---|

| Belt Tension | 500 N |

| Pulley Diameter | 0.2 meters |

| Desired Belt Speed | 1.5 m/s |

| Duty Cycle | 16 hours/day |

Our task was to select a durable and cost-effective solution. The focus was purely on consistent, long-term operation.

Calculating the Core Requirement: Torque

First, we need to determine the required output torque. This is a straightforward calculation. It ensures the gearbox can handle the load without stalling or failing.

The Torque Formula

The formula is simple: Torque (τ) equals Belt Tension (F) multiplied by the Pulley Radius (r).

τ = F × r

Using our case study numbers:

- Force (F) = 500 N

- Radius (r) = 0.2 m / 2 = 0.1 m

- Torque (τ) = 500 N × 0.1 m = 50 Nm

This 50 Nm is our minimum required torque. We also consider a Service Factor11 to account for the long duty cycle. This ensures durability.

Justifying the Gearbox Choice

For this application, high precision is unnecessary. This immediately rules out more expensive options like high-precision planetary gears. We need robust, reliable reduction gears.

The best choices are helical or worm gearboxes. Both offer excellent reliability for constant-speed applications.

| Gearbox Type | Kluczowa zaleta | Najlepsze dla |

|---|---|---|

| Spirala | High efficiency (90-98%) | Energy-conscious systems |

| Robak | Self-locking, low noise | Safety-critical applications |

Given the need for cost-effectiveness and reliability, a helical gearbox was the ideal fit. Its efficiency also provides long-term operational cost savings. A worm gearbox is also a strong contender.

In this case study, we calculated the 50 Nm torque requirement for a conveyor. Based on the need for reliability over precision, a cost-effective helical or worm gearbox was the clear and justified choice for long-term performance.

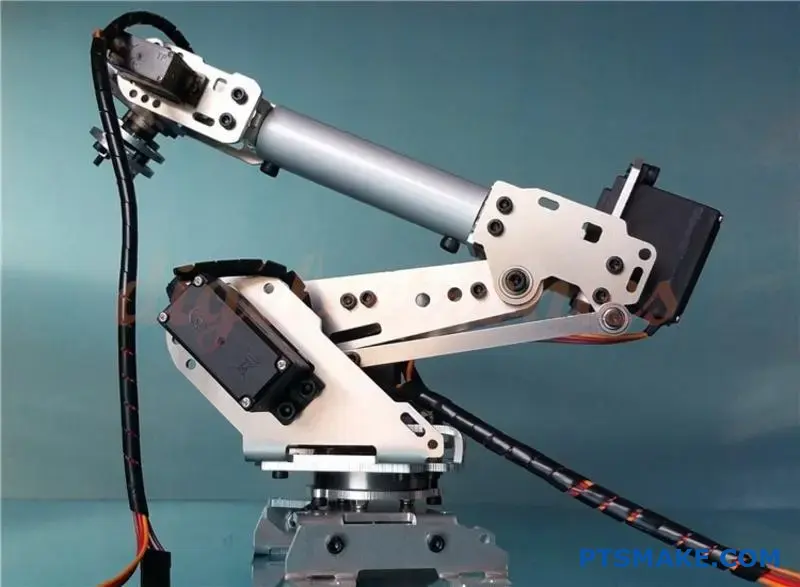

Select a gearbox for a specific robotic arm joint.

Let’s analyze a high-precision robotic joint. Think of a robot assembling a smartphone. Every movement must be perfect. This level of accuracy demands specific features from the gearbox.

Wymagania krytyczne

High stiffness is essential for resisting deflection under load. We also need minimal backlash to eliminate play. Low inertia allows for rapid acceleration and stops. The choice of reduction gears here is critical.

Application Needs at a Glance

| Cecha | High-Precision Joint | Standardowa aplikacja |

|---|---|---|

| Dokładność | Sub-millimeter | Niski |

| Prędkość | Bardzo wysoka | Umiarkowany |

| Powtarzalność | Crucial | Not critical |

| Backlash | Blisko zera | Tolerowalny |

Diving into High-Precision Gearing

For high-precision tasks, every detail matters. High stiffness ensures the arm doesn’t bend or vibrate when moving or carrying a load. This directly impacts the final positioning accuracy.

Low inertia is another key factor. A lighter, low-inertia system allows the motor to accelerate and decelerate the joint much faster. This shortens cycle times in pick-and-place operations, boosting productivity.

The mechanical play, or luz12, must be almost zero. Any slop in the gears translates to positioning errors at the end of the arm. This is unacceptable in microelectronics or medical device assembly. In past projects at PTSMAKE, we’ve seen how even tiny errors can cause major production failures.

Contrast this with a simple conveyor belt gearbox. Its main job is continuous motion. A little play or slight deflection doesn’t affect its function. Therefore, a standard, less expensive gearbox is suitable.

Top Contenders for Precision

For demanding applications, two types of reduction gears stand out.

| Gearbox Type | Kluczowa zaleta | Najlepszy przypadek użycia |

|---|---|---|

| Napęd harmoniczny | Zero Backlash, Compact | Robotic wrists, high-accuracy joints |

| High-Precision Planetary | High Stiffness, High Torque | Heavier payload joints, CNC machines |

Choosing between them often depends on the specific joint’s torque and stiffness requirements. Our test results show harmonic drives excel in compact spaces requiring the highest precision.

For high-precision robotics, you cannot compromise. The application’s demands for high stiffness, near-zero backlash, and low inertia guide your selection. This leads directly to advanced solutions like harmonic drives or high-precision planetary gearboxes, unlike simpler, more tolerant applications.

How do you troubleshoot excessive noise and vibration in a gearbox?

A logical approach is crucial. I use a diagnostic tree to systematically eliminate potential causes. This method saves time and prevents guesswork. It guides you from simple checks to more complex inspections.

Start with the Basics

First, gather information. When did the noise start? Has anything changed recently? Answering these questions provides valuable clues. Then, move to sensory checks.

Isolate the Cause

Pinpointing the exact source is next. Different problems create different sounds. This systematic approach ensures you don’t miss a critical step. It’s about being methodical.

Here are some common tools I use:

| Narzędzie | Cel |

|---|---|

| Stethoscope | Isolate noise sources (bearings, gears) |

| Infrared Thermometer | Check for overheating components |

| Feeler Gauges | Verify alignment and clearance |

This structured process quickly narrows down the possibilities.

To dive deeper, we must differentiate between the types of sounds and vibrations. A methodical process is your best tool. At PTSMAKE, we apply this same rigor when manufacturing high-precision components for gear systems, including complex reduction gears.

Listening for Clues

A mechanic’s stethoscope is excellent for this. Place the probe on different parts of the gearbox housing. A worn bearing often produces a rumbling or grinding noise. Damaged gear teeth might create a whining or clicking sound that changes with speed.

Visual and Physical Checks

After listening, perform a visual inspection. Check for leaks, which could indicate a seal failure or overheating. Look for any signs of external damage to the housing.

Next, check the alignment between the motor and the gearbox. Misalignment is a very common source of vibration. We often find that even a small error here can cause significant issues down the line. Using proper tools ensures accuracy. The principles of Analiza wibracji13 can quantify these issues with incredible precision.

| Symptom | Potencjalna przyczyna | Next Step |

|---|---|---|

| High-pitched whine | Damaged gear teeth | Inspect gears |

| Rumbling/Grinding | Worn bearings | Isolate and inspect bearings |

| Consistent clicking | Broken tooth | Immediate shutdown & inspection |

| Intense vibration | Niewspółosiowość | Check and correct alignment |

This diagnostic tree helps isolate problems efficiently. It moves from general observations to specific tests. This ensures a thorough and accurate diagnosis every time.

A diagnostic tree provides a structured path to identify the root cause of noise and vibration. It starts with simple sensory checks and progresses to specific tool-based inspections, efficiently isolating issues from misalignment to internal component wear.

What are the challenges of coupling a motor to a gearbox?

Choosing the right coupling is more than a simple mechanical connection. It is a critical decision that directly impacts your system’s lifespan and performance.

A coupling must accommodate minor misalignments between the motor and gearbox. It also needs to absorb vibrations and transmit torque reliably.

Ignoring these factors leads to premature failure. This can cause costly downtime and repairs. A poor choice here undermines the entire powertrain design. It is a small part with a huge impact.

Misalignment: An Unavoidable Reality

No assembly is perfectly aligned. There will always be small parallel or angular misalignments. A rigid coupling cannot handle this. It transfers stress directly to the motor and gearbox bearings. This leads to rapid wear and eventual failure. Flexible couplings are designed to absorb these minor imperfections. They protect the more expensive components.

Vibration Damping and Torque Transmission

Vibrations are another major issue. Motors naturally produce vibrations that can harm delicate gearbox components, especially in high-precision reduction gears. A good coupling dampens these vibrations. This prevents resonance and extends the life of bearings and gears. It also ensures smoother, quieter operation. The coupling’s Torsional stiffness14 plays a key role here. It must be stiff enough to transmit torque without loss, but flexible enough for damping.

Consequences of a Poor Choice

In our projects at PTSMAKE, we’ve seen the direct results of poor coupling selection. The wrong choice can be disastrous. The table below outlines some common issues we’ve observed with clients.

| Coupling Issue | Konsekwencje |

|---|---|

| Too Rigid | Premature bearing failure |

| Wrong Size | Slippage, lost torque, failure |

| Poor Damping | Increased noise and vibration |

| Material Incompatibility | Corrosion, early failure |

Choosing correctly from the start saves significant time and money. It is a foundational step for a reliable mechanical system.

Selecting the right coupling is crucial. It protects your system by accommodating misalignment, damping vibration, and transmitting torque effectively. A poor choice leads to premature wear, increased noise, and costly failures, undermining the entire design’s reliability and performance.

When should you choose a high-efficiency vs. a lower-cost gearbox?

Thinking beyond the initial price tag is crucial. The total cost of ownership (TCO) tells the real story. It includes the purchase price, energy costs, and maintenance over the gearbox’s life.

For applications that run constantly, this is a big deal.

Initial Cost vs. Long-Term Savings

A lower-cost gearbox might save you money today. But it could cost more in the long run. High-efficiency reduction gears use less energy. This saves money every hour they operate.

Consider this simple breakdown:

| Współczynnik kosztów | High-Efficiency Gearbox | Lower-Cost Gearbox |

|---|---|---|

| Initial Price | Wyższy | Niższy |

| Koszt energii | Niższy | Wyższy |

| Konserwacja | Często niższe | Potencjalnie wyższy |

This perspective shift is key to smart engineering and procurement.

Analyzing Continuous-Duty Applications

Let’s get specific. Continuous-duty means the machine runs 24/7 or for very long shifts. In these cases, energy consumption becomes a major operational expense. A high-efficiency gearbox, like a helical gear, can be over 95% efficient.

A lower-cost worm gear might only be 70-80% efficient. That difference in energy waste adds up quickly.

A TCO Scenario: Helical vs. Worm Gear

Imagine two motors running continuously. One has a helical gearbox, the other a worm gear. The initial investment for the helical setup is higher.

However, after running tests with clients, we’ve seen the energy savings from the helical gear start to offset that initial cost within a couple of years. The specific Payback Period15 depends on local energy prices and how much the machine is used.

Here’s a simplified look at costs over time:

| Ramy czasowe | Helical Gearbox (High-Efficiency) | Worm Gearbox (Lower-Cost) |

|---|---|---|

| Year 1 | High Initial Cost + Low Energy Cost | Low Initial Cost + High Energy Cost |

| Year 3 | Total Cost lower due to savings | Total Cost higher due to energy use |

| Year 5 | Significant long-term savings | Continually rising operational costs |

For any system intended for long-term, non-stop operation, the high-efficiency route often proves to be the most economical choice. At PTSMAKE, we guide clients through this analysis to ensure they get the best value over the product’s entire lifecycle.

When an application runs continuously, the total cost of ownership often favors a high-efficiency gearbox. The long-term energy savings can easily surpass the higher initial purchase price, making it the smarter financial choice over time.

What are the emerging trends in reduction gear technology?

The future of reduction gear technology is exciting. We are moving beyond simple mechanics. Gears are becoming smarter and more efficient every day.

Smart Gears and IIoT

Sensors are now embedded into gear systems. This allows for real-time condition monitoring. It predicts failures before they happen, which saves valuable production time.

Material and Coating Innovations

New materials and coatings are also key. They enhance durability and reduce friction. This directly leads to higher performance and longer lifespans for modern reduction gears.

| Cecha | Podejście tradycyjne | Emerging Trend |

|---|---|---|

| Monitorowanie | Inspekcja ręczna | Real-time Sensors (IIoT) |

| Materiały | Standard Steel Alloys | Advanced Composites/Coatings |

The Mechanics of Smart Reduction Gears

Integrating sensors is more than just adding electronics. It’s about creating a feedback loop. Data on temperature, vibration, and lubrication quality is constantly collected. This information helps us predict and prevent failures.

This approach, known as predictive maintenance, minimizes unexpected downtime. In past projects at PTSMAKE, we’ve seen this shift save clients significant operational costs over the long term.

Pushing the Limits with Materials

The materials we use are changing everything. Advanced polymers and ceramic composites offer lighter weight and better wear resistance compared to traditional metals.

Rola zaawansowanych powłok

Coatings like Diamond-Like Carbon (DLC) are incredible. They create an ultra-low friction surface. This reduces energy loss and heat generation. Based on our tests, this can improve efficiency by a few percentage points, a big deal in high-performance applications.

Specialized Gearboxes for New Frontiers

Robotics and electric vehicles (EVs) have unique demands. Robotic arms require gearboxes with near-zero luz16 for precise movements.

EVs need reduction gears that can handle very high input speeds quietly and efficiently. This requires entirely new design philosophies and manufacturing techniques, which we are actively developing with our partners.

The future of reduction gears hinges on intelligence and specialization. Integrating sensors for monitoring, using advanced materials for better performance, and designing specialized units for robotics and EVs are the key trends shaping the industry’s next chapter.

Unlock Reduction Gear Excellence with PTSMAKE Today

Take your projects to the next level with precision reduction gears and flawless manufacturing from PTSMAKE. Contact us now for a fast, no-obligation quote—benefit from proven expertise, rapid lead times, and unwavering quality for your next CNC machining or injection molding requirement!

Learn how gear design and lubrication impact the real-world power output of your mechanical systems. ↩

Explore how this core principle of physics enables force multiplication in mechanical systems. ↩

Understand how fluid dynamics affect lubricant efficiency and overall gear performance in our detailed guide. ↩

Understand this key gear dimension and how it directly impacts torque calculations and gear design. ↩

Learn how this small mechanical gap can lead to significant inaccuracies in precision motion control systems. ↩

Learn about this key stress factor that determines the surface life and load capacity of gears and bearings. ↩

Understand how axial thrust influences bearing selection and the overall mechanical design of your gearbox. ↩

Understand how inertia mismatch impacts system stability and precision in our detailed guide. ↩

Understand how operational patterns and load conditions influence the expected lifespan of mechanical parts. ↩

Learn how these forces affect your design’s efficiency and long-term reliability. ↩

Learn how to apply the right factor to ensure gearbox longevity in demanding applications. ↩

Learn how backlash impacts robotic arm accuracy and what to look for. ↩

Learn how vibration analysis helps predict and prevent catastrophic gearbox failures. ↩

Understand how this property impacts system responsiveness and precision. ↩

Learn how to calculate this critical financial metric for your equipment investments. ↩

Learn how minimizing this mechanical gap is critical for achieving high-precision positioning in robotic systems. ↩