PEEKの優れた特性は高性能用途に最適ですが、この先端ポリマーの加工には独特の課題があります。多くのメーカーは、熱の蓄積、バリの形成、重要な航空宇宙および医療部品に要求される厳しい公差の達成に苦労しています。

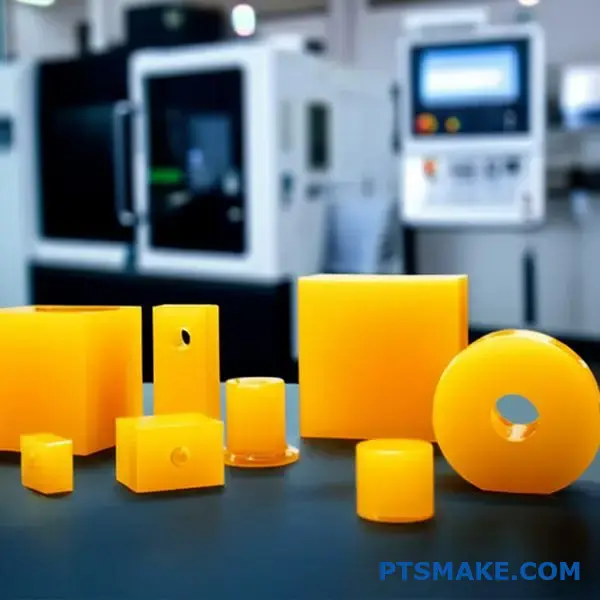

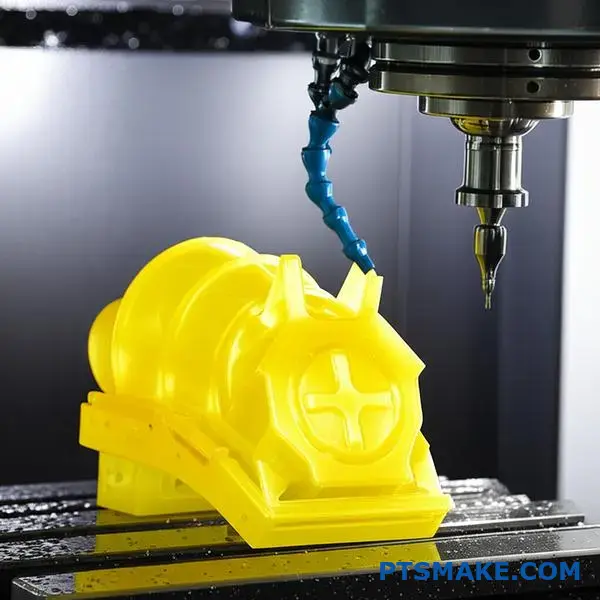

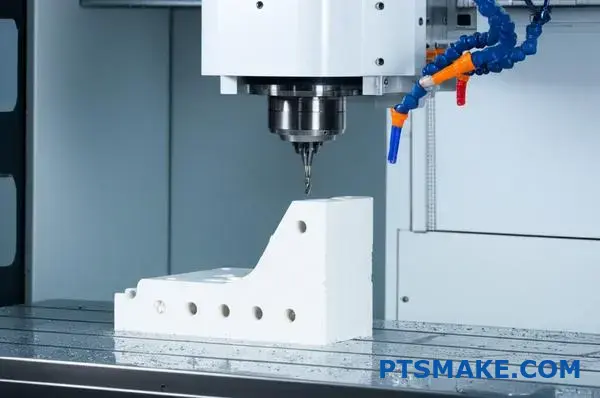

PEEKのCNC加工は、従来の製造方法では不十分であった航空宇宙、医療、自動車用途において、優れた寸法精度、複雑な形状、卓越した表面品質を実現します。

私は、妥協することなく厳しい仕様を満たすPEEKパーツを必要とするエンジニアと仕事をしています。重要なのは、加工中のPEEKの挙動を理解し、熱管理や応力緩和といった一般的な課題を克服するために適切な技術を適用することです。生体適合性が要求される医療用インプラントから、構造的完全性が要求される航空宇宙用ブラケットまで、PEEKの加工を成功させるには、専門的な知識と実証済みのプロセスが必要です。

なぜPEEKは高性能産業向けCNC加工に優れているのか?

重要な部品に材料を指定したのに、極度の熱や化学薬品にさらされただけで故障してしまったことはありませんか?従来の金属は重すぎ、標準的なプラスチックは設計に十分な強度がありません。

PEEK(ポリエーテルエーテルケトン)は、極めて高い熱安定性、優れた機械的強度、幅広い耐薬品性、生体適合性という独自の組み合わせにより、CNC加工に優れています。このため、部品の故障が許されない産業では、金属に代わる軽量で高性能な代替材料として利用されています。

PEEKの比類なき特性

エンジニアが最も過酷な環境に耐える材料を必要とする場合、PEEKはしばしばリストの最上位に挙げられます。その分子構造により、他の材料ではすぐに劣化してしまうような過酷な用途に最適な特性を備えています。PTSMAKEのプロジェクトでは、PEEKが金属や他のポリマーでは解決できない課題を解決するのを見てきました。それでは、PEEKがCNC機械加工においてどのような力を発揮するのか、詳しく見ていきましょう。

優れた熱安定性

PEEKの最も有名な特徴のひとつは、非常に高い温度でも機械的特性を維持できることです。最高260°C(500°F)の連続使用温度で、他の多くのプラスチックのように軟化したり変形したりしません。これは、自動車エンジン、航空宇宙システム、坑内掘削装置の部品にとって極めて重要である。また、この安定性は、CNC加工工程で発生する熱を非常にうまく処理することを意味し、次のようなことが可能になります。 厳しい公差 材料が反ることなくこの素材は熱伝導率が低いため、加工時には特殊なアプローチが必要となるが、その結果、非常に安定した信頼性の高い部品が得られる。

優れた耐薬品性

PEEKは、腐食性の強い酸、塩基、炭化水素を含む広範囲の化学薬品に耐える。また 耐加水分解性1つまり、高圧蒸気や水に何千時間さらされても分解しない。そのため、蒸気滅菌(オートクレーブ)を繰り返す医療機器や、化学処理産業の部品に最適な素材です。ジェット燃料や過酷な工業用溶剤にさらされる部品が必要な場合、PEEKを最初にお勧めすることがよくあります。

PEEKと他の高性能材料の比較

その能力を客観的に見るために、素材サプライヤーからのデータと社内テストに基づく簡単な比較をご覧いただきたい。

| プロパティ | PEEK(未充填) | アルミニウム 6061-T6 | ウルテム1000 |

|---|---|---|---|

| 引張強度 | ~95 MPa | ~310 MPa | ~105 MPa |

| サービス温度 | ~260°C | ~150°C | ~170°C |

| 密度 | 1.32 g/cm³ | 2.70 g/cm³ | 1.27 g/cm³ |

| 耐薬品性 | 素晴らしい | 悪い(腐食する) | グッド |

この表が示すように、アルミニウムはより強度が高いが、PEEKはほぼ半分の重量で高温性能と耐薬品性の優れた組み合わせを提供する。PEEKの強度対重量比は他の追随を許さず、金属代替プロジェクトの理想的な候補となっています。

PEEKの実際:競合を凌駕する性能

PEEKの理論的特性は素晴らしいものですが、その真価は実際のミッションクリティカルな用途で発揮されます。様々な重要な産業において、CNC加工されたPEEK部品は、金属や他のポリマーでは実現不可能であったソリューションを提供しています。そのユニークな特性の組み合わせにより、エンジニアは設計と性能の限界を押し広げることができます。

航空宇宙妥協なき軽量化

航空宇宙産業では、1グラム1グラムが重要です。金属部品をより軽量な代替品に置き換えることで、航空機の寿命を通じた大幅な燃料節約と積載量の増加につながります。当社は、電気コネクターやケーブル絶縁から構造用ブラケットやスラストワッシャーに至るまで、幅広い用途のPEEK部品を加工してきました。PEEKは軽量化だけでなく、航空燃料や油圧作動油に対する優れた耐性を備えています。PEEK固有の難燃性と低発煙性は、客室内装部品として当然の選択となる重要な安全機能です。

医療:生体適合性と滅菌性

医療分野では、人が触れても安全で、厳密な滅菌処置に耐える材料が求められる。PEEKは生体適合性があり、生体組織と接触しても有害な反応を起こさないため、脊椎固定用ケージや歯科用器具のようなインプラントに適しています。さらに、蒸気滅菌、ガンマ線滅菌、エチレンオキサイド(EtO)滅菌を何百サイクルも繰り返しても劣化しない耐性も大きな利点です。PTSMAKEでは、PEEKから特注の手術器具や診断機器部品を製造しており、その放射線透過性(X線に対する透明性)により、干渉のない鮮明なイメージングが可能です。

電子・半導体製造

エレクトロニクス産業の要求は独特です。材料は多くの場合、電気絶縁性、寸法安定性、敏感なプロセスを汚染しないための純度が求められます。CNC加工されたPEEKは、高温でも強度と剛性を維持し、アウトガスが非常に少ないため、ウェハーハンドリングツール、テストソケット、絶縁体の製造に使用されています。このため、半導体製造の妨げとなる揮発性化合物の放出を防ぐことができます。また、優れた誘電特性により、シグナルインテグリティが最優先される高周波コネクターや絶縁体にも最適です。PEEKの耐久性は、連続使用の製造環境においても、これらの部品の長寿命を保証します。

PEEKは、その特性がほとんどの材料に匹敵しないため、高性能産業向けのCNC機械加工に優れています。極端な温度、過酷な化学物質、機械的ストレスに耐えるその能力は、故障が許されない場合に信頼できる選択肢となります。航空宇宙分野における軽量化から医療機器における患者の安全性の確保まで、PEEKは最も要求の厳しいエンジニアリングの課題に対して多用途で強力なソリューションを提供し、最高の高性能ポリマーとしての地位を正当化しています。

設計の柔軟性:複雑な形状とカスタムソリューション。

複雑なPEEKコンポーネントを設計したものの、射出成形のような従来の製造方法では製造できないことに気づいたことはありませんか?これは技術革新にとって大きな障害となり得ます。

CNCマシニングは、PEEKに優れた設計の柔軟性を提供し、複雑な形状と厳しい公差を持つ複雑で高度にカスタマイズされた部品の作成を可能にします。このサブトラクティブ工法は、CADファイルから直接加工できるため、ラピッドプロトタイピング、設計の繰り返し、少量から中量の生産に最適です。

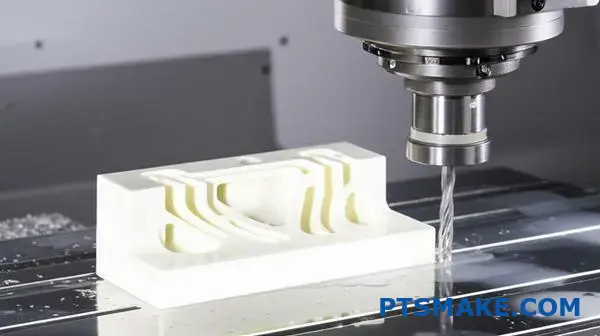

CNCマシニングは射出成形とは根本的に異なります。固定された金型に溶融材料を注入する代わりに、コンピューター制御のツールを使用して、PEEKの固体ブロックから材料を正確に除去します。このサブトラクティブ・プロセスが、驚異的な設計の自由度の鍵である。抜き勾配の角度、パーティングライン、内部形状の制限など、金型設計による制約がなくなります。これにより、エンジニアは製造上の制約ではなく、機能に基づいて部品を設計することができます。

なぜPEEK CNC加工は複雑性に優れているのか

PTSMAKEでは、成形不可能な部品を必要とするクライアントと仕事をすることがよくあります。CNC加工の減法的な性質は、目に見える設計上の利点に直結します。

複雑な形状と内部機能

多軸CNCマシンを使えば、金型では不可能な形状を作り出すことができます。これには、連動する部品、流体や気体の流れのための湾曲した内部流路、奇妙な角度に正確に配置されたネジ穴などが含まれます。金型は、完成品から引き抜かなければならないコアやピンに依存しているため、内部設計に大きな制限があります。CNCマシニングにはそのような制限はなく、工具がさまざまな角度からワークピースにアプローチし、必要な形状を削り出すことができる。このように材料の 結晶性2 地表の状況もまた、私たちが注意深く管理する要素である。

アンダーカットと不均一な壁

アンダーカットは、部品が金型から直接排出されるのを妨げる特徴である。サイドアクションのある複雑な金型でもアンダーカットを作ることはできますが、コストと複雑さが増します。CNC機械加工はアンダーカットを簡単に処理します。同様に、射出成形では、材料の適切な流れを確保し、ヒケのような欠陥を防ぐために、均一な肉厚が好まれます。PEEKのCNC加工では、製造上の欠陥を心配することなく、強度と軽量化のために最適化されたさまざまな肉厚の部品を設計することができます。

| フィーチャー・タイプ | CNC加工の実現可能性 | 射出成形 実現可能性 |

|---|---|---|

| 複雑なアンダーカット | 高い | 低い(高価な副作用が必要) |

| シャープな内角 | 高い | 低い(金型強度に半径が必要) |

| さまざまな肉厚 | 高い | 低い(沈みやすく、反りやすい) |

| マイクロサイズの特徴 | 高い | ミディアム(金型精度による制限あり) |

| カスタムスレッドプロファイル | 高い | 低い(カスタム金型インサートが必要) |

この表は、CNC加工がいかにPEEKのような高性能ポリマーの設計の可能性に新しい世界を開くかを明確に示している。

CNC加工の柔軟性は、単に「不可能」な形状を作り出すということではなく、製品開発サイクル全体を加速させ、特定の用途のためにコスト効率の高い生産を可能にするということです。最初のプロトタイプから最終的な生産に至るまで、戦略的なアドバンテージを提供します。

ラピッドプロトタイプからニッチ生産まで

金型が不要であることは、PEEKカスタム部品におけるCNC加工の最大の利点であることは間違いない。射出成形用金型を作らないことで節約できる時間と費用は、特に開発中においてはかなりのものです。

デザイン・イテレーションの加速

製品開発では、スピードが重要です。PEEKのプロトタイプをテストする必要がある場合、CNC加工は機能的なパーツを手に入れる最速の方法です。当社では、CADファイルを数日で物理的な部品に変えることができます。これにより、お客様のエンジニアリングチームは、設計のテスト、検証、反復を迅速に行うことができます。変更が必要な場合は、デジタルファイルを更新し、新しいバージョンを機械加工するだけです。この迅速なフィードバック・ループにより、射出成形金型を修正するのに必要な数週間から数ヶ月に比べ、開発期間が大幅に短縮されます。

費用対効果の高い中・少量生産

射出成形は数字のゲームである。金型の高額な初期費用は、何万もの部品に渡って初めて正当化されます。しかし、特殊な医療機器や航空宇宙用途で、数百個から数千個の部品しか必要ない場合はどうでしょう?そこでPEEKのCNC加工が輝くのです。少量から中量生産の場合、最も経済的な選択肢となります。PTSMAKEの経験では、CNCマシニングを最終的な生産方法として使用することで、多くのお客様がニッチ市場の需要を持つ製品のための6桁の金型投資を回避するお手伝いをしてきました。

| 生産段階 | CNC加工 | 射出成形 |

|---|---|---|

| 初期設定費用 | 低い(プログラミングとセットアップ) | 非常に高い(金型設計・製作) |

| リードタイム(第一部) | 日数 | 週/月 |

| 部品単価(少量) | 中程度 | 極めて高い |

| 部品単価(高ボリューム) | 高い | 非常に低い |

| デザイン変更の容易さ | とても簡単(CADファイルの修正) | 非常に困難かつ高価(ツールの改造) |

例えば、過去のプロジェクトでは、新しい自動化ライン用に高度にカスタマイズされたPEEKグリッパーを必要とするロボット会社と協力しました。そのデザインは、複雑で非対称な輪郭と統合されたエアチャネルを特徴としていました。この部品を成形することはほとんど不可能であっただけでなく、必要なユニット数も200個しかありませんでした。PEEKのCNC加工は完璧なソリューションで、高精度で機能的なパーツを金型費用なしで提供することができました。

CNCマシニングは、PEEKコンポーネントの真の設計の自由を解き放ちます。射出成形の制約を取り除くことで、複雑な形状、アンダーカット、カスタム形状の作成が可能になります。この能力は、ラピッドプロトタイピングや迅速な設計の反復にとって非常に貴重です。さらに、少量生産から中量生産まで、費用対効果の高い実用的なソリューションを提供し、製造用のカスタム金型を作成することに伴う法外な費用や長いリードタイムをかけずに、革新的な製品を市場に投入することができます。

PEEKのCNC加工における材料効率とコスト最適化?

部品に使用するPEEKの高コストでお困りですか?廃棄部品やチップの山が、プロジェクト予算に大きな打撃を与えるように感じますか?

PEEKのCNC加工における材料効率の最適化には、スマートツールパスのための高度なCAMソフトウェアの使用、ニアネットシェイプストックの選択、厳格な工程管理の実施が含まれます。これらの戦略は、無駄を最小限に抑え、PEEKの各ブロックからの歩留まりを最大化することで、高い材料費と直接戦います。

PEEKは高価な高性能ポリマーです。1グラムの廃棄物も収益に直接影響するため、材料の利用率を最大化することは単なる目標ではなく、必要不可欠です。従来の金属とは異なり、原材料のコストは最終的な部品価格に大きく影響します。そのため、加工プロセスへのアプローチ方法は根本的に異なる必要があります。PTSMAKEでは、プロジェクト計画の最初の段階から、無駄を省く考え方に重点を置いています。これにより、CNC加工本来の利点である精度と制御が十分に発揮され、貴重な材料を節約することができるのです。

廃棄物を最小限に抑える工程内戦略

効果的な廃棄物削減は、マシンのスイッチを入れるずっと前から始まっている。そのためには、入念な計画を立て、高度な技術を駆使して、すべてのカットが計画的かつ効率的に行われるようにする必要がある。目標は、絶対に必要な材料だけを取り除くことです。

原材料のスマートな調達

PEEKの大きな標準サイズのブロックから始める代わりに、ニアネットシェイプのブランクを調達することがよくあります。これは、最終的な部品の寸法に近い特注サイズや押し出しプロファイルです。この決断ひとつで、機械加工が必要な材料の量を大幅に減らすことができ、材料費と貴重な機械加工時間の両方を節約することができます。ニアネットシェイプ・ブランクの初期コストは、キログラムあたり若干高くなるかもしれませんが、廃棄物の削減とサイクルタイムの短縮により、プロジェクト全体のコストはしばしば低くなります。私たちの過去のプロジェクトでは、この方法で30%以上の材料廃棄を削減したものもあります。

高度なツールパス最適化

切削工具が材料を通過する方法は非常に重要です。最新のCAM(コンピューター支援製造)ソフトウェアでは、無駄を最小限に抑える高度にインテリジェントなツールパスが可能です。例えば、トロコイド加工のような技術では、高速で噛み合いの少ない切削を行い、より小さく扱いやすい切り屑を生成します。これにより、材料へのストレスが軽減されるだけでなく、以下のような問題を防ぐことができます。 加工硬化3のみならず、より精密な材料除去を可能にする。ツールパスの計画を誤ると、過剰な熱や工具の摩耗を引き起こし、最終的には最も高価な廃棄物であるスクラップパーツの原因となります。

| ツールパス戦略 | 典型的な廃棄物発生量 | サイクルタイムへの影響 | 最適 |

|---|---|---|---|

| 従来のフライス加工 | 高い | 遅い | 単純な形状、荒削り |

| 高速加工 (HSM) | ミディアム | より速く | 複雑な表面、仕上げ |

| トロコイド加工 | 低い | 変動あり | 深いスロット、ポケット |

内部工程管理は不可欠ですが、CNCマシニングと他のPEEK製造方法との比較を理解することも重要です。それぞれの製造方法には、独自の材料効率プロファイルがあり、適切な製造方法を選択するかどうかは、生産量、複雑さ、予算など、プロジェクト固有の要件に大きく依存します。CNC加工の減法的な性質は、無駄が多いと思われがちですが、適切に管理されていれば、それは誤解です。

CNC機械加工と他の製造方法との比較

PEEKパーツの製造方法を評価する際には、原材料費だけでなく、工具、セットアップ、労働力を含む製造の総コストを検討することが極めて重要です。

射出成形との比較

射出成形は、大量生産のための極めて材料効率の高いプロセスです。鋼鉄製の金型が出来上がれば、部品1個あたりの廃棄物の量はごくわずかで、多くの場合、スプルーとランナーに限られ、これらはリサイクルできることもある。しかし、その金型を作るための初期費用は相当なものになり、数万ドルに上ることもしばしばです。プロトタイプや少量生産の場合、金型のコストは射出成形を金銭的に非現実的なものにしてしまう。そこで ピークCNC加工 カスタム金型が不要なため、少量生産でのコスト効率がはるかに高い。

3Dプリンティング(積層造形)との比較

FDM(Fused Deposition Modeling)やSLS(Selective Laser Sintering)のような3Dプリンティング方式は積層造形方式である。そのため、材料効率が非常に高く、無駄がほとんどありません。これらは、非常に複雑なワンオフのプロトタイプを作成するのに適しています。しかし、3DプリントされたPEEK部品は、多くの場合、機械的強度、厳しい公差、または卓越した技術には及びません。 表面仕上げ ソリッドブロックから機械加工された部品の航空宇宙や医療機器のような要求の厳しい用途の機能部品にとって、CNC機械加工部品の信頼性は通常譲れないものです。

| 製造方法 | 廃棄物 | 初期費用 | 理想的な生産量 |

|---|---|---|---|

| CNC加工 | 低~中 | 低い(工具なし) | 1 - 10,000 |

| 射出成形 | 非常に低い | 非常に高い | 10,000+ |

| 3Dプリンティング(FDM/SLS) | 非常に低い | 低~中 | 1 - 100 |

最終的に、適切な方法を選択することは、コスト、量、およびPEEKコンポーネントの性能要件のバランスをとることです。

PEEKのCNC加工におけるコスト管理は、材料効率の最大化にかかっている。これは、単一のアクションではなく、包括的な戦略によって達成されます。それは、ネットシェイプに近い材料を調達し、スクラップを最小限に抑えるために最適化されたツールパスに高度なCAMソフトウェアを使用することから始まります。射出成形や3Dプリンティングと比較すると、CNCマシニングはユニークなバランスを提供している。CNCマシニングは、成形の高額な初期金型費用を回避し、ほとんどのアディティブ手法ではまだ達成できない優れた機械的特性と精度を実現します。

表面品質と寸法精度:厳しい公差への対応

鏡面仕上げで公差の厳しいPEEK部品を指定したのに、検査で不合格になったことはありませんか?これは、プロジェクト全体を頓挫させかねない、よくある失敗です。

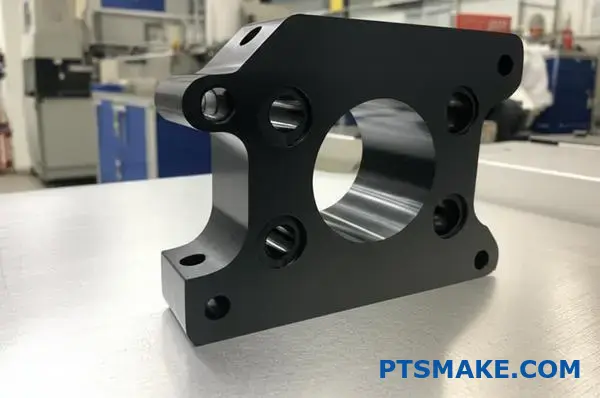

PEEKパーツの優れた表面品質と寸法精度を実現するには、専門的なCNC機械加工が不可欠です。この工程では、最適化された切削工具、速度と送りの正確な制御、戦略的な熱管理を使用し、最も厳しい業界基準を満たす、一貫した欠陥のない部品を提供します。

高性能のアプリケーション、特に医療や航空宇宙分野では、「これで十分」という選択肢はありません。PEEKコンポーネントの表面品質と寸法精度は、単なる美観上の問題ではなく、その機能、安全性、信頼性の根幹をなすものです。PTSMAKEでの経験では、この2つの要素がお客様との議論の最も重要なポイントになることがよくあります。

優れた仕上がりへの譲れないニーズ

部品の表面は、その性能特性を劇的に変化させます。最終用途によって要求は変わりますが、制御の必要性は不変です。

医療機器アプリケーション

整形外科用インプラントや手術用ガイドなどの医療機器では、生体適合性のために表面が滑らかであることが最も重要である。表面が粗かったり凸凹していると、細菌が繁殖しやすい微細な隙間ができ、感染のリスクが高まります。さらに、インプラント内の可動部品には、より低 表面粗さ4 は摩擦や摩耗を減らし、装置の寿命を延ばします。また、適切な仕上げにより、生物学的物質を閉じ込めることなく、コンポーネントを効果的に滅菌することができます。

航空宇宙およびハイテク産業

航空宇宙分野では、表面の欠陥が材料破損の致命的な起点となることがあります。マイクロクラックやツールマークは応力の集中源となり、飛行中によくある極端な振動や圧力の変動下で疲労亀裂につながる可能性があります。シールやガスケットの場合、表面仕上げはシール効果に直接影響し、重要な液体やガスの漏れを防ぎます。

厳しい公差がミッションクリティカルである理由

寸法精度は、部品が意図した通りに組み合わされ、機能することを保証します。人工衛星の展開機構やロボット手術用アームのような複雑なアセンブリでは、複数の部品にわたる公差の積み重ねが成功と失敗の分かれ目となります。PEEKのCNC加工では、成形などの他の方法ではしばしば不可能な公差を、特に重要なフィーチャーで保持することができます。

ここでは、私たちが手掛けたプロジェクトに基づき、業界によって要件がどのように異なるかを簡略化してご紹介します。

| 応用分野 | 標準公差 (mm) | 表面仕上げ (Ra, µm) | コア要件 |

|---|---|---|---|

| 医療用インプラント | ±0.010 | < 0.4 | 生体適合性、低摩擦 |

| 航空宇宙用シール | ±0.025 | < 0.8 | シール性、耐摩耗性 |

| 半導体ハンドリング | ±0.020 | < 0.8 | 非汚染性、寸法安定性 |

| 自動車パワートレイン | ±0.050 | < 1.6 | 耐熱性、耐久性 |

これらの仕様を一貫して達成するためには、単に優れた設備が必要なだけでなく、PEEKが機械加工のストレス下でどのような挙動を示すかを深く理解する必要があります。

精度の必要性を説明することと、それを提供することは別のことです。CNC加工は、PEEKのブロックを厳密な基準を満たす部品に変える鍵です。この工程は本来、精度を高めるために構築されたものですが、PEEKのような素材を使いこなすには、特有の課題を克服するための専門知識が必要です。

CNC加工はどのように比類のない一貫性を提供するか

CNC(Computer Numerical Control)の核となる利点は、その再現性です。ツールパス、速度、送り、クーラントフローを最適化し、PEEK部品に最適な加工プログラムをダイヤルインすれば、実質的に同じ部品を何百、何千と生産することができます。これは手作業では不可能なことです。

欠陥を未然に防ぐ

ポリマー加工に関連する一般的な問題の多くは、最初から工程から除外することができる。

バリの防止

バリとは、切削加工後に残る、小さくて不要な盛り上がりのことです。医療部品や電子部品では、バリの発生は大惨事になりかねません。当社では、非常に鋭利で特殊なコーティングを施した超硬工具を使用し、工具が材料に「下向き」に切り込むクライムフライス加工などの技術を採用することで、PEEKのバリを防止しています。これにより、プラスチックを押したり引き裂いたりするのではなく、きれいな剪断作用が生まれます。

反りと内部応力の制御

PEEKは熱的に安定していますが、切削点で発生する熱が応力を誘発し、特に薄肉部品では反りの原因となります。当社の社内テストによると、加工前のアニール(原材料の製造による内部応力を緩和する)と加工中の高圧フラッドクーラントの使用の組み合わせが非常に効果的です。クーラントは潤滑するだけでなく、さらに重要なことに、部品と工具から瞬時に熱を運び去ります。

業界の品質基準を守る

ISO13485(医療機器)やAS9100(航空宇宙)などの規格を満たすことは、最終的な部品だけにとどまりません。それは、製品全体を管理する包括的な品質管理システムに関わっています。 ピークCNC加工 ワークフロー。これには以下が含まれる:

- 材料のトレーサビリティ: サプライヤーから完成部品に至るまでの原材料ロットを文書化する。

- プロセス・バリデーション: 当社の機械加工工程が一貫して仕様を満たす部品を生産していることを証明する。

- 工程内検査: CMM(三次元測定機)やその他の計測ツールを使用して、最終段階だけでなく重要な段階でも寸法を検証する。

この厳格なアプローチにより、PTSMAKEから出荷されるすべてのPEEK部品は、単に印刷されるだけでなく、その品質と信頼性を保証するプロセスによって裏付けられています。

医療や航空宇宙などの重要な用途では、PEEK部品の表面品質と寸法精度が安全性と性能にとって不可欠です。要求される厳しい公差と滑らかな仕上げを達成するには、特殊なPEEK CNC機械加工が必要です。この方法は、バリや反りなどの一般的な欠陥を排除するために必要な再現性を提供し、すべての部品がISO 13485やAS9100などの厳しい業界標準に一貫して適合することを保証します。これは、精度が目標ではなく、基準であるプロセスです。

機械加工の課題を克服する:熱、バリ、清浄度。

微細なバリや目に見えないコンタミが原因で、重要なPEEK部品が故障したことはありませんか?これは、プロジェクト全体のタイムラインと予算を危険にさらす可能性のある一般的な後退です。

PEEKのCNC加工をマスターするには、3つのコア戦略が必要です。それは、高度な冷却による熱蓄積の積極的な管理、最適化されたツールパスとシャープなカッターによるバリの防止、そして医療や半導体製造のような業界の厳しい要求を満たすための厳格な洗浄プロトコルの実施です。

PEEKの低い熱伝導率は諸刃の剣です。最終的な用途では優れた断熱材となる一方で、加工時には大きな課題となります。切削工具から発生する熱は行き場を失い、工具先端と加工面に集中する。このため、局所的な溶融、表面仕上げの不良、工具の急速な摩耗が発生する可能性がある。

暑さを和らげる

熱蓄積を効果的に管理することが最初の重要なステップです。従来のフラッドクーラントも有効ですが、それだけでは不十分な場合が多く、コンタミネーションのリスクがあります。高精度のPEEK CNC加工には、より高度な方法を用います。例えば、高圧クーラントは、切削ゾーンから切屑をより効果的に吹き飛ばし、切屑が溶けて表面に再付着するのを防ぎます。最も要求の厳しい用途には、液体窒素を使用して材料を過冷却し、より脆くすることで、よりきれいなせん断を可能にする極低温加工を探求してきました。工具の選択も重要です。鋭利でコーティングされていない超硬工具は、摩擦を最小限に抑えることができるため、非常に優れた性能を発揮します。状況によっては、ダイヤモンドライクカーボン(DLC)コーティングを施すことで、摩擦係数をさらに下げることができます。

バリとの戦いに勝つ

バリは、PEEKのような延性のある素材につきまとう問題です。きれいに削り取られる代わりに、材料は変形したり押されたりする傾向があり、厄介な付着したプラスチックの繊維が残ります。これらは単なる外観上の欠陥ではなく、組み立てを妨げたり、部品の性能に影響を与えたり、医療機器の無菌性を損なったりする可能性があります。バリとは本質的に、加工後に部品に付着したまま残る、小さくて不要な材料の破片のことです。PEEKは延性ポリマーであるため、バリが発生しやすい。 塑性変形5 切削工具が噛み合ったときにきれいに破断するのではなく、破断してしまうのだ。解決策は、最適化された切削戦略にある。

戦略的ツールパスとパラメータ

PEEKの加工では、従来のフライス加工よりもクラ イムフライス加工が好まれることがほとんどです。切削開始時に最も厚く、切削終了時に薄くなるチップを生成するため、切削終了時に大きなバリが発生する可能性が大幅に低くなります。当社では、社内テストに基づき慎重に制御されたパラメータと組み合わせています。

| パラメータ | 推薦 | 根拠 |

|---|---|---|

| 切断速度 | 高い | 工具の接触時間を短縮し、部品への熱伝達を最小限に抑えます。 |

| フィード・レート | 中~高 | 余分な熱を発生させ、工具を摩耗させる摩擦を防ぐ。 |

| 工具の切れ味 | 極めてシャープ | 材料が変形することなく、きれいな剪断作用が得られる。 |

| 冷却水 | 高圧・大容量 | カッティングゾーンから熱と切りくずを積極的に除去。 |

完璧なプログラミングを行っても、微細なバリが残ることがあります。このような場合、最終的な部品が仕様に適合していることを確認するために、手動または自動にかかわらず、検証され、制御されたバリ取りプロセスが必要です。

熱やバリだけでなく、汚染はPEEKのような高性能ポリマーを含むプロジェクトの静かな殺人者です。一般的な工業用部品であれば、標準的な洗浄工程で十分かもしれません。しかし、医療用インプラント、半導体製造装置、航空宇宙システムで使用される部品では、「クリーン」の定義はまったく異なるレベルです。残留する切削液、工具から出る微細な粒子、あるいは人の手から出る油分さえも、致命的な故障につながる可能性がある。

絶対純度のためのプロトコル

部品の清浄度を確保することは後付けではなく、最初のカットが行われる前から始まる製造工程の中核部分です。PTSMAKEでの私の経験では、多段階アプローチは、重要な用途に必要なレベルの純度を保証する唯一の方法です。

第1段階:発生源での予防

私たちはまず、汚染物質の混入を最小限に抑えることから始めます。これは、残留物を残さない、特定の医療グレードのオイルフリークーラントを使用することを意味します。プロジェクトによっては、熱を管理するために非常に特殊な工具とパラメータを必要とするドライ加工も行います。さらに、金属による二次汚染のリスクを排除するため、特に長期にわたって医療機器を扱っているお客様には、ポリマー加工専用のCNCマシンを用意することもあります。これにより、以前の鉄やアルミニウムの加工で発生した微細な金属片がPEEKの表面に埋め込まれるのを防ぐことができます。

ステージ2:検証された洗浄とすすぎ

単純な洗浄だけでは十分ではありません。私たちの加工後のプロトコルは、すべての異物を除去するように設計された堅牢な多段階プロセスです。

- イニシャル・ウォッシュ 重大な汚染物質とクーラントを除去する。

- 超音波バス: 部品はイソプロピルアルコール(IPA)のような溶剤の浴槽に浸され、高周波音波にさらされる。このプロセスは、キャビテーションを発生させ、あらゆる表面をこすり、最も複雑な内部形状から粒子を取り除きます。

- 純水洗浄: 脱イオン(DI)水で何度もすすぎ洗いをすることで、残った洗浄剤を除去し、部品が乾燥してもミネラルや化学物質が残らないようにします。

ステージ3:管理された環境での取り扱い

工程は、部品が安全に顧客の手に渡るまで完了しない。最終すすぎの後、パウダーフリーの手袋を着用し、管理された環境ですべての取り扱いが行われます。部品はその後、出荷と保管中に純度を維持するために、認定されたクリーンバッグに梱包され密封されます。

| ステージ | アクション・アイテム | 目的 |

|---|---|---|

| 機械加工 | 専用の機械/工具を使用する。 | 金属の二次汚染を防ぐ。 |

| 機械加工 | 生体適合性のあるクーラントを選択する。 | 有害な残留物を残さないようにする。 |

| クリーニング | 多段式超音波バス。 | すべての表面から微細なゴミを取り除く。 |

| すすぎ | 脱イオン(DI)水を使用する。 | ミネラルや化学物質のシミが残らないようにする。 |

| ハンドリング | パウダーフリーの手袋を着用すること。 | 油や粒子の移動を防ぐ。 |

| パッケージング | 清潔な認定袋に密封する。 | 輸送中の無菌性と清潔さを維持する。 |

PEEKの複雑なCNC加工を成功させるには、3つのアプローチが必要です。適切な冷却とツーリングで高熱を管理し、最適化された切削戦略でバリの形成を制御し、厳密な多段階洗浄プロトコルを遵守することで、すべてのコンポーネントが最高基準を満たしていることを保証します。この綿密なプロセスは、精度、純度、性能が譲れない、要求の厳しい医療や半導体用途では特に重要です。

アニーリングとストレス解消:長期的なパフォーマンスの確保

PEEK部品を完璧に加工したのに、数日後にゆがんだり割れたりしたことはありませんか?このような不具合の発生が遅れると、プロジェクト全体が危うくなり、イライラが募り、スケジュールが遅れてしまいます。

アニーリングは、PEEK部品に不可欠な制御された熱処理です。アニーリングは、原料の製造工程と機械加工工程の両方から生じる内部応力を緩和し、反りを防止し、最終部品の寸法安定性と長期的な機械的性能を保証します。

PEEKの未加工の形状(棒や板)は、固く巻かれたバネのようなものだと考えてください。材料を押し出したり成形したりする過程で、内部に応力が生じます。材料は安定しているように見えますが、これらの力は内部に閉じ込められています。PEEKのCNC加工で切り込みを入れた瞬間、蓄積されたエネルギーが不均等に放出され始めます。そのため、機械加工を終えた直後は完璧に見える部品でも、その後24~48時間かけて徐々に変形し、残った応力が落ち着くのです。アニーリングは、このようなバネが問題を引き起こす前に、注意深くバネをほぐす方法です。

PEEKの内部応力を支える科学

PEEKは半結晶性ポリマーである。つまり、規則正しい結晶領域と無秩序な非晶領域の両方を有しています。材料が最初に冷却される間、応力は主にこの非晶質領域に閉じ込められます。材料を機械加工すると、これらの応力を均衡に保っていた層が取り除かれる。その結果、部品は新しい安定した状態を探そうとし、寸法が変化することがよくあります。適切なアニーリングを行うことで、ポリマー鎖は弛緩し、低エネルギーで安定した状態に再沈降する。 ガラス転移温度6 しかし融点以下である。このプロセスは、要求の厳しい用途で要求される厳しい公差を達成するために極めて重要である。

いつアニールするか:二段階アプローチ

アニールのタイミングは、プロセスそのものと同様に重要です。重要な部品については、PTSMAKEではしばしば2段階のアプローチを採用しています。

第1段階:予備加工(ノーマライジング)

このステップでは、重要な切削を開始する前に、原材料をアニールする。これにより素材が安定し、機械加工がより予測しやすくなり、荒加工中に大きな反りが発生するリスクも軽減される。ステージ2:ポスト・マシニング(ストレス・リリーフ)

主要な材料除去の後、特に最終仕上げパスの前に、中間または最終焼鈍サイクルが実行されます。これにより、切削工具によってもたらされた新たな応力が除去され、最終寸法が正確に保持され、部品の寿命まで安定した状態を保つことができます。

下の表は、私たちのプロジェクトの経験に基づき、これらのステップをスキップすることのリスクを示しています。

| アニーリングステージ | アニーリングなし | 適切なアニーリング |

|---|---|---|

| プレマシニング | 荒加工中の材料の動きが予測できず、ひび割れの可能性がある。 | 安定した予測可能なストック、加工性の向上。 |

| ポストマシニング | 最終カット後に部品が反ったり、寸法が変わったりする。 | 最終寸法は安定しており、信頼性が高い。 |

| 最終パート | 熱や機械的負荷による故障のリスクが高い。 | すべての仕様に適合し、意図された環境で確実に機能する。 |

アニーリングを成功させるには、単に部品を加熱して冷ますだけではありません。高度に制御された手順であり、すべての変数が重要である。不適切な冷却は、次のような問題を引き起こす可能性があるため、これを誤ると、まったく行わないよりも悪くなる可能性があります。 新しい 熱応力を部品に与えます。PTSMAKEでは、特定のPEEKグレードと部品形状に合わせて、綿密に文書化された手順に従っています。

アニーリングサイクルの3つの重要な段階

PEEKの典型的なアニーリングサイクルは、3つの異なるフェーズで構成されています。いずれかの段階でレシピから逸脱すると、プロセス全体が損なわれる可能性があります。

暖房(ランプアップ): PEEK部品はプログラム可能なオーブンに入れられ、ゆっくりと均一に加熱されます。一般的な加熱速度は、1時間あたり約25°F~50°F(15°C~30°C)です。急速に加熱すると、部品の表面とコアの間に熱勾配が生じ、応力が緩和されるどころか、さらに応力が加わる可能性があります。

浸す(Dwell): 目標温度に達したら(通常、非強化PEEKの場合150℃前後)、その温度で部品を "浸漬 "します。浸漬時間は非常に重要で、部品の最も厚い断面に完全に依存する。一般的な目安は、厚さ1インチにつき1時間の浸漬です。これにより、熱が材料に完全に浸透し、部品全体が応力緩和のために均一な温度に達することが保証されます。

冷却(ランプダウン): これは間違いなく最も重要な段階である。部品は、加熱されたときと同じようにゆっくりと冷却されなければならない。多くの場合、1時間当たり10°F~25°F(5℃~15℃)の制御されたランプダウンが必要です。部品をオーブンから取り出して外気で冷やすと、ほぼ間違いなく反りや故障の原因になります。部品を安全に取り出す前に、オーブンが65°C(150°F)以下になるまで徐々に冷却するようプログラムする必要があります。

下表は、さまざまなPEEK材質のアニーリングパラメータの簡略化した例です。具体的な推奨事項については、必ず材料メーカーのデータシートを参照してください。

| PEEKグレード | 標準的な浸漬温度 | 冷却速度(最大) | 備考 |

|---|---|---|---|

| 非強化PEEK 450G | 300°F / 150°C | 毎時10°F / 5°C | 最も一般的で、急冷に弱い。 |

| 30% ガラス充填 | 390°F / 200°C | 毎時25°F / 15°C | フィラーのため、より高い温度が必要。 |

| 30% カーボン充填 | 390°F / 200°C | 毎時25°F / 15°C | ガラス繊維入り同様、精密なコントロールが必要。 |

要約すると、アニーリングはオプションの工程ではなく、PEEKのCNC加工、特に公差の厳しいパーツの加工を成功させるための基本的な要件です。アニーリングは、未加工の素材と加工プロセス自体の内部応力を緩和します。ゆっくりとした加熱、十分な浸漬、徐冷のサイクルを正確に制御することは、反りや割れを防止するために不可欠であり、それによって部品の長期的な寸法安定性と最終用途での性能を保証します。

産業用途:インプラントから航空宇宙部品まで。

ある素材が、ジェットエンジンに十分な強度を持ちながら、脊椎インプラントに十分な安全性を確保できることを不思議に思ったことはないだろうか。その性能要求は、どうしようもなく矛盾しているように思える。

生体適合性、耐薬品性、機械的強度を併せ持つPEEKは、このような要求の厳しい用途に最適です。PEEKのCNC加工により、医療、航空宇宙、自動車、エレクトロニクス産業向けの精密な部品を製造し、最も厳しい性能基準を満たしています。

PEEKの特性は、医療分野において非常に価値のある材料となっている。その性能は、特に精度が最も重要な場合、チタンのような従来の材料を凌駕することがよくあります。

医療革命PEEKインプラントとデバイス

最も重要な用途のひとつは、脊椎固定術である。PEEK製脊髄ケージが広く使われているのは、その弾性率が人間の骨に非常に似ているからである。この類似性は、応力遮蔽(硬いインプラントが過大な荷重を受け、周囲の骨が弱くなる現象)を軽減するのに役立ちます。さらに、PEEKはX線に対して透明である。このため外科医は、治癒過程や骨癒合を経時的に明瞭にモニターすることができる。これは、視界を遮る金属製インプラントでは不可能である。PTSMAKEの過去のプロジェクトでは、患者の予後を改善する複雑な脊椎ケージを加工してきました。

デンタルヒーリングキャップとアバットメント

歯科医療では、金属を使用しないソリューションの人気が高まっています。PEEKは、ヒーリングキャップ、テンポラリーアバットメント、そして義歯の永久フレームワークにも最適な素材です。軽量であるため患者の快適性が向上し、金属よりも自然な色合いで審美性に優れています。生体適合性が高いため、アレルギー反応を起こすこともありません。歯科用部品は、ミクロン単位の公差で完璧にフィットさせる必要があるため、PEEKのCNC機械加工で達成される精度は非常に重要です。これらの部品は、炎症や将来の合併症を引き起こすことなくシームレスに統合する必要があり、製造工程は材料そのものと同じくらい重要です。この材料は、骨と結合する能力があり、その過程で オステオインテグレーション7も成功の重要な要因である。

| 特徴 | 覗き見 | 医療グレード・チタン |

|---|---|---|

| 放射線透過性 | X線透過性 | 不透明、視界を遮る |

| モジュラス | 人間の骨に似ている | 骨よりはるかに硬い |

| 重量 | 軽量 | より重い |

| 生体適合性 | 優れた不活性 | 優れた不活性 |

PEEKはその弾力性と軽量性により、人体だけでなく、故障が許されない産業分野でも使用されています。空から道路まで、その用途は急速に拡大している。

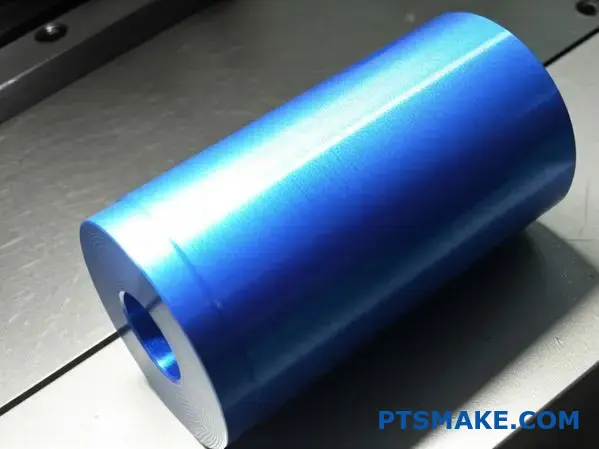

新たな高みへ航空宇宙用途

航空宇宙産業では、1グラム1グラムが重要です。軽量化は燃費の向上や積載量の増加に直結します。PEEKは、金属に匹敵する強度対重量比を提供しますが、密度はほんのわずかです。当社では、ブラケット、クランプ、ファスナーなど、航空機全体に使用される部品のためにPEEKを加工することがよくあります。重量だけでなく、PEEKは優れたFST(難燃性、耐煙性、毒性)評価を得ており、航空機キャビン内で重要な安全要件である火にさらされても有害なガスを放出しないことを意味します。また、ジェット燃料や油圧作動油のような腐食性の強い航空流体にも耐性があり、長期的な信頼性を保証します。

自動車用ギアとシール

自動車産業もPEEKが輝く分野です。高性能なPEEKギアは、金属製のギアに比べ、少ない潤滑と騒音で作動することができます。優れた耐摩耗性を示し、重要なトランスミッションやエンジン部品の寿命を延ばします。PEEK製のシールやスラストワッシャーも、現代のエンジンに見られる高温や腐食性の化学薬品に耐えることができるため、一般的に使用されています。電気自動車(EV)の台頭により、PEEKの優れた電気絶縁特性は、バッテリーパックや電気モーター内の部品にとってさらに重要になってきています。

現代のエレクトロニクスに電力を供給

エレクトロニクス分野では、PEEKは高性能の絶縁体、コネクター、半導体チップのテストソケットに使用されています。非常に高い温度でも機械的・電気的特性を維持できるため、ウェハーハンドリングのような要求の厳しい製造工程に最適です。化学的純度が高いため、繊細な電子部品を汚染することはありません。PEEKのCNC加工の精度は、現代のデバイスの小型化に不可欠な、信じられないほど小さく複雑な絶縁体を作成することを可能にします。

| 産業 | 主要業績要件 | PEEK CNC機械加工部品の優れた点 |

|---|---|---|

| 航空宇宙 | 高い強度対重量比、FST規格 | 燃料消費を減らし、安全性を高める |

| 自動車 | 耐摩耗性、化学的安定性 | 部品の寿命を延ばし、ノイズを低減 |

| エレクトロニクス | 電気絶縁性、熱安定性 | 小型化を可能にし、信頼性を確保 |

PEEKの多用途性は注目に値する。医療分野では、その生体適合性と骨に似た特性がインプラントの鍵となります。航空宇宙分野では、金属に代わる軽量かつ強靭な代替材料を提供します。自動車やエレクトロニクス分野では、その耐久性と絶縁性が貴重なものとなります。PEEKのCNC加工は、様々な業界でこれらの利点を引き出し、妥協することなく性能を発揮するコンポーネントを提供します。この適応性により、PEEKは現代のエンジニアリングの課題にとってトップクラスの材料となっています。

PEEKのCNC加工と他の製造方法を比較する?

高性能PEEK部品の正しい製造方法の選択に行き詰まったことはありませんか?間違ったプロセスを選択すると、コストのかかる遅延や性能基準を満たさない部品につながる可能性があります。

PEEKのCNCマシニングは、プロトタイプや少量生産に比類のない精度と柔軟性を提供しますが、射出成形や3Dプリンティングのような代替案は、それぞれ大量生産や迅速で非機能的なプロトタイプに適しています。最適な選択は、特定のプロジェクト要件、予算、スケジュールによって異なります。

製造オプションを評価する際、最初に比較されるのはCNC機械加工と3Dプリンターであることが多い。どちらも 複合部品 高価な金型を必要としないが、得意とする分野は異なる。

PEEK CNCマシニングと3Dプリンティング(FDM/FFFF)の比較

3Dプリンティング、特に溶融積層造形法(FDM)は、レイヤーごとにパーツを造形します。このプロセスは、初期コンセプトモデルを非常に迅速に作成するのに適しています。形状やフィット感をテストするために、数時間以内に物理的なパーツを手にすることができます。しかし、性能に関しては、3DプリントされたPEEKパーツには固有の弱点があります。レイヤーごとの構造は、以下のようなパーツを作る可能性があります。 異方性8つまり、かかる力の方向によって強度が異なるのです。PTSMAKEでのテストでは、レイヤーの接着ポイントが、応力下で最初に破損することが多いことがわかっています。

対照的に、PEEKのCNC加工は、押し出されたPEEKのソリッドブロックから始まります。材料は、最終的な部品を明らかにするために減法的に除去されます。この工程により、部品は母材の等方的強度を完全に保持します。出来上がった部品は、3Dプリンターで作られた部品と比較して、強度が高く、耐久性に優れ、機械的特性も優れています。さらに、CNC機械加工は、はるかに優れた表面仕上げを提供し、精度が譲れない医療、航空宇宙、自動車用途に不可欠な、はるかに厳しい公差を保持することができます。

頭から頭まで比較:スピード、クオリティ、そして強さ

| 特徴 | PEEKのCNC加工 | PEEK 3Dプリンティング(FDM) |

|---|---|---|

| 寛容 | 0.025mm(±0.001インチ)以内の精度 | 通常±0.010インチ(0.25mm) |

| 表面仕上げ | 優れた滑らかさ(粉砕したまま) | 目に見えるレイヤーライン、ラフ |

| 部品強度 | 等方性、完全な材料強度 | 異方性、レイヤーラインで弱い |

| ベスト・ユースケース | 機能的プロトタイプ、少量生産 | コンセプトモデル、フォーム/フィット・テスト |

| リードタイム(1~10部品) | 断食(日) | 非常に速い(数時間から数日) |

機械的ストレス、高温、過酷な化学薬品にさらされるあらゆる用途に、 PEEK CNC加工 が明らかに勝者である。3Dプリントは初期段階の検証には適しているが、適切に機械加工された部品の品質と信頼性にはかなわない。

次の主な比較対象は PEEK射出成形.ここで話は、プロトタイピングから移行する。 少量 大量生産にCNC機械加工と射出成形のどちらを選択するかは、そのほとんどが数量と部品当たりのコストに左右される。

PEEK CNC機械加工と射出成形の比較

射出成形では、特注の鋼鉄製の金型を作る必要があり、多額の先行投資が必要となる。この金型費用は相当なものになるため、数個の部品を生産するには現実的ではありません。しかし、一度金型を作れば、その後の各部品の製造コストは驚くほど低くなり、製造スピードも非常に速くなります。何千個もの同じ部品を迅速かつ効率的に生産することができる。

とは正反対である。 PEEK CNC加工.機械加工では、金型費がかからない。セットアップも比較的短時間で済むため、試作品1個から数百個の部品を生産するのに最適です。数量に関係なく、部品あたりのコストは比較的一定です。しかし、生産規模を拡大するにつれて、機械加工の部品当たりのコストは、最終的には射出成形よりもはるかに高くなります。

コストと数量の損益分岐点

PTSMAKEでクライアントを指導した経験では、損益分岐点を決定するお手伝いをすることがよくあります。射出成形の金型費用と両工程の部品単価を分析します。PEEKパーツの場合、射出成形がCNC機械加工よりもコスト効率が良くなる分岐点は、一般的に数千個の範囲です。

| ファクター | PEEKのCNC加工 | PEEK射出成形 |

|---|---|---|

| 金型費用 | なし | 高い(数千から数万) |

| 部品単価(低ボリューム) | 中程度 | 非常に高い(金型償却による) |

| 部品単価(高ボリューム) | 比較的一定 | 非常に低い |

| リードタイム(最初の部品) | 短期間(数日から数週間) | 長い(カビの場合は数週間から数ヶ月) |

| デザインの柔軟性 | 高い(デザイン変更が容易) | 低い(変更には金型の修正が必要) |

私たちが採用する一般的な戦略は、最初のプロトタイプと最初の生産数を製造するためにCNC加工を使用することです。これにより、高価な金型にこだわることなく、デザインの反復と市場テストを行うことができます。設計が確定し、需要が証明された後は、スケーラブルで費用対効果の高い大量生産のために射出成形に移行します。このハイブリッド・アプローチは、両方の長所を生かしたものです。

PEEKの適切な製造方法を選択することは非常に重要です。 PEEK CNC加工 CNCマシニングは、その精度、強度、柔軟性で際立っており、高品質の機能的プロトタイプや少量生産のための優れた選択肢となっています。3Dプリンティングが初期段階のモデルにスピードを提供し、射出成形が大量生産に比類のないコスト効率を提供する一方で、CNCマシニングはそのギャップを完璧に埋めています。CNCマシニングは、金型製作のような高額な初期費用をかけることなく、堅牢で生産品質の高いパーツを作ることができます。

PEEK加工の持続可能性と環境への影響?

PEEKのような高性能ポリマーを使用する際の環境コストについて考えたことはありますか?より環境に優しい製造業を推進する中で、材料のライフサイクルへの影響を無視することは、最も革新的なプロジェクトでさえも頓挫させる可能性があります。

PEEK加工は、持続可能性の目標に沿うことができます。廃棄物とエネルギーを最小限に抑える効率的なCNC工程と、切削くずの強固なリサイクルプログラムにより、環境フットプリントは大幅に削減されます。PEEKの優れた耐久性は、部品が長持ちすることを意味し、循環経済を促進します。

高機能素材というと、機械的特性とコストが話題の中心になることが多い。しかし、持続可能性はもはや二次的な関心事ではなく、責任ある製造業の中核をなす要件である。朗報は ピークCNC加工 環境保護と本質的に相反するものではありません。最初から最後までスマートな戦略を実行することが重要なのです。PTSMAKEでは、コンプライアンス遵守のためだけでなく、優れたエンジニアリングであることから、これらの実践を中核業務に組み込んでいます。

屑を飼いならす:効果的な廃棄物管理

どのような機械加工プロセスにおいても、最初に、そして最も目に見える形で環境に影響を与えるのは、発生する廃棄物、すなわち切り屑や端材である。PEEKは高価なポリマーであるため、廃棄物が1グラム出るごとに経済的な損失が生じます。

棲み分けの重要性

PEEKの廃棄物を管理する上で最も重要なステップは、厳密な分別です。PEEK切粉に他のプラスチックや金属、切削液が混入すると、リサイクルできなくなります。当社では、各機械でPEEK切粉専用のゴミ箱を使用しています。このシンプルな規律により、廃棄物の流れが純粋に保たれ、リサイクルの価値が維持されます。クリーンで分別されたPEEKスクラップは、純度要件がそれほど厳しくない用途向けにペレットに再加工することができます。

廃棄物を発生源から削減する

廃棄物を管理する最善の方法は、廃棄物を減らすことである。これはプロセスの最適化から始まる。

- ニア・ネット・シェイプ・ストック 可能な限り、最終的な部品の寸法に近いストック材から始めます。こうすることで、削り取る必要のある材料の量を最小限に抑えることができます。

- ネスティングパーツ: 1枚のシートやブロックから複数の小さな部品を作るプロジェクトでは、CAMソフトウェアを使用して、クッキーの抜き型のように効率的に部品を入れ子にし、材料の歩留まりを最大化します。

これらの戦略がサステイナビリティにどのような影響を与えるかを簡単に説明しよう。

| 戦略 | 環境面でのメリット | 経済的利益 |

|---|---|---|

| 材料の分別 | リサイクルを可能にし、廃棄物を埋立地から迂回させる。 | 材料価値を回収し、廃棄費用を削減する。 |

| ニア・ネット・シェイプ・ストック | より少ない材料除去、より少ないエネルギー使用。 | 原材料費の削減、サイクルタイムの短縮 |

| パーツネスティング | 材料利用を最大化し、スクラップを減らす。 | ストック単価が上昇し、収益性が向上した。 |

PEEKスクラップを単なる廃棄物ではなく、価値ある資源として扱うことで、私たちは経済的・環境的な方程式全体を転換します。このアプローチは、潜在的な負債を資産に変え、持続可能な社会の礎となるものです。 ピークCNC加工.その 熱可塑性9 PEEKの性質が、この循環型アプローチを可能にしている。

物理的な廃棄物の管理だけでなく、エネルギー消費もCNC加工における環境フットプリントの重要な要素です。高速スピンドル、強力なサーボ、クーラントポンプはすべて、かなりの電力を消費します。しかし、材料廃棄物と同様に、戦略的な最適化によってエネルギー使用量を大幅に削減することができます。

グリーン製造における効率的プロセスの役割

効率的な加工工程は、単に速いだけでなく、環境にも優しいのです。1分1秒のサイクルタイムの短縮は、エネルギー消費量の削減と二酸化炭素排出量の削減に直結します。

最適化されたツールパスと機械効率

最新のCAMソフトウェアでは、10年前には考えられなかったような高効率なツールパスの作成が可能です。

- 高速マシニング(HSM): トロコイド加工などの技術は、重くて遅い切削ではなく、軽くて速い切削を使用します。直感に反すると思われるかもしれませんが、HSMはしばしば全体のサイクルタイムを短縮し、機械への負担を減らし、ピーク時のエネルギー需要を低減します。PTSMAKEでの過去のプロジェクトの経験では、PEEKにHSMを適用すると、加工時間を15~30%短縮でき、その結果、部品あたりのエネルギー使用量も比例して減少します。

- 近代的な設備: 最新のCNCマシンは、エネルギー効率を念頭に置いて設計されています。サーボモーターの回生ブレーキや、アイドル時のインテリジェントパワーダウンモードなどの機能は、生産稼働中に大きな違いをもたらします。機器のアップグレードとメンテナンスは、生産性と持続可能性の両方への投資です。

ライフサイクルの優位性PEEKの永続的な価値

おそらくPEEKの最も説得力のある持続可能性の議論は、その長期的な性能にあります。PEEKから機械加工された部品は、標準的なプラスチックから作られたものよりも製造に多くのエネルギーを必要とするかもしれませんが、その寿命は、特に過酷な化学的、熱的、または高摩耗環境において、多くの場合、桁外れに長くなります。

| 特徴 | PEEKコンポーネント | 従来の素材 |

|---|---|---|

| 耐用年数 | 非常に寿命が長く、アセンブリの寿命まで使用できることが多い。 | より短く、複数回の交換が必要。 |

| 耐薬品性 | 様々な化学薬品に対して不活性であり、劣化を防ぐ。 | 腐食または劣化し、故障につながる可能性がある。 |

| メンテナンス | 最小限。"フィットして忘れる"。 | 定期的な点検と交換が必要。 |

| 環境負荷 | 交換頻度の低減と経年による材料使用量の減少により、低水準。 | 製造と廃棄を繰り返すため、高い。 |

この耐久性は、製品寿命の間に製造、輸送、設置する交換部品の数が少なくて済むことを意味します。総所有コスト(金銭面と環境面の両方)を考慮すると、PEEKは重要な用途においてより持続可能な選択肢として浮上することがよくあります。高品質の ピークCNC加工 このプロセスは、早期故障や生産サイクルの繰り返しによる環境コストを防止することで、利益をもたらす。

要約すると ピークCNC加工 は当たり前のことではなく、意図的な戦略の結果なのです。廃棄物を綿密に管理し、端材をリサイクルし、エネルギー消費を抑えるために加工工程を最適化し、PEEKの驚異的な耐久性を活用することで、私たちは責任を持って高性能部品を製造することができます。重要なのは、製品のライフサイクル全体を通して持続可能性を捉えることであり、PEEKの長寿命が環境面で決定的なアドバンテージとなり、より循環的で無駄の少ない製造エコシステムに貢献することが多いのです。

高精度:優れたPEEK CNC加工用PTSMAKE

専門家によるPEEK CNC加工で高性能プロジェクトを最適化する準備はできていますか?迅速な見積もり、比類のない品質、信頼できるサービスを提供する次世代のパートナー、PTSMAKEにお任せください。カスタマイズされたお見積もりをご希望の方は、今すぐお問い合わせください!

この特性により、PEEK部品が温水や蒸気の環境でも完全性を維持できることをご覧ください。 ↩

このポリマー特性が、PEEKの最終強度、耐薬品性、加工挙動にどのような影響を及ぼすかをご覧ください。 ↩

機械加工中に材料特性がどのように変化し、コストのかかる部品の不具合をどのように防ぐかを学びます。 ↩

機械加工表面のテクスチャーを定義し、制御するために使用される主要なメトリクス(Raなど)を理解する。 ↩

応力に対する材料の応答が、最終部品の品質と加工の成功にどのように影響するかをご覧ください。 ↩

この重要なポリマー特性を理解し、PEEK特有のアニーリング要件の「理由」をマスターしてください。 ↩

より強く、より成功する医療用インプラントのために、材料がどのように骨の成長を促進するかについて、さらに詳しく学んでください。 ↩

方向によって材料特性がどのように異なり、部品の性能と信頼性に影響を与えるかを理解する。 ↩

PEEKをリサイクル可能にする材料特性と、持続可能な製造におけるその意味を理解する。 ↩