Your nylon CNC parts arrive with dimensional variations that fall outside your specifications. The root cause? Your supplier lacks the specialized knowledge to handle nylon’s unique machining requirements, leading to costly delays and quality issues.

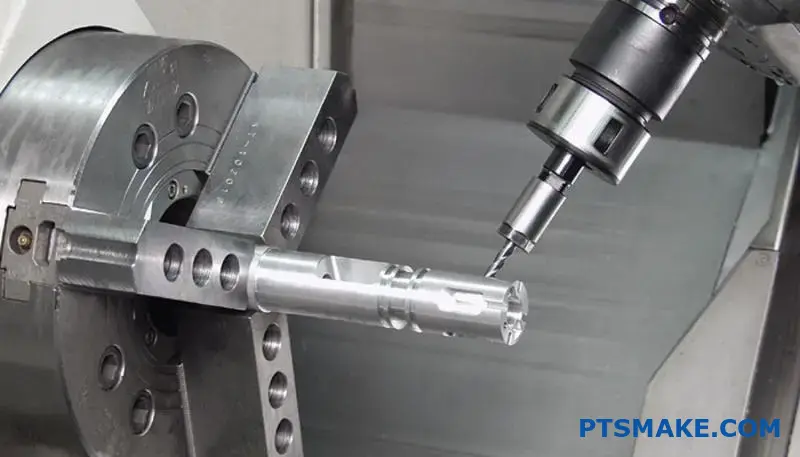

Nylon CNC machining requires specific expertise in material preparation, parameter optimization, and environmental controls to achieve consistent precision parts that meet tight tolerances and performance standards.

I’ve worked with dozens of clients who switched suppliers after receiving out-of-spec nylon components. The difference between success and failure often comes down to understanding nylon’s hygroscopic nature, proper drying protocols, and optimized cutting parameters. This guide covers the critical factors that separate experienced nylon machining suppliers from those who treat it like any other plastic, helping you make informed decisions for your next project.

Why Nylon Is a Top Choice for CNC Machined Components?

Have you ever specified a material for a critical part, only to watch it wear out prematurely, forcing costly downtime and redesigns? This frustration is a common challenge in product development.

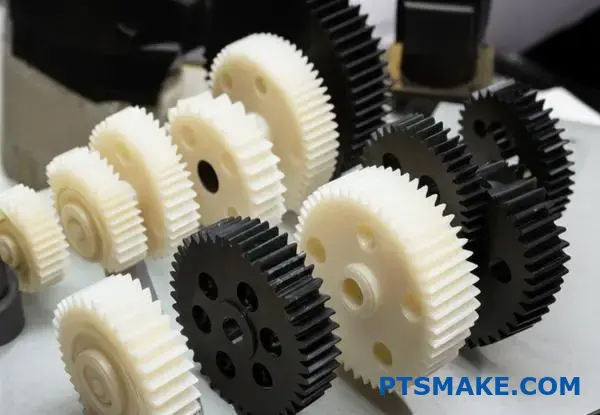

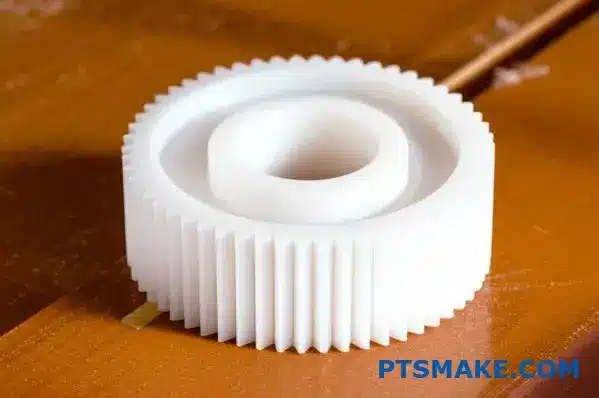

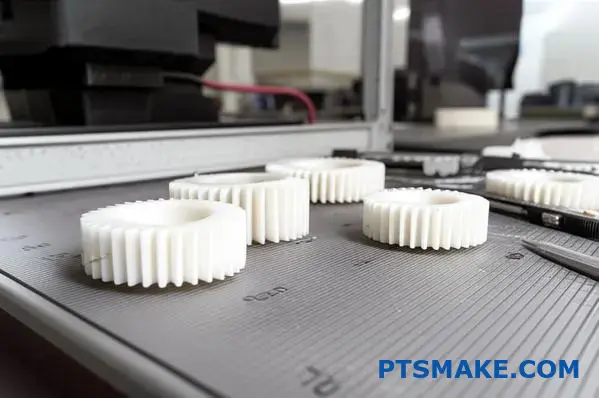

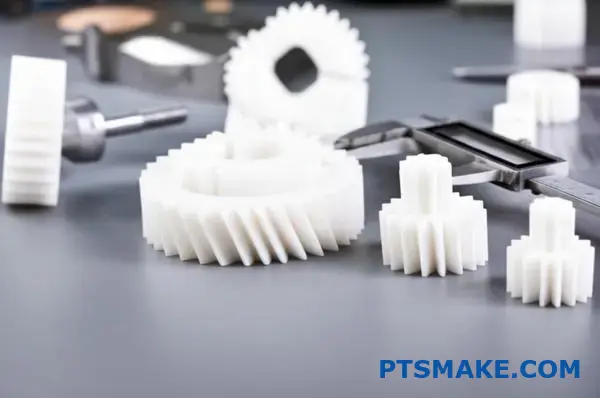

Nylon is a top choice for CNC machined components because its unique blend of high tensile strength, excellent wear resistance, and chemical stability makes it exceptionally durable. It provides a reliable and cost-effective alternative to metals for high-performance parts like gears, bushings, and bearings.

The Core Strengths: What Sets Nylon Apart?

When engineers and procurement managers look for a material that bridges the gap between standard plastics and metals, nylon often becomes the focus of conversation. Its versatility isn’t just a claim; it’s proven in thousands of demanding applications. At PTSMAKE, we frequently turn to nylon for parts that require a balance of strength, resilience, and machinability. The success of nylon CNC machining hinges on understanding its fundamental properties.

Unpacking Tensile Strength and Durability

Nylon boasts impressive tensile strength, which is its ability to withstand pulling forces without breaking. This makes it a formidable candidate for replacing metal in certain applications, especially where weight reduction is critical. For instance, in automated machinery, nylon gears can handle significant torque while being much lighter than their steel or aluminum counterparts. This reduces inertia, allowing for faster and more energy-efficient operation. Unlike some plastics that become brittle under load, nylon exhibits excellent toughness, meaning it can absorb impacts and deform without fracturing—a crucial trait for components subjected to vibration or sudden shocks. One thing to keep in mind is its hygroscopic1 nature; nylon absorbs moisture from the environment, which can slightly alter its mechanical properties and dimensions. This is a key design consideration we always discuss with our clients to ensure long-term part stability.

Superior Wear and Abrasion Resistance

One of nylon’s most celebrated features is its low coefficient of friction and high abrasion resistance. This is why it’s a go-to material for parts that slide or rub against each other, such as bearings, bushings, and wear pads. It often has self-lubricating properties, which reduces the need for external lubricants and minimizes maintenance. In past projects with clients, we’ve found that switching from bronze bushings to nylon ones not only reduced part cost but also decreased operational noise and extended the service life of the assembly.

| Property | Nylon 6/6 | Aluminum 6061 | ABS |

|---|---|---|---|

| Tensile Strength | High | Very High | Medium |

| Wear Resistance | Excellent | Poor | Fair |

| Weight | Low | Low | Low |

| Machinability | Excellent | Excellent | Good |

| Cost | Low | Medium | Low |

This inherent resistance to wear ensures that precision-machined parts maintain their tight tolerances for longer, which is essential for the reliability of any mechanical system. The smooth operation it provides is a significant advantage in applications from consumer electronics to industrial robotics.

Nylon vs. The Competition: A Practical Comparison

Choosing the right material is a strategic decision that impacts performance, cost, and manufacturing feasibility. While metals like aluminum and steel have their place, nylon presents a compelling case in many scenarios. It’s not about which material is "best" overall, but which is best for a specific application. In our experience, a thoughtful comparison often reveals nylon as a smart, practical choice that delivers both performance and value.

The Weight and Cost Advantage Over Metals

The most immediate advantage of nylon over metals is its significantly lower density. A nylon part can be up to seven times lighter than an identical steel part. This weight reduction is a game-changer in industries like aerospace and automotive, where every gram counts towards improving fuel efficiency and performance. But the benefits extend beyond that; lighter parts are also cheaper to ship and easier to handle during assembly, contributing to overall cost savings. Furthermore, raw nylon material is typically more affordable than aluminum or stainless steel, and the nylon CNC machining process can be faster due to lower cutting forces, reducing machine time and tooling wear. This combination of lower material cost and more efficient manufacturing makes nylon a highly economical solution without compromising mechanical integrity for suitable applications.

Outperforming Other Plastics in Demanding Roles

Nylon also holds its own against other engineering plastics. Compared to a general-purpose plastic like ABS, nylon offers far superior wear resistance and a higher operating temperature. While polycarbonate might be stronger in terms of impact resistance, nylon’s low-friction surface makes it the clear winner for moving parts. Delrin (Acetal) is another strong competitor, known for its stiffness and excellent dimensional stability in wet environments. However, nylon generally provides better toughness and is more resistant to abrasion, making it better suited for high-impact, high-wear situations. The choice often comes down to the specific environmental and mechanical stresses the component will face.

| Feature | Nylon | Delrin (Acetal) | Polycarbonate |

|---|---|---|---|

| Wear Resistance | Excellent | Good | Fair |

| Toughness (Impact) | Excellent | Good | Excellent |

| Moisture Absorption | High | Low | Very Low |

| Chemical Resistance | Good (oils, fuels) | Excellent | Fair |

Chemical Resistance: A Hidden Benefit

An often-overlooked advantage of nylon is its excellent resistance to a wide range of chemicals, particularly hydrocarbons like oils, greases, and fuels. This makes it ideal for components used in automotive engines, industrial machinery, and hydraulic systems. Unlike some metals that can corrode or plastics that can degrade when exposed to harsh chemicals, nylon maintains its structural integrity, ensuring reliability and a long service life in challenging chemical environments.

Nylon stands out for CNC machining due to its blend of strength, wear resistance, and chemical stability. It offers a lightweight, cost-effective, and durable alternative to both metals and other plastics, making it a reliable choice for high-performance components like gears, bushings, and custom industrial parts.

Selecting the Right Nylon Grade for Your Application.

Have you ever specified a nylon grade that looked great on paper, only to see it warp or fail in the real world? This misstep can lead to costly redesigns and delays.

To select the right nylon, you must match the material’s properties to your application’s demands. Evaluate factors like strength, temperature, and chemical exposure to choose between PA6, higher-performance PA66, rigid glass-filled grades, or low-friction oil-filled variants for optimal results in nylon CNC machining.

The world of nylon is more varied than many engineers initially assume. The two most common grades we machine at PTSMAKE are PA6 and PA66. While they seem similar, their subtle differences can have a major impact on your part’s performance. Understanding these distinctions is the first step to making an informed decision.

The Foundation: PA6 vs. PA66

At a glance, PA6 and PA66 are both polyamide plastics known for their toughness and wear resistance. However, their molecular structure differs, which translates into distinct mechanical and thermal properties. The choice between them often comes down to balancing cost, performance, and environmental conditions.

PA6 (Nylon 6): The Versatile Workhorse

PA6 is generally a bit more ductile and has better impact resistance, especially in conditioned states. It also offers a superior surface finish after machining, which can be crucial for aesthetic parts. However, its main drawback is that it is more Hygroscopic2 than PA66, meaning it absorbs more moisture from the air. This absorption can cause dimensional changes and a reduction in stiffness. Because of its slightly lower melting point, it’s also marginally easier and faster to process, sometimes offering a slight cost advantage in production.

PA66 (Nylon 66): The High-Performance Standard

PA66 is the go-to for more demanding applications. It is harder, stiffer, and has a higher melting point than PA6. This makes it more suitable for parts that will be exposed to higher temperatures or require greater mechanical strength and rigidity. Its lower moisture absorption rate also contributes to better dimensional stability in fluctuating humidity. For critical components in automotive or industrial machinery, PA66 is often the safer, more reliable choice, providing a performance edge that justifies its typically higher price point.

Here is a quick comparison based on our internal testing and project data:

| Property | PA6 (Nylon 6) | PA66 (Nylon 66) | Key Consideration for CNC Machining |

|---|---|---|---|

| Tensile Strength | Good | Excellent | PA66 holds up better under load. |

| Stiffness | Moderate | High | PA66 is preferred for rigid parts. |

| Melting Point | ~220°C (428°F) | ~265°C (509°F) | PA66 offers a wider operating temperature range. |

| Moisture Absorption | Higher | Lower | PA66 provides better dimensional stability. |

| Cost | Lower | Higher | PA6 offers a more budget-friendly option. |

Beyond the standard PA6 and PA66, many applications require properties that these base polymers just can’t deliver on their own. This is where additives and fillers come into play, creating specialized grades engineered for specific challenges like extreme stress or constant movement. These modified nylons unlock a new level of performance, but they also introduce new considerations for the design and machining process.

Beyond the Basics: Modified Nylon Grades

When your part needs to be stronger, more stable, or self-lubricating, it’s time to look at filled nylons. The two most common variants we work with are glass-filled for structural reinforcement and oil-filled for low-friction applications.

Glass-Filled (GF) Nylon: For Strength and Stability

Adding short glass fibers, typically in concentrations of 15% to 30% (e.g., PA66-GF30), dramatically changes nylon’s properties. The fibers act as a reinforcement, significantly increasing tensile strength, stiffness, and dimensional stability, especially at elevated temperatures. In one project with an automotive client, we switched from standard PA66 to PA66-GF30 for an engine bay component. The change prevented the part from warping under heat, solving a critical field failure issue. The trade-off? Glass-filled nylon is highly abrasive. It causes faster tool wear during CNC machining, which is a factor we must account for in our process planning and costing to ensure consistent part quality.

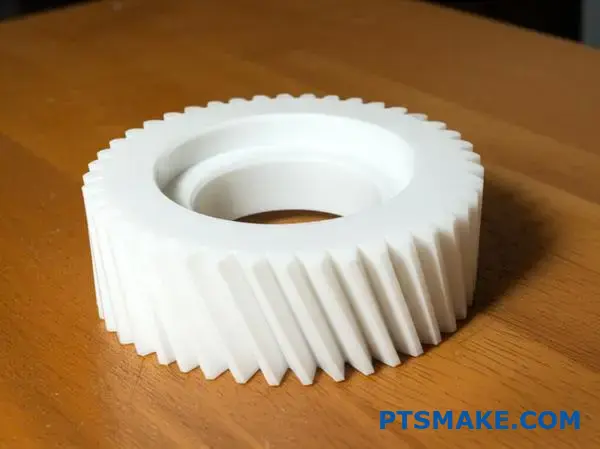

Oil-Filled Nylon: For Low-Friction Performance

For applications involving moving parts like gears, bearings, or slide plates, oil-filled nylon is an excellent choice. A liquid lubricant is integrated directly into the polymer matrix during manufacturing. This creates a material with an extremely low coefficient of friction and excellent wear resistance. The self-lubricating property means the parts run smoothly without the need for external grease or oil, reducing maintenance and simplifying design. Machining oil-filled nylon is similar to standard grades, but the result is a part that is inherently slippery, perfect for creating long-lasting, quiet, and efficient mechanical assemblies.

Here’s how these modified grades stack up:

| Grade | Key Advantage | Best For | Machining Consideration |

|---|---|---|---|

| Standard PA66 | Balanced properties | General-purpose components | Standard tooling and speeds. |

| PA66-GF30 | High strength & stiffness | Structural parts, housings | Abrasive; requires hardened tools. |

| Oil-Filled Nylon | Low friction, self-lubricating | Gears, bearings, wear pads | Produces smooth, slippery surfaces. |

Choosing the right nylon is a critical design step. It requires balancing the need for strength, heat resistance, and dimensional stability against the specific environment your part will face. The difference between PA6, PA66, glass-filled, and oil-filled grades can determine the success or failure of your project.

Critical Pre-Machining Steps: Drying and Stress Relief.

Have you ever machined a nylon part to perfection, only to find it warped or out of spec a few days later? This common frustration often points back to neglecting two critical preparation stages.

Properly drying nylon before CNC machining is essential to remove absorbed moisture, preventing dimensional instability. Additionally, stress relief (annealing) removes internal stresses from manufacturing, which is key to avoiding warping and cracking, ensuring the final part meets tight tolerances.

The Challenge of Nylon’s Hygroscopic Nature

Nylon is a fantastic engineering plastic, but it has one characteristic that every machinist must respect: it’s hygroscopic. This means it readily absorbs moisture from the surrounding atmosphere, much like a sponge. This isn’t a surface-level issue; water molecules work their way into the material’s molecular structure, acting as a plasticizer. This process directly impacts the material’s properties and, most critically for us, its dimensional stability. When we machine nylon that hasn’t been properly dried, we are essentially machining a material that is in a swollen state. As the part later dries out and releases that moisture, it will shrink and potentially warp, throwing all our precise work out the window. In our work at PTSMAKE, we’ve seen that even a small percentage of moisture content can lead to significant dimensional changes that cause a part to fail inspection.

Why Moisture is a Silent Saboteur

The consequences of machining "wet" nylon go beyond just dimensional change. Excess moisture can turn to steam when heated by the friction of the cutting tool, leading to a poor surface finish. It can also cause the material to become "gummy," resulting in difficulties with chip control and increased tool wear. To achieve the consistent results required for high-precision nylon cnc machining, starting with a stable, dry material is non-negotiable. Based on our tests, we’ve established strict drying protocols for all hygroscopic materials we machine.

| Property | Dry (As-Molded) Nylon 6/6 | Conditioned (50% RH) Nylon 6/6 | Impact on Machining |

|---|---|---|---|

| Tensile Strength | ~12,000 psi | ~8,500 psi | Requires adjustment of cutting forces |

| Dimensional Change | Baseline | Can swell by up to 0.5-1.0% | Critical for holding tight tolerances |

| Impact Strength | Lower | Higher | Material becomes less brittle |

| Hardness (Rockwell) | R120 | R108 | Affects surface finish and tool life |

This absorbed water increases the material’s Polymer chain mobility3, which alters its mechanical characteristics. For any project demanding accuracy, ignoring this step introduces an unacceptable level of risk.

Annealing: Your Insurance Against Warping

The second critical pre-machining step is stress relief, commonly known as annealing. Internal stresses are an unavoidable byproduct of the manufacturing process for raw nylon stock, whether it’s extruded rods or molded plates. During production, the material cools at different rates—the outside cools and solidifies faster than the core. This differential cooling locks internal stresses into the material. These stresses are balanced and dormant in the raw stock. However, the moment we start nylon cnc machining and remove material, we disrupt that balance. The remaining internal forces are no longer opposed, causing them to release by moving the material, which we see as warping, bowing, or twisting.

The Annealing Process Explained

Annealing is a controlled heating and cooling process designed to relieve these internal stresses before any cutting begins. The process involves three main stages:

- Heating: The material is slowly and uniformly heated to a temperature below its melting point. For Nylon 6/6, this is typically around 150°C (300°F).

- Soaking: The material is held at this temperature for a specific period, usually calculated based on the material’s thickness (e.g., one hour per inch of thickness). This allows the polymer chains to relax and settle into a lower-energy, stress-free state.

- Cooling: The material is then cooled down very slowly and uniformly back to room temperature. Rapid cooling would simply reintroduce new stresses.

This controlled cycle ensures that the material is as stable as possible before it ever touches a cutting tool. In past projects at PTSMAKE, particularly those involving thin walls or complex geometries, we’ve demonstrated that annealing is the single most effective way to prevent post-machining deformation.

| Annealing Stage | Purpose | Typical Parameters (Nylon 6/6) |

|---|---|---|

| Ramp-Up | To heat the material uniformly without thermal shock. | Increase temperature slowly, ~10-20°C per hour. |

| Soak (Hold) | To allow internal stresses to fully relax. | Hold at 150°C for 1-2 hours per inch of thickness. |

| Cool-Down | To cool the material without re-introducing stress. | Decrease temperature slowly, ~10-20°C per hour. |

For any high-precision nylon cnc machining application, especially where tolerances are tight and part geometry is intricate, skipping annealing is a gamble not worth taking. It’s an investment in stability and quality.

To guarantee part quality, pre-machining preparation is key. Properly drying nylon removes absorbed moisture to prevent dimensional changes, while annealing relieves internal stresses to stop warping. These two steps are foundational for any successful high-precision nylon machining project, ensuring stability from start to finish.

Optimizing CNC Machining Parameters for Nylon?

Ever struggled with gummy chips, poor surface finishes, or warped parts when machining nylon? That inconsistency can derail a project, turning a seemingly simple material into a major headache.

To optimize nylon CNC machining, you must use very sharp cutting tools, high cutting speeds, and moderate feed rates. This combination ensures a clean shearing action rather than pushing the material, preventing melting, maintaining dimensional accuracy, and achieving a superior finish on the final part.

The Core Trio: Speed, Feed, and Depth of Cut

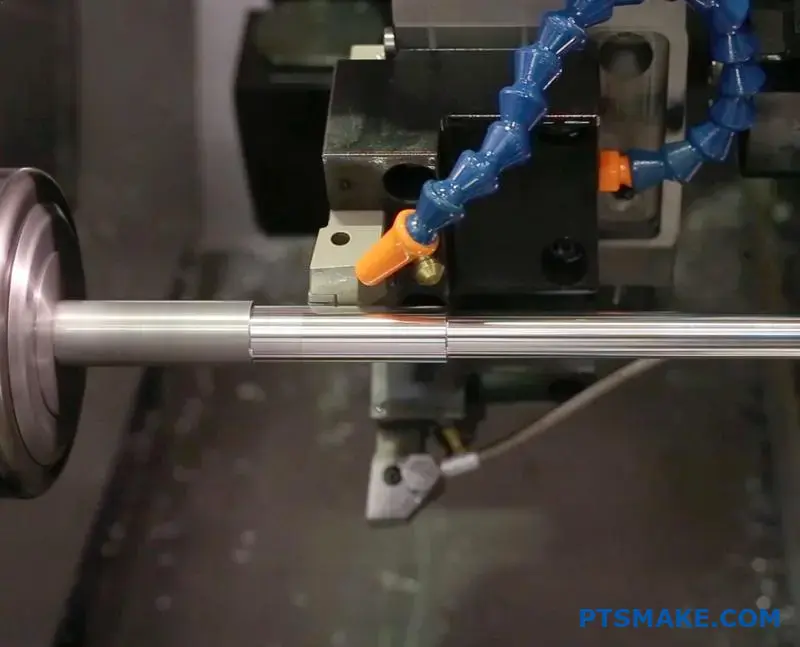

Getting the parameters right for nylon is a balancing act. Nylon has a low melting point and is a poor thermal conductor, meaning heat builds up at the cutting edge quickly. If you get it wrong, you end up with a melted mess instead of a precision part. The goal is to create a distinct chip and evacuate it before it can transfer heat back into the workpiece.

Cutting Speed

For nylon, think fast. Higher spindle speeds (RPM) translate to a higher Surface Feet per Minute (SFM), which promotes a clean shearing action. A slow cutting speed tends to push and tear the material, generating excessive friction and heat. In our experience at PTSMAKE, we’ve found that starting on the higher end of the recommended range for a given tool often yields better results. This is counterintuitive for some machinists who are used to working with metals, where higher speeds mean more heat. With plastics like nylon, the speed helps the tool get in and out before significant heat can transfer.

Feed Rate and Chip Load

While the spindle runs fast, the feed rate—the speed at which the tool moves through the material—must be carefully controlled. The key metric here is chip load4, or the thickness of material removed by each cutting edge. A feed rate that is too low results in a very thin chip, causing the tool to rub against the material rather than cut it. This rubbing action is a primary source of heat. Conversely, a feed rate that is too high can put excessive pressure on the tool and the part, leading to tool deflection and dimensional inaccuracies.

The following table provides a general starting point for unfilled nylon grades. Remember to adjust based on your specific machine, tooling, and the exact nylon grade.

| Operation | Tool Material | Cutting Speed (SFM) | Feed per Tooth (IPT) |

|---|---|---|---|

| Milling | HSS | 400 – 800 | 0.004" – 0.012" |

| Milling | Carbide | 800 – 1500 | 0.005" – 0.015" |

| Turning | HSS | 600 – 1000 | 0.005" – 0.010" |

| Turning | Carbide | 1000 – 1800 | 0.007" – 0.015" |

For glass-filled or carbon-filled nylons, you’ll want to start at the lower end of the speed range and use carbide tooling due to the material’s increased abrasiveness.

Best Practices for Tooling and Fixturing

The best parameters in the world won’t save you if your setup is wrong. Tool selection and workholding are just as critical for successful nylon CNC machining. These foundational elements directly influence the final part’s quality and the efficiency of the entire process.

Tool Selection: Sharpness is Non-Negotiable

Dull tools are the number one enemy when machining nylon. A worn cutting edge won’t shear the material; it will plow through it, generating immense friction and heat.

- Tool Material: While High-Speed Steel (HSS) can work for short runs, we strongly recommend using uncoated carbide tools. For filled nylons, a wear-resistant coating like Diamond-Like Carbon (DLC) can significantly extend tool life.

- Tool Geometry: Look for tools with a high positive rake angle and a large relief angle. This geometry creates a sharper cutting edge that slices through the nylon cleanly, reducing cutting forces and heat generation.

- Flute Count: For milling, fewer is better. A 2-flute or even a single-flute end mill provides maximum space for chip evacuation. Clogged flutes are a fast path to a melted workpiece and a broken tool.

Fixturing: Firm but Gentle

Nylon is a flexible material. If you clamp it too tightly in a standard vise, it will deform. You might machine a perfectly dimensioned part while it’s clamped, but once you release the pressure, the part will spring back, and your dimensions will be off.

- Distribute Pressure: Use soft jaws or custom-machined fixtures that conform to the part’s shape. This distributes the clamping force over a larger area, preventing deformation.

- Use Stops: To combat cutting forces that can push the material, always use a solid work stop.

- Torque Control: Don’t overtighten your clamps. Use a torque wrench to apply consistent, minimal pressure that is just enough to hold the part securely.

The table below outlines how these setup choices impact the final outcome.

| Factor | Optimized Approach | Poor Approach | Consequence of Poor Approach |

|---|---|---|---|

| Tool Sharpness | New or freshly sharpened carbide tool | Worn or incorrect geometry tool | Melting, poor finish, dimensional inaccuracy |

| Flute Count | 2-flute for good chip evacuation | 4-flute or more | Clogged chips, heat buildup, tool breakage |

| Workholding | Soft jaws, distributed pressure | Vise jaws, excessive force | Part deformation, out-of-spec dimensions |

| Coolant | Flood coolant or compressed air | None or oil-based coolant | Heat buildup, chip welding, material swelling |

By implementing these best practices, we ensure that the parts we deliver at PTSMAKE, from the first prototype to the ten-thousandth production piece, meet the exact specifications our clients depend on.

Optimizing nylon machining requires balancing high cutting speeds with correct feed rates and sharp tools. Secure, non-deforming fixturing and effective chip evacuation are equally critical. Mastering these elements ensures dimensional accuracy, excellent finishes, and overall cost-efficiency from prototype to full-scale production.

Managing Tolerances and Dimensional Stability in Nylon Parts?

Have you ever machined a nylon part to perfect specifications, only to find it out of tolerance a few days later? It’s a common frustration when a material’s natural properties challenge your precision work.

Achieving stable nylon parts requires managing its two biggest challenges: heat and humidity. This involves controlling the machining environment, using effective coolants, and applying post-machining conditioning techniques like annealing or moisture conditioning to normalize the material before final inspection and use.

Nylon’s tendency to shift dimensionally can be a major headache in any precision CNC machining project. This instability stems from two core material characteristics: its high coefficient of thermal expansion (CTE) and its ability to absorb moisture from the surrounding air. Understanding these factors is the first step toward mastering nylon machining. At PTSMAKE, we’ve learned to treat nylon not just as a plastic, but as a dynamic material that responds actively to its environment.

The Challenge of Moisture Absorption

Nylon is hygroscopic5, meaning it naturally attracts and holds water molecules from the atmosphere. When a nylon part absorbs moisture, it swells. The dimensional change can be significant—sometimes up to 2% or more, depending on the specific grade of nylon and the ambient humidity. This absorption doesn’t just change the size; it also alters mechanical properties, often making the material less brittle and more impact-resistant, but also reducing its tensile strength and stiffness. A part machined to a tight tolerance in a dry environment can easily fall out of spec when moved to a more humid location. This is a critical consideration for parts intended for use in varying climates or conditions.

Battling Thermal Expansion

Like most materials, nylon expands when heated and contracts when cooled. However, its CTE is substantially higher than that of metals. The heat generated during the CNC machining process itself—from the friction of the cutting tool—can cause the part to expand. If you measure the part while it’s still warm, you’ll get a false reading. Once it cools to room temperature, it will shrink, and you may find it’s undersized. In our experience, even a few degrees of temperature change in the workshop can affect the final dimensions of a high-precision nylon component. This is why consistent temperature control during and after machining is not a luxury, but a necessity.

| Nylon Type | Typical Moisture Absorption (at saturation) | Coefficient of Thermal Expansion (CTE) | Key Machining Consideration |

|---|---|---|---|

| Nylon 6 | ~9.5% | ~8.1 x 10⁻⁵ /°C | Prone to significant swelling; requires conditioning. |

| Nylon 6/6 | ~8.5% | ~7.2 x 10⁻⁵ /°C | Slightly more stable than Nylon 6, but still requires care. |

| Cast Nylon | ~6.5% | ~9.0 x 10⁻⁵ /°C | Lower internal stress, but has a higher CTE. |

| MDS-Filled Nylon | ~7.0% | ~6.3 x 10⁻⁵ /°C | Improved stability, but more abrasive to cutting tools. |

Knowing the challenges is one thing, but implementing effective strategies is what delivers consistent, in-spec parts. Overcoming nylon’s inherent instability requires a disciplined approach that spans the entire manufacturing process, from material handling to final inspection. You can’t fight the material’s nature, but you can certainly work with it. The key is to establish equilibrium within the part before it ever leaves the shop.

Pre-Machining: Setting the Stage for Success

The journey to dimensional stability begins before the first cut is even made.

Material Acclimatization

Before machining, the raw nylon stock should be allowed to acclimate to the environment of your workshop. We recommend storing the material in the same climate-controlled area where it will be machined for at least 24 hours. This allows the material to reach a state of thermal and moisture equilibrium with its surroundings, providing a more stable and predictable starting point.

Strategic Material Selection

Not all nylons are created equal. If tight tolerances are a primary concern, consider using a filled grade of nylon. For instance, glass-filled nylons exhibit a significantly lower CTE and reduced moisture absorption compared to unfilled grades. While they can be more abrasive on cutting tools, the trade-off is often worth it for the enhanced dimensional stability.

During Machining: In-Process Controls

Maintaining control during the cutting process is critical.

Effective Coolant Use

Heat is the enemy of tolerance. Using a flood coolant is one of the best ways to dissipate heat generated at the cutting interface. This minimizes thermal expansion during the machining operation, ensuring the dimensions being cut are as close to the final, cooled dimensions as possible. Air blasts can also be effective for clearing chips and providing some cooling without introducing moisture.

Post-Machining Conditioning: The Key to Stability

What you do after the part comes off the machine is often the most critical step.

Stress Relieving (Annealing)

Machining induces stress into the material. Annealing is a process where the part is heated to a temperature below its melting point and then slowly cooled. This process relieves those internal stresses, which can otherwise cause warping or dimensional changes over time.

Moisture Conditioning

To prevent future swelling from moisture absorption, parts can be pre-conditioned. This involves intentionally exposing the machined part to a controlled moisture environment to stabilize it. By allowing the part to absorb a nominal amount of moisture evenly, its dimensions will remain consistent when it’s put into service in a typical atmospheric environment. This step is a game-changer for achieving long-term reliability.

Nylon’s dimensional stability hinges on managing its absorption of moisture and its reaction to heat. By controlling the environment, acclimatizing material, using proper machining techniques, and applying post-machining conditioning like annealing, you can achieve the tight tolerances your designs demand for any nylon CNC machining project.

How Surface Finish Impacts Your Nylon Part’s Performance and Appearance?

Ever wonder why a seemingly perfect nylon part failed unexpectedly? The culprit might be hiding in plain sight: its surface finish. It’s more than just about looks.

The surface finish of a CNC machined nylon part is critical. It directly impacts friction, wear resistance, and even chemical exposure. A proper finish also enhances aesthetic appeal, which is vital for consumer-facing products, affecting user perception and brand value.

The finish you choose for a nylon part is a decision that extends far beyond aesthetics. It has a direct and measurable impact on the part’s functional performance. In my experience, overlooking this detail often leads to premature failure or subpar operation, especially in dynamic applications.

Functional Implications of Surface Finish

The microscopic peaks and valleys on a part’s surface dictate how it interacts with its environment and other components. A rougher surface, straight off the machine, might be acceptable for a static internal bracket, but it’s a non-starter for a moving part.

Friction and Wear Resistance

A smoother surface generally has a lower coefficient of friction6, which is crucial for parts like gears, bushings, and sliding components. In a high-cycle mechanism, a rough nylon surface will generate more heat and wear down much faster, shedding particulate that can contaminate the entire assembly. We’ve seen this in robotics projects where a simple vapor polish on a nylon gear dramatically extended its operational life.

Sealing and Fluid Dynamics

For parts that require a seal, like valve bodies or fluidic manifolds, surface finish is everything. A rough surface provides a potential leak path for liquids or gases under pressure. Achieving a specific surface roughness (Ra) value is often a key requirement on the engineering drawing to ensure a perfect mate with an O-ring or gasket.

The table below gives a simplified overview of how different finishes affect key performance metrics for nylon CNC machining parts.

| Finishing Method | Typical Surface Roughness (Ra) | Impact on Wear | Sealing Capability |

|---|---|---|---|

| As-Machined | 1.6 – 6.3 µm | Standard | Poor to Fair |

| Bead Blasting | 2.5 – 5.0 µm (Matte) | Improved | Poor |

| Vapor Polishing | 0.4 – 1.6 µm | Excellent | Good to Excellent |

| Mechanical Polishing | < 0.4 µm | Excellent | Excellent |

As you can see, moving from an as-machined finish to a polished one can reduce surface roughness by more than tenfold, which is a game-changer for performance.

Beyond the technical specs, the look and feel of a part can be just as important, especially when it ends up in the hands of a consumer. The perceived quality of a product is heavily influenced by its tactile and visual properties. A premium finish signals a premium product.

Aesthetic and Application-Specific Considerations

The final application of your nylon part is the ultimate guide to selecting the right finish. You must balance performance requirements with aesthetic goals and, of course, the budget.

Consumer Products vs. Industrial Machinery

In the world of consumer electronics or high-end sporting goods, a flawless, glossy finish might be a core part of the brand identity. For these applications, post-processing steps like polishing and painting are not optional; they are essential. The extra cost is justified by higher perceived value and customer satisfaction.

Conversely, for an internal component in a piece of industrial equipment, aesthetics are secondary to function and durability. An as-machined or bead-blasted finish is often perfectly sufficient and more cost-effective. Spending extra on a cosmetic finish here would be a waste of resources.

Industry-Specific Finishing Choices

Different industries have different standards and expectations. What works for an automotive prototype might not be suitable for a medical device. Based on projects we’ve handled at PTSMAKE, here’s a look at common finishing choices by industry.

| Industry | Common Nylon Part | Typical Finish Choice | Justification |

|---|---|---|---|

| Medical | Surgical guides, handles | Vapor Polishing, Painting | Smooth, easy to sterilize, non-porous surface. |

| Automotive | Engine bay components, clips | As-Machined, Bead Blasting | Function over form, cost-effectiveness. |

| Robotics | Gears, gripper fingers | Vapor Polishing | Low friction, high wear resistance. |

| Consumer Electronics | Housings, buttons | Painting, Mechanical Polishing | Premium look and feel, brand consistency. |

Ultimately, the best approach is to consider the part’s entire lifecycle. Where will it be used? Who will interact with it? What environment will it operate in? Answering these questions early in the design phase ensures the chosen finish for your nylon cnc machining project delivers on all fronts: performance, appearance, and cost.

The surface finish of your nylon CNC part is not an afterthought. It directly influences critical performance characteristics like friction, wear, and sealing, while also defining its aesthetic appeal and perceived value. Choosing the right finish is a balance of function, appearance, and cost.

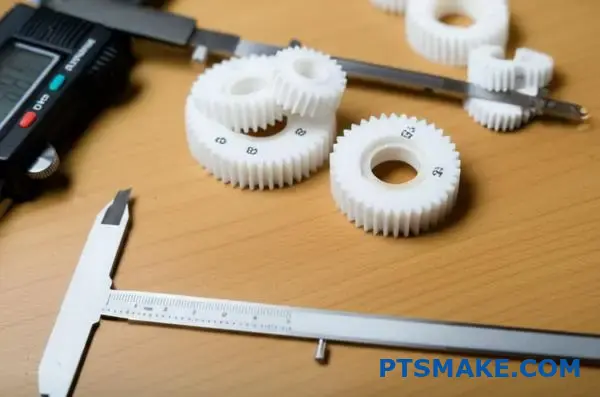

Quality Assurance: Inspection and Testing for Nylon Machined Parts?

Have you ever received a batch of nylon parts that looked perfect but failed under real-world stress? Or found that critical dimensions were just slightly off, causing frustrating assembly delays and project setbacks?

Ensuring quality for nylon machined parts involves a multi-layered approach, combining meticulous dimensional verification with advanced tools, thorough material certification to confirm grade and properties, and rigorous functional testing that simulates real-world application stresses to guarantee performance and reliability.

The Cornerstones of Nylon Part Inspection

Quality assurance isn’t just a final step; it’s a continuous process woven into every stage of production. For a material like nylon, which can be sensitive to moisture and temperature, a robust inspection plan is non-negotiable. It’s the only way to guarantee that the part you designed is the part you receive. At PTSMAKE, we build our quality process on two fundamental pillars: verifying the part’s physical form and confirming its material integrity.

Verifying Every Dimension

The first check is always dimensional accuracy. Does the part match the CAD model and technical drawings? This goes beyond a simple visual check.

Standard Metrology Tools: For most features, we start with the essentials. Calibrated digital calipers, micrometers, and height gauges are our first line of defense. They provide quick, reliable measurements for diameters, lengths, and step heights, making them perfect for in-process checks right at the machine.

Advanced Coordinate Measuring Machines (CMM): When dealing with complex geometries, tight tolerances, or critical features that are difficult to access, we rely on our CMMs. These machines use a high-precision probe to touch various points on the part, creating a 3D map of its surface. This data is then compared directly against the original CAD file, allowing us to verify complex profiles, hole positions, and geometric dimensioning and tolerancing (GD&T) callouts with incredible accuracy. This level of Metrology7 is essential for high-performance

nylon cnc machiningapplications.Non-Contact Optical Scanning: For delicate parts that could be deformed by a CMM probe or for parts with highly intricate surfaces, non-contact methods are ideal. 3D laser scanners and optical comparators capture millions of data points without ever touching the component, providing a complete surface analysis that ensures every curve and contour is perfect.

A comparison of these methods is useful:

| Inspection Method | Primary Use | Accuracy Level | Speed |

|---|---|---|---|

| Calipers/Micrometers | Basic dimensions (length, diameter) | Good | Very Fast |

| CMM | Complex geometries, GD&T | Highest | Moderate |

| 3D Laser Scanner | Intricate surfaces, reverse engineering | High | Fast |

Confirming Material Integrity

Using the wrong grade of nylon can lead to premature failure. That’s why material certification is just as important as dimensional verification. We ensure that every raw material block or rod comes with a Certificate of Conformance (CoC) from the supplier. This document certifies the material type (e.g., Nylon 6/6, Glass-Filled Nylon), its specifications, and its lot number. This creates an unbroken chain of traceability, so we know the exact origin of the material in your finished part.

Beyond the Blueprint: Functional and Performance Testing

A part that meets all dimensional and material specifications is great, but the ultimate question is: will it perform its job correctly and reliably? This is where functional testing comes in, moving beyond static measurements to simulate the dynamic conditions the part will face in its final application. This step is critical for de-risking new designs and ensuring long-term durability.

Simulating Real-World Conditions

We tailor our functional tests to the specific requirements of the part and its intended environment. This is a collaborative process we often undertake with our clients to define the most critical performance criteria.

Fit and Assembly Testing: One of the most common and practical tests involves a trial assembly. If a machined nylon gear needs to mesh with a metal pinion, we assemble them to check for proper engagement, backlash, and smooth operation. For enclosures or housings, we test the fit of mating components, seals, and fasteners to ensure everything aligns perfectly without interference or excessive gaps.

Load and Stress Testing: For structural components like brackets, mounts, or linkages, we need to know how they behave under load. In our in-house test lab, we can design and build custom fixtures to apply specific tensile, compressive, or torsional forces. We then monitor the part for deflection, creep, or signs of fracture, ensuring it has the strength and stiffness to handle its operational stresses. This data is invaluable for validating engineering simulations.

Environmental Conditioning: Nylon’s mechanical properties can be affected by its environment, particularly temperature and humidity. For parts used in automotive engine bays or outdoor equipment, we may perform environmental testing. This can involve subjecting the part to cycles of high heat or controlled humidity and then re-testing its mechanical properties to ensure it remains stable and functional.

This table highlights the purpose of each test type:

| Test Type | Purpose | Common Application |

|---|---|---|

| Fit & Assembly | Verify clearance, alignment, and smooth interaction | Mating gears, electronic enclosures, snap-fit features |

| Load & Stress | Confirm strength, stiffness, and durability | Structural brackets, load-bearing bushings, lever arms |

| Environmental | Assess performance in non-ideal conditions | Automotive components, medical devices, outdoor products |

By combining dimensional accuracy checks with robust functional testing, we provide a complete quality assurance picture. This ensures that the parts we deliver not only match the drawing but will perform flawlessly in the real world.

Effective quality assurance for nylon parts requires a holistic strategy. It starts with precise dimensional verification and strict material certification, then advances to functional and performance testing that simulates real-world stresses. This comprehensive approach guarantees every component meets design specifications and performs reliably in its application.

Supplier Selection: What Buyers Should Ask Before Ordering?

Have you ever faced project delays because your nylon parts arrived out of spec? The frustration of choosing a supplier who couldn’t deliver on their promises is a costly, time-consuming experience.

Before ordering, you must ask about their specific experience with nylon CNC machining, their documented quality control processes, their communication practices, and how they guarantee lead times. These questions are essential for vetting a reliable long-term partner.

Gauging Technical Expertise and Material-Specific Knowledge

Selecting a supplier for nylon CNC machining isn’t just about finding someone with a CNC machine. It’s about finding a partner who understands the unique challenges of this material. A general machinist might treat nylon like any other plastic, leading to poor surface finishes, internal stresses, and parts that fail in the field. To avoid this, you need to dig deeper into their technical capabilities.

Specific Experience with Nylon Grades

Don’t accept a simple "yes" when you ask if they machine nylon. A truly experienced supplier will be able to discuss the nuances between different grades. Ask them directly: "What is your experience machining Nylon 6 versus glass-filled Nylon 66?" A proficient shop, like us at PTSMAKE, knows that glass-filled variants are highly abrasive and require specialized tooling (like carbide or diamond-coated cutters) to maintain tolerances and prevent rapid tool wear. They should also be able to explain how they control for nylon’s tendency to absorb moisture, which can compromise the dimensional stability8 of the final part. This often involves climate-controlled storage and quick machining cycles after the material is unsealed.

Ability to Handle Complex Geometries

Your design’s complexity will quickly reveal a supplier’s limitations. Provide them with your most complex part design and ask them how they would approach it.

- What machines will they use (3-axis, 4-axis, 5-axis)?

- How will they secure the workpiece to prevent vibration and deflection?

- What is their strategy for achieving the specified tightest tolerances and surface finishes?

Their answers will give you a clear picture of their problem-solving skills and equipment capabilities.

A good way to vet suppliers is to compare their answers on material-specific challenges. Here’s a quick guide:

| Question Category | For a General Machinist | For a Nylon CNC Machining Specialist |

|---|---|---|

| Material Handling | "Do you machine plastics?" | "How do you manage moisture absorption in nylon stock before and during machining?" |

| Tooling Strategy | "What tools do you use for plastics?" | "What specific cutter geometries and coatings do you use for glass-filled nylon to prevent abrasion and heat buildup?" |

| Quality Verification | "Can you measure the parts?" | "How do you verify tolerances on features prone to deflection during machining?" |

Asking these targeted questions helps you filter out the generalists and identify a true specialist.

Assessing Operational Reliability and Communication

A supplier’s technical skill is useless if their operational processes are chaotic. Missed deadlines, inconsistent quality, and poor communication can derail your entire production schedule. Vetting a supplier’s operational reliability is just as critical as assessing their machining capabilities. This is about finding a partner who can integrate seamlessly into your supply chain and provide peace of mind.

Lead Time Guarantees and Capacity

A vague lead time is a major red flag. Instead of asking, "What’s your lead time?" ask, "How do you guarantee your lead time?" A reliable supplier should be able to walk you through their production scheduling process. At PTSMAKE, we provide a detailed timeline and have systems in place to flag potential delays before they become critical problems. Also, ask about their current capacity. A shop that is over capacity is more likely to rush jobs, leading to quality issues, or subcontract your work without your knowledge. You want a partner who has the bandwidth to give your project the attention it deserves.

Quality Control and Inspection Processes

Never assume quality. Ask for proof.

- Do they have an ISO 9001 certification or a similar quality management system?

- Can they provide a sample inspection report?

- What specific equipment do they use for inspection (e.g., CMM, profilometer, calipers)?

A commitment to quality should be evident in their documentation and processes. Insist on receiving a first article inspection (FAI) report with your initial order. This ensures the parts meet every specification before you move into full production, preventing costly mistakes down the line. We find that establishing these quality checkpoints early builds trust and ensures project success.

Communication and Transparency

How a supplier communicates during the quoting process is often indicative of how they’ll communicate during production. Are they responsive? Do they provide clear, concise answers? Who will be your dedicated point of contact? Clear and proactive communication is the foundation of a good partnership. You need a supplier who will alert you to potential issues and work with you to find solutions, not one who goes silent when problems arise.

| Inquiry | Red Flag Response | Green Flag Response |

|---|---|---|

| "What’s your lead time?" | "About 3-4 weeks." | "Our standard lead time is 18 business days. We will provide a detailed GANTT chart and weekly updates. Do you have a firm deadline we need to hit?" |

| "Can you hold this tolerance?" | "Yes, should be fine." | "Yes, that tolerance is achievable with our 5-axis CNC. We’ll verify it with our CMM and include the inspection report with your shipment." |

| "What if there’s an issue?" | "We will let you know." | "You will have a dedicated project manager. Any issues are flagged within hours, and we will contact you immediately with a root cause analysis and a proposed solution." |

Choosing the right supplier means asking detailed questions. Go beyond surface-level inquiries to assess their specific experience with nylon CNC machining, their quality control systems, and their communication protocols. This due diligence prevents costly delays and ensures you receive high-quality parts on time.

Understand how moisture absorption can impact your material selection and part performance. ↩

Learn how moisture absorption impacts nylon’s dimensional stability and mechanical performance. ↩

Understand how molecular movement affects material properties and machining outcomes for better part design. ↩

Understand how calculating chip load is vital for preventing tool breakage and achieving optimal material removal rates. ↩

Discover how this material property impacts your design choices and machining strategies. ↩

Learn how this fundamental property affects the wear life and efficiency of your moving parts. ↩

Discover the science of measurement and how it ensures your part’s precision and accuracy in manufacturing. ↩

Learn how material properties like this impact the precision and performance of your final machined parts. ↩