State riprogettando un sistema di trasmissione e gli ingranaggi cilindrici generano livelli di rumore inaccettabili. I tempi del progetto sono stretti, il budget è limitato e il passaggio agli ingranaggi elicoidali implica la riprogettazione dell'intero sistema di cuscinetti e dell'alloggiamento.

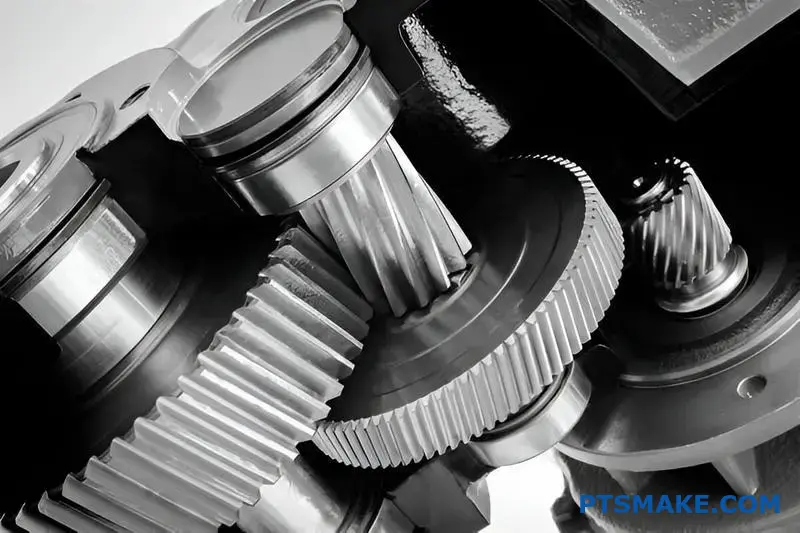

Gli ingranaggi cilindrici hanno denti dritti paralleli all'asse dell'albero, mentre gli ingranaggi elicoidali hanno denti angolati che creano un'elica attorno alla circonferenza dell'ingranaggio. Questa differenza fondamentale influisce su tutto, dai livelli di rumorosità e capacità di carico ai costi di produzione e ai requisiti dei cuscinetti.

Nel mio lavoro presso PTSMAKE, ho aiutato gli ingegneri a prendere questa decisione decine di volte. Ogni tipo di riduttore ha punti di forza specifici che lo rendono ideale per determinate applicazioni. Questa guida vi illustrerà le differenze tecniche, i compromessi di prestazioni e i criteri di selezione per aiutarvi a fare la scelta giusta per il vostro progetto.

Qual è la geometria fondamentale che definisce il dente di un ingranaggio cilindrico?

Il segreto delle prestazioni di un ingranaggio cilindrico non è solo la sua forma, ma una curva molto specifica. Questa curva è alla base del suo design.

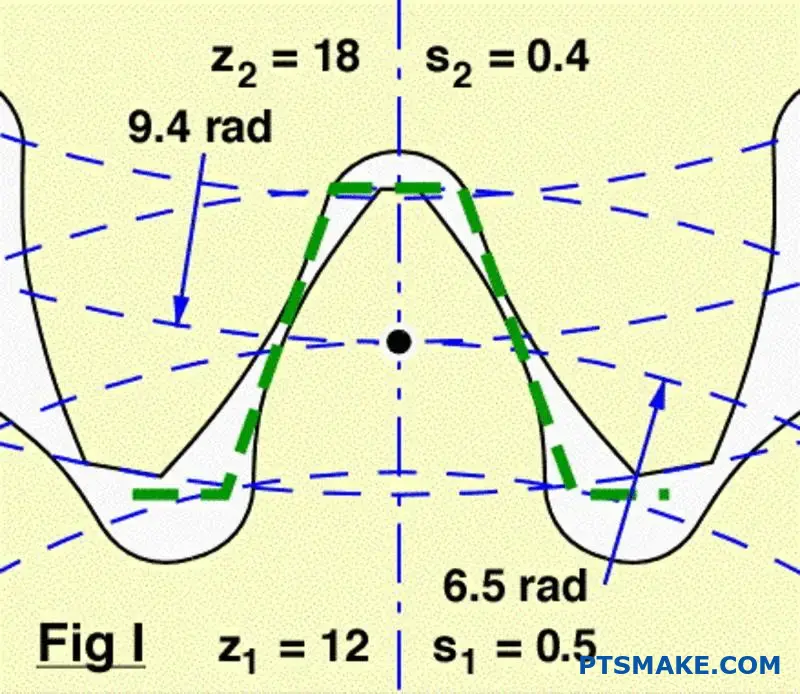

Il profilo Involute

Il profilo del dente di un moderno ingranaggio cilindrico è una curva involuta. Pensate a questo come allo srotolamento di una corda da un cilindro.

Questa geometria specifica è fondamentale. Garantisce che, con l'ingranaggio, la velocità di rotazione rimanga perfettamente costante. In questo modo si evitano scossoni e flussi di potenza non uniformi.

| Caratteristica della geometria | Scopo |

|---|---|

| Curva involuta | Rapporto di velocità costante |

| Dente dritto | Trasferimento di potenza assiale |

| Spaziatura corretta | Coinvolgimento senza problemi |

In che modo Involute assicura un funzionamento regolare

La forma involuta non è arbitraria. È un preciso profilo matematico progettato per una ragione primaria: mantenere un rapporto di velocità costante tra gli ingranaggi. Si tratta di un principio irrinunciabile per una trasmissione efficiente della potenza.

La magia della normalità comune

Quando due denti di un ingranaggio entrano in contatto, la normale comune (una linea perpendicolare alle superfici nel punto di contatto) passa sempre per un punto fisso. Questo punto fisso è chiamato punto di passo.

Questa geometria coerente garantisce che l'ingranaggio motore spinga l'ingranaggio condotto a una velocità costante. Non ci sono accelerazioni o decelerazioni durante l'ingranaggio. Questa è una differenza fondamentale nel confronto Ingranaggi cilindrici vs ingranaggi elicoidalipoiché entrambi si basano su questo principio per un funzionamento regolare.

La curva involuta è generata da una cerchio di base1. La dimensione di questo cerchio è fondamentale per la forma finale del dente e le sue caratteristiche prestazionali. Nel nostro lavoro all'PTSMAKE, ottenere una geometria corretta è fondamentale per i pezzi di alta precisione da cui dipendono i nostri clienti.

| Aspetto progettuale | Conseguenza della geometria involuta |

|---|---|

| Punto di contatto | Si muove lungo la faccia del dente |

| Linea d'azione | Rimane costante e tangente a entrambi i cerchi di base |

| Rapporto di velocità | Rimane costante per tutta la maglia |

La curva involuta è la geometria fondamentale del dente di un ingranaggio cilindrico. Questo profilo specifico è essenziale per ottenere un rapporto di velocità costante, che garantisce una trasmissione di potenza fluida, affidabile ed efficiente tra gli ingranaggi.

In che modo l'angolo d'elica cambia radicalmente la natura di un ingranaggio?

L'angolo d'elica è la caratteristica più importante. Separa un ingranaggio elicoidale da un ingranaggio cilindrico. Non si tratta solo di una modifica visiva.

Gli ingranaggi cilindrici hanno denti diritti. Si innestano lungo l'intera faccia in una sola volta. Questo crea un contatto brusco, linea su linea.

Gli ingranaggi elicoidali, con i loro denti angolati, si innestano in modo diverso. Il contatto inizia da un'estremità del dente. Si sposta poi dolcemente sulla faccia durante la rotazione dell'ingranaggio.

L'impegno graduale è la chiave.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Allineamento dei denti | Dritto | Ad angolo (angolo elica) |

| Contatto iniziale | Linea completa | Punto di contatto |

| Stile di fidanzamento | Brusco | Graduale e uniforme |

La meccanica del coinvolgimento graduale

Questo processo di ingranamento graduale cambia tutto. A differenza dell'impatto improvviso degli ingranaggi cilindrici, i denti elicoidali scivolano in posizione. Il carico viene applicato progressivamente, non tutto in una volta. Questo riduce notevolmente gli urti e le vibrazioni.

Il risultato è un funzionamento molto più silenzioso. Questo è uno dei motivi principali per cui i progettisti scelgono gli ingranaggi elicoidali rispetto agli ingranaggi cilindrici. Nei progetti passati dell'PTSMAKE, il passaggio agli ingranaggi elicoidali ha ridotto il rumore operativo di un margine considerevole. Si tratta di un aspetto cruciale per i dispositivi medici e l'elettronica di consumo.

Tuttavia, questo contatto angolato crea un effetto collaterale. Genera spinta assiale2, una forza parallela all'asse dell'ingranaggio. Questa forza non esiste negli ingranaggi cilindrici e deve essere gestita. La scelta di un cuscinetto adeguato è essenziale per gestire questo carico ed evitare guasti prematuri.

Il fulcro del dibattito tra ingranaggi cilindrici e ingranaggi elicoidali è questo compromesso.

| Aspetto del coinvolgimento | Vantaggio | Svantaggio |

|---|---|---|

| Contatto graduale | Funzionamento più fluido e silenzioso | Crea una spinta assiale |

| Denti angolati | Rapporto di contatto totale più elevato | Richiede cuscinetti robusti |

| Distribuzione del carico | Maggiore capacità di carico | Produzione più complessa |

Un cambiamento nella distribuzione del carico

Questo innesto graduale significa anche che il carico è ripartito su più denti in qualsiasi momento. Ciò contrasta con gli ingranaggi cilindrici, dove uno o due denti sopportano l'intero carico. Questa capacità di ripartizione consente agli ingranaggi elicoidali di gestire carichi maggiori e di avere una vita utile più lunga.

L'angolo di elica cambia radicalmente il contatto dell'ingranaggio da una linea brusca a un'area liscia e progressiva. Questo cambiamento è all'origine dei vantaggi in termini di rumorosità e capacità di carico, ma introduce anche la sfida della spinta assiale.

Quali forze agiscono su un singolo dente di una corona dentata durante l'ingranaggio?

Per capire cosa succede durante l'ingranaggio, dobbiamo scomporre la forza totale. Questa forza non agisce in modo diretto. Agisce con un angolo rispetto alla superficie del dente.

Gli ingegneri semplificano questo aspetto dividendo la forza in due componenti chiave. Questo facilita l'analisi e la progettazione. Si tratta delle forze tangenziali e radiali. Ciascuna ha un effetto molto diverso sul sistema di ingranaggi.

Comprendere le componenti della forza

Ecco una rapida descrizione di queste due forze e dei loro ruoli principali in un sistema di ingranaggi.

| Componente della forza | Funzione primaria | Impatto principale |

|---|---|---|

| Forza tangenziale | Potenza di trasmissione | Crea una coppia per azionare il carico |

| Forza radiale | Separa gli ingranaggi | Carico su cuscinetti e alberi |

La forza "di lavoro": Componente tangenziale

La forza tangenziale è la componente che svolge tutto il lavoro utile. Agisce tangenzialmente al cerchio del passo dell'ingranaggio. È la forza che trasmette effettivamente la coppia e fa ruotare l'ingranaggio azionato. Quando si ha bisogno di una coppia maggiore, si ha a che fare con una forza tangenziale più grande.

La forza di separazione: Componente radiale

La forza radiale, invece, non è utile per la trasmissione di potenza. Il suo compito è quello di allontanare i due ingranaggi, agendo lungo una linea che collega i loro centri. Questa forza di separazione è un fattore critico per la progettazione. Carica direttamente gli alberi e i cuscinetti che li sostengono.

In passato, in PTSMAKE abbiamo visto progetti fallire perché i cuscinetti non erano stati specificati per gestire i carichi radiali. Questa è una distinzione cruciale nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali, in quanto gli ingranaggi elicoidali introducono anche una forza assiale (di spinta).

L'entità di queste forze è determinata dalla Angolo di pressione3. Un angolo maggiore aumenta la forza radiale rispetto a quella tangenziale.

Panoramica della direzione della forza

| Forza | Direzione dell'azione | Conseguenza |

|---|---|---|

| Tangenziale | Tangente al cerchio del passo | Trasmissione di coppia |

| Radiale | Verso il Centro Ingranaggi | Carico del cuscinetto |

La forza totale sul dente di un ingranaggio cilindrico è meglio compresa dalle sue componenti tangenziali e radiali. La forza tangenziale aziona la macchina, mentre la forza radiale crea carichi sugli alberi e sui cuscinetti. Una corretta progettazione tiene conto di entrambe.

Quale nuova componente della forza viene introdotta dagli ingranaggi elicoidali?

Gli ingranaggi elicoidali introducono una componente di forza significativa non presente negli ingranaggi cilindrici: la spinta assiale. Questa forza agisce parallelamente all'asse dell'ingranaggio, spingendo essenzialmente l'ingranaggio lateralmente.

La sua origine risiede nei denti angolati dell'ingranaggio.

Una differenza di design fondamentale

Quando i denti elicoidali si ingranano, il contatto crea una forza non perpendicolare all'albero. Questo crea la componente assiale.

| Tipo di ingranaggio | Forze primarie | Nuova componente della forza |

|---|---|---|

| Ingranaggio cilindrico | Radiale, tangenziale | Nessuno |

| Ingranaggio elicoidale | Radiale, tangenziale | Spinta assiale |

Questa nuova forza richiede un'attenta gestione del progetto.

La fisica dietro la spinta assiale

L'angolo di elica è la causa diretta della spinta assiale. Durante la trasmissione della potenza, la forza sulla superficie del dente è perpendicolare al dente stesso. Poiché il dente è angolato, questa forza si risolve in due componenti chiave.

Una è la forza tangenziale, che guida la rotazione. L'altra è la forza assiale, che spinge lungo l'albero. Questo è un concetto fondamentale quando si confrontano gli ingranaggi cilindrici con quelli elicoidali. Maggiore è l'angolo di elica, maggiore è la spinta assiale per una data coppia.

Calcolo dell'impatto

Questa spinta non è un problema di poco conto. Deve essere contrastata con cuscinetti adeguati, come i cuscinetti a rulli conici o i cuscinetti reggispinta. Ignorarla può portare alla rottura prematura dei cuscinetti e al disallineamento del sistema.

Il carico totale sul dente crea un forza risultante4 che è una combinazione di questi componenti. Nel nostro lavoro all'PTSMAKE, calcoliamo con precisione questi carichi per garantire che ogni componente che produciamo funzioni in modo affidabile nell'assemblaggio finale.

Effetto diretto dell'angolo elicoidale

| Angolo dell'elica | Spinta assiale relativa |

|---|---|

| 15° | Basso |

| 30° | Medio |

| 45° | Alto |

Questa relazione è fondamentale per gli ingegneri. La scelta di un angolo d'elica più alto per un funzionamento più fluido ha come contropartita la gestione di carichi assiali maggiori.

Gli ingranaggi elicoidali introducono una spinta assiale a causa dei loro denti angolati. Questa forza è direttamente proporzionale alla coppia trasmessa e alla tangente dell'angolo d'elica. La corretta selezione dei cuscinetti è essenziale per gestire questo carico, una considerazione critica assente nei sistemi di ingranaggi cilindrici.

Come si definisce il "rapporto di contatto" per gli ingranaggi cilindrici ed elicoidali?

Il rapporto di contatto è una metrica fondamentale per gli ingranaggi. Definisce il numero medio di coppie di denti in contatto in un dato momento. Un rapporto più alto significa che più denti condividono il carico.

Il risultato è una trasmissione di potenza più fluida. Inoltre, riduce notevolmente la rumorosità e le vibrazioni.

Rapporti di contatto tra sperone e elica

Il disegno dei denti dell'ingranaggio influisce direttamente su questo rapporto. Confrontiamoli.

| Tipo di ingranaggio | Rapporto di contatto tipico | Impegno del dente |

|---|---|---|

| Ingranaggio cilindrico | Da 1,2 a 1,8 | Sequenziale, una coppia si innesta mentre un'altra si disinnesta |

| Ingranaggio elicoidale | > 2.0 | Sovrapposizione, più coppie in contatto simultaneamente |

Questa differenza è fondamentale per le loro prestazioni.

Comprendere la meccanica del rapporto di contatto

La differenza nel rapporto di contatto dipende dalla geometria dei denti. Gli ingranaggi cilindrici hanno denti diritti. Ciò significa che il contatto avviene lungo l'intera superficie del dente in una sola volta. L'innesto è brusco.

Gli ingranaggi elicoidali, invece, hanno denti angolati. Questo crea un innesto graduale. Il contatto inizia da un'estremità del dente e si estende lungo la sua superficie durante la rotazione dell'ingranaggio.

Innesto graduale negli ingranaggi elicoidali

Questo design angolato estende la percorso di contatto5. Ciò consente a una nuova coppia di denti di iniziare a impegnarsi prima che la coppia precedente si sia completamente disinnestata. Questa sovrapposizione è il motivo per cui il loro rapporto di contatto è sempre superiore a 2,0.

Nella nostra esperienza di PTSMAKE, questo è un fattore decisivo. Quando i clienti discutono Ingranaggi cilindrici vs ingranaggi elicoidali Per le applicazioni che richiedono una bassa rumorosità, il rapporto di contatto più elevato degli ingranaggi elicoidali li rende spesso la scelta migliore.

Implicazioni pratiche

Un rapporto di contatto più elevato distribuisce il carico su più denti. Ciò riduce le sollecitazioni sui singoli denti. Aumenta la capacità di carico e prolunga la vita operativa dell'ingranaggio.

| Caratteristica | Ingranaggio cilindrico (rapporto inferiore) | Ingranaggio elicoidale (rapporto superiore) |

|---|---|---|

| Distribuzione del carico | Concentrato su 1-2 coppie di denti | Distribuito su più di 2 coppie di denti |

| Livello di rumore | Più alto | Più basso |

| Vibrazioni | Più pronunciato | Funzionamento più fluido |

| Stress sui denti | Più alto | Più basso |

Ciò rende gli ingranaggi elicoidali ideali per le applicazioni ad alta velocità e ad alta potenza, dove la scorrevolezza è essenziale.

Il rapporto di contatto misura l'impegno simultaneo dei denti. Gli ingranaggi elicoidali presentano un rapporto di sovrapposizione più elevato rispetto agli ingranaggi cilindrici. Ciò si traduce in un funzionamento più fluido e silenzioso e in una migliore distribuzione del carico, una distinzione fondamentale nella selezione degli ingranaggi.

Quale fenomeno fisico è la fonte principale del rumore degli ingranaggi cilindrici?

Il cuore del problema è l'impatto. La fonte principale del rumore degli ingranaggi cilindrici è l'urto brusco e frontale dei denti al momento dell'innesto.

A differenza di una rullata regolare, si tratta di un evento improvviso. L'impatto crea un picco di pressione istantaneo.

Questa variazione di pressione provoca delle vibrazioni. Queste vibrazioni attraversano il materiale dell'ingranaggio e l'aria circostante e vengono percepite dalle nostre orecchie come rumore.

Il processo si ripete con l'ingranamento di ogni singolo dente, creando un caratteristico sibilo.

| Passo | Azione fisica | Risultato |

|---|---|---|

| 1. L'impegno | I denti si scontrano bruscamente | Impatto improvviso |

| 2. Impatto | Trasferimento di energia | Forte picco di pressione |

| 3. Propagazione | Il picco si irradia verso l'esterno | Vibrazioni (rumore) |

Questo impatto rapido e ripetitivo è il fenomeno fisico fondamentale che dobbiamo affrontare.

La meccanica dell'impegno improvviso

Approfondiamo questo impatto. I denti degli ingranaggi cilindrici si incontrano simultaneamente lungo tutta la loro larghezza. Questo contatto di linea istantaneo significa che non c'è un trasferimento graduale del carico. Si tratta di un evento "tutto o niente".

Questo carico d'urto è la causa principale. Ogni innesto agisce come un piccolo colpo di martello sul sistema, creando un'onda di pressione.

Dalle vibrazioni al rumore udibile

Quest'onda di pressione si irradia lontano dagli ingranaggi. Quando viaggia nell'aria, la percepiamo come un suono. La frequenza di questo suono è direttamente legata alla frequenza di ingranamento dei denti.

Noi di PTSMAKE vediamo spesso come questa energia persa abbia un impatto sull'efficienza, non solo sull'acustica. Il rumore che si sente è energia sprecata che potrebbe essere utile. Un fattore chiave è il variazione della rigidità del dente6 durante il ciclo di ingranamento, che può amplificare queste vibrazioni.

Questo è uno dei principali punti di differenza nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali. Gli ingranaggi elicoidali si innestano gradualmente sulla faccia del dente, attenuando in modo significativo l'impatto.

| Tipo di ingranaggio | Stile di fidanzamento | Livello di impatto | Rumore tipico |

|---|---|---|---|

| Ingranaggio cilindrico | Istantaneo, a tutta larghezza | Alto | Forte |

| Ingranaggio elicoidale | Graduale, angolato | Basso | Tranquillo |

I nostri test dimostrano che questa differenza fondamentale nella meccanica di innesto è la ragione principale della disparità di rumore. Affrontare l'impatto è la chiave per un funzionamento più silenzioso.

La fonte principale del rumore degli ingranaggi cilindrici è l'impatto improvviso dei denti durante l'innesto. Questo crea brusche variazioni di pressione e vibrazioni. La natura di questo contatto è il fenomeno fisico principale responsabile del caratteristico fischio dell'ingranaggio.

Perché gli ingranaggi elicoidali sono intrinsecamente più silenziosi degli ingranaggi cilindrici?

Il motivo principale è il "coinvolgimento graduale". È un concetto semplice che ha un enorme impatto sul rumore.

A differenza degli ingranaggi cilindrici, i denti degli ingranaggi elicoidali sono angolati. Ciò significa che non si ingranano tutti insieme.

Il segreto di un contatto agevole

Il contatto inizia in un punto del dente. Si diffonde poi dolcemente su tutta la superficie durante la rotazione degli ingranaggi.

In questo modo si elimina l'impatto improvviso che causa il rumore. Il trasferimento di potenza è molto più fluido e silenzioso.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Impegno del dente | Brusco, a tutta larghezza | Graduale, da punto a punto |

| Livello di impatto | Alto | Basso |

| Vibrazioni | Significativo | Minimo |

La meccanica del funzionamento silenzioso

Approfondiamo l'argomento. Gli ingranaggi cilindrici si innestano istantaneamente su tutta la superficie del dente. Questo contatto brusco crea un carico d'urto, che è la fonte principale del rumore e delle vibrazioni degli ingranaggi. È come battere le mani: un suono improvviso e acuto.

Dall'impatto al flusso

Gli ingranaggi elicoidali cambiano completamente questa dinamica. I denti angolati assicurano che mentre una parte di un dente ruota fuori dall'ingranaggio, un'altra parte sta già iniziando a innestarsi. Questa sovrapposizione crea un flusso di potenza continuo e ininterrotto.

Questo passaggio fluido tra i denti è fondamentale. Impedisce i picchi di pressione che generano rumore.

Comprendere il modello di contatto

Il linea di contatto7 su un dente di un ingranaggio elicoidale si muove diagonalmente sulla sua superficie. Questo innesto e disinnesto progressivo rende il funzionamento così silenzioso.

Noi di PTSMAKE lavoriamo questi angoli con grande precisione. In questo modo il carico viene distribuito in modo uniforme, massimizzando la silenziosità e la durata degli ingranaggi. Quando si considerano gli ingranaggi cilindrici rispetto a quelli elicoidali, questa trasmissione fluida è spesso il fattore decisivo per i nostri clienti in settori sensibili al rumore.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Applicazione del carico | Carico d'urto improvviso | Carico graduale e distribuito |

| Trasmissione di potenza | Interruzione a livello dei denti | Continuo, liscio |

| Rumore risultante | "Lamento" ad alta frequenza | Ronzio basso e costante |

I denti angolati degli ingranaggi elicoidali consentono un innesto graduale. Questo processo riduce al minimo l'impatto, gli urti e le vibrazioni che rendono rumorosi gli ingranaggi cilindrici. Il risultato è un trasferimento di potenza molto più fluido e silenzioso.

Quali sono i principali compromessi di prestazioni tra questi due ingranaggi?

La scelta tra ingranaggi cilindrici e ingranaggi elicoidali non si basa su quale sia il migliore. Si tratta di capire i compromessi specifici per la vostra applicazione. Ogni tipo di ingranaggio eccelle in aree diverse.

La decisione influisce sulla rumorosità, sulla capacità di carico, sul costo e sulla complessità. Un confronto strutturato tra ingranaggi cilindrici e ingranaggi elicoidali può chiarire la scelta migliore. Ecco una rapida panoramica.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Livello di rumore | Più alto | Più basso |

| Spinta assiale | Nessuno | Presente |

| Costo | Più basso | Più alto |

| Capacità di carico | Buono | Eccellente |

Questo quadro aiuta a bilanciare le prestazioni con i vincoli del progetto.

La scelta giusta richiede un'analisi più approfondita di questi assi prestazionali. Ogni decisione comporta un compromesso che può influire in modo significativo sul prodotto finale. Noi di PTSMAKE guidiamo quotidianamente i clienti in questo processo.

Rumorosità rispetto alla spinta assiale

Gli ingranaggi elicoidali sono apprezzati per la loro silenziosità. I loro denti angolati si innestano gradualmente, riducendo il suono lamentoso comune agli ingranaggi cilindrici. Questo li rende ideali per i prodotti di consumo o per le trasmissioni automobilistiche.

Tuttavia, questo design angolato crea spinta assiale8. Si tratta di una forza parallela all'asse dell'ingranaggio. Per gestirla sono necessari cuscinetti reggispinta, che aggiungono complessità e costi all'assemblaggio. Gli ingranaggi cilindrici non producono questa forza.

Semplicità e capacità di carico

Gli ingranaggi cilindrici sono più semplici da progettare e produrre. I loro denti dritti li rendono facili da tagliare e installare. Questa semplicità si traduce in costi inferiori e manutenzione più facile.

Gli ingranaggi elicoidali, con la loro geometria complessa, possono sopportare carichi più elevati. I denti angolati offrono un'area di contatto più ampia, distribuendo meglio le sollecitazioni. Questo è un vantaggio fondamentale nelle applicazioni a coppia elevata.

Costo vs. scorrevolezza

Il processo di produzione influisce direttamente sui costi. La rettifica di precisione necessaria per gli ingranaggi elicoidali li rende più costosi degli ingranaggi cilindrici. Questa differenza di costo può essere sostanziale in caso di grandi produzioni.

A fronte di un costo maggiore, gli ingranaggi elicoidali offrono una trasmissione di potenza eccezionalmente fluida e costante. Questa scorrevolezza è fondamentale per i macchinari di precisione in cui le vibrazioni sono indesiderate.

Efficienza vs. complessità

Gli ingranaggi cilindrici sono altamente efficienti e spesso raggiungono 98-99%. Il loro contatto di rotolamento genera un attrito molto ridotto.

Gli ingranaggi elicoidali introducono un movimento di scorrimento tra i denti, che può ridurre leggermente l'efficienza a causa dell'attrito. Tuttavia, questo è spesso un piccolo compromesso per le loro prestazioni superiori in altre aree.

La scelta tra ingranaggi cilindrici ed elicoidali è un atto di equilibrio. Le vostre priorità - bassa rumorosità, elevata capacità di carico, budget o semplicità di progettazione - determineranno il riduttore ideale. Non esiste un'unica risposta "migliore", ma solo quella più adatta alla vostra specifica applicazione.

Come si confronta la capacità di carico tra ingranaggi cilindrici ed elicoidali?

Quando si confrontano gli ingranaggi cilindrici con quelli elicoidali della stessa dimensione e dello stesso materiale, gli ingranaggi elicoidali vincono nettamente sulla capacità di carico. E non si tratta di un margine esiguo.

La differenza deriva dalla loro struttura fondamentale. Gli ingranaggi cilindrici si innestano bruscamente su tutta la superficie del dente in una sola volta.

Gli ingranaggi elicoidali, con i loro denti angolati, si innestano gradualmente. Questa transizione più dolce distribuisce il carico in modo più efficace, consentendo prestazioni più elevate in condizioni identiche.

| Tipo di ingranaggio | Capacità di carico tipica | Fattore chiave |

|---|---|---|

| Ingranaggio cilindrico | Più basso | Contatto istantaneo, a pieno viso |

| Ingranaggio elicoidale | Più alto | Contatto graduale e distribuito |

La meccanica alla base di una maggiore capacità

La capacità di carico superiore degli ingranaggi elicoidali deriva da due vantaggi meccanici fondamentali. È un concetto che spieghiamo spesso ai clienti di PTSMAKE quando si tratta di scegliere il riduttore giusto per le applicazioni più complesse.

Coinvolgimento graduale e condivisione del carico

A differenza dell'impatto improvviso dei denti degli ingranaggi cilindrici, i denti elicoidali scivolano nel contatto. Il carico viene applicato gradualmente, partendo da un'estremità del dente e spostandosi lungo la sua faccia.

Ciò significa che più denti sono spesso in contatto contemporaneamente, condividendo il carico totale. L'aumento del rapporto di contatto riduce significativamente la sollecitazione su ogni singolo dente. La distribuzione di Sollecitazione di contatto hertziana9 è molto più efficiente.

Spiegazione dell'aumento del rapporto di contatto

Il rapporto di contatto è una misura di quanti denti sono in contatto tra loro in un dato momento. Un rapporto più alto significa una migliore distribuzione del carico e un funzionamento più fluido. Nei nostri test, gli ingranaggi elicoidali dimostrano un rapporto di contatto significativamente più alto.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Impegno del dente | Improvviso, tutto in una volta | Graduale, progressivo |

| Distribuzione del carico | Concentrato su una coppia di denti | Condiviso tra più denti |

| Rapporto di contatto tipico | Da 1,1 a 1,7 | 2.0 o superiore |

| Stress risultante | Picco di sollecitazione elevato | Sollecitazioni più basse e distribuite |

Questa distribuzione consente agli ingranaggi elicoidali di gestire coppie e potenze maggiori senza aumentare il rischio di guasti dovuti alla fatica di flessione o al pitting superficiale.

Gli ingranaggi elicoidali superano gli ingranaggi cilindrici in termini di capacità di carico grazie ai loro denti angolati. Questo design garantisce un rapporto di contatto più elevato e un'applicazione graduale del carico, distribuendo le sollecitazioni su più denti e ottenendo una trasmissione di potenza più fluida e robusta in condizioni identiche.

Come si confrontano i costi di produzione e la complessità?

Nel confronto tra ingranaggi cilindrici e ingranaggi elicoidali, la produzione è il principale fattore di costo. La differenza è data dalla geometria.

La semplicità degli ingranaggi cilindrici

Gli ingranaggi cilindrici hanno denti diritti. Questo design semplice ne facilita la produzione. Possiamo utilizzare processi standard come la dentatura o la sagomatura.

L'intero dente può essere tagliato in una sola passata. Ciò comporta tempi di ciclo più rapidi e costi inferiori.

La complessità degli ingranaggi elicoidali

Gli ingranaggi elicoidali hanno denti angolati. L'angolo introduce una certa complessità. La produzione richiede impostazioni di macchina più precise e utensili specializzati per creare l'elica.

| Tipo di ingranaggio | Facilità di produzione | Processo tipico |

|---|---|---|

| Ingranaggio cilindrico | Alto | Dentatura, sagomatura |

| Ingranaggio elicoidale | Moderato | Dentatura specializzata |

Questa complessità si traduce direttamente in tempi di lavorazione più lunghi e in costi di produzione più elevati.

Il processo di produzione stesso racconta la storia dei costi. Per molti dei nostri clienti di PTSMAKE, la comprensione di questo aspetto è fondamentale per una pianificazione efficace dei loro progetti.

Approfondimento dei metodi di lavorazione

Lavorazione di ingranaggi cilindrici

La produzione di ingranaggi cilindrici è un processo molto diretto. Spesso utilizziamo una dentatrice a creatore. L'utensile da taglio, o creatore, e il grezzo dell'ingranaggio ruotano insieme. Il creatore taglia i denti dritti in modo efficiente.

Questo processo è altamente automatizzato e veloce. Richiede impostazioni meno complesse, riducendo al minimo la manodopera e i tempi macchina. Questa è la ragione principale della loro economicità.

Lavorazione di ingranaggi elicoidali

La produzione di ingranaggi elicoidali è più complessa. La macchina deve tagliare i denti con un angolo d'elica specifico. Ciò richiede un movimento elicoidale sincronizzato tra il creatore e il grezzo dell'ingranaggio.

Questo processo crea anche una significativa spinta assiale10che richiedono un'impostazione robusta della macchina per mantenere la precisione. L'impostazione richiede più tempo e le velocità di taglio sono spesso più basse per garantire la precisione.

| Caratteristica | Lavorazione di ingranaggi cilindrici | Lavorazione di ingranaggi elicoidali |

|---|---|---|

| Percorso dello strumento | Dritto, parallelo all'asse | Percorso angolare ed elicoidale |

| Impostazione della macchina | Più semplice, più veloce | Più complesso, richiede una sincronizzazione angolare |

| Tempo di ciclo | Più breve | Più lungo |

| Utensili | Piano cottura standard | Piano cottura specifico per l'angolo |

| Forze associate | Principalmente forze radiali | Forze radiali e assiali |

Ogni fase aggiunge tempo e richiede una maggiore abilità da parte dell'operatore, aumentando il costo finale per pezzo.

Gli ingranaggi cilindrici sono più economici e veloci da produrre grazie alla loro semplice geometria a denti diritti. Gli ingranaggi elicoidali, con i loro denti angolati, richiedono configurazioni di lavorazione più complesse, utensili specializzati e tempi di ciclo più lunghi, con conseguente aumento dei costi di produzione.

Quali tipi di cuscinetti sono necessari per ogni tipo di ingranaggio?

La scelta del cuscinetto giusto è fondamentale. Ha un impatto diretto sulle prestazioni e sulla durata del sistema di ingranaggi. La differenza principale è data dalle forze che ciascun tipo di ingranaggio genera.

Esigenze di cuscinetti per ingranaggi cilindrici

Gli ingranaggi cilindrici hanno denti diritti. Per questo motivo, producono principalmente carichi radiali. Questo semplifica la scelta dei cuscinetti. I cuscinetti devono solo sostenere l'albero contro queste forze esterne.

Esigenze di cuscinetti a ingranaggi elicoidali

Gli ingranaggi elicoidali, con i loro denti angolati, sono più complessi. Generano sia carichi radiali che assiali significativi. Ciò richiede un sistema di cuscinetti più robusto per gestire le forze provenienti da più direzioni.

Un rapido confronto tra Ingranaggi cilindrici vs ingranaggi elicoidali carichi è qui sotto.

| Tipo di ingranaggio | Carico primario | Carico secondario |

|---|---|---|

| Ingranaggio cilindrico | Radiale | Minimo |

| Ingranaggio elicoidale | Radiale | Assiale (spinta) |

Approfondimento sulla selezione dei cuscinetti

Le caratteristiche di carico di ciascun tipo di ingranaggio determinano la disposizione dei cuscinetti. È un concetto fondamentale che sottolineiamo sempre nelle nostre consulenze di progettazione alla PTSMAKE. Sbagliare questo concetto porta a guasti prematuri.

Cuscinetti per ingranaggi cilindrici

Per gli ingranaggi cilindrici, l'attenzione è rivolta alla gestione delle forze radiali. Spesso i cuscinetti semplici funzionano bene.

I cuscinetti radiali a sfere sono una scelta comune. Sono economici e gestiscono efficacemente i carichi radiali. In alcune applicazioni con carichi elevati, i cuscinetti a rulli cilindrici possono essere utilizzati per una maggiore capacità radiale.

Cuscinetti per ingranaggi elicoidali

Gli ingranaggi elicoidali sono diversi. L'angolo di elica dei denti crea una forza di spinta continua lungo l'asse dell'albero. Questa forza è nota come spinta assiale11.

Questo profilo di carico combinato richiede soluzioni più avanzate. Un singolo cuscinetto a sfere a gola profonda di solito non è sufficiente.

Spesso consigliamo i cuscinetti a rulli conici. Sono progettati per gestire carichi radiali e assiali pesanti contemporaneamente. La disposizione a coppie (schiena contro schiena o faccia contro faccia) è una pratica standard per contrastare le spinte in entrambe le direzioni.

Ecco una guida per la selezione dei cuscinetti.

| Tipo di ingranaggio | Tipo di cuscinetto comune | Motivo |

|---|---|---|

| Ingranaggio cilindrico | Cuscinetti a sfera a gola profonda | Eccellente per carichi radiali, conveniente. |

| Ingranaggio elicoidale | Cuscinetto a rulli conici | Gestisce carichi combinati radiali e assiali elevati. |

In breve, gli ingranaggi cilindrici richiedono cuscinetti per i carichi radiali. Gli ingranaggi elicoidali necessitano di sistemi robusti, come i cuscinetti a rulli conici, per gestire forze radiali e assiali significative. La scelta corretta è fondamentale per l'affidabilità e le prestazioni a lungo termine del riduttore.

In quali applicazioni gli ingranaggi cilindrici sono la scelta migliore?

Gli ingranaggi cilindrici si distinguono quando la semplicità e il costo sono fondamentali. Sono i cavalli di battaglia per la trasmissione diretta di potenza tra alberi paralleli.

Il loro design elimina la spinta assiale, semplificando i requisiti dei cuscinetti e la progettazione dell'alloggiamento. Questo li rende ideali per molte macchine.

Criteri di selezione chiave

Costo-efficacia

Gli ingranaggi cilindrici sono generalmente meno costosi da produrre rispetto agli ingranaggi elicoidali. Questo è un fattore importante nella produzione di grandi volumi.

Semplicità nel design

La loro semplice geometria li rende facili da progettare e installare. Noi di PTSMAKE siamo in grado di lavorarli con tolleranze precise ed efficienti.

| Caratteristica | Ingranaggi cilindrici | Ingranaggi elicoidali |

|---|---|---|

| Costo | Più basso | Più alto |

| Spinta assiale | Nessuno | Presente |

| Allineamento dell'albero | Solo in parallelo | Parallelo e perpendicolare |

| Livello di rumore | Più alto | Più basso |

Approfondimento sull'applicazione

La scelta nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali si riduce spesso alle esigenze dell'applicazione specifica. Gli ingranaggi cilindrici non sono solo un'opzione economica, ma sono la scelta tecnicamente superiore in determinati scenari. Il loro trasferimento di potenza diretto ed efficiente è imbattibile per i sistemi semplici.

Trasmissioni semplici

Si pensi alle lavatrici o ai frullatori. Questi dispositivi necessitano di un trasferimento di coppia affidabile senza la complessità o il costo di sistemi di ingranaggi più avanzati. Gli ingranaggi cilindrici forniscono questo servizio in modo perfetto. Svolgono il lavoro in modo efficiente e mantengono il prodotto finale a prezzi accessibili per i consumatori.

Pompe a spostamento positivo

Nella nostra esperienza con i clienti del settore della potenza fluida, la precisione non è negoziabile. Le pompe che utilizzano ingranaggi cilindrici, note come pompe a ingranaggi, si basano sul trasferimento di volume costante creato dai denti degli ingranaggi. Il design assicura un flusso costante e non pulsante, fondamentale per i sistemi idraulici. Gli ingranaggi devono essere precisi, un servizio in cui PTSMAKE è specializzata grazie alla lavorazione CNC. Questo è un classico caso in cui la geometria semplice di un ingranaggio cilindrico supera quella complessa.

Sistemi di trasporto

I nastri trasportatori nelle fabbriche o nei magazzini hanno bisogno di un movimento costante e affidabile. Funzionano a velocità moderate, dove il rumore è un problema minore. Gli ingranaggi cilindrici forniscono la coppia necessaria per azionare i nastri senza i costi aggiuntivi e la complessità di gestire i carichi assiali. La loro durata garantisce una lunga vita utile con una manutenzione minima. Questo è fondamentale per mantenere le linee di produzione senza intoppi.

| Applicazione | Motivo principale della scelta della corona dentata |

|---|---|

| Lavatrice | Basso costo, semplicità |

| Pompe a ingranaggi | Preciso Spostamento positivo12, Nessuna spinta assiale |

| Nastri trasportatori | Affidabilità, economicità |

| Utensili elettrici | Trasferimento di coppia elevato, montaggio semplice |

Gli ingranaggi cilindrici sono la scelta migliore per le applicazioni in cui la semplicità, l'economicità e l'assenza di spinta assiale sono fondamentali. Eccellono nei sistemi di trasmissione di potenza semplici come trasmissioni, pompe e trasportatori, offrendo affidabilità e facilità di manutenzione.

In quali applicazioni gli ingranaggi elicoidali sono la scelta obbligata?

Quando le prestazioni non possono essere compromesse, gli ingranaggi elicoidali sono l'unica scelta possibile. Il loro design è perfetto per le applicazioni che richiedono una trasmissione di potenza fluida e silenziosa. Pensate agli ambienti ad alta velocità e ad alto carico.

Gli ingranaggi cilindrici non possono competere. L'innesto graduale dei denti elicoidali riduce il rumore e le vibrazioni. Questo li rende essenziali in settori specifici.

Applicazioni ad alte prestazioni

Trasmissioni automobilistiche

Nelle automobili, in particolare nei veicoli elettrici, la riduzione del rumore è fondamentale. Gli ingranaggi elicoidali garantiscono una guida silenziosa e fluida per i passeggeri.

Riduttori industriali

Per i macchinari pesanti e le turbine, l'affidabilità è fondamentale. Gli ingranaggi elicoidali gestiscono carichi e velocità più elevati, garantendo una stabilità operativa a lungo termine.

| Applicazione | Requisito chiave | Perché gli ingranaggi elicoidali? |

|---|---|---|

| Automotive | Funzionamento silenzioso | I denti angolati riducono il rumore e le vibrazioni. |

| Turbine | Potenza ad alta velocità | L'innesto fluido gestisce gli alti regimi di rotazione. |

| Industriale | Capacità di carico elevata | Un maggiore contatto tra i denti distribuisce le sollecitazioni. |

Nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali, è l'applicazione a determinare il vincitore. Sebbene gli ingranaggi cilindrici siano efficienti e più semplici da realizzare, sono rumorosi alle alte velocità. Ciò è dovuto al brusco contatto tra i denti.

Gli ingranaggi elicoidali risolvono questo problema. I denti angolati si innestano gradualmente su tutta la superficie dell'ingranaggio. In questo modo si ottiene un trasferimento di potenza molto più fluido e silenzioso. I nostri test condotti su PTSMAKE dimostrano costantemente una significativa riduzione del rumore, delle vibrazioni e delle asperità (NVH).

Il compromesso ingegneristico

Questa fluidità di funzionamento comporta un compromesso. I denti angolati producono spinta assiale13Una forza che spinge gli ingranaggi ad allontanarsi lungo i loro alberi. Questa forza deve essere gestita con cuscinetti appropriati, come i cuscinetti reggispinta.

Questo aggiunge una certa complessità e un costo al progetto. Tuttavia, per le applicazioni in cui le prestazioni sono fondamentali, si tratta di una decisione ingegneristica necessaria. Ignorarla può portare a guasti prematuri.

Vantaggi specifici dell'applicazione

| Caratteristica | Beneficio automobilistico | Benefici industriali |

|---|---|---|

| Coinvolgimento senza problemi | Maggiore comfort di guida. | Riduzione dell'usura dei macchinari. |

| Capacità di alta velocità | Adatto ai motori moderni e ai veicoli elettrici. | Essenziale per le turbine di generazione di energia. |

| Maggiore capacità di carico | Maggiore affidabilità della trasmissione. | Durata maggiore per i riduttori per impieghi gravosi. |

Noi di PTSMAKE guidiamo i clienti attraverso questi compromessi. Li aiutiamo a scegliere il tipo di ingranaggio giusto e a progettare i sistemi di supporto per garantire prestazioni e durata ottimali per la loro specifica applicazione.

Per i sistemi ad alta velocità e ad alta potenza, come le trasmissioni automobilistiche e le turbine industriali, gli ingranaggi elicoidali sono obbligatori. Il loro design garantisce un funzionamento fluido e silenzioso, nonostante l'ulteriore complessità della gestione della spinta assiale. Gli ingranaggi cilindrici sono semplicemente troppo rumorosi per queste applicazioni esigenti.

In che modo la strategia di lubrificazione è diversa per gli ingranaggi cilindrici rispetto a quelli elicoidali?

Sebbene tutti gli ingranaggi necessitino di lubrificazione, la scelta del lubrificante non è univoca. La strategia varia in modo significativo se si confrontano gli ingranaggi cilindrici con quelli elicoidali.

Gli ingranaggi cilindrici spesso funzionano bene con lubrificanti generici. Il loro design a denti dritti si traduce principalmente in un contatto di rotolamento. Ciò significa che l'attrito e l'accumulo di calore sono minori.

Gli ingranaggi elicoidali, invece, introducono un maggiore movimento di scorrimento. Ciò è dovuto ai denti angolati. Questo scorrimento può creare pressioni e temperature più elevate nei punti di contatto.

Fattori chiave dei lubrificanti

| Tipo di ingranaggio | Contatto primario | Requisiti del lubrificante |

|---|---|---|

| Ingranaggio cilindrico | Rotolamento | Uso generale, bassa viscosità |

| Ingranaggio elicoidale | Scorrimento e rotolamento | Viscosità più elevata, additivi EP |

Questa distinzione è fondamentale per le prestazioni a lungo termine.

Il ruolo degli additivi per estreme pressioni

L'azione di scorrimento negli ingranaggi elicoidali è la ragione principale delle diverse esigenze di lubrificazione. Questo scorrimento sotto carico crea una sfida che i lubrificanti standard non sono sempre in grado di affrontare. Genera un notevole calore da attrito.

Questo calore può rompere il film d'olio tra i denti. Quando questo film si rompe, si verifica un contatto metallo-metallo, con conseguente sfregamento e usura prematura. È una modalità di guasto comune che abbiamo riscontrato nelle applicazioni ad alto carico.

Per evitare che ciò accada, i lubrificanti per ingranaggi elicoidali necessitano spesso di additivi speciali. In questo caso, i lubrificanti con specifiche Additivi per estreme pressioni (EP)14 diventano non negoziabili.

Quando sono necessari gli additivi EP?

Sulla base dei nostri test con i clienti, la necessità di additivi EP diventa evidente in condizioni specifiche.

| Condizione operativa | Lubrificante per ingranaggi cilindrici | Lubrificante per ingranaggi elicoidali |

|---|---|---|

| Bassa velocità, basso carico | Olio per ingranaggi standard | Olio per ingranaggi standard |

| Alta velocità, alto carico | Olio per ingranaggi standard | Olio con additivi EP |

| Carico d'urto | Può essere necessaria una lieve EP | Richiede robusti additivi EP |

Questi additivi formano uno strato chimico protettivo sulla superficie dell'ingranaggio. Questo strato agisce come ultima linea di difesa quando il film d'olio è compromesso. Impedisce che i denti dell'ingranaggio si saldino tra loro sotto un'intensa pressione. Noi di PTSMAKE esaminiamo sempre i carichi operativi per raccomandare la giusta strategia di lubrificazione.

Entrambi i tipi di ingranaggi necessitano di lubrificazione, ma le maggiori forze di scorrimento degli ingranaggi elicoidali richiedono spesso lubrificanti con additivi EP. Questa scelta è fondamentale per prevenire l'usura e garantire l'affidabilità della trasmissione, soprattutto in presenza di carichi elevati.

Qual è la sensibilità dell'allineamento degli ingranaggi tra i due?

L'allineamento degli ingranaggi è fondamentale per le prestazioni e la durata. Anche un leggero disallineamento può causare gravi problemi.

Gli ingranaggi elicoidali sono generalmente più sensibili a questo aspetto. I loro denti angolati richiedono un posizionamento preciso.

Senza di essa, il carico non si distribuisce in modo uniforme. Questo porta a rumori, vibrazioni e guasti prematuri. Analizziamo il perché di questo fenomeno.

| Tipo di ingranaggio | Sensibilità di allineamento | Motivo principale |

|---|---|---|

| Ingranaggi cilindrici | Meno sensibile (al parallelo) | Contatto su tutta la linea lungo la faccia del dente. |

| Ingranaggi elicoidali | Più sensibile | Il contatto angolare richiede un perfetto parallelismo dell'albero. |

La natura critica dell'allineamento dell'albero

In qualsiasi sistema di ingranaggi, l'obiettivo è un perfetto allineamento degli alberi. Tuttavia, nella realtà, esistono sempre piccole deviazioni. Il modo in cui ciascun tipo di ingranaggio gestisce questa imperfezione è un fattore chiave nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali.

Spiegazione della sensibilità dei riduttori elicoidali

Gli ingranaggi elicoidali ottengono un funzionamento fluido e silenzioso grazie all'innesto graduale dei denti. Il contatto inizia da un'estremità del dente e si sposta lungo la sua faccia.

Questo contatto graduale è un punto di forza ma anche un punto debole. Se gli alberi sono disallineati, il carico si concentra su una parte del dente. Questo crea punti di pressione localizzati, o concentrazione delle sollecitazioni15con conseguente accelerazione dell'usura e della vaiolatura.

Nel nostro lavoro all'PTSMAKE, abbiamo assistito a guasti precoci di riduttori elicoidali dovuti a piccoli errori di assemblaggio. L'usura irregolare che ne deriva è un chiaro segno di problemi di allineamento.

| Tipo di disallineamento | Impatto sugli ingranaggi elicoidali | Impatto sugli ingranaggi cilindrici |

|---|---|---|

| Parallelo | Alta. Il carico si concentra sulle estremità dei denti. | Moderato. Mantiene ancora il contatto con la linea, ma in modo non uniforme. |

| Angolare | Molto alto. Modifica drasticamente il modello di contatto e il carico. | Alta. Comporta un carico sui bordi e sollecitazioni elevate. |

Perdono della corona dentata

Gli ingranaggi cilindrici, con i loro denti diritti, sono più tolleranti nei confronti di un leggero disallineamento dell'albero parallelo. Il carico è distribuito sull'intera superficie del dente.

Pur non essendo immuni, possono tollerare meglio le piccole imperfezioni senza subire guasti catastrofici. Tuttavia, il disallineamento angolare è ancora molto dannoso.

In sintesi, gli ingranaggi elicoidali richiedono una maggiore precisione nell'assemblaggio. Il loro design, che garantisce un funzionamento regolare, li rende anche più sensibili al disallineamento. Gli ingranaggi cilindrici offrono una maggiore tolleranza, in particolare per le deviazioni degli alberi paralleli, rendendoli più robusti in alcune applicazioni.

In che modo la velocità di funzionamento limita le rispettive applicazioni?

La velocità di funzionamento è un fattore critico nella scelta tra ingranaggi cilindrici ed elicoidali. Essa influenza direttamente il rumore, le vibrazioni e i carichi dinamici di un sistema.

Per gli ingranaggi cilindrici esiste un limite pratico di velocità. La loro struttura a denti dritti provoca un contatto brusco su tutta la linea durante l'ingranamento. Questo crea forze d'impatto che aumentano con la velocità.

Si tratta di una considerazione fondamentale nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali. Di seguito è riportato un rapido confronto delle loro caratteristiche di velocità.

| Caratteristica | Ingranaggi cilindrici | Ingranaggi elicoidali |

|---|---|---|

| Idoneità alla velocità | Da basso a moderato | Alto |

| Rumore in velocità | Alto | Basso |

| Impatto sulla mesh | Significativo | Minimo |

Questo innesto brusco è il motivo per cui gli ingranaggi cilindrici diventano rumorosi e vibrano alle alte velocità.

La sfida della velocità con gli ingranaggi cilindrici

Il problema principale degli ingranaggi cilindrici ad alta velocità è la loro geometria. L'intera faccia del dente si innesta in una sola volta. Si tratta di un piccolo e rapido effetto di martellamento. Quando l'ingranaggio gira più velocemente, questi impatti diventano più frequenti e più forti.

Questo genera una significativa carichi dinamici16sollecitando i denti dell'ingranaggio e creando un rumore udibile. Oltre una certa velocità di rotazione, queste vibrazioni possono compromettere l'affidabilità e le prestazioni dell'intero sistema. Questo crea di fatto un limite pratico di velocità per il loro utilizzo.

Perché gli ingranaggi elicoidali eccellono alle alte velocità

Gli ingranaggi elicoidali superano questa limitazione in modo elegante. I loro denti angolati fanno sì che il contatto inizi da un'estremità del dente e progredisca dolcemente lungo la sua faccia. Questo innesto graduale elimina le forze d'urto tipiche degli ingranaggi cilindrici.

L'ingranamento regolare consente un funzionamento più silenzioso e una riduzione significativa delle vibrazioni. Nei progetti di cui ci occupiamo noi di PTSMAKE, questa qualità rende gli ingranaggi elicoidali la scelta obbligata per le applicazioni che richiedono alte velocità di rotazione, come nelle trasmissioni automobilistiche o nei macchinari industriali di precisione.

| Gamma di velocità | Tipo di ingranaggio preferito | Giustificazione chiave |

|---|---|---|

| Da basso a moderato | Ingranaggio cilindrico | Semplicità ed efficienza dei costi. |

| Alto | Ingranaggio elicoidale | Funzionamento fluido e silenzioso e affidabilità. |

Questa differenza fondamentale nell'impegno è ciò che distingue le loro gamme di applicazioni.

Gli ingranaggi cilindrici sono limitati dalla velocità a causa delle forze d'urto e del rumore dovuto all'innesto brusco dei denti. Gli ingranaggi elicoidali, con il loro ingranamento graduale, funzionano in modo fluido e silenzioso, rendendoli essenziali per le applicazioni ad alta velocità in cui affidabilità e bassa rumorosità sono fondamentali.

Come si seleziona il tipo di ingranaggio giusto per un'applicazione?

La scelta dell'attrezzatura giusta comporta un processo strutturato. Non si tratta solo di una singola specifica. È necessario bilanciare diversi fattori chiave.

In questo modo si garantisce che la scelta finale soddisfi tutti gli obiettivi di prestazione. Inizio sempre dai requisiti principali dell'applicazione.

Fattori decisionali chiave

Un quadro chiaro impedisce errori costosi. Considerate queste cinque aree critiche prima di prendere una decisione. Ognuna di esse influisce sull'idoneità dell'attrezzatura.

| Fattore | Descrizione |

|---|---|

| Velocità (RPM) | La velocità di rotazione operativa richiesta. |

| Coppia | La forza di rotazione che l'ingranaggio deve trasmettere. |

| Livello di rumore | Il livello di rumore accettabile durante il funzionamento. |

| Bilancio | I vincoli di costo per il componente. |

| Vincoli di spazio | Lo spazio fisico disponibile per il sistema di ingranaggi. |

Un quadro di selezione passo dopo passo

Noi di PTSMAKE guidiamo i nostri partner attraverso un processo sistematico. Si inizia con la definizione dei requisiti primari. In questo modo si garantisce la scelta dell'ingranaggio corretto sia per le prestazioni che per la producibilità.

Un punto di partenza comune è la scelta tra ingranaggi cilindrici e ingranaggi elicoidali. Gli ingranaggi cilindrici sono efficienti e convenienti per velocità moderate. Gli ingranaggi elicoidali hanno un funzionamento più fluido e silenzioso, che li rende ideali per le applicazioni ad alta velocità o sensibili al rumore.

Tuttavia, raramente la decisione è così semplice. È necessario considerare le prestazioni dei diversi tipi di ingranaggi in base a tutti i criteri. Le applicazioni di precisione introducono anche fattori quali contraccolpo17che può essere critico.

Matrice decisionale per la selezione degli attrezzi

Spesso utilizziamo una matrice decisionale con i clienti. Questo strumento aiuta a visualizzare i compromessi tra i diversi tipi di attrezzi. Fornisce un percorso chiaro e guidato dai dati per arrivare alla soluzione migliore.

| Tipo di ingranaggio | Valutazione della velocità | Capacità di coppia | Livello di rumore | Costo relativo | Efficienza |

|---|---|---|---|---|---|

| Sperone | Medio | Medio | Alto | Basso | Molto alto |

| Elicoidale | Alto | Alto | Basso | Medio | Alto |

| Smusso | Medio | Medio | Medio | Alto | Alto |

| Verme | Basso | Molto alto | Molto basso | Medio | Medio-basso |

Questa matrice è un punto di partenza. L'applicazione specifica determinerà il giusto equilibrio.

Un quadro decisionale strutturato semplifica la selezione dei riduttori. Valutando requisiti quali velocità, coppia, rumorosità, budget e spazio, è possibile identificare sistematicamente il tipo di riduttore ottimale per le proprie esigenze specifiche, evitando congetture e garantendo prestazioni affidabili.

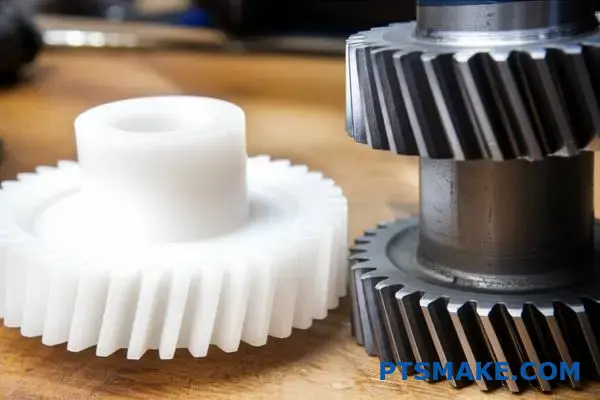

Come si sceglie il materiale giusto per un ingranaggio?

La scelta del materiale giusto per gli ingranaggi è una decisione cruciale. Ha un impatto diretto sulle prestazioni, sulla durata e sul costo complessivo del prodotto. La scelta deve essere guidata dalle esigenze specifiche dell'applicazione.

Pensate a fattori come il carico, la velocità e l'ambiente operativo. Un ingranaggio in acciaio a coppia elevata per una trasmissione automobilistica ha esigenze molto diverse da un ingranaggio in plastica a bassa rumorosità per una stampante da ufficio.

Ecco una rapida panoramica per iniziare:

| Categoria di materiale | Vantaggio chiave | Caso d'uso comune |

|---|---|---|

| Leghe di acciaio | Alta resistenza e durata | Trasmissioni automobilistiche |

| Plastica | Bassa rumorosità e resistenza alla corrosione | Apparecchiature per ufficio, medicali |

| Leghe di bronzo | Basso attrito e conformabilità | Azionamenti a vite senza fine |

Questa guida vi aiuterà a orientarvi tra queste opzioni per il vostro progetto.

Approfondiamo una guida pratica alla scelta dei materiali. La scelta migliore è sempre un equilibrio tra prestazioni e budget. Noi di PTSMAKE iniziamo spesso ad analizzare le forze operative e l'ambiente per trovare questo equilibrio.

Leghe di acciaio per lavori ad alte sollecitazioni

Per l'elevata resistenza e durata, l'acciaio è il materiale preferito. Gestisce in modo eccezionale carichi elevati e usura, sia per gli ingranaggi cilindrici che per quelli elicoidali. Il trattamento termico può anche migliorare notevolmente le sue proprietà.

| Lega di acciaio | Il migliore per | Caratteristiche principali |

|---|---|---|

| Acciaio 4140 | Coppia e resistenza elevate | Capacità di indurimento passante |

| Acciaio 8620 | Impatto e usura superficiale | Eccellente per la cementazione |

Plastica per applicazioni specializzate

Non sottovalutate le materie plastiche. Risolvono problemi comuni come la rumorosità, la corrosione e la necessità di lubrificazione esterna. In base ai nostri test, sono ideali per le applicazioni con carichi più leggeri in cui questi fattori sono critici.

L'unico proprietà tribologiche18 delle materie plastiche le rendono essenziali in molti progetti moderni.

Opzioni di plastica più diffuse

- Delrin (acetale): Noto per il suo basso attrito e l'eccellente stabilità dimensionale. Lo consigliamo per le parti mobili di precisione.

- Nylon: Offre una buona tenacità e resistenza chimica. Inoltre, è in grado di smorzare rumori e vibrazioni.

Bronzo per accoppiamento a basso attrito

Le leghe di bronzo sono una scelta classica per alcuni tipi di ingranaggi. Sono particolarmente comuni per le ruote elicoidali che si accoppiano con viti senza fine in acciaio. L'accoppiamento di questo materiale offre un attrito molto basso e impedisce la formazione di galla sotto carichi pesanti.

La scelta del materiale giusto per gli ingranaggi è un compromesso. L'acciaio offre resistenza per carichi elevati. Le materie plastiche offrono un funzionamento silenzioso e resistente alla corrosione per i lavori più leggeri. Il bronzo eccelle in applicazioni specifiche a basso attrito. Il segreto sta nell'adattare il materiale alle esigenze specifiche dell'applicazione.

Come si può riprogettare una trasmissione a ingranaggi cilindrici rumorosa per renderla più silenziosa?

Una trasmissione a ingranaggi cilindrici rumorosa è una sfida ingegneristica comune. La soluzione più efficace spesso comporta una riprogettazione completa. La semplice sostituzione delle parti non è sufficiente.

Sostituiamo i rumorosi ingranaggi cilindrici con ingranaggi elicoidali. Questa modifica riduce significativamente il rumore. Tuttavia, richiede un'attenta riprogettazione dell'intero sistema.

La chiave è capire le differenze tra ingranaggi cilindrici e ingranaggi elicoidali. I denti angolati degli ingranaggi elicoidali si innestano gradualmente e per questo motivo sono più silenziosi.

| Tipo di ingranaggio | Il fidanzamento | Livello di rumore |

|---|---|---|

| Ingranaggio cilindrico | Brusco | Alto |

| Ingranaggio elicoidale | Graduale | Basso |

Questa riprogettazione comporta modifiche alla geometria, ai cuscinetti e all'alloggiamento.

Quando riprogettiamo un azionamento per renderlo più silenzioso, andiamo oltre la semplice sostituzione degli ingranaggi. Il passaggio da ingranaggi cilindrici a ingranaggi elicoidali è una modifica tecnica fondamentale. Ha un impatto sull'intero gruppo meccanico.

Ricalcolo della geometria degli ingranaggi

Il primo passo è il ricalcolo della geometria dell'ingranaggio. L'introduzione di un angolo di elica cambia tutto. Crea un innesto più dolce e graduale dei denti. Questa è la ragione principale della riduzione del rumore. Dobbiamo regolare l'angolo di pressione e il profilo dei denti per ottimizzare il contatto e ridurre al minimo l'usura.

Specificare i nuovi cuscinetti

Gli ingranaggi cilindrici generano principalmente carichi radiali. Gli ingranaggi elicoidali, a causa dei loro denti angolati, producono carichi sia radiali sia Spinta assiale19. Questa nuova forza deve essere gestita. I cuscinetti a sfera standard possono cedere. Dobbiamo scegliere cuscinetti in grado di gestire i carichi di spinta, come i cuscinetti a rulli conici o i cuscinetti a contatto obliquo.

Modifica dell'alloggiamento

I nuovi cuscinetti e le forze di spinta richiedono modifiche all'alloggiamento. L'alloggiamento deve essere sufficientemente rigido per supportare la nuova disposizione dei cuscinetti. Deve evitare qualsiasi flessione dell'albero sotto carico. Noi di PTSMAKE spesso riprogettiamo l'alloggiamento per garantire un allineamento preciso e un'affidabilità a lungo termine.

| Aspetto progettuale | Trasmissione a ingranaggi cilindrici | Riprogettazione di ingranaggi elicoidali |

|---|---|---|

| Carico primario | Radiale | Radiale e assiale |

| Tipo di cuscinetto | Cuscinetto a sfera semplice | Contatto conico/angolare |

| Alloggiamento | Rigidità standard | Rinforzato per la spinta |

| Rumore | Alto | Basso |

Il passaggio agli ingranaggi elicoidali per un funzionamento silenzioso non è una semplice sostituzione. Si tratta di una riprogettazione completa che comprende una nuova geometria, cuscinetti specializzati per gestire la spinta e un alloggiamento modificato. Questo garantisce un sistema veramente silenzioso e affidabile.

Come si ottimizza il progetto di un ingranaggio per ottenere il minimo peso?

Per applicazioni critiche come quelle aerospaziali, ogni grammo è importante. Le strategie avanzate sono essenziali. Andiamo oltre la progettazione di base per ottenere un peso minimo.

Materiali ad alte prestazioni

La scelta di materiali come le leghe di acciaio ad alta resistenza o il titanio è il primo passo. Questi materiali offrono un rapporto resistenza/peso superiore.

Trattamenti termici avanzati

Processi come la nitrurazione o la carburazione induriscono la superficie dell'ingranaggio. Questo aumenta la capacità di carico. Ciò consente di utilizzare un ingranaggio più piccolo e più leggero per svolgere lo stesso lavoro.

Ottimizzazione del piano di ingranaggi

La fettuccia del grezzo dell'attrezzo è una tecnica fondamentale. Rimuoviamo strategicamente il materiale dal corpo dell'ingranaggio. In questo modo si riduce il peso senza intaccare l'area critica dei denti.

| Strategia | Impatto sul peso | Considerazione |

|---|---|---|

| Materiali avanzati | Alto | Costo del materiale più elevato |

| Trattamento termico | Medio | Fase aggiuntiva del processo |

| Fettuccia | Alto | Lavorazione complessa |

L'ottimizzazione avanzata del peso richiede un approccio olistico. Si tratta di combinare la scienza dei materiali, il trattamento termico e la progettazione geometrica intelligente per creare un ingranaggio resistente e incredibilmente leggero.

Ottimizzazione della struttura centrale dell'ingranaggio

La fettucciatura di un ingranaggio grezzo è più arte che scienza. Comporta la lavorazione di sacche di materiale dal disco centrale dell'ingranaggio. In questo modo si rimuove la massa non essenziale. L'obiettivo è creare una struttura a raggiera o a nastro. In questo modo si mantiene la rigidità e si riduce drasticamente il peso. Nei progetti passati dell'PTSMAKE, abbiamo ottenuto una significativa riduzione del peso in questo modo.

| Tipo di ingranaggio | Peso relativo | Complessità |

|---|---|---|

| Solido vuoto | 100% | Basso |

| Vuoto palmato | 60-75% | Alto |

Profilo e resistenza dei denti

Oltre al grezzo, le modifiche al profilo dei denti sono fondamentali. Una regolazione sottile come l'aggiunta di incoronazione20 può garantire che il carico sia distribuito uniformemente sulla faccia del dente, anche in caso di leggero disallineamento. In questo modo si evitano concentrazioni di stress alle estremità del dente.

Questa migliore distribuzione del carico significa che l'ingranaggio può sopportare maggiori sollecitazioni. Di conseguenza, possiamo progettarlo in modo che sia più piccolo e più leggero fin dall'inizio. Questo principio è fondamentale nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali, poiché ogni tipo di ingranaggio risponde in modo diverso a tali modifiche. Abbinando queste modifiche progettuali a materiali e trattamenti termici di qualità superiore, otteniamo ingranaggi leggeri e di alto livello per i settori più esigenti.

L'ottimizzazione del peso minimo comporta l'uso di materiali ad alta resistenza e di trattamenti termici avanzati. Una progettazione intelligente, come la scanalatura del grezzo dell'ingranaggio e la modifica del profilo del dente, elimina la massa non essenziale senza compromettere l'integrità strutturale o le prestazioni dell'ingranaggio.

Quando scegliereste intenzionalmente un ingranaggio cilindrico in plastica piuttosto che in acciaio?

È facile pensare che l'acciaio sia sempre meglio. È più forte, giusto? Ma la resistenza non è l'unico fattore. Per molte applicazioni, un ingranaggio cilindrico in plastica è la scelta più intelligente ed efficiente.

Questo è particolarmente vero quando le priorità cambiano. Si pensi alla bassa rumorosità, all'autolubrificazione o alla resistenza alla corrosione. In questi casi, la plastica spesso supera il metallo. Anche il costo è un fattore importante.

| Caratteristica | Vantaggio dell'ingranaggio in plastica | Vantaggio dell'ingranaggio in acciaio |

|---|---|---|

| Rumore | Molto basso | Può essere alto |

| Lubrificazione | Autolubrificante | Richiede un lubrificante esterno |

| Costo | Più basso, soprattutto in caso di volumi elevati | Costi di lavorazione e materiali più elevati |

| Peso | Leggero | Pesante |

Oltre la forza bruta: Scelte specifiche per le applicazioni

Nel nostro lavoro di PTSMAKE, guidiamo i clienti nella scelta dei materiali. Si tratta di adattare il materiale all'ambiente reale. La pura resistenza è spesso eccessiva.

Elettronica per ufficio e di consumo

Considerate una stampante o uno scanner. Questi dispositivi si trovano negli uffici o nelle case. Devono funzionare in modo silenzioso. Gli ingranaggi in acciaio creerebbero un rumore eccessivo.

Gli ingranaggi cilindrici in plastica sono perfetti in questo caso. Funzionano in modo quasi silenzioso. Inoltre, non hanno bisogno di grasso, che potrebbe macchiare la carta o danneggiare l'elettronica. La loro eccellente proprietà tribologiche21 garantiscono una lunga durata senza manutenzione.

Ambienti a rischio di corrosione

Che dire di un dispositivo utilizzato in prossimità di acqua o sostanze chimiche? Gli ingranaggi in acciaio si arrugginirebbero e si guasterebbero rapidamente. L'acciaio inossidabile è un'opzione, ma è costoso.

Gli ingranaggi in plastica sono naturalmente immuni alla corrosione. Questo li rende ideali per le apparecchiature di lavorazione degli alimenti, i dispositivi medici o i prodotti per esterni. Forniscono prestazioni affidabili laddove l'acciaio non è in grado di farlo. Quando si confrontano gli ingranaggi cilindrici con quelli elicoidali per questi impieghi, il materiale è spesso più importante del tipo di ingranaggio per la longevità.

| Area di applicazione | I principali vantaggi della plastica |

|---|---|

| Stampanti per ufficio | Bassa rumorosità, non è necessaria la lubrificazione |

| Dispositivi medici | Sterilizzabile, resistente alla corrosione |

| Lavorazione degli alimenti | Resistenza chimica, nessuna contaminazione |

| Giocattoli e gadget | Basso costo, leggero, sicuro |

In sintesi, la scelta della plastica rispetto all'acciaio non è una questione di compromessi. È una decisione strategica. È una scelta strategica che privilegia l'economicità, la silenziosità e l'assenza di manutenzione nelle applicazioni in cui la coppia elevata e la resistenza estrema non sono i requisiti principali.

Analizzare l'impatto della sostituzione di un ingranaggio cilindrico con un ingranaggio elicoidale sull'efficienza.

È opinione comune che un funzionamento più fluido equivalga a una maggiore efficienza. Ma nel dibattito tra ingranaggi cilindrici e ingranaggi elicoidali, non è sempre così.

Mentre gli ingranaggi elicoidali offrono un innesto più silenzioso e graduale, i loro denti angolati introducono una dinamica unica. Questo cambia le forze in gioco.

La fonte dell'inefficienza

La differenza principale sta nel tipo di contatto tra i denti. Si tratta di un punto sottile ma critico per qualsiasi progettista.

| Tipo di ingranaggio | Contatto primario Movimento | Risultato |

|---|---|---|

| Ingranaggio cilindrico | Rotolamento/scorrimento | Trasferimento diretto di energia |

| Ingranaggio elicoidale | Aumento dello scorrimento | Più scorrevole, ma con maggiore attrito |

Questa maggiore azione di scorrimento lungo la faccia del dente è la chiave. Genera un attrito e un calore leggermente maggiori rispetto a un ingranaggio cilindrico.

Uno sguardo più approfondito su attrito e forze

Analizziamo questo compromesso. I denti di un ingranaggio cilindrico si ingranano con un movimento che è in gran parte di rotolamento e in parte di scorrimento. Si tratta di un modo molto efficiente di trasferire la potenza.

Gli ingranaggi elicoidali, grazie al loro angolo d'elica, hanno denti che scorrono nell'innesto. Questo contatto scorrevole continuo riduce il rumore e i carichi d'urto, il che rappresenta un vantaggio significativo.

Tuttavia, questo movimento di scorrimento crea un attrito maggiore rispetto al contatto prevalentemente volvente degli ingranaggi cilindrici. In base ai nostri test interni, ciò può comportare una lieve perdita di efficienza, in genere dell'ordine di 1-3%, a seconda dell'applicazione e della lubrificazione.

Comprendere i compromessi

La struttura elicoidale crea inoltre una forza parallela all'asse dell'ingranaggio. Questa spinta assiale22 devono essere gestiti da cuscinetti appropriati, che possono introdurre perdite per attrito nel sistema. La scelta non è sempre semplice.

| Caratteristica | Ingranaggio cilindrico | Ingranaggio elicoidale |

|---|---|---|

| Funzionamento | Più forte | Più silenzioso, più fluido |

| Contatto con il dente | Contatto di linea | Impegno graduale |

| Efficienza | Molto alto | Leggermente inferiore |

| Carico assiale | Nessuno | Sì |

Noi di PTSMAKE lavoriamo spesso con i clienti per analizzare questi aspetti sottili. La scelta del tipo di riduttore giusto dipende interamente dalle priorità specifiche dell'applicazione: livello di rumorosità, capacità di carico o massima efficienza.

Gli ingranaggi elicoidali offrono prestazioni più fluide e silenziose. Tuttavia, i loro denti angolati aumentano l'attrito di scorrimento. Questo crea un leggero, ma importante, compromesso di efficienza rispetto all'azione di rotolamento più diretta degli ingranaggi cilindrici.

Ottenete soluzioni esperte di ingranaggi cilindrici ed elicoidali con PTSMAKE

Siete pronti per soluzioni di ingranaggi di precisione? Collaborate con PTSMAKE per ingranaggi cilindrici ed elicoidali personalizzati, progettati secondo i vostri standard più esigenti. Inviate subito la vostra richiesta di offerta e sperimentate una comunicazione affidabile, tolleranze ristrette, tempi di consegna rapidi e un vero impegno per il vostro successo.

Comprendere il ruolo cruciale di questo cerchio nel definire l'intero profilo del dente involuto. ↩

Imparate a gestire questa forza per ottimizzare la progettazione e la durata del sistema di ingranaggi. ↩

Scoprite come questa caratteristica geometrica critica influisce sulla distribuzione delle forze e sull'efficienza degli ingranaggi. ↩

Approfondite la conoscenza di come i diversi vettori di forza si combinano nei sistemi di ingranaggi. ↩

Consultate la nostra guida dettagliata per capire come la geometria degli ingranaggi influisce sulle prestazioni. ↩

Comprendere come questa proprietà meccanica influenzi i livelli di vibrazione e rumore nei sistemi di ingranaggi. ↩

Scoprite come la linea di contatto progressiva dei denti elicoidali assicura un trasferimento di potenza più fluido e silenzioso. ↩

Capire come questa forza influisce sulla progettazione degli ingranaggi e quali cuscinetti sono necessari per gestirla in modo efficace. ↩

Comprendere come l'analisi delle sollecitazioni superficiali possa prevenire la rottura prematura degli ingranaggi. ↩

Comprendere come questa forza influenzi la progettazione degli ingranaggi e la scelta di cuscinetti appropriati. ↩

Scoprite come questa forza influisce sulla progettazione e sulla durata degli ingranaggi. ↩

Scoprite come queste pompe utilizzano una precisa meccanica a ingranaggi per spostare i fluidi con un'accuratezza eccezionale. ↩

Imparate a calcolare e gestire questa forza nei vostri progetti. ↩

Scoprite come questi additivi chimici prevengono la rottura catastrofica degli ingranaggi in presenza di carichi estremi. ↩

Scoprite come la concentrazione delle sollecitazioni influisce sulla fatica dei materiali e sulla durata dei componenti. ↩

Capire come queste forze variabili influenzino la longevità degli ingranaggi e le prestazioni del sistema. ↩

Per saperne di più sul gioco degli ingranaggi e su come ridurlo al minimo per le applicazioni di lavorazione CNC ad alta precisione. ↩

Scoprite come l'attrito, l'usura e le proprietà di lubrificazione determinano le prestazioni e la durata degli ingranaggi. ↩

Capire come questa forza influisca sulla progettazione degli ingranaggi e sulla scelta dei cuscinetti per ottenere prestazioni ottimali. ↩

Scoprite come questa sottile modifica dei denti può migliorare drasticamente l'ingranamento degli ingranaggi e prolungarne la vita operativa. ↩

Per saperne di più su come l'attrito, l'usura e la lubrificazione influiscono sulle prestazioni dei materiali degli ingranaggi. ↩

Comprendere come questa forza influenzi la scelta dei cuscinetti e la progettazione del sistema. ↩