Medical device manufacturers face mounting pressure to deliver increasingly complex, precision components while navigating strict regulatory requirements and tight deadlines. The challenge becomes even more difficult when traditional machining methods can’t keep up with demands for patient-specific implants, intricate surgical instruments, and next-generation diagnostic devices.

The medical CNC machining industry is experiencing a major transformation in 2025, driven by breakthrough innovations in automation, smart manufacturing technologies, and advanced materials processing. These developments are enabling manufacturers to achieve unprecedented precision levels while meeting personalized medicine demands and stringent FDA compliance standards.

Working in precision manufacturing for over 15 years, I’ve watched this industry evolve rapidly. The changes happening right now in medical CNC machining represent the biggest shift I’ve seen. From AI-powered quality control systems to hybrid manufacturing approaches combining additive and subtractive methods, these innovations are solving problems that seemed impossible just a few years ago. Let me walk you through the key trends that will define medical CNC machining success in 2025.

Emerging Innovations in Medical CNC Machining.

Struggling to machine increasingly complex medical components with the precision that patient safety demands? Are outdated manufacturing processes creating bottlenecks for your innovative, patient-specific device designs?

The landscape of medical CNC machining is rapidly evolving, driven by innovations like multi-axis machining, integrated robotics, and advanced software. These technologies are unlocking new possibilities for creating highly complex, customized, and ultra-precise medical components with unprecedented speed and reliability.

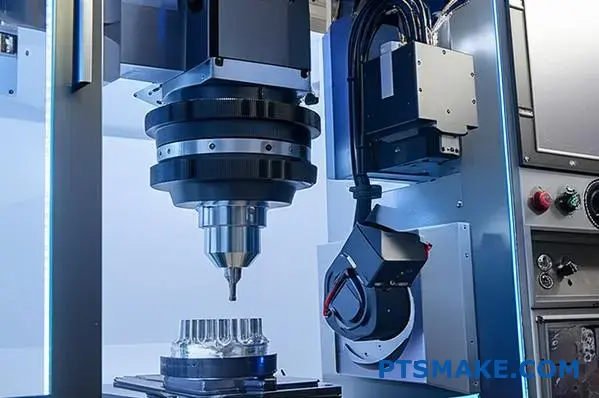

The demand for smaller, more intricate, and patient-specific medical devices has pushed traditional 3-axis machining to its limits. The real breakthrough in modern medical manufacturing comes from embracing more sophisticated technologies. In our experience at PTSMAKE, the transition to multi-axis machining has been a game-changer for clients requiring complex medical components.

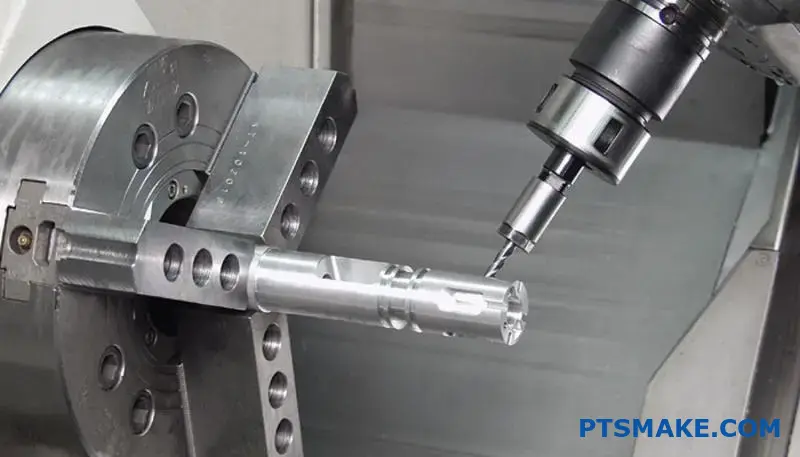

The Leap to Multi-Axis Machining

Unlike traditional machines that move along three linear axes (X, Y, Z), multi-axis machines introduce rotational axes. This allows the cutting tool to approach the workpiece from virtually any angle, enabling the creation of highly complex geometries in a single setup. This single-setup approach is a significant advantage in medical CNC machining, as it drastically reduces the risk of errors that can occur when a part is manually re-fixtured multiple times.

Beyond 3-Axis: The Power of 5-Axis

5-axis CNC machining is the cornerstone of modern medical device manufacturing. It’s how we produce components like orthopedic implants (knee and hip replacements), surgical instruments, and complex housings for diagnostic equipment. The ability to maintain a constant, optimal angle between the tool and the workpiece surface results in superior surface finishes, which is critical for biocompatibility and reducing friction in moving parts. The machine’s advanced kinematics1 allow for contoured surfaces and deep, narrow cavities that would be impossible to create otherwise. This capability directly supports the trend toward minimally invasive surgical tools and anatomically matched implants.

| Feature | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Setups Required | Multiple | Single or Few |

| Complexity | Limited to simpler geometries | Ideal for complex, organic shapes |

| Accuracy | Good, but risk of error with each setup | Excellent, higher repeatability |

| Ideal For | Brackets, simple housings, plates | Orthopedic implants, surgical tools |

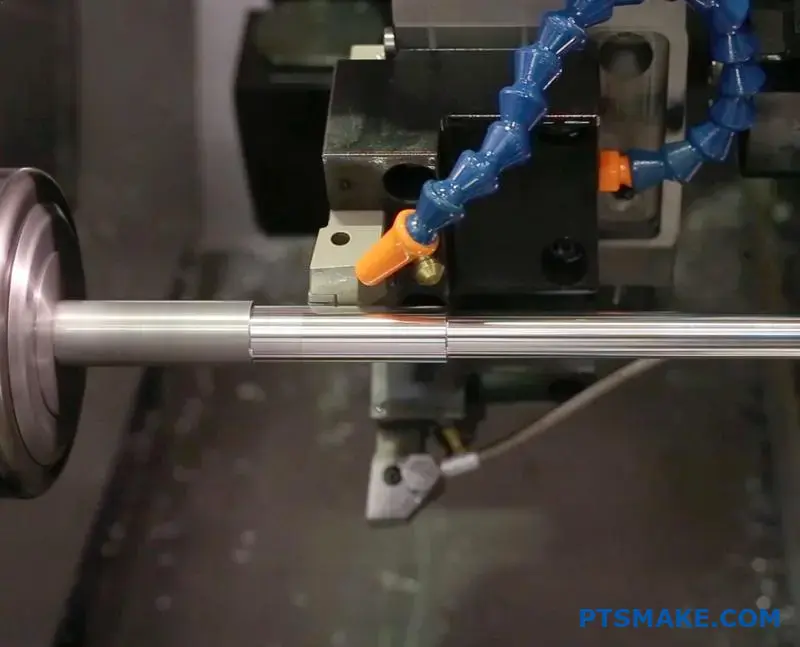

Swiss-Type Machining for Miniature Components

For micro-scale medical parts like bone screws, dental implants, and components for pacemakers, Swiss-type CNC lathes are indispensable. These machines support the workpiece with a guide bushing very close to the cutting tool. This design provides exceptional stability, allowing for the turning of very long, slender parts with extremely tight tolerances. This precision is vital, as even a minor deviation in a component like a spinal screw could have serious consequences for the patient.

While advanced machine tools are the foundation, the software that drives them and the automation that supports them are equally important innovations. The "brains" and "brawn" of the operation work in tandem to elevate medical CNC machining from a simple fabrication process to an intelligent manufacturing ecosystem. This integration is key to achieving the consistency and traceability required by stringent medical regulations like those from the FDA.

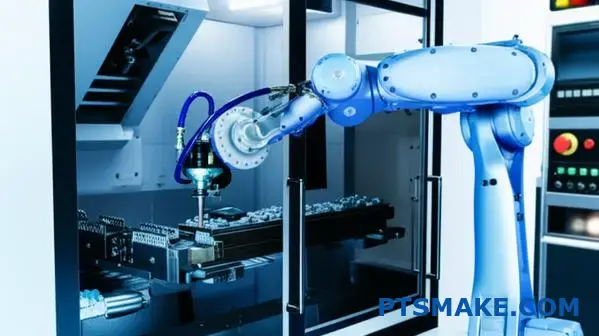

The Rise of Automation and Robotics

Human skill is irreplaceable, but automation handles the repetitive tasks, freeing up our skilled technicians to focus on quality control and process optimization. This hybrid approach enhances both efficiency and quality.

Lights-Out Manufacturing in the Medical Field

By integrating robotic arms for loading raw materials and unloading finished parts, we can run our CNC machines 24/7 with minimal human oversight. This "lights-out" manufacturing capability is particularly beneficial for high-volume production of standardized medical components. It not only accelerates production timelines but also reduces the per-part cost, making advanced medical treatments more accessible. Automated in-process inspection, where a robot presents a part to a CMM (Coordinate Measuring Machine) mid-cycle, ensures that any deviations are caught immediately, not at the end of a long production run.

The Brains Behind the Brawn: Advanced Software

The most powerful hardware is only as good as the software controlling it. Modern CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) platforms are more crucial than ever.

CAD/CAM and Simulation

Before any metal is cut, we run comprehensive simulations. Advanced CAM software allows us to visualize the entire machining process, detecting potential tool collisions, optimizing toolpaths for efficiency, and predicting the final surface finish. This is especially critical for patient-specific devices derived from CT or MRI scans. We can simulate the machining of a custom cranial plate or a unique surgical guide, ensuring a perfect fit and preventing costly material waste or delays. In past projects with clients, we’ve found that thorough simulation can reduce physical prototyping iterations by as much as 50%, a huge benefit when time-to-market is critical. This digital verification step is an essential risk-mitigation tool in the high-stakes world of medical manufacturing.

The core takeaway is that the medical CNC machining industry is in a period of rapid technological advancement. Innovations are not happening in isolation; instead, multi-axis machines, sophisticated robotics, and intelligent software are converging. This synergy enables manufacturers like us at PTSMAKE to produce medical devices that are more complex, precise, and tailored to individual patient needs than ever before. These advancements directly translate to better patient outcomes by supporting more effective and less invasive medical procedures.

Automation and Robotics: Shaping the Future of Medical Manufacturing!

Struggling to balance the intense demand for precision in medical parts with the constant risk of human error? Are you concerned that one small inconsistency could derail an entire production run?

Automation and robotics are fundamentally reshaping medical manufacturing. By integrating AI-driven systems and robotics into medical CNC machining, we achieve unprecedented efficiency, minimize human error, and enable scalable production, ensuring every component meets the strictest quality and safety standards.

The transition to automation in manufacturing isn’t just about replacing human labor; it’s about elevating precision to a level that humans simply cannot consistently maintain. In the medical field, where a single micron can be the difference between a successful surgical implant and a critical failure, this elevation is not a luxury—it’s a necessity. At PTSMAKE, we’ve seen firsthand how integrating automation transforms the production floor from a series of manual, disconnected steps into a streamlined, intelligent ecosystem.

The Core Pillars of Automated Production

Automation enhances medical CNC machining by focusing on three critical areas: efficiency, error reduction, and scalability. Each pillar supports the others, creating a robust framework for modern medical device manufacturing.

Unlocking 24/7 Efficiency

A key advantage of robotics is the ability to operate continuously without fatigue. Robotic arms can load raw material billets into CNC machines and unload finished parts around the clock. This "lights-out" manufacturing capability dramatically increases machine uptime and overall output. For projects with aggressive timelines, such as responding to a sudden demand for a new medical device, this continuous operation is a game-changer. It allows us to meet tight deadlines without compromising the meticulous machining process required for complex medical components.

Systematically Eliminating Human Error

Even the most skilled machinist can have an off day. Fatigue, distraction, or minor miscalculations can lead to variations that are unacceptable in medical applications. Automated systems, however, perform the same task with the exact same precision every single time. A programmed robot follows its instructions flawlessly, ensuring that every part is a perfect replica of the one before it. This level of repeatability is crucial for passing the stringent validation processes required by regulatory bodies. The system relies on a closed-loop feedback system2 to continuously monitor and adjust its performance, guaranteeing consistency.

| Feature | Manual Operation | Automated Operation |

|---|---|---|

| Consistency | Variable, depends on operator | Extremely high and repeatable |

| Operating Hours | Limited to shifts (8-12 hours) | Continuous (24/7) |

| Error Rate | Higher, subject to human factors | Near-zero for programmed tasks |

| Scalability | Slow, requires hiring/training | Rapid, add or reprogram cells |

This systematic approach removes the element of chance from the equation, providing a reliable foundation for high-stakes medical CNC machining.

While improving production efficiency is a primary driver for automation, its role in quality control is arguably even more critical, especially in the medical sector. Autonomous inspection systems are not just checking for defects; they are creating a new standard of quality assurance that is both faster and more reliable than traditional methods. The goal is to move from simply identifying failures to preventing them from ever occurring.

The Rise of Autonomous Inspection Systems

In the past, quality control involved technicians manually measuring parts with calipers and micrometers. This process was not only slow but also introduced the potential for human error and subjective judgment. Today, automated quality control leverages advanced technology to provide objective, comprehensive data for every single part that comes off the line.

High-Precision Metrology in Action

Modern medical CNC machining workcells often integrate automated Coordinate Measuring Machines (CMMs) and high-resolution vision systems. Here’s how it works in our projects at PTSMAKE: once a part is machined, a robotic arm picks it up and places it into an enclosed CMM station. The CMM probe then automatically touches hundreds, or even thousands, of pre-programmed points on the part, comparing the physical measurements against the original CAD model with sub-micron accuracy. This process generates a complete, unbiased inspection report in minutes—a task that would take a human inspector hours to complete with far less detail.

AI-Powered Predictive Quality

The most advanced systems take this a step further by incorporating artificial intelligence. AI algorithms analyze the vast amount of data collected by CMMs and vision systems over time. They can identify microscopic deviations or trends that are invisible to the human eye. For instance, an AI might detect that a certain dimension is slowly drifting towards its tolerance limit. It can then alert the system to a potential issue, such as tool wear on the CNC machine, before any out-of-spec parts are produced. This predictive capability is a huge leap forward, shifting the focus from reactive defect detection to proactive process control.

| Inspection Method | Manual Inspection | Automated CMM | AI-Vision System |

|---|---|---|---|

| Speed | Slow | Fast | Instantaneous |

| Data Traceability | Manual logs, error-prone | Complete digital record | Fully integrated data stream |

| Accuracy | Operator-dependent | Sub-micron precision | High, with pattern recognition |

| Predictive Power | None | Limited | High, detects trends |

This comprehensive data logging also creates an unimpeachable audit trail for every component, simplifying regulatory compliance and providing absolute confidence in the quality of the final product.

In essence, automation and robotics are revolutionizing medical manufacturing by enhancing efficiency, scalability, and, most importantly, precision. By systematically reducing the potential for human error in both production and inspection, these technologies ensure that every medical component is machined to exact specifications. AI-driven quality control and autonomous systems provide a level of assurance that manual processes simply cannot match, establishing a new benchmark for safety and reliability in medical CNC machining.

Advanced Materials for Medical CNC Machining.

Have you ever selected a material that seemed ideal on paper, only to face unexpected machining challenges or biocompatibility issues down the line? It’s a common frustration in medical device development.

Advanced materials like titanium alloys, PEEK, and bioresorbable polymers are pivotal in modern medical CNC machining. They provide superior biocompatibility, strength, and performance, enabling the creation of safer and more effective implants, surgical instruments, and diagnostic equipment.

The choice of material is one of the most critical decisions in medical device manufacturing. It goes beyond simple mechanical properties; it’s about how the material interacts with the human body and how it behaves under the stress of a high-precision machining process. In past projects at PTSMAKE, we’ve found that a deep understanding of the material’s nuances is non-negotiable for success in medical CNC machining.

The Metals: Titanium and Cobalt-Chrome

Metals remain the backbone of many load-bearing medical implants, such as hip joints and bone plates. Their strength and durability are unmatched, but they bring unique challenges to the machine shop.

Titanium Alloys (e.g., Ti-6Al-4V)

Titanium is famous for its high strength-to-weight ratio and excellent corrosion resistance. This makes it ideal for long-term implants. However, it’s notoriously difficult to machine. It has low thermal conductivity, meaning heat builds up at the cutting tool tip instead of dissipating into the chips or workpiece. This extreme heat can cause premature tool wear and even damage the material’s surface integrity, which is critical for promoting osseointegration3. To counter this, we use high-pressure coolant systems and specialized coated carbide tools, running at very specific speeds and feeds that our team has refined over many projects.

Cobalt-Chrome Alloys (Co-Cr)

Co-Cr alloys are even tougher and more wear-resistant than titanium, making them perfect for the articulating surfaces of knee and hip replacements. This same hardness, however, makes them extremely abrasive on cutting tools. Machining Co-Cr requires rigid machine setups, optimized toolpaths to minimize tool engagement stress, and cutting tools made from advanced materials like cubic boron nitride (CBN). The process is slow and requires constant monitoring to maintain the tight tolerances essential for medical devices.

| Material | Key Advantage | Main Machining Challenge | Common Medical Application |

|---|---|---|---|

| Titanium (Ti-6Al-4V) | High strength-to-weight ratio | Poor heat dissipation, work hardening | Spinal fusion cages, bone screws |

| Cobalt-Chrome (Co-Cr) | Excellent wear resistance | High abrasiveness, material toughness | Artificial hip and knee joints |

While metals set the standard for strength, advanced polymers are creating new possibilities in medical device design, offering properties that metals simply cannot match. These materials often require a completely different machining strategy, shifting the focus from managing brute force and heat to finessing delicate structures.

The Polymers: PEEK and Bioresorbables

High-performance polymers are prized for their biocompatibility, lightweight nature, and, in some cases, unique interactive properties with the human body. They are becoming increasingly common for both permanent implants and temporary medical devices.

Polyether Ether Ketone (PEEK)

PEEK is a remarkable thermoplastic that combines mechanical strength with radiolucency, meaning it’s transparent to X-rays. This allows surgeons to clearly see bone fusion progress around a PEEK implant on scans. However, its relatively low melting point presents a challenge. Too much friction or heat during machining can melt the material, leading to gummy buildup on the tool and a poor surface finish. The key is using extremely sharp, often specialized plastic-cutting tools, and employing lower spindle speeds with higher feed rates to create clean chips and minimize heat. Air blasts are often preferred over liquid coolants to prevent thermal shock and contamination.

Bioresorbable Polymers (PLLA, PGA)

These materials are at the cutting edge of medical technology. They are used for devices like sutures, stents, and fixation screws that are designed to perform a function for a set period and then safely dissolve in the body. Machining them is an exercise in delicacy. They are extremely sensitive to heat and mechanical stress, which can compromise their structural integrity and absorption rate. We use micro-machining techniques with exceptionally sharp tools and minimal cutting forces. The entire process is carefully controlled to prevent any premature degradation of the polymer.

| Material | Key Advantage | Main Machining Challenge | Common Medical Application |

|---|---|---|---|

| PEEK | Radiolucency, chemical resistance | Low melting point, can create burrs | Spinal implants, suture anchors |

| Bioresorbables (PLLA) | Absorbed by the body over time | Heat sensitivity, very brittle | Temporary fixation screws, stents |

Choosing advanced materials for medical CNC machining involves a critical trade-off between performance and manufacturability. High-strength metals like titanium and cobalt-chrome offer durability for implants but pose challenges with heat and tool wear. In contrast, polymers like PEEK provide unique benefits such as radiolucency, while bioresorbables offer temporary support before dissolving. Each material demands a specialized machining approach, turning material selection into a strategic decision balancing device function with production feasibility.

Additive Manufacturing and Hybrid CNC Approaches?

Have you ever designed a medical component with intricate internal channels, only to be told it’s impossible to manufacture? This design-for-manufacturing roadblock can be incredibly frustrating for engineers pushing for innovation.

Hybrid manufacturing merges additive processes like 3D printing with subtractive CNC machining in one seamless workflow. This powerful combination produces highly complex, patient-specific medical devices with the precision finish and tight tolerances that only medical CNC machining can deliver.

The Power Couple: How Additive and Subtractive Work Together

The integration of additive manufacturing (AM) and CNC machining isn’t about one technology replacing the other. Instead, it’s a symbiotic relationship where the strengths of one compensate for the weaknesses of the other. At its core, the hybrid process uses AM to build a part to its "near-net shape," including complex internal features, and then uses CNC machining to create the critical, high-tolerance surfaces.

Building the Form with Additive Manufacturing

Additive processes, such as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM), are perfect for the initial stage. They build parts layer by layer from a 3D CAD file using materials like medical-grade titanium or PEEK. This method allows for the creation of geometries that are simply impossible with traditional machining. We’re talking about porous lattice structures in spinal implants that encourage osseointegration4, or surgical tools with complex internal cooling channels. The additive step lays the foundation, focusing on complex geometry and overall form.

Refining the Function with CNC Machining

Once the near-net shape is printed, the part moves to the subtractive stage. This is where the precision of medical CNC machining becomes essential. A 5-axis CNC mill can then be used to machine critical features to exacting specifications. This includes creating smooth mating surfaces for device assembly, drilling and tapping precise holes for surgical screws, and achieving a surface finish that meets strict biocompatibility standards. This finishing step ensures the part not only fits its design but also functions perfectly within the human body or a larger medical assembly.

In our work at PTSMAKE, we’ve found this hybrid approach opens doors for medical device designers. The process is best understood by comparing it to traditional methods.

| Feature | Additive Manufacturing (AM) | CNC Machining Only | Hybrid Approach |

|---|---|---|---|

| Internal Complexity | High (Lattices, channels) | Low (Limited by tool access) | High (Combines both) |

| Surface Finish (as-is) | Rough | Excellent | Excellent (On critical areas) |

| Dimensional Accuracy | Moderate | Very High | Very High (On critical areas) |

| Material Waste | Low | High | Moderate (Low in AM step) |

This table, based on our project data, clearly shows how the hybrid model offers the best of both worlds for many medical applications.

Transforming Patient Care and the Supply Chain

The impact of this hybrid technology goes far beyond just making complex parts. It is fundamentally changing how medical devices are designed, delivered, and used, directly affecting patient outcomes and supply chain logistics. The ability to create custom, on-demand parts is a game-changer for the medical industry.

True Personalization: Patient-Specific Implants

One of the most exciting applications is the creation of patient-specific implants. The traditional approach uses standard-sized implants, which a surgeon must adapt during an operation. With a hybrid approach, the workflow is revolutionized.

- Scan: A patient’s anatomy is captured with a CT or MRI scan.

- Design: A custom implant is designed to perfectly match the patient’s unique anatomy.

- Produce: The implant is 3D printed with its complex internal structures and then precision-finished using CNC.

This process results in custom cranial plates that fit perfectly, joint replacements that match the patient’s exact bone structure, and surgical guides that direct the surgeon with unparalleled accuracy. These custom fits can reduce surgery times, minimize complications, and improve long-term patient recovery. In our discussions with medical clients, the potential to improve patient outcomes is their primary driver for exploring these technologies.

On-Demand Production and Supply Chain Efficiency

The hybrid model also addresses major logistical pain points. The traditional medical supply chain relies on large inventories of standard-sized parts stored in centralized warehouses, leading to high costs and potential delays.

| Supply Chain Factor | Traditional Model | Hybrid On-Demand Model |

|---|---|---|

| Inventory Levels | High (Stocking all sizes) | Very Low (Made to order) |

| Lead Time (Custom) | Weeks or Months | Days |

| Supplier Dependency | High (Centralized mfg.) | Low (Decentralized possible) |

| Waste from Unused Stock | Moderate to High | Minimal |

Hybrid manufacturing enables a shift towards a decentralized, on-demand model. A hospital or regional production center equipped with a hybrid machine could produce a specific implant or surgical tool just hours before it’s needed. This drastically reduces the need for large, costly inventories and eliminates the risk of stockouts for critical components. It makes the supply chain more resilient, responsive, and ultimately more efficient in meeting the dynamic needs of modern healthcare.

Hybrid manufacturing effectively combines the geometric freedom of 3D printing with the unmatched precision of CNC machining. This synergy allows for the creation of intricate, patient-specific medical devices that were previously impossible to produce. For engineers and designers, this unlocks new possibilities in medical innovation. Furthermore, this technology streamlines the supply chain by enabling on-demand, decentralized production, ensuring that clinicians have the exact tools and implants they need, precisely when they need them.

Smart Manufacturing and Data-Driven Quality Control?

Are your manufacturing processes still relying on post-production checks, only catching errors after they’ve already wasted materials and time? Is this reactive approach creating unacceptable risks for your medical devices?

Smart manufacturing transforms this by embedding data analytics and AI directly into the production line. Through real-time monitoring, in-process inspections, and predictive analysis, it ensures every medical component is machined with unparalleled precision and consistency, actively preventing defects before they occur.

The leap from traditional to smart manufacturing is not just about new machines; it’s about a new philosophy. Instead of simply programming a CNC machine and hoping for the best, we now create a feedback loop where the machine learns and adapts. This is where big data and artificial intelligence (AI) become game-changers in medical CNC machining.

The Power of Data in Precision Machining

Every machining operation generates a massive amount of data—spindle speed, tool wear, temperature, vibration, and axis positioning. In the past, most of this data was discarded. Today, we harness it. By analyzing these data streams in real-time, we can identify subtle patterns that precede a quality issue. For example, a minor increase in spindle vibration might indicate that a cutting tool is beginning to dull. An AI algorithm can flag this, alerting an operator or even automatically adjusting cutting parameters to compensate, long before the tool wear affects the part’s surface finish or dimensional accuracy. This shift is crucial for maintaining the tight tolerances required for medical implants and surgical instruments.

AI-Driven Process Optimization

At PTSMAKE, we’ve explored how AI can move beyond simple alerts into true process optimization. AI models can analyze historical data from thousands of production runs to determine the absolute optimal settings for a specific material and geometry. This goes far beyond standard operator knowledge. It might find, for instance, that a slightly unconventional feed rate combined with a specific coolant pressure reduces micro-fracturing in a hard-to-machine polymer by a significant margin. This allows us to achieve superior results consistently. It also enables a robust predictive maintenance5 schedule, where machines are serviced based on actual usage data rather than a fixed calendar, preventing costly unexpected downtime.

Here’s a simple breakdown of the shift:

| Aspect | Traditional CNC Machining | Smart CNC Machining |

|---|---|---|

| Quality Control | Post-production inspection | In-process, real-time monitoring |

| Process Adjustments | Manual, based on operator experience | Automated, AI-driven optimization |

| Error Handling | Reactive (scrap or rework) | Proactive (predict and prevent) |

| Data Usage | Primarily for final reporting | Used for real-time feedback and learning |

This data-driven approach removes guesswork and builds quality directly into the manufacturing process from the very first cut.

While big data and AI provide the "brains" for smart manufacturing, advanced inspection technologies act as the "eyes and ears" on the factory floor. These tools provide the real-time data needed to make intelligent decisions, ensuring that every part meets stringent medical specifications without fail. Waiting until the end of a production run to find a defect is no longer acceptable, especially when dealing with high-value materials and critical-use medical components.

In-Process Inspection: The First Line of Defense

In-process inspection involves using automated probes and sensors directly within the CNC machine. For example, after a critical feature is machined, a touch probe can be automatically deployed to measure its dimensions before the part is even moved. If any deviation from the CAD model is detected, the system can instantly adjust the tool path for subsequent operations or flag the part for immediate review. This is fundamentally different from traditional methods, where a part might be fully machined before it’s measured on a separate CMM (Coordinate Measuring Machine). Catching an error mid-process saves immense time and material, drastically reducing the scrap rate.

Laser Scanning for Complex Geometries

For medical devices with complex, free-form surfaces, like custom orthopedic implants, touch probes can be slow and may not capture the full surface profile. This is where non-contact laser scanning excels. A laser scanner can capture millions of data points on a part’s surface in seconds, creating a detailed 3D map. This map is then instantly compared to the original digital model. This technology provides a comprehensive quality check that is both fast and incredibly thorough, ensuring that organic and intricate shapes conform perfectly to the design intent. In past projects at PTSMAKE, we found this particularly effective for verifying the complex curvatures of joint replacement components.

Real-Time Monitoring for Unwavering Consistency

Beyond measuring dimensions, real-time monitoring systems track the health and performance of the CNC machine itself.

| Monitoring Technique | Key Function | Impact on Medical CNC Machining |

|---|---|---|

| Vibration Analysis | Detects imbalances or tool chatter. | Ensures superior surface finish and prevents micro-cracks. |

| Thermal Monitoring | Tracks temperature of the workpiece and spindle. | Prevents material warping and maintains dimensional stability. |

| Acoustic Sensing | "Listens" for signs of tool wear or breakage. | Allows for immediate tool changes, preventing damage to the part. |

By continuously tracking these variables, we ensure that the machining environment remains stable from the first part to the thousandth. This level of process control is non-negotiable for medical cnc machining, where product consistency can directly impact patient safety and device efficacy.

Smart manufacturing is fundamentally reshaping medical CNC machining, shifting the paradigm from reactive defect detection to proactive quality assurance. By harnessing big data and AI for process optimization, we can achieve a level of precision that was previously unattainable. Meanwhile, real-time technologies like in-process inspection and laser scanning serve as vigilant quality gates throughout production. This integrated, data-driven methodology minimizes waste, ensures unwavering consistency, and ultimately delivers the flawless, reliable components demanded by the medical industry.

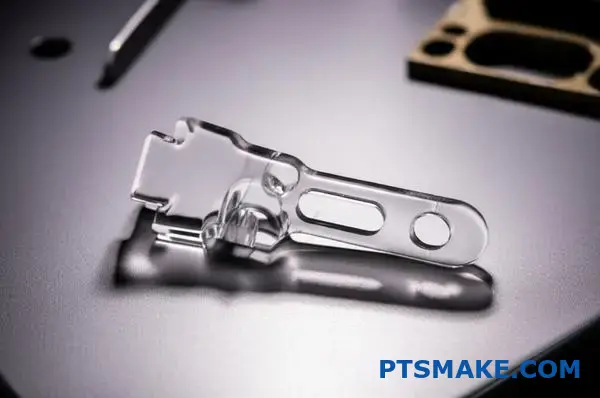

Customization and Personalization in Medical Device Production?

Have you ever considered why a standard medical implant can’t perfectly match every patient’s unique anatomy? The one-size-fits-all approach often leads to compromises in comfort, performance, and recovery time.

Medical CNC machining is the key to true personalization. It allows manufacturers to produce patient-specific implants, custom surgical tools, and tailored prosthetics directly from medical imaging data. This approach requires highly flexible design and manufacturing workflows to deliver superior patient outcomes.

The Shift Toward Patient-Specific Solutions

The medical industry is moving away from mass-produced devices and toward solutions tailored to the individual. This isn’t just a trend; it’s a fundamental change driven by the need for better clinical results. In medical device production, customization means creating a part that is a perfect match for a patient’s body. This precision minimizes risks, shortens surgery times, and accelerates healing. The demand for custom implants, for example, has grown significantly. A knee or hip replacement built from a patient’s CT scan will integrate far better than a standard-sized option.

From Digital Scan to Physical Implant

The process begins with high-resolution imaging, such as CT or MRI scans. This data creates a precise digital 3D model of the patient’s anatomy. Engineers then use this model to design an implant or instrument that fits perfectly. This is where the power of advanced medical CNC machining comes into play. The digital design is translated into CAM instructions that guide multi-axis CNC machines to carve the final product from a solid block of biocompatible material like titanium or PEEK. This seamless digital thread ensures that the final physical part is an exact replica of the virtual design, with tolerances often measured in microns. Making custom surgical tools this way, such as Patient-specific instrumentation6, ensures the surgeon can perform the procedure with maximum accuracy.

Material and Design Flexibility

Customization isn’t just about shape and size; it’s also about material selection and design features. Different applications require different material properties, from the strength of cobalt-chrome for load-bearing joints to the radiolucency of PEEK for spinal implants. CNC machining handles these diverse materials with ease. Furthermore, it allows for the creation of complex features that would be impossible with other methods.

| Feature | Standard Medical Devices | Custom CNC-Machined Devices |

|---|---|---|

| Patient Fit | Approximate; available in S/M/L sizes | Exact match to patient anatomy |

| Surgical Time | Longer; requires on-the-spot adjustments | Shorter; minimal adjustments needed |

| Osseointegration | Good | Excellent due to perfect contact |

| Recovery Period | Standard | Often faster and less painful |

| Production Model | Mass production | On-demand, single-piece flow |

This level of detail is what separates adequate medical care from excellent care. It’s about providing a solution that doesn’t just work but works perfectly for one specific person.

The Importance of an Agile Production Workflow

Achieving this high degree of personalization requires more than just advanced machinery; it demands an incredibly agile and responsive production workflow. Traditional manufacturing is built on volume and repetition. Custom medical manufacturing is the opposite—it’s about efficiently producing a single, unique item. At PTSMAKE, we’ve honed our processes to support this "lot size of one" model, which is essential for any serious medical CNC machining partner. The entire workflow, from initial quote to final inspection, must be optimized for speed, accuracy, and traceability.

Integrating Design, Prototyping, and Production

A truly flexible workflow breaks down the silos between different production stages. The design and manufacturing teams must work in close collaboration. Once a design is finalized from patient data, rapid prototyping can be used to create a physical model for validation. This allows surgeons to hold a replica of the implant or guide before the final part is machined from expensive medical-grade material. This iterative feedback loop is critical for ensuring the final product is flawless. This integration is supported by powerful software that manages the flow of data and tracks every step of the process, ensuring full compliance with medical regulations like ISO 13485.

Adapting to Unpredictable Demand

The need for custom medical devices is often urgent and unpredictable. A trauma case might require a custom cranial plate to be designed, machined, and delivered in a matter of days. This requires a production system that can pivot quickly. Key elements of an agile workflow include:

- Fast Programming: CAM software that can quickly generate complex toolpaths.

- Quick-Change Tooling: Systems that minimize machine downtime between jobs.

- Automated Quality Control: In-line CMMs and scanners to verify dimensions without creating bottlenecks.

| Workflow Stage | Traditional Manufacturing | Agile Custom Manufacturing |

|---|---|---|

| Order Intake | Large batch orders | Single-piece, on-demand orders |

| Machine Setup | Long runs, infrequent changeovers | Frequent, rapid changeovers |

| Quality Control | Statistical sampling of batches | 100% inspection of every unique part |

| Documentation | Batch-level traceability | Device-specific traceability (UDI) |

| Lead Time | Weeks or months | Days |

This level of flexibility ensures that manufacturers can meet the demanding needs of personalized medicine, providing life-changing solutions on a timeline that matters.

In short, the shift away from one-size-fits-all medical devices is driven by the superior outcomes of personalization. Medical CNC machining is the core technology enabling this change, producing custom implants, tools, and prosthetics with unmatched precision. To succeed, manufacturers must adopt agile and integrated production workflows that can efficiently handle the complexity of creating unique, patient-specific parts. This approach ensures that every device is a perfect fit, enhancing both surgical accuracy and patient recovery.

Regulatory Compliance and FDA Standards in CNC Machining?

Ever worried that a small compliance mistake in the machining process could derail your entire medical device launch? It’s a common fear that keeps many engineers up at night.

Regulatory compliance in medical CNC machining means strictly following FDA standards and keeping detailed records. This includes complete documentation, material traceability, and process validation to ensure every part is safe, effective, and ready for market approval, protecting both patients and your project.

When it comes to manufacturing medical devices, the stakes are incredibly high. Unlike other industries, a faulty component isn’t just an inconvenience; it can have serious consequences for patient safety. This is why regulatory bodies, especially the U.S. Food and Drug Administration (FDA), have established strict guidelines that every manufacturer in the supply chain must follow. For those of us in medical CNC machining, this isn’t just about making a part to a drawing. It’s about building a foundation of trust and safety into every single component.

The Foundation: FDA’s Quality System Regulation (QSR)

The primary regulation governing medical device manufacturing is the FDA’s Quality System Regulation (QSR), also known as 21 CFR Part 820. While the final device manufacturer is ultimately responsible for compliance, these requirements flow down to all critical suppliers, including CNC machining shops. The QSR is designed to ensure that medical devices are consistently produced and controlled according to quality standards. It covers everything from design controls and material purchasing to production processes and documentation. At PTSMAKE, we’ve integrated these principles into our core operations, ensuring our processes align with what the FDA and our clients expect. It’s not just about passing an audit; it’s about a culture of quality.

Key Pillars of Compliance in Machining

To meet these standards, we focus on several critical areas that form the backbone of regulatory compliance. These are non-negotiable for any project in the medical field.

Material Traceability

Every piece of raw material used in a medical device must be traceable back to its source. This means we maintain meticulous records of material certifications, including lot numbers and heat numbers, for every batch of metal or polymer we machine. This complete chain of custody is vital. If a material supplier ever issues a recall on a specific batch, we can immediately identify every single part made from that material. This prevents defective components from ever reaching patients.

Process Validation

This is where we provide documented proof that our machining process consistently produces a part that meets all specifications. Process validation ensures that the first part is identical to the last part in a production run. A key element we work on with clients involves ensuring the selected materials exhibit the necessary biocompatibility7 for their intended application. The validation process typically involves:

| Requirement | Description | Why It’s Crucial for Medical CNC Machining |

|---|---|---|

| Traceability | Tracking raw materials from source to the final component. | Ensures material integrity and allows for quick action if a defect is found. |

| Validation | Documented proof that a process consistently produces a quality product. | Guarantees that every part meets the same tight tolerances and specifications. |

| Documentation | A complete record of the manufacturing history for a batch of parts. | Provides evidence of compliance and is essential for audits and submissions. |

Beyond the foundational requirements of the QSR, a forward-looking approach to compliance involves embracing international standards and a robust Quality Management System (QMS). This proactive stance not only ensures you meet today’s regulations but also prepares you for the future. For any medical device company, partnering with a supplier that lives and breathes these principles is a critical step toward successful market entry and long-term success. The right partner doesn’t just make parts; they become an extension of your quality team.

The Gold Standard: ISO 13485 Certification

While the FDA’s QSR is a legal requirement for devices sold in the U.S., the international standard for medical device quality is ISO 13485. This certification provides a comprehensive framework for a QMS specific to the medical device industry. It aligns closely with the FDA’s requirements but is recognized globally, which is a huge advantage for companies looking to sell in multiple markets. At PTSMAKE, our ISO 13485 certification is a core part of our commitment to medical clients. It’s not just a certificate we hang on the wall; it dictates our daily operations, from how we handle incoming materials to how we control and document every step of the machining process. It also emphasizes risk management, forcing us to proactively identify and mitigate potential issues before they become problems.

Navigating Advanced Manufacturing Guidelines

The FDA recognizes that technology is constantly evolving. Advanced techniques like 5-axis CNC machining and automated quality control are changing how medical components are made. In response, the FDA encourages a "Case for Quality," pushing manufacturers to focus on critical-to-quality (CTQ) attributes rather than just checking boxes for baseline compliance. This means as your machining partner, we work with you to identify the most critical features of your design and build enhanced controls and inspection processes around them. This modern approach focuses on product quality and patient safety, moving beyond simple compliance to true manufacturing excellence.

Practical Steps for Ensuring Supplier Compliance

When you’re evaluating a CNC machining partner for your medical project, there are several practical steps you can take to verify their commitment to quality and compliance.

| Action Item | Description | Why It Matters |

|---|---|---|

| Verify Certifications | Ask for current proof of ISO 13485 certification from a reputable body. | This is the non-negotiable baseline for any serious medical machining partner. |

| Request Sample Docs | Ask to see a redacted Device History Record (DHR) or validation plan. | This shows their documentation process in action, not just in theory. |

| Discuss Risk Management | Inquire about their risk management process, such as using FMEA. | A proactive partner identifies potential failures before they happen, saving you time. |

| Clarify Change Control | Understand their documented process for managing changes to materials. | This prevents unapproved changes that could invalidate your device’s regulatory approval. |

Ultimately, regulatory compliance is a shared responsibility. By choosing a partner who has already built these rigorous systems, you can focus on innovation, confident that the components you receive are safe, reliable, and fully compliant.

Navigating FDA standards in medical CNC machining is a complex but essential task. It’s not merely a regulatory hurdle but a fundamental commitment to patient safety and product efficacy. Success hinges on a deep understanding of requirements like material traceability, process validation, and comprehensive documentation. Partnering with a supplier that has a robust QMS, such as one certified to ISO 13485, simplifies this process and transforms compliance from a challenge into a competitive advantage for your medical device.

Case Studies: Successful Medical CNC Machining Applications.

Have you ever wondered how an intricate surgical tool gets from a computer screen to a surgeon’s hand with flawless precision? That journey is filled with complex challenges where a single micron can make all the difference.

Successful medical CNC machining applications include biocompatible titanium orthopedic implants with complex surfaces, high-precision stainless steel surgical instruments, and intricate components for diagnostic equipment. These projects overcome extreme material and tolerance challenges to deliver life-saving, reliable results for patient care.

In the world of medical device manufacturing, theory only gets you so far. Real-world applications are where the true tests of skill, technology, and process control happen. In our projects at PTSMAKE, we’ve seen firsthand how CNC machining turns brilliant engineering concepts into functional, life-saving products. Let’s explore a couple of examples.

Case Study 1: High-Precision Surgical Forceps

A client came to us with a design for a new type of laparoscopic forceps. The success of their device depended on achieving a perfect balance of sharpness, durability, and ergonomic feel.

The Challenge

The primary challenges were threefold. First, the material was 17-4 PH stainless steel, known for its strength but also its difficulty in machining. Second, the tips required a razor-sharp edge with a tolerance of just ±0.005 mm to ensure clean tissue grasping without tearing. Third, the entire batch needed absolute consistency; any variation could affect a surgeon’s performance.

Our Solution

We approached this by using 5-axis CNC milling. This allowed us to machine the complex curves of the forceps handles and tips in a single setup, which is crucial for minimizing tolerance stack-up. We used specialized micro-end mills and developed custom toolpaths to create the sharp, burr-free edge. Following machining, every part underwent a passivation process to maximize its corrosion resistance, a non-negotiable step for reusable surgical tools.

Case Study 2: Custom Titanium Hip Implants

Another significant project involved producing custom titanium hip stems for a medical startup. These weren’t standard off-the-shelf parts; they were tailored to individual patient anatomy based on MRI data.

The Challenge

Machining titanium (Ti-6Al-4V) is tough. It generates immense heat and wears down tools quickly. The most critical challenge, however, was creating a specific roughened surface texture on parts of the implant. This texture was essential for promoting osseointegration8, the process where the patient’s bone naturally grows onto and fuses with the implant. Biocompatibility and complete traceability for each unique part were, of course, paramount.

Our Approach

We tackled the material challenge with high-pressure coolant systems and cutting tools with specialized coatings designed for titanium. To create the surface texture, we used advanced CNC milling strategies that precisely controlled the tool’s path to generate a consistent, porous-like finish. This eliminated the need for secondary coating processes, which can sometimes fail. Every implant was laser-etched with a unique serial number and accompanied by a full documentation package, from raw material certification to final inspection reports.

| Project Component | Key Challenge | Implemented CNC Solution |

|---|---|---|

| Surgical Forceps Tip | Achieving & maintaining sharpness | 5-axis milling with custom micro-tooling |

| Forceps Handle | Ergonomic grip & balance | Single-setup machining to avoid errors |

| Hip Implant Stem | Machining tough Titanium | Specialized coolants & cutting speeds |

| Implant Surface | Promoting bone growth | CNC-textured surface for better integration |

The applications for medical CNC machining extend far beyond implants and surgical tools. Diagnostic equipment and portable devices represent another area where precision is critical for performance and reliability. Here, the challenges often involve different materials and a unique set of functional requirements.

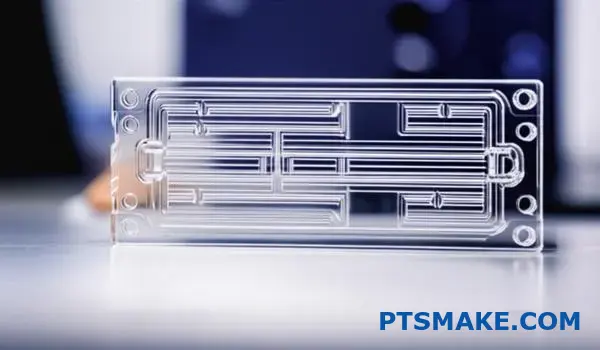

Case Study 3: Microfluidic Manifolds for Diagnostic Analyzers

We worked with a company developing a next-generation blood analyzer. At the core of their device was a microfluidic manifold, a clear plastic block with incredibly small channels that guide fluid samples past sensors.

The Challenge

The material was polycarbonate. The main difficulties were machining the tiny, intricate channels—some less than 0.2 mm wide—without causing stress cracks or burrs. Another critical requirement was achieving optical clarity on the surfaces adjacent to the channels, as the device used lasers to analyze the samples. Any haze or tool marks would ruin the readings. Finally, preventing any contamination during production was essential.

Our Solution

High-speed machining was the key here. We used extremely sharp, specialized cutters at very high RPMs to minimize cutting forces and heat buildup, preventing material stress. After machining the channels, we used a carefully controlled vapor polishing technique to restore optical clarity to the critical surfaces without altering the geometry of the micro-channels. The entire manufacturing process, from machining to packaging, was performed in a clean, controlled environment to eliminate any risk of particulate contamination.

Case Study 4: Durable Housings for Handheld Ultrasound Devices

A client needed a housing for a new portable ultrasound scanner. The device had to be lightweight for clinicians to carry all day, yet robust enough to survive accidental drops and frequent cleaning with harsh disinfectants.

The Challenge

The design called for thin walls and complex internal features to mount the sensitive electronics and a touchscreen. The material was a medical-grade aluminum alloy. The challenge was to machine the thin walls without them warping or distorting while ensuring all internal mounting points were positioned with extreme accuracy. The housing also needed to provide a perfect seal to protect the internal components from fluids.

Our Approach

Before any metal was cut, we worked with the client to run a design for manufacturability (DFM) analysis to optimize the internal rib structures for maximum strength with minimum material. We then used a 5-axis CNC machine to create all the internal features in one go. This ensured perfect alignment between the two halves of the housing. We also machined a precise groove for a custom gasket, guaranteeing a watertight seal that passed the client’s IP67 ingress protection tests.

| Project Component | Key Challenge | Implemented CNC Solution |

|---|---|---|

| Microfluidic Manifold | Tiny, precise fluid channels | High-speed machining with micro-tooling |

| Manifold Surface | Optical clarity for sensors | Specialized vapor polishing techniques |

| Ultrasound Housing | Lightweight yet strong | DFM-optimized toolpaths for thin walls |

| Housing Interior | Sealing and component mounting | Single-setup machining for perfect alignment |

These case studies show that successful medical CNC machining is far more than just fabrication. From titanium implants that encourage bone growth to optically clear diagnostic parts and durable device housings, each project demands a unique solution. True success depends on merging advanced technology with deep material expertise and a strict quality assurance framework. This combination ensures that every component functions perfectly where it matters most—in delivering exceptional patient care and reliable diagnostic results.

Sustainability and Efficiency in Medical CNC Manufacturing?

Ever wonder if going green in medical manufacturing means sacrificing precision or raising costs? It’s a common concern when every micron matters and budgets are tight.

Achieving sustainability in medical CNC machining is not about compromise. It’s about optimizing processes through smart material use, waste reduction, and energy-efficient technologies to enhance both environmental performance and the quality of critical medical components.

Improving sustainability in our field starts with looking at two core areas: the materials we use and the waste we generate. It’s not just about being environmentally conscious; it’s about being smarter and more efficient, which directly impacts the bottom line and product quality.

Mastering Material Efficiency

The most sustainable material is the one you don’t waste. In the world of medical device manufacturing, where materials like titanium and PEEK are expensive, every gram saved counts.

Near-Net Shape Manufacturing

One of the most effective strategies we’ve adopted in past projects at PTSMAKE is starting with a workpiece that is already close to the final part’s shape. This is called near-net shape manufacturing. Instead of starting with a large block of metal and machining away 80% of it, we might use a forged blank or a metal injection molded (MIM) preform. This dramatically reduces machining time, tool wear, and the amount of material turned into scrap. The initial piece might cost more, but the overall savings in machine time and material waste often make it the more economical choice for high-volume parts.

Smart Scrap Management

No matter how efficient the process, there will always be scrap metal. The key is to manage it effectively. Proper management of the swarf9 produced is crucial. We make sure to segregate different materials meticulously. Mixing titanium chips with stainless steel chips, for instance, can render the entire batch worthless for recycling. By keeping materials separate, we can recycle them at a much higher value, turning waste into a revenue stream instead of a disposal cost.

| Feature | Flood Coolant (Traditional) | Minimum Quantity Lubrication (MQL) |

|---|---|---|

| Coolant Volume | High | Very Low (Mist/Aerosol) |

| Waste Disposal | Costly & Regulated | Minimal / Near-Dry Machining |

| Workpiece Cleanliness | Requires Post-Cleaning | Often Cleaner |

| Operator Health | Potential for Skin/Respiratory Issues | Improved Air Quality |

This disciplined approach to material use and waste is fundamental to running a lean and sustainable operation for medical CNC machining.

Beyond materials and physical waste, energy consumption is a major factor in the environmental footprint of any manufacturing facility. Advanced technology provides powerful tools to reduce this impact while simultaneously boosting precision and overall efficiency. It’s about working smarter, not just harder.

Optimizing Energy Consumption

CNC machines are power-hungry, especially older models. A significant part of building a sustainable operation is tackling this energy usage head-on.

Modern, Energy-Efficient Machines

The difference in energy consumption between a 15-year-old machine and a modern one is substantial. Newer CNC machines are designed with efficiency in mind. They feature direct-drive spindles that waste less energy, servo motors that consume power only when moving, and intelligent sleep modes that power down non-essential components during idle periods. While the initial investment is higher, our analysis shows that the reduction in daily operating costs leads to a clear return on investment over the machine’s life, especially in a high-production environment.

The Role of Advanced Technology

Software and automation are game-changers for both sustainability and precision in medical CNC machining. They allow us to optimize every aspect of the manufacturing process before it even begins.

CAM Software and Simulation

Modern Computer-Aided Manufacturing (CAM) software is critical. It allows us to create highly efficient toolpaths that were impossible just a decade ago. For example, techniques like trochoidal milling use a constant, light engagement with the material. This approach reduces the load on the cutting tool and the machine’s spindle, which lowers energy consumption and extends tool life. Before we cut any metal, we run extensive simulations. This virtual process verification helps us catch potential collisions, optimize toolpaths, and ensure the part will meet specifications, eliminating the material and energy waste that comes from producing a scrapped first article.

| Toolpath Type | Engagement | Tool Wear | Machining Time | Energy Use |

|---|---|---|---|---|

| Traditional (Offset) | Inconsistent | High | Longer | Higher |

| Optimized (Trochoidal) | Consistent & Low | Lower | Shorter | Lower |

By integrating these technologies, we not only reduce our environmental impact but also enhance the reliability and precision demanded by the medical industry.

Sustainability in medical CNC machining is a practical goal achieved through a multi-faceted strategy. By focusing on material efficiency with near-net shape manufacturing and smart scrap management, we reduce waste at its source. At the same time, leveraging advanced CAM software, energy-efficient machines, and simulation technology allows us to cut down on energy consumption while improving precision. This integrated approach proves that environmental responsibility and high-performance manufacturing can, and should, go hand-in-hand, delivering better products more efficiently.

Unlock Next-Gen Medical CNC Machining with PTSMAKE

Ready to stay ahead in medical CNC machining? Partner with PTSMAKE for precision, reliability, and speed—whether you need custom implants, complex prototypes, or high-volume production. Contact us today for a rapid quote and experience world-class quality from prototype to production!

Understand the complex machine movements that enable the creation of intricate medical geometries. ↩

Learn how this core engineering concept enables self-correcting precision in automated systems. ↩

Understand how implant materials bond with bone, a critical factor for long-term device success. Click to learn more. ↩

Understand the biological process that makes titanium implants so effective and how to design for it. ↩

Understand how this data-driven strategy can prevent machine downtime and reduce unexpected maintenance costs. ↩

Learn how custom surgical guides and tools are designed to improve procedural accuracy and reduce surgery time. ↩

Learn more about material properties and how they impact device safety and performance in our detailed guide. ↩

Learn more about how surface texture influences the biological process of bone-to-implant fusion. ↩

Understand the properties of swarf and its critical role in evaluating machining process efficiency and recycling value. ↩